|

|

The GB 5 cc Diesel – Another David Owen Masterpiece By David Owen and Maris Dislers

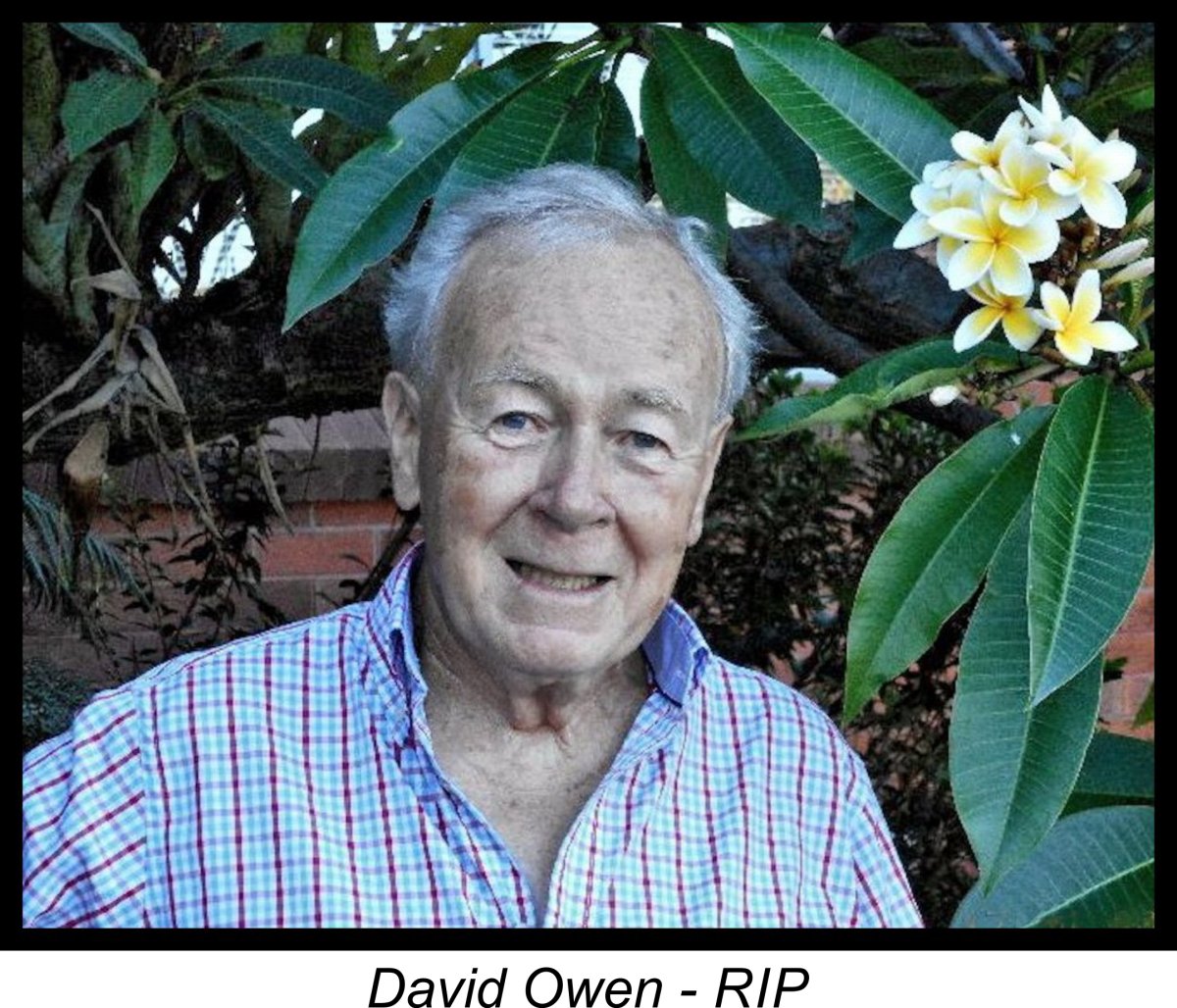

It turned out that the seller lived on the West Coast of Canada only a few miles from my home. Although the bidding was competitive, I was successful in acquiring the engine. I suppose that not having to cover postage costs and Customs charges gave me an edge ............... Although we never met face to face, I viewed David as a very good mate who was always more than willing to help me out during the preparation of my model engine Maris Dislers’ outstanding book entitled “Gordon Burford’s Model Engines” includes a short chapter written by David himself in 2009, in which the circumstances surrounding the design and production of the GB 5 cc diesel are fully documented. I felt that the re-publication of David’s article here would constitute a fitting reminder of just how talented an individual David was. Maris was gracious enough to lend his support to this concept, even going so far as to provide me with some test results which he had obtained himself from one of these engines. So here’s another tribute to a good friend, a valued informant and a mega-talented model engine builder – the late David Owen. Over to you, David – how nice to be able to say that again! A.D. The GB 5 cc Diesel By David Owen, October 2009

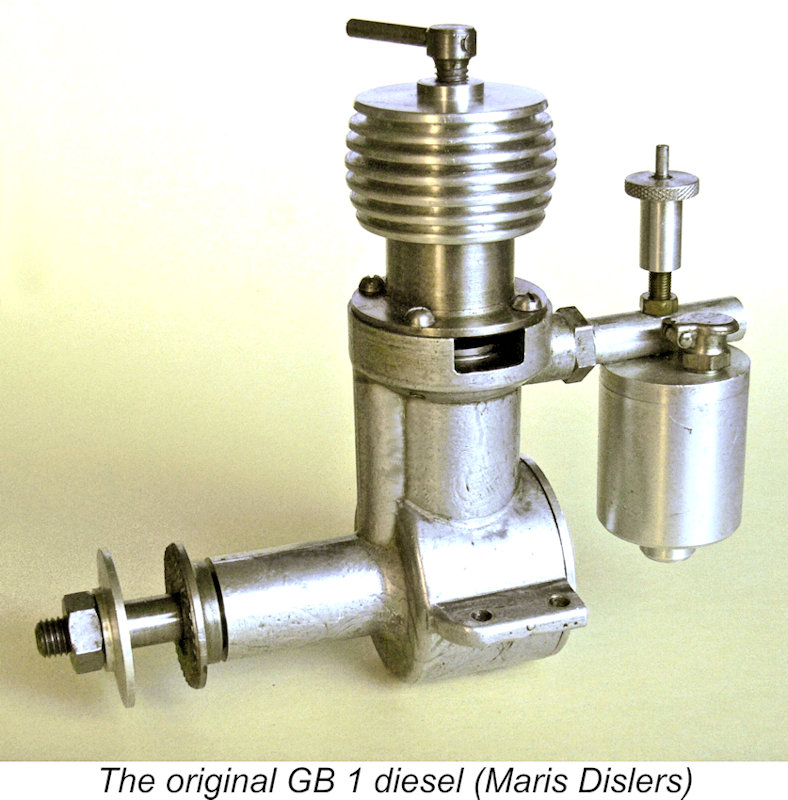

The third engine Gordon flew extensively in free-flight and early control-line models. This last engine was stolen following a display in the Handicraft Section of the 1947 Royal Adelaide Exhibition. It was not recovered. Gordon went on to build many thousands of engines, as detailed in this book.

The missing 1946 diesel was discovered in the United States in 1997. It was returned to Australia through the generosity of its perfectly innocent custodian, the renowned Bert Striegler of “Ebenezer” fame. Gordon and I often ran the engine, now known as “GB 1”, to the delight and interest of many modelers at Old Timer events. Such was the interest in this famous engine that we now discussed the idea of re-producing it for Australian Old Timer flyers.

I finished the gravity die for the crankcase casting and cast the first test cases around mid-1999. Gordon made several trips from Currumbin to Wollongong to discuss and advise on the considerable tooling required to complete the engine. I made up one prototype engine to prove the design changes and the tooling. In April 2000 this engine was submitted to and approved by SAM 1788 as an Antique engine for Old Timer contest flying in Australia. Subsequent approval was also received from SAM in the USA.

Collaborating with Gordon over a period of some 20 years has been a wonderful experience. As a result of his encouragement and willingness to pass on so much of his engine-building expertise, I have not only learned a great deal about engine design and production, but have been endowed with a remarkable insight into the Gee Bee, Sabre, Taipan and Glo Chief years. David Owen, October 2009 ___________________________________

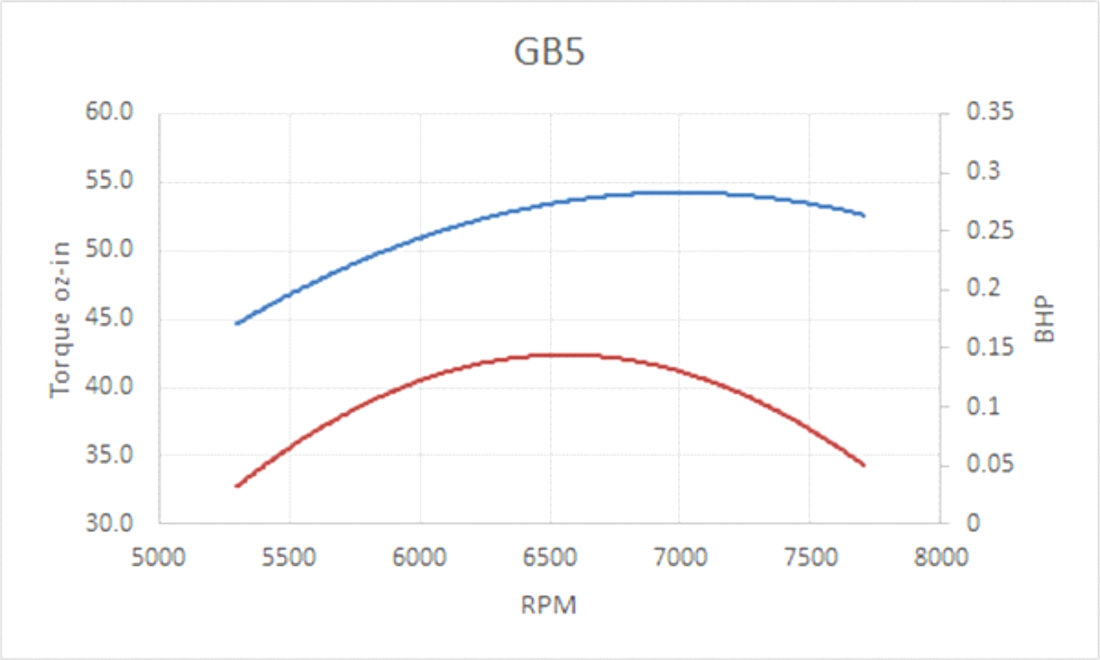

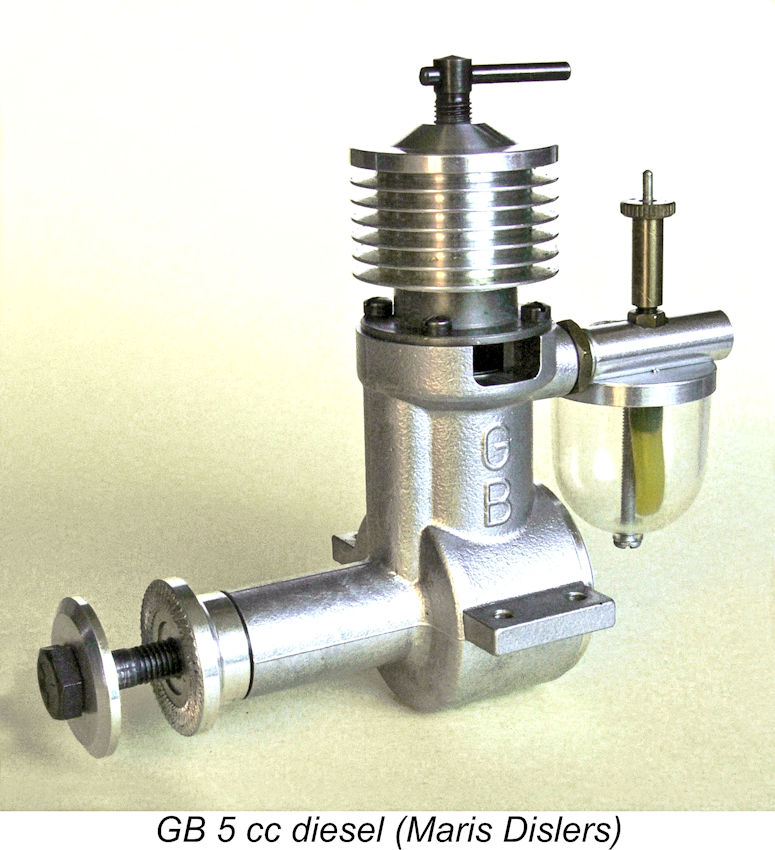

The Owen Replica GB 5 cc Diesel on Test Adrian here again! A few details which were not included by David seem worth recording here. Bore and stroke were 0.689 in. (17.50 mm) and 0.885 in. (22.50 mm) respectively for a displacement of 0.33 cuin. (5.40 cc). The GB 5 cc diesel weighed in at 9.7 ounces (275 gm). As mentioned at the outset, my good mate Maris Dislers had already run a series of tests on this engine. He was good enough to share the results for inclusion in this article. Maris tried the engine on a wide range of suitable airscrews. His prop/RPM figures were as follows, along with the resulting performance curves.

As can be seen, the engine delivered around 0.295 BHP @ 7,000 RPM. Maximum torque was 42.4 oz-in @ 6,600 RPM. These figures compare very well with those extracted from the likes of the Micron, Drone and K Vulture 5 cc diesel competition. Maris found it quite interesting that when using this engine in Texaco competitions, most Old Timer guys lugged it on 14x6 propellers. This took the engine out of its sweet spot, causing it to run rather unhappily. While the lower RPM certainly extends running time, loading the engine below its maximum torque speed range is inefficient. If the model will still climb at such a reduced power output, a smaller propeller and reduced choke area (i.e. throttle) would be a better option in Maris’s opinion. AGB-05 GB 5 cc diesel no. 074 running - left side view L This practice goes some way towards explaining the occasional observation that the crankshaft bearing is not well supplied with oil in this design. It’s logical to expect that if you pinch down the available oil and then load the bearing with a big prop, such a condition may well arise. Re-finishing the shaft to a slightly looser fit has been known to solve the problem. I saw no need to duplicate Maris’s complete test using my own example, engine no. 074. I confined myself to trying the engine using an APC 12x7 prop, just to experience its handling and running qualities. Since I wasn't planning to actually fly the engine, I saw no need to suject it to a full break-in. I decided to put around 15 minutes on it and then lean it out briefly to get some idea of its running qualities and performance. I didn't think that such a program would do it any harm.

Conclusion

__________________________ This compilation first published Original authors' rights reserved

|

|

| |

Editor’s note - In March 2024 I saw an eBay offering of one of the superb 5 cc sideport diesels produced in Australia by the late and much-missed David Owen of Woolongong in consultation with the late Gordon Burford of Taipan fame. The engine was based quite closely on Gordon’s original GB 1 model, although a few improvements were incorporated into the replica.

Editor’s note - In March 2024 I saw an eBay offering of one of the superb 5 cc sideport diesels produced in Australia by the late and much-missed David Owen of Woolongong in consultation with the late Gordon Burford of Taipan fame. The engine was based quite closely on Gordon’s original GB 1 model, although a few improvements were incorporated into the replica.

Gordon Burford first decided to build his own engine following the publication in late 1946 of drawings for the

Gordon Burford first decided to build his own engine following the publication in late 1946 of drawings for the

The new engine was named simply the GB 5 cc Diesel. It was decided that I would re-engineer the design to include a couple of desirable changes to the shaft balance and cylinder assembly. With Gordon's approval, these and other minor changes to the original engine were finalized. We planned to build about 100 engines and, as soon as this was known, we started to receive orders from both Australia and overseas.

The new engine was named simply the GB 5 cc Diesel. It was decided that I would re-engineer the design to include a couple of desirable changes to the shaft balance and cylinder assembly. With Gordon's approval, these and other minor changes to the original engine were finalized. We planned to build about 100 engines and, as soon as this was known, we started to receive orders from both Australia and overseas.  The large bulk of component parts was produced and finished in my Wollongong workshop, including the cylinder bores which were ground on the same Overbeck internal grinder which had originally ground tens of thousands of Taipan and Glo Chief cylinders. We developed new production procedures to facilitate piston/ cylinder/ contra-piston fitting, with me doing the external grinding and Gordon testing and approving the final fits. These ideas worked remarkably well in practice. The actual production engines received considerable world-wide acclaim, resulting in the necessity of producing a second run of GB 5 cc diesels. Total production was 175 engines, of which many were used in competition, and some still are nearly ten years later (in 2009).

The large bulk of component parts was produced and finished in my Wollongong workshop, including the cylinder bores which were ground on the same Overbeck internal grinder which had originally ground tens of thousands of Taipan and Glo Chief cylinders. We developed new production procedures to facilitate piston/ cylinder/ contra-piston fitting, with me doing the external grinding and Gordon testing and approving the final fits. These ideas worked remarkably well in practice. The actual production engines received considerable world-wide acclaim, resulting in the necessity of producing a second run of GB 5 cc diesels. Total production was 175 engines, of which many were used in competition, and some still are nearly ten years later (in 2009).