|

|

Converting Glow Heads for Turbo Plugs - Why and How By Maris Dislers

LeRoy Cox showed the way ahead towards improved performance in the early to mid 1950’s by integrating the glow-plug element very neatly into a replaceable head for his Space Bug and Thermal Hopper .049 cuin. models. This eliminated any discontinuity in the combustion chamber. The evident success of this approach led other manufacturers of small-displacement engines to adopt a similar design approach, including McCoy, Holland, K&B, OK, Gilbert and Fox. Although Cox extended the use of this technology to his larger models up to 0.15 cuin. displacement, it became undeniably more expensive as size went up. This led Super Tigre to adopt a glow plug that was installed in a blind hole (aside from a small aperture to provide communication between the glow-plug element and the combustion chamber) in their X-series racing engines of the 1970’s.

Henry Nelson created a larger 3/8 in. thread taper-seat plug of his own, while a number of plug manufacturers picked up on the Novarossi Turbo design having an 8 mm installation thread, making it something of an industry standard. Taper-seat Nelson and Turbo plugs have now gained a secure place in competition engines, since they present a flat face which blends neatly with the rest of the combustion chamber. The main defining feature of a Turbo glow-plug is its use of a tapered installation seat as opposed to the normal flat interface which requires a copper washer to seal. The Turbo plug relies upon the very close high-pressure wedge-fit between the tapered end of the plug body and the correspondingly-tapered inner portion of the installation opening, both to provide a secure seal and to promote excellent heat transference. No sealing washer of any kind is used with these plugs. The advantages of a Turbo plug are a reduction in the potential for compression leakage around the glow plug; optimization of heat transference from the element cavity walls; and minimal disruption of the combustion chamber. The hole in the cylinder head that exposes the glow plug to the air/fuel mixture in the cylinder is much smaller, and there are fewer rough edges to create unwanted hot spots. Many classic smaller-displacement glow-plug motors use integrated glow heads of the type pioneered by Cox and illustrated above. The problem for many of them is that replacement glow-heads are difficult or impossible to obtain today. The common remedy is to drill out a burned-out head and tap it ¼ -32 to accept a standard glow-plug. This certainly restores the engine to operating condition, but often at the cost of a significant decrease in performance.

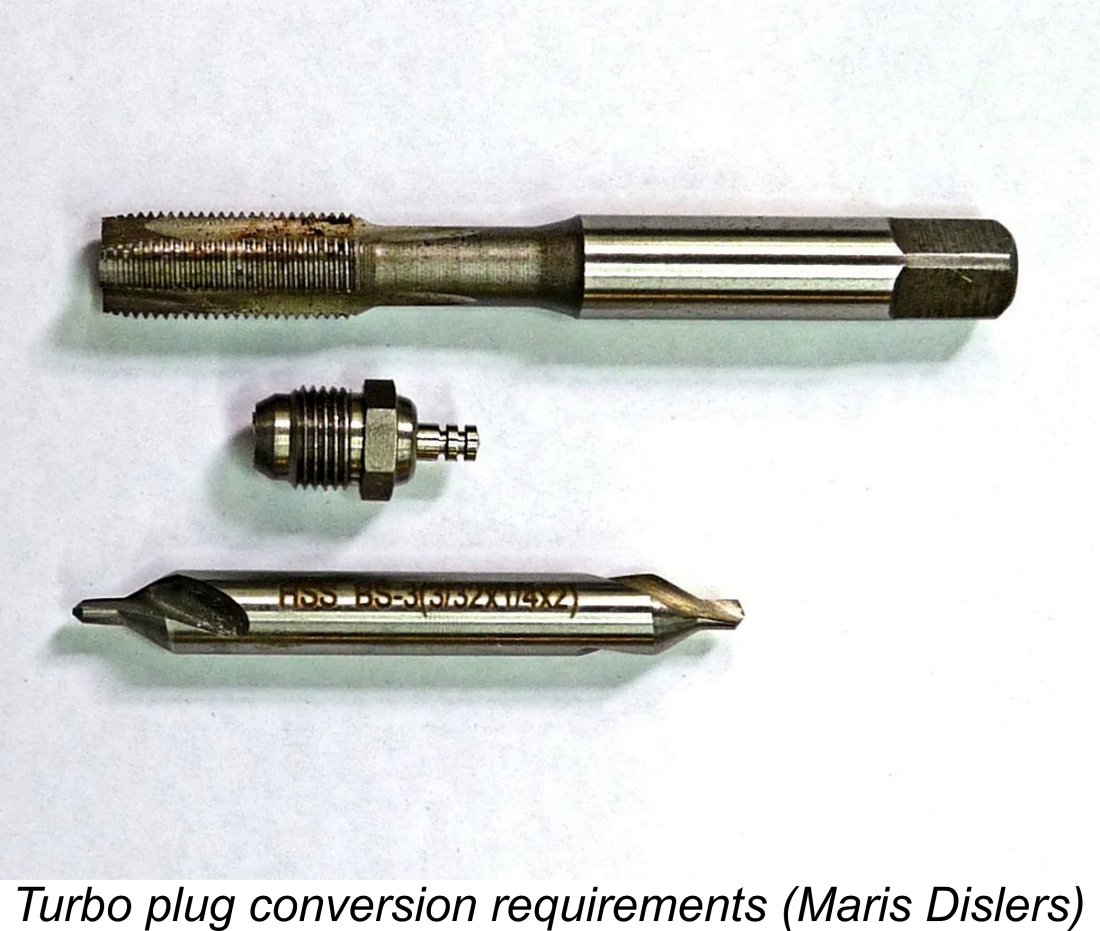

My recent acquisition of some Fox .049 components provided me with an opportunity to give this a try myself using a Fox .049 glow-head as my test piece. All but one of the heads that came with this group were non-functional, so I had nothing to lose. Here’s how I went about it. The seat of an O.S. Turbo plug has a 60 degree taper - same as the countersink angle on a standard centre drill. Its face diameter as presented to the combustion chamber is 3/16 in. (4.8 mm) and the installation thread is M8x0.75 mm metric fine (not the far more common M8 x 1.25 metric coarse thread, note!). Note also that a short length of the lower end of the plug above the taper is undercut with no thread.

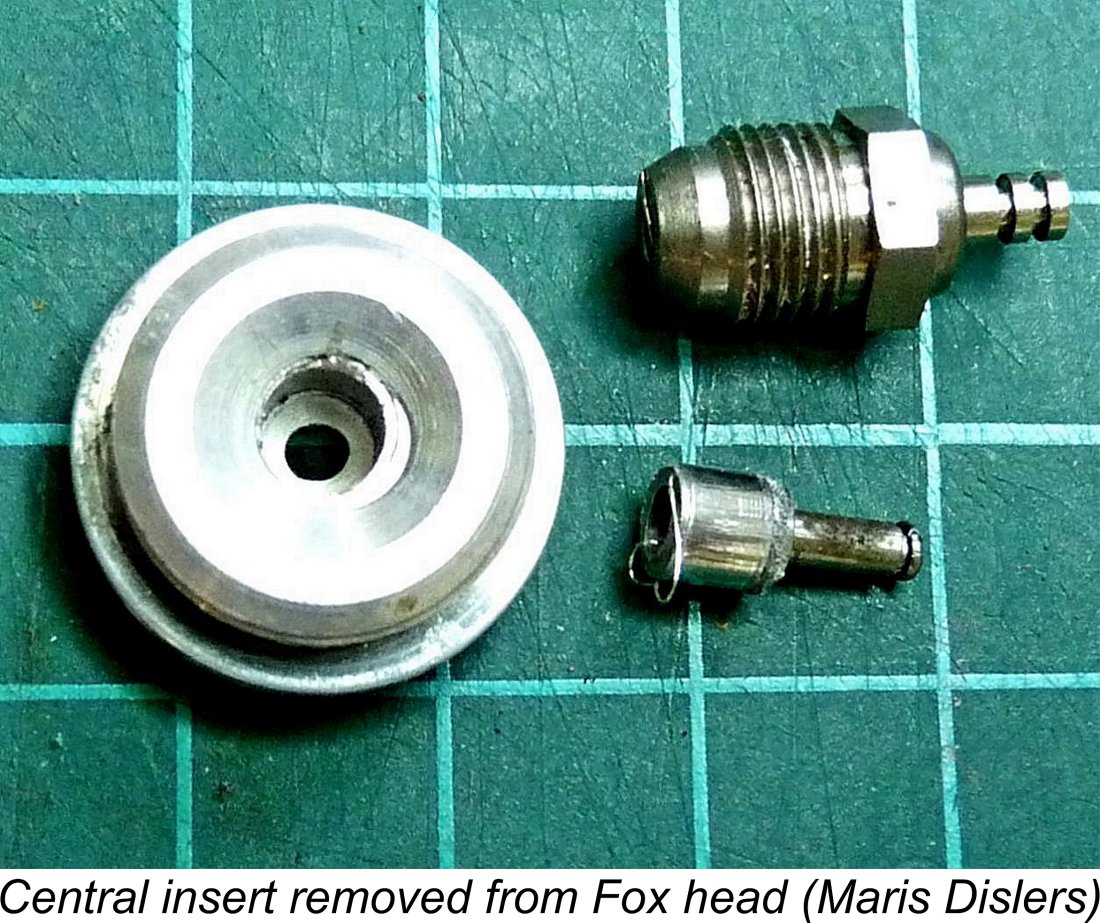

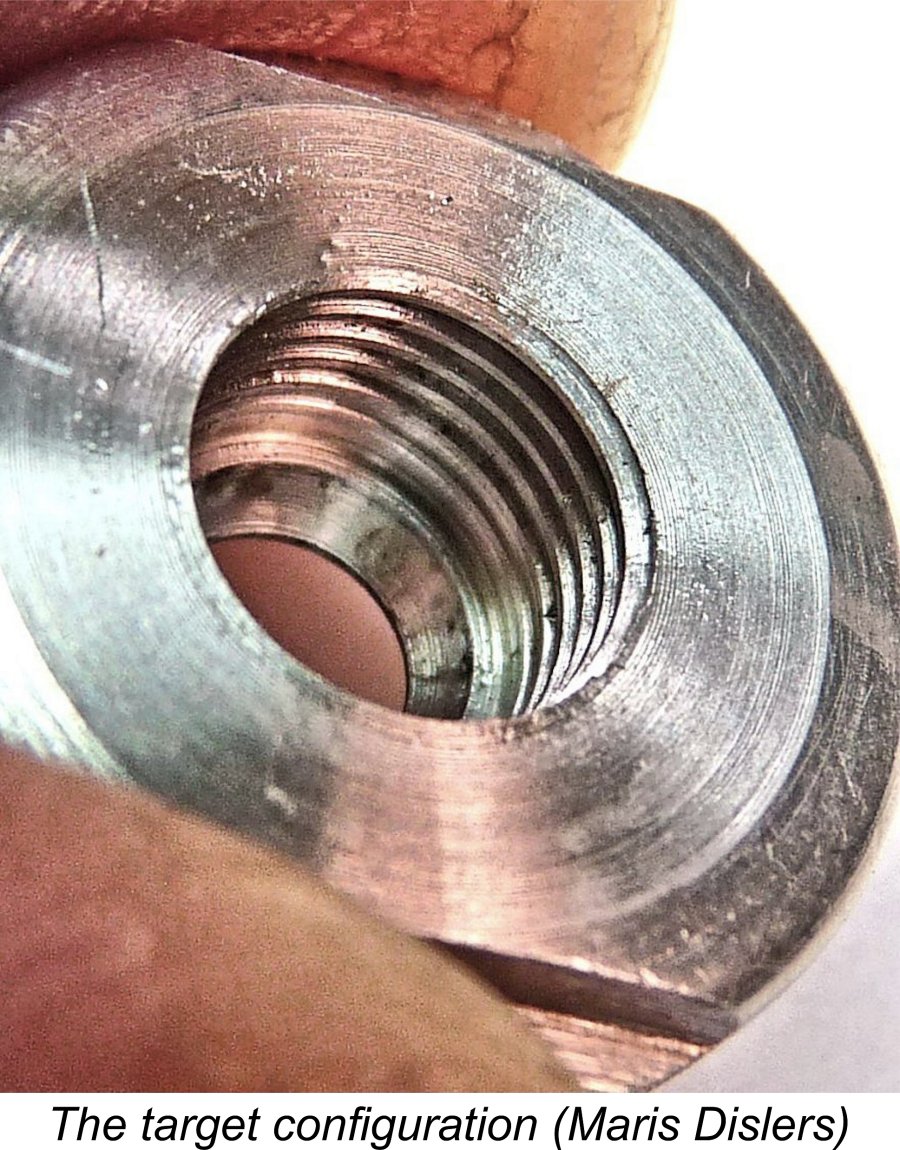

Apart from the plug itself, you’ll need a no. 3 centre drill (¼ in. dia. shank), a 0.285 in. dia. twist drill (a K letter drill or a 9/32 item should both work OK) and an M8x0.75 tap. For heads other than the Fox, you’ll also require a 5 mm twist drill (a 3/16 in. dia. drill will also work). The steel central post on the Fox head is pressed in from below against a fibre washer, with the emergent contact post on top. Put the head in a vise against soft jaws and press that out towards the combustion chamber side. If you’re working with a head from a different engine, note that some of them have to be removed in Returning to the Fox head, the body diameter of the steel insert that you just removed is 3/16 in., which is very close to the base diameter of the O.S. Turbo plug. If working with another head, you’ll have to drill it through at 5 mm diameter. Once you have that 5 mm dia. hole established, use a No. 3 centre drill (which has the required 60 degree countersink angle) presented from the top side to cut the seat. This is perhaps the most delicate step in the operation. Great care is required to ensure that you don't go too far - you have to preserve that 5 mm dia. aperture at the bottom of the countersink while at the same time approaching it as closely as possible. I stopped about 15 thou short of a breakthrough, which seemed to work OK. The attached illustration below at the right shows the final result at which to aim - a delicate touch is required!

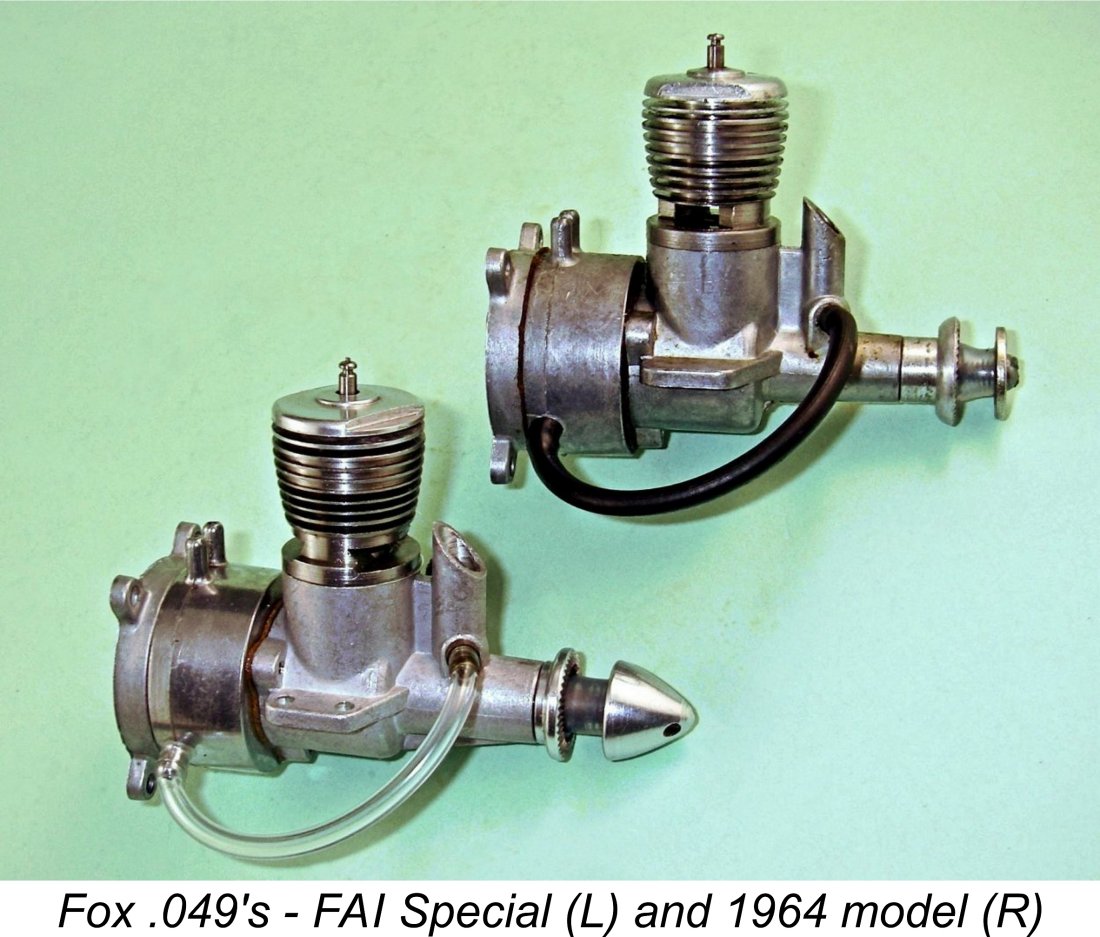

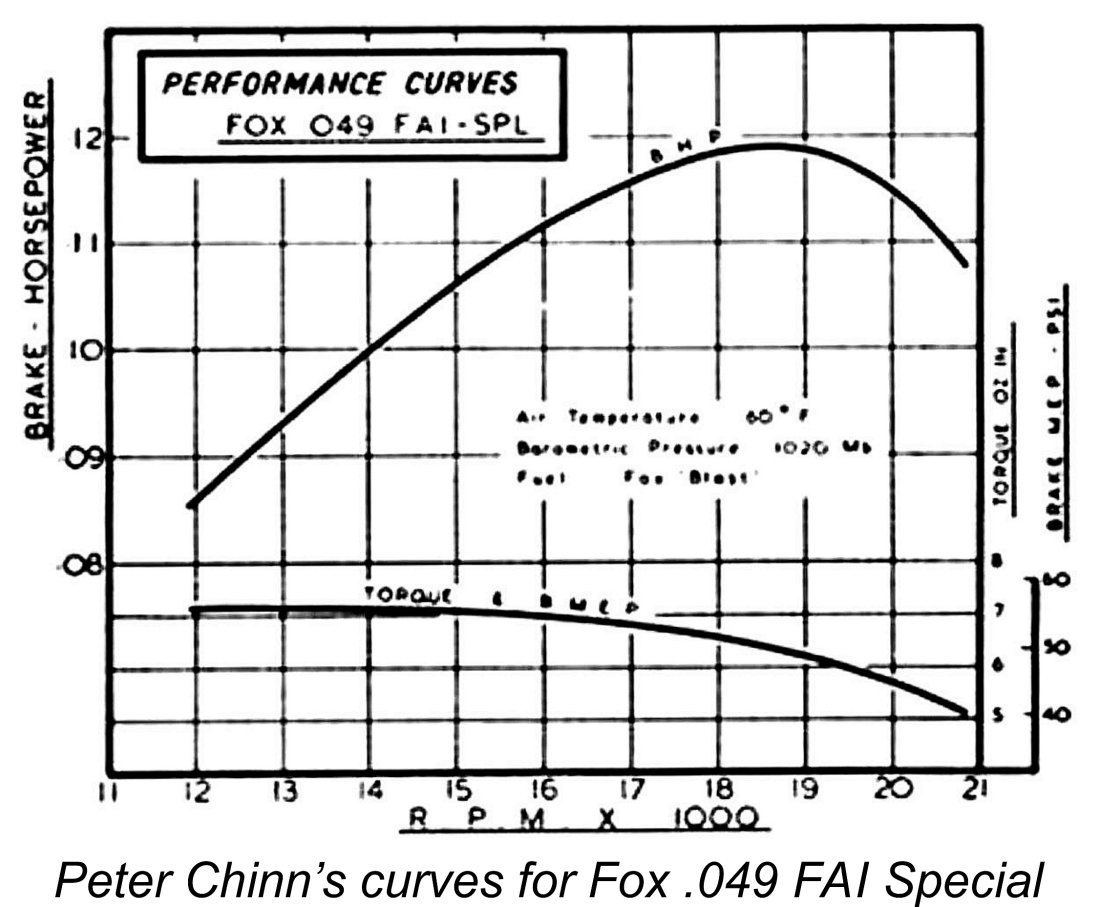

Before trying the above procedure, I had previously modified another Fox .049 glow-head to accept a standard ¼ - 32 glow-plug, allowing a comparison between it and my Turbo-modified head. So how does the Turbo adaptation compare with the Fox head drilled and tapped for a regular glow plug? Around 1,500 RPM extra and likely as good as the original. As a bonus, you can now choose from a selection of Turbo plugs having different heat ranges instead of being stuck with whatever the original manufacturer provided. I first tested my regular (1964) Fox .049 fitted with an FAI Special twin transfer piston/cylinder, using the head which I'd machined for a regular ¼-32 glow plug. It’s important to keep in mind that this conversion only extends to the cylinder porting and does not include the far larger intake diameter and I tested the resulting hybrid using a fuel containing 25% nitro. By way of comparison, I also tried Bill Britcher’s all-original Fox FAI Special with a standard Fox head using the manufacturer-recommended 30% nitro. That engine proved to be prone to both pre-ignition and reverse-direction starts. The fitting of an extra head shim greatly improved it in those respects. Evidently a case of an excessively elevated compression ratio. Peter Chinn reported having similar difficulties in his September 1965 test of the Fox .049 FAI Special. For comparison purposes, I tried my own hybrid engine again on the 25% nitro fuel, but this time using the alternative head machined to accept a Turbo plug. The improvement in performance of the otherwise unaltered engine was quite impressive! The comparative speeds registered in all three test series were as follows:

The Turbo figures were obtained using an O.S. P7 (medium) plug. The engine also ran OK using a P8 (cold) plug. However, it’s entirely possible that a hotter plug might yield even better results. And at least I now have the option!

Neither Bill's original engine nor my own hybrid example indicated power curves approaching those published by Peter Chinn in his test of the original Fox FAI Special which appeared in the September 1965 issue of “Model Airplane News”. My engine showed a distinctly flat BHP output across the usable range, from 11,000 RPM upwards before dropping off. Even so, I’ve shown that the conversion of a Fox .049 head to accept a Turbo glow-plug is both eminently feasible and very effective in use. I’m sure that this approach would work just as well for other similarly-equipped engines. Of course, many people will find it far easier to buy a head than to machine one. Such heads for certain engines may be available ready-made from suppliers such as Kamtechnik. That company currently (2021) offers Turbo heads for the full Cox range from .020 cuin. up to .15 cuin as well as Turbo heads for the G-Mark .03, the Norvel engines and the Testors/McCoy .049 models. The Cox .15 Turbo head will also fit the Gilbert 11, Fox .09 and Fox 10 designs. So no need to feel shut out from such modifications! ___________________________________ Article © Maris Dislers, Glandore, South Australia First published May 2021 |

|||

| |

It seems to me that combustion chamber design for g

It seems to me that combustion chamber design for g As the performance of model glow-plug engines continued to increase, new problems presented themselves. The development of the so-called Turbo glow-plug by the Italian Novarossi company came about due to increasing concern with both leakage around the sealing surface between the plug and the head and heat transference from the plug body to the head. There was also a continuing recognition of the previously-noted desirability of minimizing any discontinuities in the combustion chamber.

As the performance of model glow-plug engines continued to increase, new problems presented themselves. The development of the so-called Turbo glow-plug by the Italian Novarossi company came about due to increasing concern with both leakage around the sealing surface between the plug and the head and heat transference from the plug body to the head. There was also a continuing recognition of the previously-noted desirability of minimizing any discontinuities in the combustion chamber. It appeared to me that a far better alternative would be to re-machine such a head to accept a Turbo plug rather than a standard component. This should permit the retention of the original combustion chamber configuration more or less unchanged. Nelson 3/8 in. plugs require special tooling to machine the head and are far more challenging to source, but it seemed that it would be quite straightforward to configure a head to accept, say, an O.S. Turbo plug, which is readily available. It’s been done before by others ………….

It appeared to me that a far better alternative would be to re-machine such a head to accept a Turbo plug rather than a standard component. This should permit the retention of the original combustion chamber configuration more or less unchanged. Nelson 3/8 in. plugs require special tooling to machine the head and are far more challenging to source, but it seemed that it would be quite straightforward to configure a head to accept, say, an O.S. Turbo plug, which is readily available. It’s been done before by others …………. This task is most precisely accomplished using a lathe, although it would theoretically be possible to complete it using a drill press if great care was take. That having been said, the Editor found a forum posting from a fellow who reported having failed three times to successfully create a Turbo mounting in a glow head using a drill press. You don’t have to be far out to compromise the plug’s seating and hence its sealing capacity. Use a lathe if at all possible.

This task is most precisely accomplished using a lathe, although it would theoretically be possible to complete it using a drill press if great care was take. That having been said, the Editor found a forum posting from a fellow who reported having failed three times to successfully create a Turbo mounting in a glow head using a drill press. You don’t have to be far out to compromise the plug’s seating and hence its sealing capacity. Use a lathe if at all possible. the opposite direction. For example, to remove the centre post from a Cox head you have to machine away the protruding crimp on top before pushing the post out from the combustion chamber side using a suitable mandrel.

the opposite direction. For example, to remove the centre post from a Cox head you have to machine away the protruding crimp on top before pushing the post out from the combustion chamber side using a suitable mandrel. The next step is to bore out or drill the opening from the top side to a point just a very little shy of the 60 degree seat that you cut previously. The required diameter is 7.25mm (.285 in.) - a K letter drill or a 9/32 drill should both work if you prefer) Finally, cut the plug installation thread into this hole using a M8x0.75 tap. Make sure that the tap is presented in a precise axial alighnment - the sealing effect of the tapered seat depends on this. Hand-held won't do! An intermediate tap for cutting the thread would be ideal, but a regular taper tap actually also works OK. The previously-noted undercut on the plug clears the first few partly-formed threads.

The next step is to bore out or drill the opening from the top side to a point just a very little shy of the 60 degree seat that you cut previously. The required diameter is 7.25mm (.285 in.) - a K letter drill or a 9/32 drill should both work if you prefer) Finally, cut the plug installation thread into this hole using a M8x0.75 tap. Make sure that the tap is presented in a precise axial alighnment - the sealing effect of the tapered seat depends on this. Hand-held won't do! An intermediate tap for cutting the thread would be ideal, but a regular taper tap actually also works OK. The previously-noted undercut on the plug clears the first few partly-formed threads.

I very much doubt that the small extra dose of nitro had much to do with the original FAI Special’s relatively small performance edge over the Turbo-equipped hybrid motor, since it only gained around 600 rpm over the speeds obtained previously using 10% nitro. The performance edge is almost certainly due to the Special’s far more open induction system compared to that of the hybrid. Even with that handicap, the hybrid is a very sturdy performer - I've ended up with a nice engine!

I very much doubt that the small extra dose of nitro had much to do with the original FAI Special’s relatively small performance edge over the Turbo-equipped hybrid motor, since it only gained around 600 rpm over the speeds obtained previously using 10% nitro. The performance edge is almost certainly due to the Special’s far more open induction system compared to that of the hybrid. Even with that handicap, the hybrid is a very sturdy performer - I've ended up with a nice engine!