|

|

The VA 0.4 cc Micro Diesel Replica Re-Assessed By Maris Dislers

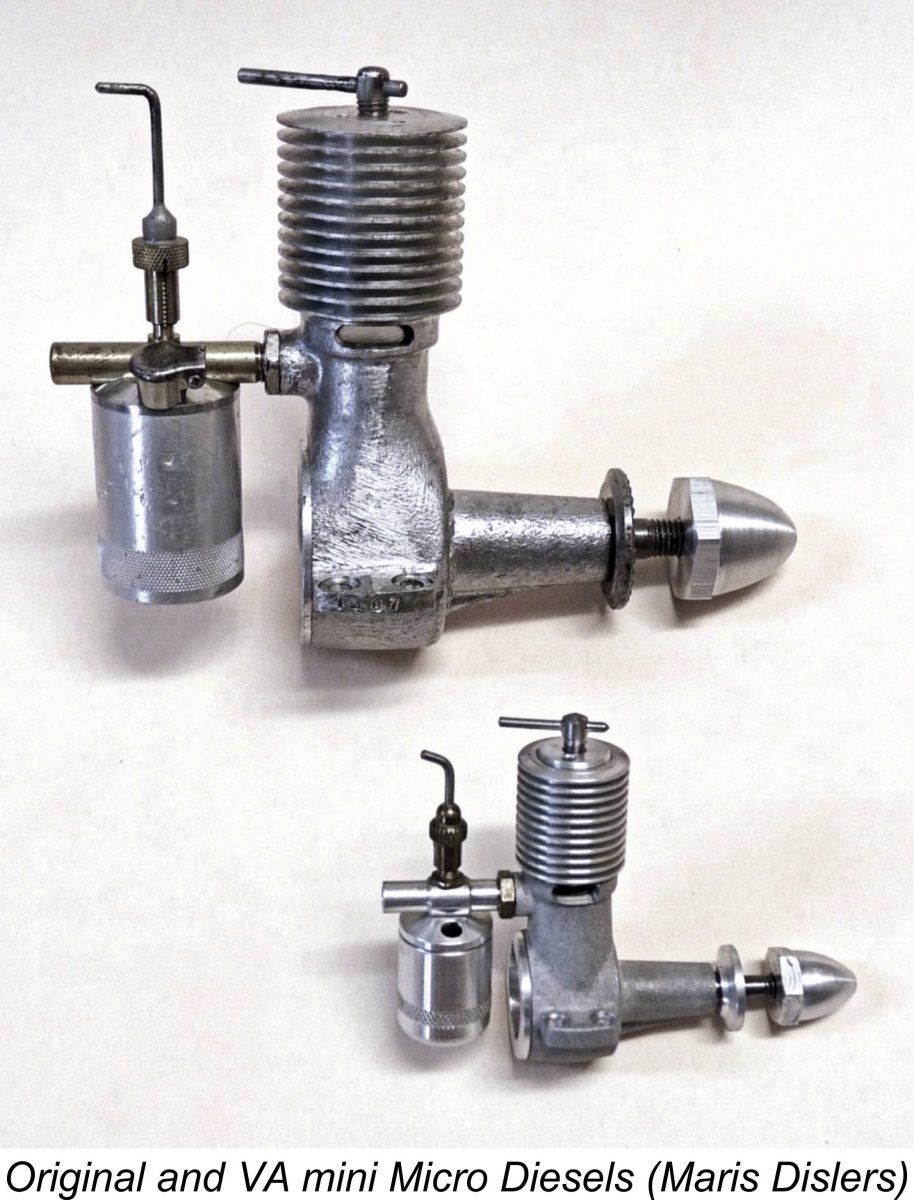

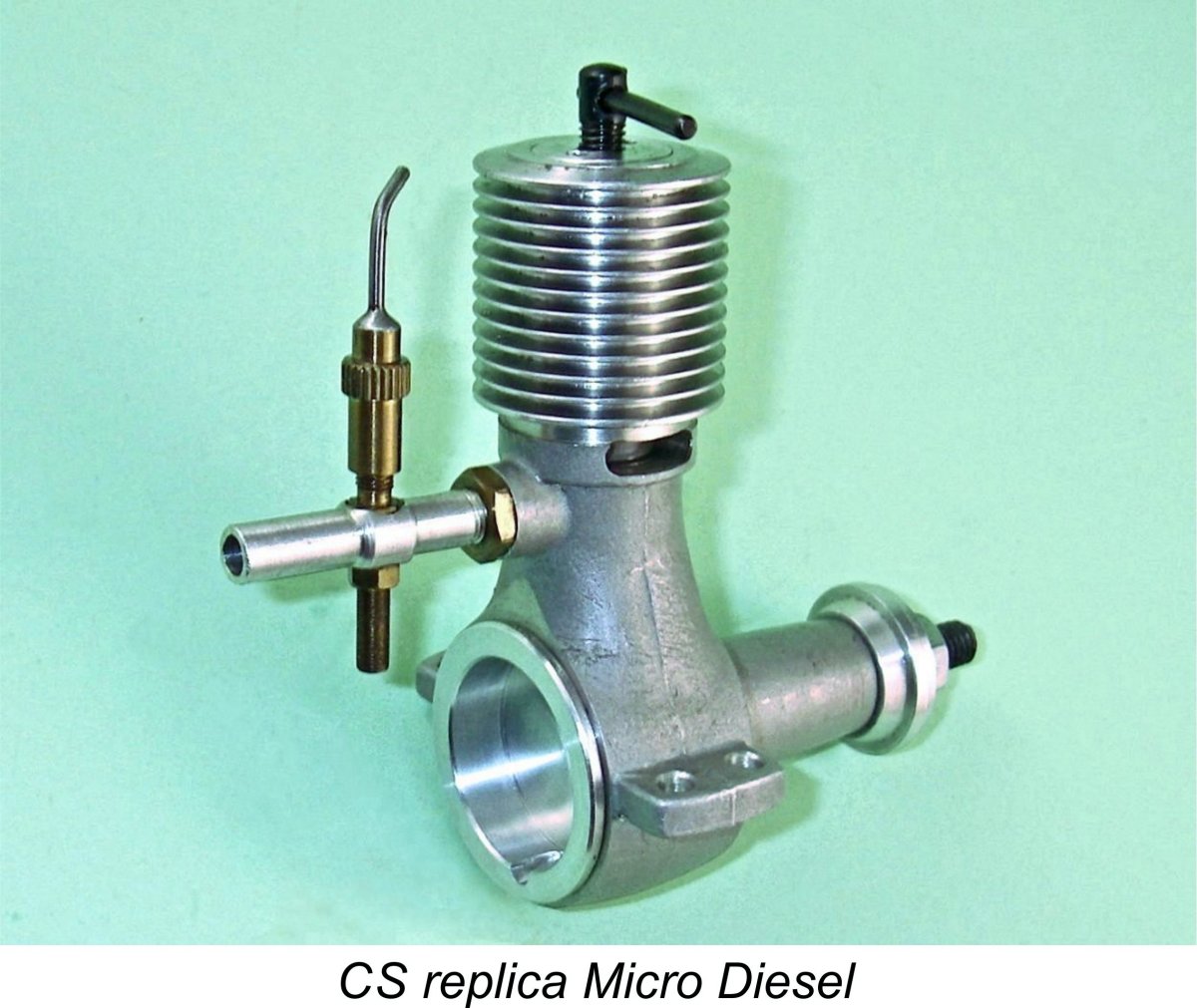

They certainly did so with respect to the original Micro Diesel reviewed recently by Adrian, whose test subjects (original and CS replica) both featured very mild exhaust and transfer durations coupled with seemingly excessive intake and sub-piston induction durations. It’s true to say that a given engine's timing figures are generally chosen by the designer for reasons which seem valid to him. Not unreasonably assuming this to be the case for the Micro Diesel, Adrian presented an analysis of just what those reasons might have been in this instance. However, it occurred to me that there might be an alternative and far simpler explanation. Knowing that the piston movement in a sideport engine like this one controls all of the respective port durations, I envisioned the possibility that somebody might have goofed somewhere along the line linking design, drawing and execution, with the result that either the conrod was made too long or the socket for the ball joint at the top was located too low in the In that article, Adrian also mentioned the fine little 0.40 cc mini-Micro replica manufactured in small numbers in St. Petersburg, Russia by Valentin Aloshkin under his VA brand name. Aloshkin also manufactured mini replicas of a number of other classic diesels such as the Mills .75, the E.D. Bee, the Elfin 1.8, the Elfin 50, the E.D. Baby, the FROG 50 and the Kalper .32. These engines were effectively promoted and marketed by Dave Banks of England, hence often being referred to on eBay and elsewhere as “Dave Banks engines”. However, they are all VA products. The priorities of most people buying Aloshkin’s mini replica diesels probably fell into something like the following order. First, it should look like the prototype in miniature. Secondly, it has to be easy starting. Thirdly, it has to deliver a reasonable performance to fly an appropriate model effectively. And finally, it has to deliver a reasonable service life. As most of the VA miniatures were made in very small numbers, relatively little time was spent optimizing every visual detail. Some VA mini diesels perform better than others, essentially mimicking the relative performance strengths of their full size prototypes, while others fall somewhat short.

I’d previously tested my example of the VA miniature, finding that its power output fell somewhat short of my VA/Dave Banks 0.4 cc mini Mills replica. After reading Adrian’s piece on the full size Micro and forming my previously-noted theory regarding the possibly erroneous basis for its seemingly strange timing numbers, I decided to experiment with altering the port timing of the 0.4 cc VA replica to something more closely approaching normality. As the performance curves and RPM values presented below demonstrate, my efforts were crowned with success! The VA mini-Micro Diesel has bore and stroke dimensions of 7.15 mm (.281 in) and 9.69 mm (.381 in) respectively for a calculated displacement of .389 cc (.024 cu in). It weighs in at 29.7 g (1.05 oz). The intake features an effective choke area of 1.55 mm2.

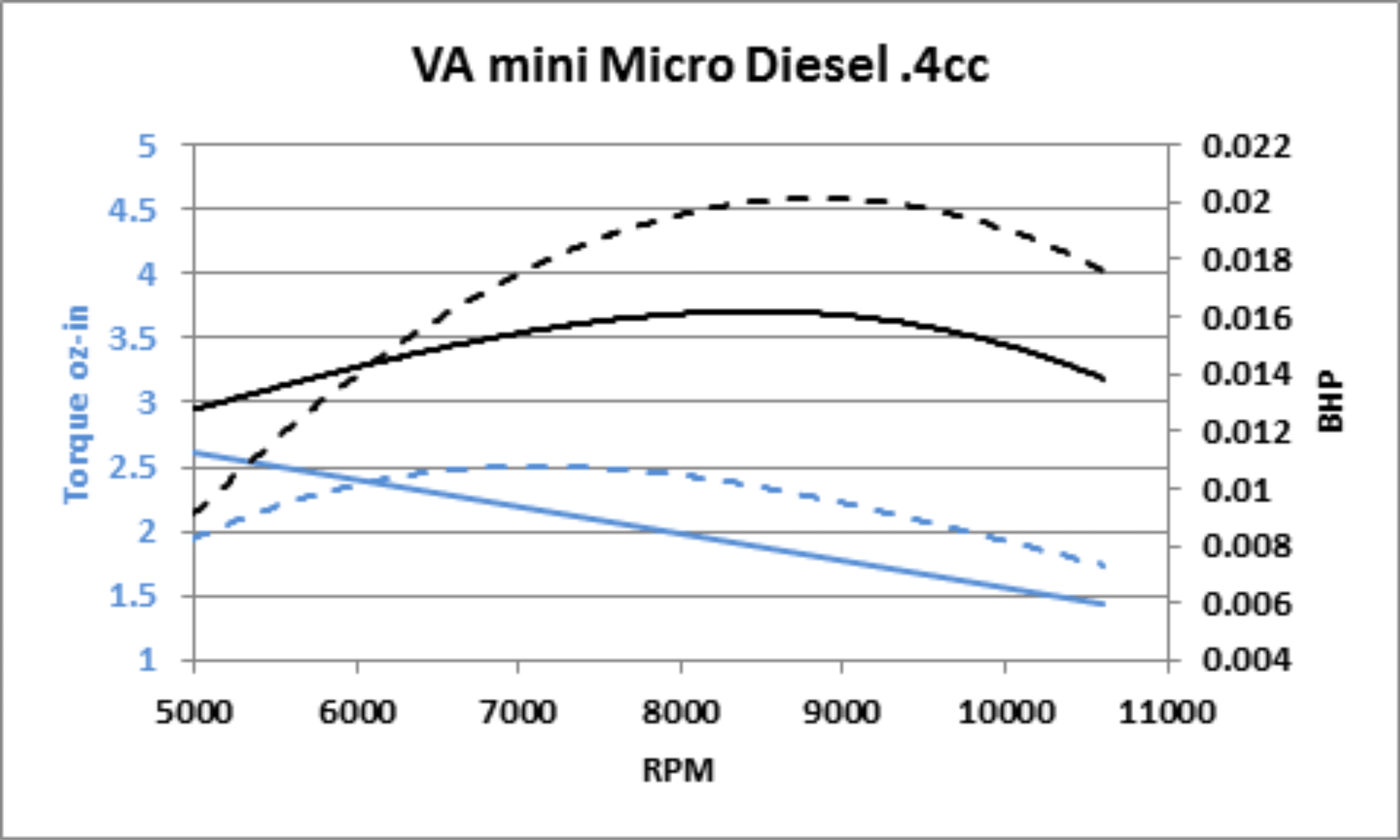

In standard form, good torque development at low speeds allows the mini Micro to turn a 7x6 propeller at 5,000 RPM. A bit of a challenge, as suction is well below reliable levels. Since maximum power is developed at around 8,000 to 9,000 RPM, a 6x4 or 7x3 flight propeller is more appropriate. You then get quite acceptable throttling by reducing the compression setting. Like all of Valentin’s engines of similar size and layout, this is an easy going engine well suited to sport model flying. Power output is quite adequate as it stands.

I tried a number of metal spacer rings, ending up using a ring of 0.7 mm (.027 in) thickness. This raises the cylinder ports by that amount to rationalize the timing somewhat, thereby improving performance. Any competent machinist can make the ring (8.9mm OD and 7.5mm ID). The creation of a pin spanner for undoing the cylinder retaining nut is not beyond a good modeller’s skills. I’ve presented test results extracted from the VA 0.4 cc Micro in its standard and retimed forms. The power curve graph shows performance trends in standard (solid lines) and modified (dotted lines) form. As delivered, torque drops quite rapidly with rising RPM, losing 25% by the time the engine's relatively modest 0.017 BHP peak power point is reached at around 8,500 RPM. Comparable mini-diesels generally retain 80 – 85% of their maximum torque at the peak BHP point, which the VA Micro also did in its modified form, lifting peak power output to just over 0.020 BHP around 9,000 RPM.

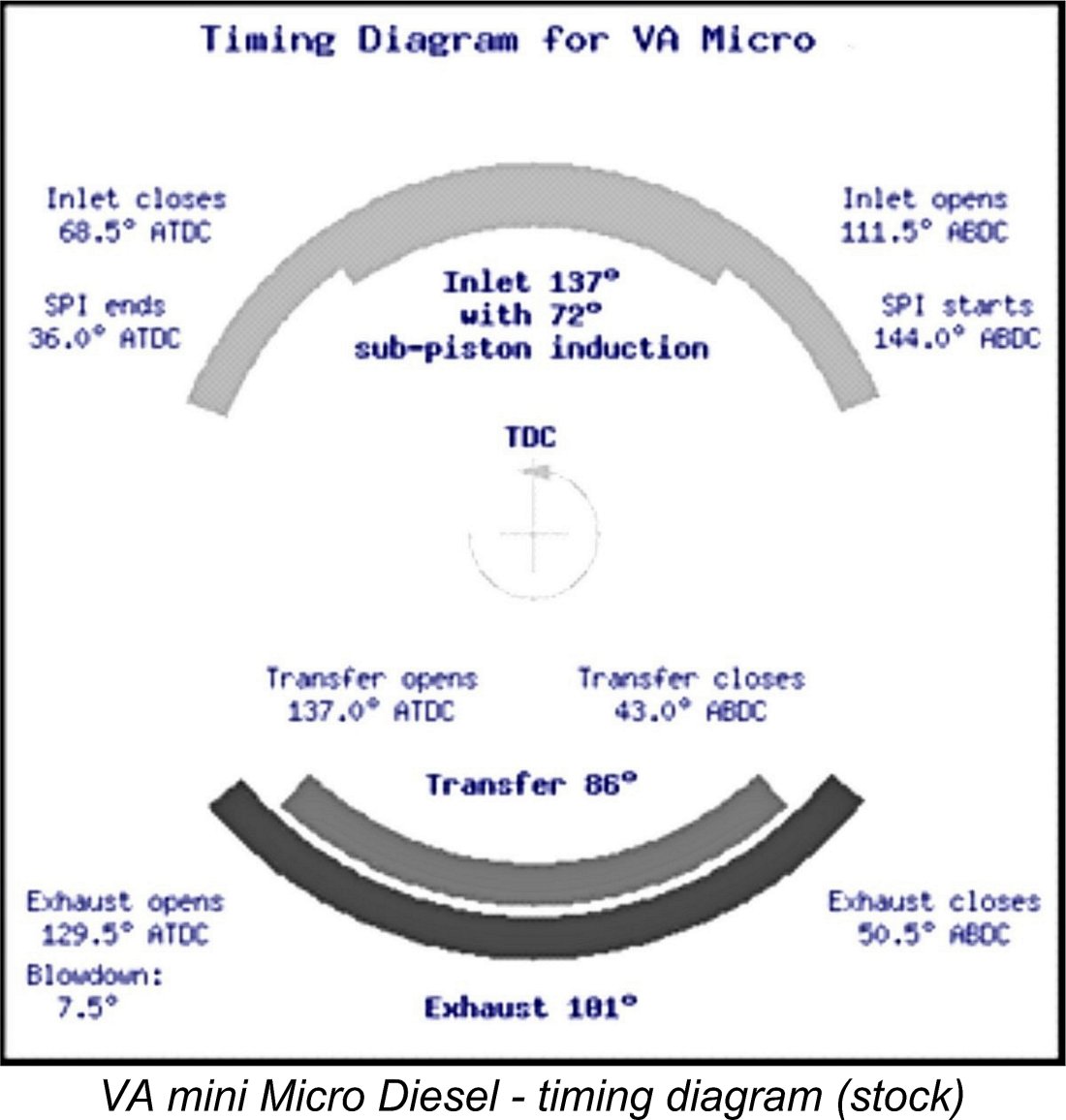

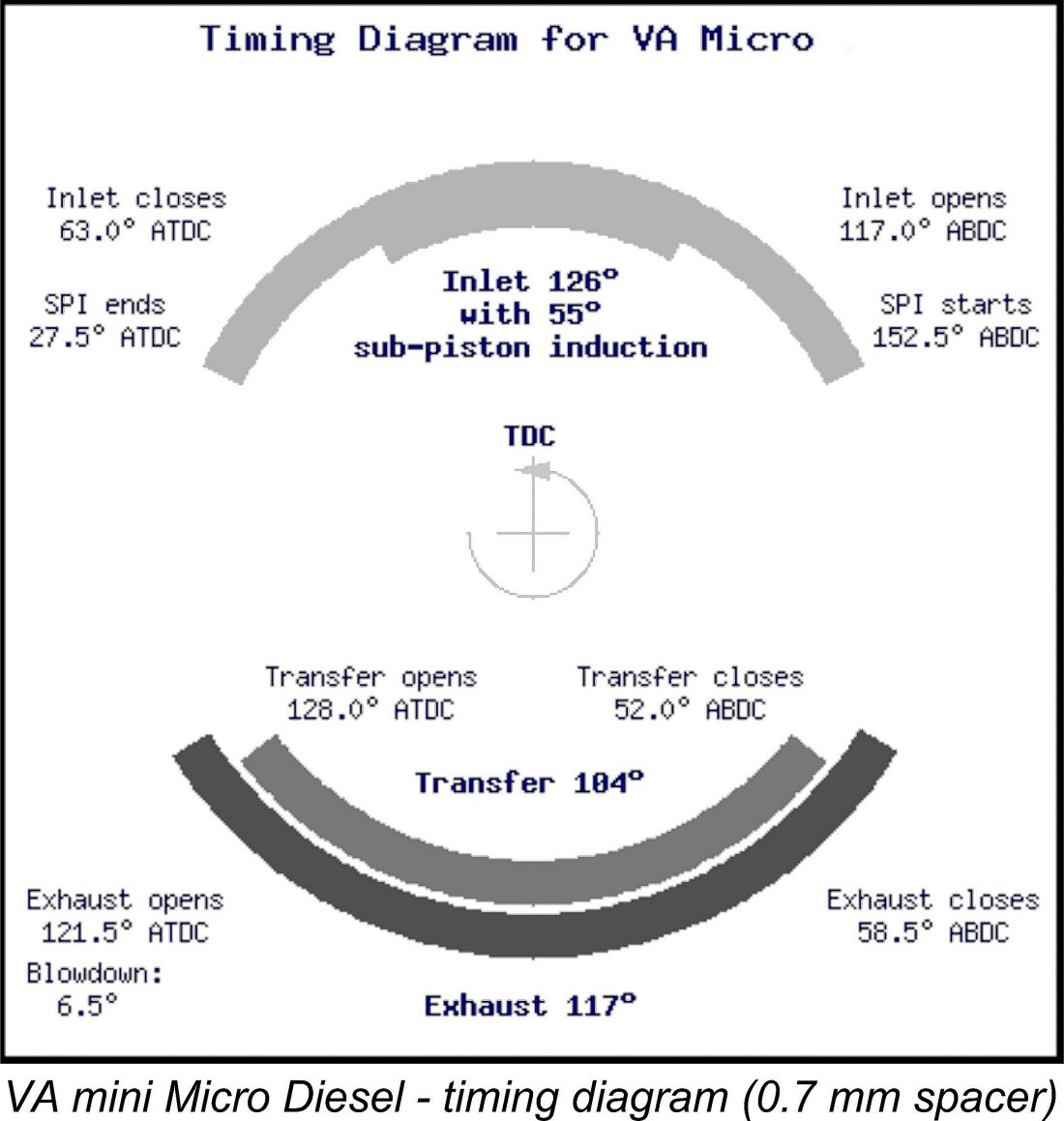

As can be seen from the above figures, the modified engine delivers an extra 500 or more extra RPM with useful flight propellers. Proportionally speaking, that’s a very worthwhile gain for a low-revving engine, putting the VA Mini-Micro Diesel on par (for example) with VA’s Mini-Mills 0.4cc diesel. The re-timed VA mini-Micro might give its best all-round consistency in flight along with improved throttling flexibility with a wide bladed 6x3 or perhaps Master Airscrew’s easy-going 6x4 propeller. Doing It by the Numbers The above text summarizes the ultimate results achieved through this experiment. However, if you’re interested in the nitty gritty of such experiments, here ‘tis. Anything unusual in a model engine design is usually there for a reason. We don’t know for sure why the original Micro has such odd cylinder port timing values – we can only make an educated guess. For better or worse, the VA replica quite faithfully copies As the attached timing diagram shows, the stock engine features very mild exhaust and transfer durations coupled with excessive intake duration and an unusually long period of supplementary sub-piston induction around the top of the stroke. Stan Pilgrim, my much respected engine tuning guru, reckons that 120 degrees intake is the practical limit before primary compression and subsequent transfer effectiveness are significantly reduced. As documented earlier, I had tested the engine in that configuration, finding that while it ran OK its performance was down on other mini diesels of similar displacement. My theory was that the designer or perhaps the builder(s) of the Micro had somehow made a mistake with the conrod length and that “fixing” this construction error would restore the port timing to the intended values, giving improved performance. The easiest approach to testing this theory was to make a simple spacer ring to lift the cylinder liner instead of making a shorter conrod. This would have the disadvantage of putting the cylinder ports out of alignment with their corresponding apertures in the crankcase, but I felt that this would not affect the validity of the results to any significant degree. The most important alignment consideration was to ensure that the bridge at the base of the cylinder bypass slot remained sufficiently well aligned with its corresponding channel in the crankcase (see Adrian’s article) that bypass and transfer efficiency would not be adversely affected. Inspection showed that there was enough wiggle room in the VA Micro to keep the bypass open with the spacer installed.

A second series of tests with this spacer fitted showed a useful increase of around 500 RPM with typical flight propellers. Proportionally speaking, that’s quite a bit for a slow-revving engine. However, the engine had a tendency to hunt at higher running speeds. I concluded that this was because the piston no longer covered the top of the intake port towards the bottom of its stroke. Some exhaust gas could thereby enter the venturi, potentially upsetting gas flow during the induction phase.

The revised exhaust and transfer periods are far closer to what might be considered ideal for an engine of this type. However, the inlet period of 126 degrees is still longer than ideal, as is the 55 degree sub-piston induction period. The achievement of really good port timing numbers would require further juggling of the relationship between piston length, conrod length and wrist pin location to essentially eliminate sub-piston induction and balance the rest. My experiment has shown that this is not achievable with the cylinder ports cut as they are, so a redesign of the cylinder ports would also be required to achieve optimal results. Even so, I expect that the original Micro 2.1 cc engine would also gain performance with my simple tweak.

This error, if error it was, is unfortunate because whoever designed the original Micro Diesel engine did a fine job generally. However, he could only draw upon the then-available understanding of two-stroke porting requirements. That understanding was still very much evolving when the Micro Diesel was designed. Assuming that the error theory with the original Micro Diesel is correct (and we'll never be able to prove it!), the question remains regarding how the error crept in. It would have been hard to draw the engine with the wrong conrod length, so it seems most likely that the error occurred during the transfer of the conrod length from the drawing to the machine shop. Perhaps it was incorrectly scaled off the drawing.

Finally, and perhaps prohibitively, it would put the cylinder ports out of alignment with their corresponding apertures in the crankcase casting, most critically including the internal bypass bridging cavity at the front, which might have to be extended upwards to maintain adequate bypass function. Again, the customers would doubtless be deterred by such an obvious mis-match. As if this wasn't enough, it would require the partial disassembly and reassembly of all the engines. All of this would cost both time and money, which the manufacturers quite possibly did not have. The most elegant solution (and perhaps the only truly viable approach in technical terms) was clearly to retro-fit the entire batch of engines with con-rods made to the correct length. However, the naval bronze rod used in the original Micro Diesel with its ball top end was a challenging and hence expensive component to produce. Correction of the problem would not only require the manufacture of enough new rods to retro-fit the entire batch, but would also require that each and every engine be completely torn down and re-built from scratch. This would undoubtedly be even more expensive than the first alternative of raising the cylinder. In looking at the expense involved in undertaking such a correction, the manufacturer would have been only too well aware of the arrival of the glow-plug upon the American scene and the predictable impending eclipse of the diesel in sales terms. For this reason, it's very likely that the first late 1947 batch of engines was the only batch ever made. It would be completely understandable for the manufacturer to decide to cut his losses by going ahead with the marketing of the engine with the conrod error left uncorrected. After all, the original engine actually started and ran surprisingly well in that configuration, as Adrian demonstrated in his review. It's just that it would almost certainly have run even better with a shorter rod fitted. This may not be the end of the story! Adrian has indicated his intention to take measurements from his CS replica Micro Diesel to determine how much shorter the rod could be made and still leave the inlet closed at BDC. If a worthwhile shortening proves to be possible, he will make a replacement rod and re-test his engine. Stay tuned ……………… (Editor's note - I did just that, with very positive results! I found that a rod made 2.5 mm shorter (34 mm as opposed to 36.5 mm) completely transformed the engine. See details in my separate article - A.D.) _________________________________ Article © Maris Dislers, Adelaide, South Australia First published September 2017 |

||

| |

When copying the 2.1 cc Micro Diesel at one-fifth displacement, Valentin faithfully scaled down most of the principal design elements, including the oddball cylinder port timing figures. The main exceptions were that his mini-replica has a relatively generous effective choke area relative to its displacement, also using a regular wrist pin at the top of the conrod rather than the ball joint featured in the original.

When copying the 2.1 cc Micro Diesel at one-fifth displacement, Valentin faithfully scaled down most of the principal design elements, including the oddball cylinder port timing figures. The main exceptions were that his mini-replica has a relatively generous effective choke area relative to its displacement, also using a regular wrist pin at the top of the conrod rather than the ball joint featured in the original. Overall, the engine is nicely made. The piston fit in my example could have been made tighter, but this probably doesn’t affect power output and starting is fine with a light exhaust prime. Still, it’s best to keep the oil content high and use only castor oil for the job. The engine requires little or no ignition improver – in fact, upping the improver never did eliminate a slight tendency to misfire at peak settings.

Overall, the engine is nicely made. The piston fit in my example could have been made tighter, but this probably doesn’t affect power output and starting is fine with a light exhaust prime. Still, it’s best to keep the oil content high and use only castor oil for the job. The engine requires little or no ignition improver – in fact, upping the improver never did eliminate a slight tendency to misfire at peak settings. As stated earlier, the very unorthodox timing figures for the engine were copied more or less exactly from the original 2.1 cc Micro Diesel. Since jacking up the cylinder slightly with a suitable spacer would have more or less the same effect upon timing as shortening the rod, I elected to take that far simpler approach to my experiments with more rational timing.

As stated earlier, the very unorthodox timing figures for the engine were copied more or less exactly from the original 2.1 cc Micro Diesel. Since jacking up the cylinder slightly with a suitable spacer would have more or less the same effect upon timing as shortening the rod, I elected to take that far simpler approach to my experiments with more rational timing.

those values. According to measurements taken from my example, I get the numbers shown in the attached timing diagram, using the handy calculator found in the “design center” area of the late Ron Chernich’s “

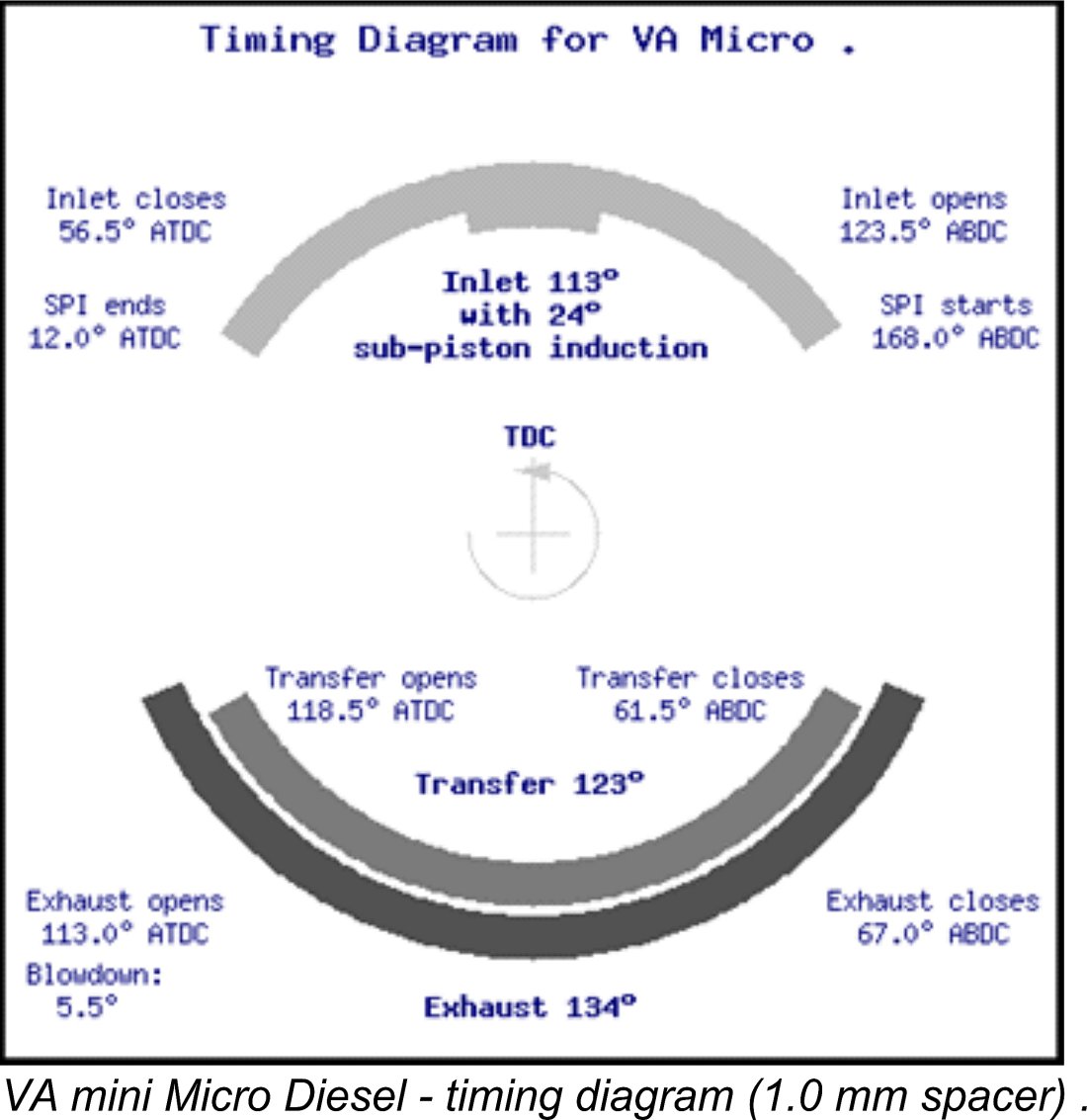

those values. According to measurements taken from my example, I get the numbers shown in the attached timing diagram, using the handy calculator found in the “design center” area of the late Ron Chernich’s “ I began by fitting a 1.0mm spacer ring, giving the port timing figures shown in the attached timing diagram. Note that the spacer not only decreases the intake and sub-piston induction periods but also gives a significantly greater period of induction through the venturi before the sub-piston induction puts an end to that phase. Both of these changes undoubtedly move things in the right direction. The earlier closing of the intake after TDC will result in an increase in primary compression for improved transfer efficiency. The extended transfer and exhaust durations are probably of secondary importance – nonetheless, they were almost certainly less than optimal as originally configured, so this too may well be seen as a positive change.

I began by fitting a 1.0mm spacer ring, giving the port timing figures shown in the attached timing diagram. Note that the spacer not only decreases the intake and sub-piston induction periods but also gives a significantly greater period of induction through the venturi before the sub-piston induction puts an end to that phase. Both of these changes undoubtedly move things in the right direction. The earlier closing of the intake after TDC will result in an increase in primary compression for improved transfer efficiency. The extended transfer and exhaust durations are probably of secondary importance – nonetheless, they were almost certainly less than optimal as originally configured, so this too may well be seen as a positive change. Back to the drawing board, and further testing with other spacer rings finally arrived at a “Goldilocks” spacer ring thickness of 0.7 mm. This just prevented the piston from uncovering the inlet port at BDC, thus eliminating the potential exhaust backflow problem. It proved to give the best overall performance gain, despite actually losing some power at impractically low RPM. Considering the fact that really good suction only begins at around 8,000 RPM, that’s unimportant. The performance figures and associated power curve obtained with the engine in this ultimate configuration were presented earlier in this article.

Back to the drawing board, and further testing with other spacer rings finally arrived at a “Goldilocks” spacer ring thickness of 0.7 mm. This just prevented the piston from uncovering the inlet port at BDC, thus eliminating the potential exhaust backflow problem. It proved to give the best overall performance gain, despite actually losing some power at impractically low RPM. Considering the fact that really good suction only begins at around 8,000 RPM, that’s unimportant. The performance figures and associated power curve obtained with the engine in this ultimate configuration were presented earlier in this article.

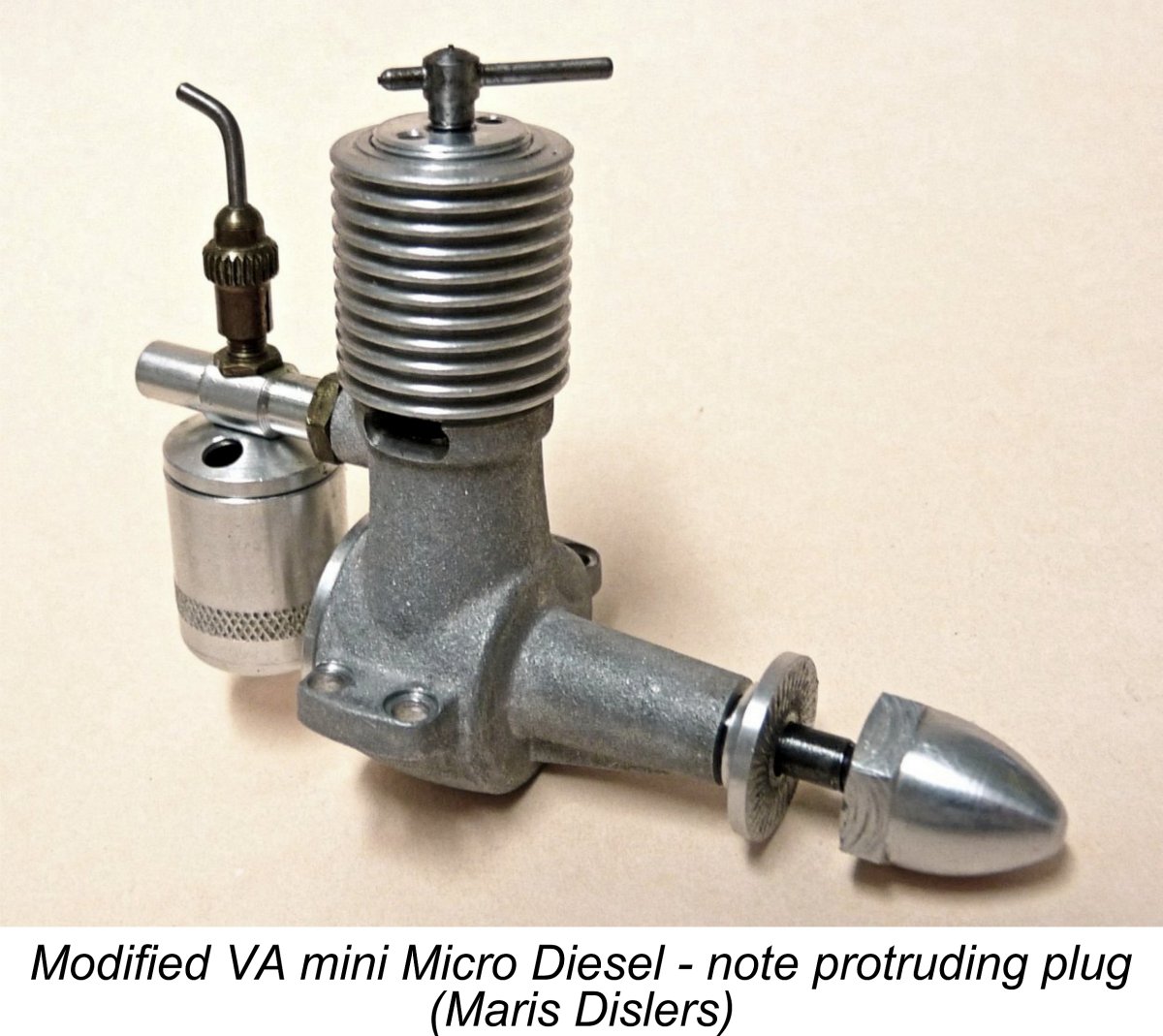

However the error crept in, we are left with the ultimate question - once the error became apparent (as it surely would upon close examination of the assembled engines in that first batch), why didn't the manufacturer take action to correct the situation? The simplest solution would have been to raise the cylinder through the use of a spacer at the base, as I did in my experiments. However, this in turn would require that the cylinder be shortened at the top so that the screw-in retaining plug could still be utilized – the customers would certainly be put off by that obviously mis-matched protruding plug! It would also require the manufacture of the required spacers.

However the error crept in, we are left with the ultimate question - once the error became apparent (as it surely would upon close examination of the assembled engines in that first batch), why didn't the manufacturer take action to correct the situation? The simplest solution would have been to raise the cylinder through the use of a spacer at the base, as I did in my experiments. However, this in turn would require that the cylinder be shortened at the top so that the screw-in retaining plug could still be utilized – the customers would certainly be put off by that obviously mis-matched protruding plug! It would also require the manufacture of the required spacers.