|

|

The Mats Böhlin K&B 15 Team Race Special

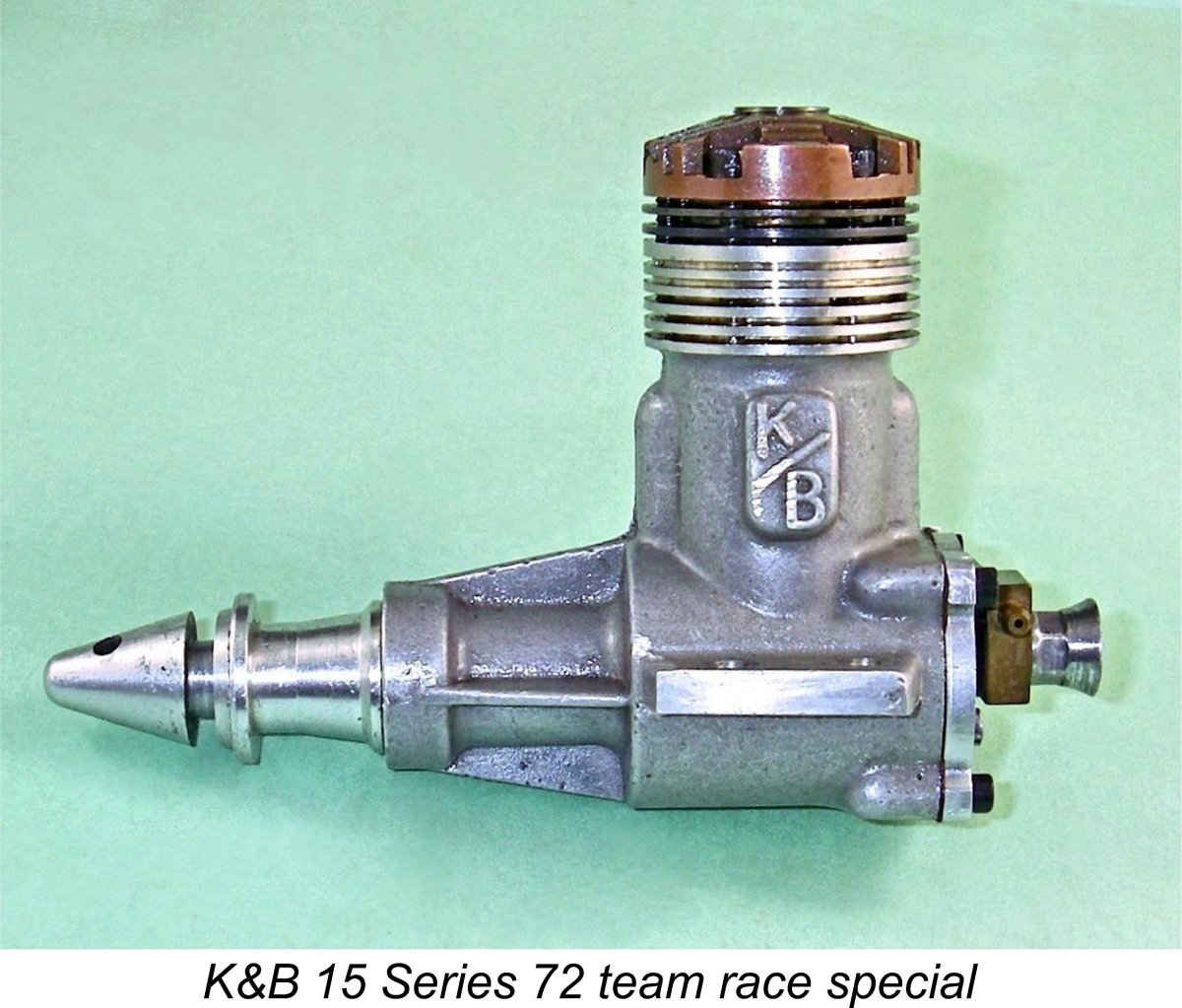

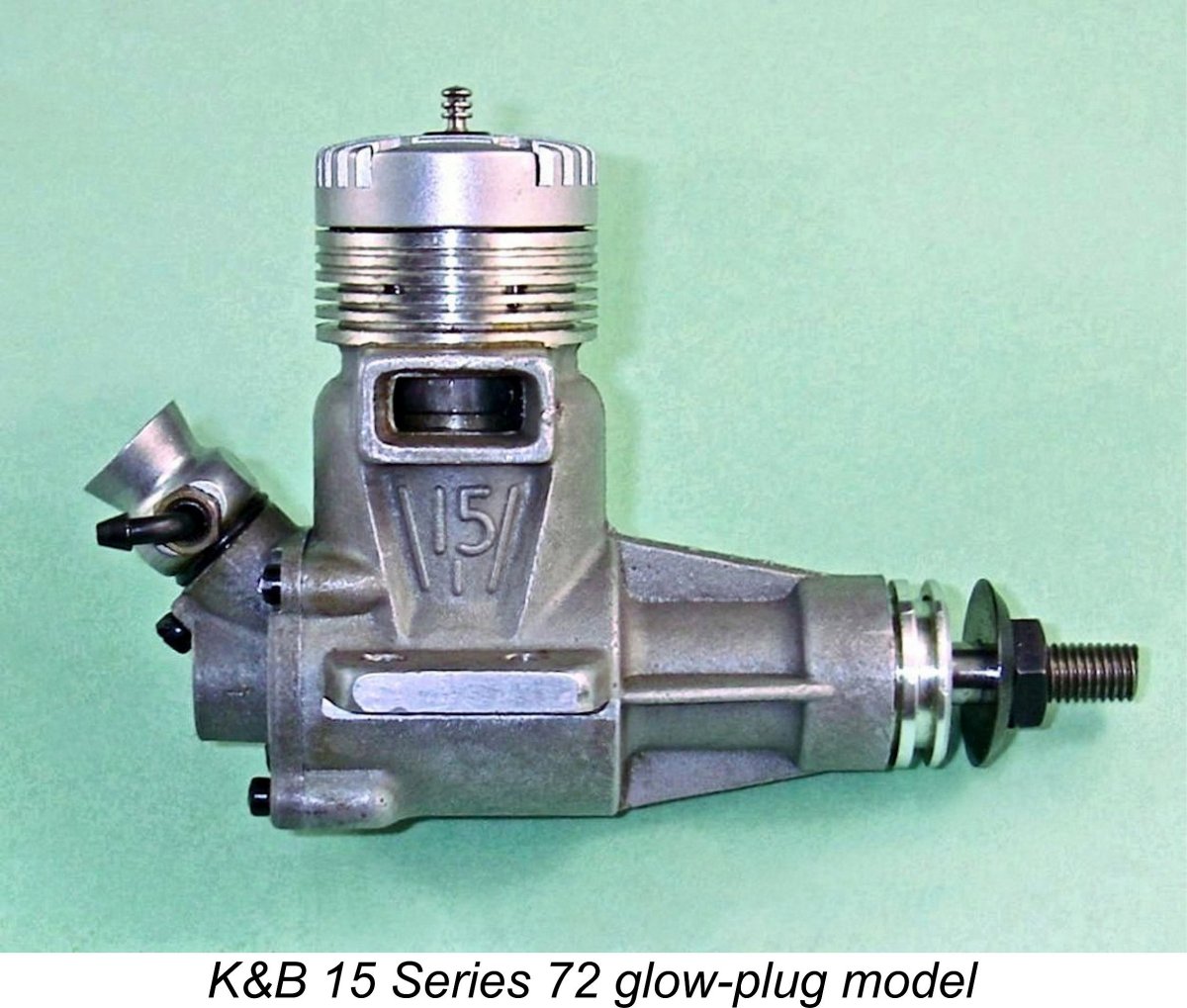

The subject of the present article displays so many points of technical interest that I felt it warranted making another exception! Moreover, my research revealed that this engine provides an opportunity to acknowledge the talents of one of the modelling world's true master craftsmen. As an example of what can be accomplished by such an individual, this engine stands as a real source of inspiration! I acquired the 2.5 cc diesel in question on eBay in July 2017 from a US seller. However, I never got around to researching it until recently. It's a very competently designed and constructed “team race special” based on the Schnuerle-ported K&B 15 Series 72 glow-plug model of 1972. From the outset, consideration of its general arrangement left me in no doubt at all that this engine's intended purpose was FAI (F2C) team racing. However, I had no clues to the identity of its clearly very talented constructor. It was only in late 2018 that I embarked upon a serious attempt to identify that individual. Based on its antecedents as well as consideration of the evolving state of F2C team race technology at the time, it seemed clear to me that the engine almost certainly dated from the 1970's. Obviously, it couldn’t date from before 1972, since the original glow-plug model on which it was based didn't exist before then. However, by 1980 its clearly knowledgeable constructor would have been well aware that it would no longer be competitive against the ever-improving Bugl, BG, Nelson and Rossi opposition which was then collectively dominating the results along with the Russian entrant-constructed "specials". Moreover, its design is such that it would not have responded well to the ever-lower oil contents which were increasingly required in team race fuels to achieve success at the highest levels as the 1970's drew on.

For another thing, it was beyond question that the constructor was a serious team race competitor who really knew team race diesels. This says that he was undoubtedly a dedicated practitioner or at least follower of the sport. This being the case, there was a good chance that he would have been known to some of the top-flight competitors of the day. Finally, he was clearly a well-equipped machinist of considerable talent given the very high standard of workmanship on display. Individuals possessing this combination of enthusiasm, experience and machining capacity can't have been thick on the ground! This engine is rather unusual in that although it’s an extremely professional job throughout which has apparently seen service in competition, it seems to have completely escaped any previous documentation. It’s nothing like the original K&B 15 Series 72 diesel illustrated on page 126 in Volume 2 of Tim Dannels' "American Model Engine Encyclopedia" (AMEE) which is reproduced in its place below. It also bears no resemblance to the K&B 15 Series 72 diesel which appears on page 403 (I/D no. 998) of Jim Dunkin’s generally comprehensive 2.5 cc reference book. Those are the only diesel versions of the K&B Series 72 which appear in either book, so this is definitely “one that got away”! It incorporates the main crankcase casting and possibly the piston and One obvious suspect who immediately came to mind was Roger Theobald of the USA. Apart from working at K&B and hence having unrestricted access to their excellent machine tooling, Roger was an active F2C team race competitor. Having developed the ARM (American Racing Machine) team race diesel in the late 1960's, he and John Barr used that engine to finish a very creditable fourth at the 1970 F2C World Championship meeting at Namur, Belgium. Roger subsequently went on to develop the ARM-based K&B Series 72 team race diesel model, of which more in due course. However, the American team of Hodgkins/McCollum used one of Roger's earlier ARM units to finish fourth once again at the 1972 event held at Helsinki, Finland. So Roger Theobald was an experienced team race engine designer/builder with a pedigree plus a direct association with K&B. It seemed to me that this engine could well be his work. However, "could well be" didn't cut it - I wanted to know!! I began my search for enlightenment by seeking the advice of a number of good friends, beginning with my Danish mate Luis Petersen, who was a top-flight F2C competitor and engine builder during the period when this engine must have been created. This being the case, Luis might know either the engine itself or its creator (or both). However, Luis did not recall having previously seen this unit at any time. He recalled a few American competitors using dieselized K&B powerplants, but not this one.

In a final attempt to obtain some information regarding the origins of the K&B "special", I published a photo plus some limited information on the engine in my Editorial for the February 2019 issue of my website. I've tried this before, with limited success. However, this time it paid off in spades! Almost immediately I heard from Swedish reader Jim Lindqvist, who informed me that the creator of my engine was a Swedish gentleman named Mats Böhlin. Jim provided ample photographic and documentary evidence to back up his claim. Now that I had a name, I went back to Luis Petersen to inquire if that name meant anything to him. Back came an immediate response - of course it did! Luis knew Mats very well indeed, having competed against him in numerous F2C team race competitions back in the day. Mats was a serious F2C competitor in the 1970's with his team-mate Gösta Bengstar. He and Luis had remained good friends down through the years. More recently, Mats had focused upon tether car racing, a discipline in which he won many titles and set numerous records. Luis last met Mats in 2018 while attending a tether car race meeting in Sweden. Having learned about Mats' involvement with tether car racing, I next contacted Hugh Blowers of the outstanding OnTheWire website which is dedicated to preserving the ongoing history of tethered car and hydroplane racing. As I expected, Hugh knew Mats Armed with this background, I finally contacted Mats directly, with the assistance of Luis Petersen in establishing my own credentials as a serious researcher and writer. Mats graciously responded to my inquiry by confirming that he did indeed make this engine and a short series of others along the same general lines. As I had suspected, they were all built in the 1970's when Mats was deeply involved with F2C team racing. Mats recalled making between 10 and 15 examples, although he no longer had a record of the exact number. Mats remembered having experimentally constructed my engine's bell valve backplate (of which full details below), but also stated his recollection that the standard K&B internal drum valve unit was found to work better. This finding had the added benefit of relieving Mats of the need to make the rather challenging and time-consuming backplate assembly featured on my engine. Indeed, my unit may have been the sole example of Mats' team race "specials" which featured the bell valve. One rather odd piece of information provided by Mats was the fact that although my engine's cylinder head is undoubtedly his work, he did not add the colour anodizing to that component. His engines as produced always featured plain un-anodized heads. He had no idea who might have added the anodizing, or why. My sincere thanks went out to Mats for his kindness in supplying the above information. Sadly, Mats subsequently passed away on December 20th, 2020 from complications arising from heart and kidney issues which he had been fighting for some time coupled with his contracting the COVID-19 virus. He was 71 years old. A great loss - he's missed. Now that we have the name of the very talented constructor of this extremely interesting engine, let's have a close look at its inspiration and development. Mats Böhlin's K&B-based Team Race "Special" - Origins and Development The K&B 15 Series 72 glow-plug motor was a Roger Theobald design which was introduced in May 1972 in both control line/free flight and R/C versions. Its design drew quite heavily upon that of Roger's earlier ARM team race diesel. It was preceded by a The main target application for the new .15 model was the emerging category of R/C Quarter Midget Pylon Racing. However, the engine was also offered in an un-throttled version for free flight or control-line use. Like Theobald's ARM design, it utilized a rear drum valve as opposed to the disc valve employed in the earlier K&B 40R, but was otherwise very similar apart from its displacement. A published test of the R/C K&B 15 Series 72 glow-plug model conducted by Peter Chinn appeared in the June 1973 issue of “Model Airplane News” (MAN). Chinn was most complimentary about the engine, praising its quality and stating that it established a new performance standard for 2.5 cc R/C units. He measured a peak output of 0.510 BHP @ 21,500 rpm on K&B Supersonic 1000 fuel, while the engine managed 0.450 BHP @ 20,500 rpm on straight FAI fuel. It was Chinn's opinion that the un-throttled free flight/control line version would if anything perform at an even higher level. However, he found the engine to be extremely sensitive to the needle setting on straight FAI fuel, clearly preferring a higher-nitro blend. At the time of the engine’s release in May 1972, a short run of some 100 diesel versions of basically the same model was also produced specifically for F2C In his invaluable “American Model Engine Encyclopedia” (AMEE), Tim Dannels noted that when they were pushed, problems were experienced with the pressed-in crankpins initially used in the Series 72 .15 cuin. models. This caused a number of them to be returned to the factory for repair. There was also an issue with premature wear of the piston/cylinder combination. The returned engines were fitted with a revised crankshaft having an integral crankpin. They were also equipped with a harder piston/cylinder assembly which wore better. This was an issue given the very low oil contents in the fuel which were then coming into vogue. We’ve seen that limited numbers of the K&B 15 Series 72 diesel model were available to serious team race enthusiasts from May 1972 onwards. It was presumably a very capable powerplant (at least once any crankshaft issues had been addressed). However, over in far-off Sweden, a very talented team race enthusiast named Mats Böhlin took a long look at it and decided that he could see potential improvements to the design. Not only that, but he had the machining capability to put his ideas into practise.

Mats developed his own version of the basic K&B design in stages. Jim Lindqvist sent some images of an example in his possession which has the same drastically redesigned cylinder and head as my engine but retains the standard K&B drum valve backplate. It also has a Super Tigre needle valve assembly in place of the Cox set-up used by K&B. Jim's engine also bears the engraved numbers 77-78.2 as written, perhaps recording the date of development and the number in the development sequence. My own example has an induction valve of far more sophisticated design (see below) but bears no numbers at all.

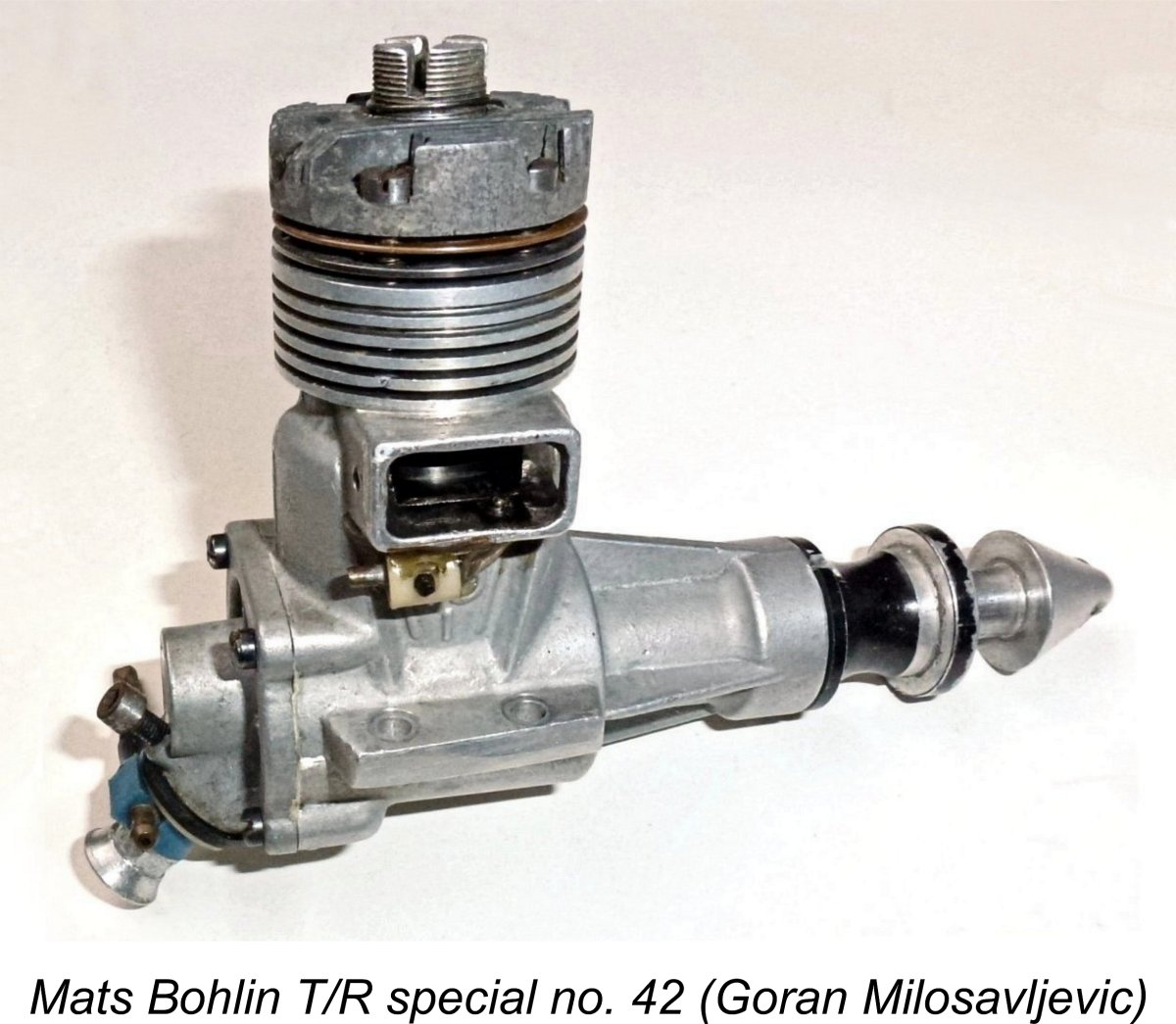

Another example of one of these engines was reported from Australia, where Goran Milosavljevic confirmed his ownership of a similar engine bearing the engraved number 42. It's very similar to Jim's example but retains the Cox needle valve assembly in place of the Super Tigre unit used on Jim's engine. It also has a very different comp screw configuration. After seeing images of this engine, Mats Böhlin confirmed that it is indeed another example of his work. He stated that the engine actually belonged to his former team race partner Gösta Bengstar and was one of a number of these engines which Mats and Gösta disposed of in 1982 after ceasing to use them. Mats confirmed that he generally used the standard K&B backplate assembly as featured on Jim's and Goran's examples. Those engines are therefore more typical of Mats' development of the K&B 15 Series 72 for team racing. As stated earlier, he recalled constructing the rather unique backplate assembly seen on my example, but actually found the standard K&B arrangement to be superior. We'll discuss the possible reasons for this in due course. Not having an opportunity to examine it at first hand, I'm unable to comment further on the technical details of Jim's example of Mats' work, although it seems to be more representative of Mats' efforts than my own seemingly experimental example. I'll have to confine myself to a full description of the unit in my own possession. To understand what Mats accomplished, it’s perhaps best to go through this engine component by component, highlighting both the similarities and the differences between the "special" and the K&B original.

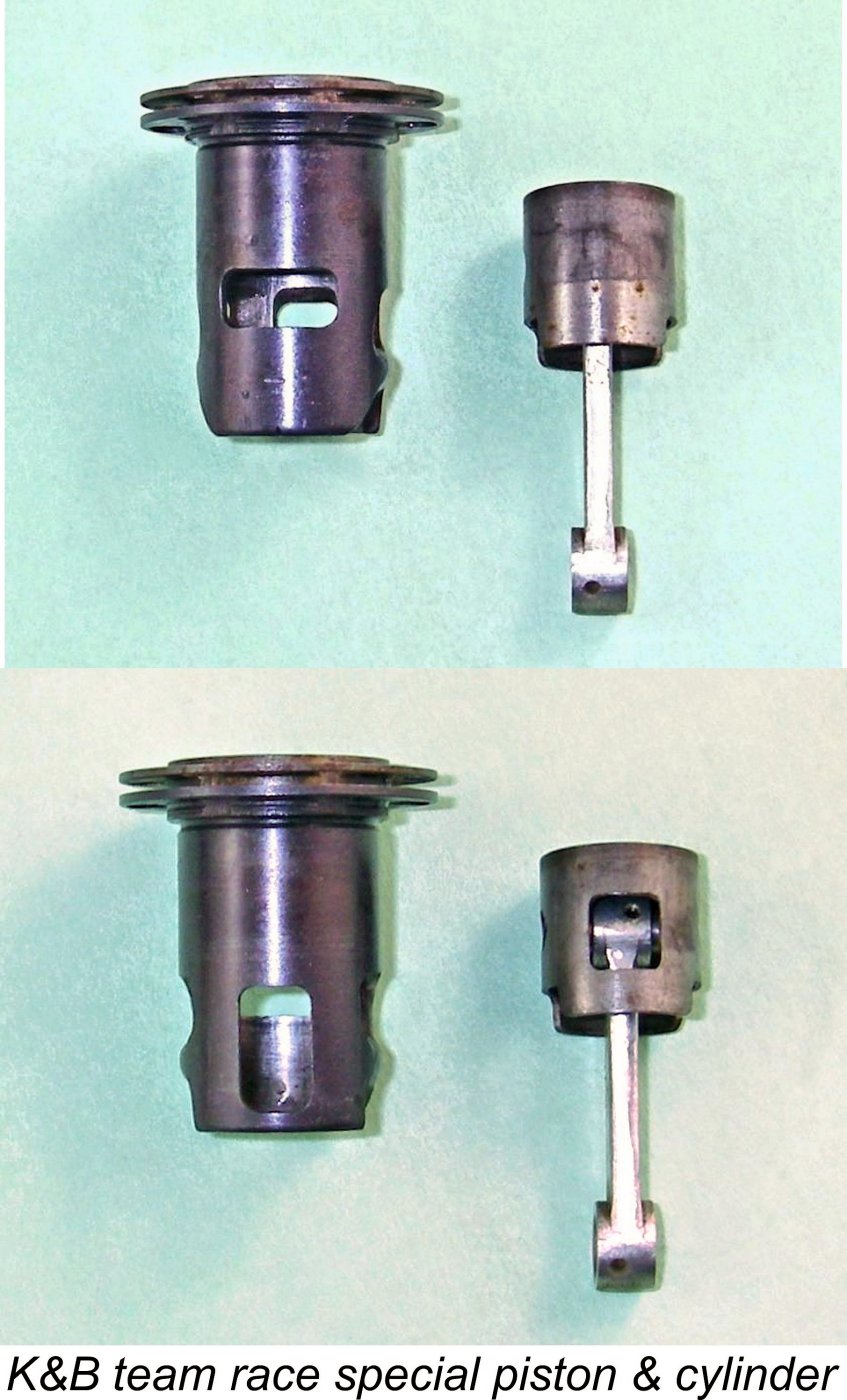

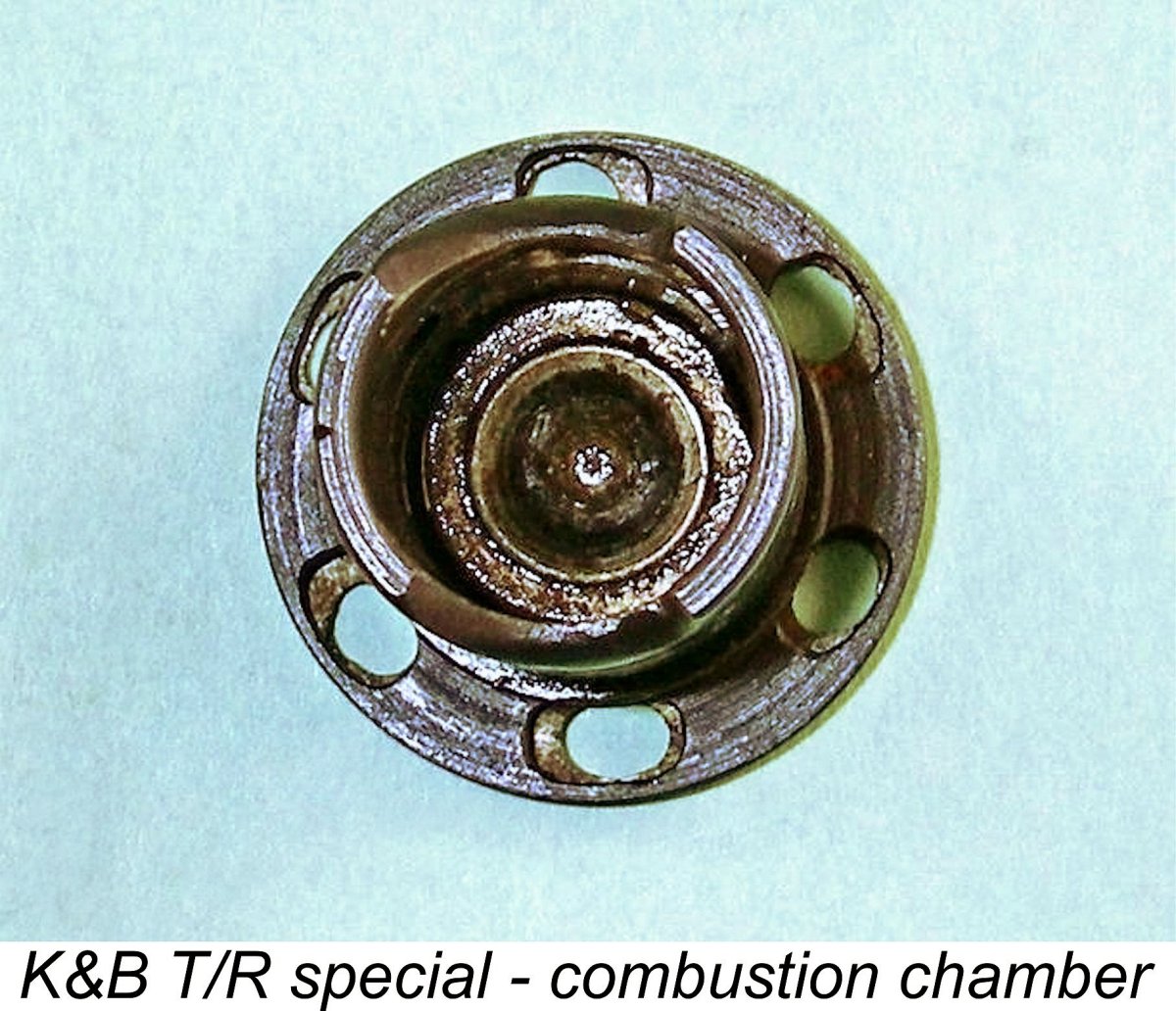

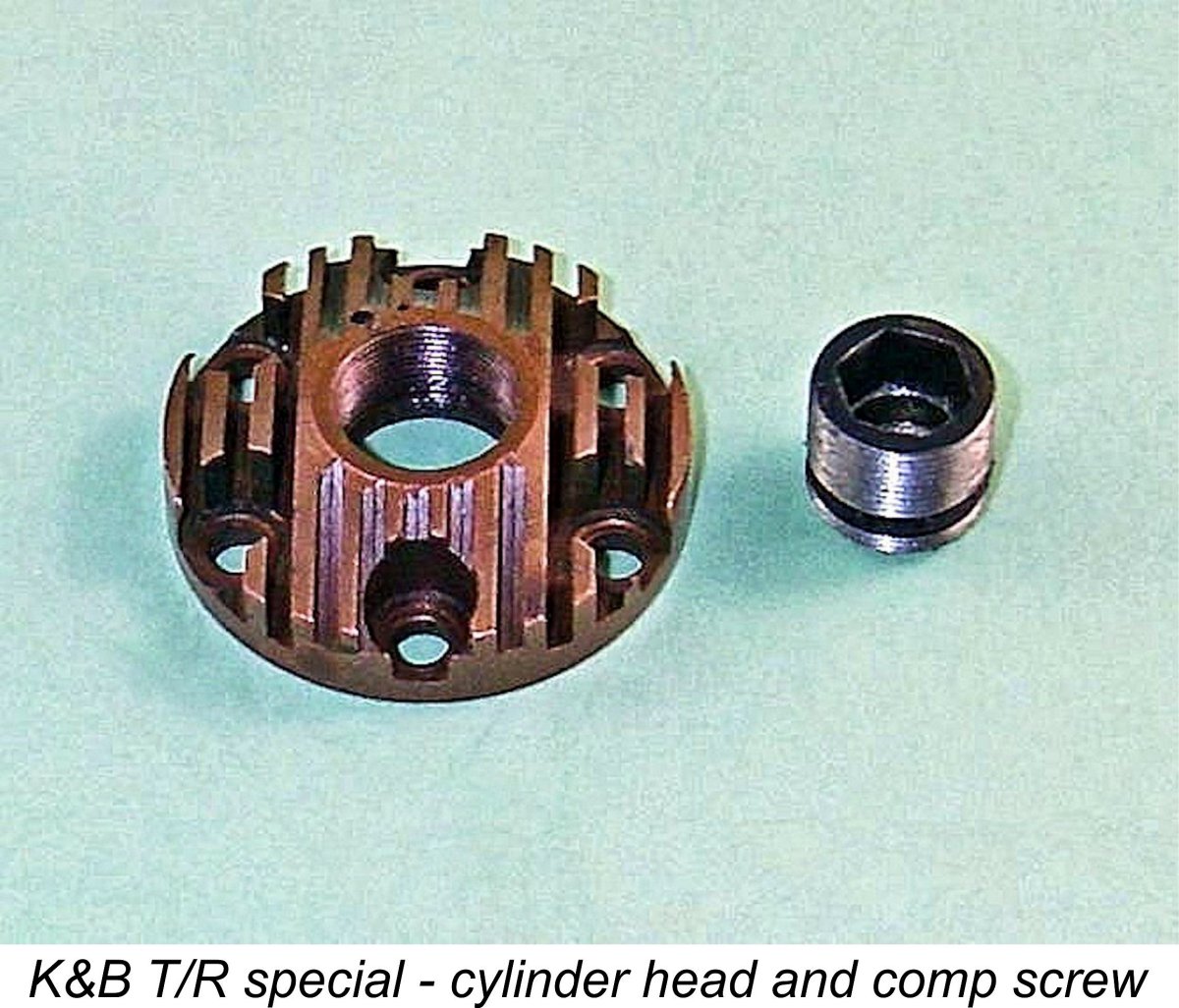

Bore and stroke of the diesel are nominally the same as those of the glow at 0.575 in (14.605 mm) apiece for a “square” internal geometry and a calculated displacement of 2.447 cc (0.1493 cuin.). The diesel weighs in at 188 gm (6.63 ounces) – only a little more than the un-throttled glow version’s figure of 180 gm (6.35 ounces). The one-piece drop-in hardened steel cylinder liner of the diesel is completely different from that of the glow, being in fact an all-new component produced by the engine’s creator. Since it interacts with the same crankcase casting as the glow model, it naturally features the same basic cylinder porting. However, the transfer and boost ports have been very carefully matched and gas-flowed by hand. The major differences are to be found at the upper end. The cylinder is bored half-blind, leaving a reduced-diameter section Naturally, the accommodation of the contra piston requires that the cylinder be made a little taller. The extra height is utilized externally to create two extra cooling fins. Being formed integrally around the hottest part of the engine, these should do much to ensure adequate cooling during operation. Mats confirmed that the beautifully machined cylinder head on my example is undoubtedly his work. However, he stated that he never colour-anodized the heads of his engines, leaving them in their natural finish as displayed on Jim Lindqvist's example. He had no idea who went to the trouble of colour-anodizing the head seen on my engine. All I can say is that it must have been a subsequent owner who valued the engine very highly and wanted to dress it up to the maximum extent possible. In keeping with emerging design trends for team race diesels in the 1970’s, the K&B diesel “special” dispenses with a conventional tommy-bar compression screw. Instead, it utilizes a large-diameter set screw having a ¼ in. hexagonal socket, into which an Allen key or equivalent can be inserted to make compression adjustments. This set screw has an unusually fine thread, which should facilitate the establishment of extremely precise compression settings. A neat touch is the inclusion of an O-ring in an annular groove which interrupts the set screw's installation thread near its base. The purpose of this is clearly to ensure that compression settings remain stable at all times, particularly if a reduction is made during a race. It is very effective - the screw operates very smoothly but with a more than adequate degree of tension. Moving on downwards, the flat-topped cast iron piston is generally similar to that of the standard glow model, as indeed it has to be given the fact that the cylinder porting is basically the same. It may even be an original K&B piston. It features cutaways fore and aft to avoid conflict with the main bypass passages at bottom dead centre, along with a rectangular skirt port to feed the boost port bypass. The tubular steel wrist pin is retained by a pair of tiny circlips, just as in the glow model. Perhaps surprisingly, cylinder port timing is actually somewhat more aggressive than that of the glow model. The following table provides comparative figures.

There is also a short period of sub-piston induction extending for some 10 degrees either side of top dead centre for a total period of 20 degrees.

The shaft has what appears to be an aluminium alloy “cap” or "dish" covering both the rear face of the crankweb and its outer rim. The standard shaft has an alloy ring around the rim, but its rear face is left uncovered. Presumably the set-up employed in the diesel is aimed at reducing crankcase volume to increase pumping efficiency. A hole is very accurately drilled and countersunk in this “cap” to accommodate the crankpin. Since I chose not to dismantle what appeared to be a perfectly fitted main bearing assembly, I can’t comment on whether or not the crankpin is a pressed-in item. However, the care displayed in the design and execution of the rest of the engine leads me to suspect that this is a different shaft which more than likely has an integral crankpin or at least an improved pressed-in component. I very much doubt that it’s the standard K&B Series 72 glow shaft under that “cap”!

Mats recalled that he did indeed make this rather complex assembly just to try it out. However, he found that the standard K&B backplate assembly was actually superior when fitted with an appropriate needle valve assembly. The backplate featured on my engine is a completely new component rather than a modified K&B item. It has been very neatly machined from solid barstock. It accomodates a very large diameter thin-walled steel drum as its working component. This operates within a bronze bushing which is set into the alloy backplate itself. The backplate also accommodates a concentric non-metallic core which is made from Ryton or some similar material and is held in position by three small Phillips-head screws which are inserted from the rear. The non-metallic core is formed so as to be a precise fit for the internal diameter of the drum, which thus operates in the very narrow annular space between the outer bronze bearing and the inner non-metallic core. The alignment and relative dimensions of this assembly obviously have to be perfect if excessive friction and leakage are to be avoided. Mats made a fine job of it. The drum is fed internally through a horizontal screw-in Cox peripheral jet venturi and needle valve assembly, as also used in the “official” K&B-made diesel models. This was something of a standard among team race exponents at the time. The drum (or "bell") discharges upwards into the crankcase from within through a large port formed in the upper portion of the backplate installation spigot. The upper rear portion of the crankcase itself is cut back to exactly match the opening in the backplate. The very large diameter of the drum makes it possible to provide an unusually large induction port area with extremely rapid and precise opening and closing. The system also has the advantage of minimizing crankcase volume in the closed state, thus promoting improved pumping efficiency. In terms of gas flow, I would expect the system to function very well in operation, although friction levels would doubtless be somewhat higher than normal. The induction timing provided by this bell valve doesn’t differ all that much from the figures applied to the standard glow model. The table below gives the comparison.

But perhaps a more insidious factor was the well-documented tendency of the bell valve system to starve the conrod big end of oil, causing it both to run hot and to wear rapidly. This is because the system throws the incoming mixture upwards into the crankcase interior above the elevation of the crankpin, even at top dead centre. The conrod big end thus receives no direct spray of incoming mixture. With a “normal” oil content in the fuel, this is generally not too much of an issue, as witness the excellent service record of the pipe-valved FROG 349, for example. However, the very nature of team racing tends to promote the use of low oil contents since the oil content in the fuel is not available to burn, thus contributing nothing to range. By the early 1970’s oil contents in team race fuels were already down around 20% and moving fairly rapidly towards 15% or even lower (today, oil contents of 5-10% are not unusual). I would not expect this engine to do well on a low oil content fuel. Finally, there was the inescapable fact that the form of drum valve featured on my engine would have been very time-consuming and exacting to produce. Using the standard K&B system with suitable modifications was undoubtedly the path of least resistance in terms of construction.

I strongly suspect that this particular engine has actually seen some use in a model. The mounting lugs have been very neatly trimmed, presumably to match an alloy pan, and the witness marks around the mounting holes prove that it has been mounted. The state of the cylinder head, piston crown and combustion chamber all confirm that it has done quite a bit of running. However, all fits remain outstanding. The evidence suggests that any such use of the engine in a model must have been undertaken by whoever applied the colour anodizing to the cylinder head following its acquisition from Mats. This deduction is based upon the clear evidence of heat cycles having been applied to that component following the anodizing process. If any reader knows who this might have been, please get in touch! It would be really nice to complete this engine's story! When or if time and opportunity combine at some point in the future I will conduct a full test of this engine and add the results to this article. Summary

However, by the late 1970's the emergence of improved models such as the American-made Nelson 15D, the Rossi 15D and above all the Bugl Mk. II and the derivative BG Mk. I would have combined to begin pushing Mats' K&B specials towards also-ran status. The progressive reduction in team race oil contents which was becoming increasingly necessary to maximize range would also have compromised the engines' competitiveness. That of course takes absolutely nothing away from the quality of the thought and work that went into this engine.

Today the engine is equipped with a silencer and installed in Luis's 3.5 cc Weatherman model. That motor/model secured the Danish 3.5 cc Weatherman record for Luis, a record which still stood at the time of writing (March 2019). So Mats' converted K&B diesels have continued to run up front! My thanks to Luis for supplying the attached image of the engine. I hope you've enjoyed this look at the accomplishments of one of the modelling world's most talented model engineers. Hats off to the late Mats Böhlin for the very capable execution of a whole series of front-running home-constructed powerplants! _______________________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published March 2019

|

||

| |

I don't generally write articles on "specials", although I have made exceptions in the past when a particular example posesses unusual historical or technical significance. My articles about

I don't generally write articles on "specials", although I have made exceptions in the past when a particular example posesses unusual historical or technical significance. My articles about

Both the conrod and the crankshaft differ from those used in the standard glow model. The conrod is a nicely machined barstock component which has a bronze-bushed big end as opposed to the un-bushed bearing of the standard rod. It is somewhat more sturdy in section than the standard rod, as it doubtless needed to be for diesel operation.

Both the conrod and the crankshaft differ from those used in the standard glow model. The conrod is a nicely machined barstock component which has a bronze-bushed big end as opposed to the un-bushed bearing of the standard rod. It is somewhat more sturdy in section than the standard rod, as it doubtless needed to be for diesel operation.  At the front end, the engine features an extended prop driver of typical “European” style which is nothing like the component used on the standard glow model or even that seen on the factory K&B 15 Series 72 diesel. Nor does it match the combination of components seen on Jim Lindqvist's previously-illustrated engine. The prop is secured by a conical alloy sleeve nut in the conventional manner. Some idea of the care which went into the construction of this engine may be gauged from the fact that the prop washer is diametrically turned to a tapered outer configuration which exactly matches the conical shape of the sleeve nut – you can barely detect that the washer is there when the assembly is tightened. I suspect that the two components were turned together at the same setting.

At the front end, the engine features an extended prop driver of typical “European” style which is nothing like the component used on the standard glow model or even that seen on the factory K&B 15 Series 72 diesel. Nor does it match the combination of components seen on Jim Lindqvist's previously-illustrated engine. The prop is secured by a conical alloy sleeve nut in the conventional manner. Some idea of the care which went into the construction of this engine may be gauged from the fact that the prop washer is diametrically turned to a tapered outer configuration which exactly matches the conical shape of the sleeve nut – you can barely detect that the washer is there when the assembly is tightened. I suspect that the two components were turned together at the same setting.  I’ve saved the best for last! The team race special has a rear induction valve of totally different design to that of the glow version. That model has a relatively conventional drum valve which is fed by a downdraft intake venturi. The diesel uses a rather complex assembly designed on the bell valve principle whereby the interior of the large-diameter drum is open to the outside atmosphere and the drum discharges outwards and upwards into the crankcase when the port is open.

I’ve saved the best for last! The team race special has a rear induction valve of totally different design to that of the glow version. That model has a relatively conventional drum valve which is fed by a downdraft intake venturi. The diesel uses a rather complex assembly designed on the bell valve principle whereby the interior of the large-diameter drum is open to the outside atmosphere and the drum discharges outwards and upwards into the crankcase when the port is open.  As stated earlier, Mats recalled trying this backplate design, but quickly formed the opionion that the standard K&B set-up was superior. Why might this have been? Well for one thing, the level of friction and viscous drag would undoubtedly have been far higher with the large-diameter drum than with the smaller-diameter K&B arrangement. This would inevitably have affected the engine's performance to some degree.

As stated earlier, Mats recalled trying this backplate design, but quickly formed the opionion that the standard K&B set-up was superior. Why might this have been? Well for one thing, the level of friction and viscous drag would undoubtedly have been far higher with the large-diameter drum than with the smaller-diameter K&B arrangement. This would inevitably have affected the engine's performance to some degree.  The whole dieselization project was very professionally carried out by its very talented constructor Mats Böhlin. The required standard of workmanship was very high, particularly in relation to the induction valve set-up, and Mats was clearly well up to the challenge. Given his later accomplishments in the tether car racing field, this comes as no surprise!

The whole dieselization project was very professionally carried out by its very talented constructor Mats Böhlin. The required standard of workmanship was very high, particularly in relation to the induction valve set-up, and Mats was clearly well up to the challenge. Given his later accomplishments in the tether car racing field, this comes as no surprise!

The K&B 15 Series 72 was not the only K&B design to undergo the dieselization treatment from Mats. He also converted a few examples of the 1976 K&B 3.5 (0.21 cuin.) FRV model to diesel operation. My good friend Luis Petersen retains one of these engines to this day, having used it initially in a Goodyear racer.

The K&B 15 Series 72 was not the only K&B design to undergo the dieselization treatment from Mats. He also converted a few examples of the 1976 K&B 3.5 (0.21 cuin.) FRV model to diesel operation. My good friend Luis Petersen retains one of these engines to this day, having used it initially in a Goodyear racer.