|

|

The Clanford Clan 0.24 cc Diesel Revisited By Maris Dislers

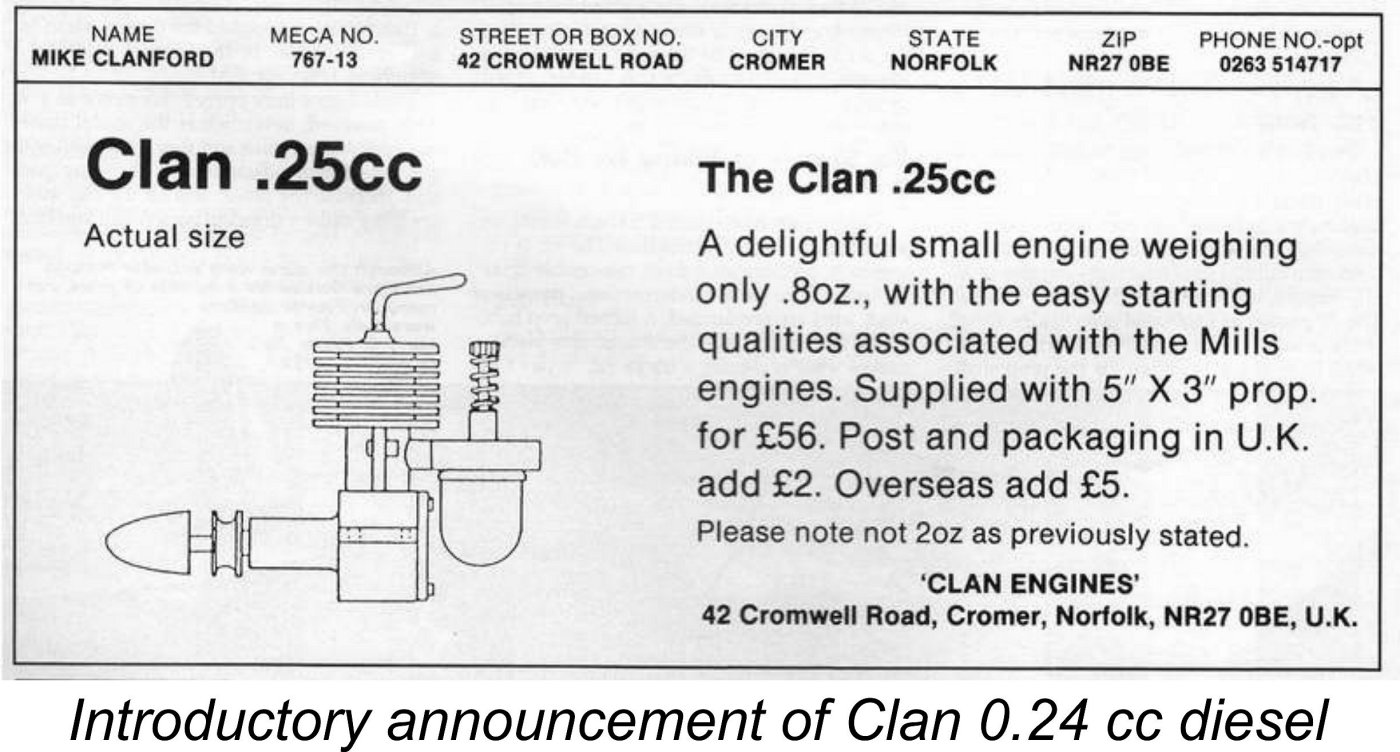

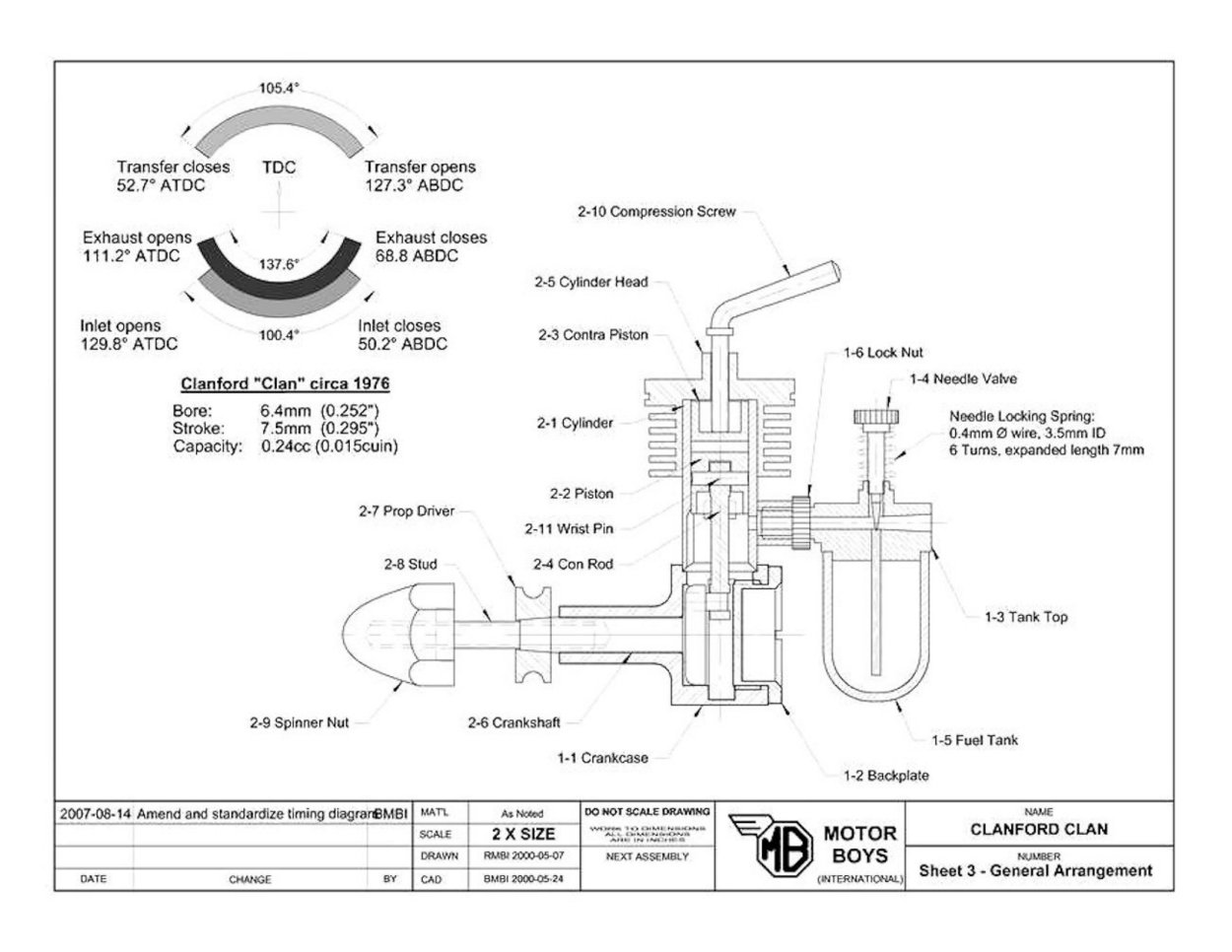

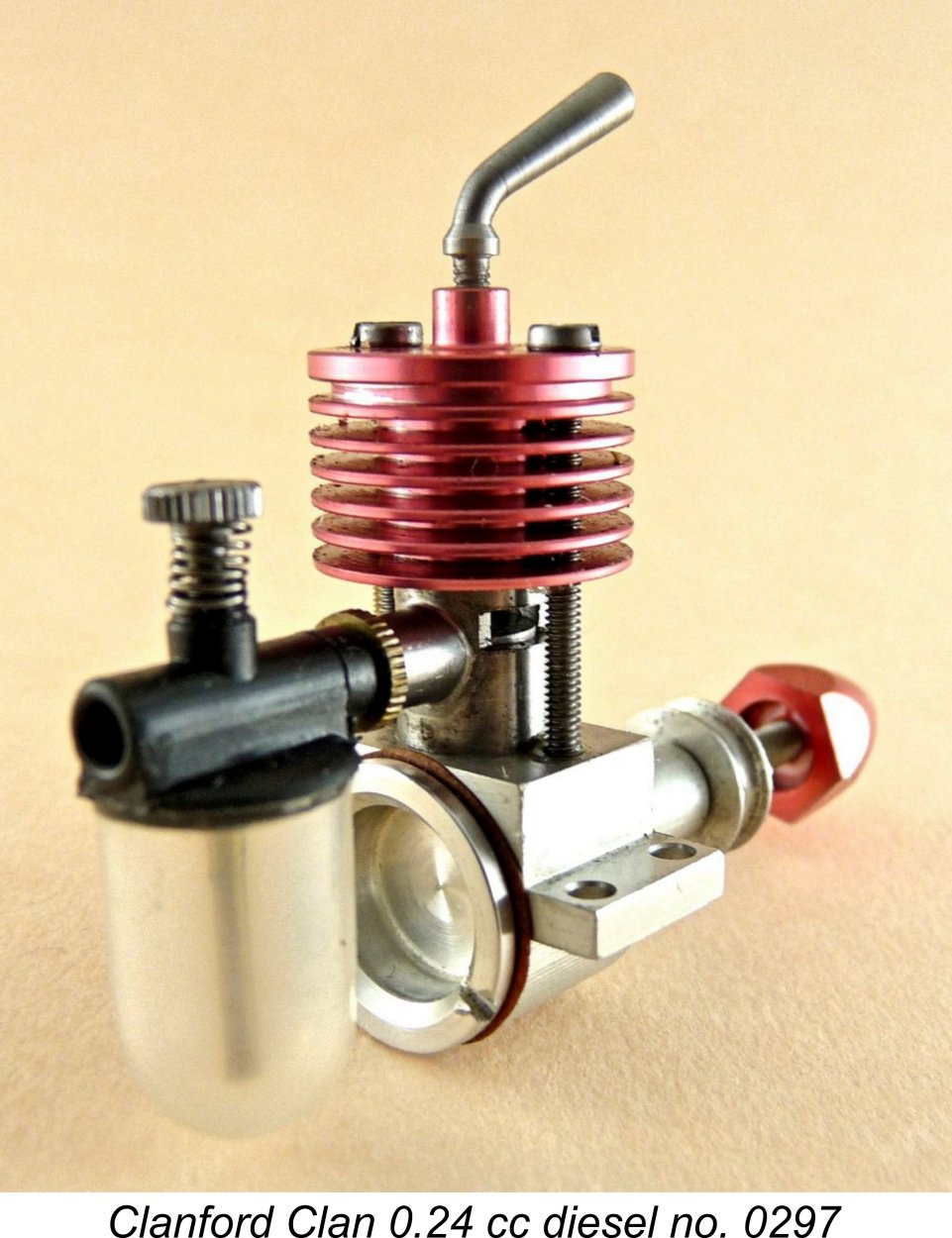

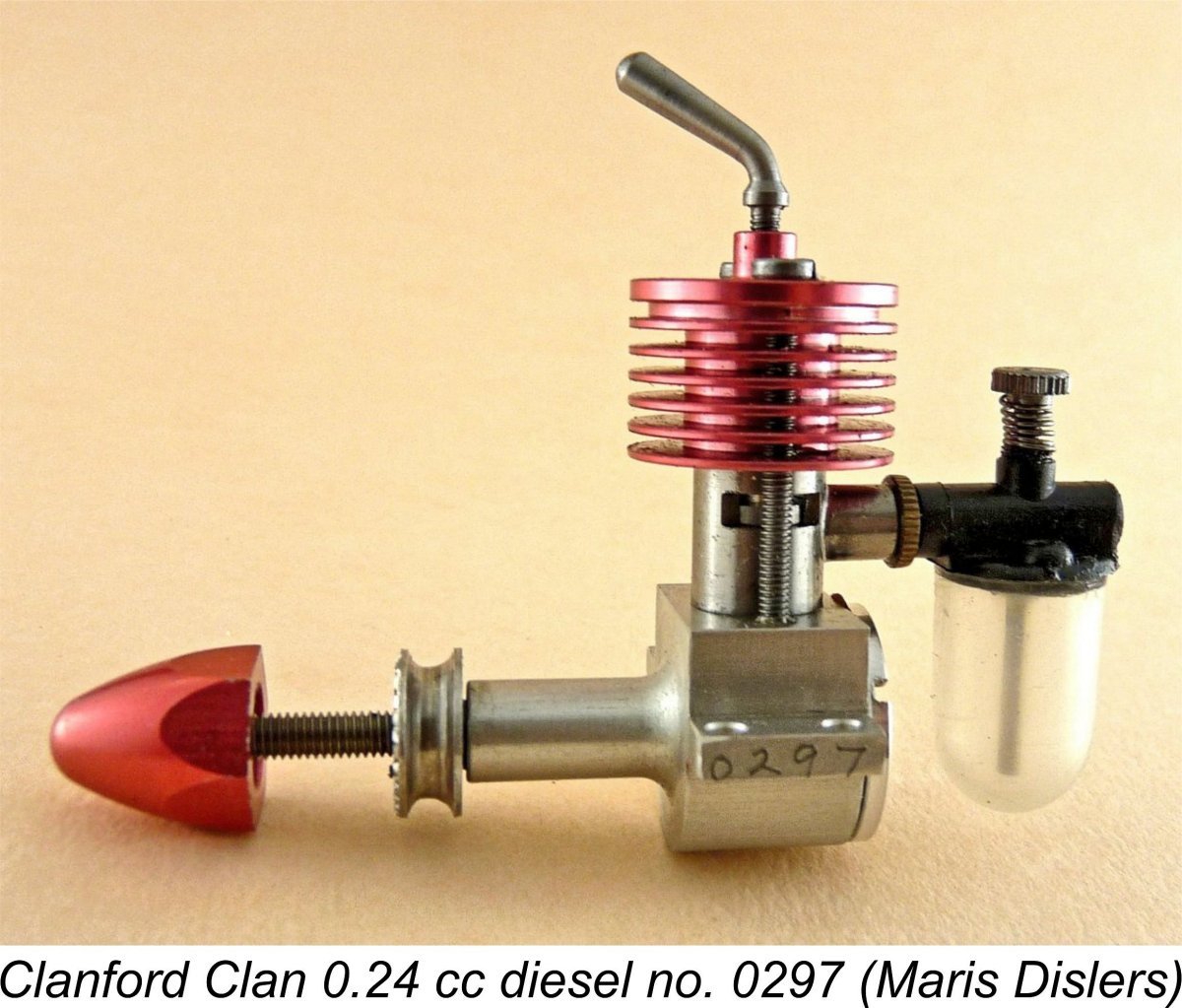

The Clanford Clan 0.24 cc diesel is not to be confused with the far earlier Clan 0.9 cc model from Scotland which appeared in early 1947, passing through several variants before vanishing from the scene in mid 1948. The story of this entirely distinct earlier engine has been covered in a separate article on this website. The original Clanford Clan 0.24 cc diesel which is the subject of the present article was commissioned in 1991 by the well-known model engine enthusiast and writer Mike Clanford. Mike is best known today for his authorship of the very interesting but at times Bore and stroke of this neat little unit are 6.40 mm (0.252 in.) and 7.50 mm (0.295 in.) respectively for a displacement of 0.24 cc (0.015 cuin.). The engine weighs in at a measly 24 gm (0.846 oz.) complete with tank. The engines were supplied with a supposedly matching KeilKraft 5x3 nylon propeller. The original batch of some 500 or so engines sold out fairly quickly. Some years later, Mike Clanford arranged for the production of a number of further examples by the CS company of Shanghai, China. These were manufactured in both 0.24 cc and 0.48 cc displacements. More of these below. After spending time with a New In Box Clan 0.24 diesel from the original 1992 batch that recently came our way, we were “disappointed” that we could find nothing wrong to justify the Clan’s not so lustrous reputation. Actually, all fits were excellent and it proved to be a very capable performer. We formed the impression that Richard’s example was indeed below par. Accordingly, in order to balance the record we decided to present our test results for engine no. 0297 as representing one of the best of its type. Preparation

Moreover, Ron went even further than this by publishing a detailed article describing the construction of a Clan 0.24 cc diesel from the Motor Boys plans. In his article, Ron mentioned the periodic occurrence of transfer port errors, which I think might be confined to some of the previously-mentioned Clan engines made by CS. I can only report my own observations of one engine from the original 1992 batch, which was found upon inspection to be free from any such errors. Adrian Duncan advises that his two examples nos. 0170 and 0316 are also correctly configured, both running well. After 25 years in the box since its factory test run, our Clan 0.24 no. 0297 had to be disassembled and thoroughly degummed. Had we read Richard’s report more carefully, we would not have wasted time trying to start an engine with crankcase compression leaks via the cylinder to crankcase joint and the two cylinder retaining screw threads that go right through to the inside. They were originally sealed by the makers. An We fixed this potential problem with a smear of Loctite 243 thread locker on the cylinder seat and balsa cement on the screw threads. These were left to cure overnight. Balsa cement has the advantage of letting go easily when required, especially if soaked in acetone beforehand. We also added a paper backplate gasket, just to be sure.

Mike Clanford advised owners that the presumably usual “tightish” fit takes lots of gentle running in. Probably true, but we’d rate piston fit on our example as excellent, hence having no such problem. An excessively loose fit would be a problem, however. In such a case, starting will become difficult and the engine won’t tolerate a decent propeller load. If your example feels “soft”, try upping the oil content to 40%. Use castor oil, of course. Operation Precise priming is the key to easy starts with tiny diesels. You just can’t expect finger choking or dousing it from a filler bottle not to flood the engine. It appears that Jose Maria González-Calatayud Saiz has fallen for the old trap of over priming, as seen in this clip We’ve all done it at some time, so I find life easier if I get the priming technique and initial compression setting for short bursts down pat before even fuelling up the tank or finding the mixture setting. I use a disposable syringe with blunted 18G needle. Syringes with one-piece plastic plungers are better than the regular type with rubber pistons. Mike Clanford’s recommended fuel mix of “1/3 each ether, kerosene and castor oil with a touch more ether” (to around 40%) proved to be bang on for the Clan. That extra ether isn’t mandatory, but helps a little when starting. The idea is to introduce a little fuel into the crankcase and get the engine going more or less on the ether fumes alone with a bit of flicking. The very wide explosive limits of ether vapour in air greatly facilitate this. Our routine ended up being pretty much like Richard Herbert’s. Needle around ½ turn open, but no finger choking. One or two drops in the venturi from a syringe was far less likely to lead to flooding. Compression set a bit below peak, and a few flicks had it going, sometimes after backing off compression to clear any excess prime. Test The real surprise on test was that the included KeilKraft 5x3 propeller is really too small for the job! As our performance curves show, power output rises sharply to near peak level by 6,500 RPM. Thereafter, torque is exchanged for more RPM, but power output remains essentially flat at 0.013 BHP all the way up into the 10,000 RPM range. We saw no point in squeezing the engine much past 10,000 RPM, as it becomes less pleasant to operate and the wear rate will inevitably go up. Actually, the best flight propellers are likely somewhere in the 6x4 to 6x3 bracket for decent torque with a reasonable capability of throttling back with reduced compression to around 5,000 RPM for trim flights. We found a 7x3 prop to be about the largest practical option. Nice flywheel effect from that, but could be too much

The CS Clan Models

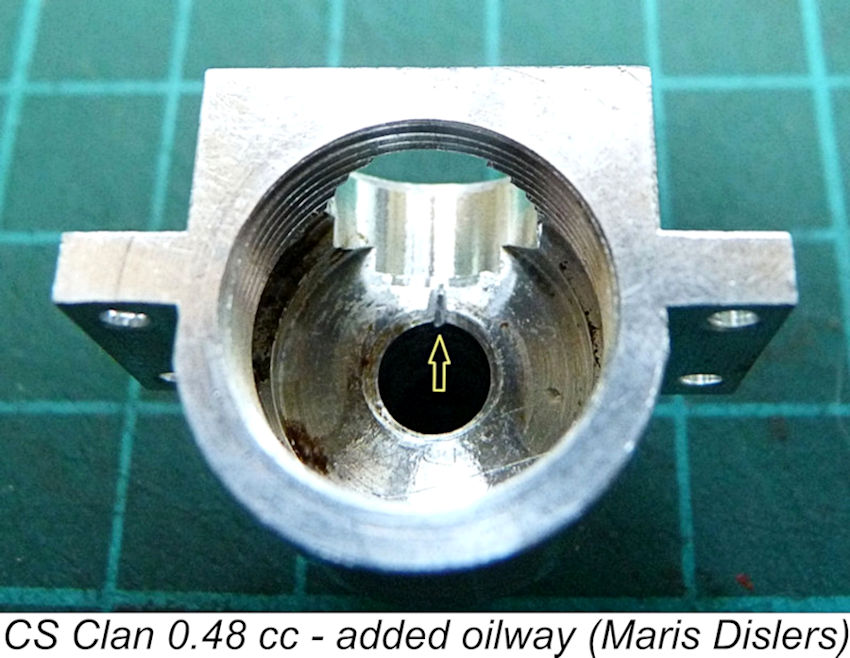

The 0.48 cc version of the engine featured bore and stroke measurements of 8.16 mm (0.321 in.) and 9.56 mm (0.376 in.) respectively for a calculated displacement of exactly 0.50 cc. Weight was 36 gm (1.27 ounces). Fortunately it’s very easy to distinguish between the “original” 1992 Clan 0.24 cc engines and their latter-day CS counterparts. For starters, the CS versions have carburettor bodies made from aluminium alloy rather than the moulded high-density black plastic employed in the British-made originals. In addition, the backplates of the CS renditions are sealed with an O-ring as opposed to a paper gasket or no gasket at all. Another defining indication is the style of identification

Several experimenters tried fitting a 3 mm O/D tube inside the standard venturi, burring it at either end to keep it in place to act as a sleeve for the original tube. This reportedly improved suction to the point that the engine became easier to start and would run the tank out reasonably well. However, it still tended to get very hot near the end.

The effective choke area on the tested example of the original made-in-England Clan (no. 0297) is 0.84 sq. mm, which according to my calculator should work fine at around 7,000 RPM. As a comparison, a Mills P.75 has 3.5 sq. mm effective choke area, which by proportion to swept volume (three times larger) is a good deal more generous. Of course, the Mills runs better at chugging RPM if choked down, but seems OK as delivered as far as most users are concerned. So I'd say that choke area is not a problem with the original Clan 0.24. If CS duplicated those dimensions, then any suction problems must be down to some other cause. Regardless, it does appear to be entirely possible that much of the less-than-stellar reputation of the Clan 0.24 cc diesel stems from negative experiences with the CS renditions of the engine. Neither I nor website editor Adrian Duncan have found any issues about which to complain with the original British-made units from 1992. The CS Clan 0.48 cc Diesel on Test Among the engines owned by my mate Anthony Williams that I agreed to help dispose of was an NIB example of the 0.48 cc CS rendition of the Clanford Clan, serial number 494. Finding that its condition was such that I couldn't in good faith sell it to others as a "user", I bought it myself as a test subject. As stated earlier, the Clan 0.48 was made for Mike Clanford by CS in Shanghai, China, proclaiming this in neat engraving on top of the cylinder cooling jacket as well as bearing the designation on the crankcase side. The engine’s external appearance is very pleasing, particularly the machined crankcase finish, anodized cooling fins and neatly-engraved identification. Appearances to the contrary, this example was not an out-of-the-box goer, despite having supposedly undergone the claimed pre-dispatch proving run. As mentioned earlier, this failure to run appears to be a not-infequent characteristic of these CS renditions. The prop driver was cracked (not uncommon with similar CS engines – poor material) and the contra piston was well and truly stuck. I machined and pressed on a steel collar for the prop driver and dressed the contra piston down by almost 10 microns for a nice fit. The good news was that the cylinder retaining screw holes in the crankcase are blind and the cylinder-to-crankcase joint in this example was snug. The O-ring back plate seal is excellent. Overall, no opportunity for crankcase compression leaks there! Initial runs were encouraging. This one is not nearly as fussy about priming as the smaller .24 cc version. Traditional finger choking the venturi worked with care, although in this case the challenge was to get adequate fuel in, rather than the more common small-engine tendency towards flooding. This is because a generous lower cylinder bore taper does a poor job of sealing crankcase compression without adequate residual oil. The choking action can just as easily draw air into the crankcase via the exhaust ports as fuel via the needle valve. Moreover, with symmetrical timing, keeping one’s finger over the intake past top dead centre will cause blow-back.

Once running, repeatable readings could not be achieved despite adequate piston bedding-in through a series of break-in runs. The tendency to sag when seeking top RPM with a given load might seem to confirm the previously-mentioned reports from other owners of a tendency to overheat. However, in this case we diagnosed a dry crankshaft bearing problem. This is not uncommon with side-port induction designs if no pathway to the bearing for lubricating oil is provided. The issue is easily solved by cutting a vertical groove in the crankcase face where the crankweb bears when running. Following this simple modification, the Clan .48 ran reliably. Response to the controls was progressive and a useful range of toned-down speeds could be had with balanced adjustment of compression lever and needle. Regular diesel fuel formulas are fine, as is our preferred brew: equal parts ether, kerosene and SAE 50 mineral oil, with 0.8% added ignition improver. Performance analysis As noted earlier, absolute performance numbers from such small engines are significantly affected by piston fit. Ours was a bit tight (at least when cold) and, judging by progress during the bedding-in stage, will likely remain that way for a lot of useful flying time. That said, it showed no sign of causing trouble and can thus be considered “good”.

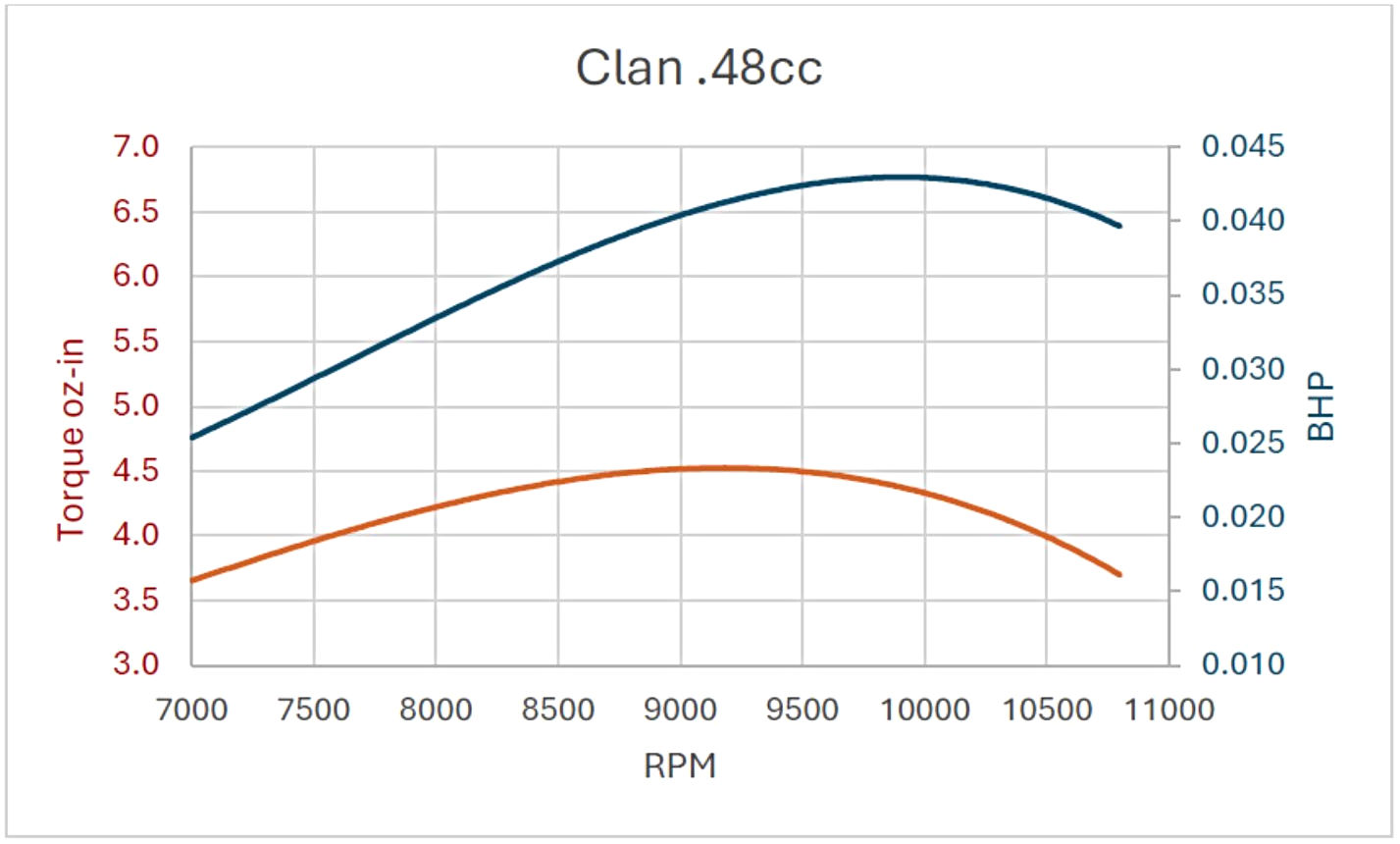

Torque and power curves are closely matched, much like typical first-generation model diesels. Peak power is reached near 10,000 RPM for an indicated .042 BHP, which is broadly in line with 1950’s British rotary valve point-fives, although the sideport Clan will not sustain this level with the lighter loads that those models can work with. Its forte is delivering a very useful torque figure of 4.5 oz-in torque at around 9,000 RPM, very close to where peak power is achieved. By choosing suitable propellers to run within this relatively narrow range, the Clan .48 will deliver a very solid performance. Although working on the wrong side of the torque peak, it will run acceptably with a 7x4 propeller. Certainly, if diameter is trimmed to 6.5 inches with the engine set at an easy running speed, it is then likely to give very a useful level of thrust for sport flying. A 7x3 or 6x4 propeller both match its comfort zone for flat-out settings. Overall, the Clan .48’s design is sound. Even though having the top third of the intake ports opened towards bottom dead centre is frowned upon, the porting numbers are good. And the steel connecting rod is a sensible choice for real-world users. Much good work by CS is apparent here, but our identified faults (if appearing in other examples) are not easily remedied by many potential users. Nevertheless, the final verdict is positive. After correction, it passes the “would I build a model for it and put it to use, expecting a good time” test! I subsequently spent a little more time with the Clan .48 with sport FF flying in mind, rather than seeking top BHP. Fuel suction seemed to be OK in a Mills P.75 kind of way, if you didn't know that it could be better! The standard choke area is 1.65 mm2. I made a tubular upstream venturi insert with a bore of 1.3 mm, bringing the choke area down to 1.32 mm2 and increasing the incoming air velocity by 25% upstream of the needle position. This modification resulted in no loss of power when turning a 7x4 propeller, but improved consistency at backed-off speeds down to 4,500 RPM. At a likely "sport flying" setting of 6,000 RPM with the 7x4 propeller, the routine is then very simple. Open the needle ¼ to ½ turn from running setting for cold starts, or leave it at running setting if still warm from the previous run. Prime with two drops into venturi (engine pointing down to be sure it goes in), apply a couple of turns over compression to pump fumes into combustion chamber, and it starts instantly. Exactly how a good sports diesel should be! The Dave Jones Clans

While not for beginners, the engine started very readily and ran superbly. Calculated to delight the most demanding purchaser, in fact! The little motor typically reached 8,000 rpm on a Cox 5 x 4 black nylon prop, with a 2½ min. run on the supplied hang tank. (Editor's note - I acquired engine no. 04 of this batch, and can report that it conforms to the above comments in every way! - A.D.) Our valued late friend Ken Croft also completed his own rendition of the Clan in January 2020. Ken was kind enough to provide a set of builder's notes for the engine, to which Dave Jones added his own input at the Editor's request. This material will appear on this website in due course. Conclusion

We hope that the present test has demonstrated that a good example of the original engine (which do exist – I have two of them! A.D.) was actually a very capable performer for its size. There’s no guarantee when you buy an example on eBay or similar sight unseen, but if you have the opportunity to examine the engine before buying it and are satisfied that its piston/cylinder fit is OK, you’ll be getting a well-made and very useful miniature diesel for small free flight sport or scale models. ____________________________ Article © Maris Dislers, Adelaide, South Australia First published July 2017 Updated December 2025 - test of CS 0.48 cc Clanford Clan |

|

| |

Back in the August 1992 issue of “

Back in the August 1992 issue of “

The Clan’s design is so simple that the late Ron Chernich drew up a set of Motor Boys International plans for home constructors. The attached General Arrangement drawing from Ron's plan set includes the engine's basic timing parameters for those interested.

The Clan’s design is so simple that the late Ron Chernich drew up a set of Motor Boys International plans for home constructors. The attached General Arrangement drawing from Ron's plan set includes the engine's basic timing parameters for those interested.

We have often emphasised the key role of the piston/cylinder fit in determining an engine’s performance. Not just that little extra, but with the miniatures it can be the dividing factor between a good performer and a real disappointment. Achieving the perfect fit is not an easy task at the Clan 0.24 cc diesel’s size, and its dead parallel cylinder bore leaves very little margin for error.

We have often emphasised the key role of the piston/cylinder fit in determining an engine’s performance. Not just that little extra, but with the miniatures it can be the dividing factor between a good performer and a real disappointment. Achieving the perfect fit is not an easy task at the Clan 0.24 cc diesel’s size, and its dead parallel cylinder bore leaves very little margin for error. with a tighter piston fit.

with a tighter piston fit. As mentioned earlier, Mike Clanford arranged for the manufacture of an extra batch of engines by the CS company of Shanghai, China, which has since abandoned the model engine manufacturing field. These examples were manufactured in two displacements – the “standard” 0.24 cc model and a double-sized variant of 0.48 cc displacement. These engines appear to have been manufactured in comparable numbers to the originals.

As mentioned earlier, Mike Clanford arranged for the manufacture of an extra batch of engines by the CS company of Shanghai, China, which has since abandoned the model engine manufacturing field. These examples were manufactured in two displacements – the “standard” 0.24 cc model and a double-sized variant of 0.48 cc displacement. These engines appear to have been manufactured in comparable numbers to the originals.

One very knowledgeable owner of the 0.24 cc version of the CS Clan was the late and much missed David Owen of Woolongong, Australia. He reported having run his example and experiencing similar problems. In his case, the piston/cylinder fit was not exceptional and the engine lost power as it warmed up. In addition to this, the venturi/tank assembly left some room for improvement. David sleeved the venturi bore slightly, but the result was still not satisfactory, although there was an improvement.

One very knowledgeable owner of the 0.24 cc version of the CS Clan was the late and much missed David Owen of Woolongong, Australia. He reported having run his example and experiencing similar problems. In his case, the piston/cylinder fit was not exceptional and the engine lost power as it warmed up. In addition to this, the venturi/tank assembly left some room for improvement. David sleeved the venturi bore slightly, but the result was still not satisfactory, although there was an improvement. Instead, it was best to go with several 45-degree chokes approaching compression. Dropwise priming from a syringe to the intake is an alternative option. Exhaust priming is best avoided. With the right intake prime, the Clan is an instant starter, just as the sales blurb says.

Instead, it was best to go with several 45-degree chokes approaching compression. Dropwise priming from a syringe to the intake is an alternative option. Exhaust priming is best avoided. With the right intake prime, the Clan is an instant starter, just as the sales blurb says.

In 2019, the skilled model engineer Dave Jones of Hervey Bay in Queensland, Australia built a batch of five examples of the 0.24 cc Clan using the published Motor Boys plans. These engines were constructed to very high standards, with fits and finish in the best Australian tradition as established by the late

In 2019, the skilled model engineer Dave Jones of Hervey Bay in Queensland, Australia built a batch of five examples of the 0.24 cc Clan using the published Motor Boys plans. These engines were constructed to very high standards, with fits and finish in the best Australian tradition as established by the late  The reputation of the Clan 0.24 cc diesel has never really recovered from the rather negative review published by Richard Herbert in “AeroModeller”. Ever since the appearance of that test report, the engine has been widely seen as a cute collectible and nothing more. Ron Chernich’s later comments regarding problems with the cylinder porting have done nothing to alleviate this perception of the engine. Finally, negative experiences with the later CS versions seem to have done their part to further undermine the engine’s reputation as a useable model powerplant.

The reputation of the Clan 0.24 cc diesel has never really recovered from the rather negative review published by Richard Herbert in “AeroModeller”. Ever since the appearance of that test report, the engine has been widely seen as a cute collectible and nothing more. Ron Chernich’s later comments regarding problems with the cylinder porting have done nothing to alleviate this perception of the engine. Finally, negative experiences with the later CS versions seem to have done their part to further undermine the engine’s reputation as a useable model powerplant.