|

|

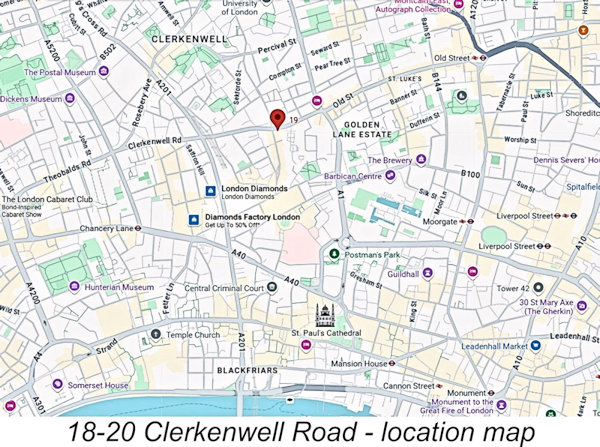

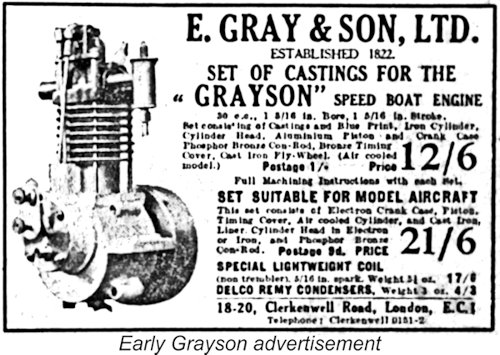

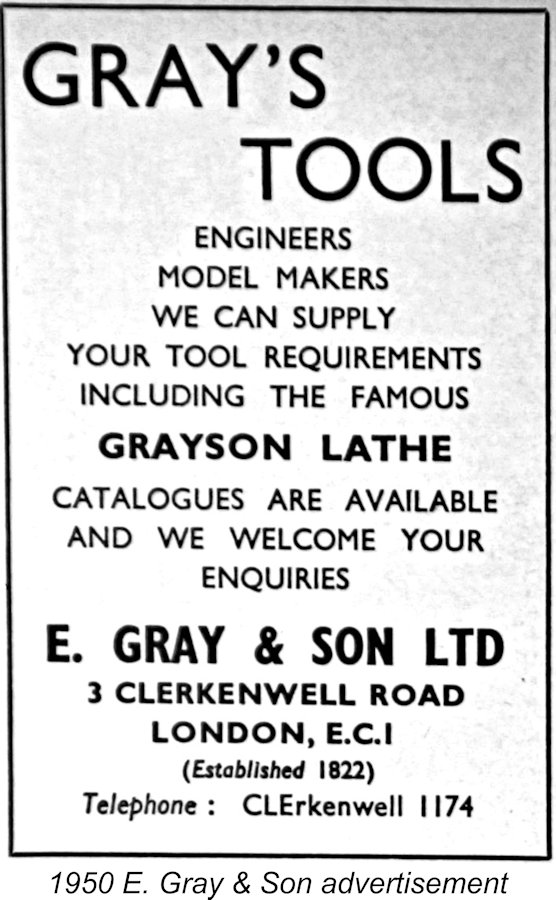

Forgotten Pioneers - the Grayson Engines In this article, I’ll present a little information on a mostly-forgotten range of pioneering model engines manufactured in London, England during the 1930’s by a long-established firm of toolmakers named E. Gray & Son Ltd. of Clerkenwell Road. Founded way back in 1822, over 100 years before it made its first model engine, this company apparently started out as a supplier of tools, accessories and components to the watch-making and clock-making trades, By the time of which we’re speaking here, E. Gray & Son had become well-established as leading suppliers to the model engineering community. The level of British participation in this hobby was then far higher than it is today - a surprising number of model enthusiasts possessed some basic metalworking equipment such as a small lathe, or had access to such equipment through their places of work. The prevailing level of British involvement in model engineering was sufficient to support the publication of a magazine devoted exclusively to the activities of its practitioners. At the time of which we are speaking, this magazine was entitled “Model Engineer & Practical Electrician”, later shortened to just “Model Engineer” (ME). Established in 1898 by its publisher Percival Marshall, the magazine is still in publication today (2025) under the title “Model Engineer & Workshop”, albeit now owned by Mortons Media Group. The ready availability of low-cost machine tools from China and Taiwan has triggered something of a latter-day resurgence in this long-established hobby. “Model Engineer & Practical Electrician” magazine was joined in October 1933 by a rival publication entitled “Newnes Practical Mechanics” (NPM) which was published by George Newnes Ltd. Although this magazine dealt with a very wide range of do-it-yourself projects, it included quite extensive coverage of both model engineering and the development of the pioneering power aeromodelling movement in Britain. Indeed, it was the best available source of aeromodelling infomation during its first couple of years - "Aeromodeller" magazine did not commence publication until November 1935. I'm very much indebted to my friend and colleague Gordon Beeby of Australia for bringing this invaluable resource to my attention.

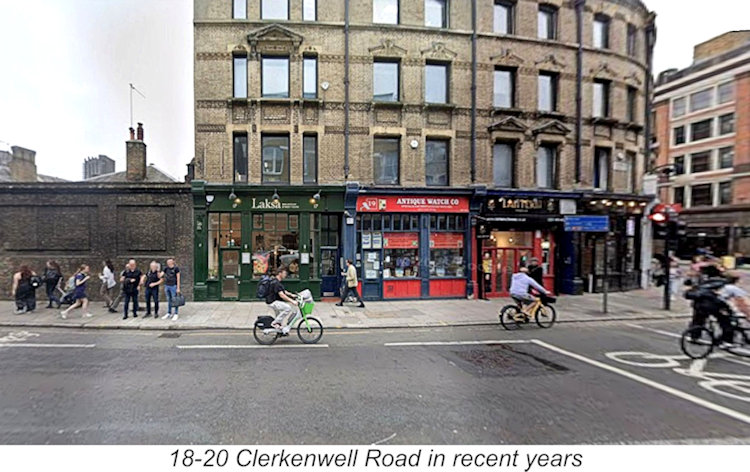

One of Gray & Son's flagship products was the highly-regarded Grayson 3-inch swing screwcutting lathe. They also continued to serve as major suppliers to the British watch-making and clock-making industry, for which Clerkenwell Road was something of a focal point, with a number of horological firms being located there in close proximity. Indeed, a portion of E. Gray & Son’s former premises at no. 19 Clerkenwell Road is still occupied today by the Antique Watch Company (the red-fronted premises in the photograph at the right). Very little information has previously been made generally available on the model engines manufactured by Gray & Son, particularly those used in power aeromodelling applications. By far the best reference that I’ve been able to find appeared in the late Tim Dannels’ ever-informative Engine Collectors Journal (ECJ), Volume 6, Number 3 for Spring 1968. This took the form of a short "Engine of the Month" article by Dr. R. E. Nichol sub-titled “Engines of E. Gray & Son, Ltd.” Dr. Nichol had collaborated with engine historian Alan Denham to ferret out some details of this company’s activities. The ECJ article is reproduced here below at the left.

The Gray company seems to have decided to enter the model engine market in around 1930. They did not design their own engines, since that wasn’t their area of expertise – instead, they produced casting kits and complete engines to designs developed by others who were willing to assign the manufacturing rights on some basis. It’s really difficult to be certain, but it appears from the advertising record that they only remained in the model engine business for around 9 years until the onset of WW2, thereafter returning to their toolmaking roots. Let’s now have a look at what can be ascertained about the various engines produced by E. Gray & Son Ltd. The Gray Engines – an Overview One of the most useful resources for tracking the Grayson model engine range is the series of advertisements that the company placed in "Newne's Practical Mechanics" (NPM) magazine beginning in late 1933 soon after the magazine's October 1933 establishment and continuing on a regular basis throughout the balance of the 1930's. Although this magazine covered a very wide range of do-it-yourself projects, it did include a fair bit of information on the development of power aeromodelling in Britain during the pre-war pioneering era to which the Grayson engines belong. My thanks to Gordon Beeby for drawing my attention to this invauable reference - some really fun reading there! In his previously-cited ECJ article, Dr. R. E. Nichol tells us that the model engine series manufactured by E. Gray & Son included the following models (in order of ascending displacements rather than chronological):

Obviously, all of these engines were spark ignition units. Other models may have existed, but there is no record of them.

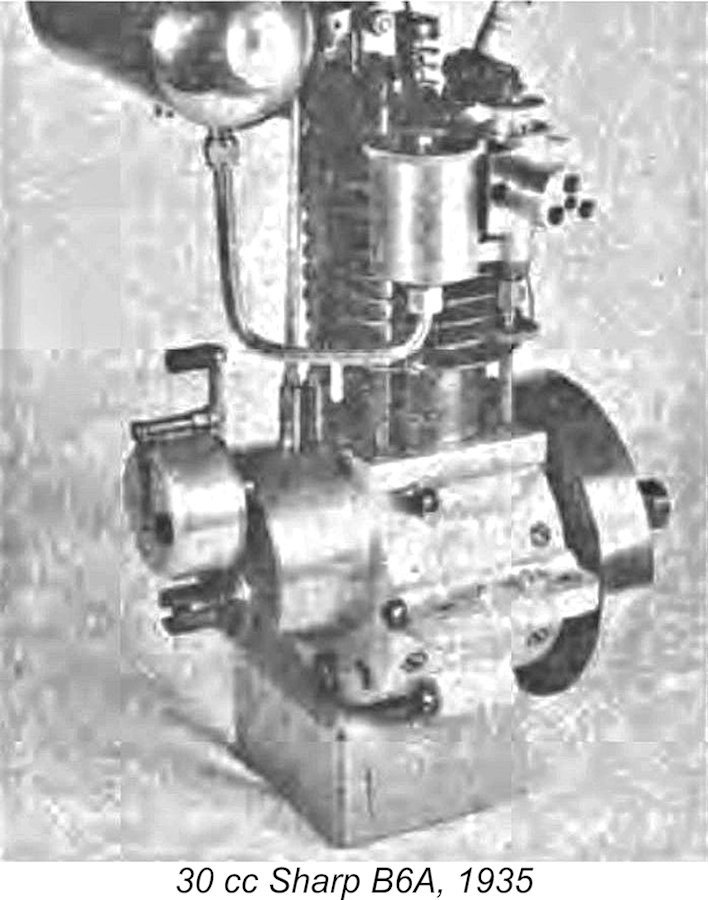

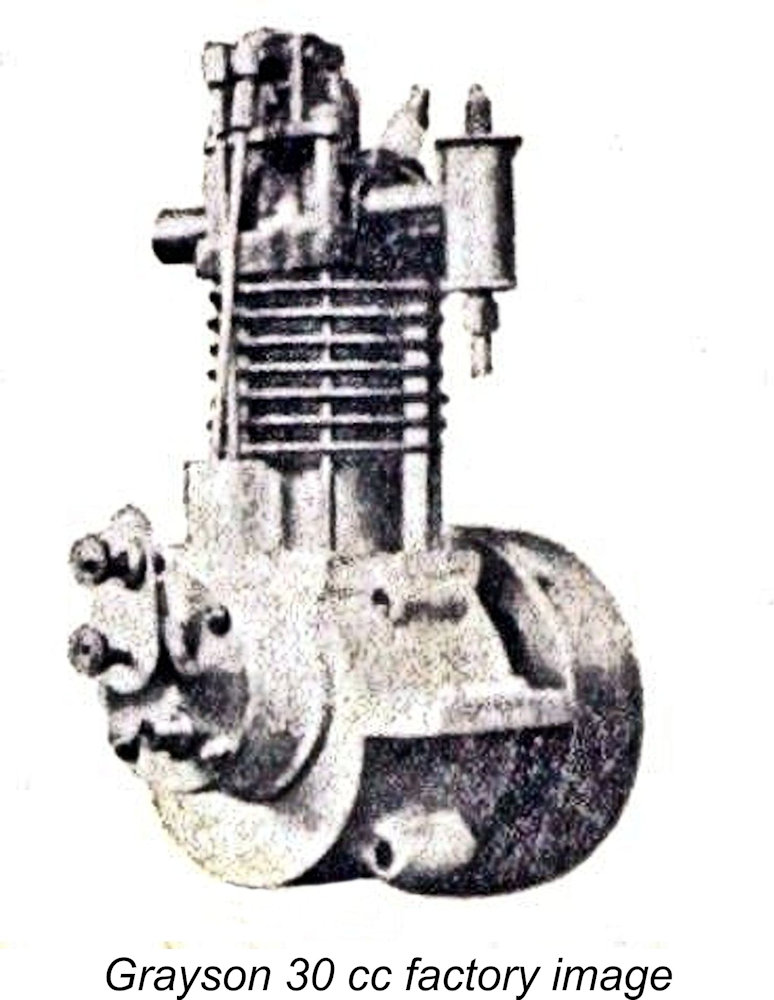

The Grayson four-stroke design was based upon that of an earlier boat engine designed by one F. N. Sharp, who had been The Sharp engines were developed through a succession of variants, culminating in the Model B6A which was originally built in 1931 as a 25 cc unit but was subsequently refined into the 30 cc variant of 1935 illustrated here. The 30 cc displacement reflected the expectation that the engine would be used to power tethered hydroplanes. Mr. Sharp had evidently reached some kind of arrangement with E. Gray & Son which allowed them to draw very heavily upon his design. Presumably some kind of compensation was involved – possibly a royalty payment on units sold. There was nothing underhand about this situation - Sharp’s design involvement was openly acknowledged in a number of the earlier advertisements for the Grayson engines. As previously stated, his name was also attached to the offerings from other companies as well.

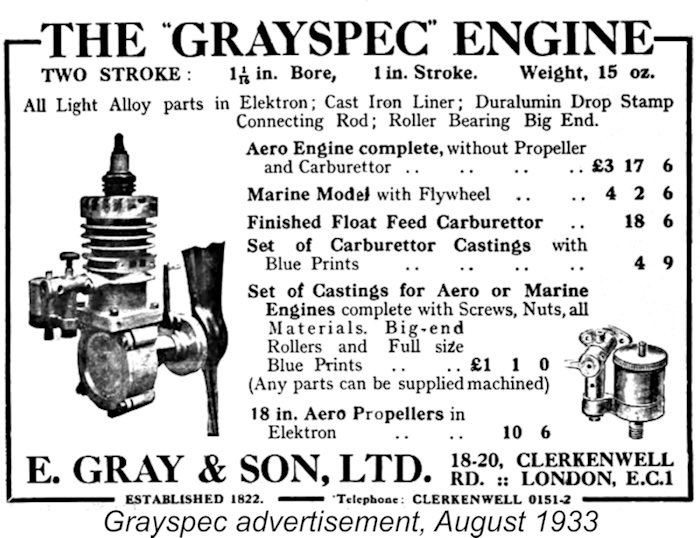

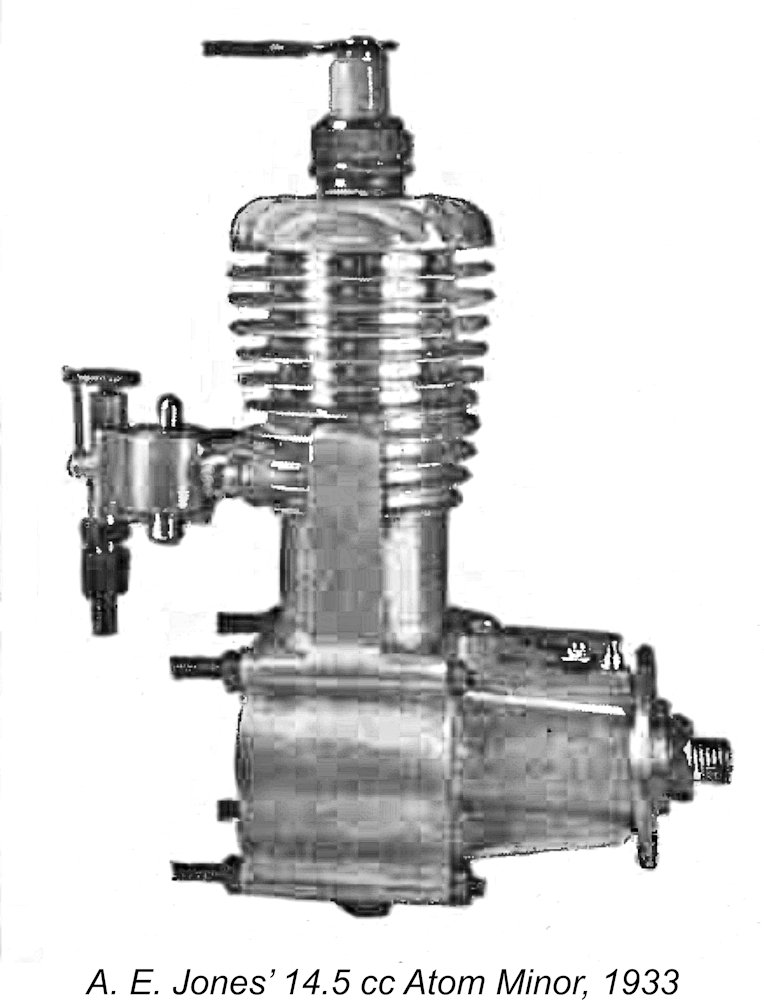

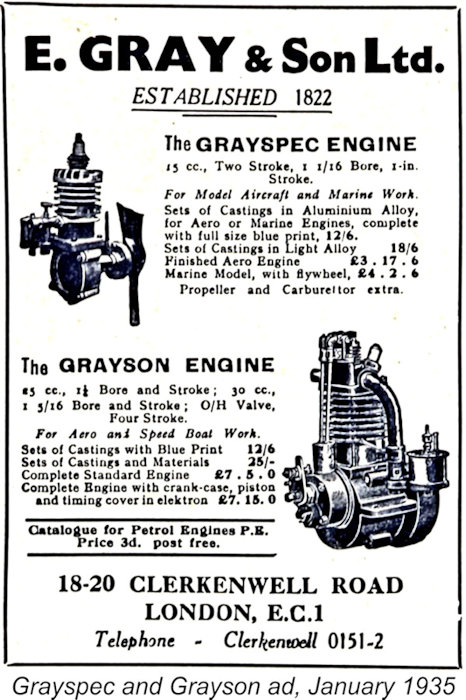

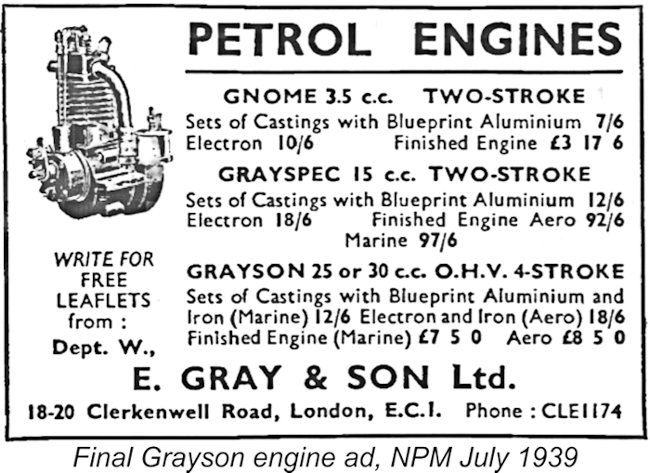

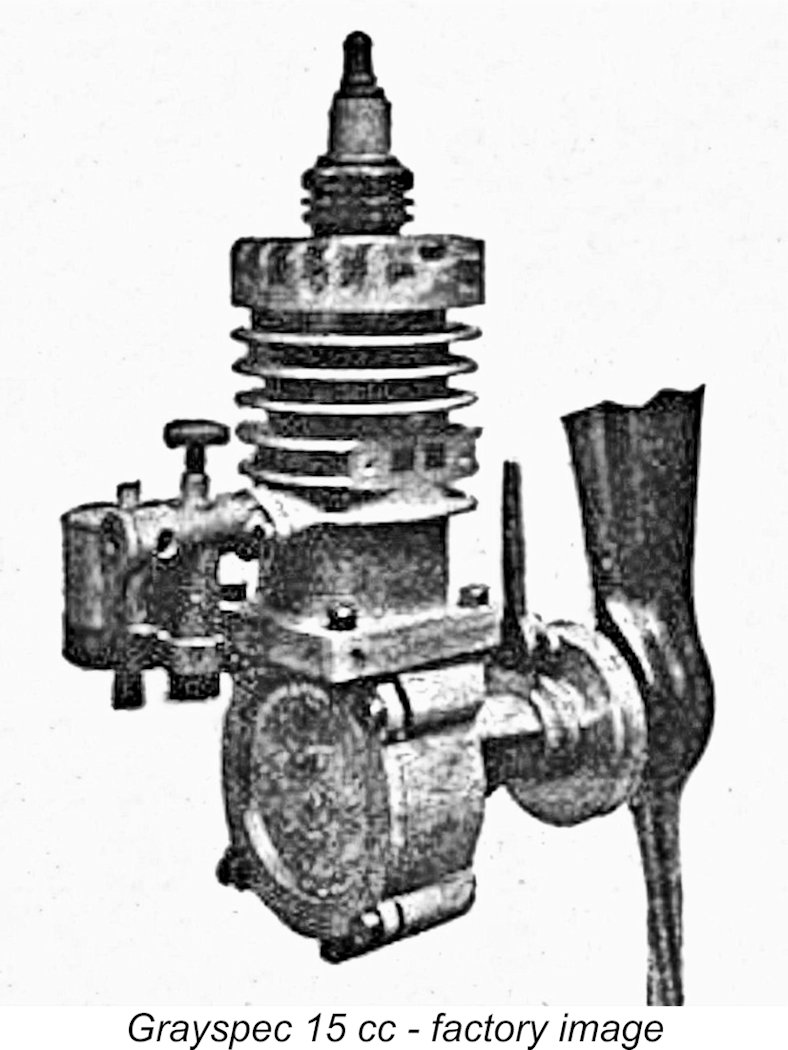

The production version of French’s design reached the market in mid-1933, being offered as the Grayson Special (hence “Grayspec”) model. Although designed primarily as an aero engine, it was offered in both aero and marine configurations (both air-cooled), also being available both complete and in casting form. As far as I'm currently aware, the Grayspec was the The appearance of the Grayspec initiated something of a trend among British manufacturers. Before the end of 1933, the London model goods supply firm of A. E. Jones had released their well-made and techologically-advanced but very expensive 14.5 cc Atom Minor unit. This was the first-ever British model aero engine to feature a twin ball-race crankshaft. J. Hallam & Son of Poole in Dorset followed in early 1934 with their 13.5 cc aero model, while Rogers & Geary of Leicester joined in the fun in 1935 with the 18 cc Comet aero engine. The Grayspec was priced at what sounds like a remarkably reasonable £3 17s 6d (£3.88) for the aero version and £4 2s 6d (£4.13) for the flywheel-equipped air-cooled "marine" variant. However, we must remember that the price of one of these engines would have represented over a week's wages for the average British working individual in 1933. Puts a little perspective into latter-day engine prices, doesn't it?!?

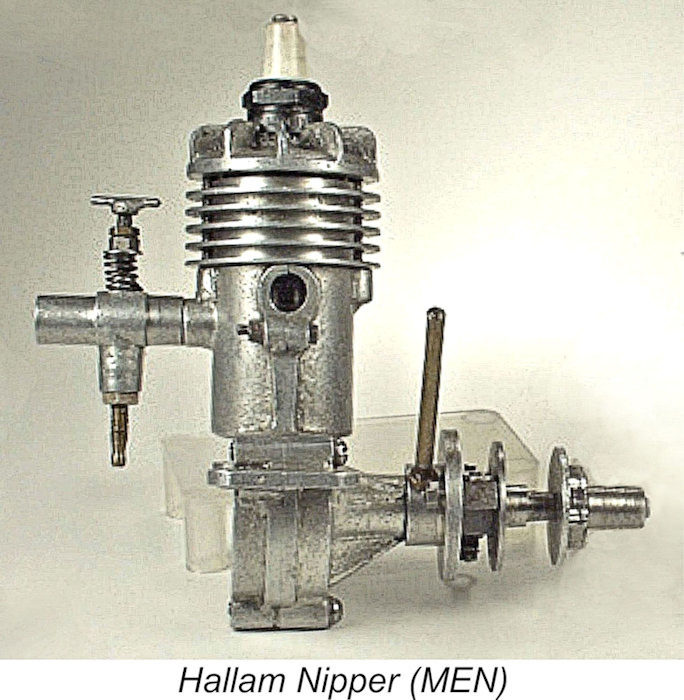

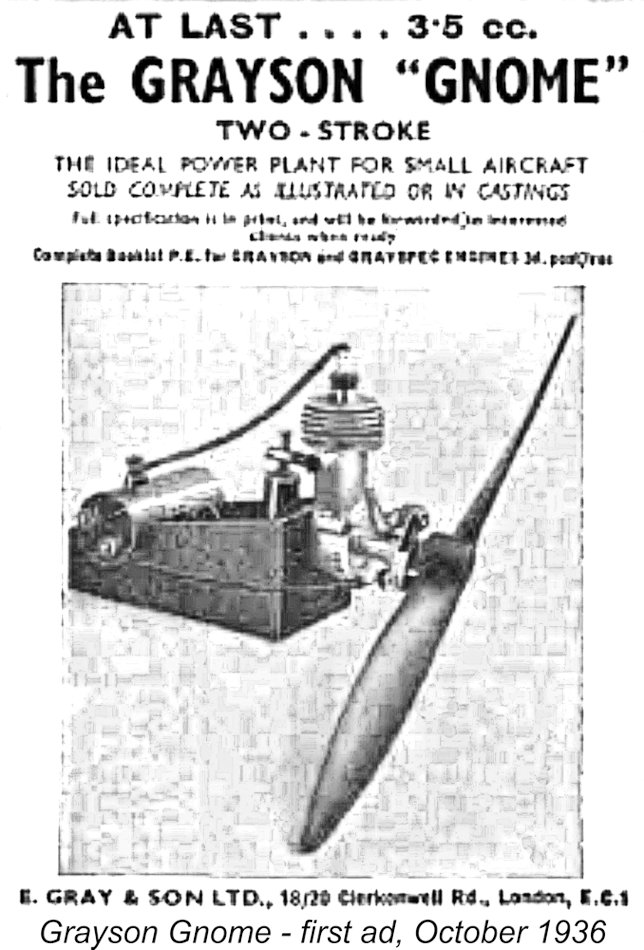

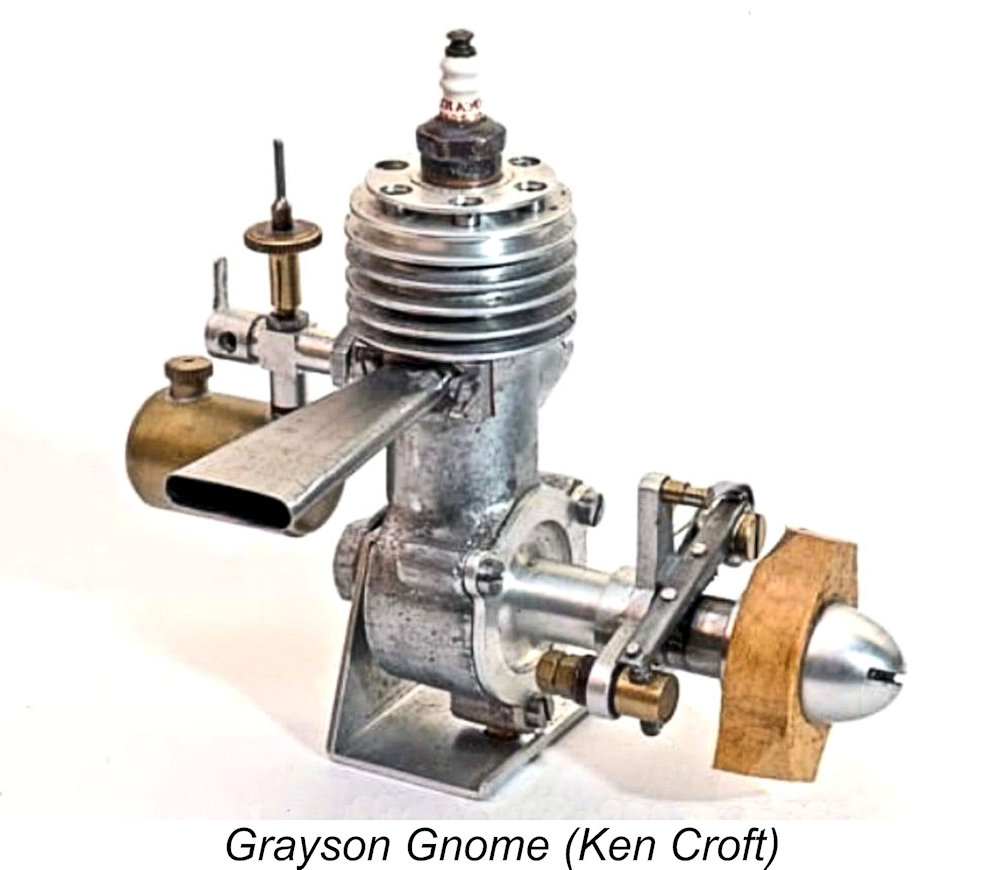

Sets of castings, materials and blueprints were also available at a price of £1 1s 0d (£1.05) for both aero and marine engines, with castings and blueprints for the carburettor also available at 4s 9d (£0.24). A presumably matching 18 in. dia. airscrew cast in elektron alloy was also available at a price of 10s 6d (£0.53). Clearly, this was not a high-speed engine! The Grayson OHV four-stroke model continued in concurrent production at this time, still being offered in displacements of 25 cc and 30 cc and remaining available in both “standard” form with aluminium alloy castings and a “lightweight” version with elektron castings. The “standard” engine with aluminium alloy casings was offered at £7 5s 0d (£7.25), with the lightweight version based on elektron castings selling for £7 15s 0d (£7.75). A basic set of castings and blueprints was available for 12s 6d (£0.63), while for a price of £1 5s 0d (£1.25) one could buy a complete kit comprising castings, materials and blueprints. Both models were still being advertised at the same prices as of 1935. However, as 1936 approached, British model engine manufacturers had come to appreciate the fact that many prospective aeromodelling customers were put off by the challenge of constructing, transporting and storing the very large models needed to accommodate the Grayson, Jones, Rogers & Geary and Grayspec aero offerings. The advent of smaller motors like Hallam & Son had reacted promptly to this market trend by bringing out their 6 cc Nipper in late 1935. Gray & Son were a little slower to react to the situation, but they eventually did so by introducing a 3.5 cc two-stroke model called the Grayson Gnome in The first public appearance of the Gnome came at the 1936 Model Engineer Exhibition (September 17th-26th). Writing on the Exhibition in the Oct 8th, 1936 issue of "Flight", M. R. Wright reported that the Gnome was displayed in a biplane model and was just about to be released. This engine represented an aggressive move by the company towards participation in what was still a small but growing power aeromodelling market in Britain. It was competitively priced at £3 17s 6d (£3.88) complete with carburettor and tank. Casting sets and blueprints were also available at 7s 6d (£0.38) for the aluminium alloy castings and 10s 6d (£0.53) for the considerably lighter elektron components. A suitable coil/condenser set could be purchased for 14s 6d (£0.73), while a suitable airscrew was available for 5s 6d (£0.28). The financial incentive driving the home-construction option was very clear. Unfortunately, the Gnome does not appear to have been a commercial success. Its appearance was evidently overshadowed by the simultaneous April 1937 introduction of both the 3 cc Hallam Baby (essentially a down-scaled rendition of the Nipper) and the 2.31 cc Rogers & Geary Spitfire (basically a scaled-down Baby Cyclone). The Gnome continued to be advertised along with the other Grayson models on a somewhat sporadic basis almost right up to the onset of WW2, but I suspect that by that time the company had lost interest in pursuing its model engine production activities and was simply attempting to liquidate existing stock, actual manufacturing probably having ceased quite a bit earlier.

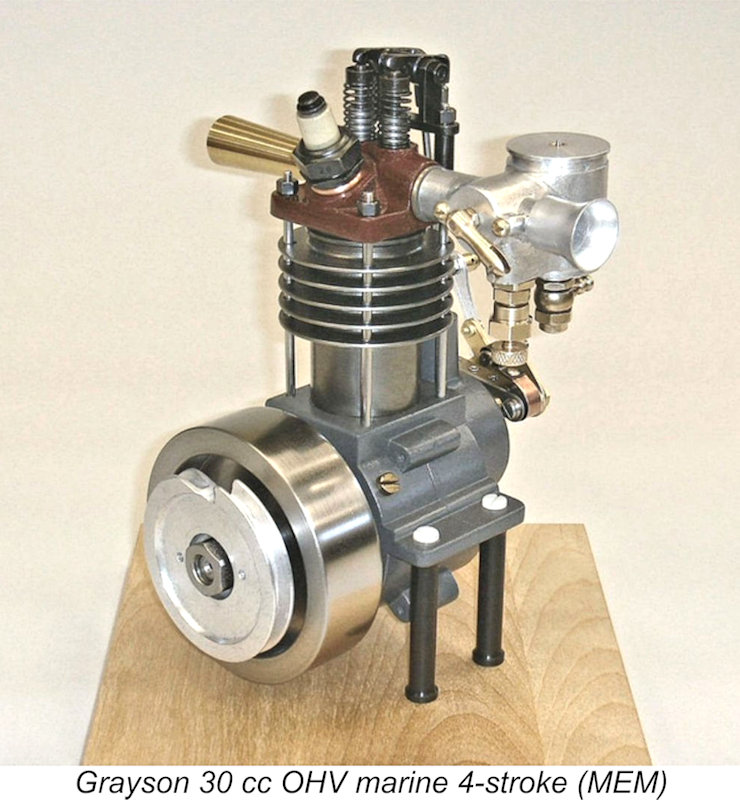

The number of examples of the various Gray & Son model engines which were manufactured by the company or were constructed from castings by home builders is now impossible to determine. All The company survived the WW2 years, resuming its model engineering supply business thereafter but not returning to the model engine manufacturing field. They were still promoting the Grayson lathe along with a wide range of associated tools and accessories. By 1953, the company had relocated its operations to 12-14 Clerkenwell Road after a brief interim residence at no. 3 Clerkenwell Road (which may have been merely an office address). They were still advertising in this vein in mid-1956. As of 1959, they apparently remained active as suppliers to the watchmaking trade, rebuilding the combined premises at 12-16 Clerkenwell Road (now known as Grayson House) in that year. I have no information regarding their subsequent activities or their long-term fate. Having set out what is recorded about the model engine manufacturing activities of E. Gray & Son, it remains for me to provide a description of the various model engines that they produced. In doing so, I wish to acknowledge the fact that some of the images which appear here are derived from those presented by the Miniature Engineering Museum (MEM) operated by Paul & Paula Knapp. Their photo gallery is well worth a visit by anyone interested in model engines! Images of some truly amazing examples of the model engineer’s craft may be found there. My sincere thanks to Paul and Paula! The Grayson OHV Four-stroke Engines

As of the early to mid-1930’s, tethered hydroplanes were the sole all-out model racing category being practised, since tether car racing and control-line speed contests still lay in the future. To give some idea of the levels of performance then viewed as competitive, F. N. Sharp won a Bronze Medal in the 1930 Model Engineer Speedboat Competition at a speed of 27 mph using one of his own four-stroke engines in his boat "Mona". The fastest hydros were then pushing 40 mph. At this time, four-stroke engines pretty much ruled the roost in the prestigious 30 cc tethered hydroplane racing category along with their flash steam compatriots, which actually held all the records up to 1936 - it took over forty years for the two-strokes to catch up!

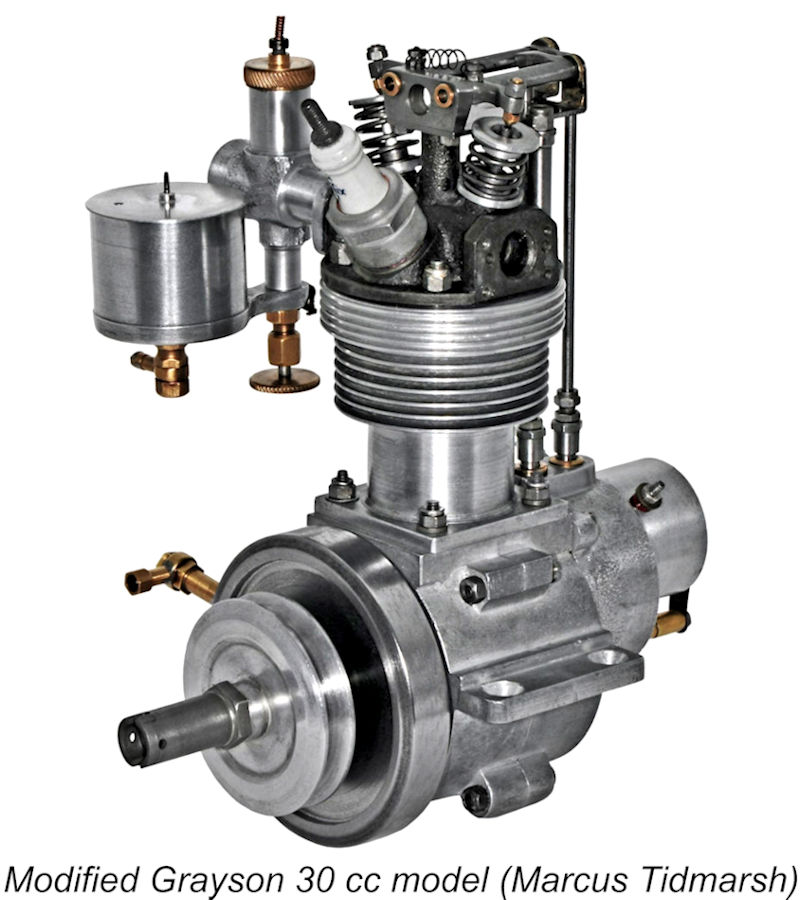

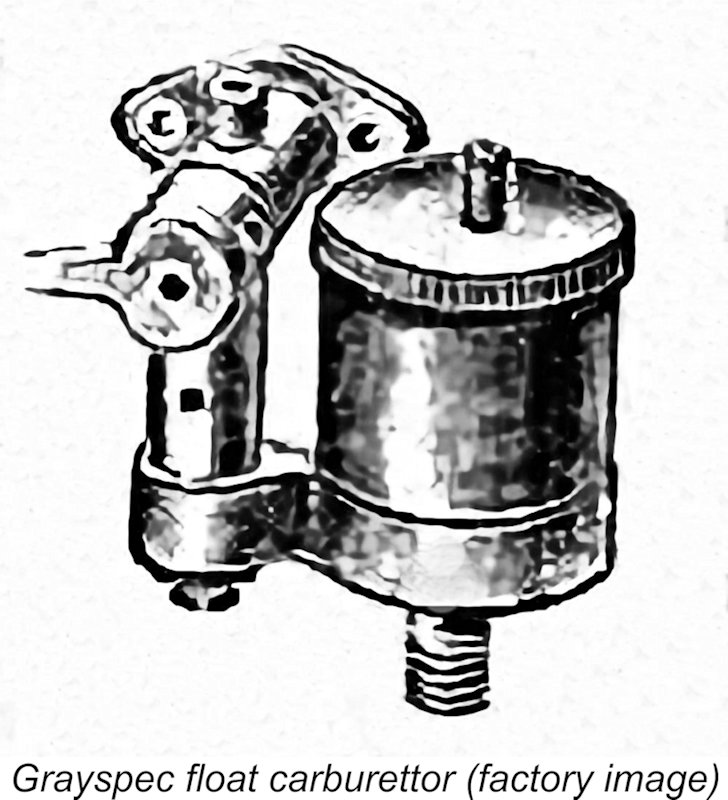

The engine used mechanically-activated overhead valves and a ringed light alloy piston. It relied on oil-bath splash lubrication internally, with manual lubrication being applied to the exposed valve gear. It was equipped with a float chamber carburettor along "full sized" lines.

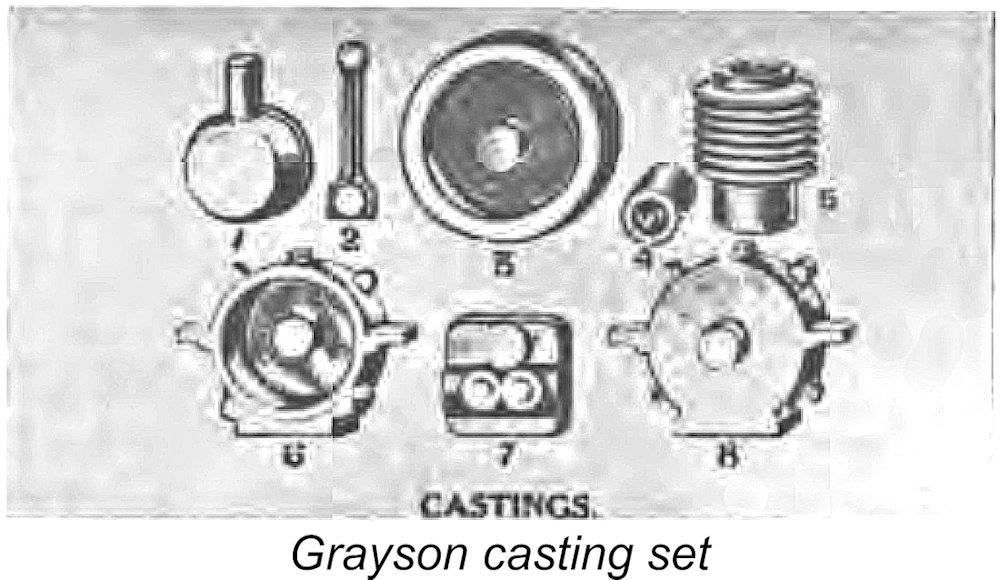

In the “standard” marine version of the engine, the components were produced in the materials described above. A “lightweight” marine version was also available in which components 1, 4, 5, 6 Finally, the “aero” version of the Grayson dispensed with the heavy flywheel, also featuring elektron castings throughout with the exception of the forged aluminium alloy conrod. In the absence of the very heavy flywheel, this unit must have weighed considerably less than the “standard” marine model, but I don’t have any actual figures. The complete kit of castings and materials which was available to would-be constructors of these engines included the illustrated castings, blueprints, piston rings, finished timing gears, all necessary nuts and bolts and sufficient materials to complete all other components.

Marcus advised that this engine came to him from a former member of the South London club located in Brockwell Park, which was primarily a tethered hydroplane club. Both Grayson engine designer F. N. Sharp and the legendary E. T. Westbury were members of this club. Marcus himself was the club's last secretary, serving in that capacity until the club was dissolved following the loss of use of the Brockwell Park ponds in the mid-1970's due to noise complaints. Examples of the Grayson engines appear to be very rare these days – I’ve never seen one myself in the metal. I have no way of knowing how many examples were either manufactured by E. Gray & Son or built by home constructors. However, the engine was apparently used quite widely in various categories of power boat modelling. Given the company’s toolmaker background, I would expect the examples made by Gray & Son to be of quite high quality, while that of the homebuilt examples would doubtless vary somewhat depending on the skill of the constructor. The Grayspec 15 cc Engine

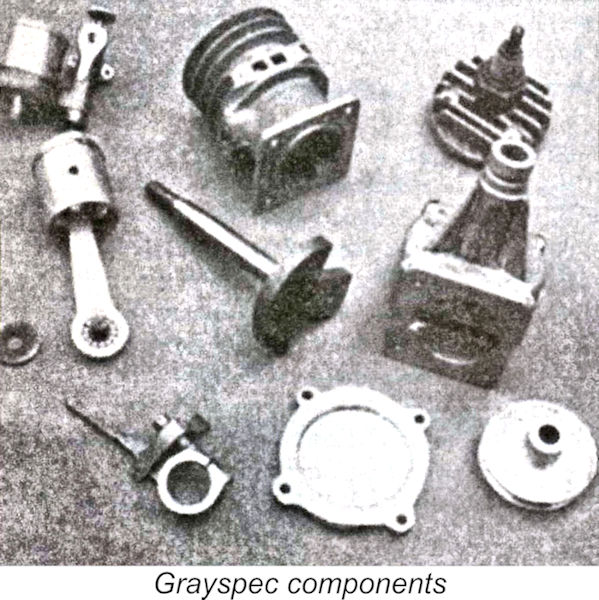

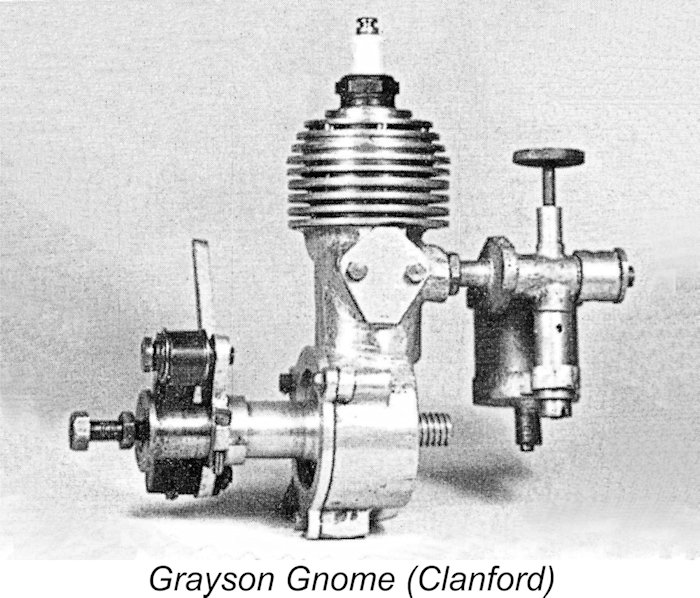

The Grayspec was basically a standard plain-bearing two-stroke sideport spark ignition engine of a type that was to become very familiar. With a bore of 1.0625 in. (26.99 mm) and a stroke of 1.00 in. (25.40 mm), it was a short-stroke engine having an actual displacement of 14.53 cc (0.887 cuin.). It weighed in at a not unreasonable 16 ounces minus the ignition support system (typically around 4 ounces at the time in question).

At some point, the material of the castings was switched from elektron to aluminium alloy. Reportedly, examples built around aluminium alloy castings as opposed to elektron are somewhat more commonly encountered today. This suggests that the change to aluminium castings was made fairly early on. The Grayspec presented several quite unusual features. For one thing, its conrod had a roller bearing big end which engaged with a screw-in crankpin. This is clearly seen in the accompanying component view. A similar feature (without the screw-in crankpin!) was to be found on the far later Dooling 61 models, but its use in the 1933 Grayspec is by far the earliest case of this feature being applied to a model engine that I’ve ever encountered. The engine could also be supplied with bronze bushings if preferred.

An example of this variation is to be seen in the superb example of the Grayspec which is featured on the previously-cited Miniature Engineering Museum (MEM) website. The example of the Grayspec which appears on that site is clearly a home-built example made by some unknown but highly competent constructor. It is built up from aluminium alloy castings as opposed to the elektron used originally. Note that the builder has chosen to use a conventional model engine spraybar carburettor rather than go with the original Grayson float-chamber design. The builder has also added a neat bolt-on exhaust stack. A final oddity was the design of the open-framed timer. This incorporated a tiny spring-loaded bell-crank, one end of which carried the moving point. The other arm of the bell-crank bore upon the rear face of the prop driver, which was machined to form a cam.

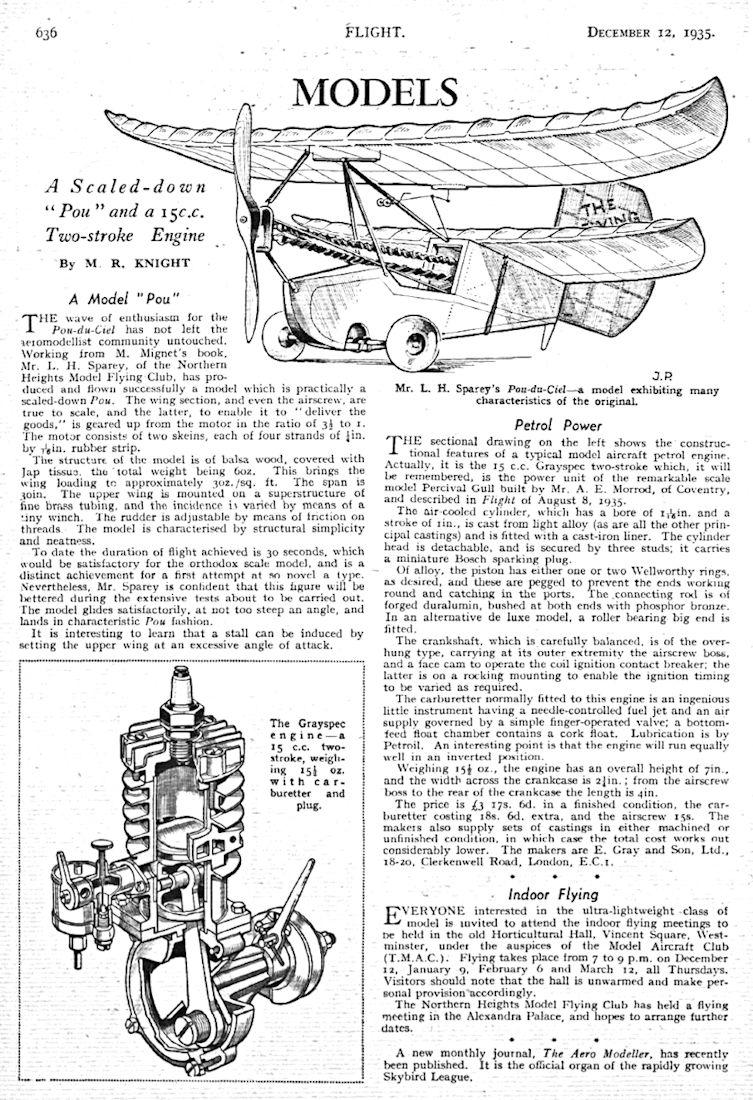

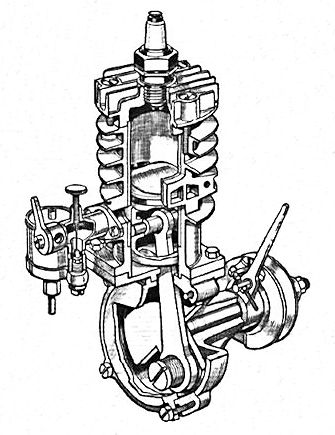

The review of the Grayspec was included in the "Models" feature of the magazine. It included a quite detailed description of the engine, including a most instructive cut-away view of the engine as reproduced here below at the left. Apparently the engine was supplied with a Bosch spark-plug, one of the few model-sized options at the time. Unfortunately, no operating data were provided.

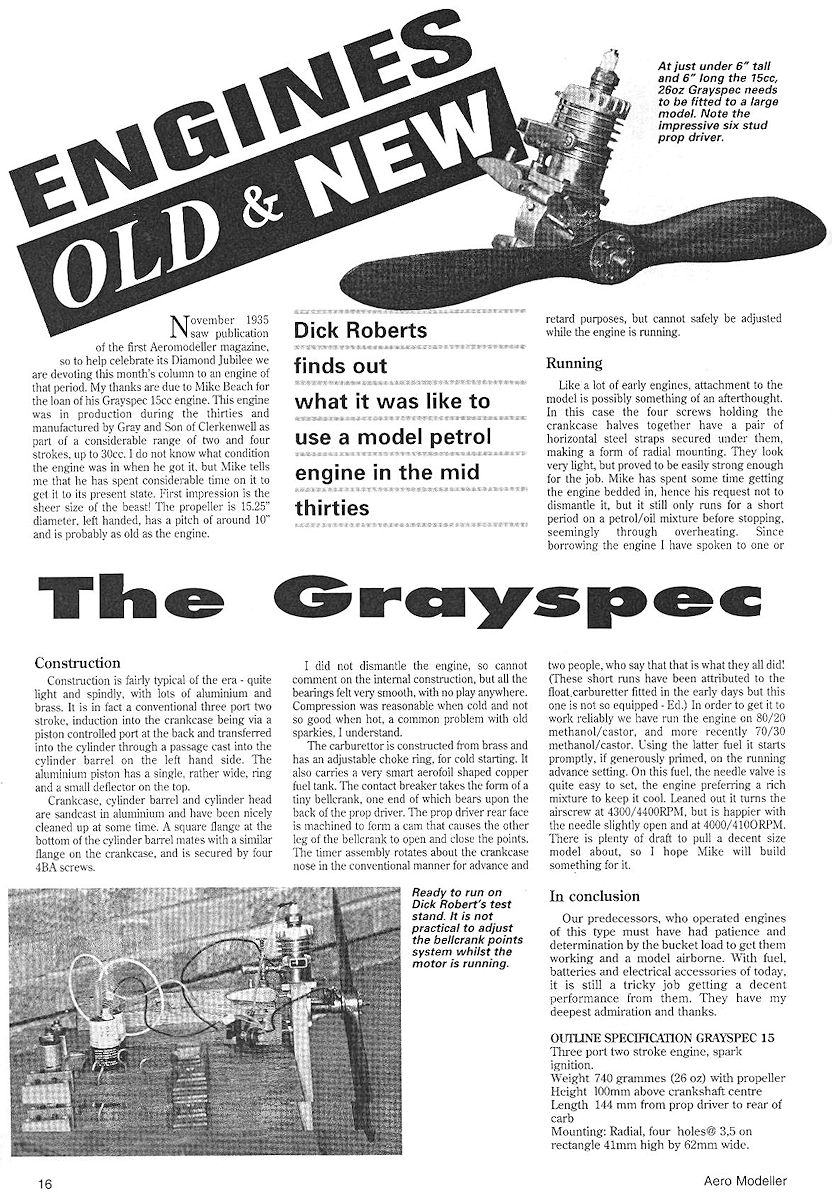

In addition to the above contemporary commentaries, a retrospective test of the engine appeared in the November 1995 issue of "Aeromodeller". This test was conducted by Dick Roberts using an example of the Grayspec which had been fully restored by Mike Beach and loaned to Dick for the test. Dick didn't know the state in which the engine came into Mike's hands - he only knew that Mike had spent "considerable time" getting it into the tested condition. All bearings were said to be very well fitted, while the compression provided by the single rather wide ring was "reasonable" when cold but less so when hot.

Dick found the engine to be a prompt starter if generously primed. However, using a standard petrol/oil mix typical of that used back in the 1930's, the engine would only run for "a short period" before stopping, seemingly due to overheating. Based upon the recollections of others who have tried the Grayspec, this was a typical problem with this engine. Dick had far more success using a fuel consisting of 70% methanol and 30% castor oil. As most sparkie aficionados know, such engines run far cooler on methanol than they do on petrol. Using this fuel mix, the engine started promptly following a generous exhaust prime and would keep running, although it still preferred a slightly rich mixture to keep temperatures under control. Dick found that when fully leaned out the Grayspec turned the matching airscrew at 4,300/4,400 RPM, although it was happier running slightly rich at 4,000/4,100 RPM. Apparently it was moving plenty of air, being well able to power a sizeable model in Dick's opinion. Dick concluded this test by expressing his "deepest admiration and thanks" to the pioneering power modellers who managed to get good results using engines such as the Grayspec, thereby laying the groundwork for our hobby. He commented that those modellers who used such engines successfully must have posessed "patience and determination by the bucket-load"! The successful overcoming of the associated challenges must have given those pioneers immense satisfaction - something which today's bought-in-a-box push-button model fliers will never experience. Once again, I have no idea how many examples of the Grayspec ended up being built in total. All I can say is that the engine is mega-rare today – I’ve never so much as seen one myself! The Grayson Gnome 3.5 cc Model

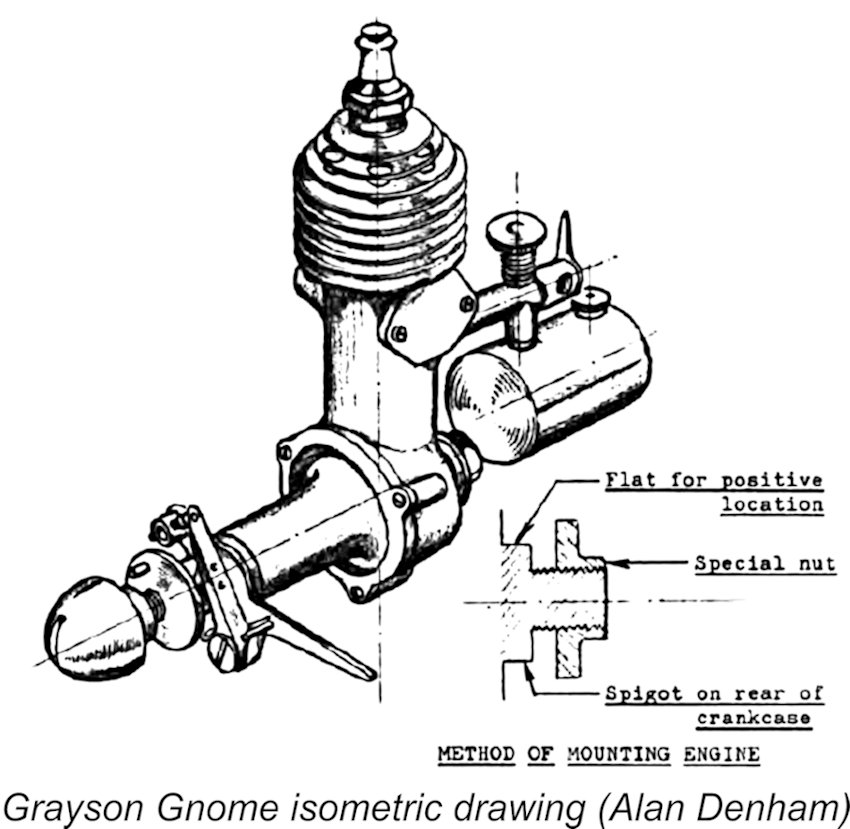

From these commentaries we learn that the Gnome had nominal bore and stroke figures of 5/8 in. (15.875 mm) and 3/4 in. (19.05 mm) for an actual calculated nominal displacement of 3.77 cc. The engine's weight was reported as 5¼ ounces with electron castings and 8 ounces in aluminium alloy castings. The only performance indication was the suggestion that props in the 8 in. to 9 in. dia. range appeared to be a good match.

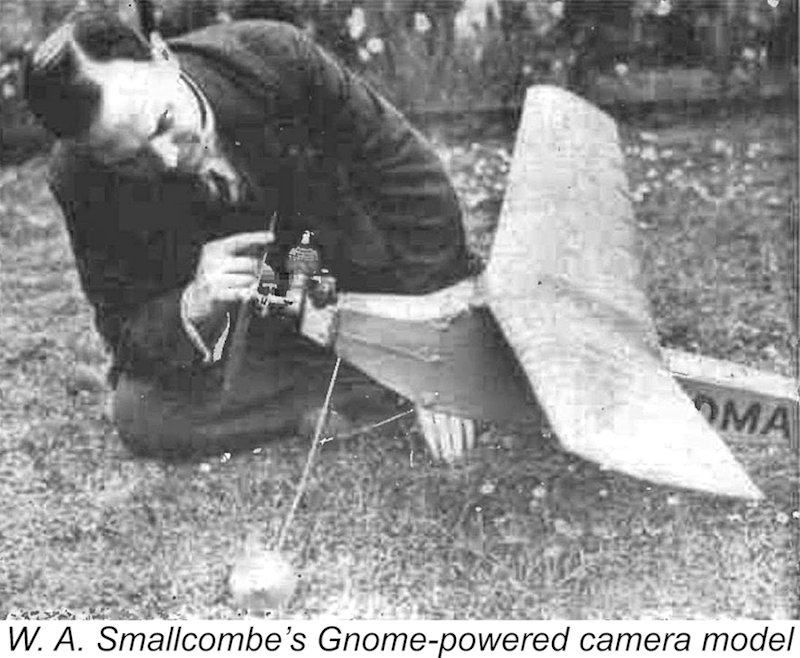

The most noteworthy feature of the Gnome was its method of mounting. The crankcase had no mounting lugs at all, either beam or radial. Instead, the engine featured a large integrally-cast externally-threaded spigot protruding from the centre of the integrally-cast backplate. A flat cut into the top of the unthreaded full-diameter portion of this spigot provided a reference plane for The Gnome must have been quite a sturdy performer. The "Model Aero Topics" feature in the January 1939 issue of "Newnes Practical Mechanics" included a description of a Gnome-powered model built by W. A. Smallcombe of Reading which was capable of carrying a small camera aloft to take aerial photographs. This model had a wingspan of just under 6 feet and weighed 50 ounces in flying trim with the camera on board. Reportedly, a ten-inch diameter airscrew was used. Quite a load for a 3.8 cc sparkie! That’s about all that I can tell you about this extremely elusive pioneering model engine from pre-WW2 England! If any reader knows more, let’s hear from you!! Conclusion Following the original publication of this article in December 2025, I was very pleased to hear from my good Aussie mate Maris Dislers, who was able to provide a fascinating post-script to the Grayson story. It appears that the Grayson engines didn't die in 1939, instead emigrating by making the trip down to Australia to re-appear there following the conclusion of WW2. One of the more prominent model shops in Australia was The Model Dockyard of Melbourne. Owned by a Mr. Ducket, this iconic store supplied a wide range of model goods, including plan/casting sets for a number of model aero engines. The company's 1950 catalogue listed "The "GRAYSON" Pattern O.H.V. 25 cc (four cycle) Engine" castings and plan set for £1 10s (£1.50). Also listed was "The "GRAYSPEC" Pattern Engine" castings and plan set, again at £1 10s (£1.50). A complete Grayspec engine with coil, plug and carburetor could be had for £12 10s (£12.50) - an extremely high price by the standards of the day. This engine was claimed to produce ¼ BHP at 4,600 RPM. A finished Grayson float-feed carburetor was available at a cost of £2 5s (£2.25), while a casting/plan set for this carb cost 4s 6d (£0.23).

It's clear that these offerings were aimed primarily at the model engineering community, since the highly retrospective designs were unlikely to appeal to the aeromodelling crowd as of 1950. It would be interesting to know if the Model Dockyard was offering its own made-in-Australia casting sets or had somehow acquired the residue of the original Grayson manufacturing venture of the 1930's. The use of the term "pattern" implies the former possibility, but it would be nice to know for sure. The rarity of the engines produced by E. Gray & Son is such that few of us will ever so much as see one, let alone own one! Still, that’s no reason to let this pioneering model engine marque sink into the quicksands of history to be lost forever. The odd example undoubtedly does still exist, and it’s only fitting that there should be some accessible record of the company which made them. Hope you agree!! __________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published December 2025 |

| |

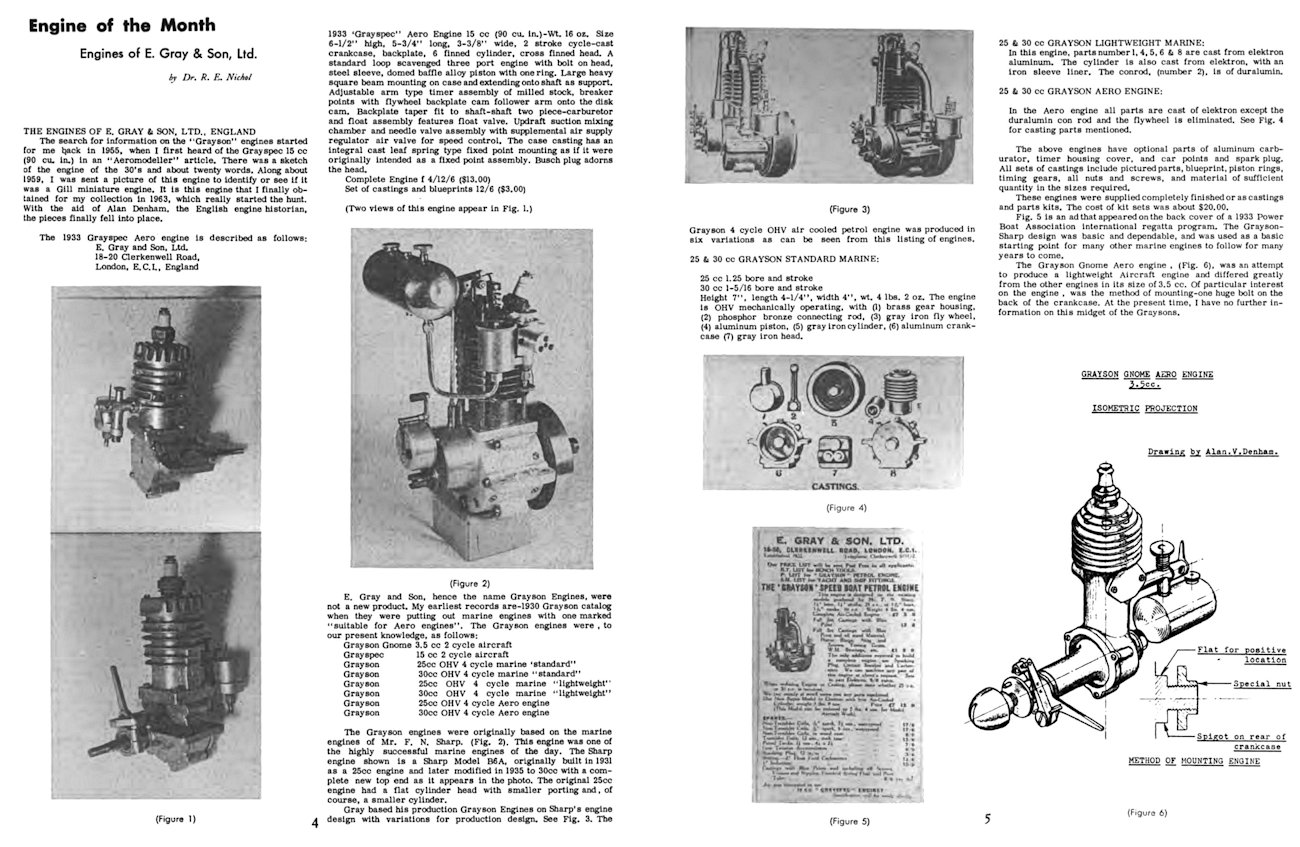

According to Dr. Nichol, the company began advertising its model engine casting sets in 1930-31, at which time they were characterizing their 30 cc offering as the “Grayson speed boat engine”. This implied that the engine’s primary anticipated use was powering tethered hydroplanes in the 30 cc class, then the Blue Riband category in that genre, in which four-stroke engines and flash steam powerplants predominated. The "standard" castings were formed of aluminium alloy, but a set of lightweight castings was also offered in elektron alloy (a very lightweight magnesium alloy), creating a variant said to be “suitable for model aircraft”. Clearly, they built model airplanes BIG in those days!

According to Dr. Nichol, the company began advertising its model engine casting sets in 1930-31, at which time they were characterizing their 30 cc offering as the “Grayson speed boat engine”. This implied that the engine’s primary anticipated use was powering tethered hydroplanes in the 30 cc class, then the Blue Riband category in that genre, in which four-stroke engines and flash steam powerplants predominated. The "standard" castings were formed of aluminium alloy, but a set of lightweight castings was also offered in elektron alloy (a very lightweight magnesium alloy), creating a variant said to be “suitable for model aircraft”. Clearly, they built model airplanes BIG in those days!

While Gray & Son were getting their Sharp-based Grayson four-stroke model into production, an individual named Lionel French was working on the development of a lightweight 15 cc two-stroke model powerplant designed primarily for aero applications. Gray & Son reached a manufacturing agreement with French, presumably similar to that which they had negotiated with Sharp.

While Gray & Son were getting their Sharp-based Grayson four-stroke model into production, an individual named Lionel French was working on the development of a lightweight 15 cc two-stroke model powerplant designed primarily for aero applications. Gray & Son reached a manufacturing agreement with French, presumably similar to that which they had negotiated with Sharp.  first lightweight two-stroke model aero engine to be offered commercially by

first lightweight two-stroke model aero engine to be offered commercially by

The final advertisement for the Grayson model engine range appeared in NPM in July 1939 (left). Thereafter the company returned to a focus upon its toolmaking roots, with the flagship product being an upgraded Grayson 3½ in. screw-cutting lathe along with a wide range of model engineering tools and accessories. They were presumably involved in war-related production of some kind, but I have no information regarding that side of their activities.

The final advertisement for the Grayson model engine range appeared in NPM in July 1939 (left). Thereafter the company returned to a focus upon its toolmaking roots, with the flagship product being an upgraded Grayson 3½ in. screw-cutting lathe along with a wide range of model engineering tools and accessories. They were presumably involved in war-related production of some kind, but I have no information regarding that side of their activities.

It’s amazing how many present-day modellers believe that the four-stroke model engine was a development of the 1970’s and beyond! In reality, the use of four-stroke model engines to power both model boats and model aircraft goes way back into the first decade of the 20

It’s amazing how many present-day modellers believe that the four-stroke model engine was a development of the 1970’s and beyond! In reality, the use of four-stroke model engines to power both model boats and model aircraft goes way back into the first decade of the 20

This engine was doubtless introduced in mid-1933 in response to the obvious need for lighter powerplants for use in aeromodelling applications. Although it was offered in an air-cooled marine version with flywheel, it would appear that its primary envisioned use was in power aeromodelling. As far as I'm presently aware, it was the first-ever lightweight model aero engine to enter series production in Britain.

This engine was doubtless introduced in mid-1933 in response to the obvious need for lighter powerplants for use in aeromodelling applications. Although it was offered in an air-cooled marine version with flywheel, it would appear that its primary envisioned use was in power aeromodelling. As far as I'm presently aware, it was the first-ever lightweight model aero engine to enter series production in Britain.  Initially, all light alloy castings were formed in elektron alloy, underscoring the evident expectation that the engine would be used primarily in aero service, hence encouraging minimum weight. The conrod was a drop forging in aluminium alloy. The elektron cylinder jacket enclosed a cast iron liner. The domed light alloy piston was fitted with either a single ring or a pair of rings at the purchaser's discretion. The rings were supplied by the well-known Wellworthy firm of Lymington, Hampshire. The counterbalanced crankshaft ran in a bronze bushing.

Initially, all light alloy castings were formed in elektron alloy, underscoring the evident expectation that the engine would be used primarily in aero service, hence encouraging minimum weight. The conrod was a drop forging in aluminium alloy. The elektron cylinder jacket enclosed a cast iron liner. The domed light alloy piston was fitted with either a single ring or a pair of rings at the purchaser's discretion. The rings were supplied by the well-known Wellworthy firm of Lymington, Hampshire. The counterbalanced crankshaft ran in a bronze bushing.

The Grayspec is undoubtedly the best-documented of the Gray & Son engines, attracting a certain amount of media attention during its introductory period. It was described in very general terms in a brief article which appeared in the March 1934 issue of NPM. However, a far more useful reference is the review reproduced at the right which appeared in the December 12

The Grayspec is undoubtedly the best-documented of the Gray & Son engines, attracting a certain amount of media attention during its introductory period. It was described in very general terms in a brief article which appeared in the March 1934 issue of NPM. However, a far more useful reference is the review reproduced at the right which appeared in the December 12

As stated earlier, this engine appears to have represented E. Gray & Son’s final attempt to crack the mid-1930’s model aero engine market before they returned to their toolmaking roots. Almost no information on this model has ever been published – all that I've been able to find is a couple of commentaries on the engine which appeared in the

As stated earlier, this engine appears to have represented E. Gray & Son’s final attempt to crack the mid-1930’s model aero engine market before they returned to their toolmaking roots. Almost no information on this model has ever been published – all that I've been able to find is a couple of commentaries on the engine which appeared in the

stability, and the threaded reduced-diameter portion of the spigot protruded rearwards through the front bulkhead of the aircraft. A large T-nut threaded onto the spigot from behind to clamp the engine tightly against the bulkhead. A somewhat convoluted and inconvenient mounting system, it must be said! Hopefully the accompanying drawing by Alan Denham will make this arrangement clear.

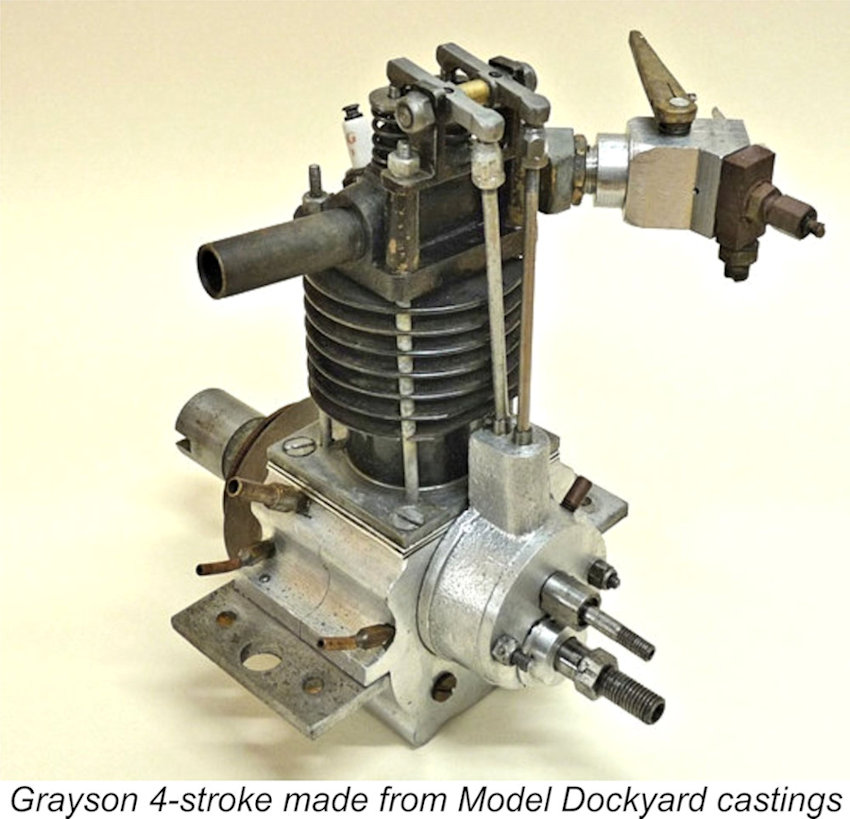

stability, and the threaded reduced-diameter portion of the spigot protruded rearwards through the front bulkhead of the aircraft. A large T-nut threaded onto the spigot from behind to clamp the engine tightly against the bulkhead. A somewhat convoluted and inconvenient mounting system, it must be said! Hopefully the accompanying drawing by Alan Denham will make this arrangement clear.  Maris was able to supply the accompanying image of an example of the Grayson 25 cc four-stroke model which was constructed by an Australian modeller using the Model Dockyard castings. Maris recalled that the builder of this example used it in a tethered hydroplane, doing so by wading out into the Patawalonga river (near the beachside community of Glenelg in Adelaide), hammering a stake into the riverbed, attaching his tether line and running the boat! The inventive approaches which modellers develop to the pursuit of their hobbies..............

Maris was able to supply the accompanying image of an example of the Grayson 25 cc four-stroke model which was constructed by an Australian modeller using the Model Dockyard castings. Maris recalled that the builder of this example used it in a tethered hydroplane, doing so by wading out into the Patawalonga river (near the beachside community of Glenelg in Adelaide), hammering a stake into the riverbed, attaching his tether line and running the boat! The inventive approaches which modellers develop to the pursuit of their hobbies..............