|

|

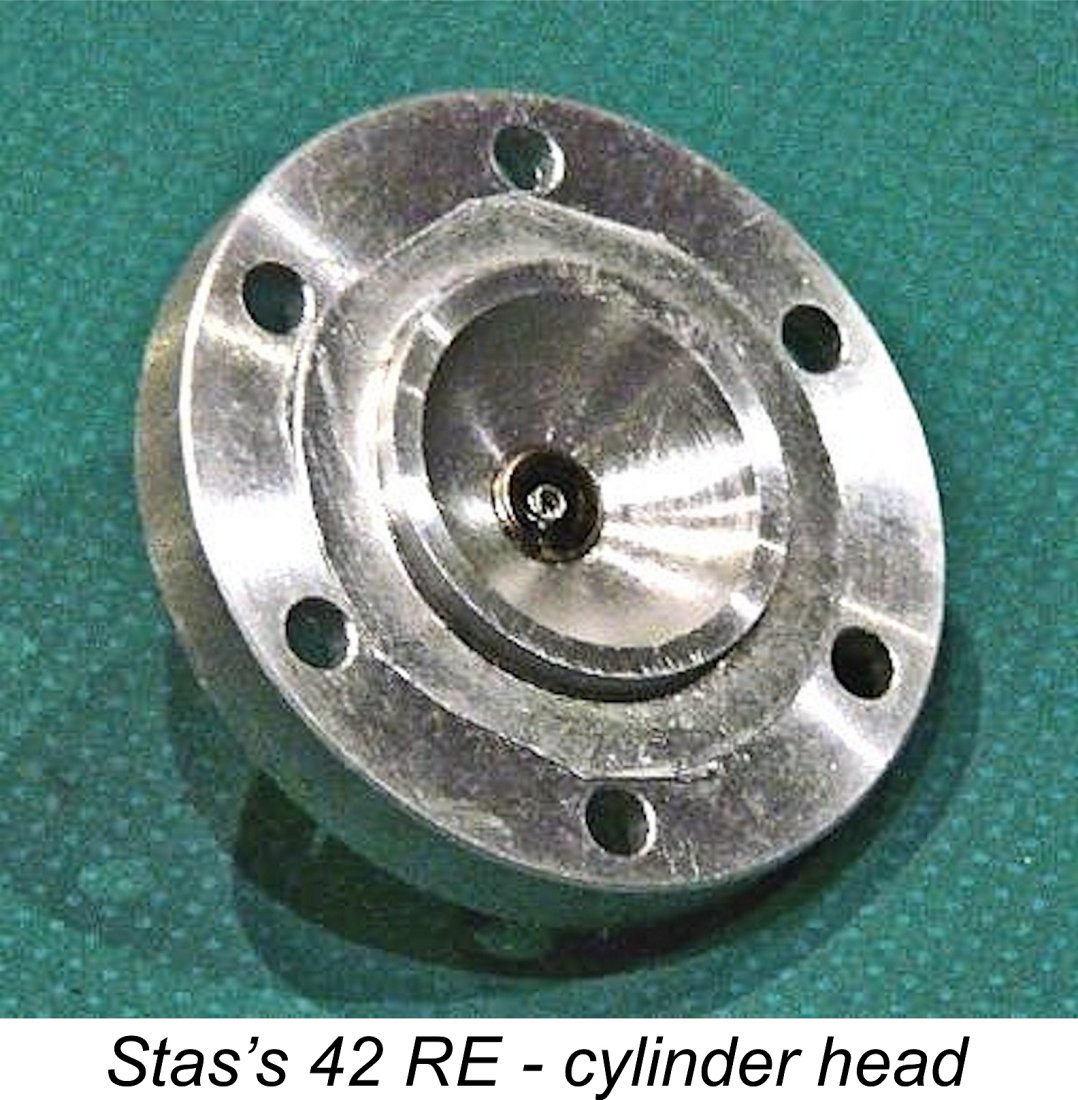

The Stas’s 42 Rear Exhaust Glow-Plug Motor By Brian Hampton

The article which appears below is a case in point. It was written by Brian Hampton of Adelaide, South Australia as a contribution to the newsletter of his model flying club, the Holdfast Model Aero Club. Regular readers of my own site will be familiar with Brian’s outstanding contribution to the preservation of model engine history through his ever-informative Sceptre Flight website, which contains almost every published test of a model engine that has ever appeared in the modelling media down through the years. I refer to Brian's site on a regular basis. The engine under discussion in this article is a very obscure Russian-made unit called the Stas’s 42 RE. The apostrophe in the engine's name is not a typo! I have no idea what prompted the inclusion of the apostrophe, but the markings on the engine don’t lie! Check out the above heading photo........

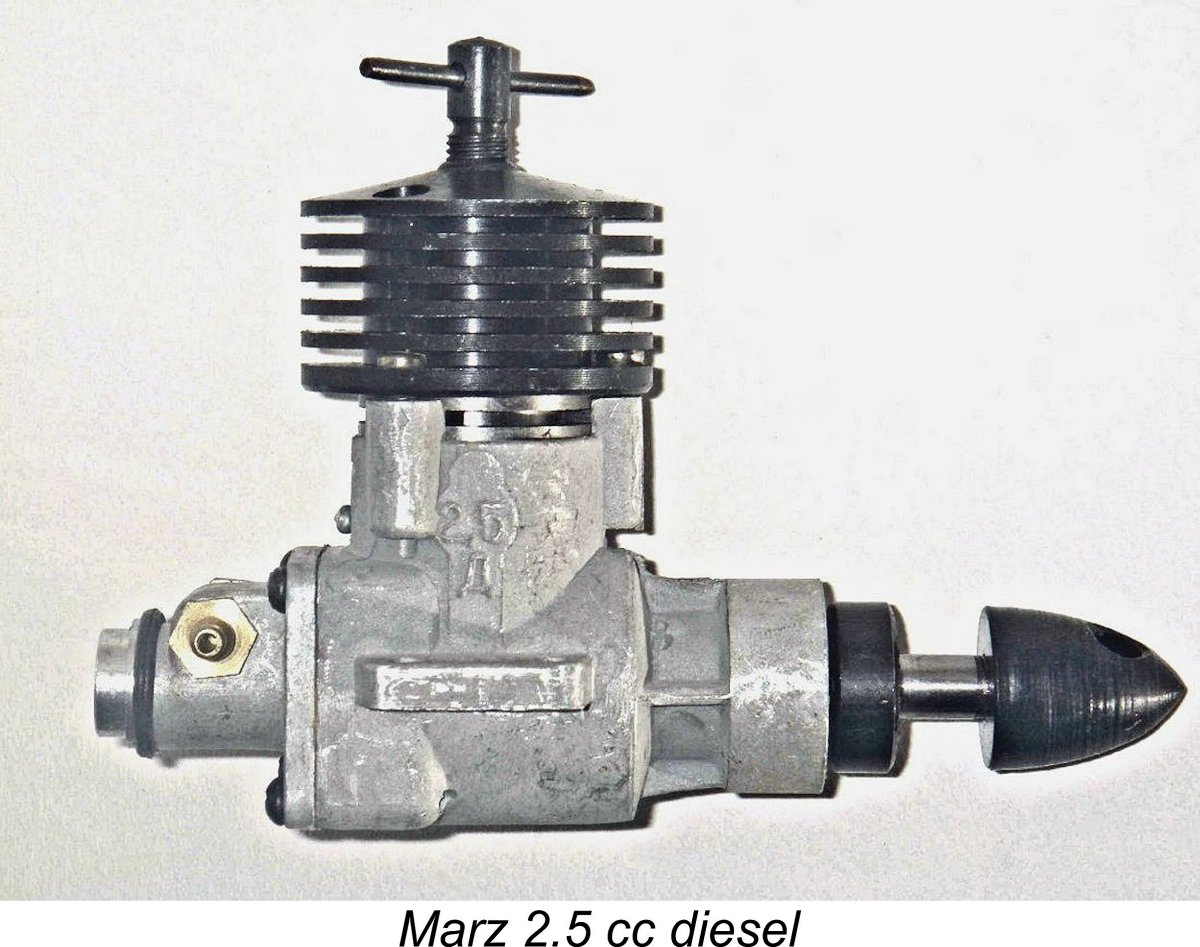

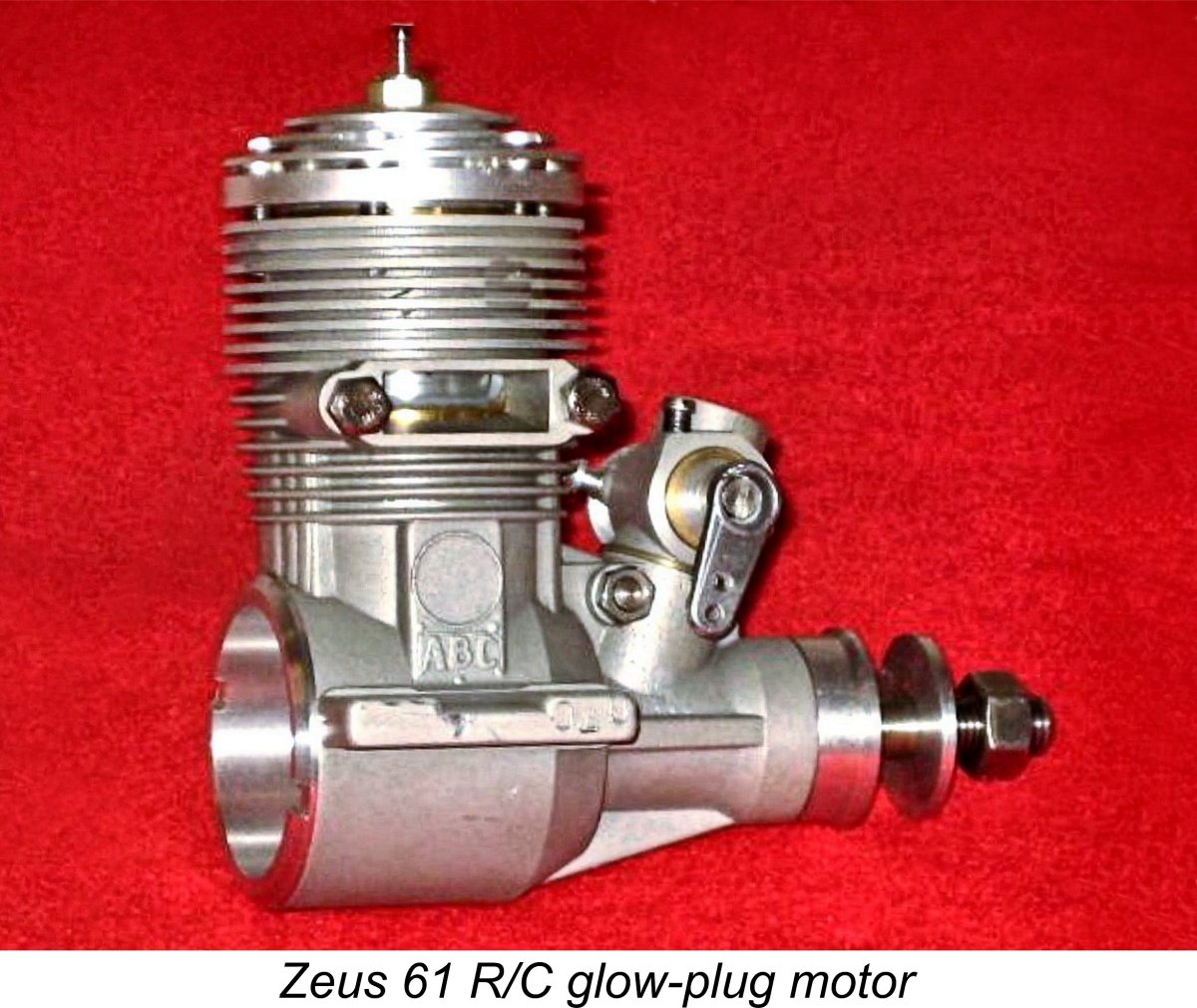

In 1991, Ilya Leydman went to Russia and teamed up with a small group of Russian businessmen to buy up all the machinery that had been used to make the Marz engines. The first trial motors that they made using this equipment were basically intended as test pieces to try out various casting finishes, test the practicality of machined cooling fins, experiment with etched surfaces and so on. In all, they made some 200 side exhaust (SE) and 50 rear Once they'd made a decision on finish as well as a few design details, the partners commenced the series manufacture of the engines that were originally planned and towards which all of this had been leading. These of course were the far better-known Zeus models. Most of them were 61’s, but there was also a 42 model, of which a few were RE 42's. By all accounts, they were well-made engines which ran very nicely. Reviewing the above information, I felt it to be well worthwhile to share Brian’s review of the Stas’s 42 RE control line model. This very rare series is an inseparable part of the Zeus story, hence being well worth preserving. My thanks to Brian for sharing it with the rest of us! A.D. Engine Review - Stas’s 42 RE By Brian Hampton

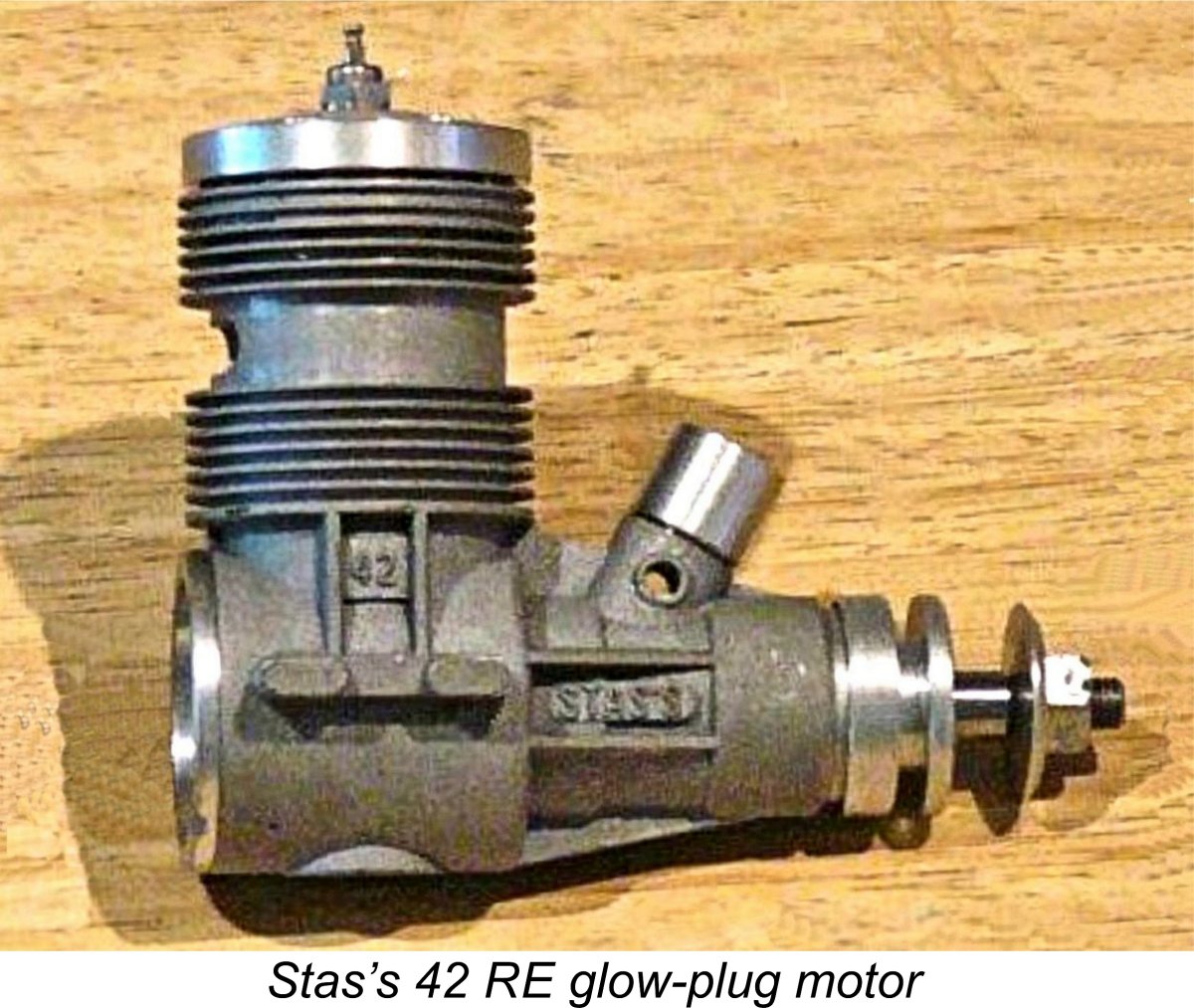

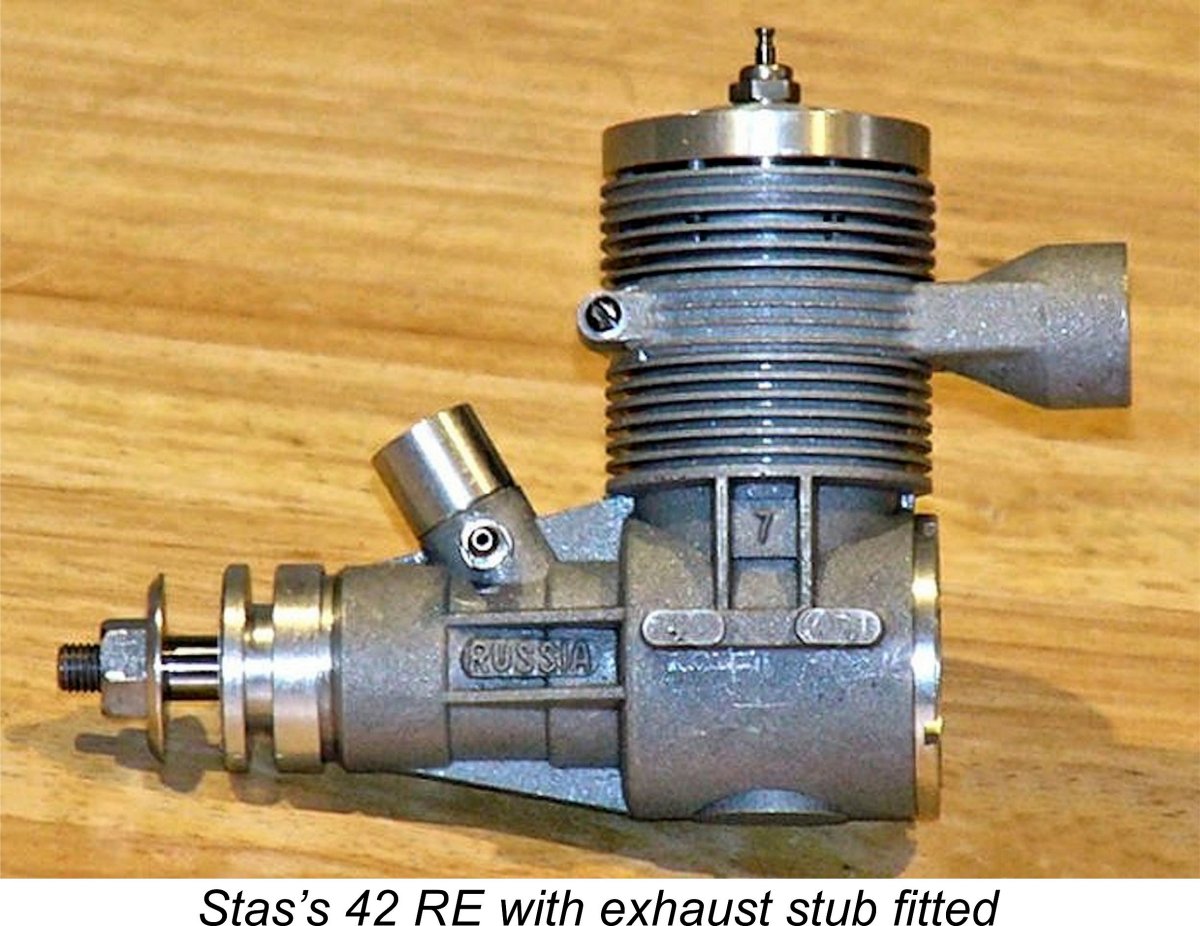

A couple of years ago I picked up the side exhaust R/C glow-plug engine seen in the heading photo above. Despite appearances, it turned out to be a plain bearing design. After a quick look inside, I decided that I’d never run it because there’s a huge void in the casting directly under the rear of the crankshaft bushing. Given the engine’s obvious obscurity, I also assumed that I’d never come across another example. However, some time later a brand-new rear exhaust C/L version of the same engine came up on eBay. This intrigued me, since I have a soft spot for rear exhaust (RE) engines. Thankfully, I was able to acquire it for a very reasonable price. Other than their having Both engines are very similar, being Schnuerle-ported plain bearing glow-plug units with lapped cast iron pistons running in steel cylinder liners. For this review I’ll concentrate on the RE version. Luckily that example was much better made than its predecessor! It came with the C/L venturi but no needle valve, so I adapted an Enya needle valve to fit. Interestingly, one side of the engine (above right) displays the displacement in cubic inches while the other side (at left) shows the nominal metric equivalent of 7 cc. The actual calculated displacement is 6.87 cc (0.42 cuin.). At first glance it seems that there’s no easy way to attach a muffler or pipe to the exhaust. The same goes for the side exhaust (SE) version. However, there’s a specially designed muffler/RE stub with a clamp

There’s nothing remarkable about the piston or liner other than the fact that the solid gudgeon pin seems to be a little on the small side for an engine of this displacement. On RE engines, one end at least of the gudgeon pin must be blanked off to prevent fresh mixture from the boost port escaping through the exhaust port.

After due consideration, I decided not to try easing the fit by lapping but just run it and see what happened. This seemed to me to be a good opportunity to test the theory that running a new ABC unit rich and cool will overstress the rod and causing a possible break, supposedly from the piston jamming into the pinch on every stroke and the rod having to pull it back out. This one was going to get into that huge pinch no matter how hot it got (or didn’t get!). So onto the test stand went the Stas’s RE C/L model, initially with the SE engine’s muffler which of course then pointed sideways. Fuel was 75/25 all castor. Using an 11×4 prop, the engine met expectations by being a bear to start because of that pinch - there was no possibility of a successful hand start. However, eventually I found a way to get the starter to spin the engine over enough to fire. Once running, the engine was as smooth as silk! I ran it extremely rich, as required with a lapped cast iron piston, seeing 6,000 RPM and a head temperature of 63 degrees C (146 degrees F). At the end of the third tank, I fitted the stub exhaust and attached a tuned pipe, setting it very long so that it acted only as a muffler. Surprisingly, this reduced head temperature to 53 degrees C (128 degrees F), showing that the muffler was very restrictive. For about the first hour of running, every time the engine ran out of fuel (hence going to near peak revs for a couple of seconds) it would stop with the piston locked into the pinch. It took around another 30 minutes of running time before I was finally able to hand-start the engine past the pinch. Once properly run in, tuning was incredibly easy with about one turn of the needle needed to go from 6,000 RPM to 11,900, at which point the engine began its transition into 2-stroke mode. Steady 2-stroke operation began at around 12,000 RPM on this prop. As for all that pinch and its effect on the rod, there’s been no detectable change in the rod bearing clearances. More significantly, the engine most certainly has not broken the rod, nor is it likely to do so now that the pinch has been relieved somewhat. Despite all my initial doubts about this engine, I’m really starting to like it! Some specifications: Bore - 21 mm Port Timing:

_____________________ Article © Brian Hampton, Adelaide, South Australia First published on this website February 2020 |

| |

Editor’s note - Generally speaking, the articles on this website focus on engines from the pioneering and classic eras from the 1930’s on up to the early 1970’s, when rather formulaic “modern” Schnuerle-ported designs began to take over and my personal interest began to wane. However, once in a while a story comes along from a later era that seems to me to be well worth sharing.

Editor’s note - Generally speaking, the articles on this website focus on engines from the pioneering and classic eras from the 1930’s on up to the early 1970’s, when rather formulaic “modern” Schnuerle-ported designs began to take over and my personal interest began to wane. However, once in a while a story comes along from a later era that seems to me to be well worth sharing.

Here’s something you don’t see every day, and I’m quite certain that you won’t find it in any model magazines because they understandably restrict themselves to reviews/tests of engines that their advertisers would like to sell! However, why only publish reviews of engines which everybody already knows about?

Here’s something you don’t see every day, and I’m quite certain that you won’t find it in any model magazines because they understandably restrict themselves to reviews/tests of engines that their advertisers would like to sell! However, why only publish reviews of engines which everybody already knows about?  been made in Russia, as clearly stated on the crankcases, I had no further information on these engines, not even when they were made. However, looking at the design, I suspected a likely 1980’s origin (as noted above, it was actually the early 1990’s - A.D.).

been made in Russia, as clearly stated on the crankcases, I had no further information on these engines, not even when they were made. However, looking at the design, I suspected a likely 1980’s origin (as noted above, it was actually the early 1990’s - A.D.).  suitable for both types. The accompanying photo above at the left shows the RE stub fitted to the engine. Both the clamp and the stub are provided with cast fins.

suitable for both types. The accompanying photo above at the left shows the RE stub fitted to the engine. Both the clamp and the stub are provided with cast fins.

The crankshaft is quite sturdy, with a large counterbalance to accommodate that heavy cast iron piston. It seems to be effective, since the

The crankshaft is quite sturdy, with a large counterbalance to accommodate that heavy cast iron piston. It seems to be effective, since the