|

|

McCoy’s First FRV Model - the McCoy “9”

So why am I bothering with this seemingly unremarkable little engine? Well, before giving up on further reading due to the seemingly mundane character of the main subject, consider the following:

Starting to sound a little more interesting? Read on …………….. Dick McCoy Before getting into my review and test of the McCoy “9” model, it seems worthwhile spending a little time tracing the early career of Dick McCoy up to the point at which the McCoy “9” made its appearance. This is the first article on this website which has given me an excuse to cover at least part of Dick's story - might as well take full advantage! For those interested, a complete biography of Dick McCoy may be found on the AMA History Project website.

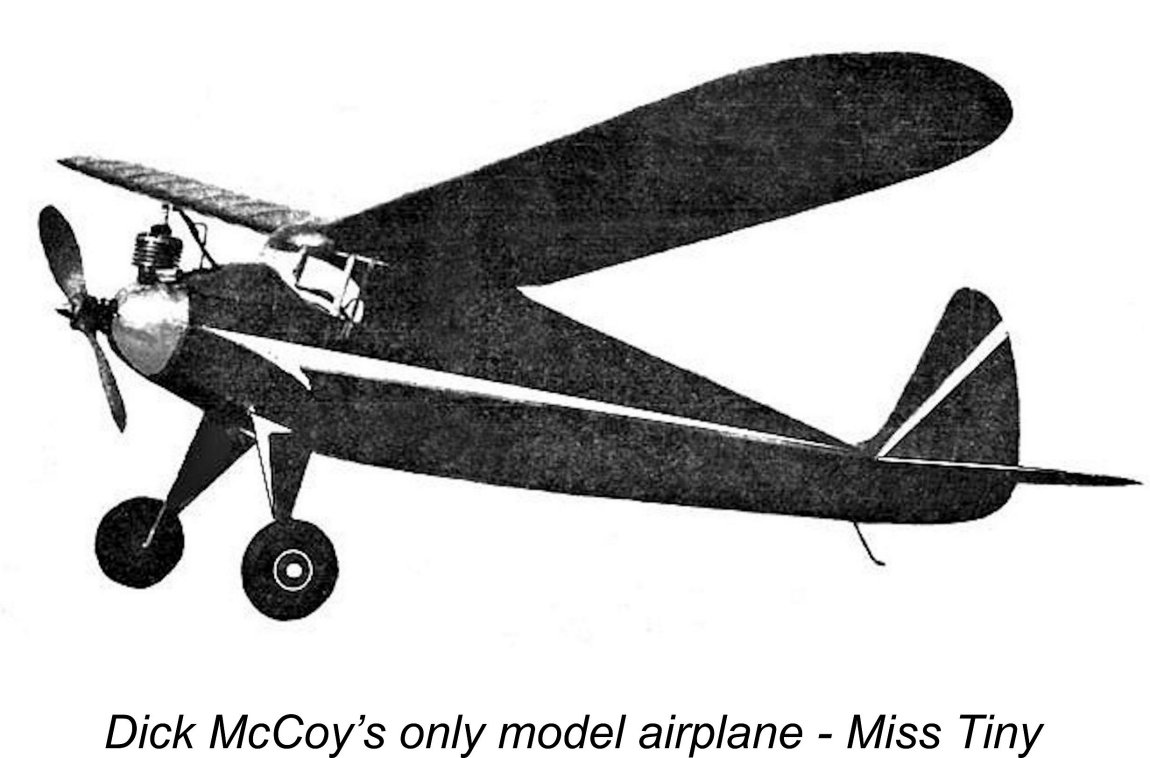

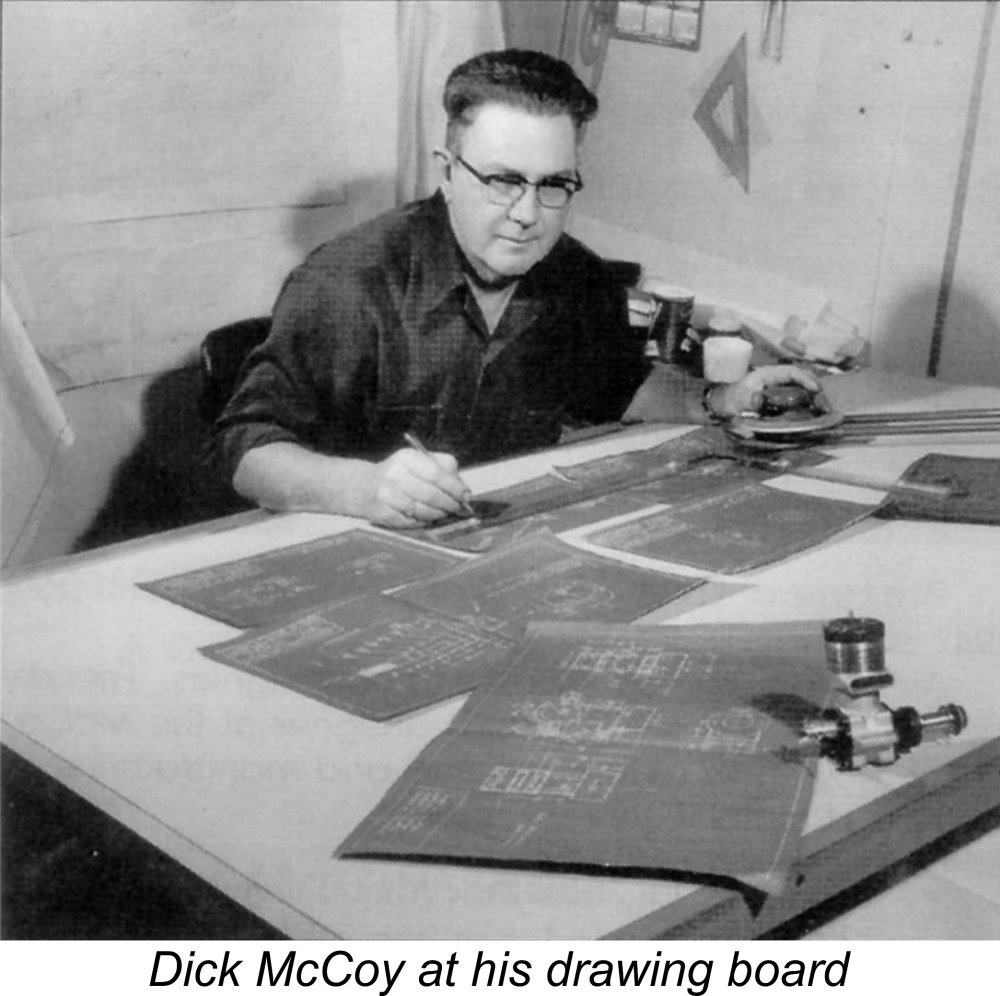

Returning to the early years, in 1918 when Dick was 11 years old his father sold the Indiana farm and moved the family to Walnut, California. There he worked on a ranch maintaining 15 acres of orange trees and 20 acres of walnut trees. For his services, he received $75 per month and the use of a house without electricity or plumbing. Country living at its finest! Dick attended Walnut Elementary School, where there were only three other students in his grade. In 1923, believing that their son could get a better education in a larger school, his parents moved again to Pomona, California. There Dick rode his brother’s motorcycle or took the bus to La Puente High School, where he graduated in 1925 at age 18. Dick's father now had a job as a bus driver; his route was from Pomona to San Dimas. Following graduation, Dick got a job driving the same bus in the evening. However, he lost this job when the owner of the bus company learned that he wasn’t 21 years of age! Instead, Dick went to work for Pomona Pumps operating a drill press for 40 cents an hour. After the passage of a little time, he went back to working for the bus company as a mechanic. A little later, the family moved yet again to Los Angeles. However, they found it to be too crowded to suit the “country” way of life to which they were accustomed. Accordingly they moved back to Pomona, where Dick’s father opened a gas station. He would sometimes run a special sale on gas – six gallons for 96 cents. A sign of changed times, or what?!? Dick did most of the oil changes and mechanical work for his Dad, being paid $16 per week. In July 1929 he married, just in time to become embroiled along with everyone else in the start of the Great Depression. Despite this setback, the marriage lasted 63 years until his wife's death on November 29th, 1992. During the Depression years one had to pick up work where one could. The mid-1930’s found Dick working for a fruit and vegetable packing house called Bordex. However, a big freeze hit the Pomona area, causing severe levels of crop failure. This resulted in Dick losing his job at Bordex. It was at this point that Dick’s activities began to centre once more upon machining and mechanical work. In 1937 he gained a position at the H. W. Loud Machine Shop in Pomona. At the time this was a relatively small company with 17 employees manufacturing tooling for the oil industry along with aircraft parts for Dick's one and only personal venture into the field of model airplanes came in 1939 when he purchased an Ohlsson 23 and built a Miss Tiny free flight model for it. He had planned to take the airplane to a contest, but the night before the meet his daughter accidentally crushed his plane. Dick stayed up most of the night making repairs. The airplane crashed shortly after it was launched at the contest, putting an end to Dick McCoy's one-flight model airplane career!

This situation prompted Fred Schott of Duro-Matic Products located at 1039 North La Brea Avenue in Hollywood, California to contact Dick for the purpose of negotiating a contract to produce McCoy engines and cars in quantity as soon as the war was over. After this contract was signed, Dick was approached by Ray Snow, the designer and manufacturer of Hornet Motors. Dick viewed the Hornet as the only model engine that was capable of giving him any serious competition at the time, although Ira Hassad might have had something to say about this viewpoint! Ray wanted Dick to team up with him in a manufacturing venture to produce the world's fastest racing engines. The idea of this partnership appealed strongly to Dick, but Fred Schott informed him that such a partnership would represent a violation of his contract with Duro-Matic. Accordingly, Dick had to regretfully decline Ray Snow's overtures. Ironically, it was Dick’s designs for Duro-Matic that were eventually to put Ray out of the model engine business. The contract with Mr. Schott and his successor Charles Miller proved to be a good one for Dick. The arrangement lasted for 35 years, bridging the 1956 acquisition of the McCoy range by the Testor Corporation. However, that part of Dick’s life story belongs to a far later period than that with which we are concerned here. Let’s go back and review the series of engines produced by Duro-Matic up to the point at which the little McCoy “9” set the venture off on a new course. The Early McCoys

As mentioned earlier, Dick McCoy’s earliest engines were all racing models which stemmed from his active pre-war involvement in tether car racing. Following the conclusion of WW2, a series of .60 cuin. racing models were produced by Duro-Matic under the terms of their contract with Dick McCoy. Although he was still working full time at Loud’s, never becoming a Duro-Matic employee at any time, Dick somehow found the time to continue his model engine design work for Duro-Matic on the side. He also served as their chief advisor on production issues. In recognition of this, the engines were marketed all along as McCoy models. They soon acquired the red heads for which many later variants were named. Beginning in the early 1950’s, the engine manufacturing was conducted in the name of a separate subsidiary company, the McCoy Products Company of Culver City, California. But that is to get ahead of our story ……………. Returning to the early post-WW2 years, the existence of a number of different classes for both tether cars and model airplanes based on engine displacement soon persuaded Duro-Matic that their interests would be well served by expanding the range of displacements in which their engines were available. The first such model was the 0.499 cuin. McCoy Red Head Junior of 1946. A 0.299 cuin. Red Head 29 model followed in 1947. All of the models in production up to this point featured disc rear rotary valve (RRV) induction along with twin ball-race crankshafts and ringed pistons.

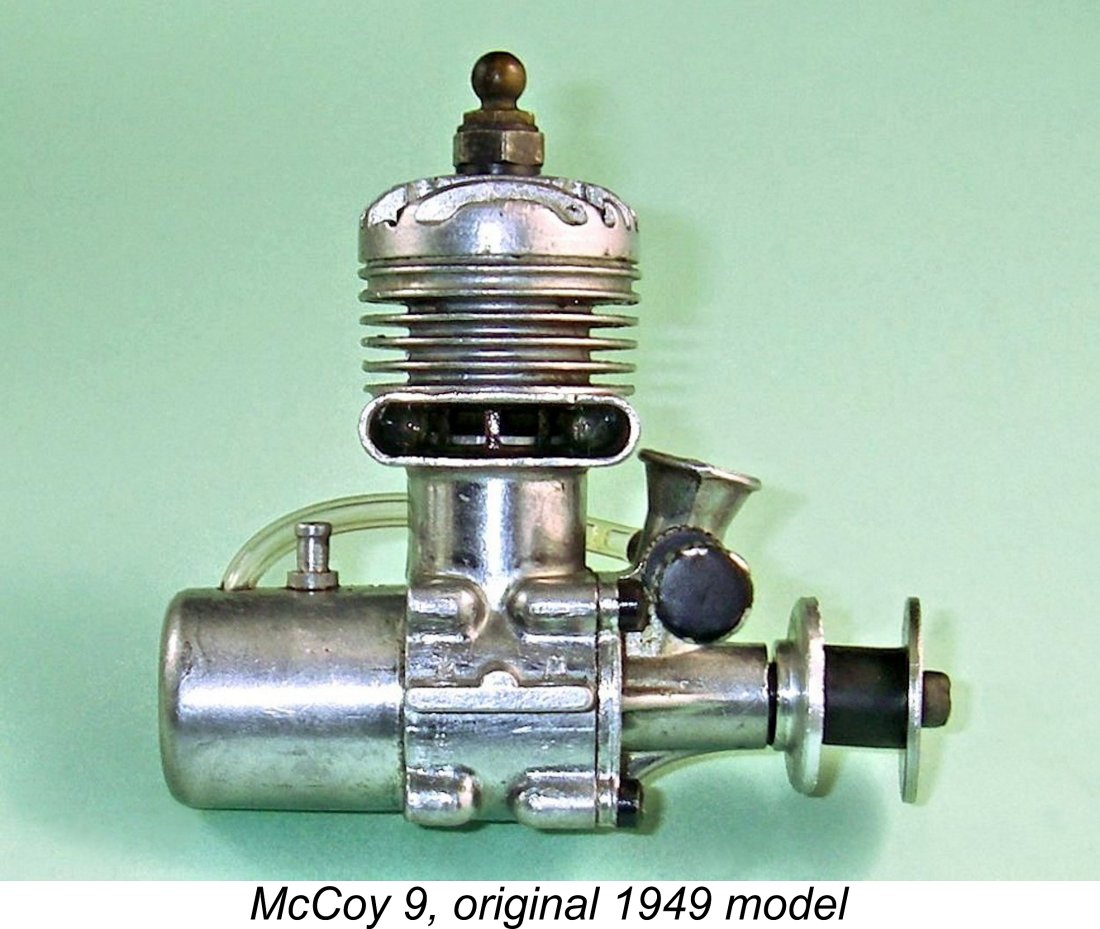

1948 also saw the birth of the iconic McCoy 60 Red Head Series 20 which was Dick McCoy’s very vigorous response to the advent of the Dooling 61. This was accompanied by an entry into yet another displacement category in the shape of the McCoy Red Head 19, which featured a single ball race as first introduced in the larger Black Head Sportsman models. All of the McCoy engines continued to use RRV induction at this stage together with ringed pistons. In the interim, an event had taken place in November 1947 which was to shake the world of power modelling to its core - Ray Arden’s commercial miniature glow plug made its appearance! Duro-Matic was not slow to foresee the coming dominance of this ignition system. Their first purpose-built glow-plug engines were 1948 examples of both However, it didn’t take long for the company to realize that the number of fly-for-fun sport fliers far outnumbered their seriously competition-oriented compatriots. Their first move towards serving that market was the 1949 introduction of the McCoy 29 Sportsman. This was basically an enlarged version of the earlier McCoy 19 glo-plug model with a natural finish head as opposed to the previously red or black components. The main difference was the use of a downdraft intake rather than a straight-in orientation. The single inboard ball-race was retained. At about the same time, the company realized that it was not serving the beginner and novice categories very well, nor was it catering to the growing numbers of relatively impecunious younger fliers on a budget. It was this realization that led to the Spring 1949 introduction of our main subject - the 0.098 cuin. McCoy “9” glow-plug unit. The McCoy “9“ Described In considering the needs of the increasingly numerous inexperienced younger modellers now coming into the hobby, Duro-Matic decided that an even smaller model than any offered previously would best fit the bill. The advantages in this context were both many and obvious - for one thing, suitable models could be built considerably more quickly and cheaply, also being far easier to transport. Moreover, they could theoretically be flown in smaller spaces, especially those of the control line variety, thus increasing the number of potential flying sites. They would generate less noise while also being far less intimidating for a beginner to learn to start. Finally, they would impose considerably smaller fuel bills. Of course, these considerations in turn suggested that the cost of the engine should be kept as low as possible. This implied simplicity of construction. Moreover, the smaller displacement promoted the notion that operating friction and viscous drag should also be minimized since there would be a far small reservoir of power upon which to draw. The latter consideration led Dick McCoy to the conclusion that FRV induction would best meet the need, since it would dispense with the extra weight, friction and viscous drag of the RRV arrangement used in all previous McCoy designs while also simplifying construction. Both weight and cost considerations obviously precluded the use of ball races, nor would these be warranted in a sport-flying context. While the use of FRV induction broke new ground for a McCoy design, the decision to use a single-ringed light alloy piston at the outset was an unmistakable hold-over from earlier McCoy designs, all of which had featured ringed pistons. The basis for the decision to use such a piston in a new model of this relatively small size was a little less clear-cut. Such a set-up would certainly minimize reciprocating weight, always a positive step in enhancing an engine’s performance potential. However, the need for absolute precision in the specialized process of making and fitting a piston ring increases with decreasing bore size. This would do little to minimize costs. Be that as it may, the decision was taken to use a single-ringed high-baffle light alloy piston in the new model.

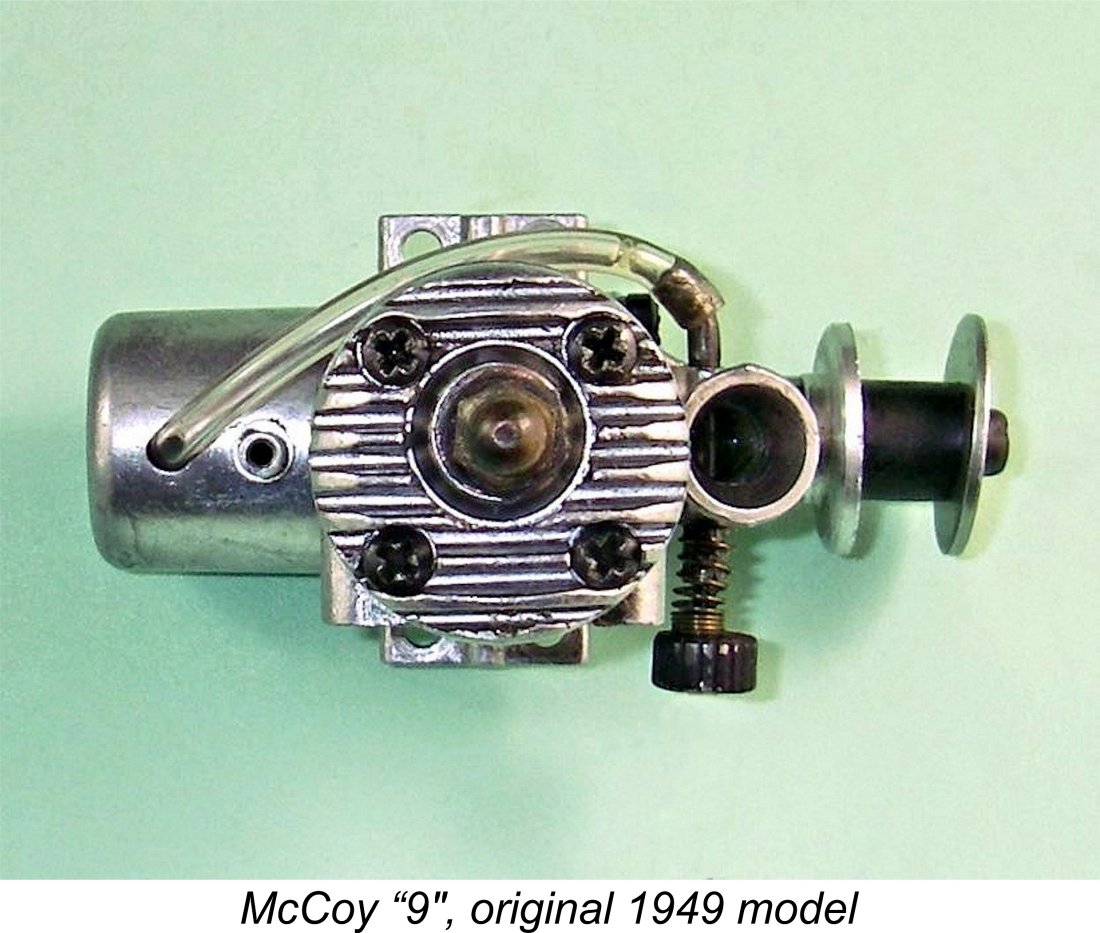

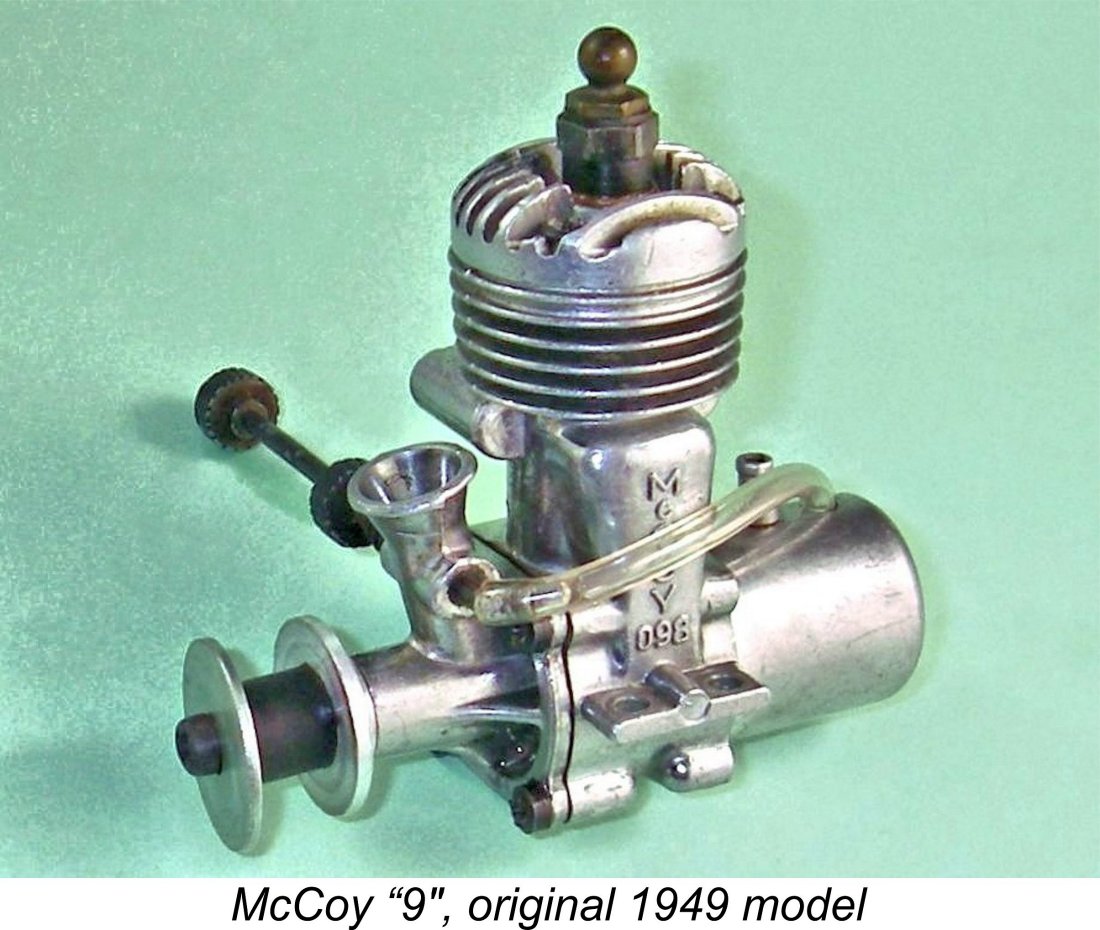

The original McCoy “9” was built around a polished die-cast crankcase which incorporated the backplate, exhaust stack, “bump” mounting lugs, bypass passage and cooling fins in a single casting. The crankshaft was carried in a separate front housing which incorporated the intake venturi in unit. This housing was secured to the crankcase by four Phillips-head machine screws passing through a relatively thin mounting flange. It incorporated a steel bushing to support the main crankshaft journal. The die-cast cylinder head was contoured on its underside to conform to the high baffle on the piston crown. It was attached to the upper cylinder barrel by four Phillips-head machine screws, with a full-diameter gasket being used to ensure a head seal. The ¼-32 plug installation hole was displaced towards the bypass side A little surprisingly for such a small engine, the plug installation hole was dimensioned to accommodate a long-reach plug. This explains the apparently excessive protrusion of the plug above the cylinder head. The plug could easily have been provided with a deeper installation recess if a short reach plug had been specified. The drop-in steel cylinder liner was provided with four rectangular exhaust openings and three similar openings for the transfer ports. These openings were separated in the usual way by narrow pillars of material to prevent ring fouling. The transfer overlapped the exhaust to a significant degree. The high-baffled single-ringed light alloy piston generally followed the pattern established with the larger McCoy racing models. It drove the one-piece steel crankshaft through an unbushed die-cast conrod. The crankdisc was quite heavily counterbalanced. On my own two ringed examples at least, the piston and ring are both excellent fits in the bore - compression in both examples is first-class. The volumetrically-measured compression ratio is around 7.5 to 1 - a seemingly appropriate figure. The internally-threaded spraybar was pressed into position. This effectively discouraged relocation of the needle valve to the opposite side of the engine, also presenting a challenge when it came to a need for replacement. On the plus side, a neat feature was the rearward bend in the fuel pickup nipple to smooth the routing of the fuel line past the crankcase.

The front end of the engine was completed by a nicely made alloy prop driver and large alloy washer. The prop driver was locked to the shaft using a self-releasing taper. The prop was retained by a separate 6-32 UNC Phillips-head machine screw which engaged with a female thread formed in the front of the crankshaft. This was a positive feature in that a hard crash would likely cause the bolt to bend rather than the shaft. A bent bolt was far less of a replacement issue than a bent shaft! Finally, the engine was equipped with a very sturdy cast alloy fuel tank which was secured to the backplate with a single screw. The tank was provided with a neat fuel nipple and small vent hole for easy filling. While very useful for bench testing purposes, these tanks were generally discarded from engines which entered service in models, particularly those used in control-line applications. Consequently they are often missing from otherwise-excellent examples of the engine encountered today. The McCoy “9” Duro-Glo Model

As usual with his various innovations, Ray Arden had been careful to seek patent protection for his new miniature glow-plugs. This meant that anyone making such plugs had to pay a royalty to Arden for the use of his invention. McCoy was among his customers, entering the glow-plug production business quite early on. It was probably the patent factor that led Dick McCoy to explore a means of circumventing the Arden patent. This materialized later in 1949 in the form of the Duro-Glo version of the McCoy “9”. It seems to have been first advertised in the November 1949 issue of “Model Airplane News” (MEN), being cited as “an improvement in ignition as far advanced as the glow plug was over spark ignition”. Quite a claim! However, as matters turned out, this proved to be one of Dick McCoy’s extremely rare design failures. Very few of the devices in question are known to exist today. Let’s have a look at this rather clumsy attempt to circumvent the Arden patents.

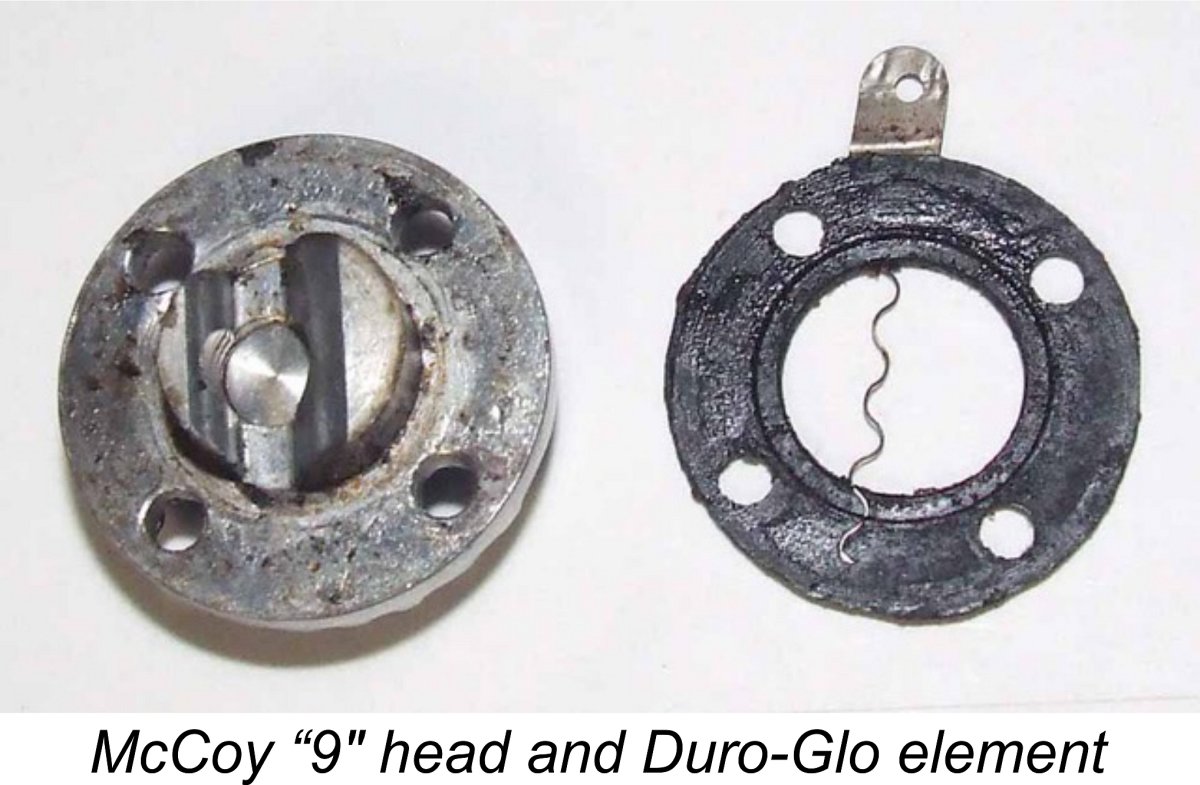

As shown in the accompanying image, the other end of the nichrome wire was exposed above both head gaskets, hence being pressed into secure contact with the top of the cylinder when the head was tightened down. This completed the electrical circuit required to cause the element to glow during starting. When properly installed, the element was supposed to be aligned with the baffle on the piston, as seen in the accompanying image below at the right.

Tim Dannels once had an opportunity to discuss this system directly with Dick McCoy. When he brought up this feature, Dick smiled, opened a drawer in his shop and produced the illustrated example of this component. Dick’s comment about it went something along the following lines:

As a result, very few of the Duro-Glo models were sold - surviving examples are extremely rare McCoy accepted the inevitable and returned to making glow-plugs along the lines of Ray Arden’s original invention but featuring their unique turned-alloy terminal posts in place of Arden's brass knob. Few of the original Duro-Glo models survive intact today, although the name was applied to several completely different models (including diesels!) during subsequent years. Other Versions of the McCoy “9”

Like many other young modellers at the time, Tim learned to fly control line with a Wee Duper Zilch powered by a McCoy “9”, getting him through that first loop and on to more ambitious efforts. Moreover, Tim’s first successful free flight model was a McCoy “9” Neither the Zilch nor the Hogan lasted much longer, and the little Mac was soon relegated to a shelf in any case as Tim progressed onto larger motors and models. However, he still held the little McCoy “9” in high regard for its role in giving him such a good start in the hobby! Doubtless many others benefited in similar fashion. One might almost see the McCoy "9" as the American glow-plug equivalent of the Mills 1.3 in Britain!

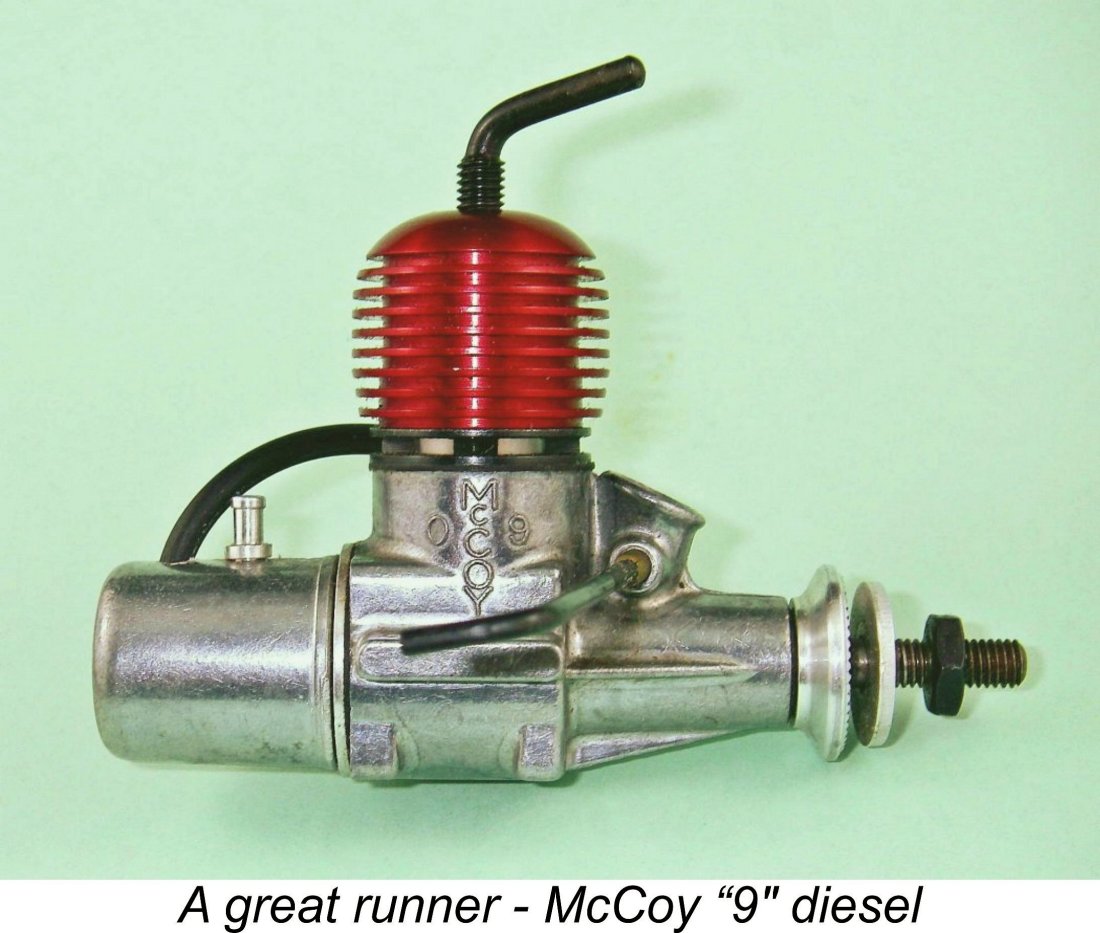

A few early examples of this matte-case model retained the ringed piston, but most were lapped. Interestingly enough, the cylinder porting remained unchanged throughout the entire production life of the McCoy “9”, with the bridged transfer and exhaust ports being retained all along despite being made redundant through the switch to a lapped piston. In the same year of 1950, the “9” was joined in the range by several new “sports” models designed along more or less identical lines. The first of these was the McCoy 19 “Stunt” model which was quickly joined by the McCoy The little McCoy “9” continued to be very popular, remaining in production as described earlier right up to 1954. In that year the design was joined by another McCoy .09 model, the excellent McCoy “9” diesel. Despite the commonality of names, this design owed little to that of the McCoy “9” glow-plug model, instead being in effect an enlarged version of the oddly-named McCoy Duro-Glo .049 diesel which had first appeared in 1953. It was an outstanding performer, as my own tests have demonstrated.

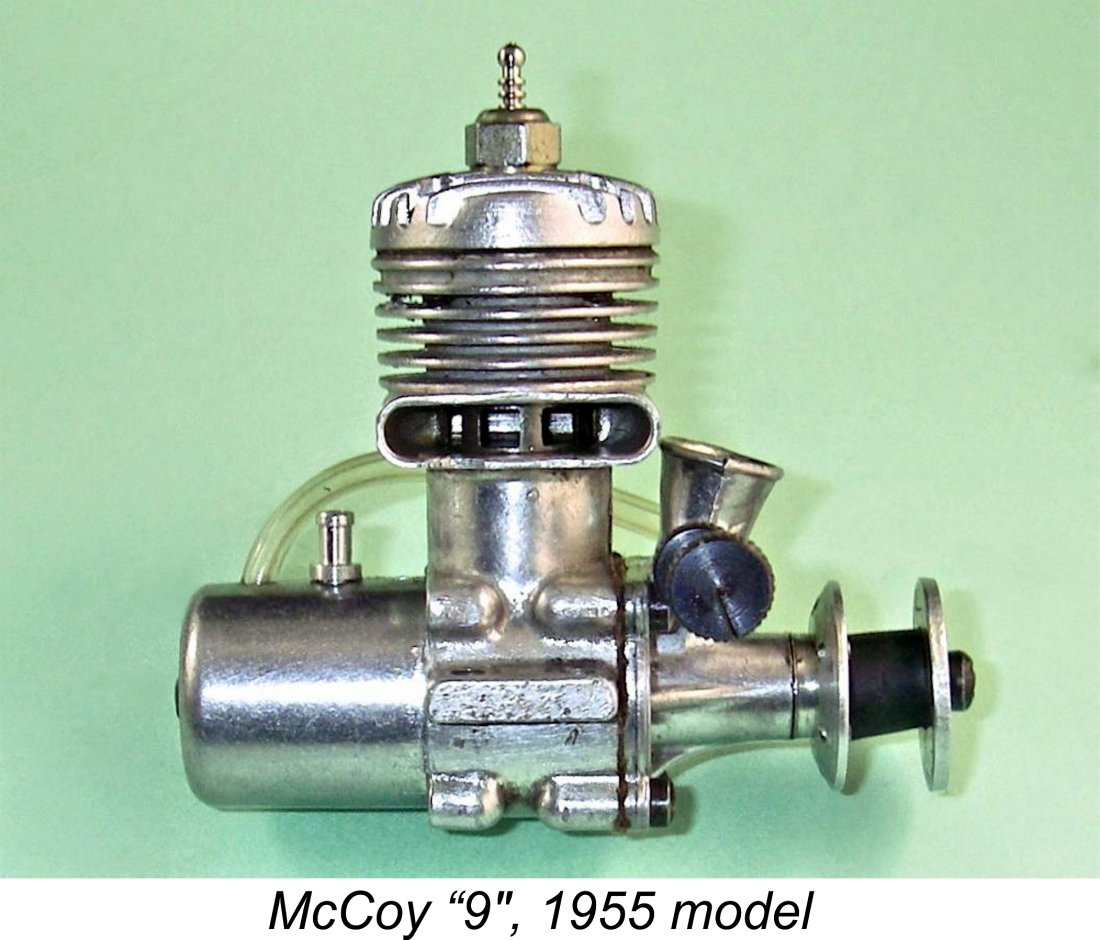

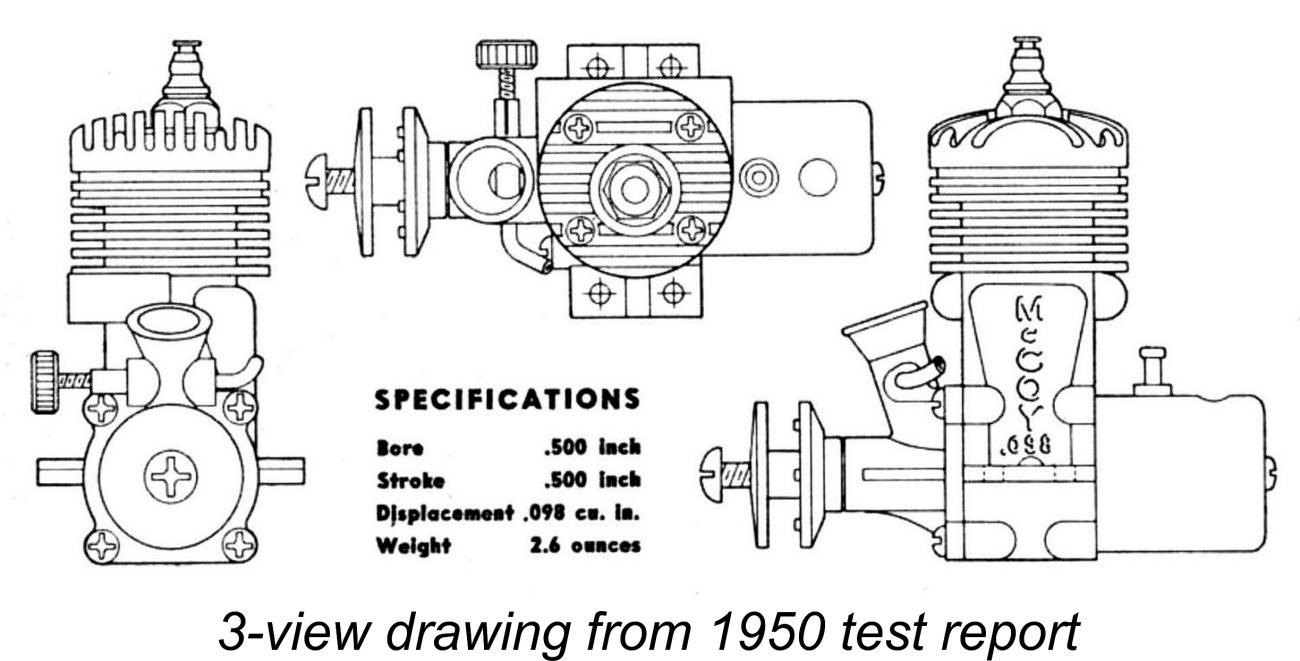

The final revision of the McCoy “9” design came in 1955. The thick-lug case reverted to a shiny finish, while the head was revised yet again to give it a sharper-edged side profile. A few examples In April 1956 the McCoy line was acquired by the Testor Corporation. Dick McCoy carried on as the engine designer for the new owners, who continued for some time to sell off previously-manufactured engines in Testors packaging. However, their intention from the outset was to replace these models with their own designs. This spelled the end of the road for the McCoy “9”, along with the rest of the earlier McCoy models - a new chapter was beginning! But that’s a story to be told elsewhere ……………. Having recounted the history of this very successful little engine, let’s now direct our attention towards its performance. The McCoy “9” on Test The McCoy “9” was the subject of a contemporary test which appeared in the American modelling media in 1950 - I have no definitive information on either the publication or the precise date. The model tested was unquestionably the original version of the engine from the first year of production, since it was specifically stated to be fitted with a single piston ring.

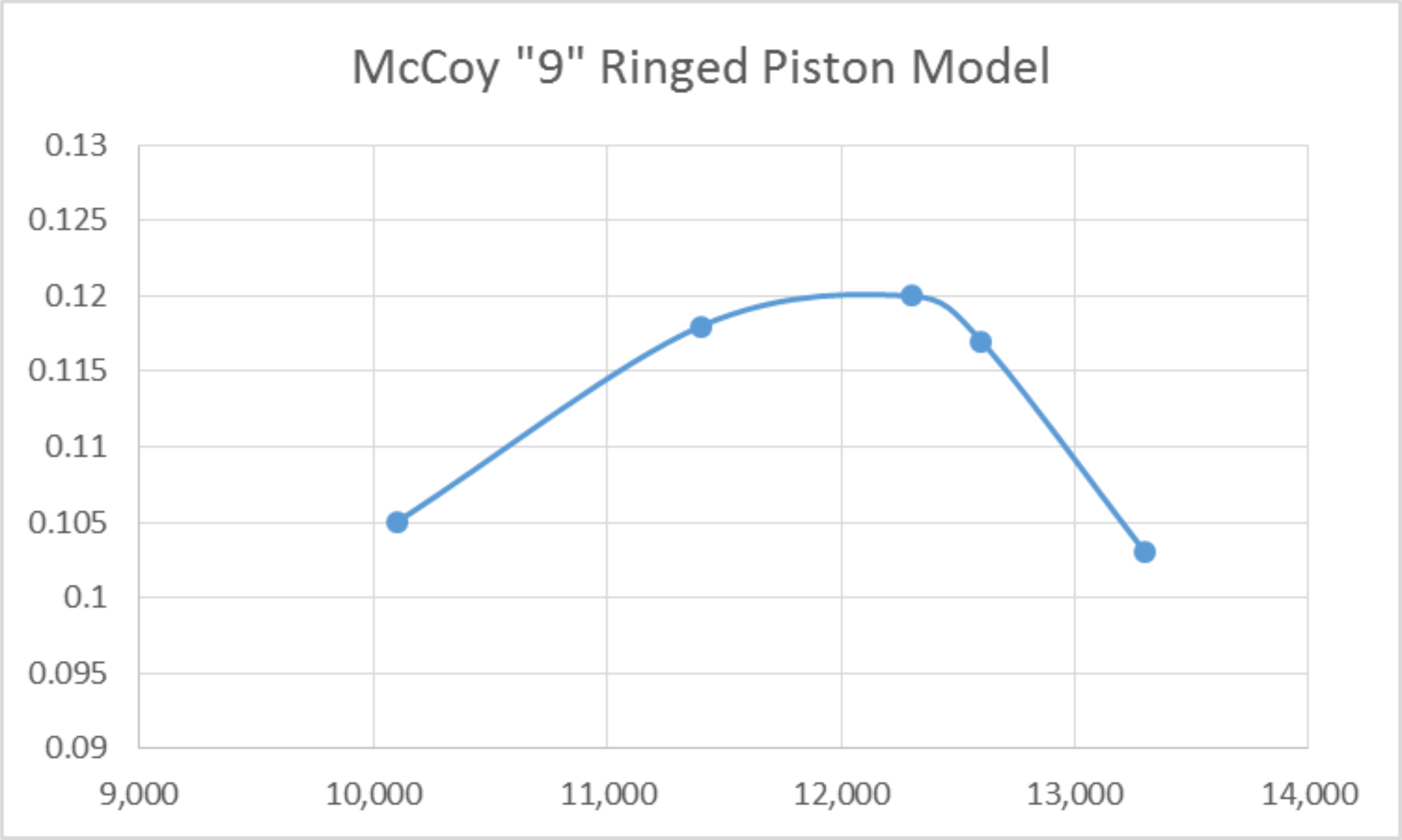

The balance of the report consisted of a succinct description of the engine. No power curves were presented - only a few prop/RPM figures which are not of much help because of the absence of any data for the props in question to derive implied power outputs from them. Moreover, the composition of the fuel used was not clarified. Suffice it to say that the “9” was found to turn props in the 7x4 - 7x3 range at speeds which varied between 10,500 and 13,000 RPM. It appears that a 7x4 would have been the favoured prop for most applications. Clearly we’ll have to do better than this! Thankfully, I have three examples of the engine to choose from as test pieces - two of the early ringed models and one of the later lapped piston units. All three examples had seen some use but remained in excellent mechanical and cosmetic condition. I was interested in testing both ringed and lapped variants to see if the change in piston technology had any effect upon performance.

All tests were conducted using the same batch of 15% nitro fuel. For convenience, I used a large separate fuel tank to eliminate the need for constant refuelling of the relatively small back tank. The engine was stopped between runs by pinching off the fuel supply line. I began by trying both of my ringed piston examples on the same 7x4 APC test prop using the same fuel and plug. I wanted to see which of the two (if either) was the faster. Compression seal in both examples was very good indeed, which is not always the case with small ringed-piston engines. Both units started very promptly following the administration of a small exhaust port prime on a full fuel line. Response to the needle was well defined, making the optimal setting very straightforward to establish. I’d objectively rate them both as very easy starters with excellent handling qualities.

I'd have to give this little engine very high points as a test subject. The McCoy started and ran just as well throughout the test, never presenting any difficulties at all. An inexperienced owner would have come to terms with it very quickly. In performance terms, the engine was certainly no world-beater, but then that wasn't its intended niche. It was designed as a basic general purpose sports engine using which a relative beginner could gain valuable experience. Viewed in that context, it was a complete success. The ringed engine turned the test props at speeds which were entirely consistent with the figures reported in the previously-cited contemporary American test. The following figures were recorded.

As can be seen, the implied output of the tested ringed piston example of the McCoy "9" was around 0.121 BHP @ 12,000 RPM. This performance compares very favourably with the figures reported for a number of contemporary British engines of similar displacement. Many 1949-50 British modellers would have found the little McCoy to be a completely satisfactory performer. A 7x5 would have worked very well as a control line prop, with a 7x4 seemingly being ideal for free flight use. After running the above test props using the better of the two ringed piston examples, I switched to the 1955 lapped piston unit, running the same props on the same plug and fuel. This unit proved to be just as easy to start and set, also running flawlessly throughout. It turned each prop at more or less exactly the same speeds as its ringed predecessor - no prop was more than 100 RPM different. For all practical purposes, the performance of the two engines may be considered identical. Of course, this means that by 1956 the performance of the McCoy "9" had fallen somewhat behind those being achieved by a number of engines of similar displacement as of the mid 1950's. To take just one example, my own tests have shown that the 1954 McCoy "9" diesel from the same manufacturer outperformed the glow-plug model by a handsome margin. Viewed in this light, it was probably time for the glow-plug model to go. Still, it had enjoyed a production run of over 6 years! Purely on that basis, it must be judged an unqualified success! Conclusion The McCoy “9” clearly represented a very successful initial foray by McCoy into the beginner/sports engine market. Although it didn’t offer anything special in the way of performance, it was a well-made and sturdy little unit which handled extremely easily and ran very well. It’s easy to see why so many young modellers like Tim Dannels and Wes Pettinger were able to use it to get a good start to their power modelling careers! I hope that I’ve convinced at least a few of you that even the seemingly humblest of engines can have an interesting story to tell! Despite its seemingly unpretentious credentials, the little McCoy "9" is well worthy of respectful remembrance on several levels. If you ever get a chance to try one, you’ll be very favourably impressed! __________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia Canada First published January 2023

|

||

| |

In this article, I’ll look at a little glow-plug engine which many would doubtless consider to be the most humble and least noteworthy member of the famous line of model engines sold over the years under the McCoy banner. This is the McCoy .098 cuin. model which first appeared in 1949 under the McCoy “9” designation. I’m sure that many readers would consider this unpretentious little unit to be “beneath my notice”!

In this article, I’ll look at a little glow-plug engine which many would doubtless consider to be the most humble and least noteworthy member of the famous line of model engines sold over the years under the McCoy banner. This is the McCoy .098 cuin. model which first appeared in 1949 under the McCoy “9” designation. I’m sure that many readers would consider this unpretentious little unit to be “beneath my notice”!

companies such as Lockheed, Douglas and Boeing. Dick started as a lathe operator, soon being promoted to night foreman when the company began to grow. He stayed with Loud’s all the way up to 1956, becoming their chief of quality control with 50 inspectors under him.

companies such as Lockheed, Douglas and Boeing. Dick started as a lathe operator, soon being promoted to night foreman when the company began to grow. He stayed with Loud’s all the way up to 1956, becoming their chief of quality control with 50 inspectors under him.  Instead, Dick began to race model cars using

Instead, Dick began to race model cars using  Much of the information to be summarised here is derived from Tim Dannels’ invaluable “

Much of the information to be summarised here is derived from Tim Dannels’ invaluable “ Duro-Matic took their first tentative steps away from the all-out racing engine layout in 1948 with their Sportsman line of 0.349 and 0.549 cuin. Black Head models. Initially these featured a single ball race at the rear of the shaft, but later examples went to a plain bearing.

Duro-Matic took their first tentative steps away from the all-out racing engine layout in 1948 with their Sportsman line of 0.349 and 0.549 cuin. Black Head models. Initially these featured a single ball race at the rear of the shaft, but later examples went to a plain bearing.

The resulting engine was a cute little glow-plug motor displaying what was already in the process of becoming the standard design configuration for larger non-racing glow-plug engines - plain bearing, FRV induction, cross-flow loop scavenging, baffle piston, an external bypass passage and a side-stack exhaust. Bore and stroke were both 0.500 in. (12.70 mm) for a displacement of 0.0982 cuin. (1.609 cc). The engine weighed a checked 2.78 ounces (79 gm) complete with tank, fuel tubing and plug.

The resulting engine was a cute little glow-plug motor displaying what was already in the process of becoming the standard design configuration for larger non-racing glow-plug engines - plain bearing, FRV induction, cross-flow loop scavenging, baffle piston, an external bypass passage and a side-stack exhaust. Bore and stroke were both 0.500 in. (12.70 mm) for a displacement of 0.0982 cuin. (1.609 cc). The engine weighed a checked 2.78 ounces (79 gm) complete with tank, fuel tubing and plug.  directly above the baffle, a commonly-applied design feature intended to speed up the involvement in the combustion process of the isolated pocket of mixture partially trapped behind the baffle at top dead centre.

directly above the baffle, a commonly-applied design feature intended to speed up the involvement in the combustion process of the isolated pocket of mixture partially trapped behind the baffle at top dead centre.  The externally-threaded needle valve used with the original engines was extremely short, although it did have a slot in the head for adjustment using a screwdriver. Most used a coil spring for setting retention. Many examples encountered today use longer needle valves or even complete units “borrowed” from another model by a different maker, presumably following a breakage of the original assembly. One of my ringed piston examples is fitted with an early Fox assembly, which is a perfect match both visually and functionally. The transverse spraybar mounting hole has been enlarged, precluding the fitting of an original component.

The externally-threaded needle valve used with the original engines was extremely short, although it did have a slot in the head for adjustment using a screwdriver. Most used a coil spring for setting retention. Many examples encountered today use longer needle valves or even complete units “borrowed” from another model by a different maker, presumably following a breakage of the original assembly. One of my ringed piston examples is fitted with an early Fox assembly, which is a perfect match both visually and functionally. The transverse spraybar mounting hole has been enlarged, precluding the fitting of an original component.  Much of the following text is extrapolated from a reading of Tim Dannels’ article on this variant which appeared in issue no. 155 for December 2002 of Tim’s indespensable “

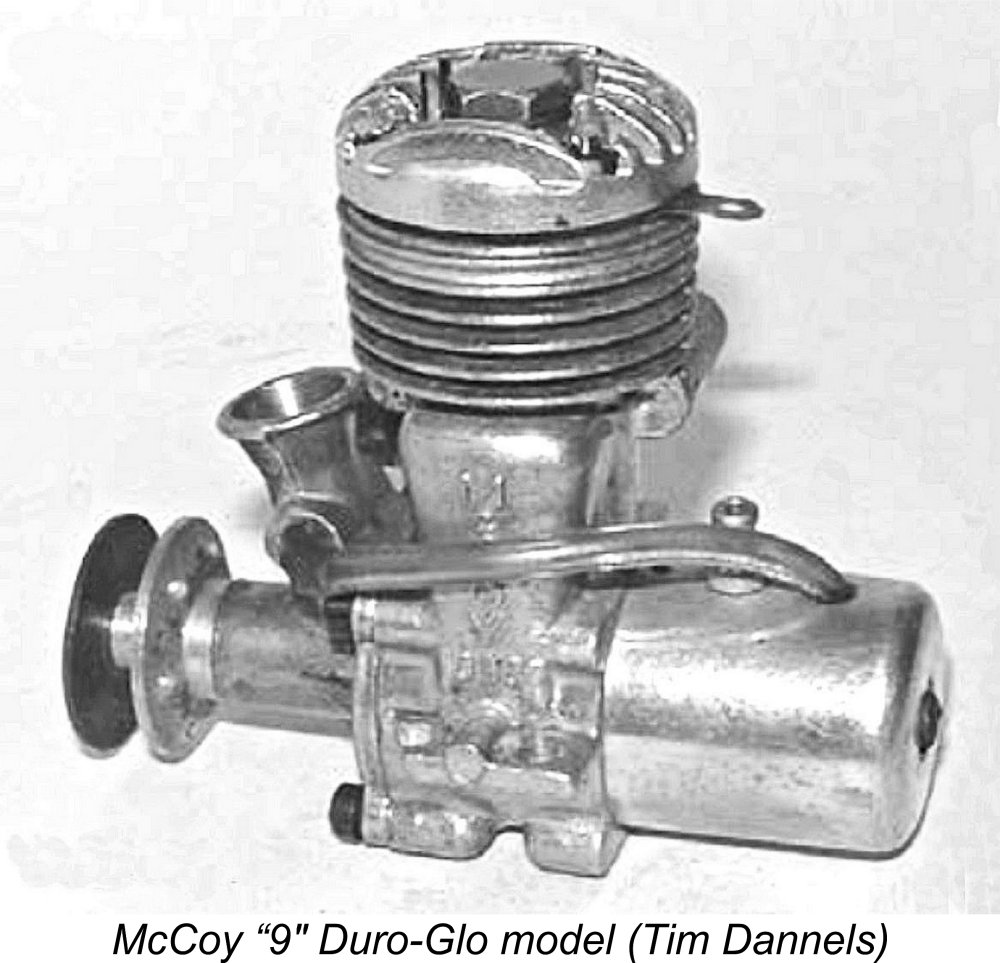

Much of the following text is extrapolated from a reading of Tim Dannels’ article on this variant which appeared in issue no. 155 for December 2002 of Tim’s indespensable “ The new design was referred to by Duro-Matic as the Duro-Glo system. An example of an engine fitted with this system is illustrated here. The first thing to notice is that Duro-Matic were hedging their bets on this system, since the heads of the engines fitted with the system were still drilled and tapped for a standard ¼-32 glow plug. The rare surviving examples of such engines are readily identified both by the red-anodized plug that was used to seal the standard glow plug hole and by the contact tab protruding from the rear of the head.

The new design was referred to by Duro-Matic as the Duro-Glo system. An example of an engine fitted with this system is illustrated here. The first thing to notice is that Duro-Matic were hedging their bets on this system, since the heads of the engines fitted with the system were still drilled and tapped for a standard ¼-32 glow plug. The rare surviving examples of such engines are readily identified both by the red-anodized plug that was used to seal the standard glow plug hole and by the contact tab protruding from the rear of the head.  The Duro-Glo element is shown in the attached image. The tab protruding from the rear of the engine between the head and cylinder served as one terminal for connection of the starting battery. This tab was attached to one end of the nichrome wire glow element. It was sandwiched between two layers of head gasket material to insulate it from the body of the engine, which served as the ground for the other battery terminal.

The Duro-Glo element is shown in the attached image. The tab protruding from the rear of the engine between the head and cylinder served as one terminal for connection of the starting battery. This tab was attached to one end of the nichrome wire glow element. It was sandwiched between two layers of head gasket material to insulate it from the body of the engine, which served as the ground for the other battery terminal.  The one potential advantage of this arrangement was the creation of a linear ignition source extending across the full bore rather than being a point source as with a conventional glow-plug. This might speed up the full involvement of the fresh charge of fuel mixture in the combustion process. An obvious downside was the potential for the element to come into contact with the piston baffle at top dead centre. The long unsupported element also appears to be potentially far more subject to vibration-induced stresses than a conventional coil element. The other clear problem was the fact that this element design was specific to a single model rather than having universal application.

The one potential advantage of this arrangement was the creation of a linear ignition source extending across the full bore rather than being a point source as with a conventional glow-plug. This might speed up the full involvement of the fresh charge of fuel mixture in the combustion process. An obvious downside was the potential for the element to come into contact with the piston baffle at top dead centre. The long unsupported element also appears to be potentially far more subject to vibration-induced stresses than a conventional coil element. The other clear problem was the fact that this element design was specific to a single model rather than having universal application.

The little McCoy “9” quickly proved to be a very popular model, remaining in production for some 6 or 7 years. Tim Dannels was a teenage user of the original model back in the day, still characterising it at the time of writing as one of his personal favourites - a high tribute from such an eminent model engine expert! Another former user, my valued friend and colleague Wes Pettinger of Texas, echoed Tim's assessment completely, stating independently that it was one of his favourites too.

The little McCoy “9” quickly proved to be a very popular model, remaining in production for some 6 or 7 years. Tim Dannels was a teenage user of the original model back in the day, still characterising it at the time of writing as one of his personal favourites - a high tribute from such an eminent model engine expert! Another former user, my valued friend and colleague Wes Pettinger of Texas, echoed Tim's assessment completely, stating independently that it was one of his favourites too.

The only really major variation on the original design was a 1950 switch from the single-ringed light alloy piston to a lapped ringless cast iron piston. This change gave the little “9” yet another badge of distinction - it was McCoy’s first-ever lapped piston design. The crankcase casting was now given a matte finish, while the alloy prop driver and prop washer were replaced by blackened steel components, still of large diameter. The cylinder head was produced from a revised die which resulted in a slightly less rounded profile. The former ultra-short solid needle valve was replaced by a somewhat longer flex component.

The only really major variation on the original design was a 1950 switch from the single-ringed light alloy piston to a lapped ringless cast iron piston. This change gave the little “9” yet another badge of distinction - it was McCoy’s first-ever lapped piston design. The crankcase casting was now given a matte finish, while the alloy prop driver and prop washer were replaced by blackened steel components, still of large diameter. The cylinder head was produced from a revised die which resulted in a slightly less rounded profile. The former ultra-short solid needle valve was replaced by a somewhat longer flex component.  29 “Stunt” design. Both of these new offerings were essentially scaled-up versions of the little “9”, although they retained the ringed pistons of their predecessors. This made it clear that the “9” had served very successfully as the prototype for the new series of McCoy sports engines.

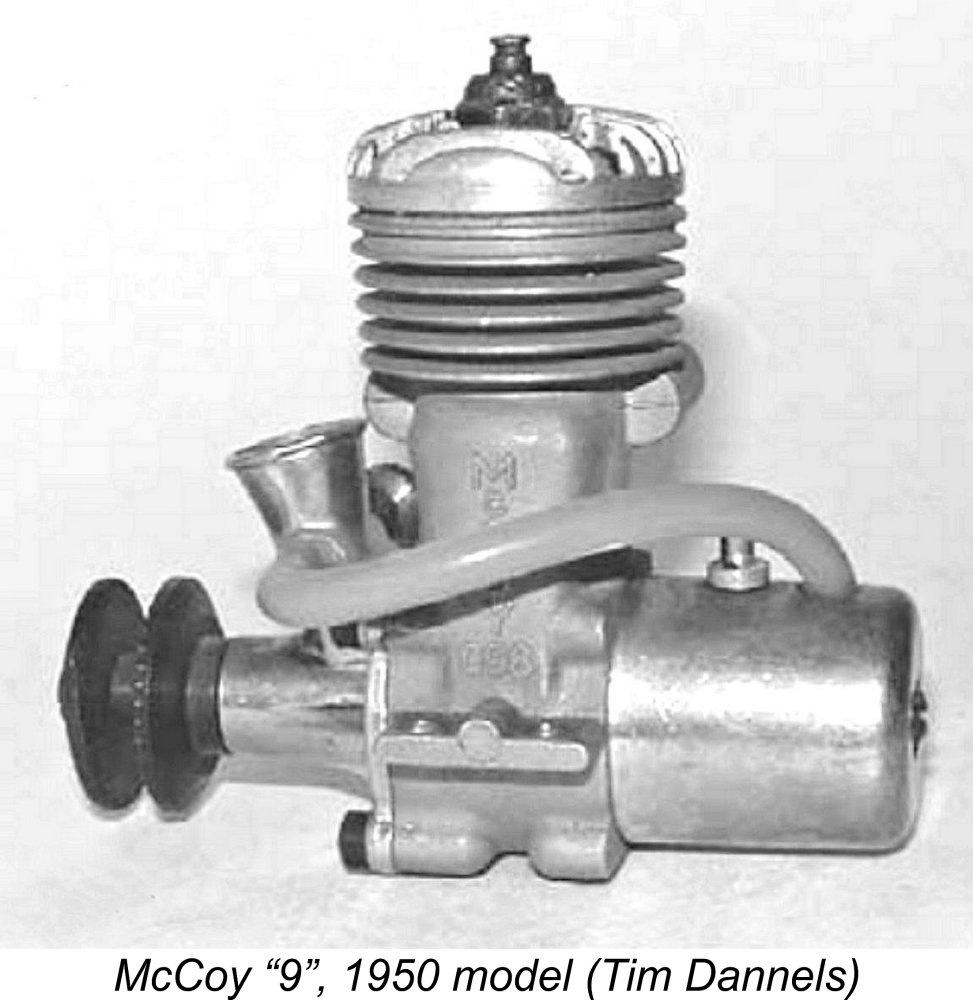

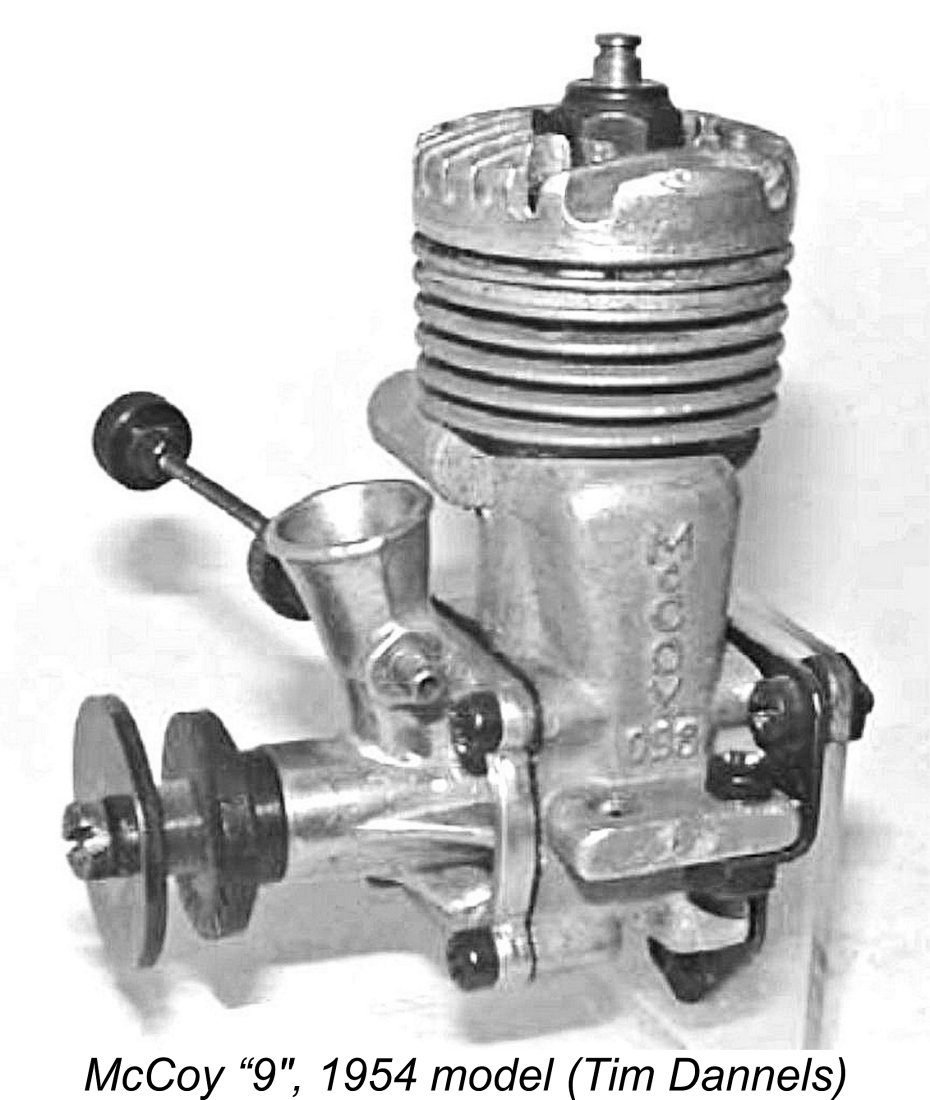

29 “Stunt” design. Both of these new offerings were essentially scaled-up versions of the little “9”, although they retained the ringed pistons of their predecessors. This made it clear that the “9” had served very successfully as the prototype for the new series of McCoy sports engines.  At the same time, the McCoy “9” glow-plug model was very slightly revised. A matte case continued to be used, but the “bump” mounting lugs used up to this point were replaced by far thicker rectangular-profile lugs, while the mounting flange for the front cover was thickened somewhat. The head die was revised yet again to yield a somewhat flatter profile, while the steel prop driver was considerably smaller in diameter. The engine continued to be sold with a tank, but an accessory radial mount was now offered which required the removal of the tank. The accompanying illustration shows an example fitted with this accessory.

At the same time, the McCoy “9” glow-plug model was very slightly revised. A matte case continued to be used, but the “bump” mounting lugs used up to this point were replaced by far thicker rectangular-profile lugs, while the mounting flange for the front cover was thickened somewhat. The head die was revised yet again to yield a somewhat flatter profile, while the steel prop driver was considerably smaller in diameter. The engine continued to be sold with a tank, but an accessory radial mount was now offered which required the removal of the tank. The accompanying illustration shows an example fitted with this accessory.

It’s clear that the concept of McCoy releasing a non-racing model featuring FRV induction was viewed as a great novelty, since the writer of the report spent about two-thirds of the article justifying the switch to FRV induction! The chief advantages cited were reduced friction, lower weight and reduced manufacturing cost - all quite valid points.

It’s clear that the concept of McCoy releasing a non-racing model featuring FRV induction was viewed as a great novelty, since the writer of the report spent about two-thirds of the article justifying the switch to FRV induction! The chief advantages cited were reduced friction, lower weight and reduced manufacturing cost - all quite valid points.