|

|

Gordon Burford’s Schnuerle Engine Developments by Maris Dislers

Introduction Many consider the classic model engine era to have ended when Schnuerle-ported designs came onto the market. For better or worse, they developed significantly more power than earlier types, further squeezing out producers who stuck to their traditional designs. This article covers the period during which Australia's pre-eminent model engine manufacturer Gordon Burford was, by urgent necessity, learning the ropes about Schnuerle-ported engines.

This exposé was made possible when Tahn Stowe recently unearthed several Burford engines and castings from the collection of his late father Ivor F and made them available for us to study, thus providing vital pieces of the puzzle. David Burke of Adelaide Aeromotive Pty. Ltd. (the current bearers of the Taipan standard) has also contributed enormously to this exercise. Now, to begin with, let’s set the scene. The key was combining Daniel Zimmerman’s rotary intake valve (for precisely controlled induction) with Schnuerle plus boost cylinder porting (for efficient scavenging at high RPM) and Kaaden’s tuned exhaust, which gave a supercharging power boost without the drag or complexity of mechanical alternatives. The Japanese Suzuki company really wanted to succeed in international motorcycle racing. They enticed Ernst Degner (MZ’s star rider) to defect, bringing with him much of Kaaden’s technology. You can read all about it in the very entertaining book “Stealing Speed” by Mat Oxley, Haynes Publishing, ISBN 978 1 84425 975 5.

Bill backed that up with another first place in the 1966 World Champs at R.A.F Swinderby, England using a further development, namely the application of Walter Kaaden's tuned exhaust pipe technology to the new TWA 15 (Theobold-Wisniewski Association) engine. The Americans again took the top three places Gordon Burford was there on the spot in 1968 and was clearly impressed by the Americans' technology. At the time, he’d more or less revamped the entire Taipan engine range, producing a series of good solid designs along established lines for general-purpose use, along with effective R/C throttles. These included diesels, glows and marine engines ranging from 1.5 cc to 10 cc. Exports to the U.S.A., the U.K, Canada, New Zealand and elsewhere were part of the company's survival strategy in an increasingly competitive market.

Gordon Burford's Schnuerle Development Program Gordon was never averse to absorbing a good idea from others and adapting it to his own engine designs. Typically, a new engine would more or less go straight through to production, building on established design parameters and machining practices using the available equipment. Gordon Burford & Co. was a small business without the resources necessary to undertake extensive research into technologies that might or might not not pay off. However, this time it would be different, requiring the creation of some dedicated experimental engines before a production design could be finalized. At the time in question, only a few people had practical knowledge regarding the size, angles and timing details of Schnuerle ports for high performance, let alone the transfer passage arrangements and internal crankcase volume that also play an important part in overall performance. Gordon could draw upon good in-house engineering skills, but there was also significant engine user input from Ivan Vodopivec, Frank Coombs, Len Buck, Jack Finneran, Jim Lynch, Mal Pring and others, as specific developments required. Designing an engine is one thing - constructing it is quite another. Gordon was never much for “tool room specials”. To him, working out how to make tooling and all the components for quantity production of a new design was just as important as its eventual performance and commercial viability. So after the preliminary design work had been carried out, the construction of a new development engine began with the creation of a crankcase die. Frank Bargwana (Gordon’s brother-in-law and an ace toolmaker) would machine and assemble the die blocks and Gordon would then do the finishing, filing, draft angles etc. Development would then proceed with various internal component alterations until a point was reached at which a new crankcase configuration was required, and so on. There was also some back-tracking when a new idea might be tried on an earlier development engine for expediency. Let's have a look at some of the Schnuerle-ported development models which were produced by Gordon Burford and his colleagues. Type 1 (1968-1970) aka Taipan 15 R-S

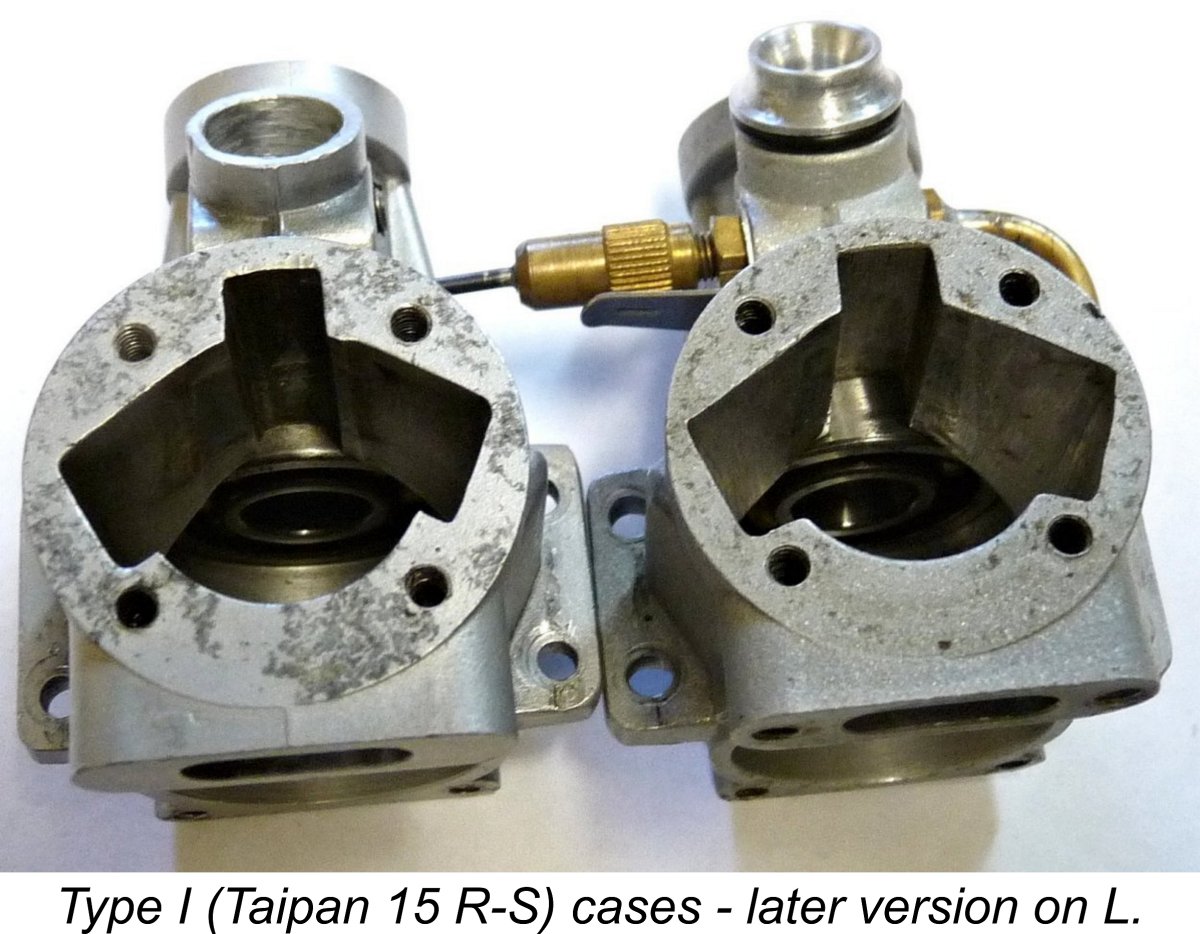

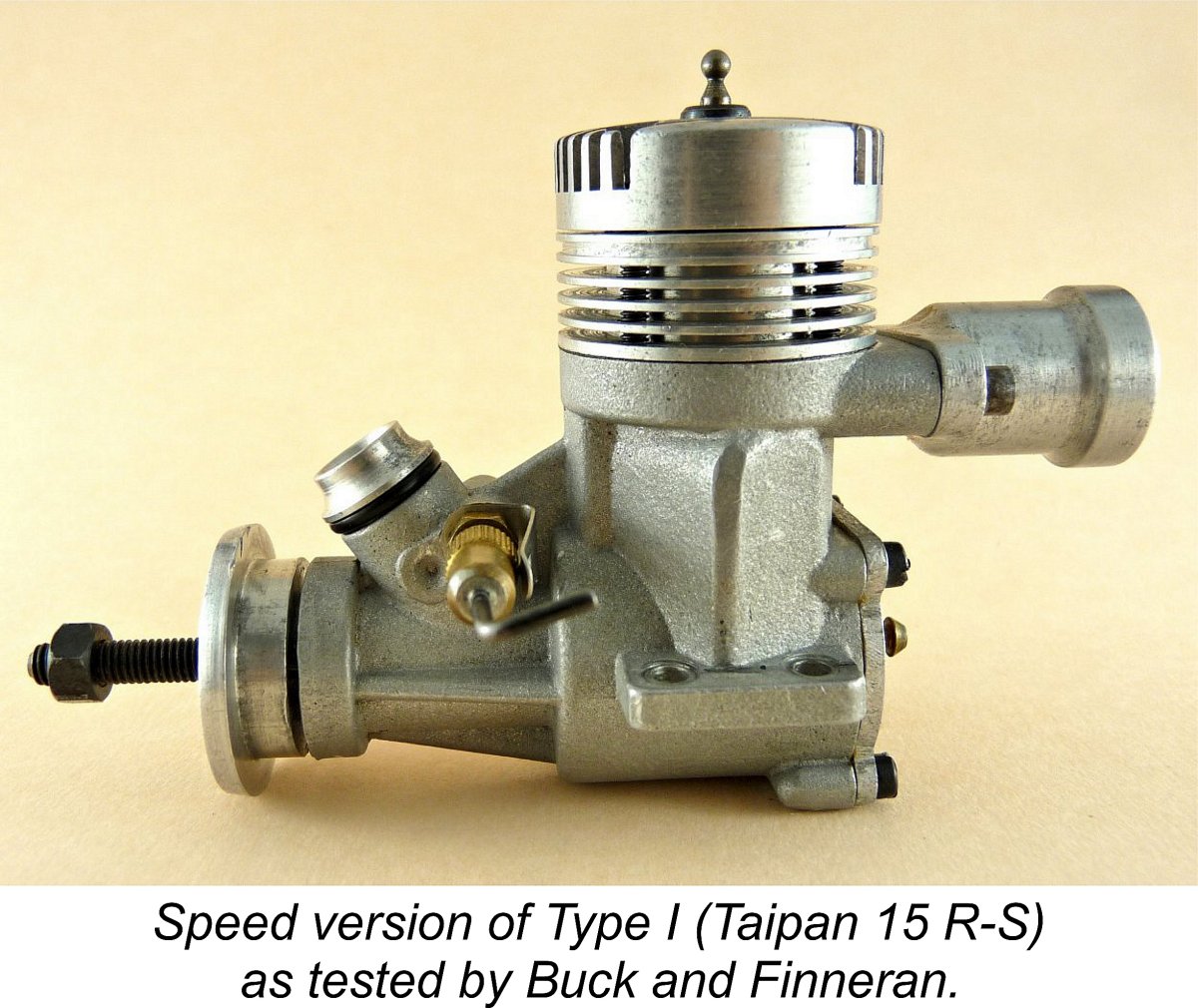

The bypass passages were formed using a simple steel die core, easily retracted from the casting. The attached image of two Type 1 cases shows the subtle but important The very first Type 1 engines reportedly used disc rear rotary valve (RRV) induction, similar to the highly regarded Super Tigre G.15 RV. Nothing more is known of them and none are now known to exist. The die was soon altered to a front induction layout as seen in the image at the right, with the first examples Three examples of a later crankcase variant (new porting core) have a curved entry to the boost passage, leaving more metal at its base (better supporting the rear ball race), together with slightly narrower and shallower transfer passages. These were intended for non-piped F1C use. Allan (Bluey) Coppock planned to fly one of these units in F1C Power at the 1970/71 Australian Nationals, but pulled out due to poor weather. A pity, as eyewitness observers were most impressed with his ground running of this engine. However, the consequent hopes that a production engine was just around the corner proved to be just wishful thinking.

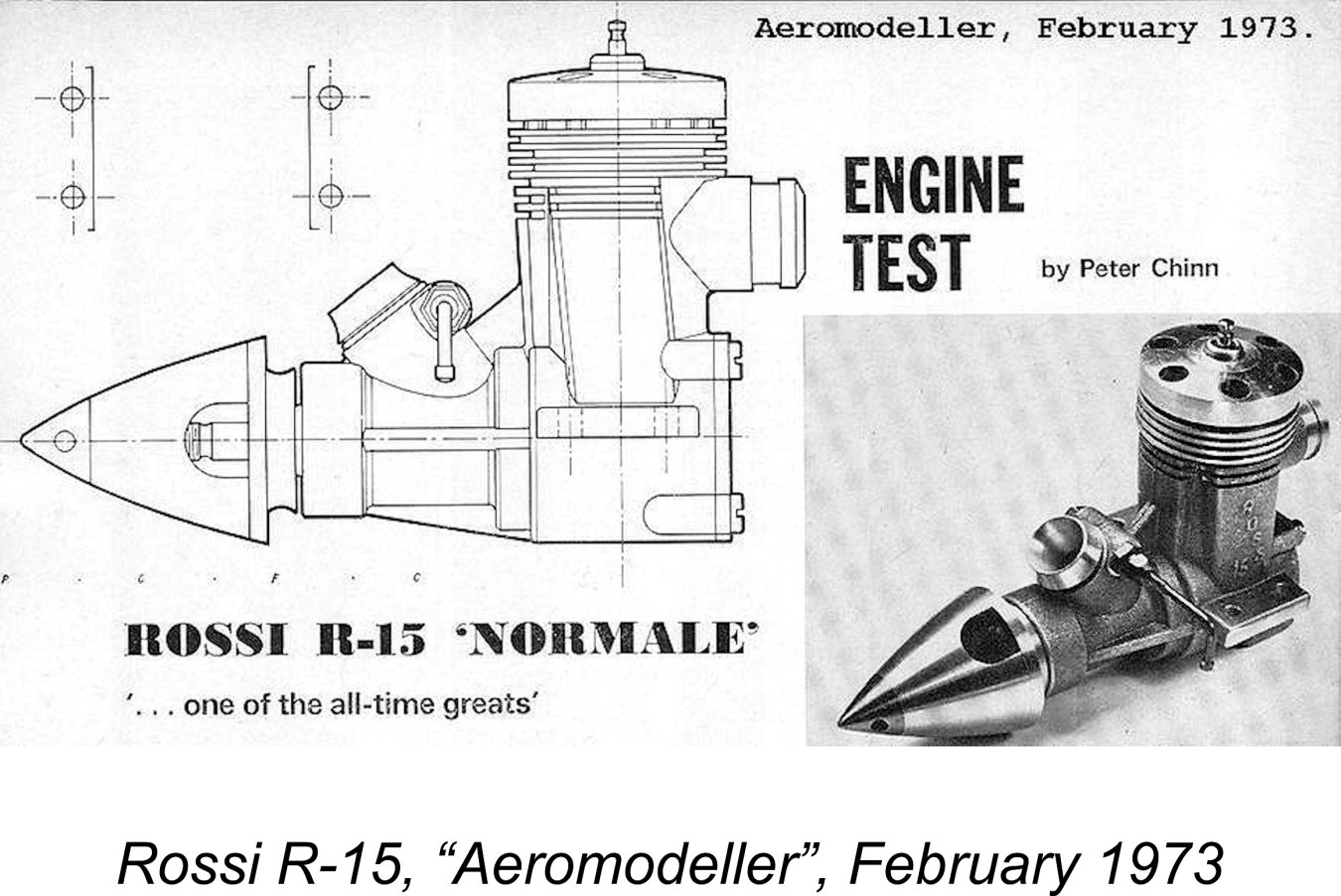

One of Tahn Stowe’s engines is of this type, but we were surprised when he also provided a Taipan 15 R-S diesel engine. Quite enigmatic! It is clearly a recycled later Type 1 crankcase, but with a new diesel cylinder assembly and a different crankshaft. We concluded that it had not been brought to running condition at the time, but was an unfinished design exercise. This engine was possibly being considered as a potential competitor to the Kosmic 15 diesel. It was seemingly left unfinished when the news came through in 1969 that the Rossi R.15 was setting a new higher performance standard. Type 1 development was axed at this point in time. Taipan Series 70 diesel – Experimental (1970-1971) Accurately cutting the more demanding Schnuerle cylinder ports on a production-line basis was a critical difficulty to be overcome. The 15 R-S ports were probably manually cut and boost port angles filed by hand. This approach was of course useless for quantity production. This difficulty was overcome when Peter Burford was finally able to cut those ports using the company's new 3-axis Bridgeport-1 NC milling machine, controlled by a punched paper tape. As Peter says, “It was quite ‘trick’ at the time to link and control the powered rotary table”.

A handful of these experimental Schnuerle diesels went out for field evaluation by regular modellers. Peter Chinn later reported on this development in the March 1972 issue of "AeroModeller". Our recent test results of a rebuilt example showed a slight power increase over the standard model, but excessive vibration prevented it from reaching higher RPM where the porting might have really delivered the goods. A major redesign was deemed uneconomic, leading Gordon to retain the original porting on production engines. However, several improvements were incorporated into later Series 70 2.5 D’s thanks to these field tests, so it was by no means a wasted effort. Type 2 (1969 – 1971)

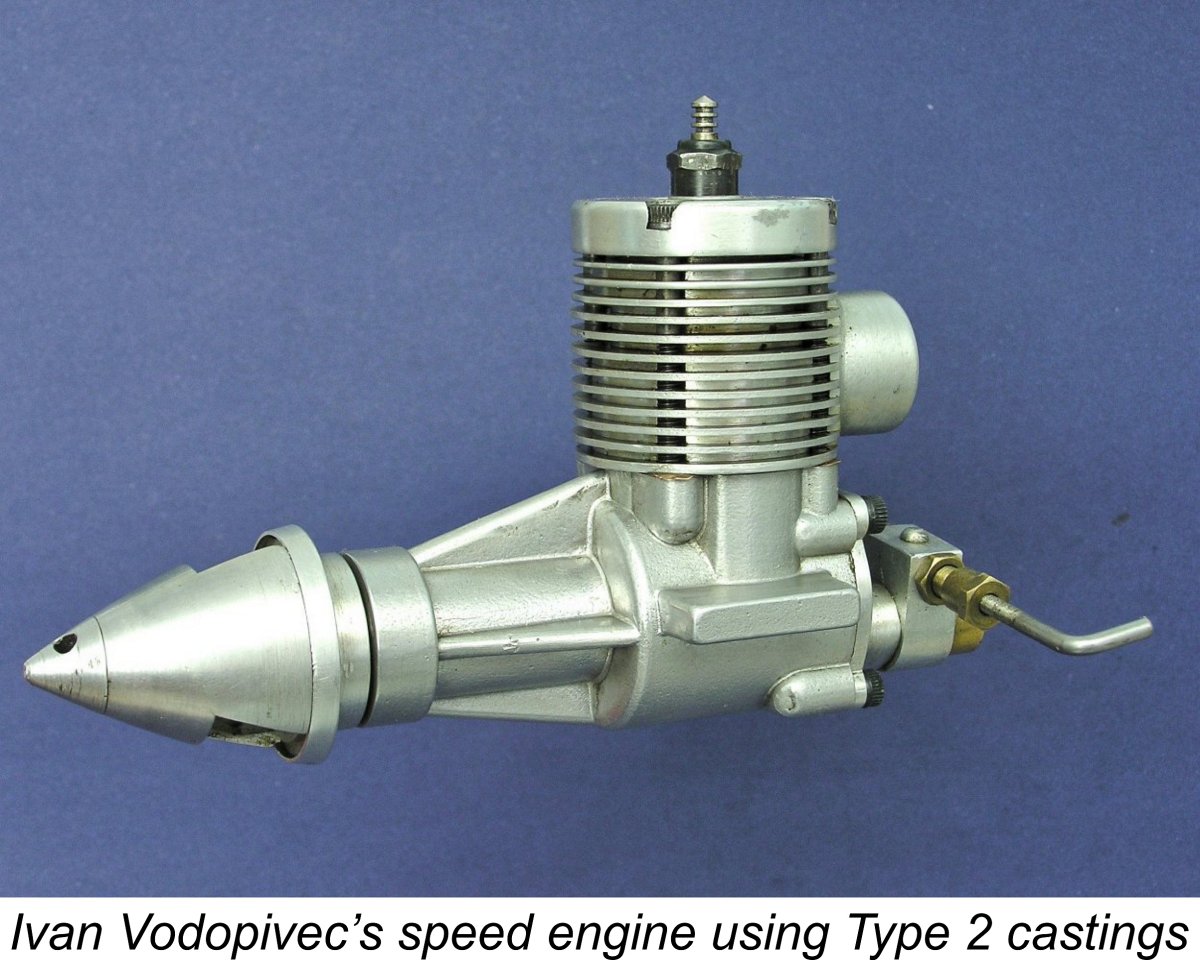

The Type 2 design was influenced by that of Natelenko’s “Start” speed engine, although Gordon’s crankcase was split below the exhaust outlet rather than through the centre. This enabled the easy casting of transfer passages having better shapes (top and bottom sections) into the upper cylinder and main crankcase components. The original Type 2 upper crankcase/cylinder casting had no cooling fins,requiring that those fins be machined after casting. Rear induction was provided using a reverse drum arrangement as per the “Start”.

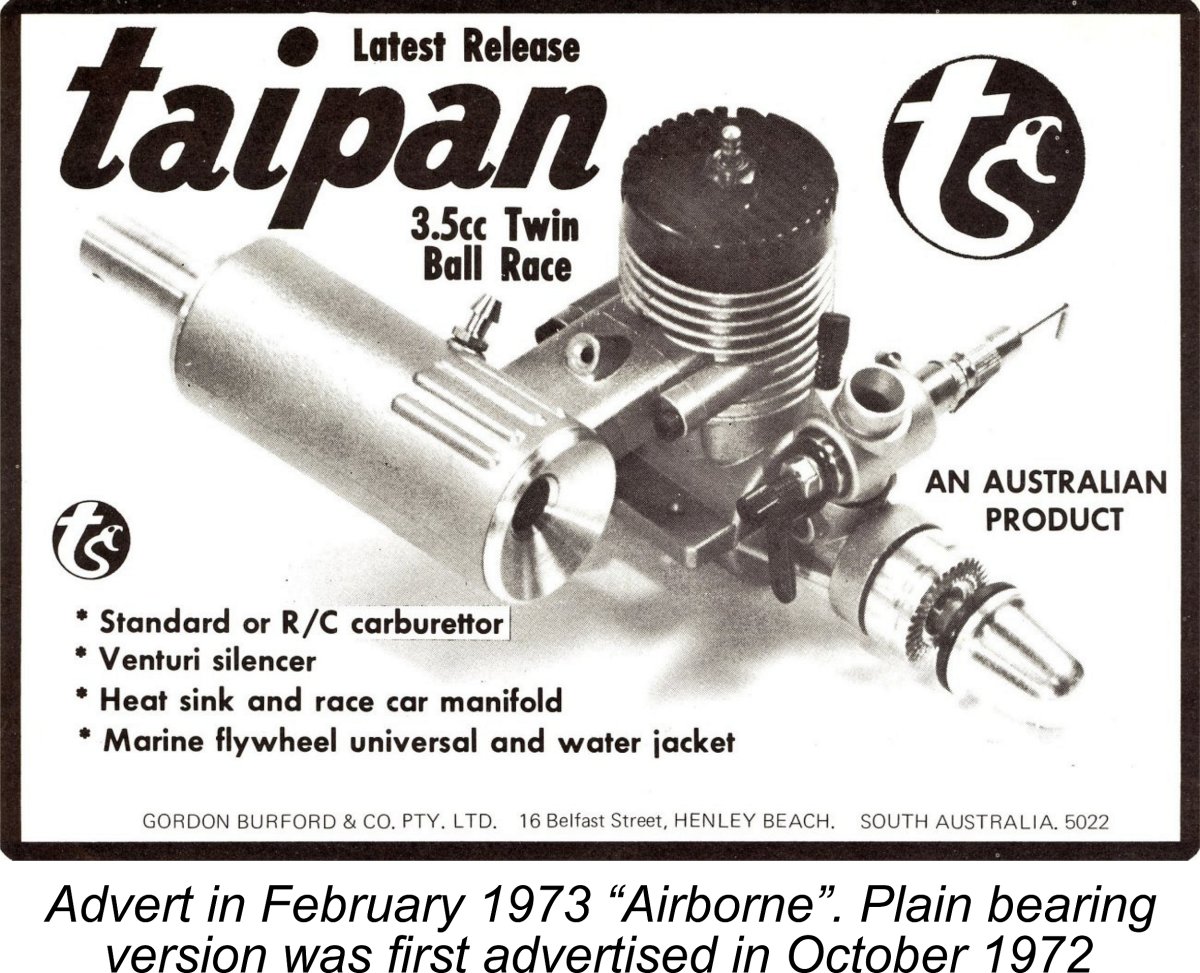

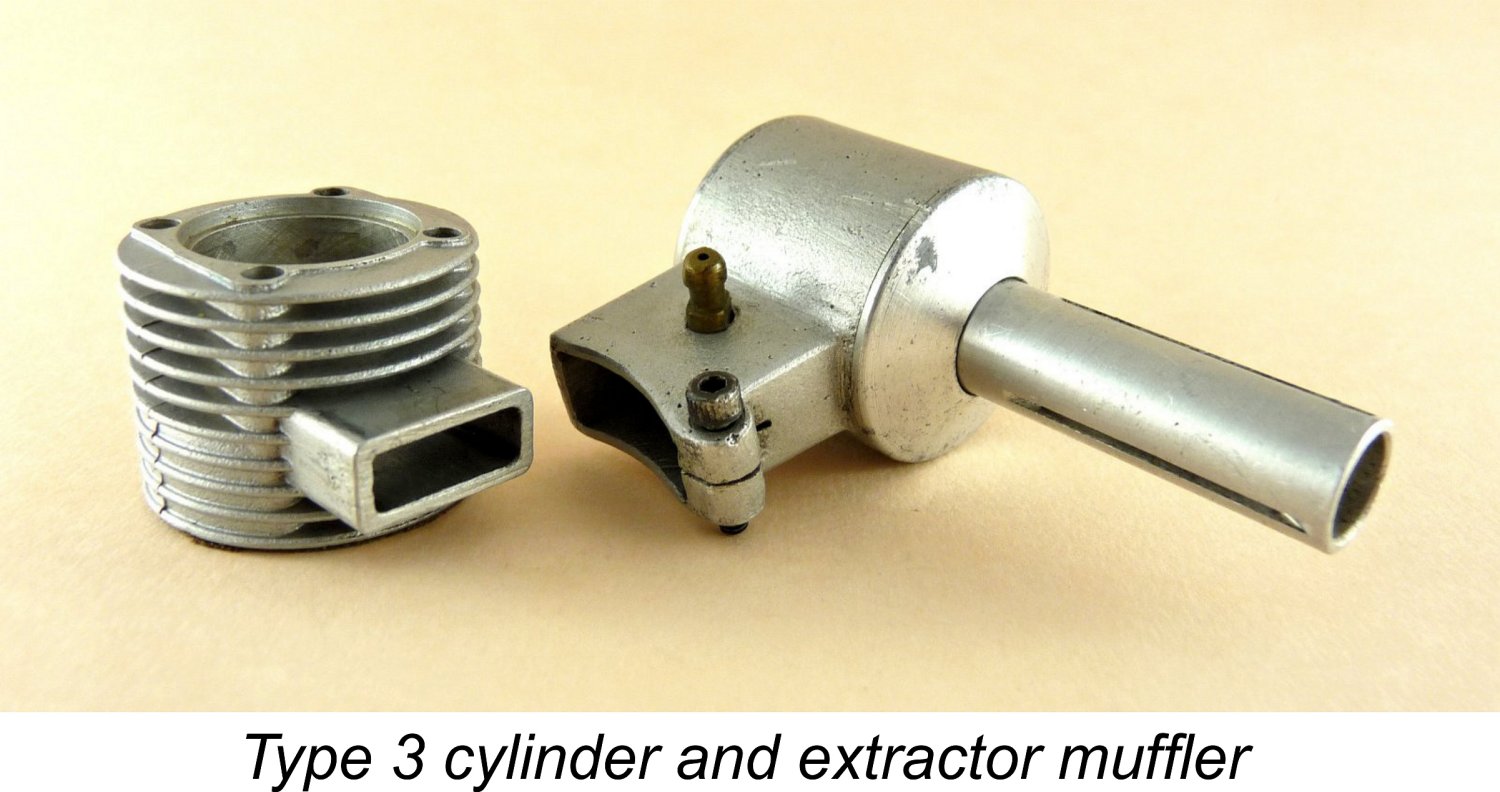

Cylinder porting was a continuation of the Komet style, including the shortened transfer port core from the Type 1 engine. The engine incorporated fully-machined cylinder ports once that technology was mastered. Clearly, a great deal of development work with Type 2’s was prompted by the shock 1969 advent of the Rossi R.15 Mk. 1. There had already been rumours of pre-production Rossi's excelling in model boat competition and F1C power model trials. Gordon got his hands on a production Mk. 1 Rossi R.15 late in 1969. Type 1 engine development was dropped immediately once the Rossi’s performance potential was assessed. Much of the previous Another big step forward was the provision of cast-in cooling fins to reduce the manufacturing costs of a future production engine. This was difficult to achieve using the gravity die-casting method, and it took Gordon some time to develop. The solution was found by making a composite die from a stack of segments. Cleverly, by careful adjustment, a tiny gap between adjoining segments would allow air to escape so that the molten aluminium reliably filled the finned profile. Initially, the exhaust outlet was small and rectangular, around the same size as the cylinder exhaust port. The lack of complete surviving Type 2 engines reflects the very rapid pace of progress, which resulted in no more than a few necessary components being made before the design progressed further. The “top secret” nature of this work also contributed. We have a few diesel cylinders, heads and finned upper crankcase portions for rear exhaust orientation. These might possibly have been paired with an alternative drum induction design inspired by that used on Stockton & Jehlik’s much modified Eta 15 Elite diesel used in their winning Team Racer at the 1968 World Championships and later adopted in the K&B 15 Series 72 engines. Die alterations created the later Type 2 crankcases with Rossi-style external transfer bulges. The example owned by David Burke has cast-in “T” and “2.5” identifiers, doubtless included to assess how they might look on a future production engine. The castings were cored for side exhaust orientation. The revised upper crankcase portion has a larger and longer exhaust stub. This was probably used to develop the venturi “extractor” style muffler, which slips over the stub and is clamped by a single screw. The knowledge gained went towards production mufflers for the Taipan 61 Mk. 2 engine and then the 3.5 cc unit. Type 3 aka Taipan 15 Pylon Special (1971 – 1972) In the field of R/C model aircraft in the early 1970's, Quarter Midget pylon racing was the latest "hot thing". Beginning in Victoria during 1966 as a class for models powered by readily-available 2.5 cc engines, it was intended to be a simpler and lower cost alternative to FAI pylon Racing. The rules required a muffler and the ability to throttle down sufficiently that the model did not roll forward when idling, probably with the intention of limiting the Class to general-purpose sport engines of that time. The class soon became popular at the Club level and the inevitable quest for a horsepower edge emerged. The class progressed to National Championship status, with the first unofficial Quarter Midget race at the MAAA Nationals being scheduled for the Christmas/New Year period 1972/1973 at Geelong, Victoria.

Importantly, while the Type 1 & 2 crankcase dies were clearly only intended to support in-house development, the Type 3 engine was aimed from the outset at possible commercial production down the road. Critically, the method of feeding molten metal into the crankcase die changed from "static head" to "inertial" gravity casting. This technical change enabled full coring for reduced machining time. Gordon's "Pylon Special" engines wowed them in Quarter Midget at the 1972 Australian National Championships. However, they were ineligible for trophies, since they were not yet production ready, only 50 examples having been made to test the waters. Their demonstration appearance at the Championship meeting was nonetheless a clever marketing exercise which paved the way for speedy acceptance of the eventual production engine.

The head carried over the domed top profile of the stillborn Type 2 racing diesel. Inside there was a trumpet shaped combustion chamber along with quite elaborately cut cylinder ports and piston skirt cutaways much like the The cylinder and piston design from this model was essentially carried over to the production 3.5 cc engines which began to appear in late 1972. This allowed the 3.5’s to move directly to production status, thanks to the development work previously undertaken with the 2.5 cc engines. At some point, the transfer cores were again changed to conform with the provision of revised cylinder porting, now very much like that of the Rossi R.15. This released more power at the cost of lesser fuel economy. The revised Taipan 15 “Pylon Specials” equipped the South Australian competitors for the 1973 National Championship meeting. The following report from the March 1973 issue of "Airborne" magazine reads; “Brian Hammond from S.A. recorded the fastest time for a 2.5 cc racer in Australia, clocked at 3 mins, 16.6 secs, so it looks like Gordon Burford has a world beater in his new 2.5 cc pylon racing motor”. Unfortunately, Brian and the other S.A. boys using the Taipans were once again disqualified from the trophy hunt, as the engines still did not comply with the “readily available to anyone” rule. As noted earlier, only 50 "Pylon Specials" were produced, as the engine was not yet considered ready for quantity production. However, the basic design had proved itself in the field, hence priming future demand. A few had anodized parts of different colours, coinciding with production of the Doonside Mills .75 replica diesels. This was probably a case of taking advantage of an opportunity to assess the colours that production engines might adopt. Attention now focused on quantity production of the 3.5 cc engines, which had progressed rapidly thanks to almost all of the development work having been done on the 2.5 cc experimentals. The 3.5’s were seen as likely commanding a larger market, delaying the introduction of an eventual production 2.5 cc model. Tooling up for that development occupied much of 1973. Taipan 15 Type 4 (1973)

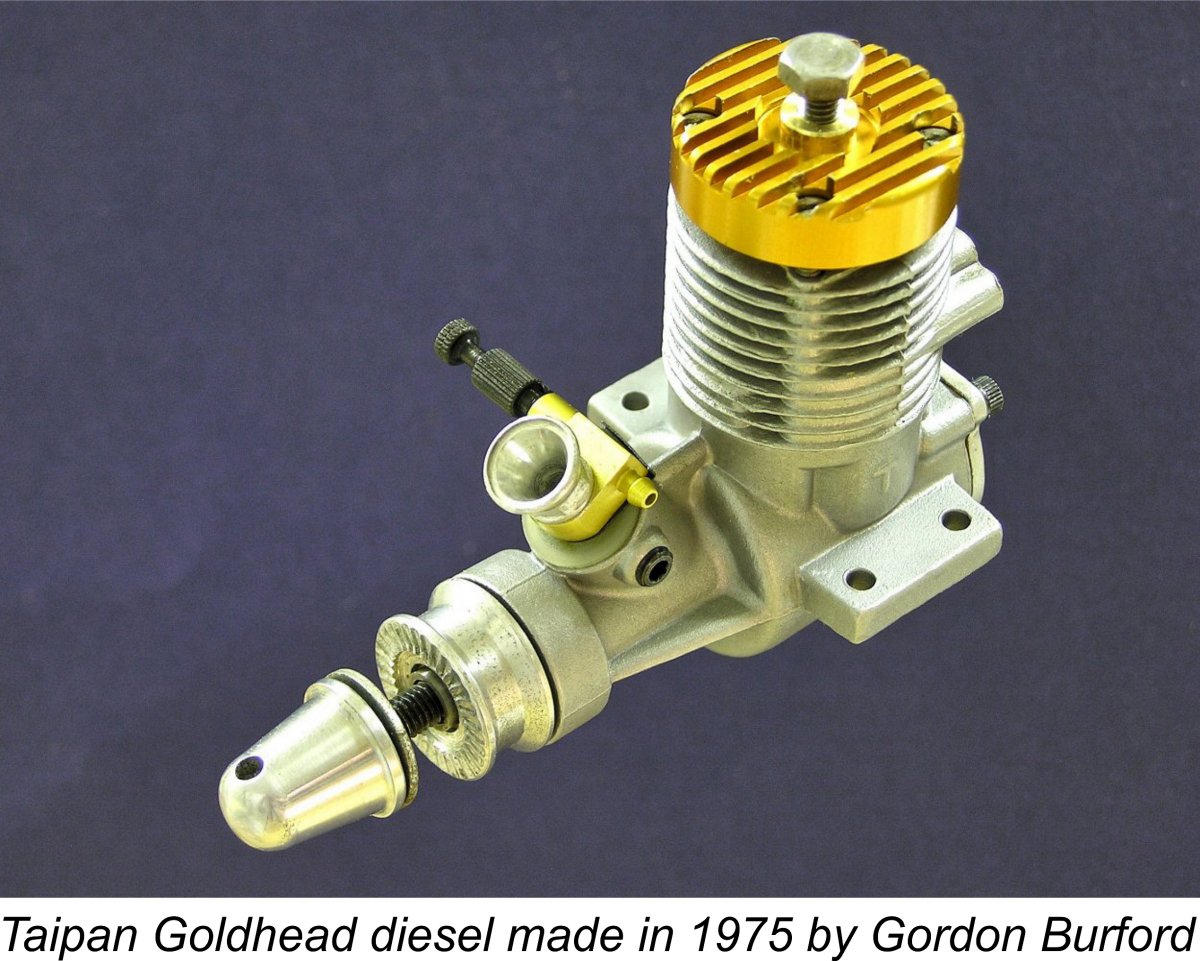

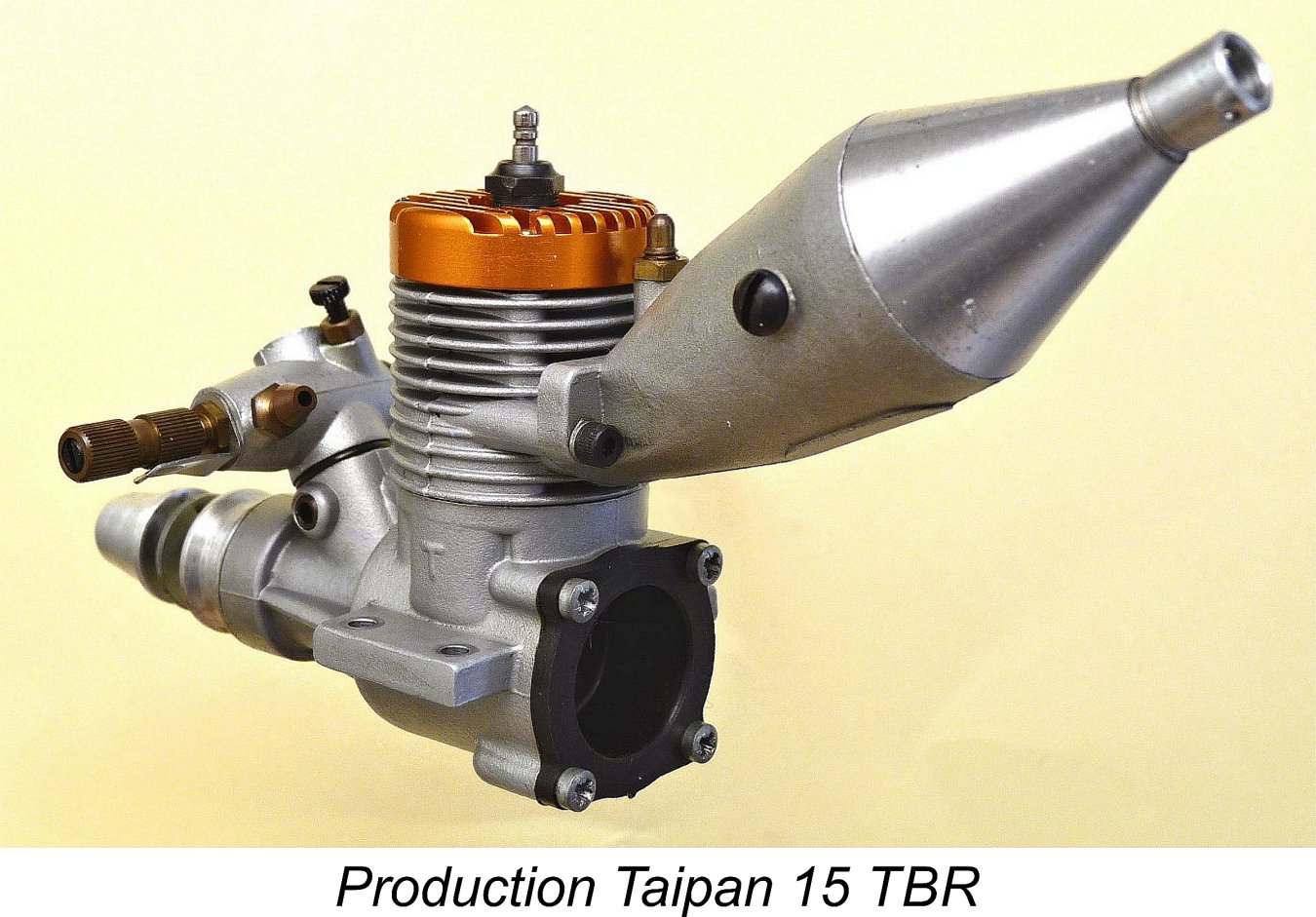

Taipan TBR 15 aka Goldhead (1973 – 1976) Based upon the lessons learned to this point, the Type 3 crankcase die, already revised for rear facing exhaust, now got the generous fillet treatment along with “T” and “2.5” markings. The upper cylinder die was again modified for a shorter exhaust outlet which included two threaded mounting holes for the unique upswept muffler shaped like a short tuned pipe. The length of the muffler is of course much too short to reach resonant frequency, but it was tucked nicely behind the cylinder, allowing a neat installation in Quarter Midget racing models. Internally, the new Taipan drew much from the Rossi R.15 - indeed, in many respects it brought those high-end features into a broader marketplace, prompting some to call these engines “poor man’s Rossi’s”. The pressed-in crankpin idea was more likely taken from K&B as a cost saving measure for an engine selling for half the Rossi’s retail price.

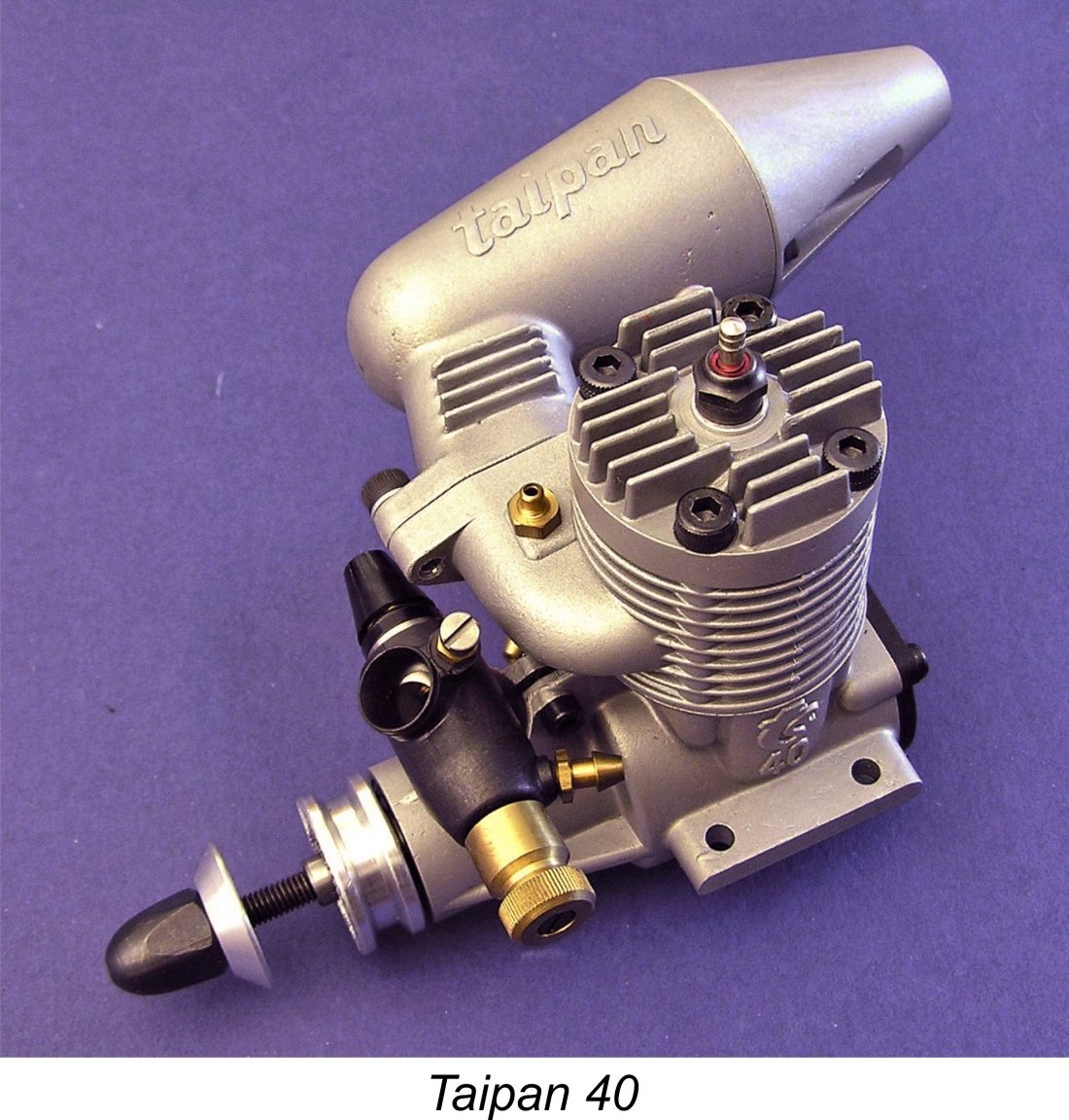

The new Taipan also did well in control line racing and combat competition. The design evolved throughout its production life to reduce cost, improve performance and enhance reliability. Some of these refinements were subtle, such as heat treatment of pistons, altered boost port angles or revised crankshaft design. However, later versions can easily be identified externally by the revised crankcase casting to accomodate a larger rear ball race, along with a black plastic back plate. Sadly, the Goldhead's competitive edge didn't last long. The Taipan Schnuerle-ported 2.5 cc and 3.5 cc engines, initially leaders in their respective categories, fell away from cutting-edge competition standard fairly quickly. This was in Even so, export sales went quite well, including to Japan, where they were distributed in association with the O.S. Company, who wished to fill gaps in their own range. When operated within reasonable limits, they provided a host of users all over the world with an affordable taste of a new level of specific power output. The subsequent Taipan .40 stood on the shoulders of all of Gordon Burford's earlier Schnuerle engine developments, taking some bold steps beyond what was already in production. In that regard it represented a passing of the torch, since the design was completely Peter Burford’s, with dad Gordon’s influence, of course. Until then, Peter’s design inputs had been of a production-oriented nature relating to individual components, jigs and the like, with economy of production in mind. You can read all about the Taipan 40 in a separate review on this Website.

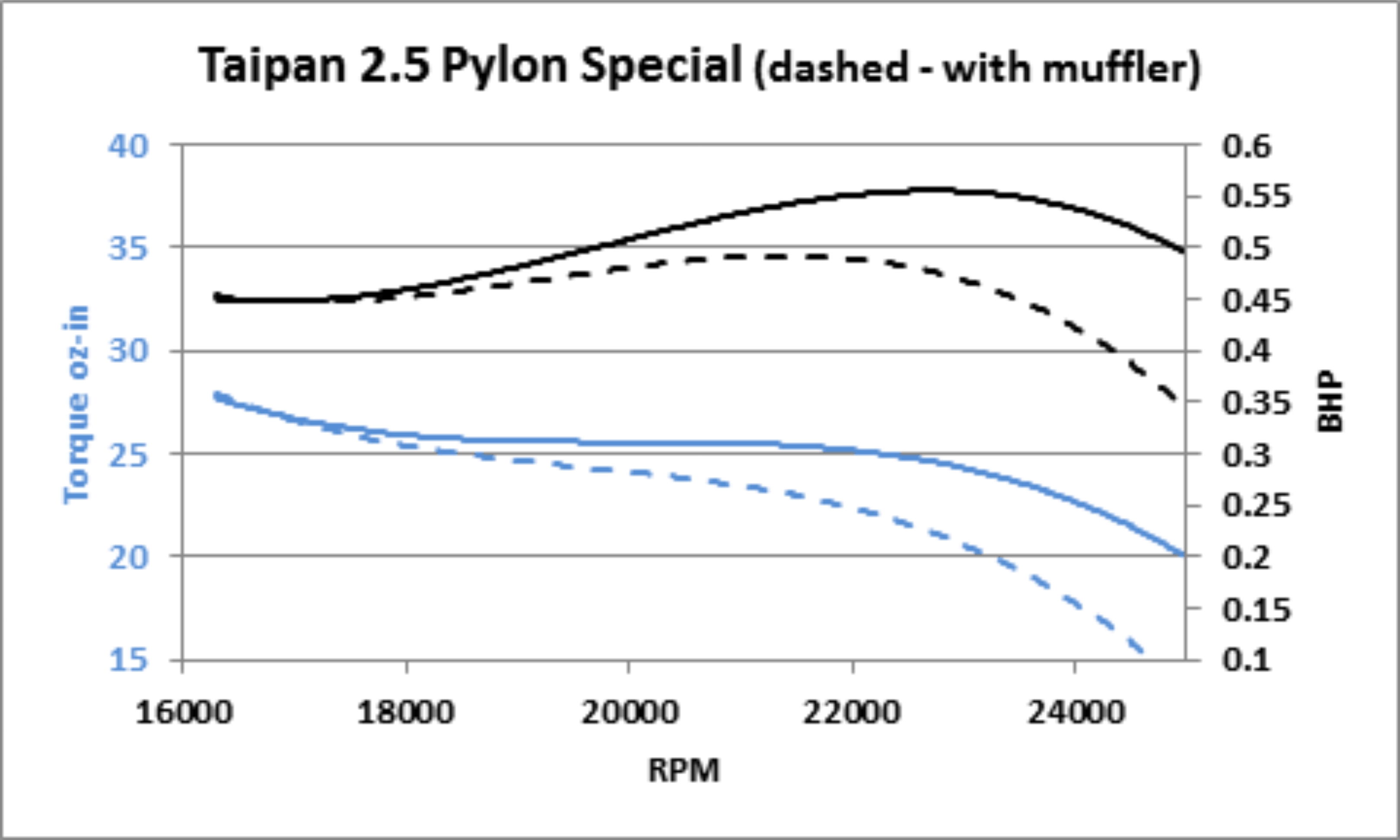

Unfortunately this brings us to the closure of the Taipan Factory in 1976 due to several previous years of “stagflation” and difficult economic circumstances which also closed thousands of other Australian companies both large and small. Gordon continued as a consultant to other manufacturers as well as carrying on with his many other engine projects in retirement, particularly after moving with his wife Jose to Currumbin in Queensland. Taipan 15 Pylon Special Test As fortune would have it, I managed to acquire a 1972 Pylon Special in reasonable shape. It was somewhat well used and not quite right in the bearing alignment, possibly from a hard “landing”, but it was at least complete along with the genuine extractor muffler. A different crankcase/bearings from our spares box soon had it feeling good enough for testing. The fuel used contained 28% castor oil to help with the piston seal along with 5% nitro, so we could compare our results with Peter Chinn’s test of the “Goldhead” production engine ("AeroModeller" August 1975). The single clamp screw muffler attachment was poor, requiring an additional bracket to support the tailpipe before we could be confident that it would not rattle loose and fall off. It’s an interesting design, with three rows of 2.7 mm holes at 120 degree spacing (51.5 sq. mm total area) in the venturi extractor tube (58 sq. mm), where it passes through the expansion chamber. Three longitudinal slots are also cut in the extractor tube after it exits the expansion chamber. Idle was certainly adequately low to meet the Quarter Midget requirement for the model not to roll forwards. Mid-range speed performance is of course irrelevant for this application, so all further tests were conducted in the fully open position. Needle response was effective and not particularly sensitive, making it quite easy to dial in top RPM. Vibration was quite low, particularly at the higher speeds close to peak power output, making the entire exercise quite uneventful. Our test results show very similar levels of performance to those reported in Chinn’s test of the production engine. Our engine gave a somewhat higher power output without the muffler, possibly due to different test conditions and the particular engines used. Certainly, comfortably clearing 0.5 BHP with little nitromethane content was excellent for a throttle equipped engine in 1972. And sustaining 25 oz-in torque until near the peak BHP speeds shows a harmonious overall design for racing applications.

Our results with the muffler showed a significant reduction in noise (when using the 7x4 propeller) from A-weighted 103 dB at three metres to a more pleasant 95.5 dB. The idea of the design is that air flowing through the extractor tube reduces pressure at the nine expansion chamber outlet holes, owing to the venturi effect, thereby reducing residual backpressure that would otherwise cause some exhaust gasses to re-enter the cylinder. Taken to extremes, no power is lost, as with the contemporary Super Tigre G.20/15 R/C Series 70-71 engine. However, the Super Tigre’s noise reduction would also be minimal. The Taipan muffler did restrict power output, resulting in a lower 0.48 BHP peak around 21,500 RPM. However, this was still enough to see off the Super Tigre or the O.S Max III 15 R/C which would have been its main competition at the time in Quarter Midget racing. _______________________________ Article © Maris Dislers, Adelaide, South Australia First Published December 2017

|

||

| |

The Taipan 3.5 cc plain bearing/ball race models introduced towards the end of 1972 were the first commercial Schnuerle-ported engines from Gordon Burford and Co. and the first on the market with this swept volume. They were the fruits of much “skunk works” effort. Production engines alone do not always tell the story, so here we’ve investigated this interesting development phase via an examination of experimental prototypes. It gives a feel for what manufacturers go through to bring a truly original product to market.

The Taipan 3.5 cc plain bearing/ball race models introduced towards the end of 1972 were the first commercial Schnuerle-ported engines from Gordon Burford and Co. and the first on the market with this swept volume. They were the fruits of much “skunk works” effort. Production engines alone do not always tell the story, so here we’ve investigated this interesting development phase via an examination of experimental prototypes. It gives a feel for what manufacturers go through to bring a truly original product to market. In a very real way, it all goes back to the East German engineer Walter Kaaden and his ground-breaking development of high performance two-stroke motorcycle engines. Kaaden was a brilliant engineer who built and developed the East German MZ racing motorcycle engines on a shoestring budget. These very rapid two-strokes immediately began to chew into the four-stroke world of motorcycle racing in the late 1950’s - definitely a case of David taking on Goliath!

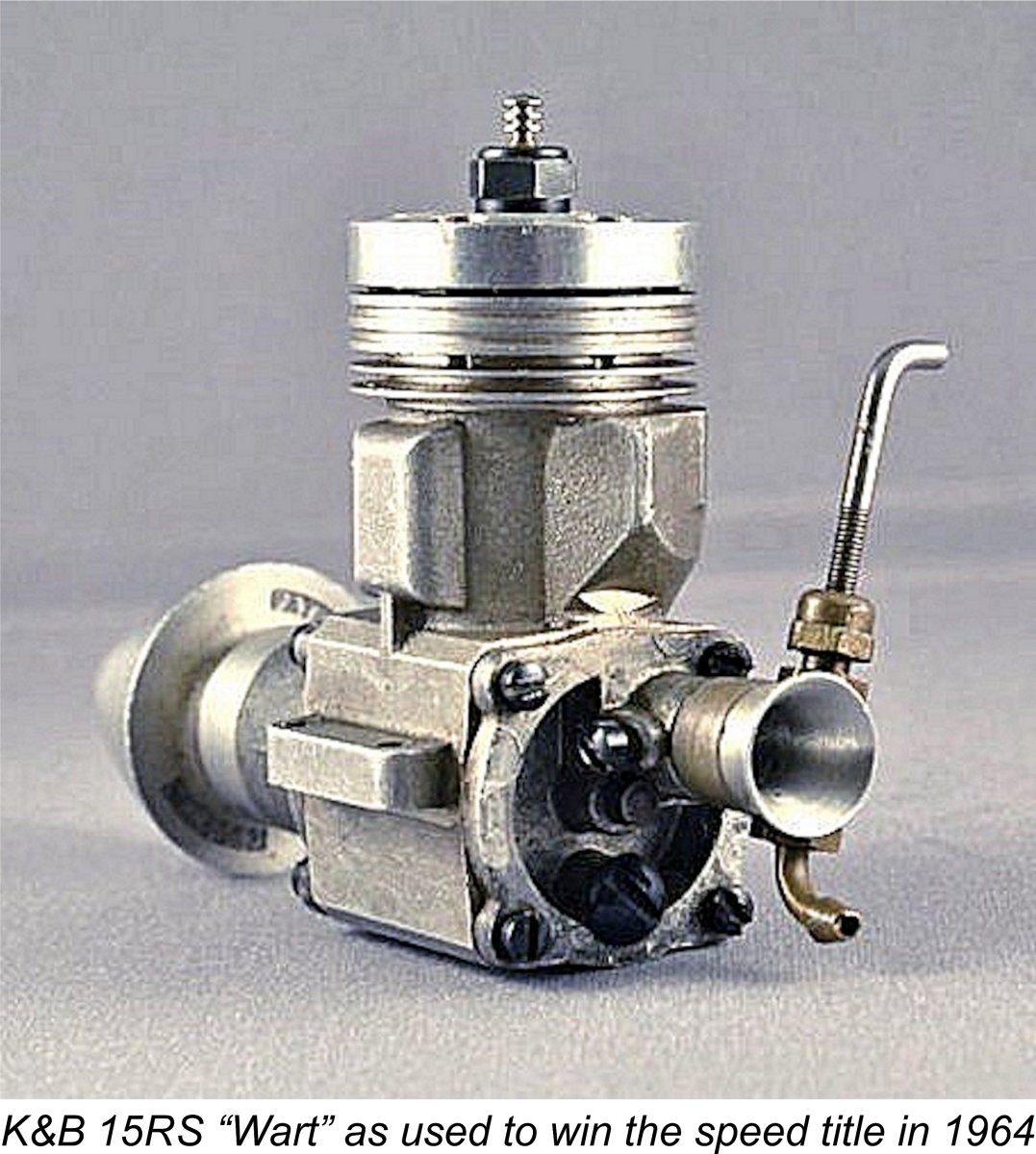

In a very real way, it all goes back to the East German engineer Walter Kaaden and his ground-breaking development of high performance two-stroke motorcycle engines. Kaaden was a brilliant engineer who built and developed the East German MZ racing motorcycle engines on a shoestring budget. These very rapid two-strokes immediately began to chew into the four-stroke world of motorcycle racing in the late 1950’s - definitely a case of David taking on Goliath!  Soon afterwards, this technology spread to others with a keen interest in two-stroke engine performance, particularly other motorbike and go-kart racers. In the world of high-performance modelling, the noted American speed flier Bill Wisniewski showed what a rotary valve induction Schnuerle plus boost ported model aircraft engine could do by winning the F2A Speed category for the USA at the 1964 Control Line World Championships in Hungary, using his special K&B 15RS “Wart” engine, so called for the distinctive transfer bulges on the crankcase. The attached image was extracted from John Lichnerowicz's

Soon afterwards, this technology spread to others with a keen interest in two-stroke engine performance, particularly other motorbike and go-kart racers. In the world of high-performance modelling, the noted American speed flier Bill Wisniewski showed what a rotary valve induction Schnuerle plus boost ported model aircraft engine could do by winning the F2A Speed category for the USA at the 1964 Control Line World Championships in Hungary, using his special K&B 15RS “Wart” engine, so called for the distinctive transfer bulges on the crankcase. The attached image was extracted from John Lichnerowicz's  in F2A Speed two years later at the 1968 World Champs at Helsinki, Finland using TWA powerplants, the winner on that occasion being Arnie Nelson, with Bill Wisniewski placing second.

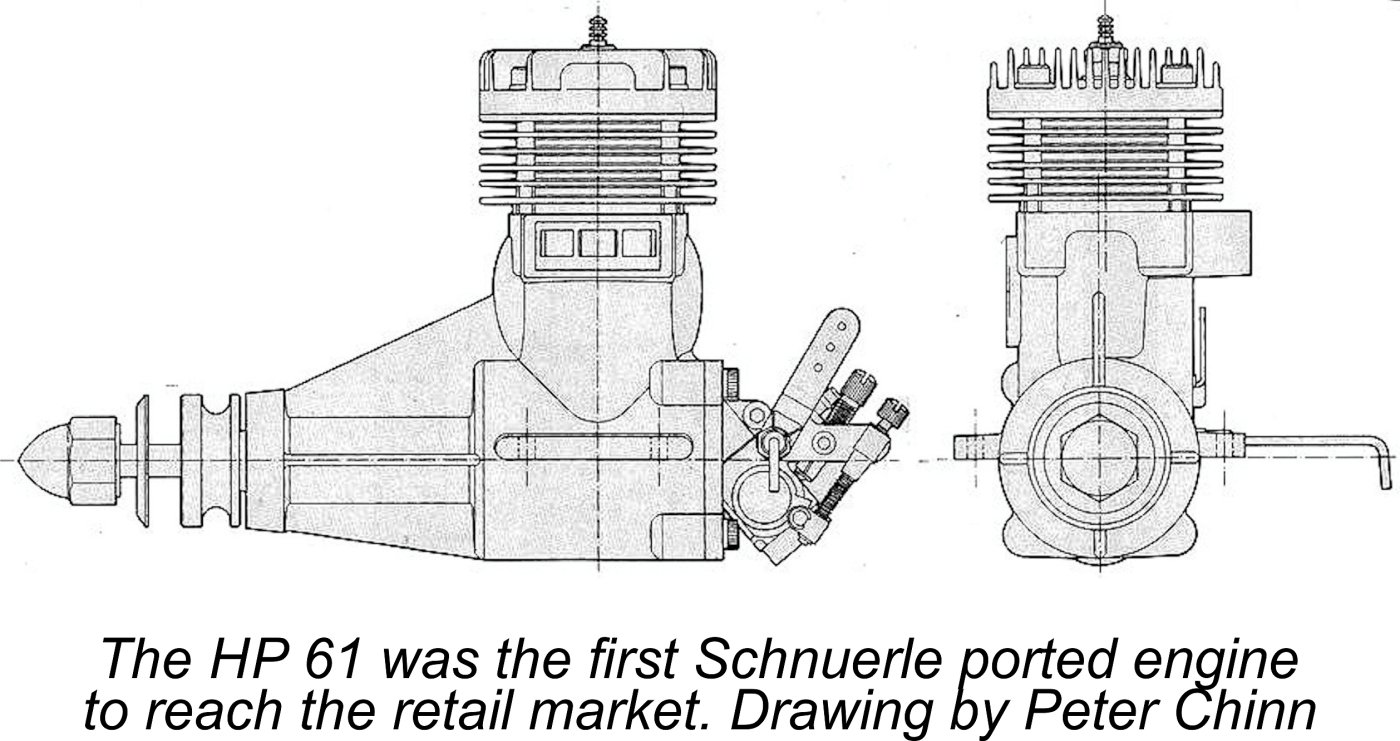

in F2A Speed two years later at the 1968 World Champs at Helsinki, Finland using TWA powerplants, the winner on that occasion being Arnie Nelson, with Bill Wisniewski placing second.  At that time Paul Bugl’s Hintenberger HP 61 designed for R/C Aerobatics was demonstrating that Schnuerle porting technology could be applied commercially to engines meeting the needs of a far broader customer base than top competition fliers. No doubt others were already gearing up to produce these new generation engines for the retail market, and it would clearly not be good to be left behind. In Peter Burford’s words “Much of our production (design?) was driven by the market we had available, the machinery we could acquire and the price we could ask.”

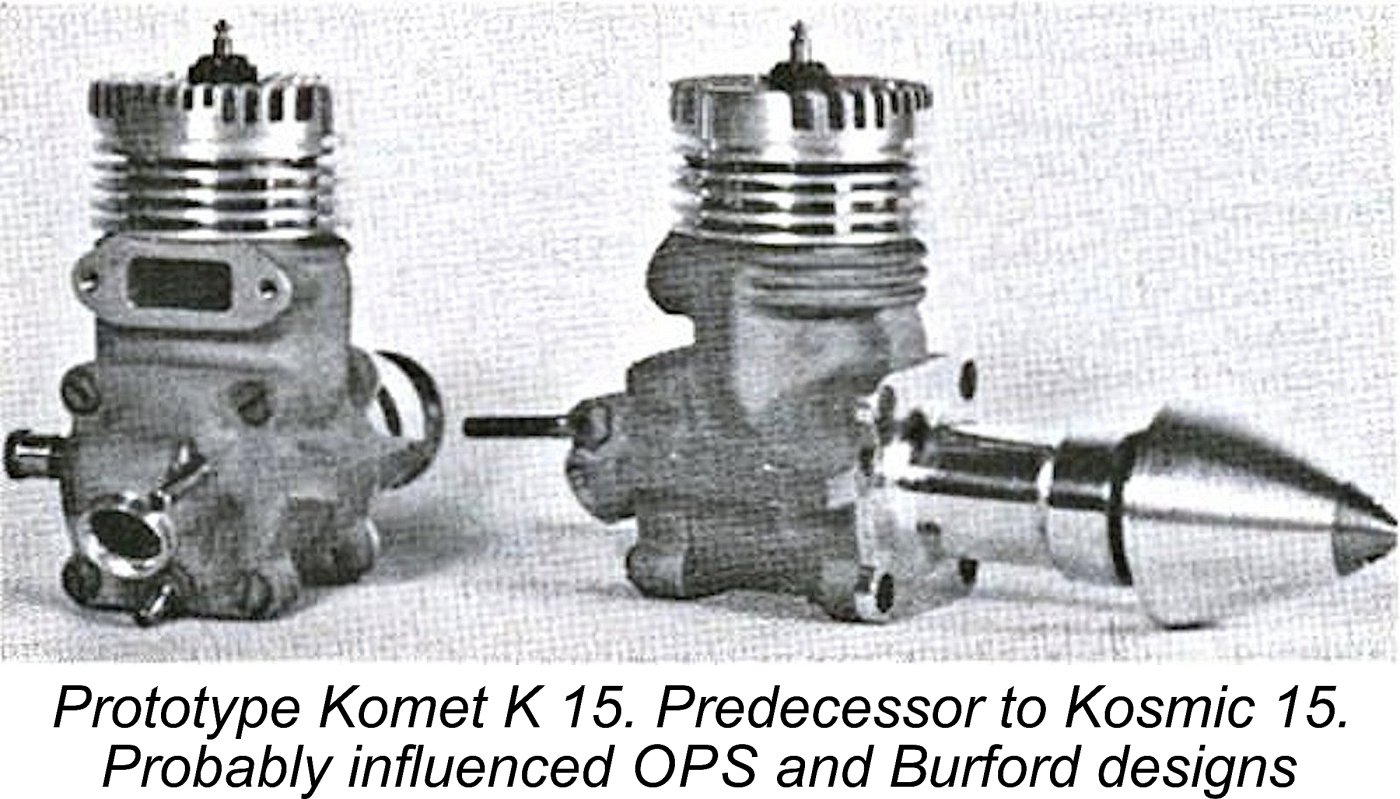

At that time Paul Bugl’s Hintenberger HP 61 designed for R/C Aerobatics was demonstrating that Schnuerle porting technology could be applied commercially to engines meeting the needs of a far broader customer base than top competition fliers. No doubt others were already gearing up to produce these new generation engines for the retail market, and it would clearly not be good to be left behind. In Peter Burford’s words “Much of our production (design?) was driven by the market we had available, the machinery we could acquire and the price we could ask.”  We’ll call the first of this series of 2.5 cc Schnuerle-ported development engines “Type 1” or 15 R-S as it became known. Gordon mainly drew inspiration from the influential 1966 prototype Komet K-15, a collaboration between Italians Vito Consiglio, Cesere Bossaglia and Italo Magrotti that was achieving good results in R/C boat racing. The attached images of this engine were extracted from "Aeromodeller". Gordon also doubtless referred to published technical books of the time, perhaps also drawing upon photos of Suzuki racing motorcycle engine parts. Any resemblance between his engines and the OPS 60 racing engine (also dating from 1968) and the later Kosmic 15 is coincidental.

We’ll call the first of this series of 2.5 cc Schnuerle-ported development engines “Type 1” or 15 R-S as it became known. Gordon mainly drew inspiration from the influential 1966 prototype Komet K-15, a collaboration between Italians Vito Consiglio, Cesere Bossaglia and Italo Magrotti that was achieving good results in R/C boat racing. The attached images of this engine were extracted from "Aeromodeller". Gordon also doubtless referred to published technical books of the time, perhaps also drawing upon photos of Suzuki racing motorcycle engine parts. Any resemblance between his engines and the OPS 60 racing engine (also dating from 1968) and the later Kosmic 15 is coincidental. For practical reasons, the general arrangement of Gordon's Type 1 prototypes followed the approach used for the existing Taipan glowplug engines, also utilizing some of their tooling. The design incorporated a one-piece crankcase casting terminating above the exhaust, with a machined finned cylinder jacket and drop-in liner.

For practical reasons, the general arrangement of Gordon's Type 1 prototypes followed the approach used for the existing Taipan glowplug engines, also utilizing some of their tooling. The design incorporated a one-piece crankcase casting terminating above the exhaust, with a machined finned cylinder jacket and drop-in liner.

In late 1970 or early 1971, development progressed with the experimental application of Schnuerle plus boost porting to the existing Series 70 2.5 cc production diesel. That design had used transverse cuts to create its two opposed and inclined transfer ports (similar to the

In late 1970 or early 1971, development progressed with the experimental application of Schnuerle plus boost porting to the existing Series 70 2.5 cc production diesel. That design had used transverse cuts to create its two opposed and inclined transfer ports (similar to the

This newly-emerging market may have been the impetus for Gordon’s next development (Type 3 in our sequence) of a high performance front induction side-exhaust Schnuerle ported 2.5 cc glow-plug engine for R/C Quarter Midget pylon racing or C/L FAI combat and racing use. By the end of 1971 the die for a new lower crankcase to suit the newer Type 2 finned upper cylinder section had been created.

This newly-emerging market may have been the impetus for Gordon’s next development (Type 3 in our sequence) of a high performance front induction side-exhaust Schnuerle ported 2.5 cc glow-plug engine for R/C Quarter Midget pylon racing or C/L FAI combat and racing use. By the end of 1971 the die for a new lower crankcase to suit the newer Type 2 finned upper cylinder section had been created.  The Pylon Specials had a Perry R/C carburettor, then considered among the world’s best, as well as being fitted with an extractor-style muffler, said to boost top-end performance. Extractor mufflers using the venturi principle were popular at that time. This one probably served as the development "mule" for the production 3.5 cc and 10 cc types to follow.

The Pylon Specials had a Perry R/C carburettor, then considered among the world’s best, as well as being fitted with an extractor-style muffler, said to boost top-end performance. Extractor mufflers using the venturi principle were popular at that time. This one probably served as the development "mule" for the production 3.5 cc and 10 cc types to follow. later Type 2’s. The conrod came from the production plain bearing cross-flow ported Taipan 15 “Lightning Bolt” glow engine. Unattractively stamped from sheet stock, it proved to be exceptionally durable.

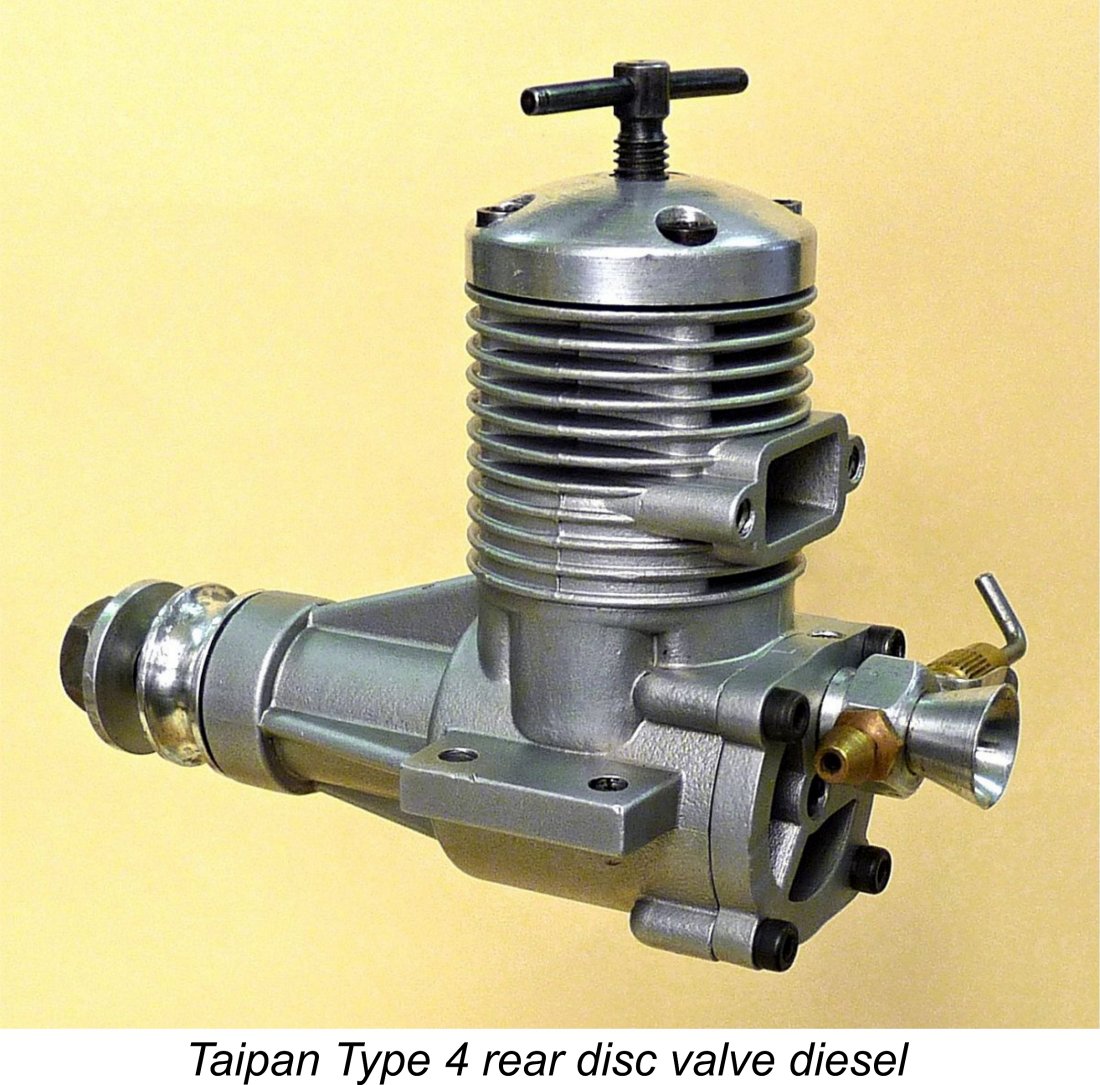

later Type 2’s. The conrod came from the production plain bearing cross-flow ported Taipan 15 “Lightning Bolt” glow engine. Unattractively stamped from sheet stock, it proved to be exceptionally durable. Gordon had now decided on front induction for glow and rear induction for diesel, with shared tooling and components where possible. By 1973, the planned diesel took form with a new rear induction crankcase (Type 4). Induction was via rotary disc valve. However, several problems remained to be addressed before series production could be considered. On test, the rear bearing size proved inadequate for diesel operation and crankcase strengthening would be required. This was not pursued, and the RV did not go into production. Only two Type 4 RV diesels are known to exist at the time of writing.

Gordon had now decided on front induction for glow and rear induction for diesel, with shared tooling and components where possible. By 1973, the planned diesel took form with a new rear induction crankcase (Type 4). Induction was via rotary disc valve. However, several problems remained to be addressed before series production could be considered. On test, the rear bearing size proved inadequate for diesel operation and crankcase strengthening would be required. This was not pursued, and the RV did not go into production. Only two Type 4 RV diesels are known to exist at the time of writing.  First deliveries began in late 1973. The Taipan 2.5 TBR “Goldhead” engines quickly found favour in Quarter Midget racing, having an edge on the K&B Series 72 model, which in turn outperformed the Super Tigre G.15 R/C. There was then no throttle-equipped Rossi R.15 around to spoil the show.

First deliveries began in late 1973. The Taipan 2.5 TBR “Goldhead” engines quickly found favour in Quarter Midget racing, having an edge on the K&B Series 72 model, which in turn outperformed the Super Tigre G.15 R/C. There was then no throttle-equipped Rossi R.15 around to spoil the show.