|

|

The Barbini Engines

These engines were built to very high standards, albeit in far smaller numbers than usual for a “name” model engine range. Their manufacturer, Amelio Giovanni Barbini (always apparently known as Giovanni), seems to have been a person of the highest integrity who put all of his considerable skill into the design and construction of the engines which bore his name. Because of their comparatively small production figures by world standards, the Barbini engines are in relatively short supply on today’s international model engine market. Most of them seem to stay in Italy. Even in today's depressed model engine market, they seem to hold their value better than most. Not having examples of the majority of the 2.5 cc models on hand, I’ll have to depend entirely upon written sources when discussing most of those models. Fortunately, this isn’t as much of an issue as it might have been with some other ranges of similar scarcity and limited worldwide circulation, since there is a wealth of source material available. I’ll start by reviewing those sources for those who may wish to follow up. Sources Although they were never specifically targeted towards markets outside of their native Italy, a series of high-profile contest successes (of which more below) led to the Barbini engines quickly acquiring a very high international reputation during the mid and late 1950’s. This led to a greater than usual level of coverage in the English-language modelling media during that period, especially for a range that was never exported from Italy in significant numbers. This coverage included the publication of a number of tests of different models.

In addition to these tests, the Barbini engines were quite frequently mentioned in the broader model engine news commentaries in both magazines during the mid and late 1950’s. Their contest records were also covered in some detail in the reports of major international competitions which appeared in those magazines. Although this coverage had dried up by the end of the 1950’s as a result of the Barbini designs having then been overtaken by more advanced models from other manufacturers, the coverage up to that point was highly informative. Again, reference will be made to specific articles during the course of what follows.

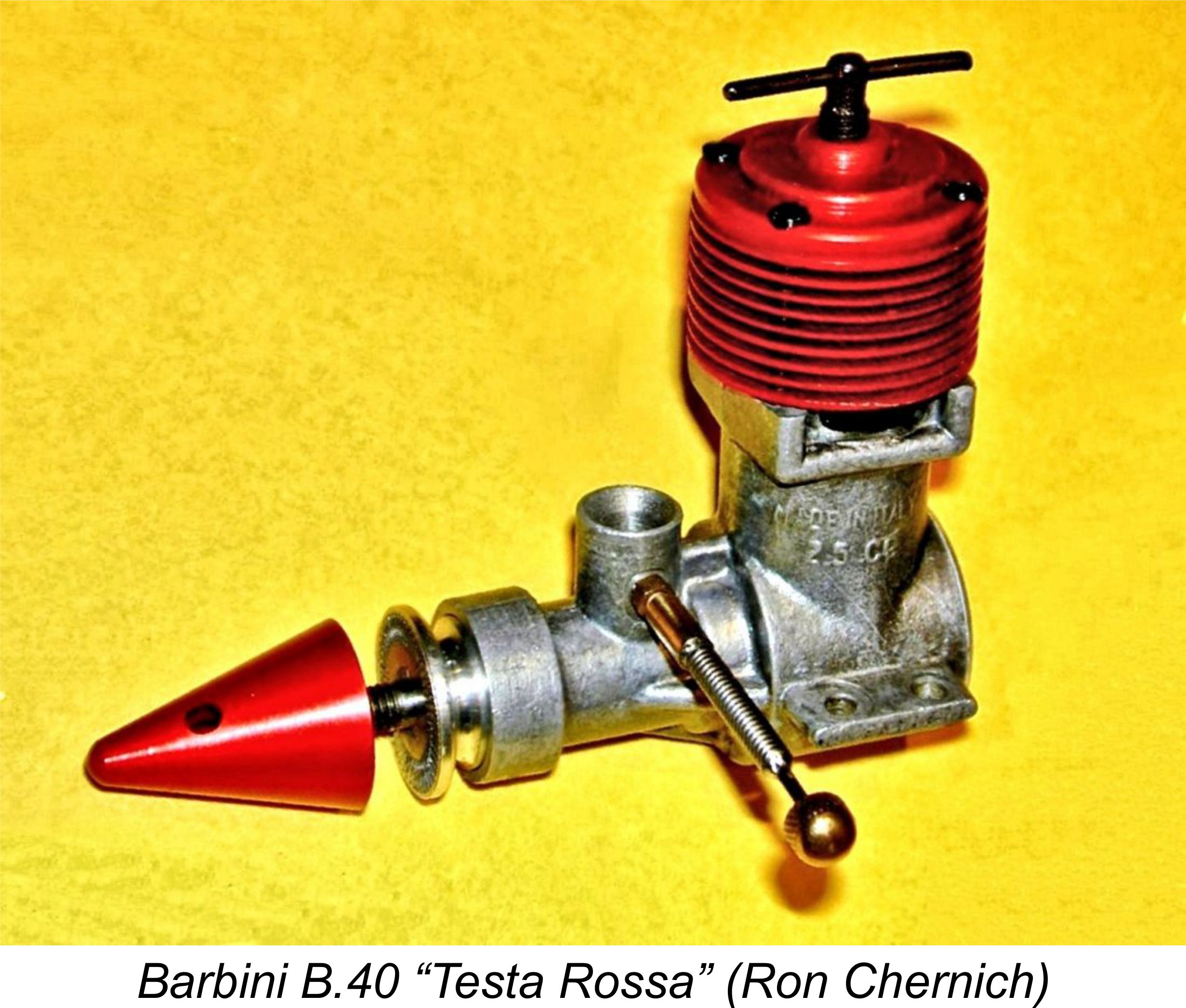

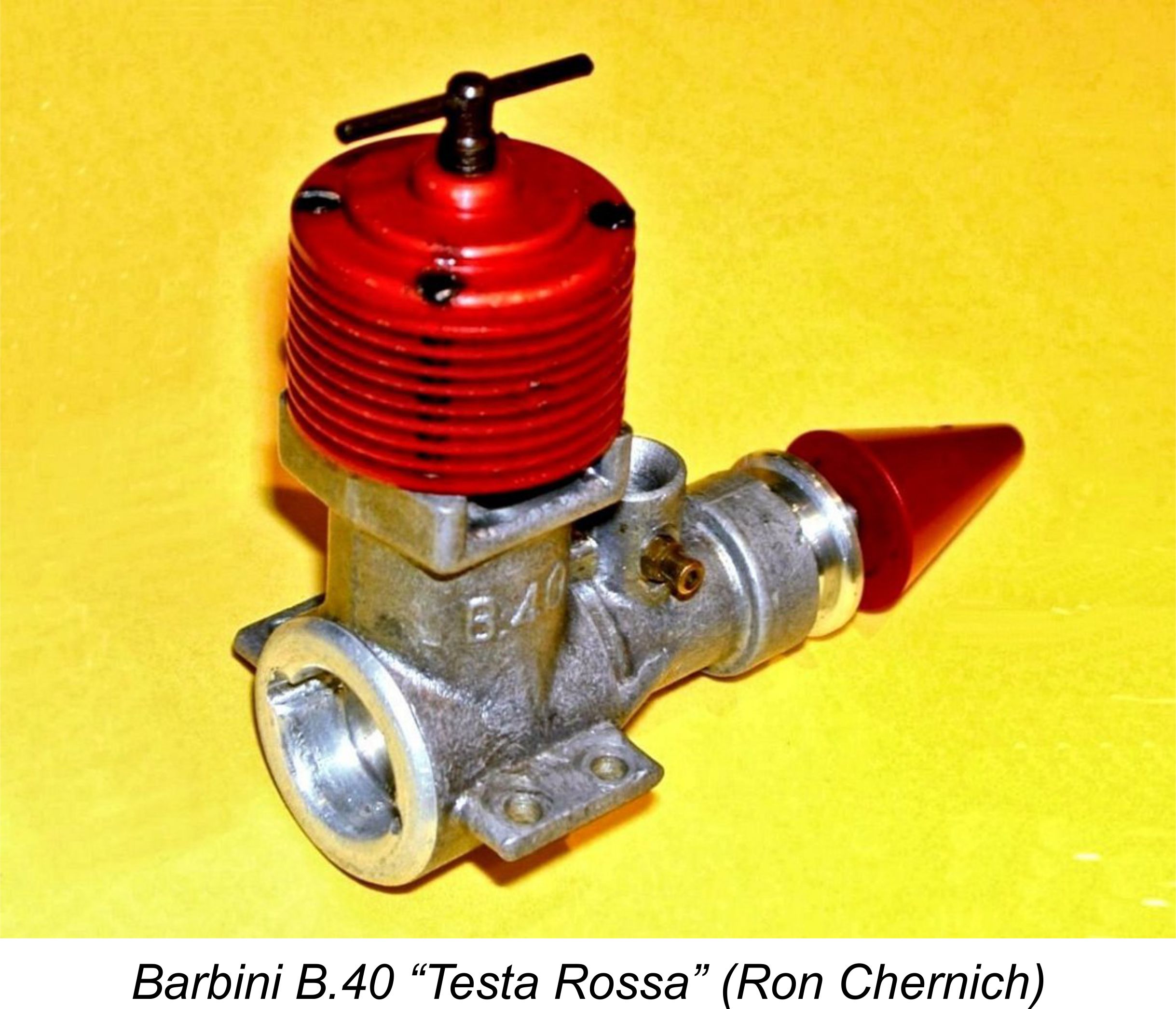

Finally, the late Ron Chernich’s now-frozen “Model Engine News” (MEN) web-site also featured several articles on the Barbini engines. A very brief descriptive piece on the Barbini B.40 "Testa Nera" glow-plug model (see below) may still be found on MEN. A companion article authored by Ron himself on the subject of the Barbini B.40 "Testa Rossa" diesel (again, see below) also appeared on MEN. This article described the engine in some detail, also outlining Ron’s restoration of the featured example of the engine. The purpose of the present article is to bring all of this information together in a single location so that readers are spared all the hunting around that I had to go through to assemble this text and associated images. These fine engines are well worth remembering and collecting if the opportunity offers. The motivation to collect and preserve them can only come from adequate documentation. That’s the overriding goal here. I've stated previously that the greatest reward for the effort involved in the preparation of these articles is the subsequent receipt of additional information or corrections from my readers. This was a case in point - very shortly after the initial May 1st, 2015 appearance of the original text of this article, I heard from reader Walter Barbui of Treviso, Italy. Walter was sufficiently inspired by the article to actually track down Bruno Barbini, the nephew of Giovanni Barbini. In the past, Bruno has generally been credited with being the main constructor of these engines, but it turns out that in fact he was only involved during the last few years of their manufacture. Walter engaged in a forty-minute phone conversation with Bruno (60 years old as of 2015) which yielded a great deal of fascinating information, much of it quite revisionist. All of this information has been incorporated into the updated text which follows. My very best thanks to both Walter and Bruno! With the above-listed sources at our disposal, let’s see what we can do to set out the true Barbini story in as clear and comprehensive a manner as possible. In doing so, I'd like to remind readers that I don't claim to know it all - in fact, I'll state categorically that there is undoubtedly much more to be learned about the Barbini range than what I'm able to present here. Furthermore, errors doubtless still remain at certain points. If any reader is able to correct any such errors or add to our knowledge, I will gladly incorporate their input with full acknowledgement. Background The Barbini engines were manufactured on a relatively small scale by Amelio Giovanni Barbini (b. 1915), initially working during 1952 from a small workshop in the basement of his home in Milan before moving very early on to a new workshop in San Stino di Livenza near Venice. His workshop at that location was established in part of a stable, which the machinery shared with a couple of cows! About as close to the time-honoured "garden shed" operation as you can get! As stated earlier, the manufacture of these engines has generally been previously credited to Bruno Barbini, which would have been a little difficult given the fact that the "real" Bruno Barbini (60 years old in 2015) had not been born at the time when the B.38 appeared in 1953! It remains unclear how and when this mis-identification first arose. In all likelihood, the fact that the "real" Bruno Barbini was involved with the manufacture of the engines during the latter years of the marque somehow led to an assumption that he was involved all along. However, we can now state with complete certainty that the "real" Bruno has positively identified his uncle Giovanni as the manufacturer of these engines. Case closed .......... Giovanni Barbini (as he appears to have been generally known) traded under the name “Officina Meccanica A. Barbini”, the "A" standing for his baptismal first name of Amelio. The manufacture of model engines was by no means his sole activity - he also made a variety of precision mechanical components such as gear wheels, clock parts and the like under contract to industrial customers. This was a major reason for the relatively small numbers of model engines produced under the Barbini name. The model engines were built in batches as time permitted and as requested by the distributors. The engines were originally distributed by Soc. Comm. “Solaria” of Largo Richini 10 in Milan. Interestingly enough, Ron Warring reported that “Solaria” maintained an office in London S.W.1., England, although they never appear to have made any serious efforts to market the Barbini engines in Britain. Bruno Barbini informed Walter Barbui that the distribution was later taken over by Mantua Models of Mantova, a location which is far closer to San Stino di Livenza than Milan. Giovanni Barbini always remained a craftsman/machinist at heart, apparently never harbouring any ambitions to expand into large-scale production. The company never at any time employed more than 4 people (Bruno and Giovanni included). Moreover, the model engines were produced intermittently in batches during intervals between work requirements on other projects. As a result, production rates remained quite small, making the Barbini engines relatively hard to find these days. As one might expect from the products of a small-scale hands-on precision machine shop, the standard of manufacture of these engines was uniformly very high. They also displayed considerable design ingenuity. Bruno Barbini remembered his uncle Giovanni as being a man who valued his personal freedom and independence above everything else. Consequently, he steadfastly resisted the notion of working for anyone else, remaining self-employed lifelong. This independent trait had led to his being a rather "restive" student during his school-days. The talented and restive dreamer is a type that any teachers among my readers will know well! As usual with such individuals, if a subject really engaged Giovanni's attention and interest, he was indefadigable in improving his knowledge - for example, he apparently taught himself trigonometry! Giovanni Barbini's dedication to complete independence was such that according to Bruno Barbini, every single operation required to manufacture the engines was carried out in-house at San Stino di Livenza. This included the creation of the required dies, the actual die-casting itself, the heat treatment operations, the colour anodizing and even the manufacture of the tiny precision rollers and cages used in the 2.5 cc compertition models (see below) Above all else, Giovanni Barbini was a talented and inventive machinist. His dedication to his craft was such that he was always exploring the outer limits of his own capabilities. Bruno Barbini recalls that his uncle's interest in models led him to construct a number of one-off prototypes in between making batches of his commercial offerings. Some of these were complex multi-cylinder types, and some were very large indeed. Bruno still had one such engine made by his uncle - a flat four opposed-cylinder four-stroke model having four overhead camshafts and a displacement of 180 cc. The fact that the Barbini engines were never marketed with any fervour outside of Italy doubtless reflects the fact that the Italian market was able to absorb pretty much all of the very limited output that Barbini was able to maintain. He appears to have been quite content to leave things that way. Long after they had been overtaken in performance terms by more advanced models from other manufacturers, the reputation of Barbini’s engines was such that they remained in demand in Italy for non-contest purposes right up to the cessation of all production in 1987. Bruno Barbini shared the interesting insight that Giovanni's objective at the outset was not to create a range of model engines having outstanding levels of performance, but rather to create a series of durable and reliable engines for the use of practical modellers. The fact that the engines performed at levels which were outstanding by the standards of their day was merely an outcome of the design process rather than an overriding objective. The identification system used by Barbini is possibly unique in the history of model engine manufacture. Barbini apparently named his engines for his own age at the time when they were introduced! As a result, the engines’ identification numbers bear no relationship whatsoever to their displacements. As far as I’m currently aware, the engines did not carry serial numbers. Now let’s begin our look at the various models offered by Barbini. The Barbini B.38

Fortuitously enough, a fine example of one of those early prototype engines from Milan was kindly made available to me in mid 2017 by my good friend Tim Dannels. This prototype unit differed from the subsequent production model in a number of key respects. Most importantly, the exhaust apertures in the upper crankcase casting of the prototype were closed-sided slots rather than open-ended recesses. They were positioned somewhat lower in the case than those of the later production versions. It appears that the prototype cylinder was originally set lower as well, matching the lower crankcase apertures and also giving rise to later opening of both the exhaust and transfer ports. Evidently Barbini decided to experiment with extending the exhaust and transfer periods. To this end, he tried the effect He clearly liked the results, because the subsequent production version of the engine had its crankcase exhaust apertures cut higher in the casting, turning them into open-topped recesses rather than closed-sided slots. The cylinder location seat was cut higher in the case to match, eliminating the need for the raising spacer. The protoype engine differed from the production model in a number of other respects. Perhaps most significantly, the external diameter of the production version's cylinder port belt was increased from 13 mm in the prototype to 13.5 mm. This allowed for a small but potentially significant increase in the width of the annular passage between the cylinder and crankcase which constituted the bypass. The prototype case lacked any form of identification, which was added to the production cases. The un-anodized cooling jacket was far more angular and "utilitarian" than the later anodized production version, although very well made, like the rest of the engine. The needle valve was completely different, being an externally threaded item which was tensioned by a split internally threaded spraybar as opposed to the split thimble design employed once production began. The prototype's compression screw was a ridiculously skimpy affair which was quite uncomfortable to use - the production version had a far more practical component. Finally the prototype's prop driver and spinner nut were both equipped with 7 mm diameter prop mounting hub extensions, which were omitted on the production model.

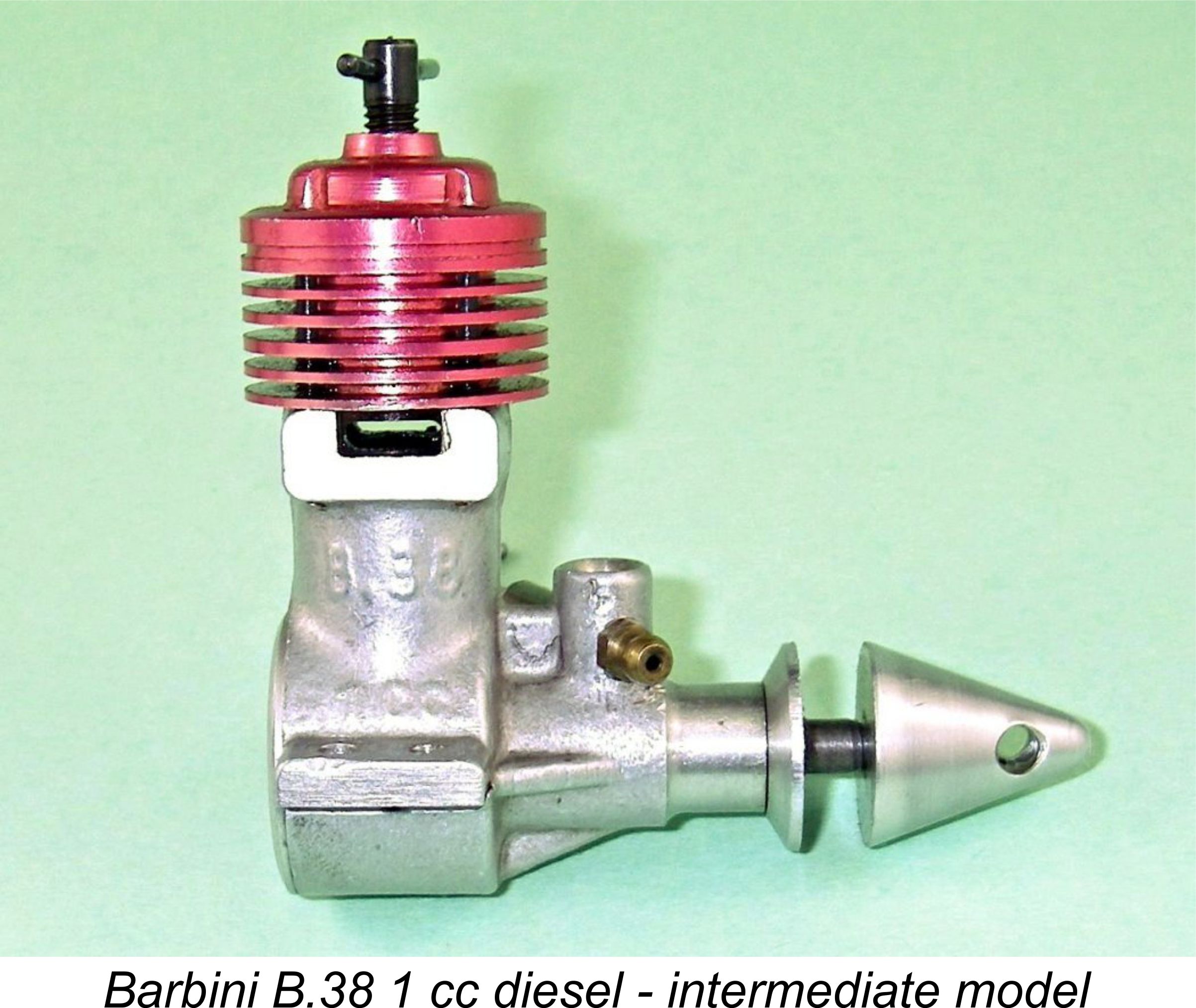

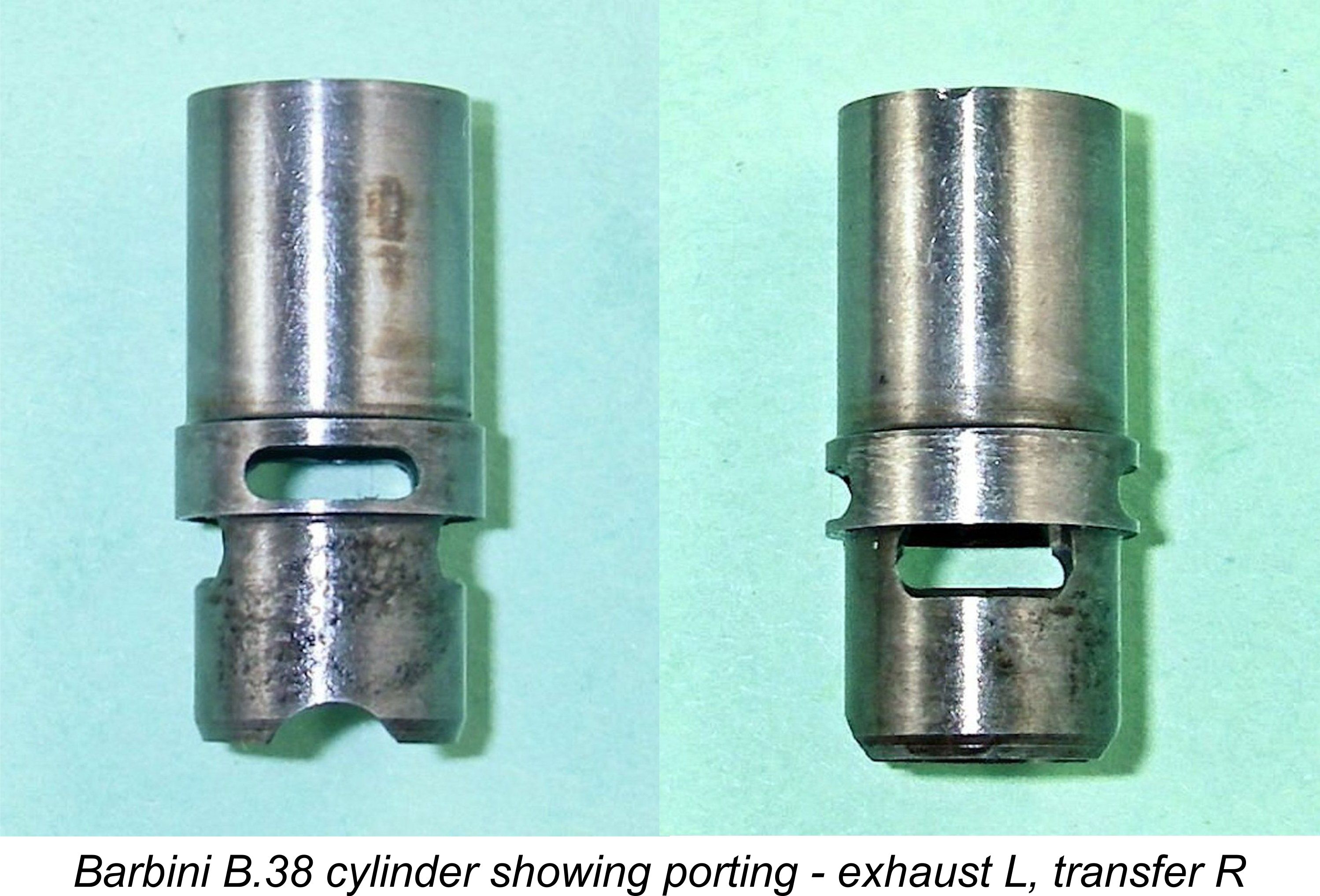

The initial production model of the Barbini B.38 diesel first appeared in 1953 when Giovanni Barbini was – you guessed it – 38 years old! This neat little engine represented a very clean break from the design patterns for engines of similar displacement which had been widely adopted at that time. To begin with, the B.38 was a long-stroke design, in defiance of then-current thinking which favoured short-stroke internal geometry. In consequence, it had a somewhat “tall” look by the standards of the day. Despite this seeming liability, the B.38 was in fact an extremely light and compact little engine for its displacement - you really have to handle one to fully appreciate this point. Nominal bore and stroke of this attractive little unit were 10.00 mm and 12.70 mm respectively for a displacement of 0.997 cc (0.061 cuin.). The engine weighed in at a commendably light 53 gm (1.87 ounces) - considerably less than many of its smaller-displacement competitors. Like many competing 1 cc diesels, the B.38 featured crankshaft front rotary valve (FRV) induction and reverse-flow scavenging. However, it broke new ground in the 1 cc class with its cylinder porting arrangements, dispensing completely with the annular style of radial porting which was then very much in vogue. Instead, there were two oval exhaust ports of ample dimensions place on opposite sides of the cylinder. These discharged through the previously-noted pair of channels formed at the top of the gravity die-cast crankcase unit.

If the arrangement had a weakness, it was the fact that the two large transfer ports were supplied with gas in the conventional manner through a bypass passage which was formed by the relatively narrow annular space between the outer wall of the lower cylinder and the inner wall of the upper crankcase casting. The size of the transfer ports was such that this arrangement almost certainly made the transfer arrangements bypass-limited.

The location of the exhaust ports coupled with the chosen length of the piston skirt resulted in the engine having an unusually long period of sub-piston induction. Indeed, as we shall see, this was almost certainly viewed by the designer as being the main means of filling the crankcase during the induction cycle. The total sub-piston induction period was of the order of 64 degrees (32 degrees each side of TDC). The cylinder liner was located in the upper crankcase by a port belt of expanded outer diameter which bore upon a narrow shelf formed near the top of the upper crankcase interior. This port belt carried only the exhaust ports – the transfer openings were cut beneath it with their interior ends formed inside the port belt by being cut at the previously-mentioned upward angle. The cylinder liner was retained by a separate light alloy cooling jacket using four slot-head screws. The cooling jackets of most examples were anodized red, although towards the end of Barbini production the engines were sold with plain unanodized heads. A conventional double-armed compression screw was employed. Moving downwards, the cast iron piston was highly unusual by the standards of the day. It had a very slightly conical crown and was milled out internally to minimize reciprocating weight – a very good move which certain others would have done well to copy! However, its most unusual feature was the fact that the lightweight tubular gudgeon (wrist) pin was retained using a pair of miniscule wire circlips – then a very uncommon feature, especially in such a small engine. This was of course forced on the designer by the very large size of the fore-and-aft transfer ports, which would inevitably have resulted in their being fouled by the ends of the gudgeon pin if it had not been secured in this manner.

That configuration had the inevitable effect of increasing the swing angle of the con-rod during operation. To allow for this, two channels were internally milled at an upward angle into the interior walls of the upper crankcase casting. These channels were supplemented by a pair of matching scallops incorporated into the lower wall of the cylinder liner, as seen in the earlier cylinder images. Apart from providing the required swing clearance for the con-rod, these features would have had the additional effect of facilitating the passage of gas through the bypass to some degree. The lower outer edge of the cylinder liner was chamfered to further improve gas access to the bypass, as seen in the earlier images.

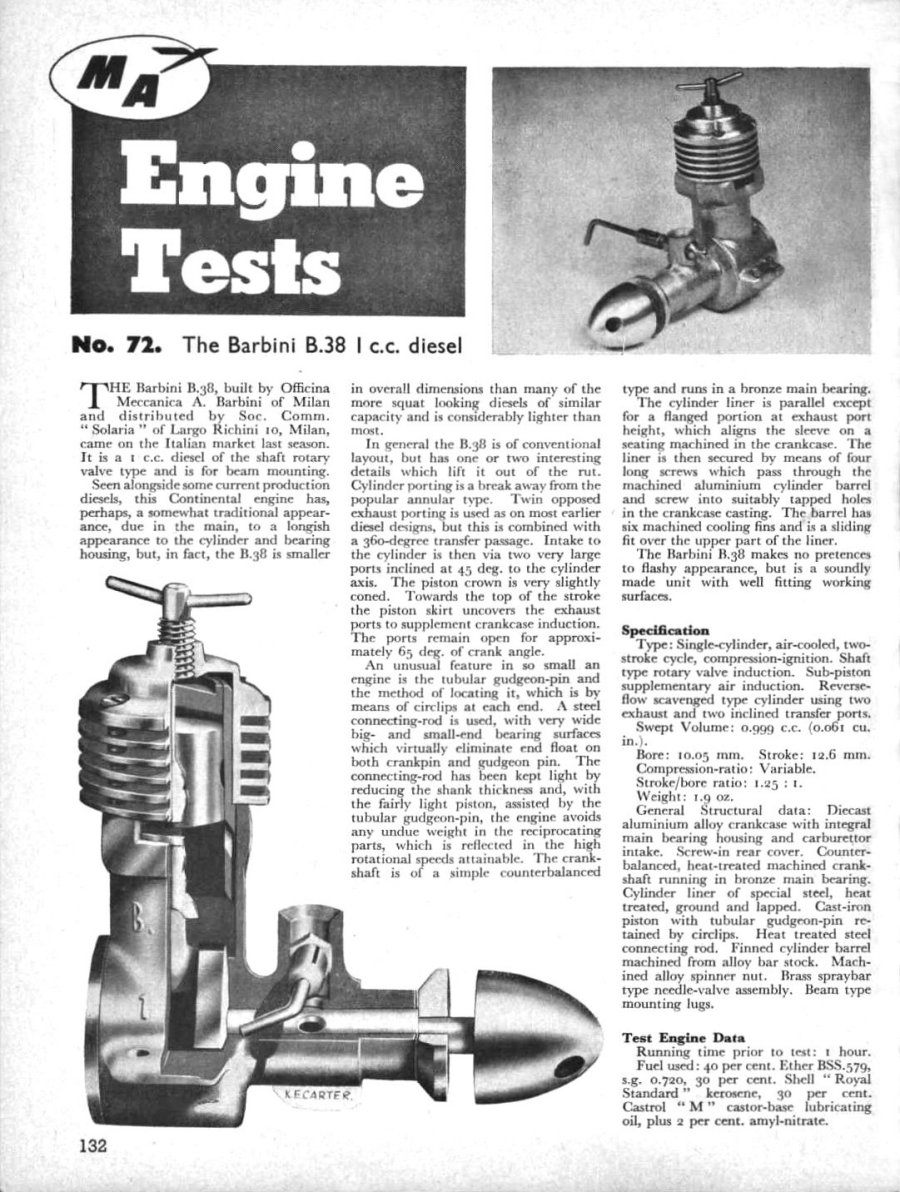

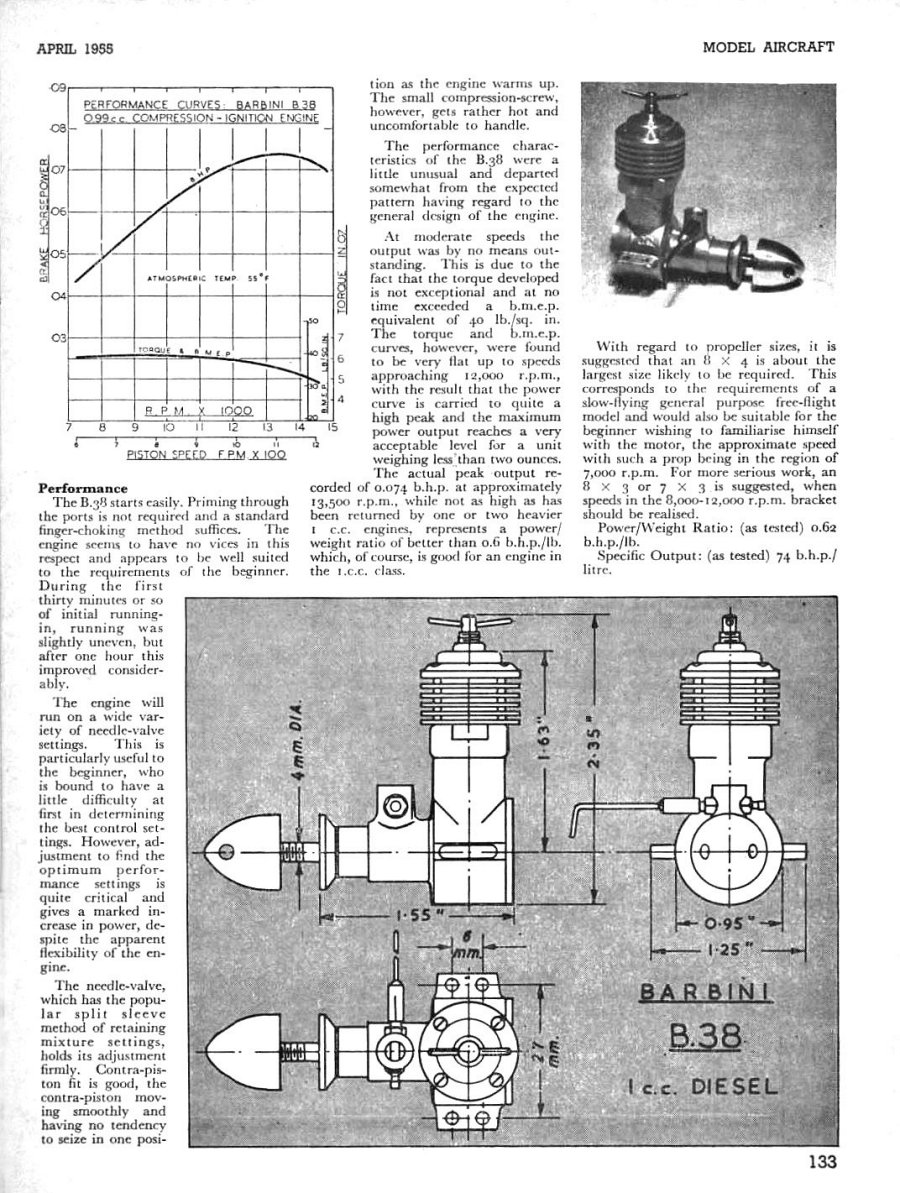

The prop driver was locked to the crankshaft in the conventional manner using a splined length of shaft just forward of the main journal. A nice touch on the early examples was the provision of a thin steel spacer between the rear face of the prop driver and the front of the main bearing housing, although this The standard of construction of this fine little powerplant was very high. Although no effort was made to clean up the gravity die-cast Along the way, the engine appeared in a number of minor variants. An amended model soon appeared which featured a lengthening of the externally turned portion of the main bearing housing. At some subsequent point the rounded spinner nut of the early examples As mentioned above, the early B.38’s had a transversely-mounted needle valve assembly. This put the needle very close to the spinning prop disc – not a good feature for safety. A further variant accordingly appeared some time later with a needle valve assembly which was angled back to place the control arm further from the prop disc. The final production models featured plain un-anodized cooling jackets along with a return to the shorter externally-machined length of the main bearing casting. The B.38 was included in the first part of Peter Chinn’s “International Engine Review” which appeared in the April 1955 issue of “Model Aircraft”. The companion plain-bearing Barbini B.40 diesel was also mentioned in this article, proving that it too was in existence as of early 1955. Interestingly, no Barbini glow-plug model was mentioned in the second part of this review which appeared in the May 1955 issue. Evidently the famous Barbini B.40 “Testa Nera” glow-plug model had yet to appear at this time. More of that model below in its place ……….. The Barbini B.38 on Test The Barbini B.38 was the subject of two published tests in the English-language modelling media. The first of these was Peter Chinn’s test which appeared in the April 1955 issue of “Model Aircraft”. For reasons which are now unclear, these tests were unattributed during this period, but there is no doubt at all that Peter Chinn was their author.

Chinn was most complimentary about the engine in general. Although he commented on the fact that the engine made “no pretences to flashy appearance”, he characterised it overall as “a soundly made unit with well-fitting working surfaces”. He reported that it started easily without the need for priming, with good response to the controls. The one issue that he reported was a certain sensitivity to the precise setting of the needle – although the engine ran well over a wide range of needle settings, he found that a considerable performance gain could be realized through very precise setting of that control. Even so, the output of 0.074 BHP @ 13,500 rpm recorded by Chinn was very much on the modest side by the standards of the day for an engine of this displacement. Despite this, Chinn was clearly quite favorably impressed with the B.38. He noted that although the engine’s output was rather on the low side for a 1 cc diesel, it reached “a very acceptable level for a unit weighing less than two ounces”. The resulting specific output of better than 0.60 BHP/pound weight was considered “good” for an engine of this displacement.

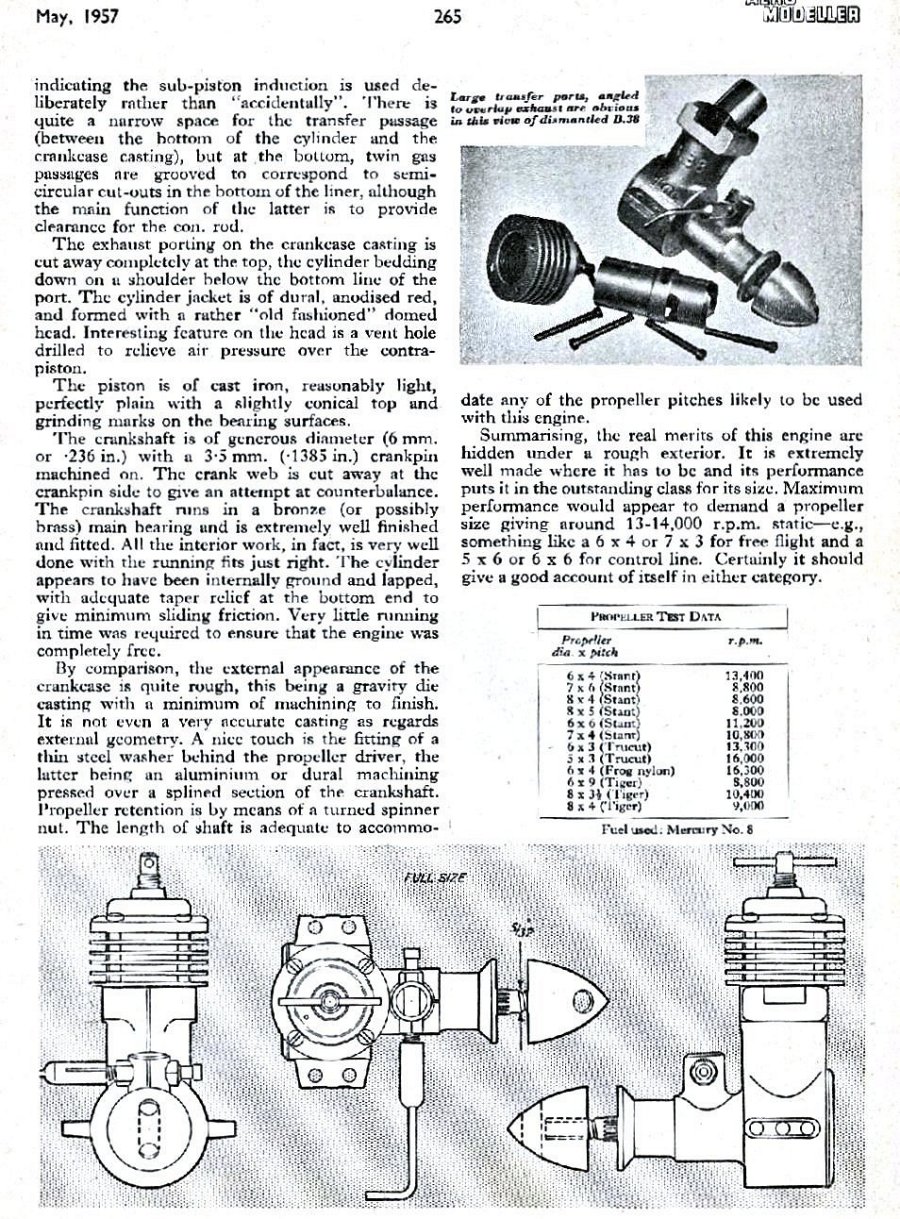

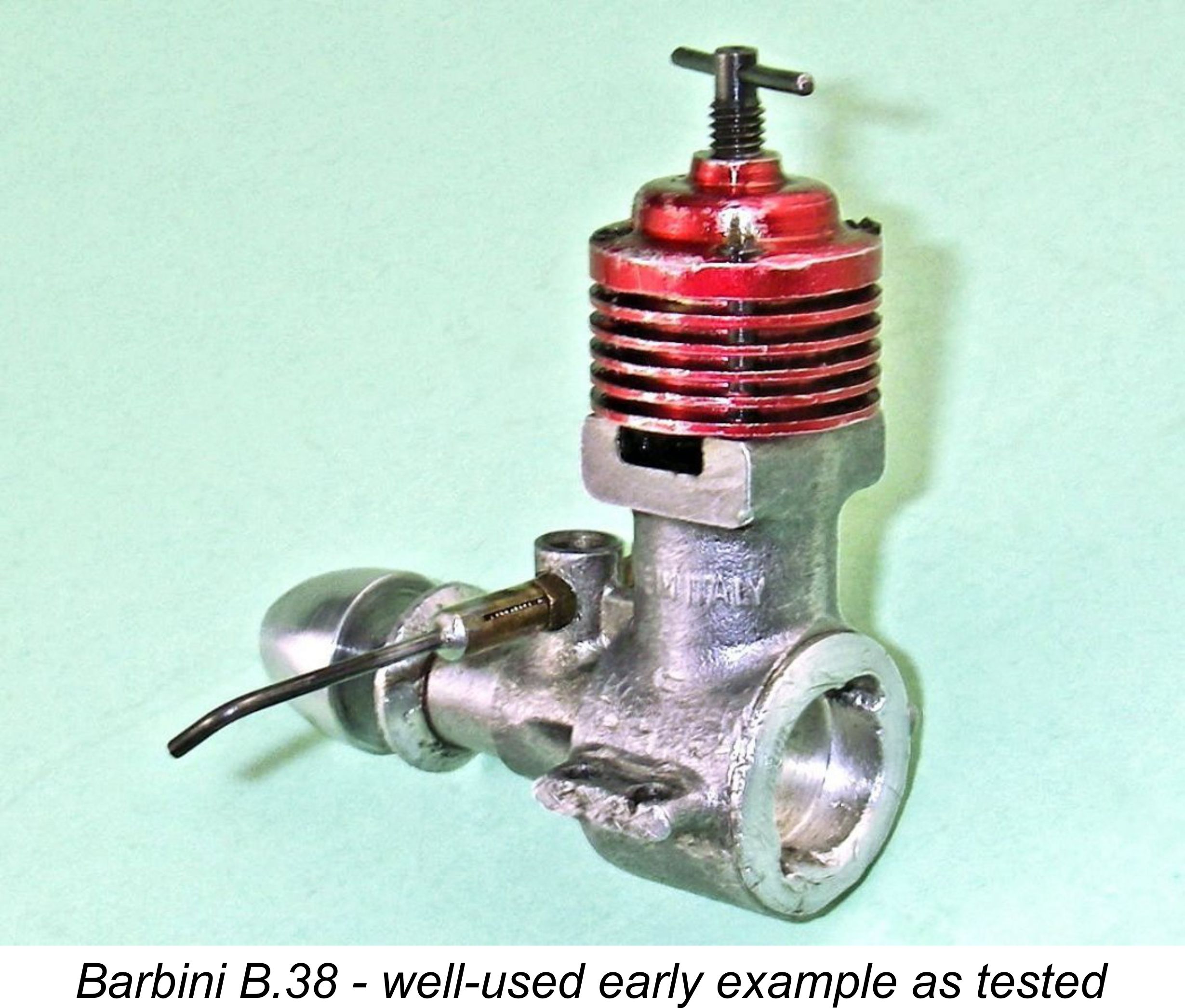

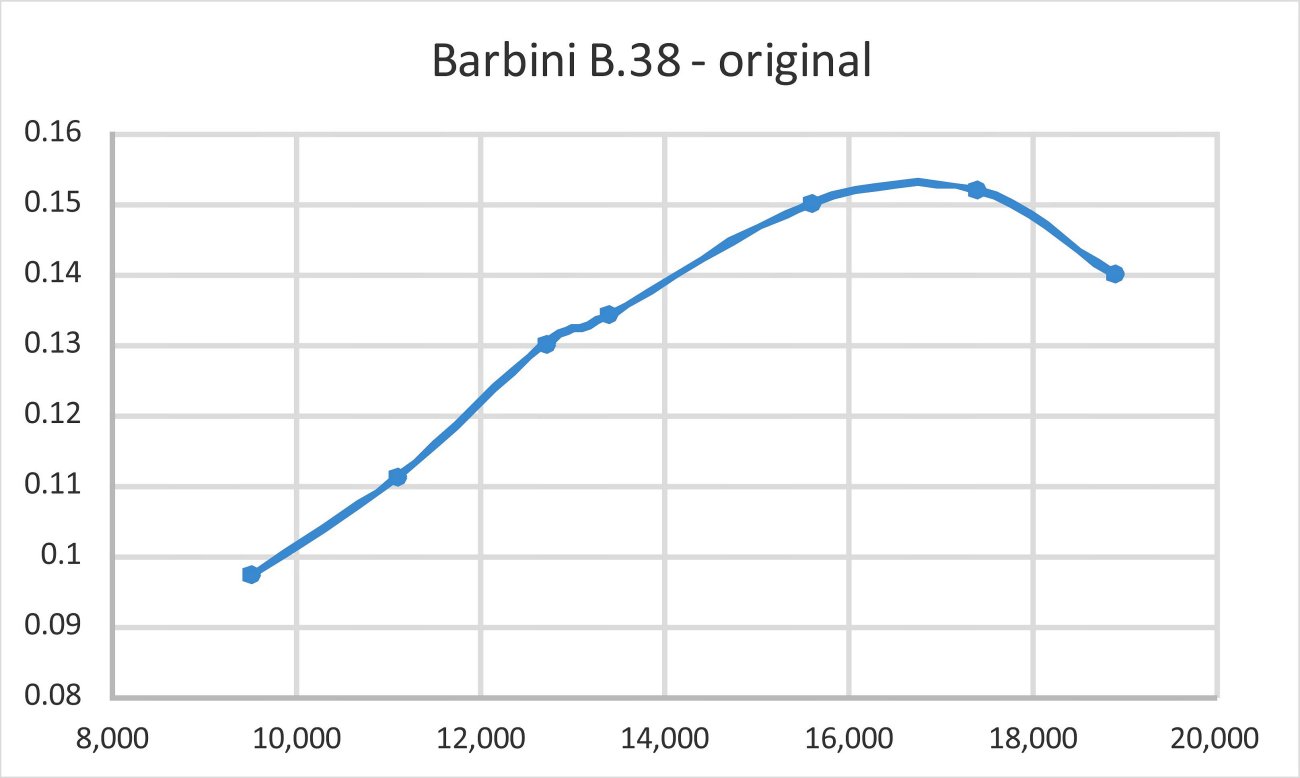

For whatever reason, the rival “Aeromodeller” magazine waited until May 1957 to release its own test of the Barbini B.38. It seems possible that certain unspecified design improvements had been incorporated into the engine by that time, since tester Ron Warring was able to extract a far more sprightly performance from his example than Chinn had done two years previously. This in itself was unusual - a review of the tests undertaken by Chinn and Warring shows quite conclusively that Chinn generally (but not invariably) found somewhat higher levels of performance than Warring for the same model. These differences must surely be down at least in part to differences in the testing and engine management procedures followed by the respective commentators. Regardless, Warring reported an output of 0.104 BHP @ 15,500 rpm on the basis of his testing. This placed the B.38 among the highest-performing 1 cc diesels of the time in question. It has to be said that the output recorded by Warring seems far more consistent with the engine’s main design features than the figures reported by Chinn. It is also very much more in line with the figures which I myself obtained on test, as recorded below. Warring was extremely impressed with the B.38, characterising it as “a remarkably fine Italian diesel” having a performance which he considered ”outstanding for an engine of this size”. He noted that while little attention had been paid to the engine’s external appearance, its internal fits and finishes were “of the highest possible order”. Precision where it counted ………… Like Chinn before him, Warring found the engine to be an easy starter without the need for priming. Response to the controls was also found to be good, the compression setting in particular being notably non-critical. Despite its long-stroke configuration, Warring found the engine to be essentially a high-speed design, requiring smaller props than usual for a 1 cc diesel to release its best performance. He suggested 6x4 or 7x3 props for free flight, with 5x6 or 6x6 items for control line. The key requirement for best performance was stated to be propping the engine for static speeds in the 13,000 – 14,000 rpm range. Subsequent present-day testing (see below) fully supports this recommendation. Warring concluded by stating that “the real merits of this engine are hidden under a rough exterior”. He summed I am able to add my own endorsement to that delivered by Warring. During the preparation of this article, I tested my own well-used but still highly serviceable example of the early variant of this engine. Although clearly showing the mileage, this example remains in completely original condition. It is very well freed-up through many hours of hard use, hence being right at the peak of its capabilities. I was frankly astounded at the performance delivered by the little beastie! In addition to starting and running just as well as its siblings appear to have done years ago for Chinn and Warring, it simply ran away and hid from another contemporary 1 cc engine from a different maker which I tested at the same time. The prop-rpm figures were so staggering, in fact, that I re-checked the calibration of my tachometer and then ran the entire series again, obtaining figures which were within 100 rpm of those noted first time around. Here they are:

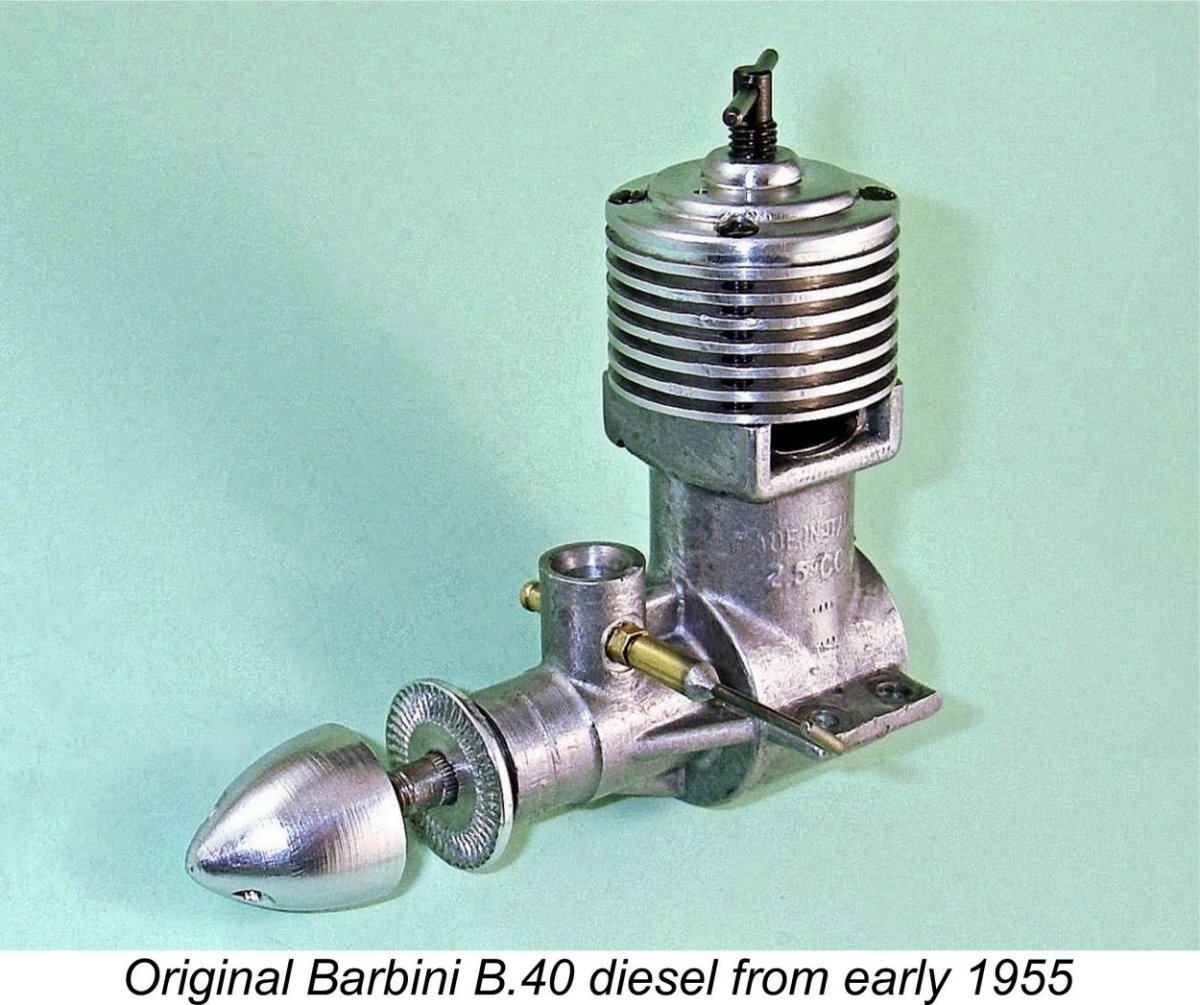

I can’t explain these results – I can only report them! The implied output of around 0.153 BHP @ 16,700 rpm is pretty hard to accept, but the set of test props which I used consistently generates figures for other engines which are well within the range of published numbers for those models. I can only speculate that my very “experienced” example of the B.38 is right at its performance peak, while those tested by Chinn and Warring were still a touch too “new” to realize their full potential. Or maybe I just have a good ‘un………….! As far as I can tell, the test engine has not been modified in any way. Whichever way you slice it, for me this test confirms that the Barbini B.38 was one of the outstanding 1 cc model diesels of the 1950’s and beyond. Full marks to Giovanni Barbini for a highly creditable achievement! In passing, it's worth noting Barbini's claim in the Italian-language instruction sheet supplied with this engine that it produced its maximum power at no less than 18,000 rpm! Viewed in this context, perhaps my results aren’t so far beyond expectations after all ………….! Enter the Barbini B.40 Series Beginning in early 1955, the year in which he turned 40 years old, Giovanni Barbini initiated the production of what was to become perhaps his most celebrated model, the B.40 of 2.5 cc displacement. He began with a plain bearing 2.5 cc diesel model which he simply designated as the Barbini B.40.

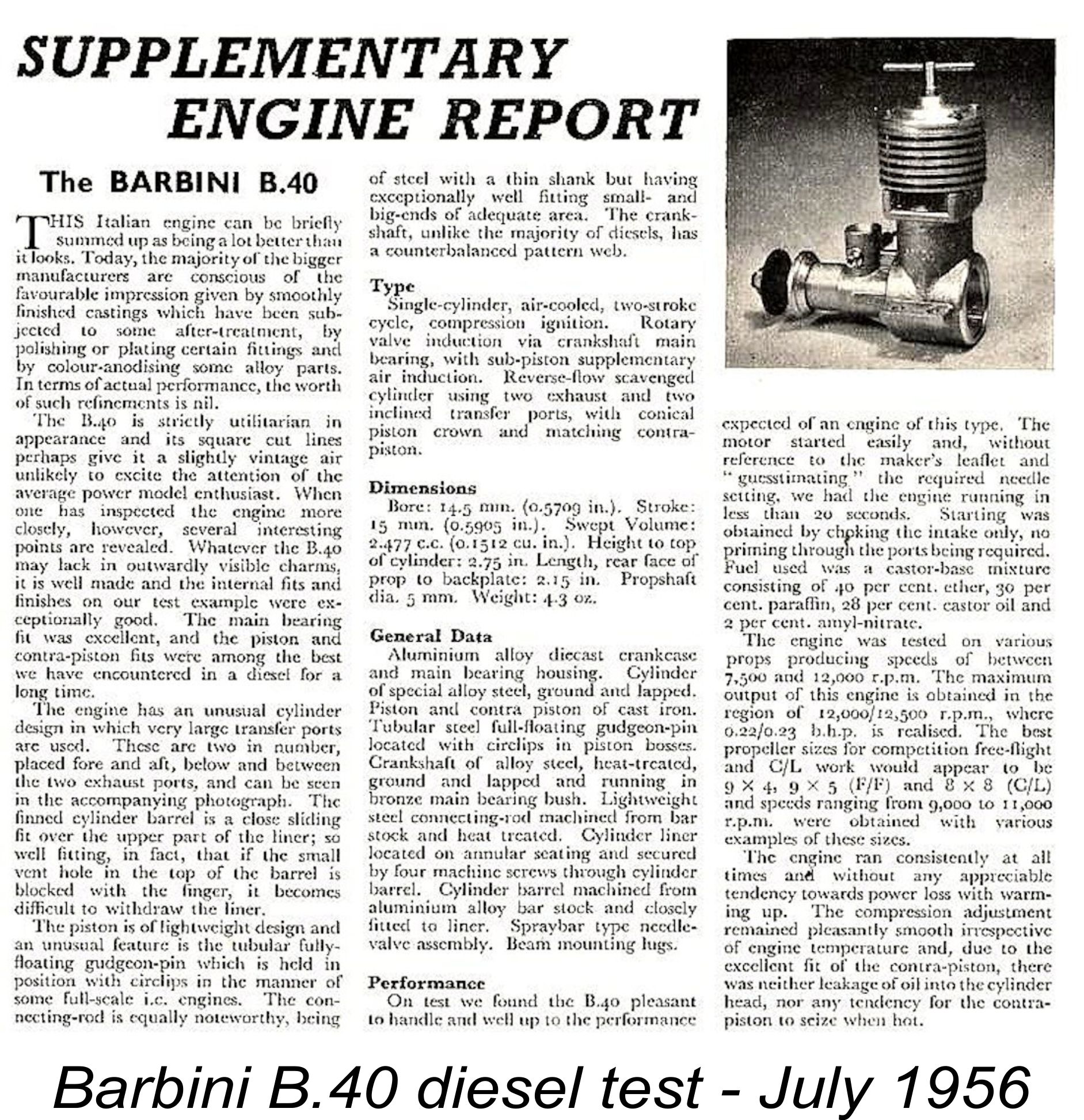

As noted previously, the existence of the Barbini B.40 diesel was first reported in Peter Chinn’s “International Engine Review” which appeared in the April 1955 issue of “Model Aircraft”. In the past, it has frequently been stated that the B.40 appeared in 1956, but Chinn’s evidence disproves this conclusively, as does the dating evidence provided by the engine's designation. Indeed, by late 1955 Chinn had an actual example of the engine in his hands for evaluation. At the time in question, new model engines were appearing on the market at a rate with which the model engine testers of the day were quite unable to keep up. A very far cry from the situation of today (2015) when electric technology dominates and present-day testers like my good mate Maris Dislers of “Aeromodeller” fame are hard put to find even one new I/C engine to test for a particular issue! How times change ………….. This situation led both Ron Warring of “Aeromodeller” and Peter Chinn of “Model Aircraft” to make up the shortfall by publishing condensed supplementary engine test reports from time to time over and above those more detailed reports which appeared in the regular series. These supplementary reports tended to be less detailed than the usual offerings in the main sequence, but they nonetheless provided a wealth of useful information.

Like the B.38, the new model displayed scant attention to external finish. The main gravity die-casting was once again left as-cast, with no attempt being made to clean it up. Even the color anodizing which had been applied to the B.38 was omitted at this stage. Chinn’s overall comment was that the B.40 was “strictly utilitarian in appearance, and its square-cut lines give it a slightly vintage air unlikely to excite the attention of the average power enthusiast”. Clearly feeling that the engine’s merits were such that it deserved attention despite what he saw as its unprepossessing appearance, Chinn then leapt to its defence. He stated outright that the B.40 was “a lot better than it looks”. He commented upon the efforts expended by many manufacturers to improve the external appearance of their products, setting such efforts in perspective by stating that “in terms of actual performance, the worth of such refinements is nil”. Chinn reported that the B.40 was very well made indeed where it counted. The internal fits and finishes were characterised as “exceptionally good”, while the fits of the piston and contra-piston were said to be “among the best we have encountered in a diesel for a long time”. This from a man who had been testing high-quality diesels from the likes of Oliver and David-Andersen…………….. Chinn’s description of the engine’s structural layout followed that of his earlier commentary on the 1 cc B.38 very closely. In performance terms, Chinn stated that the B.40 was “pleasant to handle, and well up to the performance expected of an engine of this type”. Starting was characterized as “easy” and the engine was reported as running “consistently at all times”. The perfect fit of the contra-piston came in for particular praise for its contribution to the engine’s excellent handling characteristics. Although no actual power curves were included in this supplementary test, Chinn reported a peak output of 0.23 BHP @ 12,500 rpm. This was actually a very respectable performance for a plain bearing 2.5 cc diesel weighing only 4.3 ounces in the context of the 1956 market. Coupled with the very high quality of the engine’s construction, Chinn’s report constituted a ringing endorsement of the efforts of Giovanni Barbini to produce a product of real quality and utility. Although I've never run a full test on my own example of this model, my experiences on the test bench bear out Chinn's assessment completely. The Glow-Plug Era Arrives At some point during the second half of 1955, Giovanni Barbini’s attention became drawn towards the potential of a glow-plug version of his then-new B.40 diesel. It’s extremely likely that a prime motivation for this decision was the knowledge that the 1956 World Control-Line Speed Championships were scheduled to be held on September 29th – October 1st, 1956 at Florence, Italy. Here was a golden "back-yard" opportunity to display the merits of the Barbini engines before both the Italian modelling public and the international audience. Barbini appears to have taken successful participation in this event as his ultimate goal in developing his new glow-plug model. In order to allow himself to focus upon the development and construction of the engine itself, he wisely elected to collaborate with a rising young Italian speed flier by the name of Giovanni Cellini.

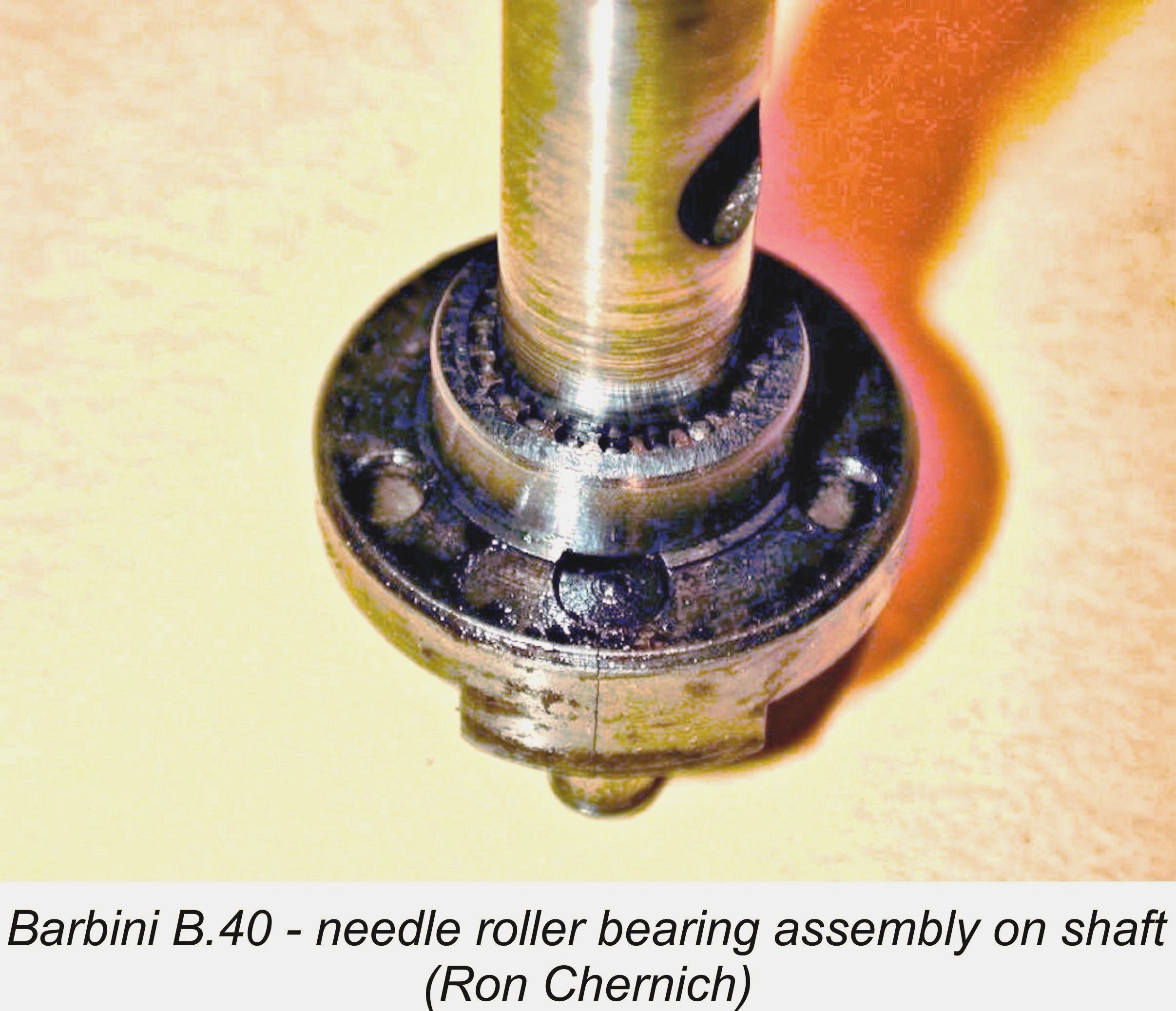

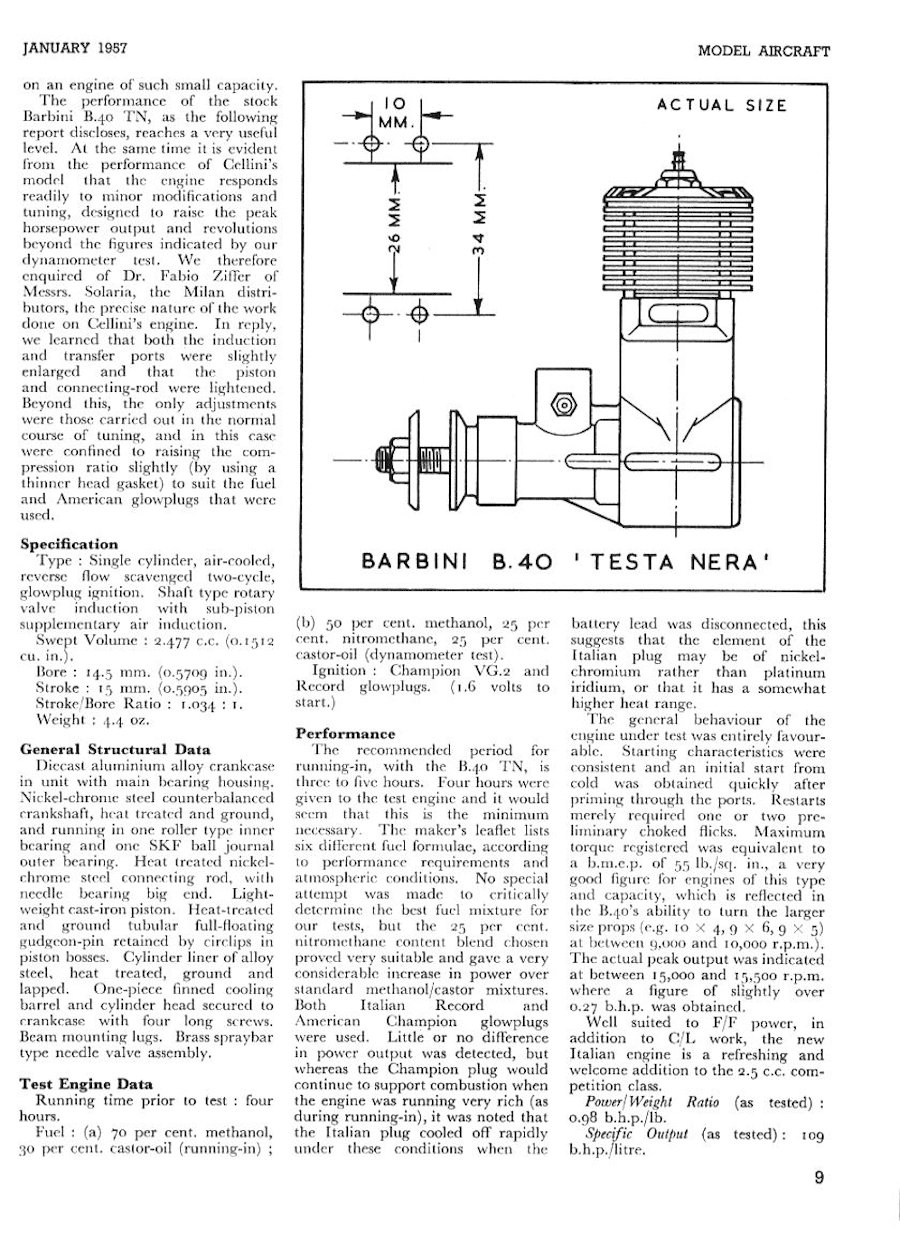

It’s worth noting at this point that the Barbini B.40 was alone among then-current speed engines in staying with both reverse-flow scavenging and long-stroke internal geometry. By this time all of the other successful speed motors were short-stroke designs which used the cross-flow loop scavenging arrangement pioneered in the USA during the 1940’s. The sole competing 2.5 cc glow-plug motor to retain reverse-flow scavenging was the Webra 2.5R from Germany, but that was a short-stroke design whose successes were mainly confined to the free flight field. Viewed in this light, Barbini’s competitors such as Jaures Garofali of Super Tigre must have anticipated little threat from this new design. How wrong they were soon proved to be ……….. Apart from the addition of the two small chamfers to the piston crown, the main departures from the earlier design were the configuration of the crankshaft and con-rod bearings. Looking first at the crankshaft, this featured an entirely novel combination of ball and roller bearings instead of the usual twin ball-races. Even more oddly, the ball-race was positioned at the front of the shaft, with its needle roller partner supporting the rear of the shaft. The ball-race was retained in position by a circlip. Incidentally, Bruno Barbini believed that this front ball race was the sole component ever "bought in" by his uncle's company - everything else was made in-house.

This highlights one of the generally-overlooked features of this fascinating and highly original design. It’s common knowledge that a needle roller bearing is designed to accommodate radial loadings only – it has absolutely no effect in terms of resisting axial loads. This was a key design weakness of the Rivers range of model diesels from England. In the case of the Rivers models, no attempt was made to address this issue – those engines generated just as much friction as a plain bearing model when resisting axial loadings. However, Giovanni Barbini was not the man to allow an issue of this nature to remain un-addressed in his design! His solution was to arrange things so that the axial load was resisted by the ball-race at the front of the main bearing! I’m presently not aware of another commercial model engine which used this approach. This of course explained the use of the circlip to retain the front ball race – it had to resist the axial thrust resulting from the action of the airscrew. An extremely ingenious approach, and a further example of Barbini’s talent for original thinking. Too bad that Rivers didn't follow suit, as they could easily have done. Even so, the choice of a needle roller bearing at the highly loaded rear of the crankshaft requires an explanation, since a needle roller bearing tends to generate substantially higher levels of friction and viscous drag than a ball-race, particularly at high speeds. Giovanni Barbini was an extremely competent engine designer who would have been well aware of this fact. This being the case, he would not have adopted such as arrangement in an engine intended for all-out competition work without a very good reason. Consideration of the design factors involved leads one to the almost inescapable conclusion that the reason for the adoption of this layout was Barbini's desire to use a main bearing journal having a sufficiently large diameter to accomodate an internal gas passage of adequate dimensions. The chosen journal diameter was a very generous 8.5 mm, stepping down to a 5 mm diameter at the front. A ball race having a 5 mm internal Of equal interest was the use of a needle roller bearing at the con-rod big end. This was a feature that had not been seen since the heyday of the famous Dooling 61 from America. Its use in an engine of this smaller size was unusual, to say the least. The bearing in this case consisted of a cageless set of 15 needle rollers of the same size as those used on the rear main bearing. These were retained in position on the pressed-in crankpin by a thin steel washer and circlip. The outer race for the big end rollers appeared to have been shrunk into the big end aperture of the steel con-rod. The small end bearing of the rod was unusually long. In terms of its timing, the engine once again placed considerable reliance upon an extended sub-piston induction period. Transfer port timing was somewhat amended from that of the earlier diesel model thanks to the addition of the chamfers in the piston crown at the transfer port locations. These chamfers increased the overlap of the exhaust ports by the transfer ports, increasing the engine’s transfer period to some degree. As usual with Barbini engines, the quality of the glow-plug B.40 was of the highest order. It should be clear from the above description that this complex design placed very severe demands upon both manufacturing precision and care in assembly. The plethora of minute rollers and circlips would have posed a significant assembly challenge all on their own! It’s greatly to Giovanni Barbini’s credit that he rose so successfully to meet these challenges. World Championship Success

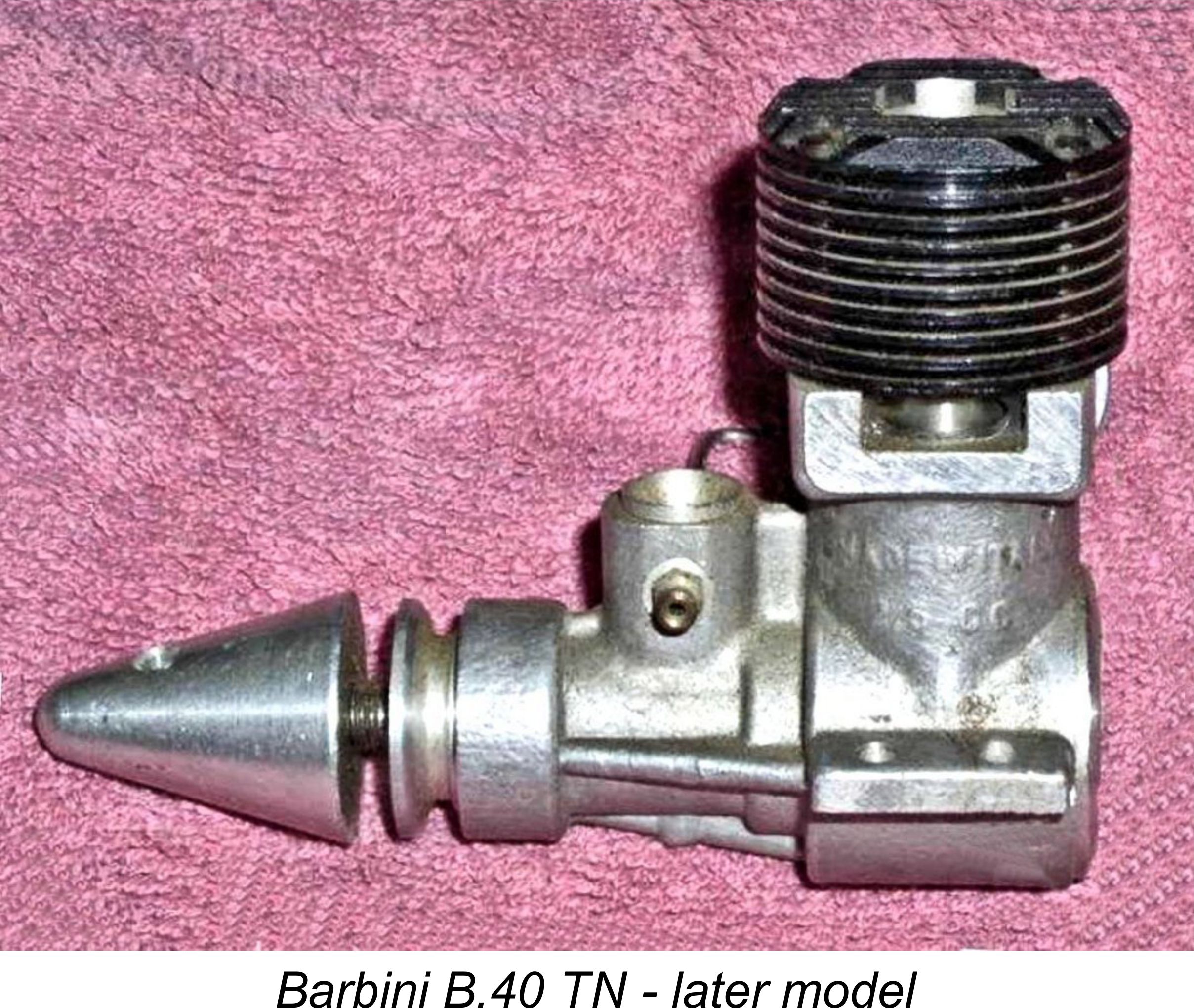

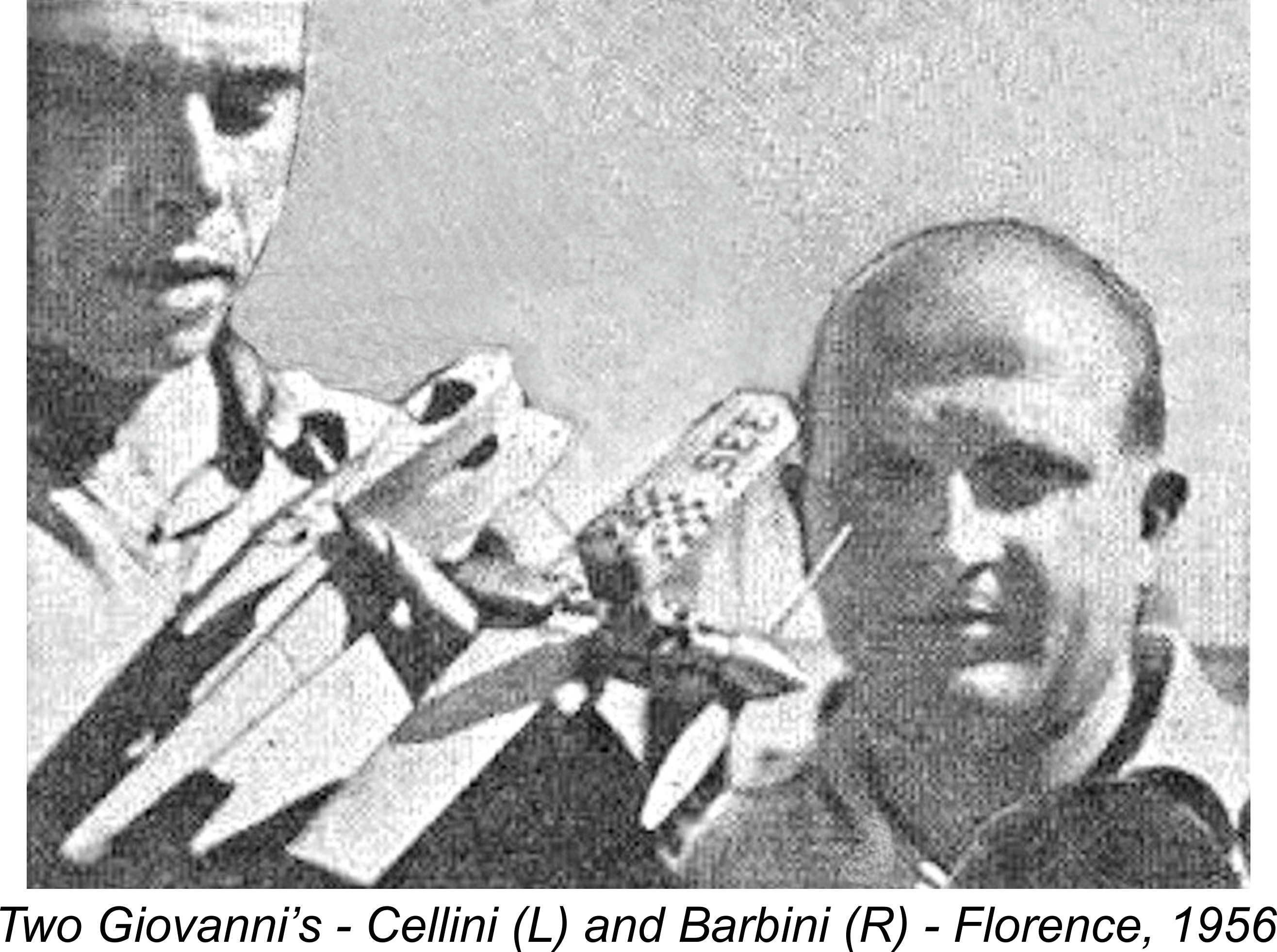

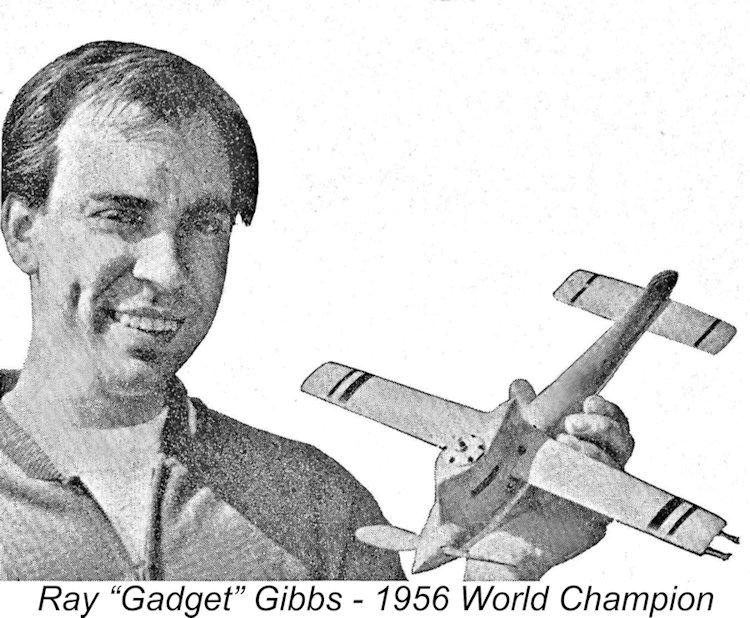

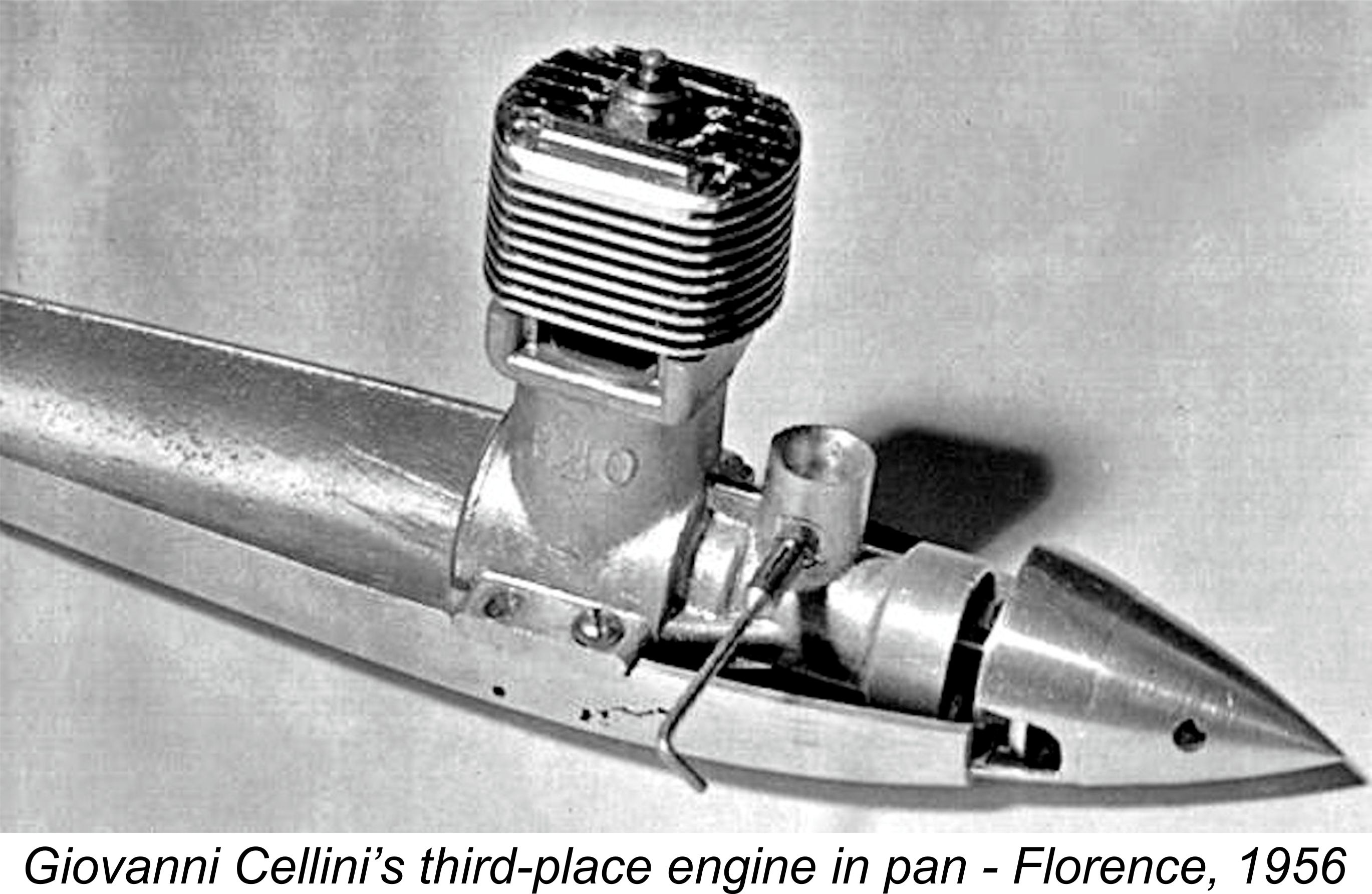

By the time of the World Championship meeting at Florence in late September, Barbini and Cellini had had ample time to sort out both the engine and model which Cellini was to use in the contest. Barbini accompanied Cellini to this event to oversee the International competition debut of his new creation in person. The attached photograph of the two of them extracted from the “Aeromodeller” report on the contest is the sole image of Giovanni Barbini that I’ve so far been able to find. If any reader has better images, please share them – this man is worth remembering! The results must surely have exceeded even Barbini’s expectations. On his first flight, Cellini returned a At this point, with one round to go, Cellini and his Barbini found themselves in second place, only 6 km/hr shy of the top spot! Cellini gave it his best in the third round, but was unable to improve on his existing best speed. This left the way clear for Gibbs to attempt to beat his own time, which he did quite convincingly on his third attempt with an improved speed of 211 km/hr (131.3 Unfortunately for Cellini, who had appeared secure in second place, Miclos Vitkovics of Hungary, who had shown little potential in the first two rounds, found the sweet spot in the third round with his BRMV Special motor (constructed by Vitkovics and his compatriot Rezső Beck, hence the initials forming the engine's name), recording a speed of 205 km/hr (127.4 mph) to displace Cellini into third place. Even so, the achievement of Barbini and Cellini had been astonishing. The new B.40 had finished on the podium as the top commercial engine in the contest, Indeed, the engine used by Cellini was surprisingly close to stock. Peter Chinn subsequently approached Dr. Fabio Ziffer of Solaria (the original Barbini distributors, remember) to inquire about the extent of the modifications applied to Cellini’s engine. Dr. Ziffer informed Chinn that these were relatively minimal. Both the induction and transfer ports were slightly enlarged and the piston and con-rod were both lightened even further. Beyond this, the only modifications were the usual fine adjustments of such factors as the compression ratio, fuel and plug. The compression ratio of Cellini’s engine was raised slightly through the use of a thinner head gasket. This was done mainly to match the American glow-plugs and specific fuel formula that were used in the contest. Chinn included this information in his January 1957 test of the B.40 TN, of which more in its place below. So ended Barbini’s first attempt to show the world what his engines could achieve. It has to be said that he could not realistically have hoped for a better outcome! The sound emanating from Bologna was probably that of Super Tigre boss Jaures Garofali gnashing his teeth……… The Range Expands Encouraged by this success, Barbini proceeded with plans to further expand the range of configurations in which the B.40 was offered. It was at this point that he began to increase the use of different hues of colour anodizing on the cooling jackets to distinguish the various models. The glow-plug speed engine which had served Cellini so well received a black-anodized head, being known thereafter as the Barbini B.40 “Testa Nera” (Black Head), generally shortened to the Barbini B.40 TN.

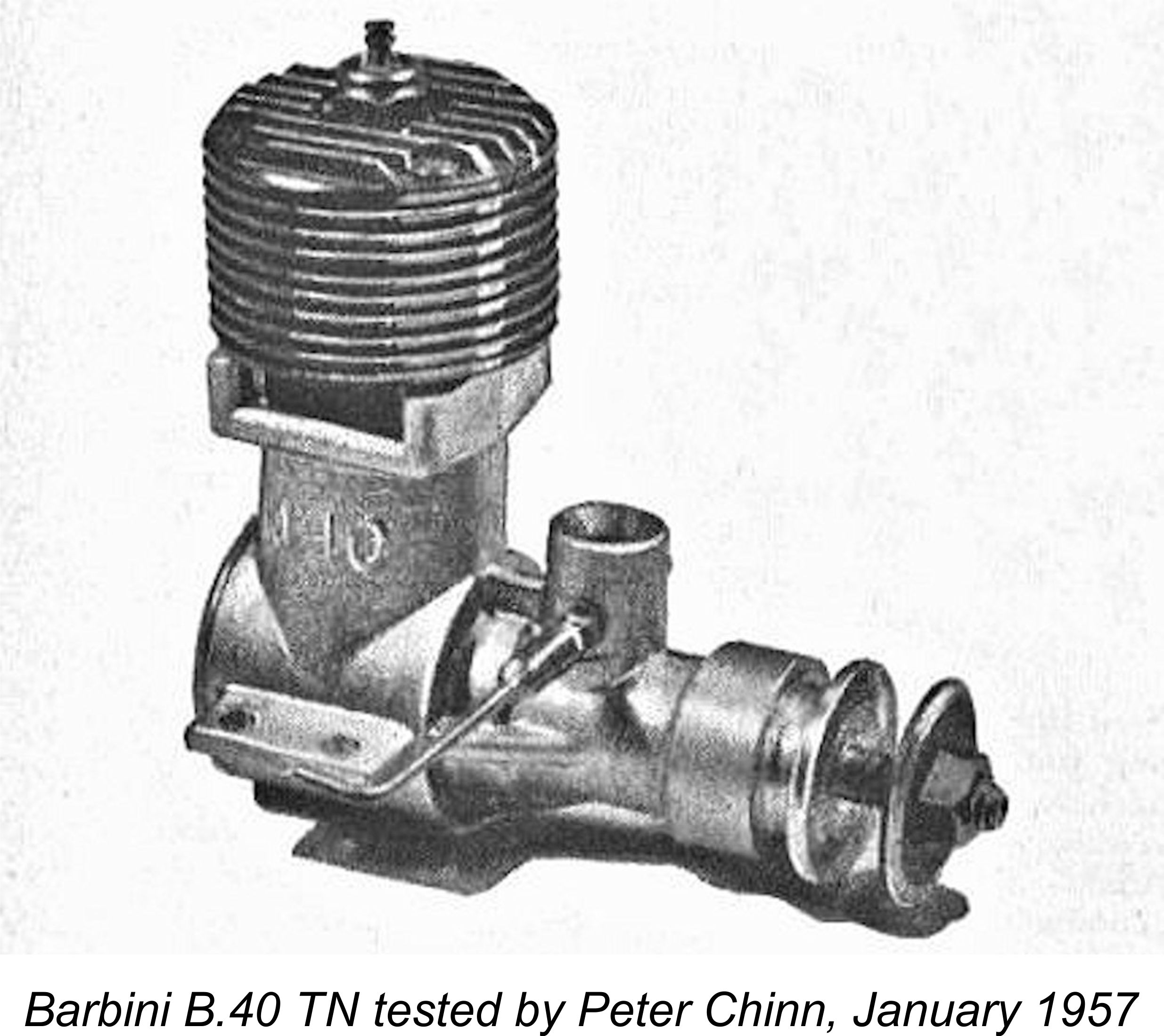

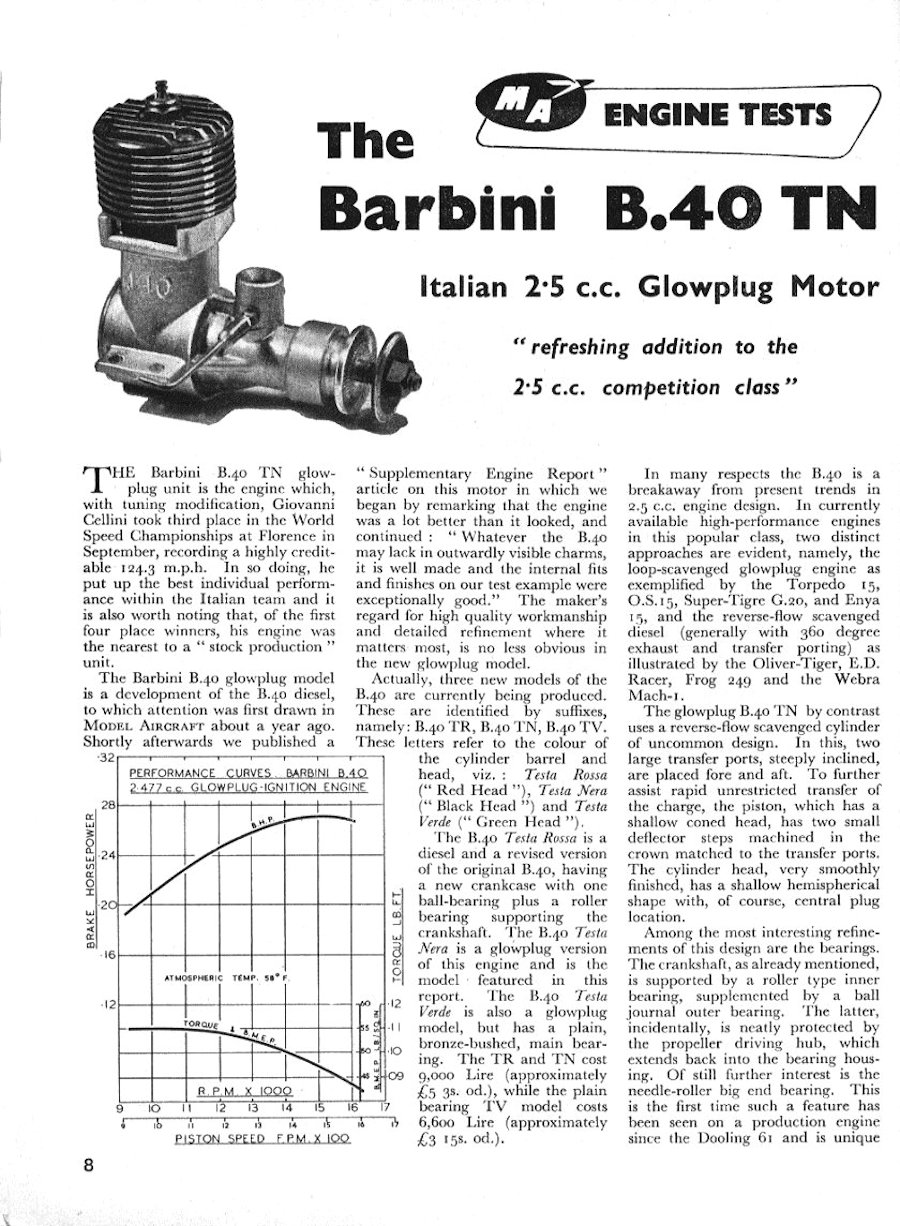

The immediate success of the glow-plug B.40 TN had of course drawn everyone’s attention to the engine in its glow-plug configuration. Giovanni Barbini was certainly sufficiently impressed to move quickly to expand his range of glow-plug models. Plain bearing glow-plug versions of both the B.38 and B.40 appeared in due course to join the other models in the range. The glow-plug version of the B.38 had a black anodized head like the all-conquering (well, almost!) B.40 TN, while the plain bearing B.40 glow-plug model was given a green cooling jacket and designated the Barbini B.40 “Testa Verde” (Green Head) or B.40 TV. Naturally, a result such as that achieved by Cellini on the international stage using a newly-introduced commercial motor caught the attention of the model engine commentators of the day. Moreover, the marque appears to have come to the notice of the international marketplace as well. The “Over the Counter” feature in the January 1957 issue of “Model Aircraft” summarized the range as it stood by that time, also announcing that arrangements were then being made for KeilKraft to begin importing the engines from Italy. This latter announcement is interesting insofar as to my knowledge there is no advertising or other evidence that this arrangement ever bore fruit. In all likelihood, Barbini’s previously-noted very modest production rate was insufficient to provide the necessary surplus to permit commercial-scale export of the Barbini engines. The Barbini B.40 TN on Test Naturally, engine testers like Peter Chinn couldn’t wait to get their hands on an example of the B.40 TN which had so surprised everyone with its performance in the 1956 World Control-Line Speed Championships. Chinn appears to have acquired a test example quite soon after its successful appearance in that event, since his report on the B.40 TN appeared in the same January 1957 issue of “Model Aircraft” in which the range was mentioned in the “Over the Counter” feature.

Chinn began by recalling the engine’s World Championship success in the hands of Giovanni Cellini. He noted that the engine had been the highest-placed commercial model in that contest. He praised the quality of the engine’s construction very highly, commenting that the manufacturer’s dedication to fine workmanship where it counted was just as evident in the B.40 TN as it had been in the case of the B.40 diesel model tested during 1956. Chinn’s description of the engine matched that already given in this article, leaving no requirement to repeat it here. Perhaps his most pertinent comment was the fact that the B.40 TN stood alone in continuing to use reverse-flow scavenging in a control-line speed context. Clearly Chinn did not consider the Webra 2.5R to fall into the speed engine category, as my own tests have shown that it might easily have done. Chinn also reported on the previously-noted modifications which had been made to Cellini’s engine. These were actually surprisingly limited in scope considering the engine's evident performance. In terms of the B.40 TN’s performance, Chinn endorsed the manufacturer’s recommendation that a minimum of four hours running-in was necessary to release maximum performance. He applied this figure to his test example. He found that the fully run-in engine was easy to start, although a port prime was apparently required for cold starting. He characterized the engine’s overall behaviour under test as “entirely favourable”. Using a fuel containing 25% nitromethane, Chinn recorded a peak output of 0.272 BHP @ 15,400 rpm. By the standards of 1956 this was a very respectable output indeed for a commercial glow-plug engine of this displacement. Chinn did however note that the performance achieved by Cellini reflected a somewhat higher output, implying that the engine “responds readily to minor modifications and tuning designed to raise the peak horsepower output and revolutions beyond the figures indicated by our dynamometer test”. It was this conclusion which led him to inquire about the exact nature of the modifications applied to Cellini’s engine, as mentioned earlier. It will be recalled that these turned out to be relatively minor. A more pertinent factor was likely the fuel used – Barbini recommended a fuel containing 40% nitromethane and 12.5% nitrobenzene for competition work, and such a mixture was most likely used by Cellini. This would have raised performance considerably all on its own. Chinn summarized his very positive findings by stating that the Barbini B.40 TN was “a refreshing and welcome addition to the 2.5 cc competition class”. Once again, a bouquet for Signor Barbini! As one would expect, the attention of the staff of the rival “Aeromodeller” magazine had also been drawn to the Barbini range as a result of Cellini’s success. The B.38 and B.40 were both mentioned in the “Motor Mart” feature of the February 1957 issue of the magazine, with the comment that the B.40 had been the top-finishing commercial engine in the 1956 World Control-Line Speed Championships. Oddly, there was no mention of the possible involvement of KeilKraft in the distribution of the engines in Britain ………

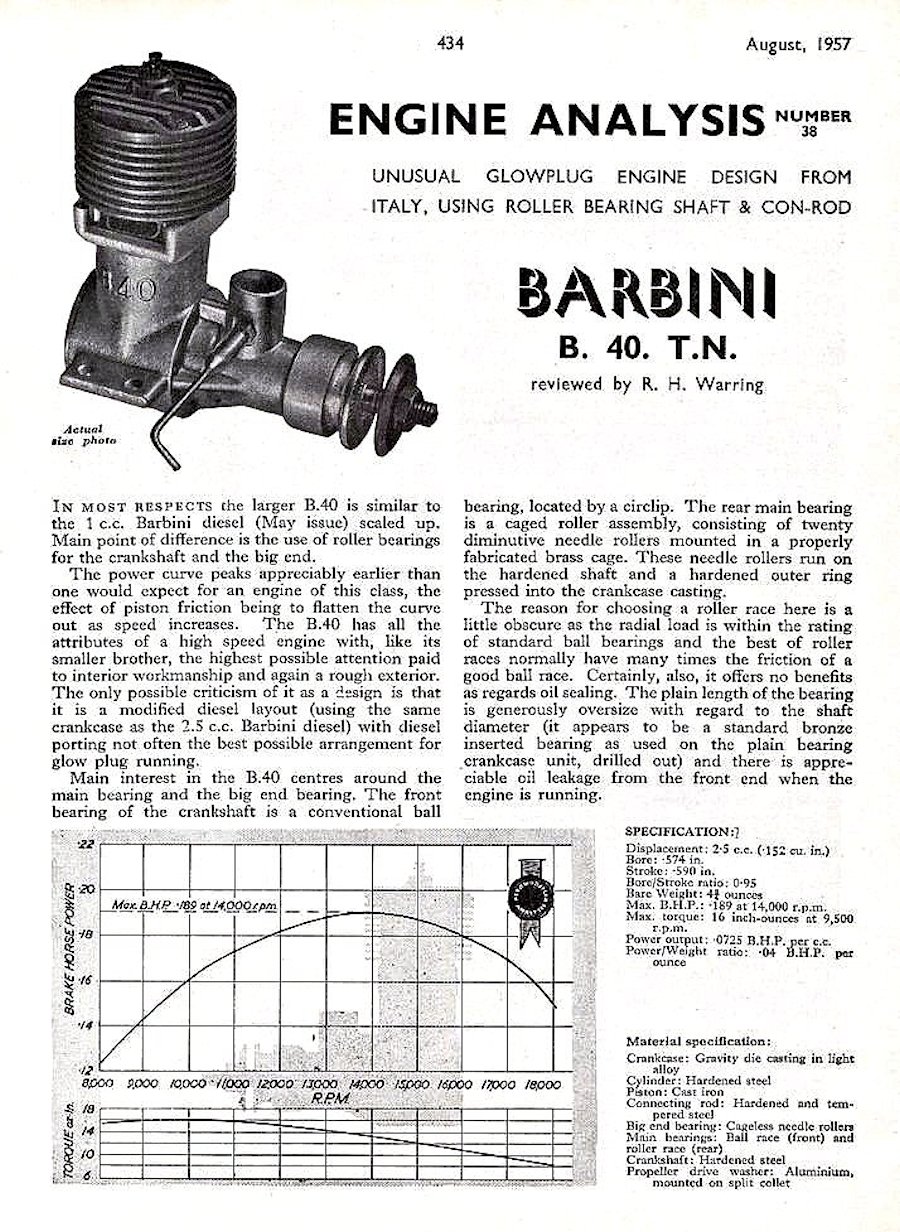

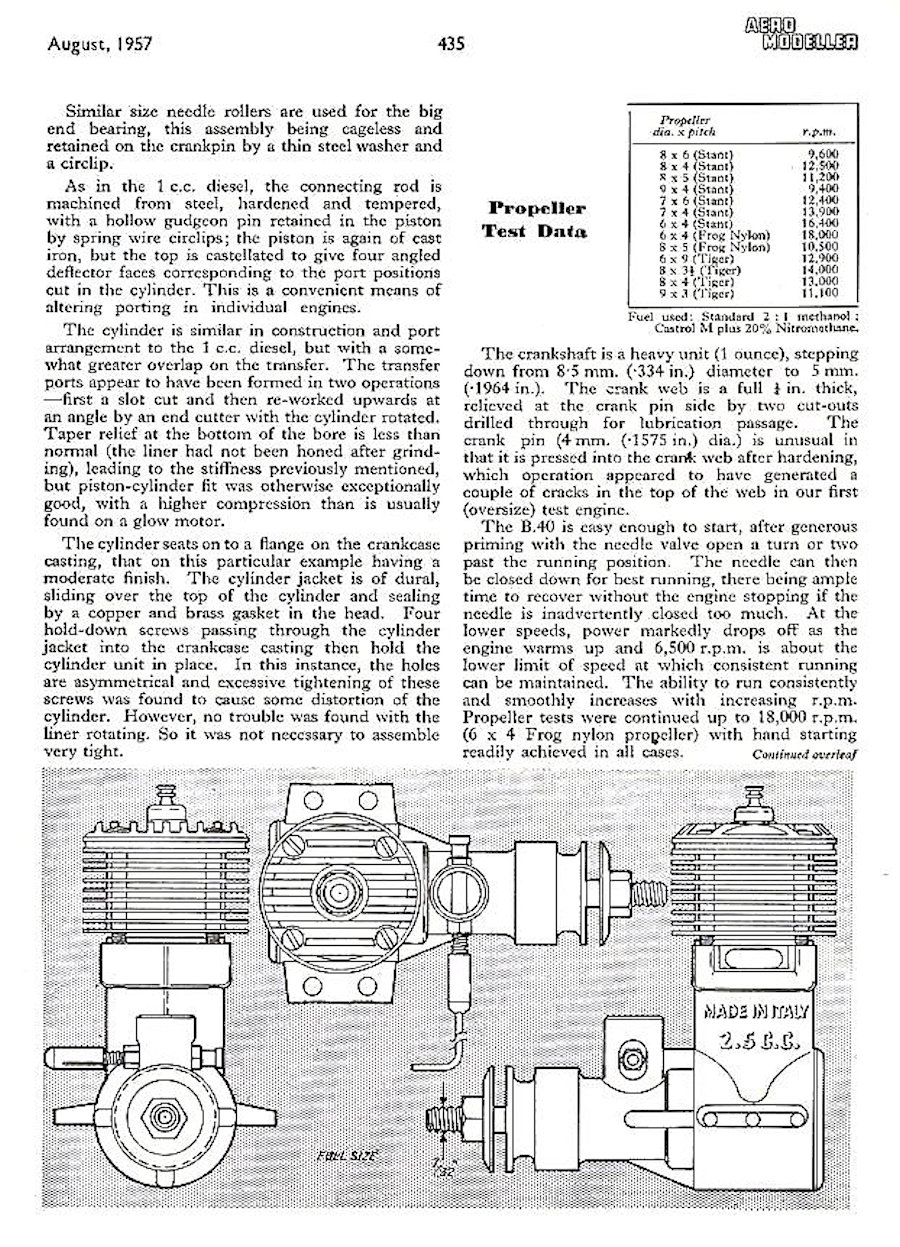

In that context, the April 1957 “Motor Mart” article also reported that the manufacturer had undertaken not only to correct this issue for the “Aeromodeller” example, but to advertise the fact that some (but apparently not all) engines supplied up to that point might not meet International regulations. Moreover, Barbini undertook to rectify the problem with any oversized engines returned to him for attention, at no charge to the customer. A mark of real integrity on his part. Peter Chinn also commented upon this issue in his “Accent on Power” column in the June 1957 issue of “Model Aircraft”. The cause of this problem was stated as having been related somehow to the hardening process applied to the crankshaft, which had apparently led to the creeping-in of some small errors in the crankpin placement. The result had been that some (but not all) examples of the B.40 had been supplied with very marginally over-long strokes. Signor Barbini was once again commended for his stated willingness to rectify any such problems in engines returned to him for that service. It appears that he was a man of considerable integrity. “Aeromodeller” magazine’s test example was soon rectified and re-tested by Ron Warring, with the resulting test report being published in the August 1957 issue of the magazine. This test added little to the information already presented in Chinn’s earlier test of the engine. Warring praised the engine’s standard of workmanship and general handling qualities very highly, as people had by then come to expect from Barbini products.

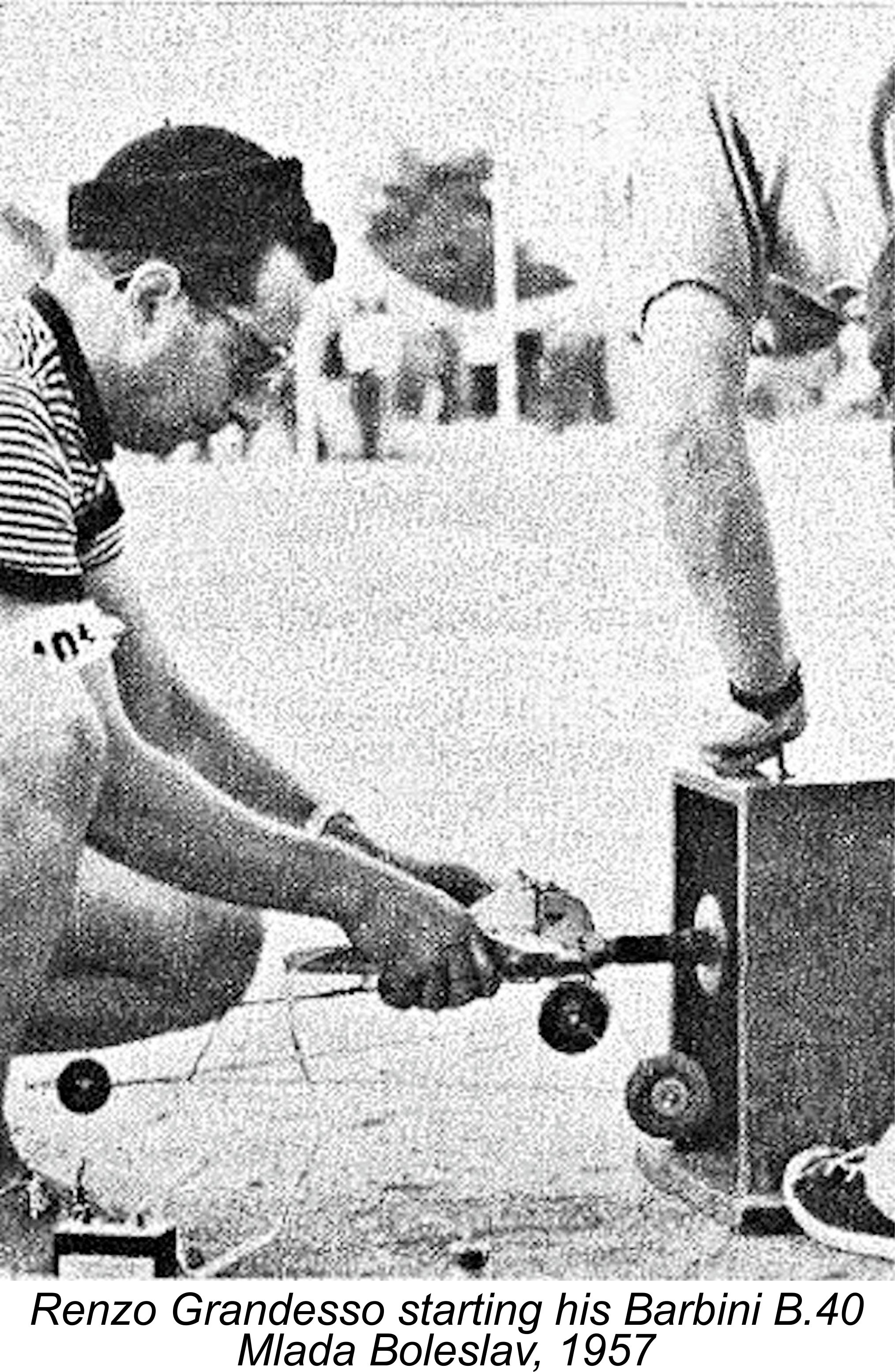

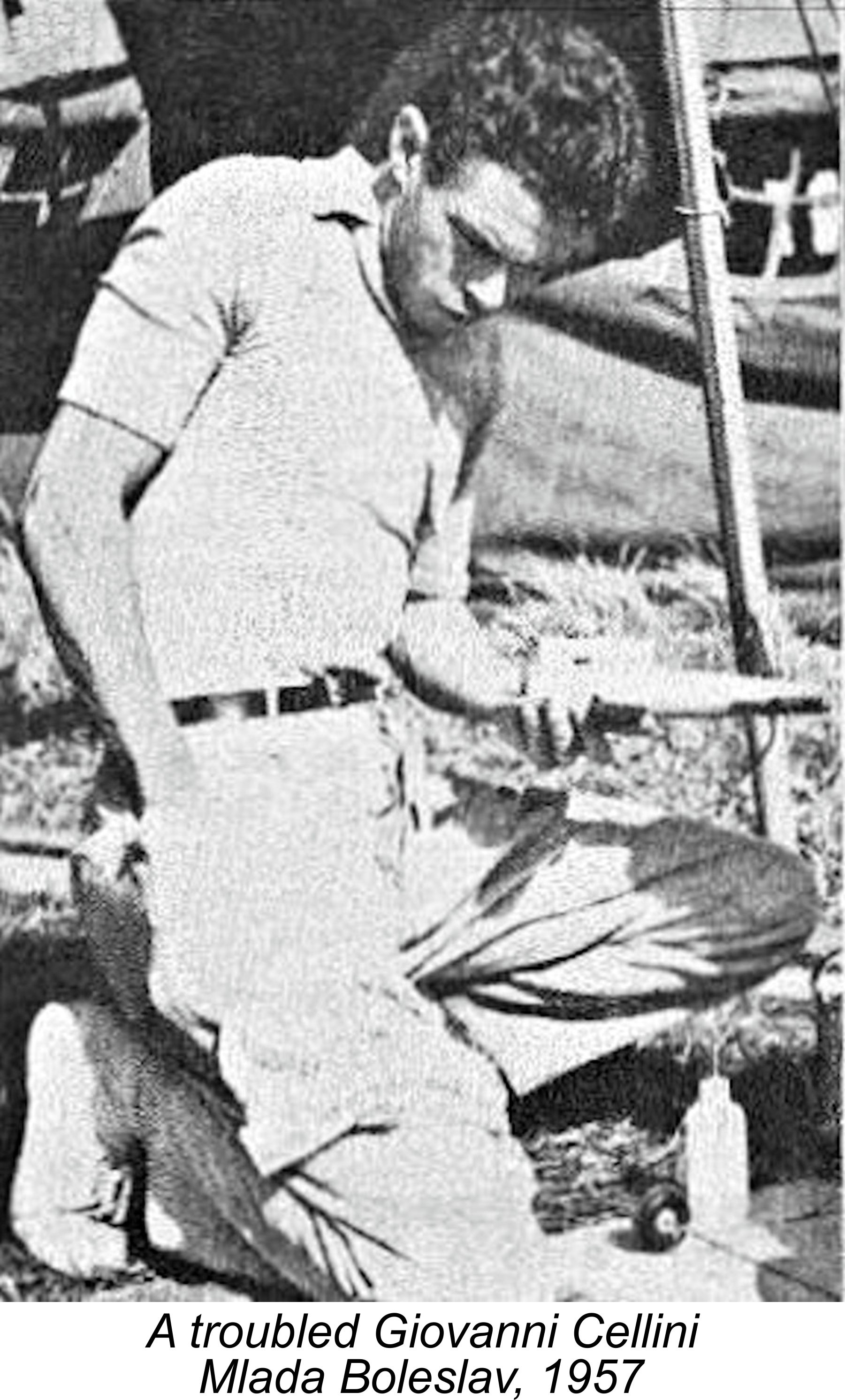

The one area in which Warring’s test presented a real There seems to be no possibility that an engine having such a weak performance as that measured by Warring could have achieved the results obtained by Cellini, leading us to the inescapable conclusion that Chinn’s figures are surely far closer to reality than those recorded by Warring. It seems possible that Warring used a fuel containing a far lower nitromethane content than Chinn, but unfortunately he did not specify the fuel with which his figures were obtained. Warring’s dismal figures notwithstanding, it must surely be clear from the results achieved that a good example of the B.40 TN was a highly competitive powerplant by the standards of 1956/57. Its potential was soon to be put to the test once again. Further World Championship Success Doubtless encouraged by the 1956 result, Barbini decided that his engines would once again be represented at the 1957 Control Line Speed World Championship meeting to be held at Mlada Boleslav, a small town located some 57 kilometres from Prague, Czechoslovakia (now the Czech Republic). For unspecified reasons he was unable to attend this event in person, but he did participate by preparing an engine for the use of Renzo Grandesso of the official Italian team. Giovanni Cellini returned with the same engine that he had used the previous year. Pete Wright of the British team also entered the contest with a Barbini-powered model – a high compliment to the international reputation of the B.40 TN at that time. By this time, the World Championship had effectively resolved itself into a two-tier competition - those competing for the top placings using the tool-room "specials" from State-sponsored institutions and individual constructors which were unavailable to the general public, and those who were using carefully-prepared examples of commercial engines which anyone could buy. By default, the Barbini-powered entries fell into the second category - they stood virtually no chance of taking the Championship, but were well in the hunt for the honor of finishing at the top of the commercial engine category. This was presumably Barbini's goal at this event. The main opposition to the Barbini squad in the "commercial engine" category would clearly come from Super Tigre. Apart from Grandesso and Cellini, the other members of the Italian team were equipped with the new lapped-piston Super Tigre G.20V engine. Despite being bas 1956 World Champion Ray Gibbs showed up again with an improved Carter Special, but sadly (for him!) the engine expired terminally during its first flight when it was doing an estimated 215 km/hr (133.595 mph) based on timing of the flight to the point where the engine failed). This kind of performance would certainly have put Gibbs in line to repeat as champion, but unfortunately the damage to the one-off engine could not be repaired, putting him out of the running since his reserve model and motor were not up to the same standard.

In the second round, Pete Wright changed over to the fuel used by Ray Gibbs, but could only manage a speed of 165 km/hr (102.526 mph). Apparently the motor sounded better on the ground than it did in the air! Grandesso managed a fairly respectable speed of 197 km/hr (122.410 mph) in this round, becoming the top Barbini user in consequence, but Cellini once again failed to register a time as a result of ongoing motor troubles. So it all came down to the final round. In this round, the Czechs with their MVVS tool-room specials finally showed what they could do. Josef Sladky returned a speed of 216 km/hr (134.216 mph) to take first place for the second time in three years, while Mir Zatocil and Frant Pastyrik filled out the next two places at 214 km/hr (132.973 mph) and 208 km/hr (129.245 mph) respectively. A clean sweep for the Czech team!

While sixth place may not sound like much, it actually represented the best performance by any member of the Italian team, once again leaving all of the new works Super Tigre G.20V motors well behind. The best Super Tigre speed in the contest was the 198 km/hr (123.03 mph) recorded by Super Tigre employee Amato Prati in the second round. For Super Tigre designer and team leader Jaures Garofali, this outcome must have really rubbed salt in the wound left over from the similar result from 1956! So once again the Barbini B.40 TN had emerged as the top-finishing commercial motor in the contest – all of the higher-placed finishers used individually-prepared “works specials”. It's true that this statement might be challenged by supporters of Hungary's Gyula Krizsma, who finished fourth with a speed of 205 km/hr (127.381 mph) using a prototype of what was to become the Alag Y-03 production motor. However, the example used by Krizsma was a factory prototype as opposed to a modified production engine. In my view, the statement with which this paragraph began remains correct. Sadly, as events were to prove, that was to be the end of the B.40’s run as a top contender in the speed category. Giovanni Barbini did make a final effort to keep the B.40 competitive against the ever-improving Eastern European and Super Tigre opposition. In his “Accent on Power” feature in the March 1958 issue of “Model Aircraft”, Peter Chinn reported that the B.40 TN had undergone some minor modifications since its introduction, including a slight lengthening of the exhaust period. This was apparently accomplished by the addition of two additional chamfers on the piston crown at the exhaust port locations, giving the piston crown a “castellated” appearance. Chinn actually commented in that article that the B.40 TN was “certainly the hottest reverse-flow glow-plug motor to date” and expressed the view that “at the moment, it seems to be an open question as to which is potentially the faster motor, the B.40 or the G.20”. Sadly as far as Barbini was concerned, that question was decisively answered during the 1958 International contest season. It quickly became apparent that the Hungarian and Czech teams now ruled the roost with their tool-room MOKI and MVVS specials. Only the now-sorted works Super Tigre G.20V powerplants could put up any real opposition – the Barbini was nowhere in sight.

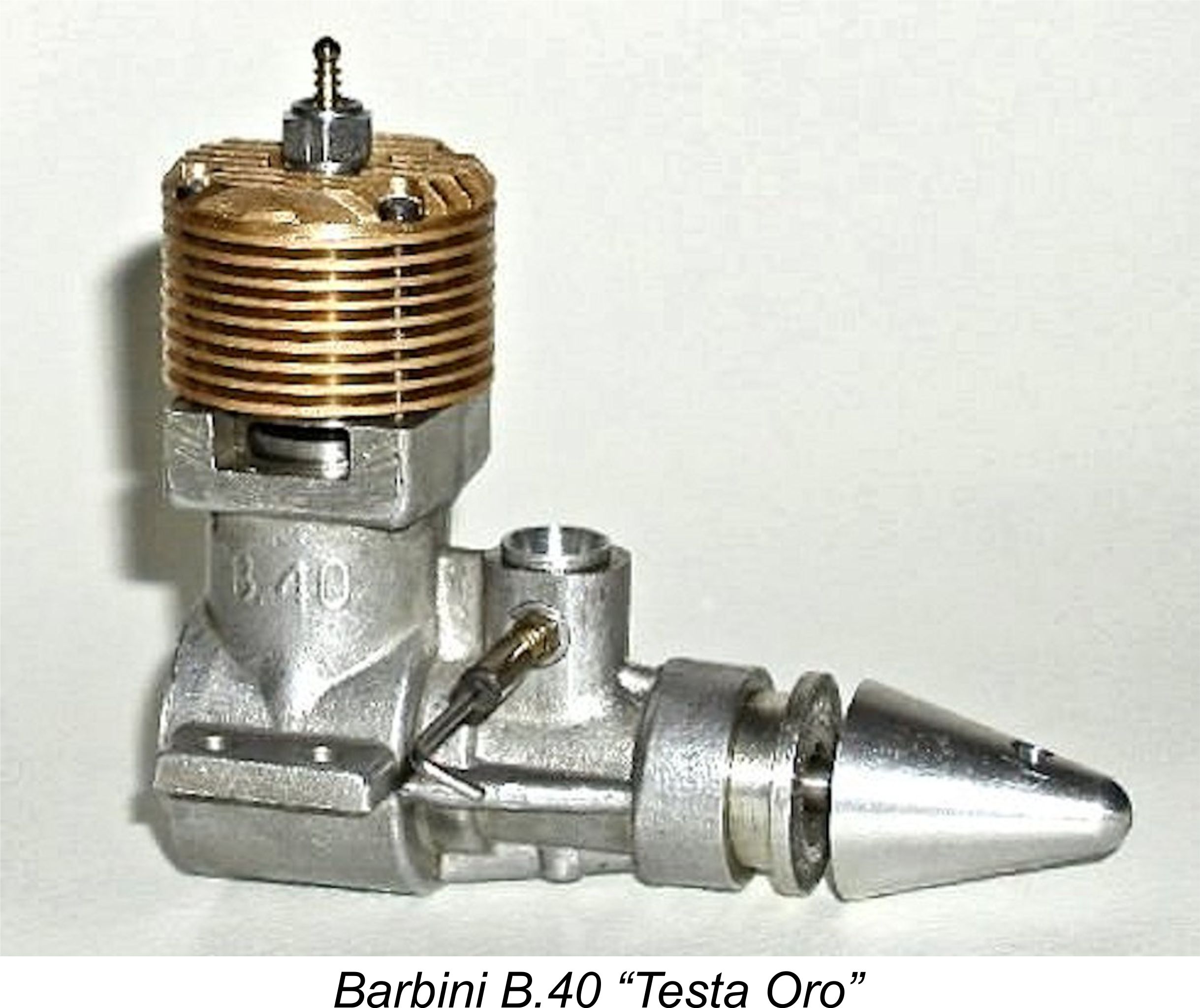

This appears to have been the final English-language media appearance of the Barbini engines, which evidently faded back into their originally-intended role of well-made and fine-running general-purpose units, for which a steady demand continued to exist within Italy. Still it had been a great ride on the international scene while it lasted! Barbini did not give up immediately in his attempts to keep the B.40 competitive. By 1960 the engine had been further modified into a final variant which was apparently tuned for all-out speed work, applying all of The revised model had a gold-anodized cooling jacket, accordingly being known as the B.40 “Testa Oro” (Gold Head), or B.40 TO for short. To my present knowledge, this was the final factory development of the B.40 glow-plug model. It was a very handsome engine indeed, as the attached images will attest. Barbini does not appear to have been alone in his attempts to further develop the B.40 in the face of the Although the creator of this unit has not been authoritatively identified, the appearance of the engraved initials "C-R" on the crankcase raises the possibility that this is the work of Cesare Rossi, who is definitely known to have been a Barbini user up to 1958. A full analysis of this engine will appear here in due course. However, despite the best efforts of Giovanni Barbini and others to maximize its performance, the B.40 never returned to prominence as a competition engine as far as the record shows. The B.40 TO thus stands as the ultimate expression of the production B.40 glow-plug model. The “standard” B.40 TN model also remained on offer at this time, featuring both the enlarged intake The B.40 TO was supplied in the generic "Motori Barbini" box which featured the humble B.38 diesel on the label regardless of the contents. The illustrated boxed 1960 example of the B.40 TO demonstrates this clearly. It would appear that the humble B.38 remained the bread-and-butter model thoughout, hence its place of honour on the box labels for all models. Durng the mid 1970's, Bruno Barbini began working with his uncle on the manufacture of the engines, thus gaining valuable experience in their production. He recalled that his uncle's health began to fail in the late 1970's, leading to the company ceasing operations in 1979. However Bruno continued intermittently to produce small batches of certain models on his own account, since there was still a market for these engines. He continued to do so until 1987, when all Barbini manufacture finally ended. The Other Barbini Models The Barbini B.40 TN was doubtless Barbini’s most recognizable model thanks to its highly-publicized World Championship success against the tool-room opposition - everyone loves a David and Goliath story! However, the companion B.38 1 cc diesel deservedly remained a firm favorite among Italian beginners and sport fliers. The other models in the range also retained their staunch adherents.

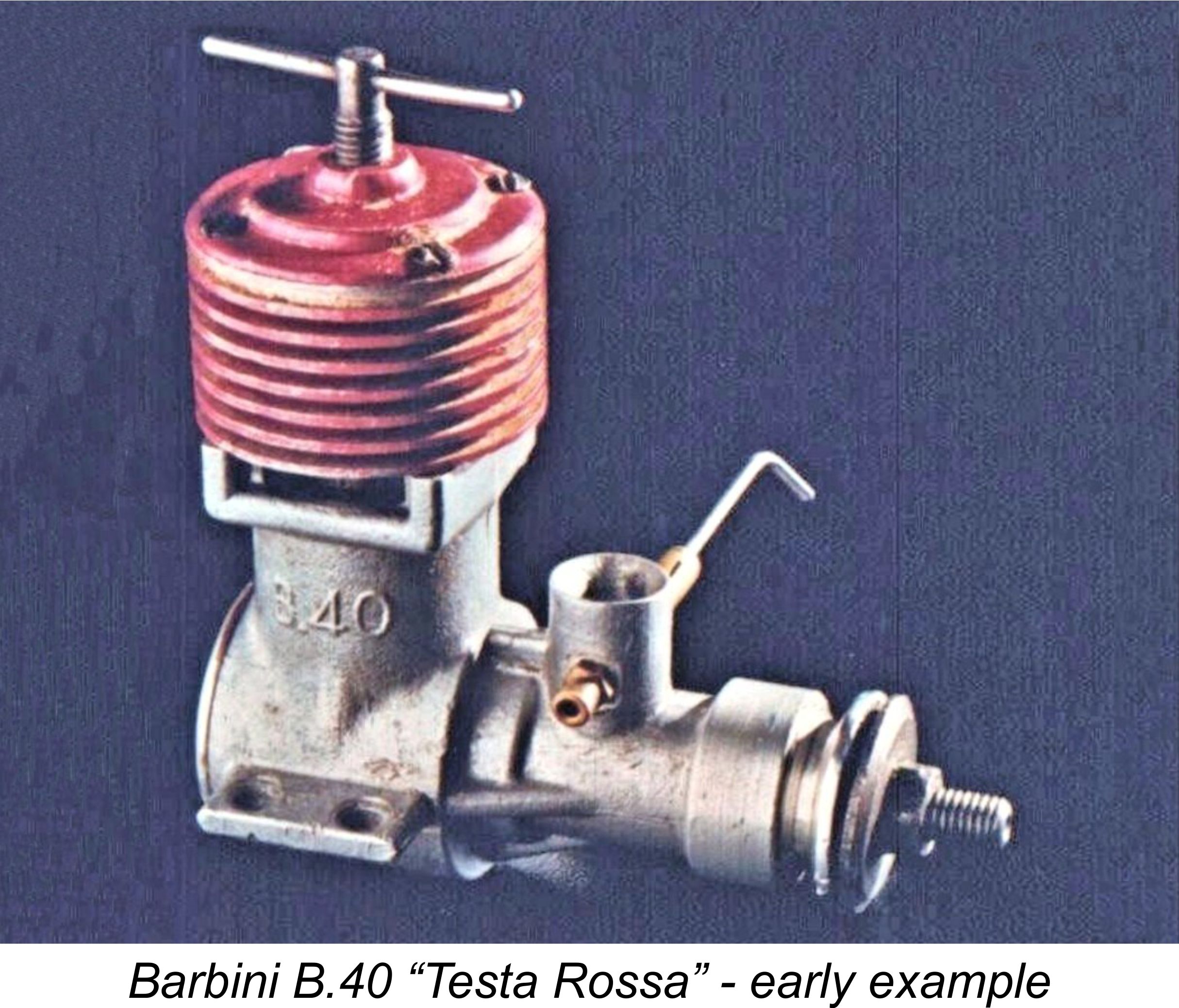

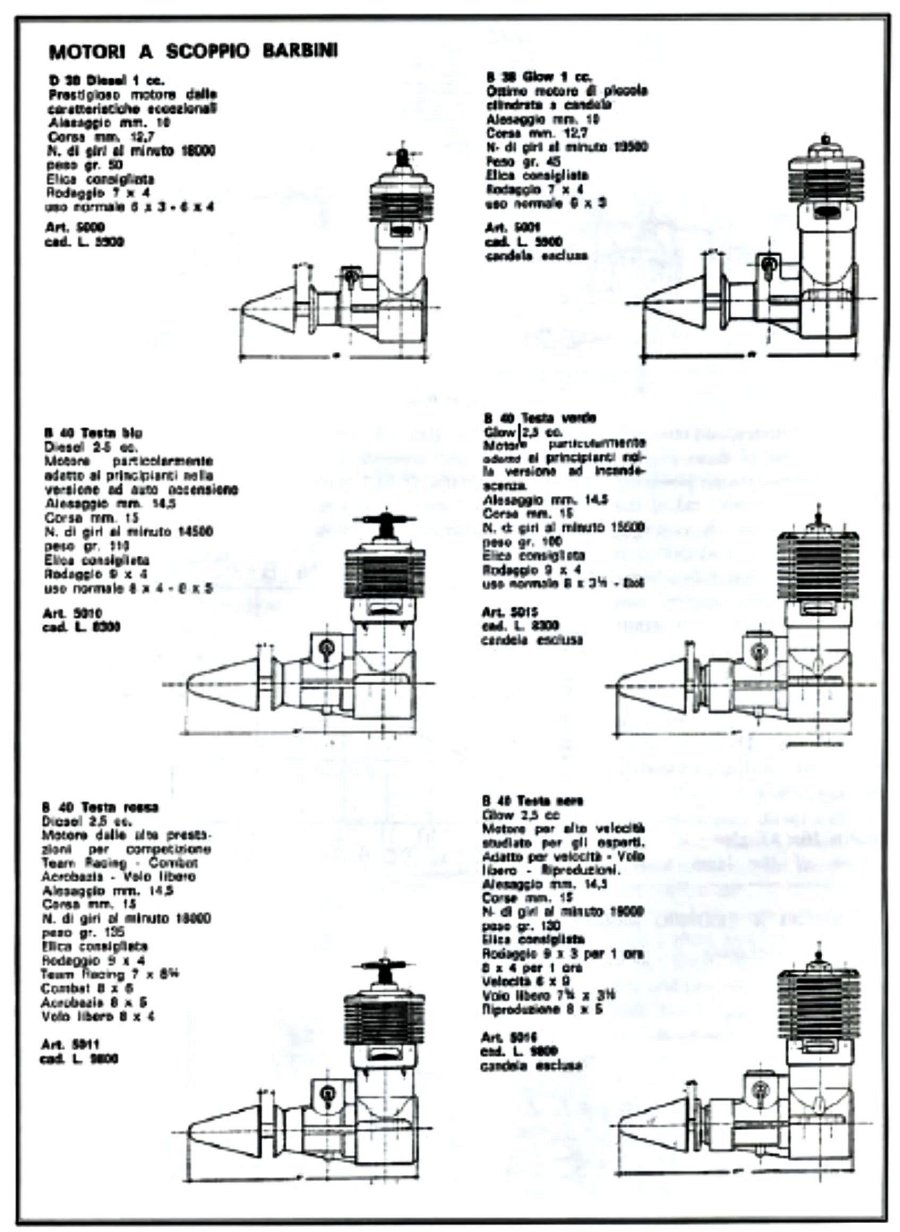

An interesting comment regarding the attached product listing is the fact that several of the elevation drawings are incorrectly matched to the associated data! The “Testa Blu” and “Testa Nera” models are correctly illustrated, but the same drawings re-appear as the “Testa Rossa” and “Testa Verde” models respectively! Oops ………. Apart from the B.38, B.40 TN and B.40 TO models, perhaps Barbini’s other greatest achievement was the previously-mentioned B.40 TR “Testa Rossa” diesel which appeared in late 1956. This engine was basically a B.40 TN with compression ignition instead of glow-plug. It followed exactly the same design configuration as the B.40 TN glow-plug model apart from having a diesel cylinder which was in effect a scaled-up version of that used in the B.38 already described in detail. Despite the added weight of this component, the engine weighed in at a commendably light 135 gm (4.76 ounces). It was intended primarily for control-line team racing and combat. Its main limitation in the latter context would have been the susceptibility of the needle roller bearings to damage resulting from dirt ingestion. Indeed, Walter Barbui tells me that the needle roller big end bearing did indeed prove to be not quite up to the stresses imposed by diesel operation. He is aware of several of the Testa Rossa units which failed in service. The fix was to replace the needle rollers with a bronze insert, after which the engines became very reliable.

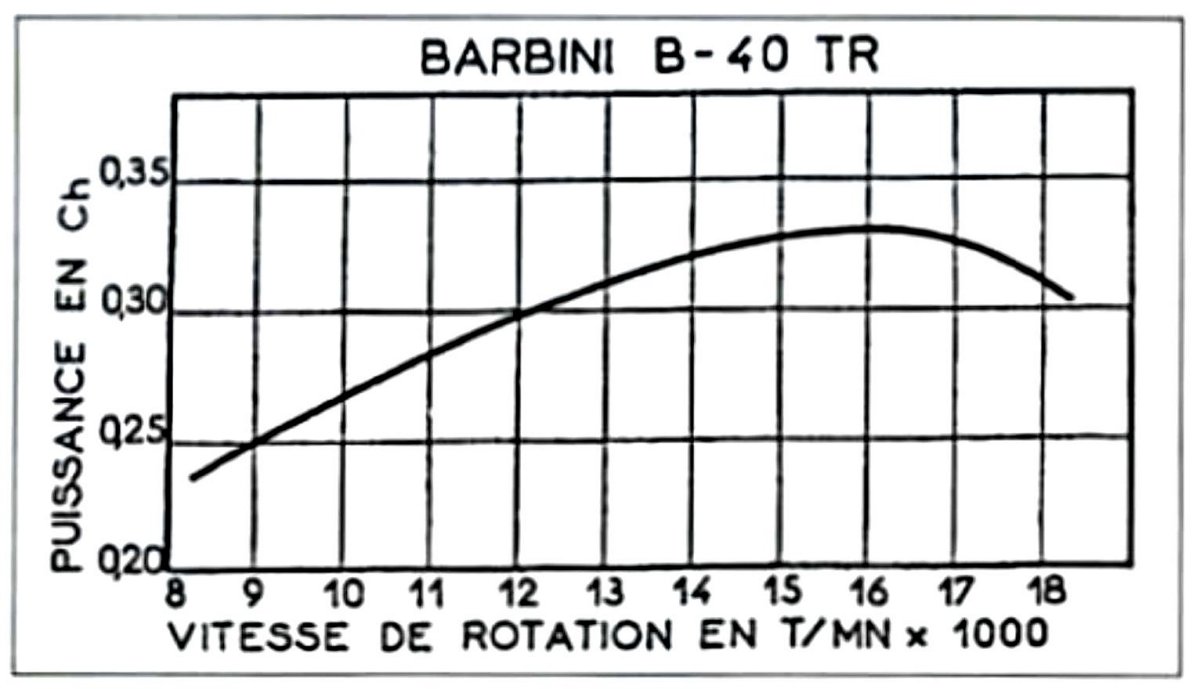

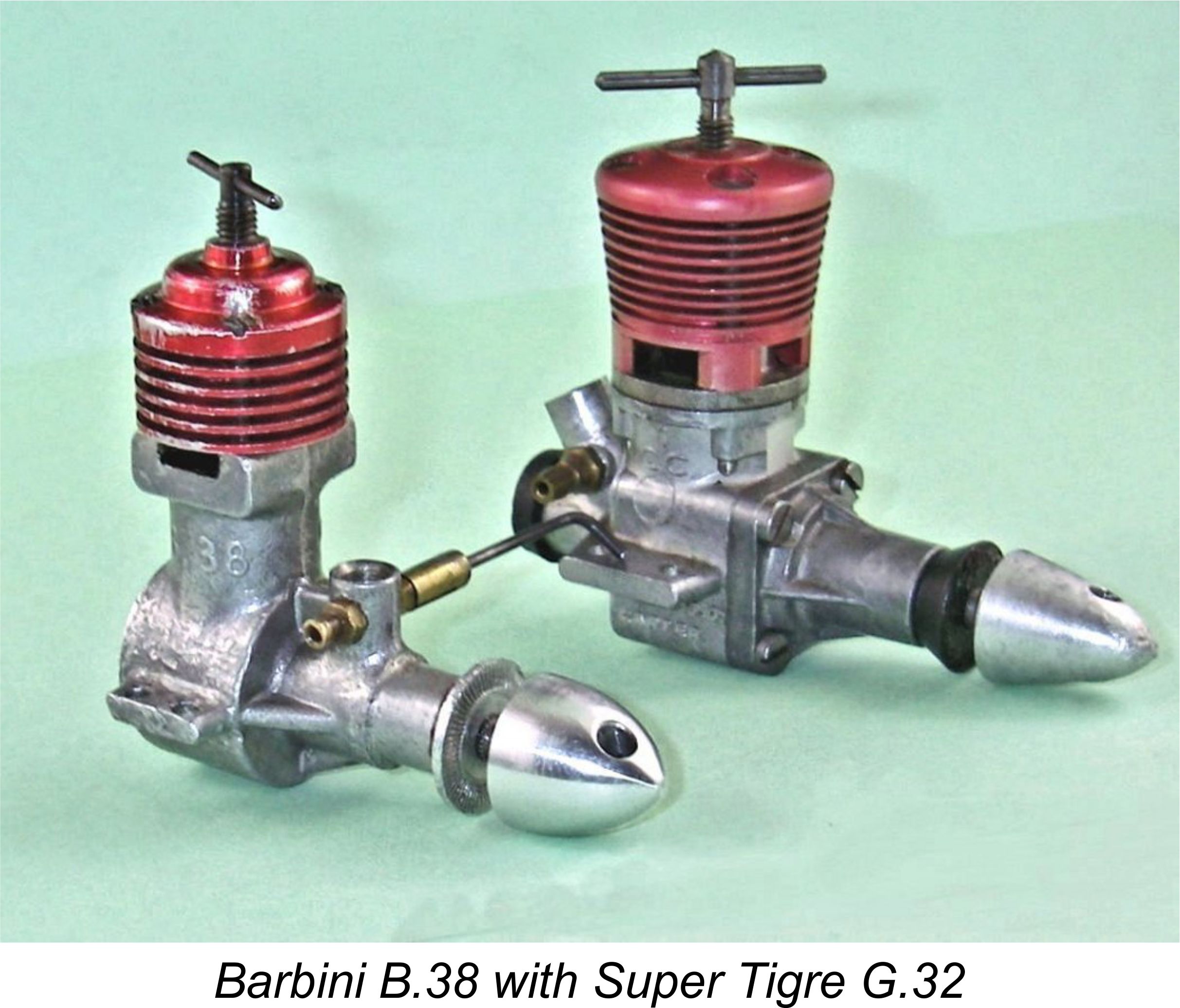

Although he reported no actual prop-rpm figures, the late Ron Chernich stated that a test-run of his illustrated restored example showed that it was a powerful, high-revving engine that started very easily. Ron could well imagine that it had the potential to be a serious team race contender, a view which the above power curve amply It appears not unlikely that the fine qualities of this engine and its B.38 diesel companion were instrumental in stimulating the creation of the Super Tigre G.30 and G.32 diesels of 2.5 cc and 1 cc respectively. These engines were developments of the earlier series of Super-Tigre diesels which employed a broadly similar cylinder porting design to the Barbini models, albeit applied to screw-in cylinders in which the annular porting alignment was random. It's actually likely that the Barbini porting system used on the B.38 influenced those earlier Super Tigre models as well, since they did not begin to appear until 1954, some time after the initial appearance of the B.38.

The fact that they were the only two Super Tigre models to adopt the Barbini cylinder design in its entirety (including the red anodizing) while also having the same displacements as the two Barbini models adds credence to the unsubstantiated possibility that they were introduced as a direct response to the success of the Barbini models. The extent to which Jaures Garofali evidently felt impelled to ensure a performance superiority over the Barbini competition is clearly demonstrated by the lengths to which he went to ensure high performance – the single ball-race G.32 in particular is amazingly complex for a 1 cc design given the fact that there was no competition Returning to the Barbini range, the two plain-bearing versions of the B.40 – the diesel “Testa Blu” or TB model and the green-headed “Testa Verde” or TV offering – both continued in production during this period. It might well be wondered how Barbini managed to offer so many distinct models all at the same time given the relatively limited production capacity which he seems to have maintained throughout. There were doubtless several factors which allowed him to do so. Firstly, the various models were by no means as distinct as might otherwise be supposed. Basically, there were only two distinct crankcase patterns for the 2.5 cc model, one with the combination ball/needle roller bearing and one with a plain bronze bushing. There were also only two cylinder configurations – diesel and glow. Finally, there were two con-rod designs – plain big end and needle roller big end. It was simply a matter of choosing the right mix of components from the parts inventory to assemble any particular model. The B.38 was even simpler – the only differences between the diesel and glow-plug versions were the cooling jacket and cylinder. This would have allowed Barbini to make the required components in batches, thus building up a parts inventory. He could then assemble engines as dictated by the order book, replenishing the parts stock as given items were used up. It’s highly likely that this is exactly what he did, although we’ll probably never know for sure.

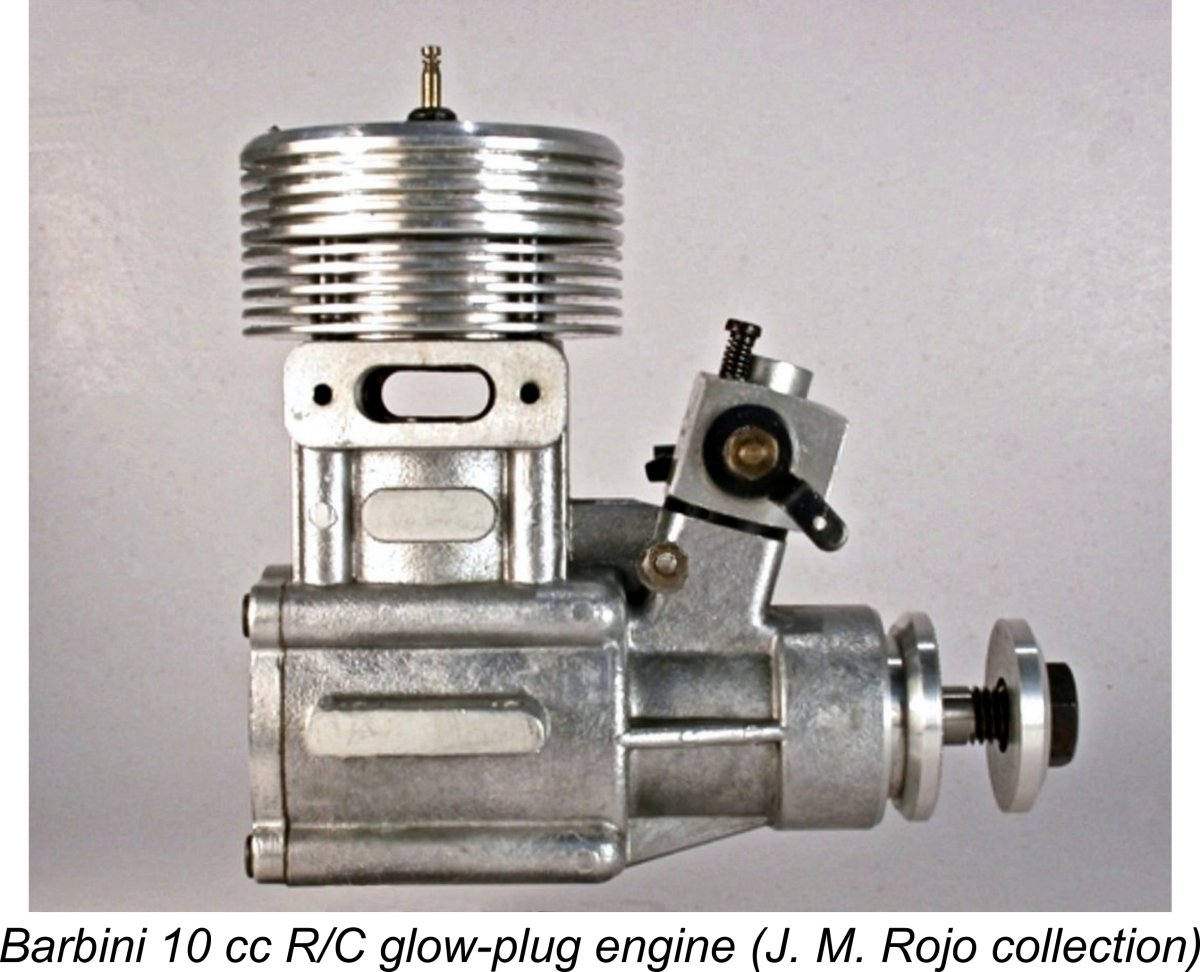

As time went on, it would appear that the humble B.38 became Barbini’s “bread and butter” offering. If the relative numbers of surviving examples are anything to go by, this model was made in far larger numbers than any of its 2.5 cc siblings. This impression of the engine’s commercial importance is underscored by the previously-noted fact that all of the Barbini models from 1960 onwards appear to have been supplied in generic boxes which featured the B.38 on the label. Towards the end of the 1960’s Barbini freed up enough time to develop and produce a few examples of what No other details of this mega–rare engine are available. However, Maris Dislers was able to find a published image of an example which forms part of the J. M. Rojo collection. It is reproduced here with full acknowledgement of the source. As stated earlier, the original Barbini company ceased operations in 1979, when Giovanni Barbini was 64 years old and beginning to experience health issues. At that point he understandably appears to have decided that enough was enough. He left a legacy of a number of innovative and superbly-executed designs which those of us fortunate enough to own examples can still enjoy today. Ben fatto, Signor Barbini!! As also noted earlier, Giovanni Barbini permitted his nephew Bruno to continue to manufacture small intermittent batches of the Barbini engines on his own account until 1987. We must all be grateful for the increase in the supply of these engines which resulted from Bruno's efforts. A Later Clone from Far, Far Away

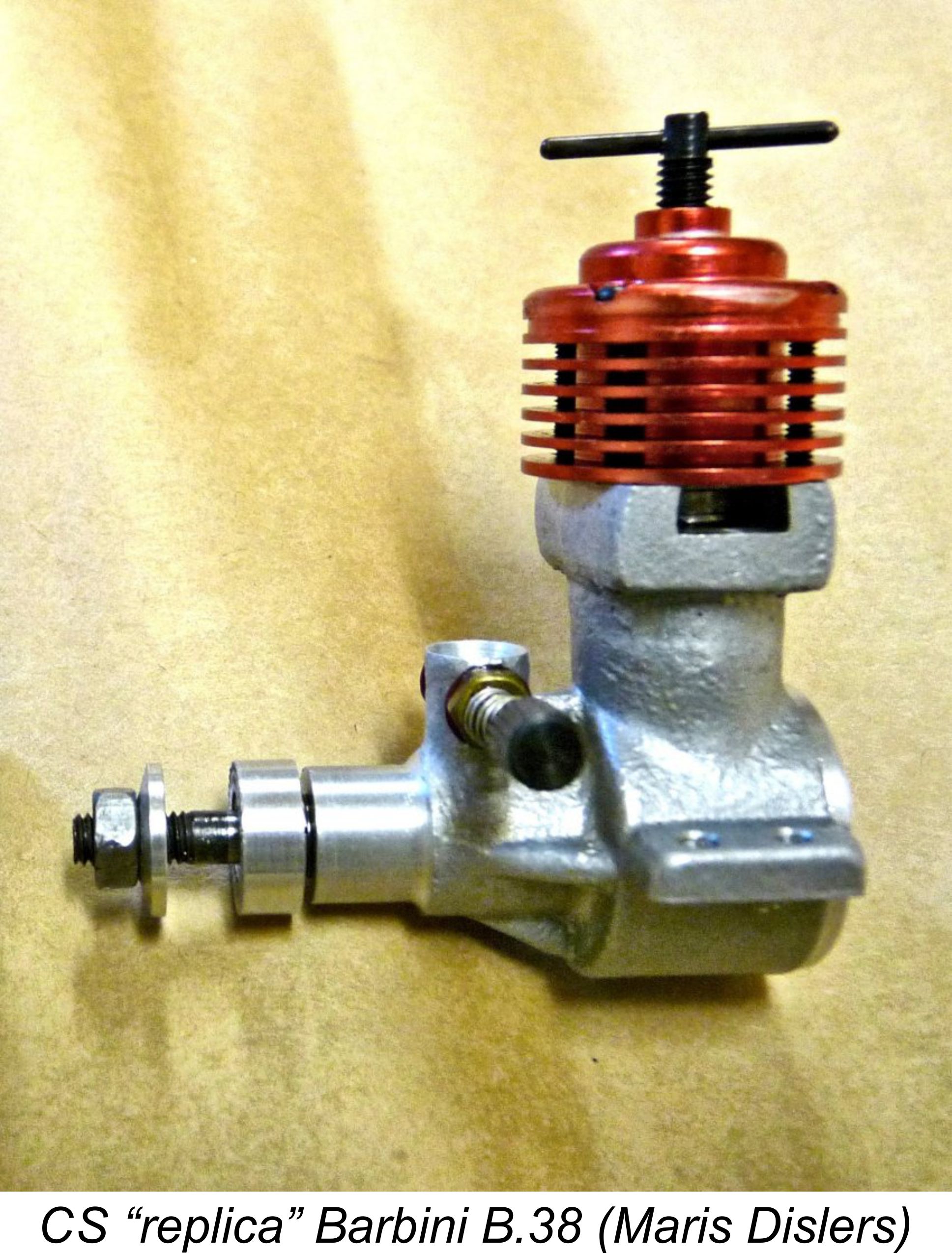

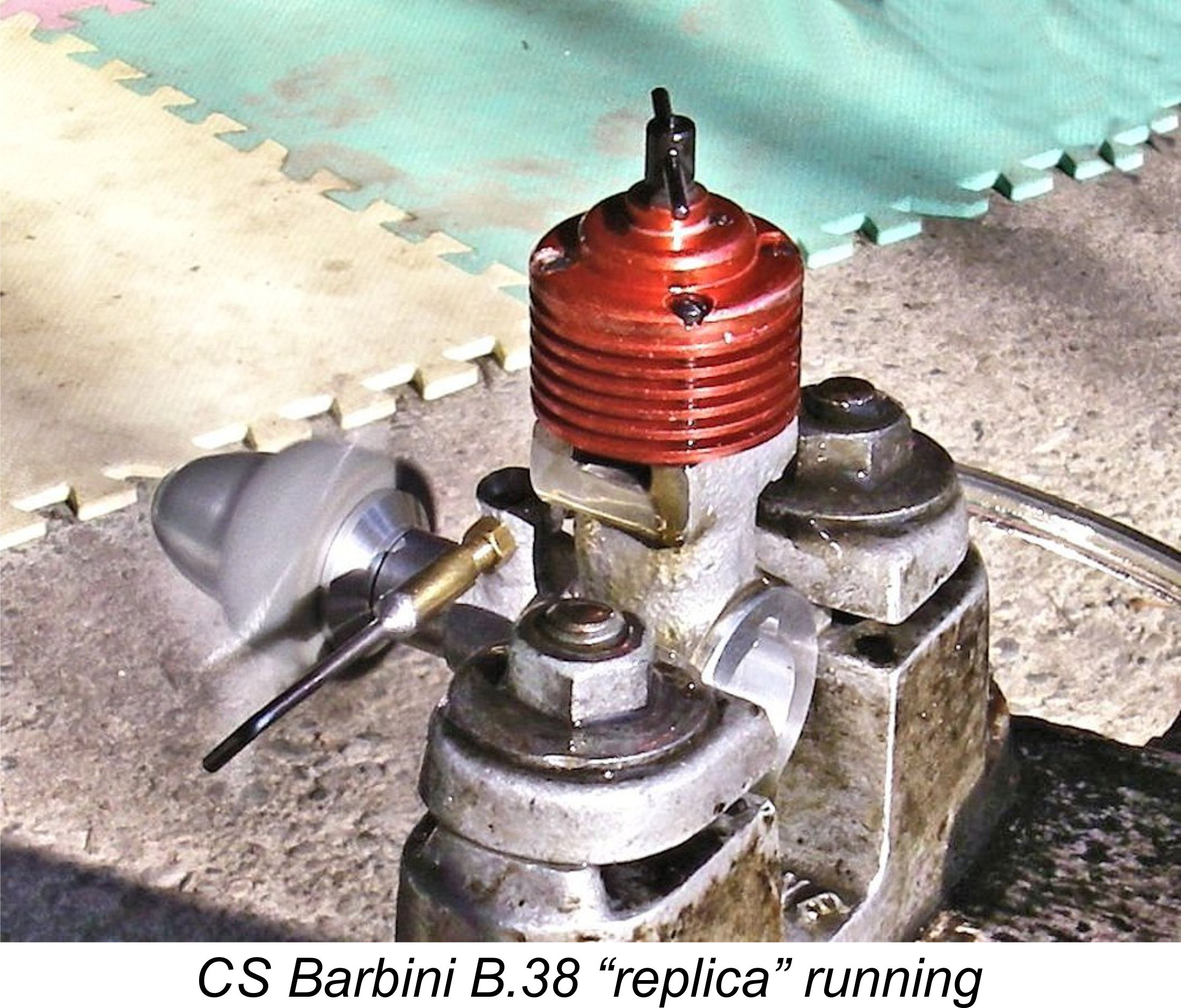

Fortunately, these differences are easily spotted. For a start, the exhaust port faces on the CS version are not milled flat as they are on the original Barbinis, being left instead in their as-cast state. In addition, the expansions at the top of the crankcase casting into which the exhaust channels are cut are somewhat bulkier on the CS version than they are on the originals. Less immediately obviously, the red-anodized CS cooling jacket has an external diameter of 22 mm as opposed to the 21 mm of the original. The gravity die-cast crankcase of the CS replica is less cleanly cast, making the cast-on model identification characters much harder to read. The spring-tensioned needle valve assembly is very different indeed from the Barbini original, although it must be said that the CS unit works very well indeed. Finally, and most obviously of all, the prop driver is completely different from the original, while a conventional prop nut and washer are use in place of the Barbini’s spinner nut. The CS prop driver is secured to the shaft using a split collet rather than splines – another dead give-away when checking for originality. Internally, the CS model has far less aggressively-chamfered transfer ports than the original. The machining of the chamfers in these ports represented a significant challenge, which Barbini met brilliantly but which CS apparently shirked. The result is that the transfer period of the CS model is nowhere near that of the original. At the same time, the exhaust ports in the CS model were relocated upwards, eliminating the sub-piston induction on which so much of the engine’s performance depended while also shortening the power stroke somewhat. The result was an engine which, while looking generally similar to the Barbini original, performed at nowhere near the same level, also presenting a sufficiently different appearance that there could be no possibility of an informed individual mistaking one for the other. As my good mate Maris Dislers pointed out, CS were probably more concerned with making a product that looked somewhat like the original than with attempting to replicate the performance of the original. It appears that the CS Barbini dates back to the time when CS was still having trouble maintaining adequate quality control (they improved greatly during their final years in the model engine business). Maris Dislers acquired an example in New condition which proved to be too loosely fitted to run. Maris sorted this, at the same time machining the exhaust port faces in the crankcase to more or less match the original. He did not alter the engine’s porting in any way at this stage.

I then tore the little CS down to correct the porting. The crankshaft induction port proved to be located too far forward on the journal, hence not aligning properly with the venturi base. I corrected this by extending the port back towards the crankweb, maintaining an oval "race-track" shape to avoid any stress-raising sharp corners. I also chamfered the transfer ports internally to original Barbini specifications – a challenging task requiring great care. To account for the higher location of the exhaust ports in the cylinder, I turned enough material off the base of the piston skirt to restore some (but by no means all) of the lost sub-piston induction. The modified CS "replica" now has a measured sub-piston induction period of around 25 degrees - nowhere near the 64 degrees of the original, but that was the best that I could do without (in my opinion) over-shortening the piston. Since Maris had started the look-alike treatment by milling the exhaust stack faces, I decided to continue the process of maximising the originality of the replica's appearance. I fitted an original Barbini needle valve assembly which I had in my spare parts stash, also making an accurate replica prop driver in place of the undersized item used by CS. An original B.38 spinner nut completed the rebuild. The result was a quite convincing look-alike of an early B.38 with transverse needle valve assembly and rounded spinner nut.

Like many CS engines of its era, the CS Barbini turned out to be something of an “engine guy’s special”, representing more of a kit than a complete ready-to-run engine. However, again like most CS products, if you’re prepared to put in a bit of well-informed effort, the result can be a really nice and very useable engine like this one which retains much of the character and performance of the original. We were far better off with these engines than without them - the 2015 departure of CS from the replica scene was very much the hobby's loss. Just don’t be gulled into buying a CS replica thinking that it’s an original! To spare some folks the frustration of a fruitless search, it's probably also worth mentioning in passing that I recently encountered a thread on a widely-read modelling forum in which the claim was made (and not challenged) that the famous Australian model engine manufacturer, the late and greatly-missed Gordon Burford, made a short series of Barbini B.38 replicas. I had never heard of such a model from Gordon's workshop, so I checked with the world's leading authority on the Burford engines, my good mate Maris Dislers. Maris confirmed that to his certain knowledge Gordon never at any time made even a single example of a Barbini replica. If someone is trying to pass off a Barbini B.38 as a Burford replica, it's a serious case of buyer beware! Conclusion

In many ways, Barbini must be seen as standing in the same relationship to the Italian model engine industry as John Oliver did in Britain. Anyone acquiring an example of his work will find themselves owning one of the outstanding examples of commercial model engine manufacture of the 20th century. Grazie, Giovanni e Bruno! _______________________________ Article © Adrian C. Duncan, first published May 1st, 2015 Last updated September 2018 |

||

| |

Here we take a look at a relatively lesser-known series of model engines from Italy which set very high standards in terms of both performance and quality. These are the Barbini engines, which originated in Milan but were mostly made in San Stino di Livenza near Venice.

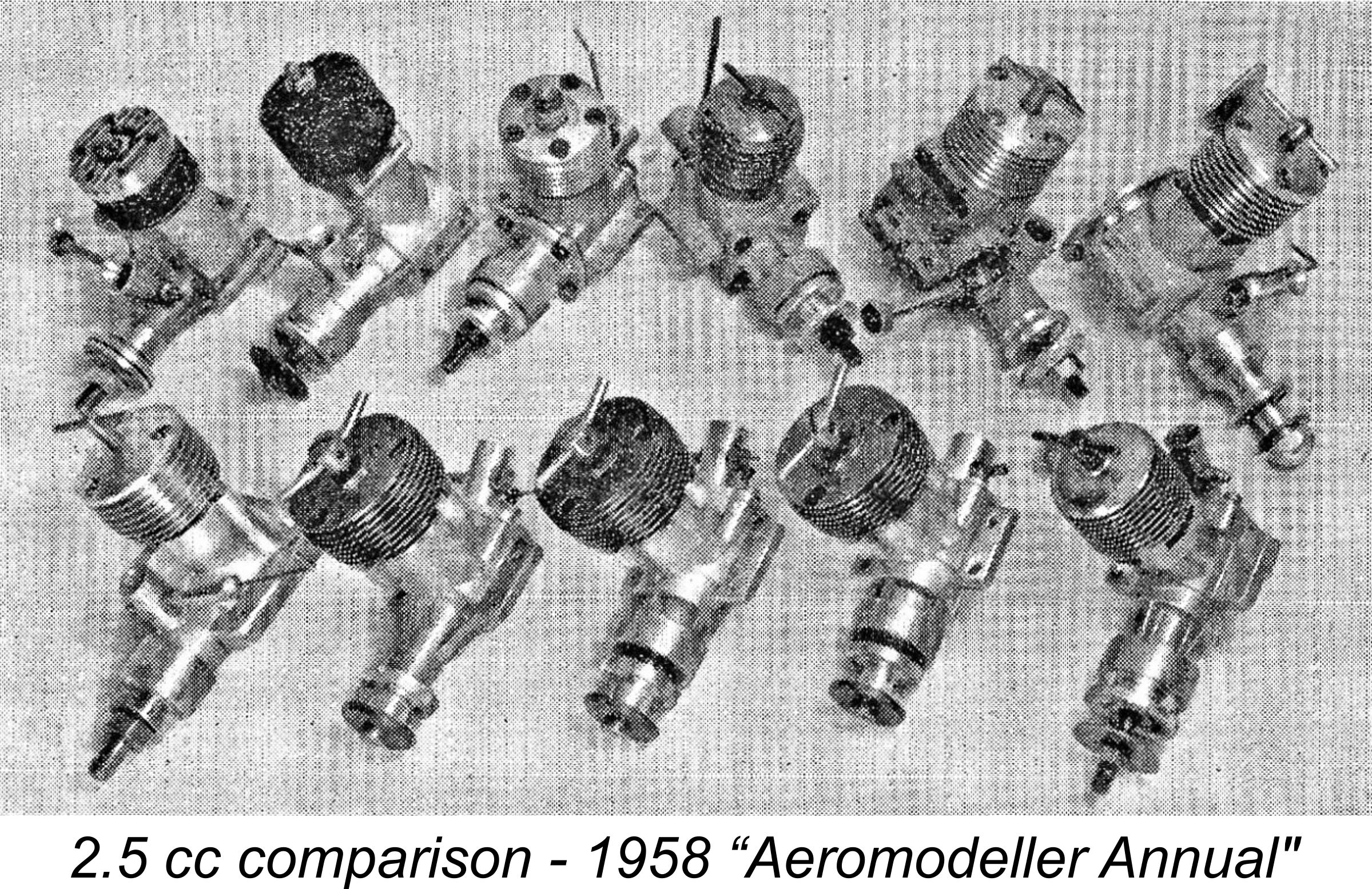

Here we take a look at a relatively lesser-known series of model engines from Italy which set very high standards in terms of both performance and quality. These are the Barbini engines, which originated in Milan but were mostly made in San Stino di Livenza near Venice. Tests were published in both “Model Aircraft” and “Aeromodeller” magazines, despite the fact that the engines were not readily available in the English-speaking world. These tests provided a great deal of information on the design, construction and performance of the Barbini engines. Coverage was quite comprehensive, including the 1 cc Barbini B.38 diesel as well as both diesel and glow-plug versions of the 2.5 cc Barbini B.40 model. The B.40 was also included in a comparative test of a number of 2.5 cc models which appeared in the 1958 “Aeromodeller Annual”. Reference will be made to specific tests at appropriate points in the text which follows.

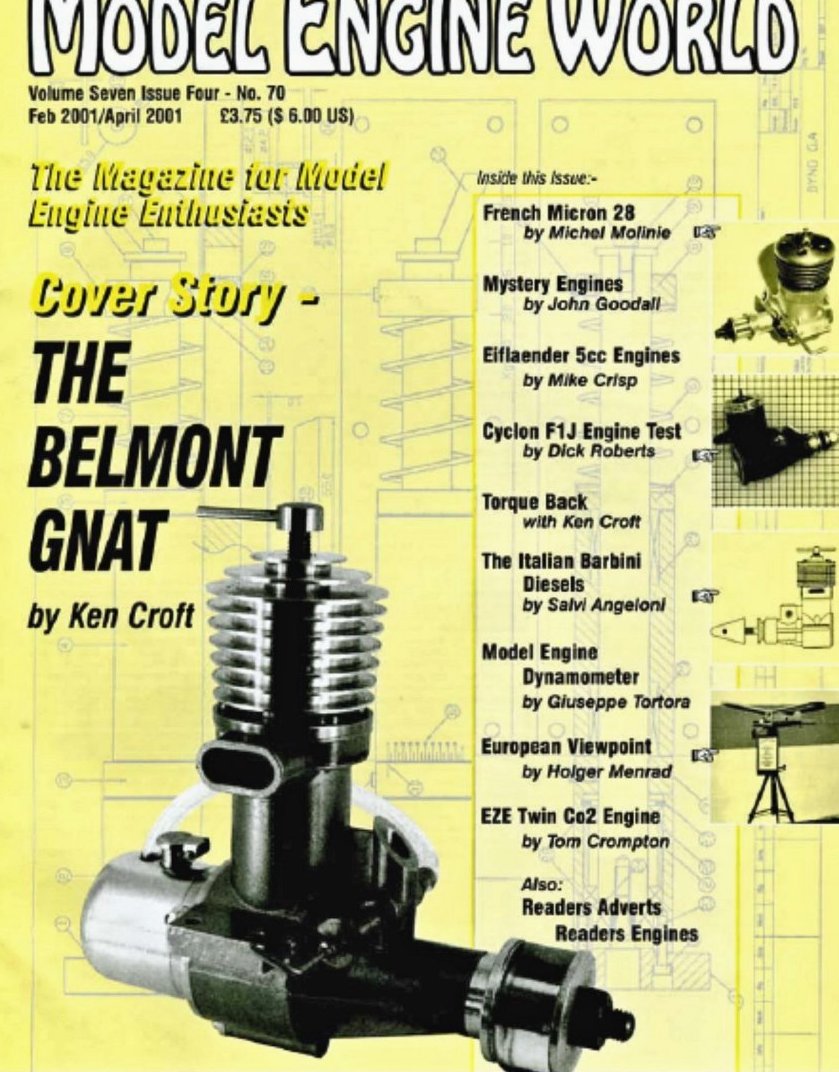

Tests were published in both “Model Aircraft” and “Aeromodeller” magazines, despite the fact that the engines were not readily available in the English-speaking world. These tests provided a great deal of information on the design, construction and performance of the Barbini engines. Coverage was quite comprehensive, including the 1 cc Barbini B.38 diesel as well as both diesel and glow-plug versions of the 2.5 cc Barbini B.40 model. The B.40 was also included in a comparative test of a number of 2.5 cc models which appeared in the 1958 “Aeromodeller Annual”. Reference will be made to specific tests at appropriate points in the text which follows. In more recent years, a very short but nonetheless informative article listing the various Barbini models appeared on page 14 of the February/April, 2001 issue of “Model Engine World” (MEW). This was Volume 7, Issue no. 70, which had the distinction of being the final issue edited by John Goodall. Entitled “The Italian Barbini”, this article was written by MEW reader Salvi Angeloni of Lodi, Italy. We are very much in Salvi’s debt for his sharing of this information.

In more recent years, a very short but nonetheless informative article listing the various Barbini models appeared on page 14 of the February/April, 2001 issue of “Model Engine World” (MEW). This was Volume 7, Issue no. 70, which had the distinction of being the final issue edited by John Goodall. Entitled “The Italian Barbini”, this article was written by MEW reader Salvi Angeloni of Lodi, Italy. We are very much in Salvi’s debt for his sharing of this information.

The two exhaust ports were separated by a pair of very large transfer ports placed fore and aft. These were internally cut at an angle of some 45 degrees to the vertical, hence directing the incoming gas upwards when opened by the downward motion of the piston crown. The arrangement of the ports allowed a considerable degree of overlap between the exhaust and transfer ports, a feature notably lacking in many of the more conventional radially-ported designs. The transfer port area was also considerably greater than in most other designs.

The two exhaust ports were separated by a pair of very large transfer ports placed fore and aft. These were internally cut at an angle of some 45 degrees to the vertical, hence directing the incoming gas upwards when opened by the downward motion of the piston crown. The arrangement of the ports allowed a considerable degree of overlap between the exhaust and transfer ports, a feature notably lacking in many of the more conventional radially-ported designs. The transfer port area was also considerably greater than in most other designs. On the basis of measurements taken from my own early example of the engine, port timing was quite conservative. The exhaust opened 120 degrees ATDC for a total exhaust period of 120 degrees, while the transfer ports opened some 7 degrees of crank angle later for a transfer period of 106 degrees. The designer appears to have been taking full advantage of the very large cylinder port areas, which naturally required less time to perform their functions than would be the case with smaller and less efficient ports. The timing adopted resulted in an unusually long power stroke period of 120 degrees of crank angle, making maximum use of the power potential of the expanding gasses in the cylinder prior to the commencement of the exhaust phase.

On the basis of measurements taken from my own early example of the engine, port timing was quite conservative. The exhaust opened 120 degrees ATDC for a total exhaust period of 120 degrees, while the transfer ports opened some 7 degrees of crank angle later for a transfer period of 106 degrees. The designer appears to have been taking full advantage of the very large cylinder port areas, which naturally required less time to perform their functions than would be the case with smaller and less efficient ports. The timing adopted resulted in an unusually long power stroke period of 120 degrees of crank angle, making maximum use of the power potential of the expanding gasses in the cylinder prior to the commencement of the exhaust phase. The design of the con-rod was also quite unusual. It was made of heat treated steel, but was machined away to logical limits in order to minimize reciprocating weight while retaining very long bearings at each end. A great deal of work went into this one component – typical of the care and skill lavished by Barbini upon his products. Together with the internally-milled piston and tubular gudgeon pin, this resulted in the B.38 having a significantly lower level of reciprocating weight than almost all of its competitors – a good feature for the achievement of high operating speeds, particularly given the engine’s long-stroke configuration.

The design of the con-rod was also quite unusual. It was made of heat treated steel, but was machined away to logical limits in order to minimize reciprocating weight while retaining very long bearings at each end. A great deal of work went into this one component – typical of the care and skill lavished by Barbini upon his products. Together with the internally-milled piston and tubular gudgeon pin, this resulted in the B.38 having a significantly lower level of reciprocating weight than almost all of its competitors – a good feature for the achievement of high operating speeds, particularly given the engine’s long-stroke configuration. The con-rod acted upon a one-piece steel crankshaft having a counterbalanced crankweb. The shaft was supported in a very well-fitted bronze-bushed plain bearing. The crankshaft induction port was a simple drilled hole. Its opening period was both relatively short and highly unusual – from 65 degrees ABDC to TDC exactly. The latter figure makes it abundantly clear that the function of the crankshaft induction was seen as being purely to draw fuel mixture into the crankcase – complete filling of the crankcase was clearly intended to be achieved through the very significant sub-piston induction period mentioned earlier. When one takes into account the fact that the sub-piston induction does not close until around 32 degrees ATDC, we have a total induction period as seen from the crankcase of some 147 degrees – a quite adequate figure.

The con-rod acted upon a one-piece steel crankshaft having a counterbalanced crankweb. The shaft was supported in a very well-fitted bronze-bushed plain bearing. The crankshaft induction port was a simple drilled hole. Its opening period was both relatively short and highly unusual – from 65 degrees ABDC to TDC exactly. The latter figure makes it abundantly clear that the function of the crankshaft induction was seen as being purely to draw fuel mixture into the crankcase – complete filling of the crankcase was clearly intended to be achieved through the very significant sub-piston induction period mentioned earlier. When one takes into account the fact that the sub-piston induction does not close until around 32 degrees ATDC, we have a total induction period as seen from the crankcase of some 147 degrees – a quite adequate figure. refinement was omitted from the later variants of the engine. A rounded spinner nut completed the prop mounting assembly. Later examples of the engine used a conical spinner nut. The engine was completed by the addition of a conventional transversely-aligned needle valve assembly (using a split thimble for tension) and a screw-in backplate.

refinement was omitted from the later variants of the engine. A rounded spinner nut completed the prop mounting assembly. Later examples of the engine used a conical spinner nut. The engine was completed by the addition of a conventional transversely-aligned needle valve assembly (using a split thimble for tension) and a screw-in backplate.  crankcase, which was left in its as-cast state, all working fits were extremely good throughout. Coupled with its better-than-average performance (see below) and light weight, this ensured the engine’s enduring popularity among Italian modellers. The B.38 diesel remained in production at modest levels for well over thirty years, surviving until the end of all Barbini manufacture in 1987.

crankcase, which was left in its as-cast state, all working fits were extremely good throughout. Coupled with its better-than-average performance (see below) and light weight, this ensured the engine’s enduring popularity among Italian modellers. The B.38 diesel remained in production at modest levels for well over thirty years, surviving until the end of all Barbini manufacture in 1987. was replaced by the conical item mentioned earlier. This variant seems to have appeared in around 1958.

was replaced by the conical item mentioned earlier. This variant seems to have appeared in around 1958.

The original Barbini B.40 was in almost all respects nothing more than a scaled-up version of the B.38. Accordingly, the earlier description of the general arrangement and construction of the B.38 applies in every respect to the original plain-bearing B.40, hence warranting no repetition here. Bore and stroke of the new model were 14.5 mm and 15 mm respectively – Barbini remained in the long-stroke camp. The engine’s displacement worked out at 2.48 cc (0.151 cuin.). It weighed a commendably light 122 gm (4.3 ounces).

The original Barbini B.40 was in almost all respects nothing more than a scaled-up version of the B.38. Accordingly, the earlier description of the general arrangement and construction of the B.38 applies in every respect to the original plain-bearing B.40, hence warranting no repetition here. Bore and stroke of the new model were 14.5 mm and 15 mm respectively – Barbini remained in the long-stroke camp. The engine’s displacement worked out at 2.48 cc (0.151 cuin.). It weighed a commendably light 122 gm (4.3 ounces).  Chinn found sufficient merit in the Barbini B.40 diesel that he felt it to be worth including in his supplementary engine report program. Accordingly, he conducted a

Chinn found sufficient merit in the Barbini B.40 diesel that he felt it to be worth including in his supplementary engine report program. Accordingly, he conducted a  The design of the resulting engine once more demonstrated Barbini’s outstanding ability to think outside the box. The layout generally followed that of the diesel model, the same cylinder porting arrangement being used. Bore and stroke remained unchanged at 14.5 mm and 15 mm respectively for a displacement of 2.48 cc (0.151 cuin.). Weight too was little changed from the diesel model at 125 gm (4.4 ounces). The one significant change in the piston/cylinder design was the addition of two small chamfers on the piston crown fore and aft to reduce the blow-down period somewhat and further assist in the direction of the incoming transfer gas.