|

|

The ARGO-Elfin 249 - Replica or What?

The original version of this article appeared in September 2013 on the widely-read “Model Engine News” (MEN) website, the valued creation of the late and greatly missed Ron Chernich of Brisbane, Australia. Thanks to Ron’s foresight in arranging for the MEN site to remain available to readers after his tragic passing in early 2014, that original ARGO article may still be accessed directly through this link. However, Ron’s foresight unfortunately did not extend to the sharing of the required administrative access codes to allow changes to be made to articles on his heavily-encrypted site. This means that no maintenance of Ron's site has been possible following his demise. Consequently, any required changes or additions to an existing article on MEN can only be made by transferring the text and images to a different site and making the changes there. Once that’s done, the revised article cannot be re-mounted on MEN. Since the publication of my original ARGO article on MEN, a considerable amount of additional information about the ARGO-Elfins has come to light. This necessitated the preparation of a significantly updated article. Previously, this would have appeared on the MEN website as a replacement for the original article, but this is no longer possible for the reasons stated earlier. It is solely due to this situation that the updated article which you are now reading appears on my own website. With that said, on to business! There’s no doubt at all about either the name or the manufacturers of this engine. In that sense, we know exactly what it is as well as who made it. The issue which remains to challenge us is - should it really be referred to as a replica?!? Is it sufficiently close to the original to warrant that designation? An interesting question, which applies to far more “replica” engines than just the ARGO!

This in turn highlighted a broader philosophical debate which has long been ongoing and will doubtless continue forever with no resolution! This is the degree to which old time (aka vintage) modelling should or should not remain faithful to its origins, including (but not limited to) the powerplants used. An evaluation of the ARGO-Elfin appeared to me to offer an excellent opportunity for what I hoped might be seen as an objective review of this issue. Accordingly, before turning my attention specifically to the ARGO, I’ll present a discussion of replica engines in general and their place in the aeromodelling and collector communities. In doing so, I realize that I will doubtless draw fire from critics on both sides of the debate! Recognizing this, I will try very sincerely to present both sides of the issue as objectively as possible, leaving it to readers to make up their own minds. If this discussion holds no interest for you, please feel completely free to skip the entire following section to get straight into the review of the ARGO-Elfin itself. No-one is required to read all (or indeed any) of the material published here! Now, before getting started I’d like to extend my thanks to all of my colleagues who shared their views on the subject at hand. In particular, I’d like to acknowledge the assistance rendered by my late and much-missed Aussie mate David Owen as well as my friends Tim Dannels, Ken Croft, Eric Offen, Maris Dislers, Jon Fletcher, the late Bert Streigler, David Zwolak, Bob Christ and Bob Stalick. Plus as always, a word of sincere thanks to the late and much-missed Editor of MEN, Ron Chernich, who helped immensely with the preparation of the original article. Thanks, guys!! OK, on into the breach ………. The “Replica” Debate

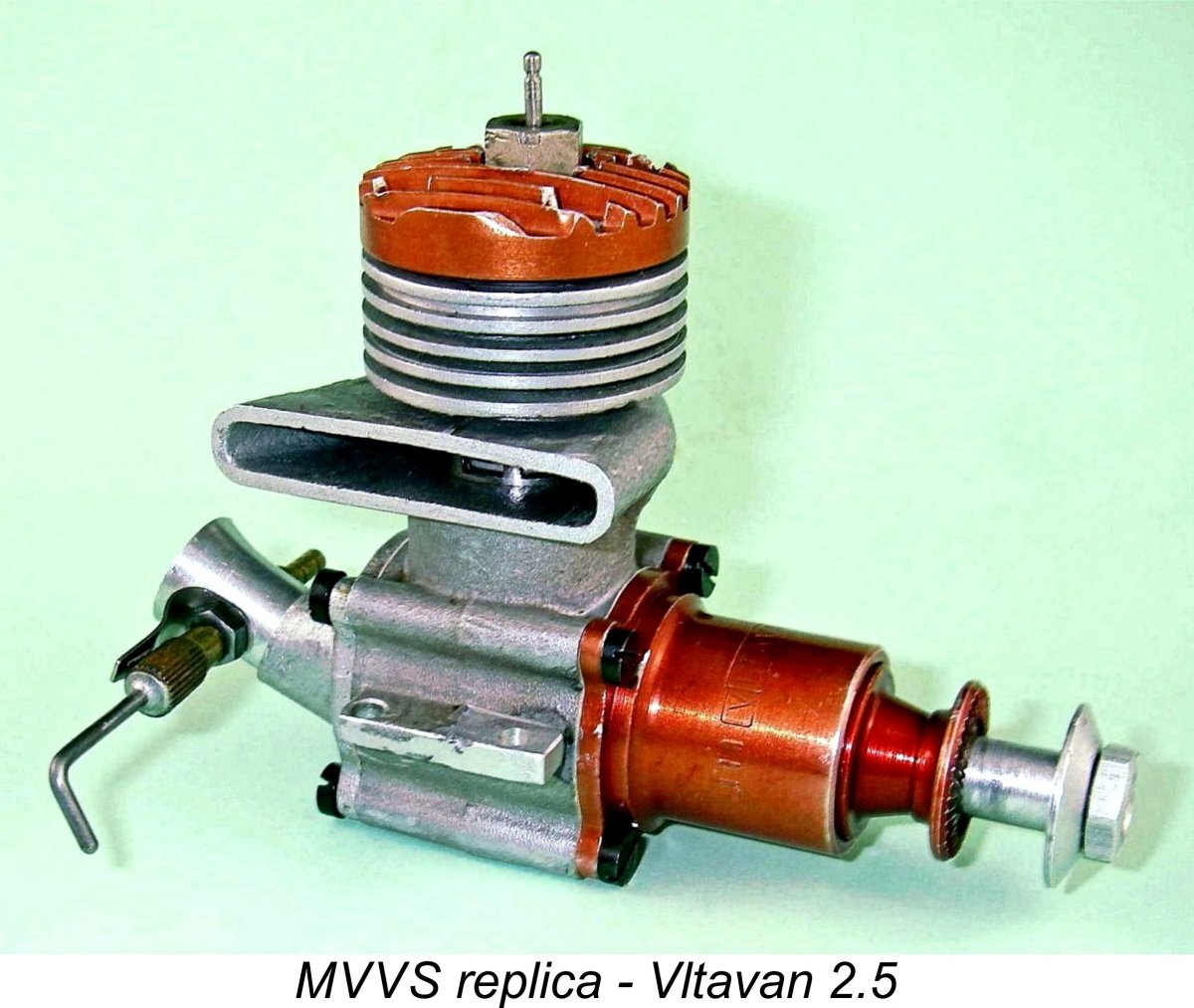

From the late 1940’s through the 1950’s, Gordon Burford of Australia made a number of engines which, while not marketed as replicas, were very strongly influenced by overseas originals. Another well-known example from 1957 was the Russian-made MD-5 Kometa glow-plug motor, which was a near-clone of the contemporary Super Tigre G21/29 model. The Russians also produced close copies of other well-known engines such as the Webra Mach I, the Super Tigre G20/15 and the MVVS 2.5R/1958. Near-replicas of several British diesel designs were also produced in Czechoslovakia (as the Czech Republic was then) by Gustav Bušek.

The important distinction between these and later replicas was their purpose. They were not replicas of out-of-production models - on the contrary, at the time of their introduction the engines on which they were based were still readily available from their original manufacturers in their countries of origin, or at least still in wide circulation. Hence these early replicas were not produced to satisfy collectors or to comply with rules for a “period” competition of some kind. Their purpose was simply to make certain then-current engines (or more precisely, copies thereof) available in countries in which the original manufacturers did not or could not market their products. If an original was not obtainable, a replica would do! In a very real sense, the appearance of such replicas was a high compliment to the reputations of their original designers - only the better and hence more desirable engines received the replica treatment. By the early 1960’s, this “first wave” of model engine replication had more or less run its course as the supply of original designs having superior performance allied to excellent quality increased to the point at which the needs of active fliers were being met without recourse to replicas. For the next 20 years or so, production of replicas remained at a relatively low level. What changed matters significantly as time went by was the increasing chronological separation of active modellers from the dates of manufacture of the older engines, particularly those from the “pioneering” era. As these engines became ever older, they became viewed with increasing nostalgia, particularly by the growing community of aging but still-active modellers who had used them in their younger years. I have to plead guilty as charged ………. This in turn led to the development of two parallel albeit closely-related movements. One was the rise of engine collecting as a recognized activity among those for whom the engines themselves had always constituted a primary focus of interest. Once again, I confess to being largely in that camp myself, although my interests go well beyond mere collecting into the pursuit of hands-on research along with the experience of actually running and flying these engines. A row of The other parallel factor was a rising interest in nostalgia flying. This involved the building and flying of models which were designed, constructed and equipped as far as possible in accordance with the standards which prevailed during the “pioneering” era which bracketed WW2. The Society of Antique Modellers (SAM) has played a major role in promoting such activities worldwide. Although quite a few individuals had their feet firmly planted in both camps simultaneously, a certain degree of competition between these two movements was of course inevitable. Both groups sought original engines either for their collections or to use in “period” models (or in some cases both). However, the pure collectors developed a marked tendency to hoard their acquisitions, the result being that many engines which ended up in collections were effectively removed from circulation. This of course reduced the availability of such engines, thus creating supply difficulties both for the flying community and the growing ranks of collectors. Since the supply was finite given the fact that production of the engines in In conservation terms, this had one very positive effect - the old “junk” engines in the attic or in Dad’s old model box became increasingly seen as having a value and thus worthy of being brought out of hibernation to be offered for sale rather than being thrown out with the rubbish when it came time to clean out the attic. This perception extended even to those engines which had suffered considerable deterioration while in storage. Would the rare Hope "B" 5 cc glow-plug model shown in the attached before-and-after images have been seen as worth restoring in the absence of any collector interest? From its rusted-up beginnings, it's now a great-looking example which runs very well! The result was that a good few collectible engines which might otherwise have ended up in the dump were returned to circulation. Not only that, but their restoration became worthwhile given the extent to which a competent restoration can increase a given engine’s interest and value. The overall result was that for a while the supply of preserved or well-restored original examples of many engines actually increased or at least held steady. However, this could not last. Many of the better original or well-restored “recovered” examples of the more desirable or less common engines were soon absorbed in turn into the collecting and vintage flying communities, once again severely limiting the remaining numbers in circulation and thus placing further upward pressure upon prices. Over time, this process continued to the point where even many of For these individuals, a reasonably-priced replica of their engine offered a viable and practical alternative to risking an original, as well as potentially permitting their original engines to be sold to the collector community to finance further modelling activities. Of course, those having the required combination of equipment and skill (like my mega-talented mate Ken Croft) were able to make their own replicas, but they were in the minority. Through the steady process of transference from the flying to the collector communities, the availability of many classic engines tended to become even further restricted. Indeed, it was not only the flying community which suffered from the effects of this process - there were many latecomers to the collecting community who wished to acquire examples of certain engines for display or bench-running purposes but In this manner, both engine collectors and vintage fliers became potential customers for replica engines. Under these circumstances, it was inevitable that the production of such replicas would enjoy a renaissance. Indeed, it was only the development of this situation that made the quantity production of replicas an economically feasible proposition. Although it began somewhat earlier, the “modern” replica engine movement really started to gain traction in the early 1980’s, continuing well into the 21st Century. An amazing variety of pioneering model engines has now been subject to the replica treatment - indeed, many of the replicas have now themselves become seen as valuable collectibles in their own right. This latter factor naturally gives rise to its own set of problems ……..here we go again!!

This brings us to the heart of the latter-day debate - why buy a replica, and what should one expect from a replica?? As far as I can tell, the original reason for the creation of replicas (making a given current design available in areas in which it would otherwise not be available) has long ago ceased to have any validity. The present-day international marketplace is sufficiently open that modellers or collectors anywhere in the world have equal access to what’s available. So what’s left? The three potential answers seem to be as follows: 1) To be able to display or experience a replica of an engine which would otherwise be too costly or too difficult to obtain. This is the basis for the “collector” market for replicas. In this situation, the replica clearly needs to be as close as possible to the original. The one exception to this is when a given replica (whether faithful to the original or not) becomes seen as a valuable collector’s item in its own right and hence as a desirable acquisition for display purposes. This actually happens quite frequently. 2) To be able to re-create an accurate “period” model aircraft for which an original contemporary engine is either not available or too valuable to risk in flight, hence using a replica of the desired engine. In this case, the objective is to keep all aspects of the model design, construction and equipment as close as possible to the originals. The goal is to experience model flying as it really was back in the pioneering era, the competitive element being of secondary importance. This approach to vintage flying has many adherents in Britain. In this instance too, the engine to be used needs to be as accurate a replica of the original as possible, very much including its handling and performance characteristics. 3) To compete in competition classes which require that models and engines bear a visual similarity to the originals without necessarily requiring complete historical accuracy. This approach seems to find more favour among vintage flying adherents in North America. Here the objective is the same as it is for any other competition class - to win the competition using whatever equipment is allowed under the prevailing rules. In this case, the rules typically do not require the equipment used to be historically accurate - it merely has to appear to be historically accurate. Such twists as the use of non-period materials and the re-scaling of model designs are viewed as perfectly acceptable. Moreover, the engine used does not necessarily have to be an exact replica of an original - it merely has to have the general appearance of the original. If it performs at a higher level than the original ever did, that’s acceptable and probably even desirable in the eyes of such users given their competitive leanings.

The first philosophy seems to be more prevalent in the UK, while North American vintage fliers generally appear to lean towards the second camp. This of course is very much a generalization - there are many individual exceptions on both sides of the Atlantic! To meet the differing needs of these two groups, replica engines have evolved along two distinct tracks. First, there are those which follow the original design and Secondly, there are those which in effect take the original design merely as a starting point and incorporate a range of design changes intended to improve performance or durability (or both) without undue regard to the effect of such changes on the visual appearance and/or performance characteristics of the engine. Our subject model, the ARGO-Elfin “replica” (remember that?!?) is a classic example, as we shall soon see. The final product will retain the general appearance of the original but will not pass scrutiny even at a distance as a true replica and may well perform at a higher level as well. These engines will appeal to modellers in category 3 above. Looking at this objectively and considering the dictionary definition of the word “replica”, it appears to me to be self-evident that such engines are more correctly characterized as “look-alikes” rather than true replicas. That’s the term that I consistently use in the articles which appear on this website. I confess to being able to see that either of the above approaches in categories 2 and 3 must subjectively appear valid to those holding those views. In my personal opinion, it’s not a question of which view is correct - for a given individual, either can be. Rather, it comes down to the experience that each individual modeller is seeking. Does he wish to experience modelling as it really was back in the day, or is he simply interested in competing against other fliers using equipment which may have the appearance of being Old Time but which may not adhere to certain aspects of modelling as it truly was “back then”? As long as the rules are clearly defined and impartially enforced, both approaches seem valid to me - you simply take your choice!

The CS company of Shanghai, China had been making a near-replica of the 3.46 cc E.D. Hunter for some time. Although they suffered from the usual CS quality control issues, these “Hunters” were actually one of CS’s better efforts. They could be made to run at least as well as the originals, as I know from my own very successful experience with one of the 3.46 cc versions which received a thorough “going-over” at my hands prior to its initial start - very necessary with all CS engines. I would objectively rate this unit as a reasonably faithful replica with a performance at least equal to that of the original. It has seen good service in the air. To get around the previously-noted difficulty relating to the Hunter’s displacement, the CS company made a run of “Hunters” which looked very much like the originals but were internally dimensioned to comply with the .199 cuin. displacement limit for Class A. The problem here is that no Hunter .19 ever left the E.D. factory!! It’s my personal view that this is carrying the replica engine thing one step too far. Nonetheless, SAM has homologated this “engine that never was” for use in US Class A competition. I will admit to having problems with that …………….. others are almost sure to follow. Sadly, another similar philosophical challenge has now arisen in connection with the Old Time Stunt category of control-line competition, with the potential to be extended into other areas of old-time competition. This is the decision to allow electric powerplants into this category, at least in North America. I would be fine with this if electric competitors were required to use late 1940’s/early 1950’s electric technology (yes, there were electric control-line models back then!). However, the use of the modern electric super-motors appears to me to make a mockery of the entire Old Time concept. Most significantly, it removes one major element of skill from the competition - the securing of that elusive perfect motor run. Flip the switch - presto!! One perfect motor run coming right up………. for me, the category has parted company with its soul. Heck, it doesn’t even sound right!! Having got that off my chest, my purpose in presenting the above survey is to try to demonstrate that there are a number of perfectly valid reasons for acquiring a “replica” engine, whether faithful to the original or otherwise. If there is one thing that I would personally change about the terminology in Regardless, once one accepts the fact that both “replica” and “look-alike” engines have their own perfectly legitimate niches in the modelling world, it then becomes necessary when evaluating a given engine to determine which user category it was aimed at and how successfully it met the needs of its target purchasers. I will adhere to this principle during the following evaluation of the ARGO 2.49 cc “Elfin replica”. Before leaving this discussion, it’s worth mentioning a third category of engines which may have appeal to some vintage modellers. This is the “retro” category. Engines which fall into this classification are not in any way intended to be replicas or even look-alikes of a classic original - rather, they are original designs in their own right which date from well into the post-vintage era but are nonetheless designed along vintage or classic lines. The Valkyrie and Viking diesel and spark ignition models produced by Dunham Engineering in the 1980’s are good examples - although conforming to vintage design protocols throughout, they were in fact designed by Barry Holmes over 20 years or so after the vintage era had ended. While in no sense being replicas or even look-alikes for any classic model engines, such units undoubtedly provide the “classic” experience for their users, in addition to possessing their own technical interest. As such, it seems to me that they have a legitimate place. Time now to commence our in-depth examination of the circumstances surrounding the introduction of our subject model, the ARGO-Elfin “replica”. The ARGO Elfin “Replica” - Background

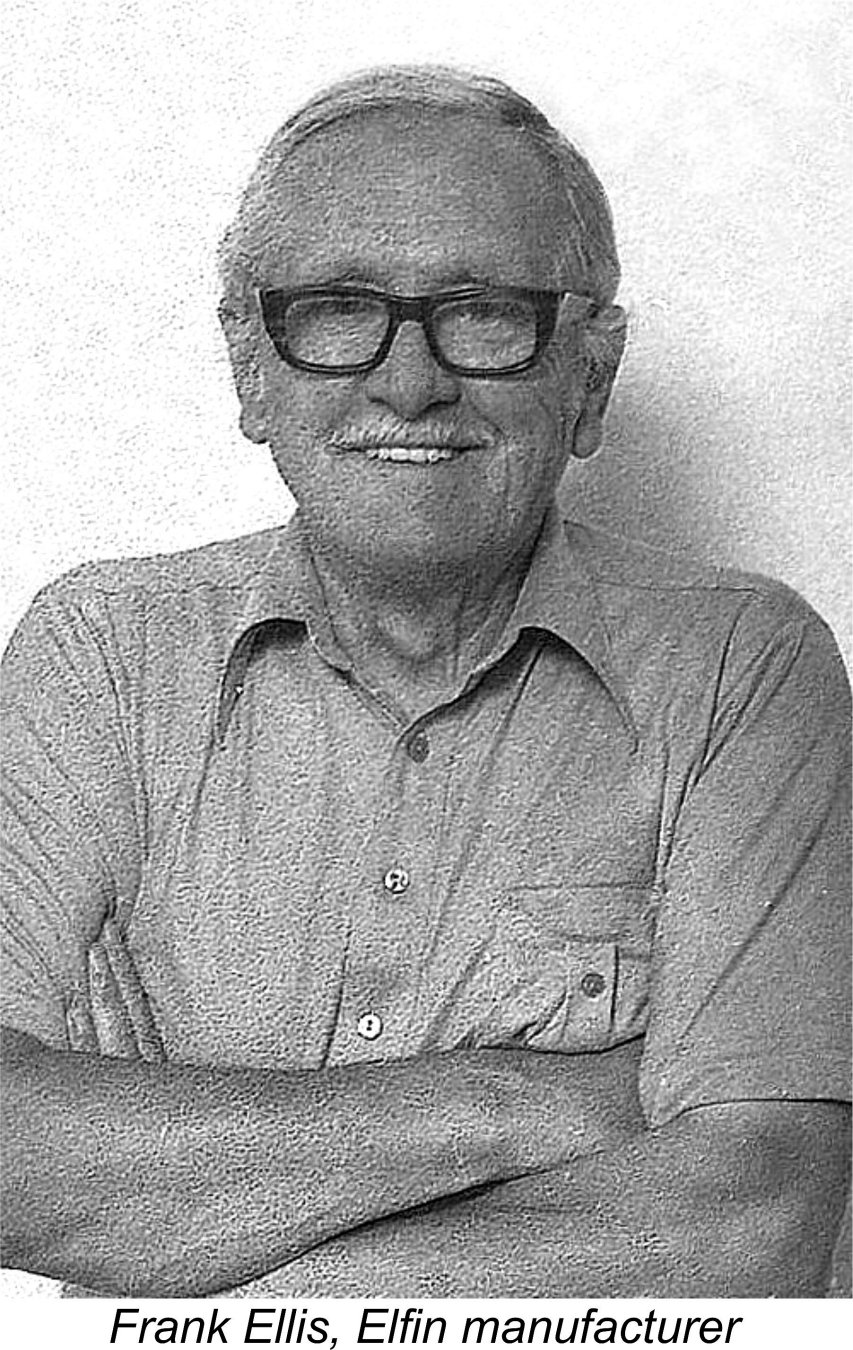

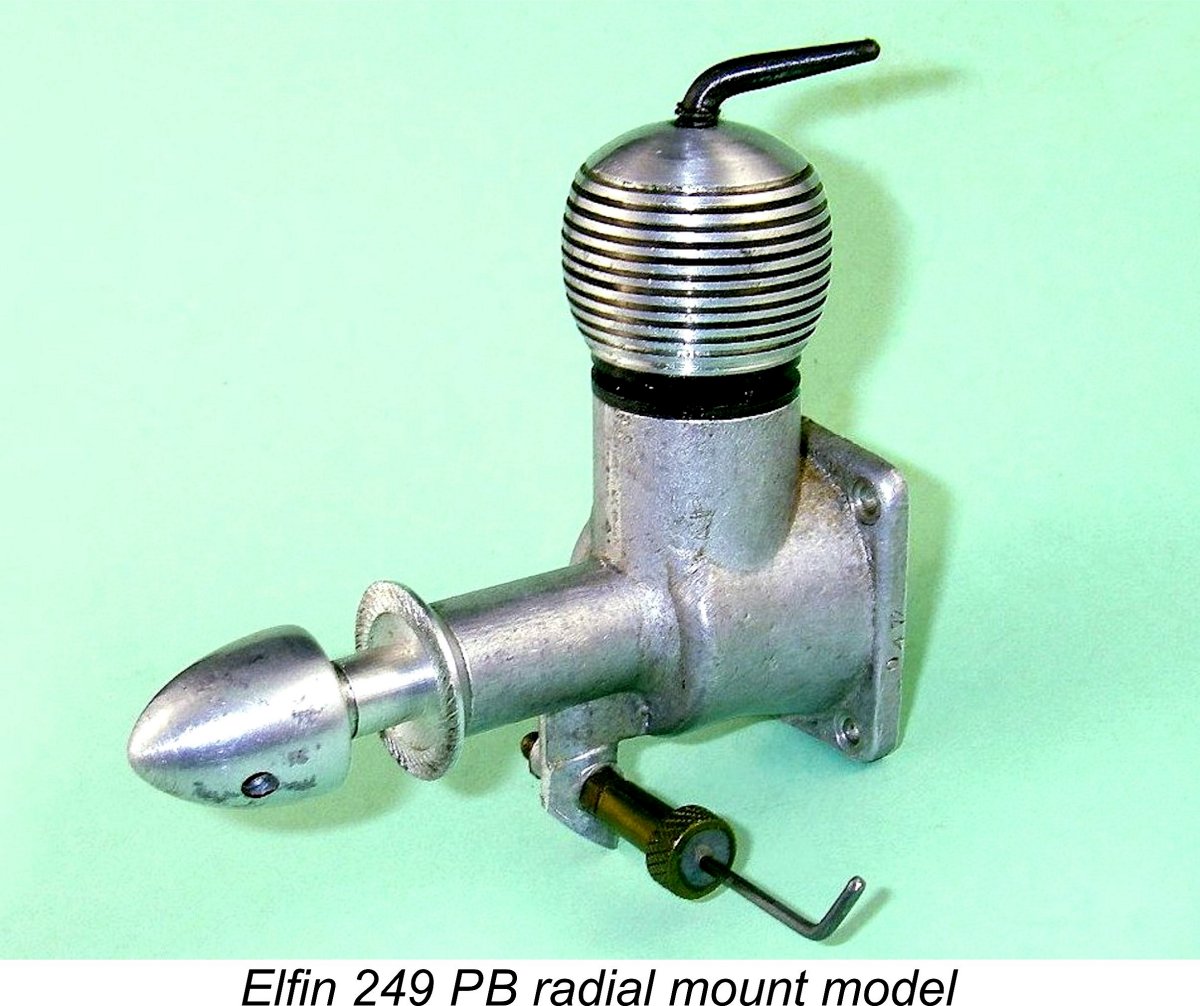

In mid 1948 the name of the range was changed from Aerol to Elfin (a combination of Frank’s surname with that of one of his associates, a certain Mr. Finn). Despite this name change, the manufacturers themselves retained the Aerol Engineering name. Their original Elfin product by that name was the radial-mount 1.8 cc plain bearing (PB) model which appeared in July 1948. The 249 PB radial mount model which is central to the present discussion followed almost a year later in June 1949. It would not be overstating the case to say that the appearance of the Aerol and Elfin engines drop-kicked British model diesel engine design straight out of its side-port past into the FRV future. The engines were lighter, more compact and far more powerful than their sideport predecessors. Their retention of long-stroke internal geometry resulted in excellent torque development, enabling them to swing airscrews of useful sizes. In addition, they were unusually light and compact for their power output. To cap it all, they handled very well indeed and were dead reliable, their gravity die-cast cases in particular being practically bullet-proof. Frank Ellis deserves great credit for his efforts in this regard.

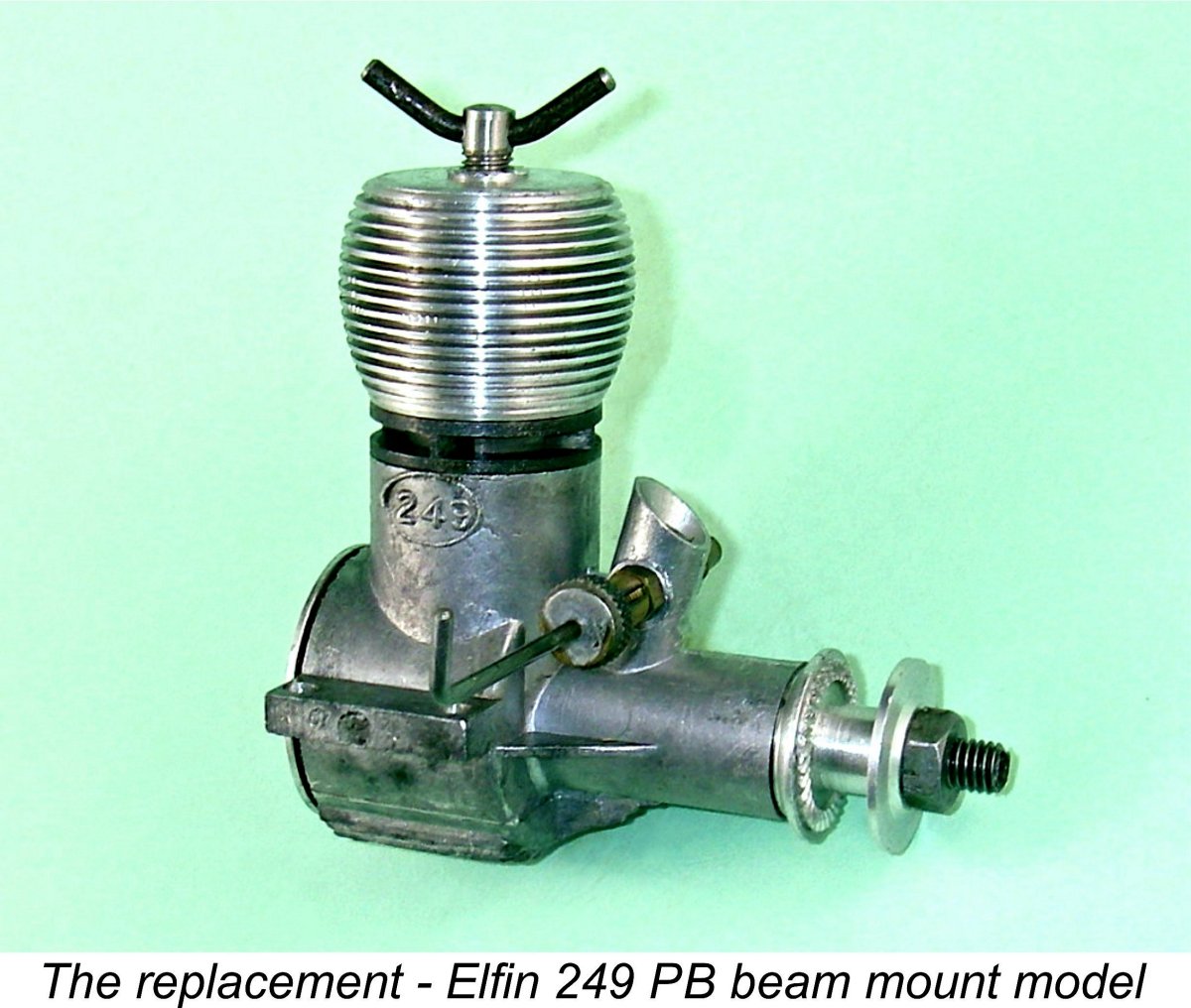

Unfortunately, the revised model was soon found to be both less powerful and less dependable than its predecessor. In particular, the revised pressure die-cast crankcase proved far less durable and resistant to distortion than the original gravity die-cast item. Consequently, the premature abandonment of the original radial mount model was widely viewed as a matter of regret, not least by Frank Ellis himself in later years. In retrospect, he reckoned that they should have continued to develop their original design regardless of the production challenges involved.

When the vintage model flying movement began to gather momentum in the 1970’s and 1980’s, many participants were quick to recognize the merits of the original radial mount Elfin 249 for such purposes. In particular, by the mid 1980’s diesel-minded members of the US old-time flier community had become aware of the advantages of this engine for use in their Class A events, particularly in terms of its power-to-weight ratio. The Elfin’s advantage in this respect more than offset any absolute horsepower handicap which might be anticipated as a result of its displacement shortfall relative to the Class A limit of 0.199 cuin. (3.26 cc).

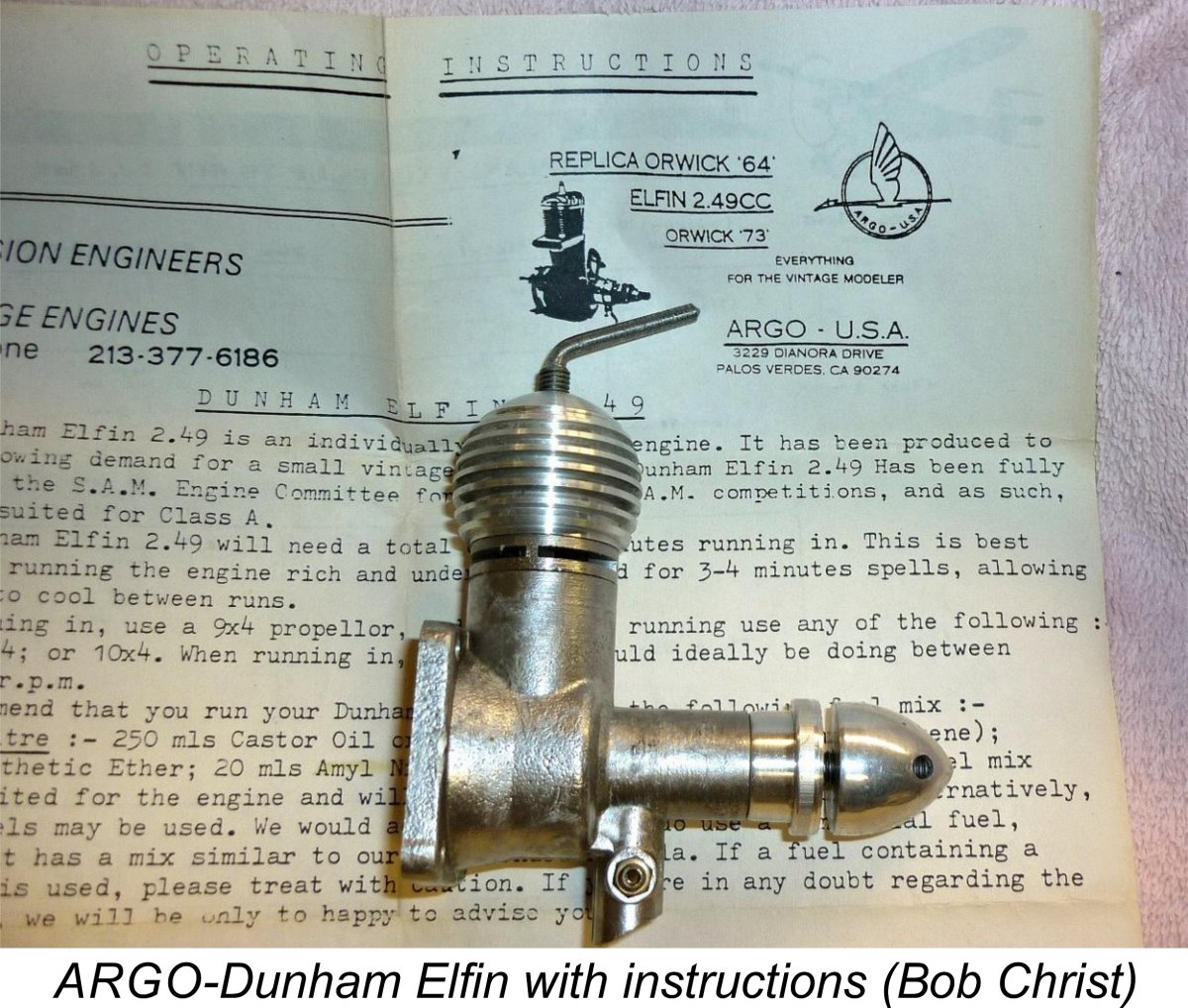

Prior to the appearance of the Dunham replica, original examples of the 1949 Elfin 249 PB were so scarce in the USA that few modellers were able to use one in competition. However, those few examples that did appear had demonstrated convincingly that the 1949 Elfin possessed a power-to-weight ratio which was unparalleled among SAM-homologated Class A powerplants at the time. Consequently, the appearance and speedy homologation of the light and powerful Dunham Elfin replica in 1984 was welcomed with open arms by SAM members in the USA. Indeed, Dunham’s former US agent, the late Examples of the Dunham Elfin quickly found their way into the Class A competition models of many SAM members in America, achieving a very high level of success. Overall, the injection of the Dunham Elfin into this category led to a huge upswing in the use of diesels for Class A competition in the USA under SAM rules. This was a good indication of how diesels might have fared in America back in the 1940’s and 1950's if they had been more actively developed or more effectively promoted (or if Ray Arden hadn’t introduced the commercial miniature glowplug in late 1947). However, all was not perfect. Supply was restricted by the limited rate at which the very small family-staffed Dunham Engineering company was able to produce the engines alongside their other models. Moreover, while the Dunham replicas were generally well-made and highly serviceable units, the occasional manufacturing flaw did show up in the odd example, together with somewhat variable levels of performance, as might be expected from an individually hand-made low-production unit. This led to the engines acquiring a somewhat chequered reputation which was largely undeserved. The Holmes family who owned and operated Dunham Engineering were highly ethical individuals who stood behind their products at all times, fixing any issues which were brought to their attention - a number of my contacts have attested to this on the basis of first-hand experience. Moreover, a well-sorted example of the Dunham Elfin was a very good engine indeed, as I know from personal experience. For a variety of reasons which are discussed in my companion article on Dunham Engineering, that company terminated production of model engines in 1988, making a very successful move into the business of making spare parts and undertaking equipment repairs relating to the agricultural industry. They remained in business for some 30 years thereafter, although they had ceased trading by 2020.

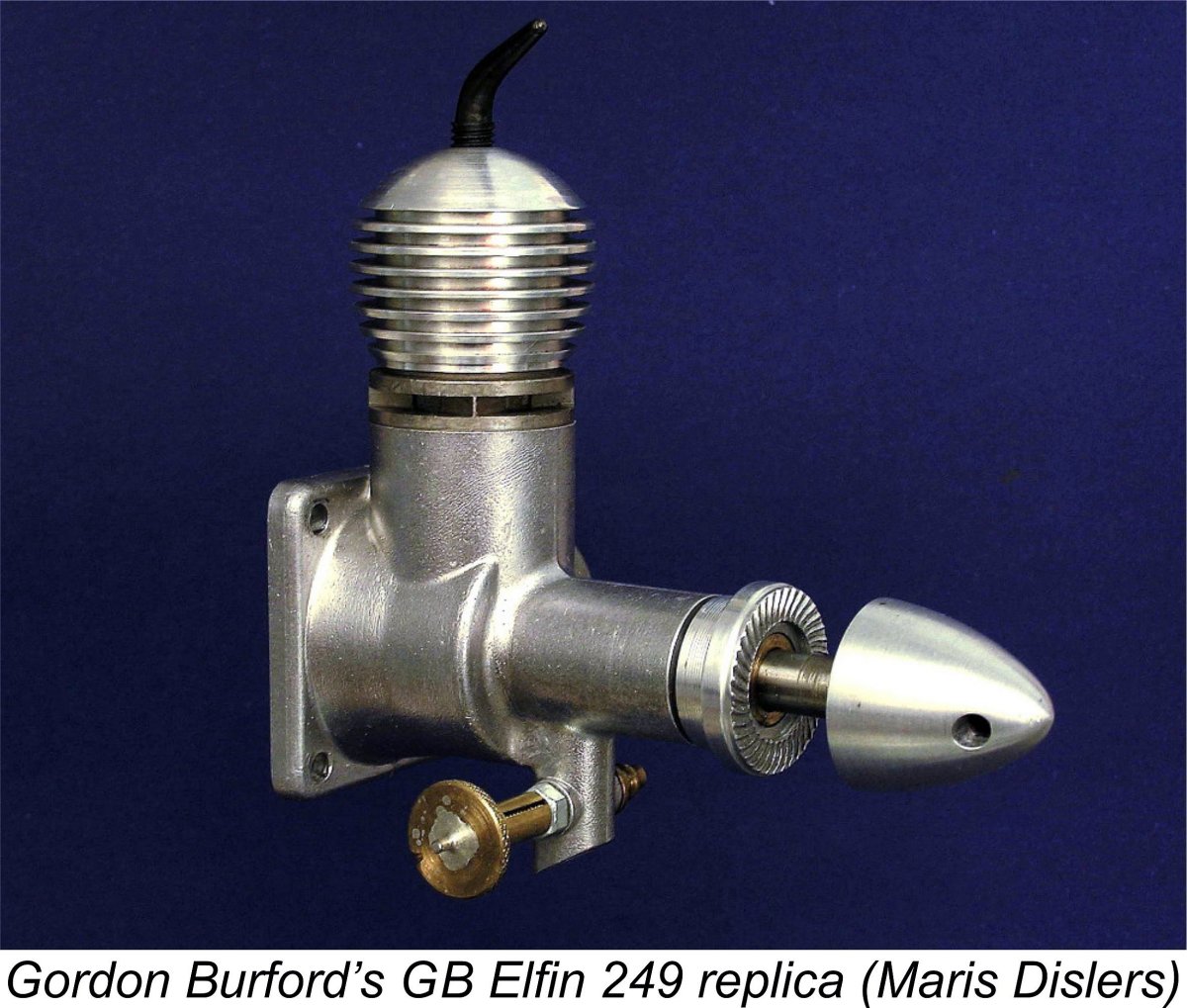

The next manufacturer to tap into this residual demand was the late and much missed Gordon Burford of Australia, who produced a number of examples of his own superb replica in 1989. However, Gordon was not alone in recognizing the market opportunity which had been opened up by Dunham’s withdrawal from the scene. An enterprising Los Angeles-based longshoreman and SAM competitor, John Targos by name, also appears to have begun to entertain ideas about entering the replica Elfin field himself at about the same time that Gordon Burford was commencing the production of his GB replicas. Through his active involvement in the SAM competition scene, Targos had a first-hand appreciation of the high regard in which the 1949 Elfin 249 and replicas thereof were held in US old-time modelling circles. Moreover, he was ideally positioned to market such an engine in the United States, since he was well connected to the US old-time modelling community. He already operated a vintage modelling supply business named ARGO - U.S.A. as a sideline.

At the same time as his approach to David Owen, Targos also contacted Gordon Burford to seek practical assistance in setting up his own manufacturing venture, offering a modest fee by way of compensation. According to David Owen, Gordon was actually quite happy to turn the replica Elfin field over to Targos. He was finding it impossible to respond to the demand for his own excellent Elfin replica in a timely manner. Accordingly, he was happy to provide the requested assistance to Targos, although he did fill his outstanding orders. Perhaps 100 examples of the GB Elfin replica ended up being manufactured. A range of advice was immediately forthcoming from Gordon, including the provision of at least one complete example of the GB Elfin replica plus a few parts and tooling sketches for Targos to study. Sadly however, this turned into the old, old story - none of Gordon’s assistance was ever acknowledged, nor was Gordon's modest fee ever forthcoming. Not a positive reflection of the ethics involved - it’s good to be able to set the record straight after all this time and finally give Gordon the credit to which he is fully entitled.

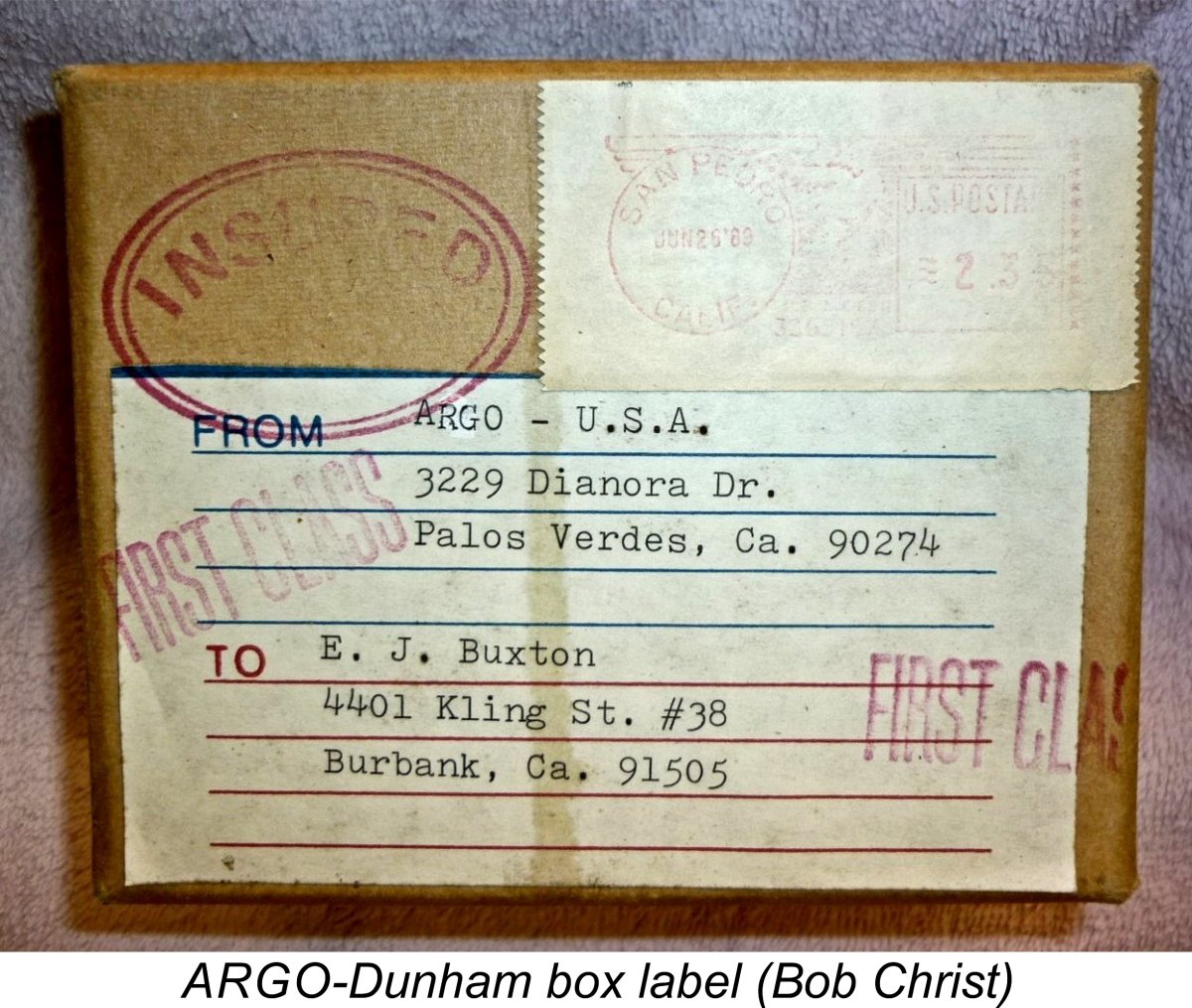

Both Bob Christ and David Zwolak have NIB late-model examples of the Dunham Elfin in ARGO - U.S.A. boxes with a Dunham instruction sheet which features Targos’s ARGO - U.S.A. logo superimposed upon the otherwise unchanged Dunham original, together with Targos’s business card on which he characterized himself as a Dunham “dealer”. The postal label on the box with Bob Christ’s example is dated June 25th, 1989, showing that Targos sold these engines on very shortly after receiving them from David Owen, well over a year after Dunham ended model engine production. Of course, the obvious explanation of this situation is that Targos was in fact a Dunham dealer! When queried on this possibility, Bert Streigler was at a loss to understand how this could have come about - he sincerely believed himself to have been the sole US distributor all along, feeling certain that if Targos had been granted a competing dealership prior to 1988 (when Dunham ceased making engines), he would have become aware of it through his many contacts. Moreover, he strongly concurred with the widely-expressed opinion that the Holmes family were extremely ethical in their business dealings and would never have knowingly undermined the status of their duly appointed American distributor by supplying a competitor under the table.

It actually seems more than likely that Targos’s intention from the outset was simply to sell the Dunham Elfins acquired from David Owen. After all, you only need one example to study, not six! Moreover, there were already plenty of Dunham Elfins in circulation in the USA, one or more of which would certainly have been available for a well-connected SAM member like Targos to study - no need to go to Australia for multiple reference samples. The above argument makes it appear likely that Targos was actually on a "fishing trip" to obtain some engines to sell. All that was necessary to turn the Dunham replicas obtained from David Owen into “ARGO-Dunhams” was to superimpose the ARGO - U.S.A. logo onto the Dunham instruction sheet and include a cobbled-up business card styling Targos as a "Dunham dealer". This over a year after Dunham had ceased model engine production .......... Unless someone can provide persuasive evidence to the contrary, I for one will continue to view this admittedly unproven scenario as by far the most probable explanation for the appearance of these “ARGO Dunhams”. If anyone out there can clarify this episode, please get in touch!!

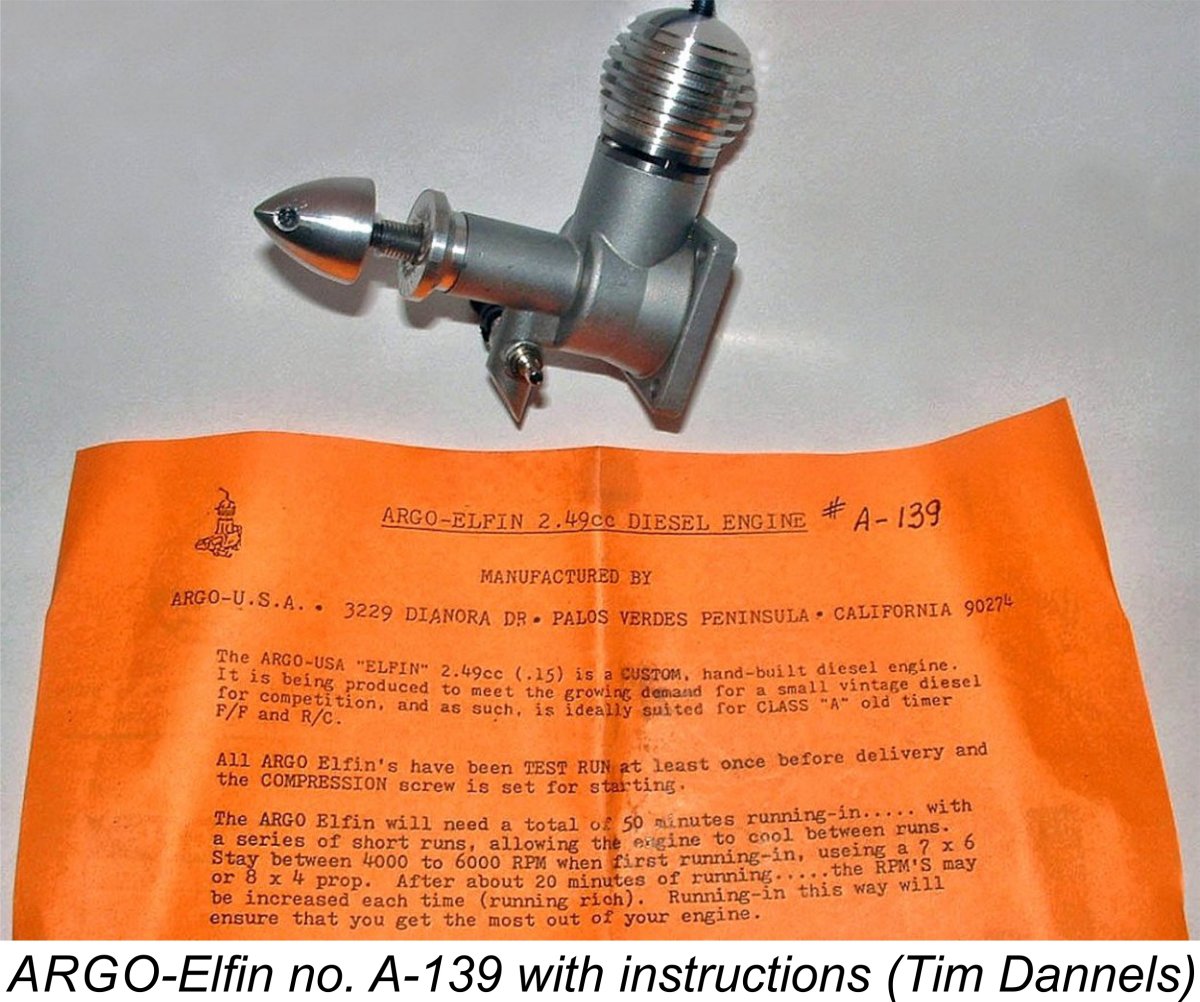

It was specifically to meet the needs of these fliers that the ARGO-Elfin was created. According to Tim Dannels, the ARGO was never intended to be an exact copy for collectors or purist vintage fliers. Rather, it was built primarily to create a strong-running modern “look-alike” version of a recognized classic model engine for use by those members of the US Old Timer competition crowd who preferred to use diesels. We have to keep this in mind when evaluating the engine. The ARGO “Elfin replica” was marketed by John Targos’s previously-mentioned ARGO - U.S.A. company, which gave its address as: ARGO - U.S.A. 3229 Dianora Drive Palos Verdes, CA 90274 USA The above company address was then (and remains today) a modest private house in a strictly residential area - clearly it has never been an industrial manufacturing facility. The implication is that in reality this was John Targos’s residential address.

“The ARGO-USA “Elfin” 2.49 cc (.15) is a CUSTOM, hand-built diesel engine. It is being produced to meet the growing demand for a small vintage diesel for competition, and as such, is ideally suited for Class A old timer F/F and R/C”. This actually appears to me to be a pretty honest statement - at no point does the manufacturer make any specific claim that this was a true replica, at least in the literature supplied with the engine. Indeed, it's worth noting that the word “Elfin” was rendered in quotation marks. Finally, it’s important to recognize that the engine’s openly-stated purpose was Class A old-timer competition under prevailing North America rules. We can't quarrel with any of this - buyers knew exactly what they were getting. Very little (if any) of the actual manufacturing was carried out at the company’s address in Palos Verdes, which was strictly a residential location as noted earlier. It appears to be a generally-known fact that the ARGO investment castings were produced to a very high standard by the recognized master of that art, Larry Jenno of Las Vegas, Nevada, USA.

According to Larry, the balance of the components for all of the additional engines were made and finished by Lew Mahieu, who sent them in unassembled batches to John Targos. The remainder of the engines in the production run were assembled from these components by Targos and his son working together. This was Targos’s sole involvement in the manufacture of these units. Apart from the components supplied by Lew Mahieu, a few proprietary components were also used - for instance, the needle valve assembly was a standard O.S. 10 FSR unit. John Targos’s personal involvement was thus confined to arranging for the manufacture of the components by others, assembling the finished components (apart from those assembled by Larry Jenno) and marketing the completed engines. He appears to have done so from what was clearly his private residence at 3229 Dianora Drive in Palos Verdes. The engines were supplied with a clearly-written instruction sheet which bore the serial number of the engine which it accompanied. All engines were supposedly test-run before dispatch, with the compression screw being left at the starting setting. The instructions regarding running-in were both clear and entirely appropriate. A total of 50 minutes running-in time in a series of short runs was suggested, with complete cooling in between. Sound advice - those heat cycles are vitally important for a new diesel using all-ferrous piston/cylinder technology! For a full discussion of the running-in issue, see my separate article on this website. Having set the scene for the introduction of the ARGO (as I will henceforth call it), let’s now take a brief look at the engine itself. The ARGO “Elfin” 2.49 - Description

The original 1949 Elfin upon which the ARGO was loosely based featured corresponding measurements of 14.07 mm and 15.87 mm respectively for an actual displacement of 2.47 cc (belying its 249 title!) and a stroke/bore ratio of 1.128:1. The ARGO thus has a considerably reduced stroke-bore ratio compared to that of the original Elfin, presumably with a view towards improving its top-end capabilities and reducing vibration. The general layout and appearance of the ARGO undeniably suggest those of the original Elfin model upon which the engine was loosely based. The cylinder porting system is the same, although the ports themselves have been modified somewhat. The ARGO retains the rather massive sub-piston induction which characterized the original Elfin model. The FRV Both the ARGO and the original Elfin are basically conventional British-style FRV plain bearing diesels which follow the emerging standard “competition” format of the late 1940’s and early 1950’s, with few if any notable design quirks. In fact, the broad descriptions of the two models remain sufficiently similar and comfortably familiar that there seems to be little need to present a detailed description here - the attached images tell the story. The amended stroke-bore ratio noted earlier provides the first clear indication of the ARGO designer’s priorities. A primary goal from the outset was clearly to realize the maximum possible performance from the engine. If this meant sacrificing originality, that was viewed as being quite acceptable. The overall design goal was obviously to produce an Elfin “look-alike” (as opposed to a true replica) which developed the maximum possible power for the layout. Such an engine would appeal to those fliers, predominantly The amended bore and stroke measurements are by no means the only design changes having a functional basis. Other changes of this nature include the previously-noted modified cylinder porting, a counterbalanced full-disc crankweb, a cast venturi intake having a larger external diameter to accommodate a significantly increased venturi throat area, a larger central gas passage in the crankshaft and a far more substantial radial mount plate at the rear. The engines also feature the O.S. needle valve assembly mentioned earlier. Admittedly this is functionally superior to the original Elfin design, but it bears no resemblance whatsoever to the original. One justifiable change in the context of the target market is the use of American threads throughout. Given the predominantly American clientele at which the engine was aimed, this appears to me to be a perfectly reasonable provision in order to facilitate repairs and replacement of damaged parts by the anticipated users of the engine.

A change that was most definitely not an improvement is the means of locking the prop driver to the crankshaft. The original Elfin used a taper machined onto the front of the crankshaft journal, with a matching internal taper in the prop driver - a practically bullet-proof system. By contrast, the ARGO uses a single flat machined into the shaft at the front, with a corresponding flat formed in the internal bore of the light alloy prop driver. This alloy flat is far too narrow to provide adequate bearing area. In service, it soon became wobbly and eventually failed, breaking the locking of the prop driver to the shaft. My own used example number A-133 suffered from this defect despite being nowhere near worn out - the prop driver was on its last legs. A few more starts would have seen it off. The only fix was the making of a tapered brass split collet used in conjunction with a matching taper machined into the rear of the prop driver bore. This approach completely solved the problem. It should have been adopted from the outset. Another really annoying feature of the ARGO is the fact that its radial mounting holes are just sufficiently different from those of the original Elfin that the two engines are not directly interchangeable in the same model. This has always been one of my own major beefs with “replicas” - if there’s one thing that they should replicate, it’s the mounting hole pattern! There are other ways of identifying a given engine as a replica ....... The matching of the mounting hole pattern allows the use of an original engine for non-competitive “fun” or demonstration flying, with a switch to a replica for higher-risk or longer-term operation if desired. It has always escaped me why so few “replicas” adhere to this principle. To close this brief descriptive section on a more positive note, it should be mentioned that the quality of construction of the ARGO appears to be well up to the better standards among “replica” engines of this nature. None of the three examples examined during the preparation of this article exhibit any noteworthy manufacturing issues. In particular, the piston/cylinder fits in all three examples were found to be pretty near perfect, nor was there any sign of distortion of the cylinder bore when everything was tightened down securely. The ARGO “Elfin” on Test In the past, when testing an engine that is overtly based upon a given prototype, I have always tested such an engine in company with the original. In the present instance, it was apparent that such a comparison might be less relevant than usual. As I trust that I've shown, the ARGO is not even close to being a true replica of the Elfin 249, nor was it intended to be. It is in fact a completely different design in functional terms, albeit dressed up to bear a general similarity to the Elfin in terms of its appearance. There is thus no basis for expecting the performance of the two engines to be remotely comparable.

It has to be admitted that of the two “replicas” tested, the CS is visually considerably more faithful to the original than the ARGO. It is also very similar indeed internally. It actually qualifies in my book as being pretty close to a "true" replica. However, in order to make it useable I had to dismantle it completely, clean it very thoroughly and then go through it carefully to correct a number of manufacturing deficiencies, including the crankshaft heat treatment and the piston fit. I also matched and optimized the porting, which was certainly amenable to improvement as delivered. After all of this was done, the engine proved to be a very good starter and runner which had an excellent performance in the air. So far, it has also proved to be quite durable, having held up well after some hours of hard use in a control line model. However, I have yet to see an example of this engine which did not require a significant amount of well-informed owner intervention to make it useable. Buyer beware!!

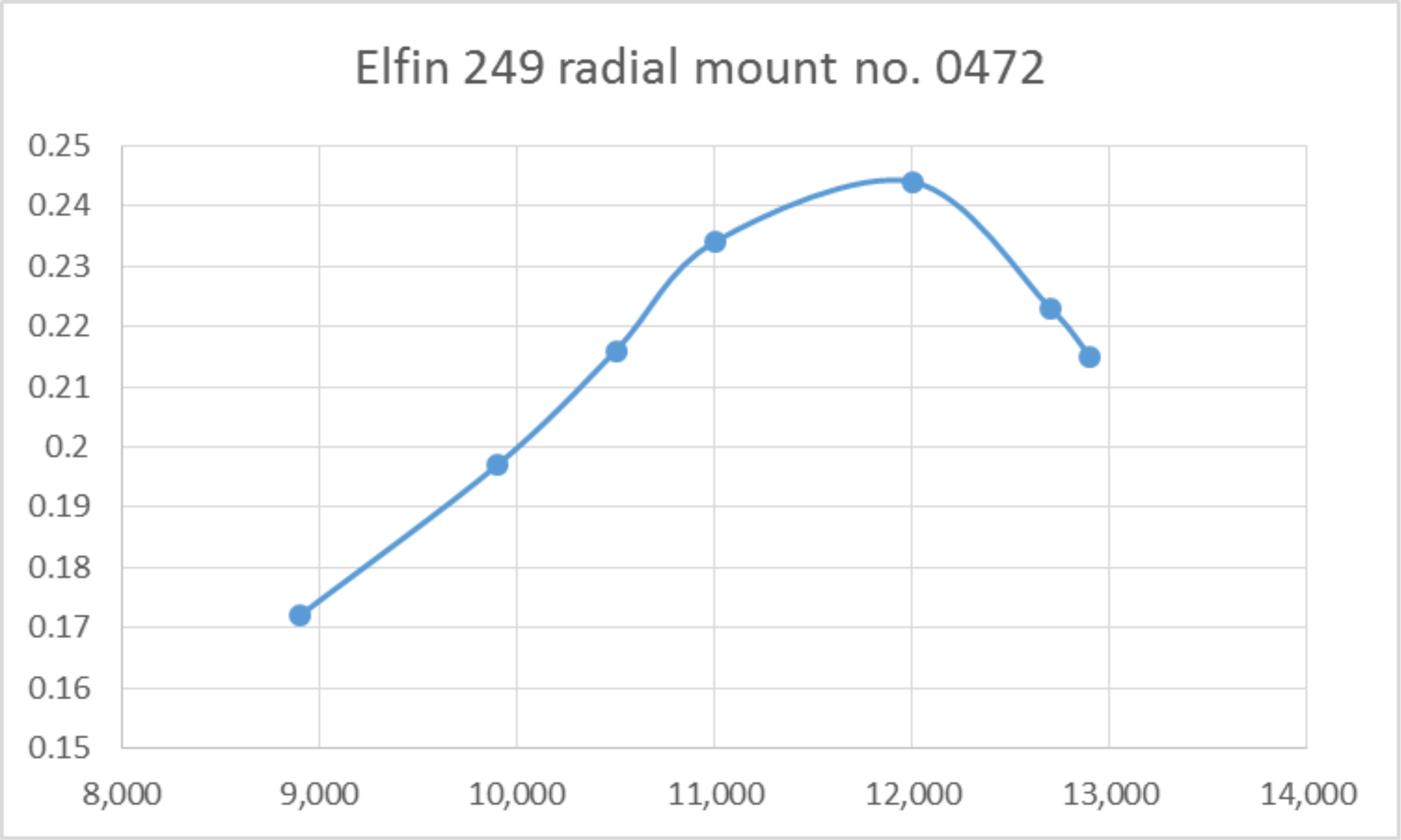

The original Elfin used in the test was (and is) in fine original condition. It bears the serial number 0472. It actually appeared to be relatively little-used, but nonetheless seemed ready to take its place in my testing line-up. Although I had owned it for many years, I had not run it prior to the original series of tests in 2013, thus having no idea of what to expect. This example has a bit of a pedigree, having been originally owned from new by my late friend R.C.A.F. Squadron Leader Laurie Ellis, D.F.C. of “Javelan” and "Vultan" fame. I'm only the engine's second owner in 71 years! The original 2013 tests required me to drill and tap my radial bulkhead test mount to take the ARGO (which I would not have had to do if they’d got the hole spacing right!). However, the earlier tests (the results of which were included in my original 2013 article) showed that the L-section radial mount which I used at that time was somewhat prone to vibration. The attached running photos from the original test series show that mount. Reasoning that excessive vibration might have skewed the results somewhat, I decided to re-test the engines for this updated article using a far more sturdy block mount. I still had all three engines on hand, making a comparative re-test perfectly straightforward. So equipped, I headed once more to the test area for my regular maintenance fix of model diesel fumes - that lovely aroma which for me has always been synonymous with the word “fun”! Allowing my curiosity to get the better of me, I started right away with the ARGO.

Once running, the ARGO proved to be very easy to set. Response to both controls was extremely positive - in particular, it must objectively be admitted that for all its lack of true Elfin character, the O.S. needle valve is functionally superior to the original Elfin item. Running qualities were very good indeed - the engine held a steady miss-free note and seemed ready to keep doing this as long as required. Overall, it proved to be a very easy engine to test, with steady rpm figures being readily obtained over what I was expecting to be the engine’s useable speed range. After finishing the ARGO tests, I switched to the other replica, the CS. It was immediately apparent that this example of the CS (which has been carefully reworked by me, remember) would out-perform the ARGO by a very substantial margin. It was just as easy After this, it was the turn of the original Elfin 2.49 radial mount model. As of 2013, this example appeared to have been run in and used, but clearly had only a few running hours on it. There may have been reasons for this - as matters turned out during the original testing session, the crankshaft journal in this example was clearly fitted way too closely, to the point that friction was excessive and lubrication supply was compromised. The bearing was soon found to overheat and tighten as the engine warmed up, with consequent sag and black exhaust residues as the poor old Elfin struggled to overcome the tight bearing. The engine would keep going on a rich needle, but there was no way that this example was going to give of its best without some attention being paid to relieving the shaft fit.

For the new round of testing, I had no problems since I'd corrected the issue back in 2013. As before, starting was foolproof provided the usual small prime was first administered. The former problem with the shaft was history - the engine would now run smoothly and steadily for as long as required on any prop, with no evidence of excessive heating of the main bearing and a nice clear exhaust residue. Quite a contrast from the initial 2013 test seen in the attached image! Since the time of the earlier tests, my calibrated set of test props has been updated. I've also refined my calibration figures somewhat as a result of a great deal of additional testing of various engines. I re-tested the three engines using the same updated test set of props, with the following comparative results.

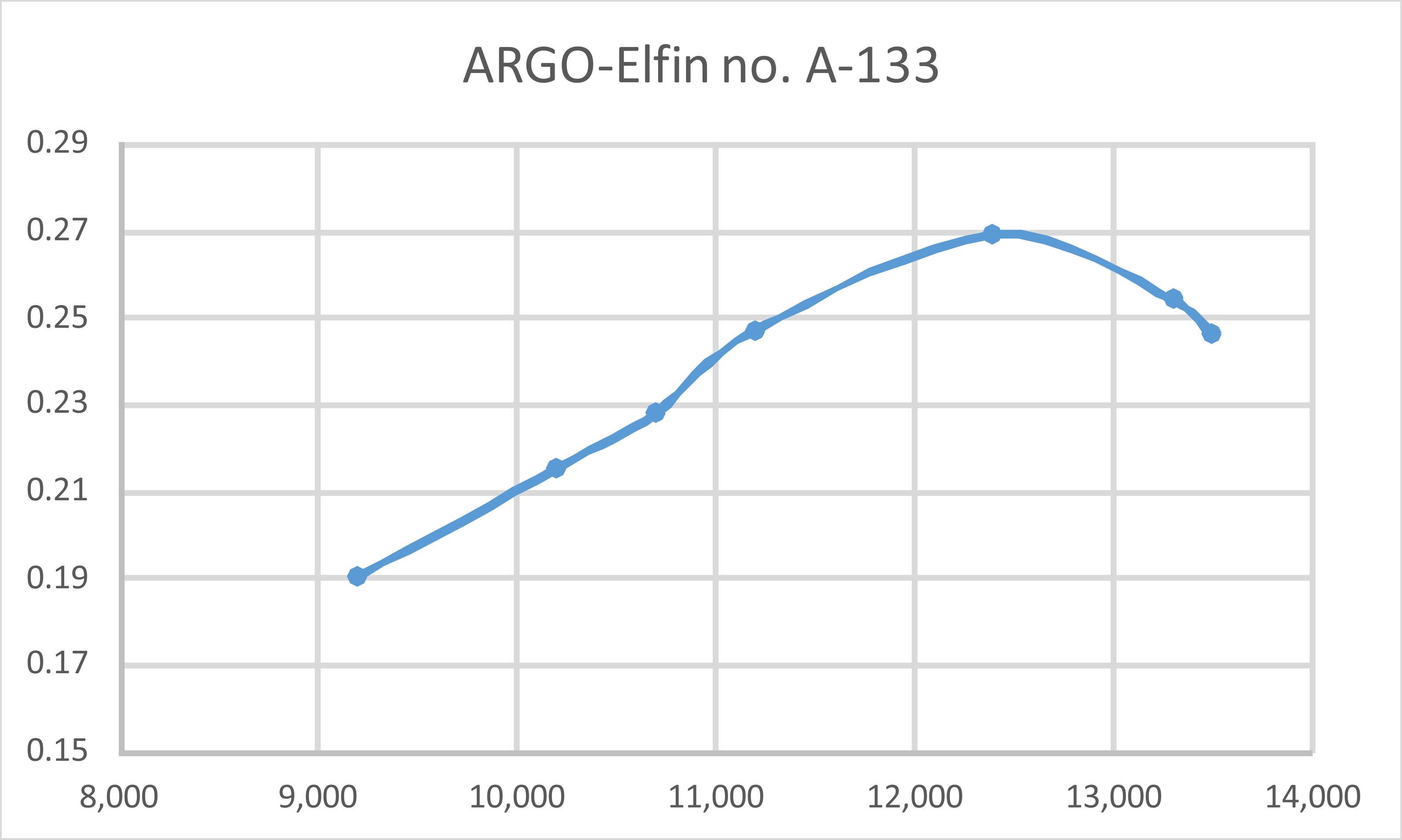

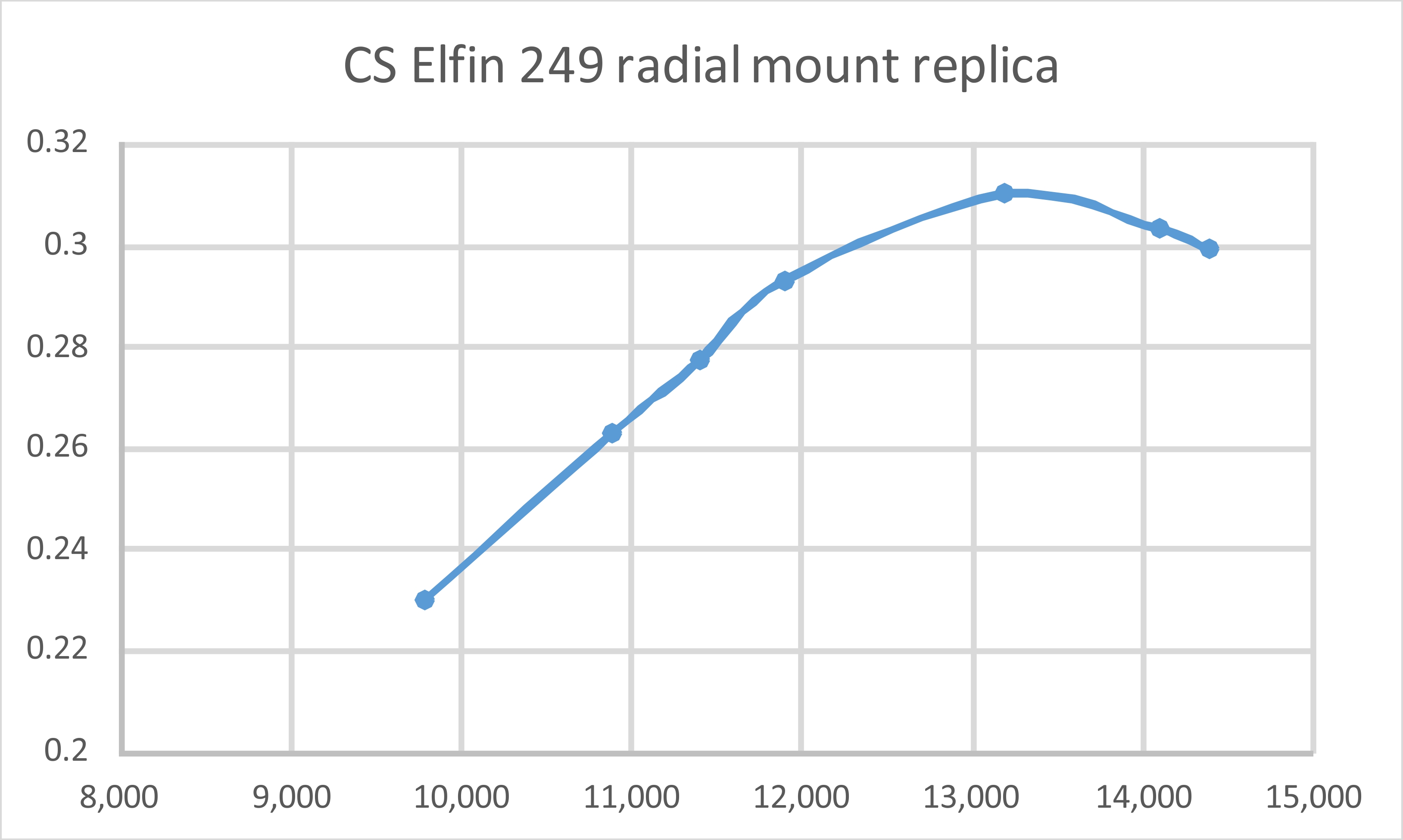

The APC 7½x4 WB (wide blade) is a cut-down APC 9x4 created and calibrated to fill a gap in the power absorption coefficients for my test set of props. The results obtained this time around were little different from those obtained during the initial series of tests, although I seem to have been a bit more careful this time in finding the absolutely best settings. I'd have to say that the above results incorporate what for me were two complete surprises! First, I was frankly expecting the ARGO to perform at a somewhat higher level than it did - the various design changes which it exhibited certainly supported such an expectation. Moreover, others have reported their impressions that the ARGO was a notably stronger runner than other renditions of the Elfin. On the basis of the above tests, it certainly is stronger than the original, but by less of a margin than I had anticipated. Secondly, I was outright amazed at the performance of the CS replica! It would appear that my efforts to sort out that engine and optimize the porting were successful beyond any reasonable expectations! I knew from some hours of flying experience that the engine ran very strongly indeed in the air, but seeing the actual numbers was still a bit of an eye-opener!

A notable feature of the ARGO’s power curve is its unusually flat shape - the engine is clearly working efficiently (within its own limitations) at all speeds between 11,300 and 13,400 rpm, since it develops in excess of 0.25 BHP at all speeds within that range. This characteristic allows considerable latitude in terms of prop selection. A cut-down APC 9x4 would appear to be an excellent choice for free flight work, while an 8x6 should work well in control line applications.

The power curve for this example of the CS Elfin implies a peak output of around 0.310 BHP @ 13,200 rpm or thereabouts - a stunning performance for this engine. I guess I got it somewhere near right in my efforts to improve upon what CS provided! The fact that the engine is very well freed up from some hours of actual use in the air doubtless doesn’t hurt either. The significance of the results for the CS Elfin replica lies mainly in the clear testimony which the numbers provide of the potential of that original 1949 Elfin PB design. As noted earlier, this example is a very close replica of the original as supplied - my intervention was confined to sorting out the manufacturing issues and optimizing the porting. Any knowledgeable owner of an original Elfin could have done as much.

The upshot of all this testing is the recognition that the ARGO-Elfin look-alike did indeed offer an improvement over the output of the basic Elfin design. As such, it would have been a very satisfactory unit indeed for modellers in the third user category which I discussed earlier. The figures for my CS replica cannot be taken as representative given the reworking to which that example has been subject. However, they do underline the performance potential of that original 1949 Elfin design in knowledgeable and capable hands. That engine was well ahead of its time - kudos to Frank Ellis! Production and Sales History We saw earlier that the marketing of the ARGO engines commenced in 1992. As anticipated, they proved to be popular and well-received in the US, which of course represented quite a large market once vintage fliers had realised the advantages of the Elfin design for Class A old-time events.

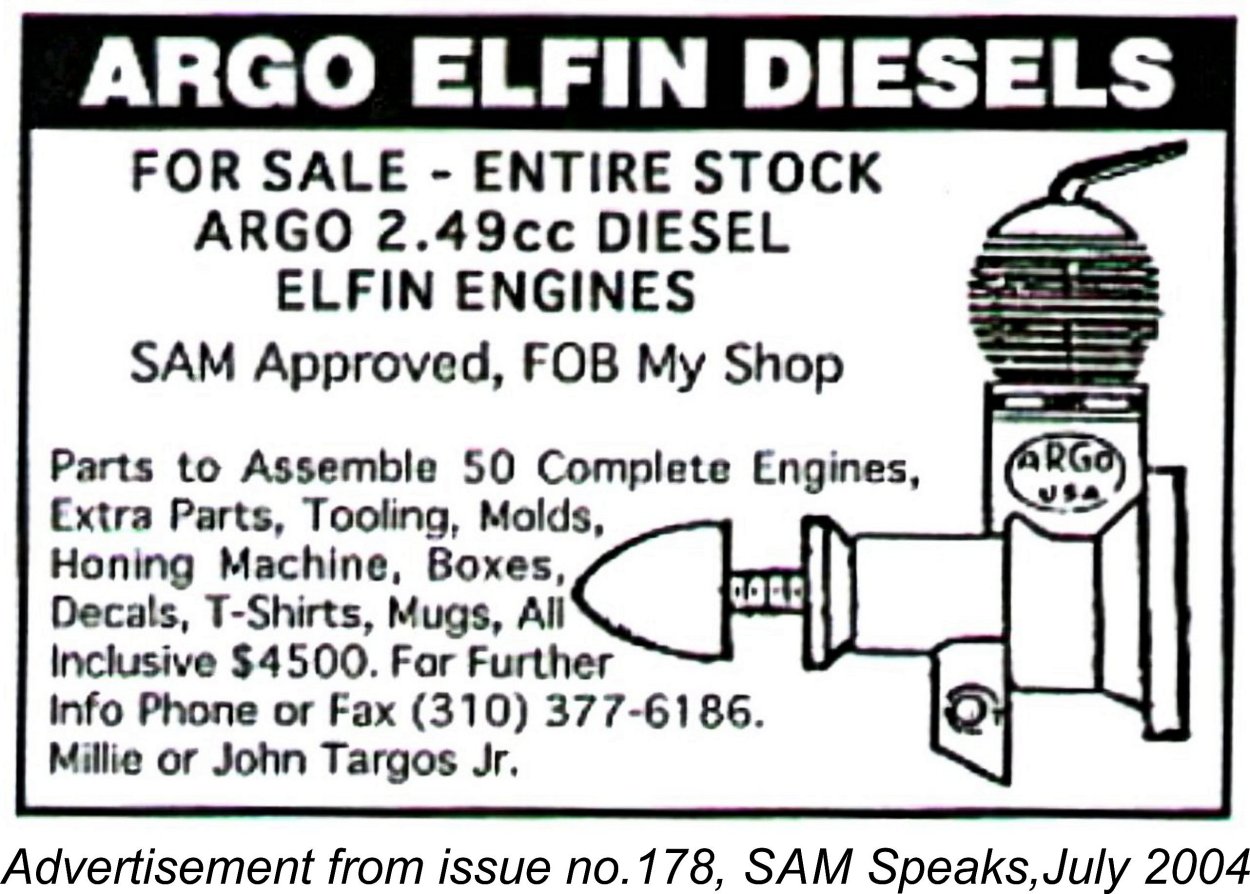

As of 1992, the earlier Dunham and Burford replicas remained in limited circulation on the second-hand market, but the performance superiority of the ARGO over these two models was soon found to be such that it became the Elfin “replica” of choice among serious vintage competitors, particularly in the USA where the engine had been homologated by SAM for vintage competition. This naturally created increased pressure upon the supply of the engine. Moreover, interest in the ARGO was not confined to America. In the face of this demand, delivery difficulties soon began to emerge. There are actually indications that John Targos may have accepted more orders for the engine than he was eventually able to fill. As an example, Ken Croft recalled ordering an ARGO-Elfin from Targos during the period when the engines were still supposedly in production, sending the cash for the engine along with his order. After at least a year had passed with no sign of the engine, Ken started asking when it was going to appear. Eventually he became totally fed up and asked for his money back! Apparently Targos became unwarrantably abusive upon receiving this request, but eventually did return Ken’s money. When Ken finally saw one of the ARGO Elfins he was actually glad that he had not received one because he knew Elfins very well, having grown up with them. The ARGO-Elfin was not an Elfin at all as far as Ken was concerned. He was expecting a true replica, not a mere look-alike. However, a look-alike was perfectly acceptable to many buyers, particularly those in the USA. As a result, production was apparently sold out by the mid 1990’s and was not resumed. The engine continued to be available on the second-hand market, with its perceived desirability being reflected in a steady rise in the second-hand prices which would-be users were willing to pay. The appearance of the CS Elfin 249 replica in 1994 in both beam-mount and radial-mount configurations initially seemed to represent salvation for modellers wishing to purchase a reasonably-priced and readily-available new Elfin replica which generally followed the design of the original quite closely. However, the highly inconsistent quality of that offering became common knowledge almost immediately. As I’ve demonstrated quite conclusively to my own satisfaction, they can be made to work very well indeed, but not without a fair bit of knowledgeable intervention on the part of the owner. Production of the CS Elfin replica ended years ago, but examples remain on offer on eBay and elsewhere on a regular basis. As a result of the CS replica’s failings, diesel-minded vintage modellers in the USA continued to view the ARGO as being very much superior to its competition, making it a highly desirable engine for anyone wishing to participate in US Old Time Class A contests using a diesel. However, it was not only the fliers who developed an interest in the ARGO. Like most limited-production replicas or “look-alikes”, the ARGO eventually became recognized as a distinct and desirable limited-edition collector’s item in its own right. This led to a further reinforcement of the demand for the engine from the engine collecting community. The ARGO continued to be in demand, at times selling among the collector community for prices as high as $150 for a new unused example complete with packaging and paper. Used examples also remained in demand among the vintage flying crowd, albeit selling for substantially lower prices depending on condition.

With a single exception to be noted below, all numbers reported to date follow the same pattern of A-xx or A-xxx. The A presumably stands for ARGO. The serial numbers which have so far been brought to my attention cover a surprisingly limited range, extending from A-82 up to A-202. This numerical range includes one engine which is something of an anomaly - engine number J-169, which I have personally examined. The significance of the letter switch from A to J is unclear at the present time. The possibility exists that the J prefix could indicate an entirely separate production series which was re-started at engine number J-1, but we have no supporting evidence for this at present. It might also have something to do with indicating the individual(s) who assembled the engines - perhaps indicating those made by Larry Jenno?!? Alternatively, it could be nothing more than a simple striking error. At present, I just don’t know. I’d appreciate clarification from any reader who may know more! Regardless, present indications are that the numbering started at A-1 and that at least 202 examples were made and sold. However, the true number was probably considerably larger. Based upon the number of survivors which seem to be still circulating, I’d guess that as many as 300 or so may have been sold over a period of several years. More serial numbers would really help - if you have them, please share them!

The fact that the advertisement disappeared after October 2004 suggests that a sale was in fact made. David Owen believed that Randy Linsalato of MECOA/RJL fame ended up in possession of the dies. It’s not known what happened to the balance of the listed items. Regardless, the fact that the ARGO engines were both well-made and durable in addition to being valued In passing, it’s worth noting that appreciation of the merits of the 1949 Elfin 249 radial-mount diesel has by no means diminished as time has gone by. Indeed, the ongoing interest prompted the appearance of yet another replica in 2007. This was offered for sale at $125 by Hobby Club as part of their PUMA range. It was a high-quality engine made in Ukraine. Like the ARGO, it was not in fact a true replica, although in a number of ways it was actually more faithful to the original Elfin design. I have no idea how many of these engines were produced. If we go back to the Fischer Castor of 1951 and follow the story through the Dunham, GB, ARGO, CS and PUMA replicas, it’s very hard to avoid the conclusion that the 1949 Elfin 249 can probably lay a persuasive claim to being one of the world’s most frequently-replicated model engines, probably second only to the various Mills models. There could be no higher tribute to the enduring excellence of the design and to the talents of Elfin designer and manufacturer Frank Ellis. Conclusion One’s perception of the ARGO will inevitably be conditioned to a large extent by one’s views on the whole replica question discussed right up front in this article. If you’re looking for an exact or near replica of the original 1949 Elfin 249, either to display or to fly, the ARGO will not satisfy you at all - it is in fact a comprehensively amended design that is dressed up to suggest the general appearance of the original Elfin.

If you don’t care about originality and merely want a fine-running and well-made 2.5 cc (.15 cuin.) diesel engine having a broadly “vintage” appearance to use for flying purposes, the ARGO could be right up your street. It certainly out-performs its Elfin prototype while retaining enough of the Elfin “look” that it does fit in visually with an overall vintage-looking package. This of course was its intended application all along, and I’d have to say that it was entirely successful in meeting that goal. It complies with the established Class A rules for vintage flying in America, which should ensure that examples remain in use for as long as there are still modellers wishing to fly that class. Whether or not you’re in the “purist” camp, it’s actually very easy to see high-quality limited edition engines like the ARGO as collectibles in their own right rather than as replicas. That’s certainly how I myself view the ARGO - in no sense a true Elfin replica, but a well-made and fine-running latter-day “classic” model diesel bearing a general stylistic resemblance to the Elfin 249 with a performance that reflects that of the original very positively. Viewed in that light, it stands firmly on its own feet both as a genuine collectible and as a very acceptable engine to use in situations where period accuracy is not an issue (or when the rules allow it!!). ________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published on “Model Engine News” September 2013 This revised edition first published April 2020 |

||||||

| |

My subject this time is a “wotizit” with a difference!! I’ll be examining a relatively recent American-built model diesel engine which was produced in the early 1990’s to meet demand from the US Old Time competition community. This is the ARGO 2.49 cc (.15 cuin.) diesel which was popularly referred to as a replica of the famous Elfin 2.49 cc plain bearing radial mount model of 1949.

My subject this time is a “wotizit” with a difference!! I’ll be examining a relatively recent American-built model diesel engine which was produced in the early 1990’s to meet demand from the US Old Time competition community. This is the ARGO 2.49 cc (.15 cuin.) diesel which was popularly referred to as a replica of the famous Elfin 2.49 cc plain bearing radial mount model of 1949.  When I began to research this topic in 2012, purely out of general interest stimulated by an example of the ARGO falling into my lap, I quickly ran head-on into a surprising range of strongly-held and often conflicting opinions regarding the true nature both of this engine and its purpose. There was general agreement that it was (and indeed is) a well-made and perfectly useable unit which combines a “classic” appearance with a very acceptable level of performance. The real bone of contention centred upon the extent to which it should be characterised as a true replica, both by collectors/fliers and (perhaps more controversially) by competition rule-makers.

When I began to research this topic in 2012, purely out of general interest stimulated by an example of the ARGO falling into my lap, I quickly ran head-on into a surprising range of strongly-held and often conflicting opinions regarding the true nature both of this engine and its purpose. There was general agreement that it was (and indeed is) a well-made and perfectly useable unit which combines a “classic” appearance with a very acceptable level of performance. The real bone of contention centred upon the extent to which it should be characterised as a true replica, both by collectors/fliers and (perhaps more controversially) by competition rule-makers. The production of replicas of model engines by someone other than their original manufacturer is by no means new. In fact, it goes back at least as far as the early post-WW2 era, and possibly even further. The original Swiss Dyno diesel of 1941 was much replicated in other countries once its design details became known. Another early example to which David Owen drew attention in the present context is the Swiss-made Fischer Castor of 1951, which was a close copy of the very same Elfin 2.49 cc radial-mount model which is central to our main subject. An example of the Fischer Castor won the first FAI World Free Flight Championship in 1951, also finishing second in the 1952 event. The superb Swiss-made AMRO 10 cc copy of the Dooling 61 is another well-known early example.

The production of replicas of model engines by someone other than their original manufacturer is by no means new. In fact, it goes back at least as far as the early post-WW2 era, and possibly even further. The original Swiss Dyno diesel of 1941 was much replicated in other countries once its design details became known. Another early example to which David Owen drew attention in the present context is the Swiss-made Fischer Castor of 1951, which was a close copy of the very same Elfin 2.49 cc radial-mount model which is central to our main subject. An example of the Fischer Castor won the first FAI World Free Flight Championship in 1951, also finishing second in the 1952 event. The superb Swiss-made AMRO 10 cc copy of the Dooling 61 is another well-known early example.  In some cases, replicas of leading competition engines were produced in those engines’ countries of origin simply to make consumer-grade examples more widely and economically available for the average modeller to use in gaining experience. The Czech

In some cases, replicas of leading competition engines were produced in those engines’ countries of origin simply to make consumer-grade examples more widely and economically available for the average modeller to use in gaining experience. The Czech

question had long ceased, this led to a steady rise in the selling prices of good examples of earlier engines.

question had long ceased, this led to a steady rise in the selling prices of good examples of earlier engines.

could not afford or even locate an original. Basically, the ever-growing demand had finally overtaken the limits of supply once and for all. This being the case, for these individuals too a replica was undoubtedly the next best thing.

could not afford or even locate an original. Basically, the ever-growing demand had finally overtaken the limits of supply once and for all. This being the case, for these individuals too a replica was undoubtedly the next best thing.  Another less common manifestation of the effects of supply and demand has been the evolution of what may more properly be termed reproductions as opposed to replicas. These are engines which are produced by others using the same designs and production equipment as the originals. They represent the resumption of production by others as opposed to the copying of the engines in question. The Tom Ridley Olivers and the Indian-made

Another less common manifestation of the effects of supply and demand has been the evolution of what may more properly be termed reproductions as opposed to replicas. These are engines which are produced by others using the same designs and production equipment as the originals. They represent the resumption of production by others as opposed to the copying of the engines in question. The Tom Ridley Olivers and the Indian-made  Leaving the collectors in the first of the above categories out of it for now, the main focus of debate among latter-day nostalgia-minded modellers seems to centre upon the second and third of the above motivations for the production of replica engines. There are two distinct camps involved - those for whom adherence to originality in the design and construction of both models and powerplants is seen as important; and those for whom it is sufficient for models and powerplants to retain a general visual similarity to the originals without requiring detailed adherence to all aspects of design, construction or performance.

Leaving the collectors in the first of the above categories out of it for now, the main focus of debate among latter-day nostalgia-minded modellers seems to centre upon the second and third of the above motivations for the production of replica engines. There are two distinct camps involved - those for whom adherence to originality in the design and construction of both models and powerplants is seen as important; and those for whom it is sufficient for models and powerplants to retain a general visual similarity to the originals without requiring detailed adherence to all aspects of design, construction or performance.

However, there is a factor creeping into the third of the above categories which in my personal view represents a far more insidious threat to the legitimacy of old time competition. This is the acceptance of “replica” powerplants based on "originals" which never existed during the old time era! A prime example which comes immediately to mind is the Chinese-made CS “E.D. Mk. IV Hunter .19". The production of this “replica” was inspired by the fact that a number of US old time modellers saw the potential advantage of using the E.D. Hunter (or a replica thereof) in their Class A competitions. However, the Hunter’s displacement of 3.46 cc (0.211 cuin.) precluded this given the American Class A displacement limit of 0.199 cuin.

However, there is a factor creeping into the third of the above categories which in my personal view represents a far more insidious threat to the legitimacy of old time competition. This is the acceptance of “replica” powerplants based on "originals" which never existed during the old time era! A prime example which comes immediately to mind is the Chinese-made CS “E.D. Mk. IV Hunter .19". The production of this “replica” was inspired by the fact that a number of US old time modellers saw the potential advantage of using the E.D. Hunter (or a replica thereof) in their Class A competitions. However, the Hunter’s displacement of 3.46 cc (0.211 cuin.) precluded this given the American Class A displacement limit of 0.199 cuin.

The MEN website includes several articles which focus upon the story of

The MEN website includes several articles which focus upon the story of  Sadly, the original Elfin 249 radial mount model did not survive long in the marketplace. This was by no means due to any failings in the product itself - rather, it came down to a simple matter of the Aerol company’s inability to meet the very considerable demand which quickly developed. In his later reminiscences recounted to family friend Jim Woodside, Frank Ellis stated that the mid 1950 replacement of the original 249 radial mount model with a completely revised beam-mounted model having a pressure die-cast crankcase was entirely due to the fact that they could make the revised models faster and at a lower unit cost.

Sadly, the original Elfin 249 radial mount model did not survive long in the marketplace. This was by no means due to any failings in the product itself - rather, it came down to a simple matter of the Aerol company’s inability to meet the very considerable demand which quickly developed. In his later reminiscences recounted to family friend Jim Woodside, Frank Ellis stated that the mid 1950 replacement of the original 249 radial mount model with a completely revised beam-mounted model having a pressure die-cast crankcase was entirely due to the fact that they could make the revised models faster and at a lower unit cost.  The fact that the original Elfin 249 radial mount model was held in such high regard had the happy result of ensuring that the engines were greatly valued by their owners. Consequently, although the total number manufactured was relatively small by industry standards, those that did find their way into the hands of modellers were well cared for, remaining in widespread use for some years following their withdrawal from production. Moreover, they were generally retained by their owners even when supplanted by other more advanced models - no rubbish bin for these engines! Accordingly, a higher-than-usual proportion of the engines which were manufactured have survived for ¾

The fact that the original Elfin 249 radial mount model was held in such high regard had the happy result of ensuring that the engines were greatly valued by their owners. Consequently, although the total number manufactured was relatively small by industry standards, those that did find their way into the hands of modellers were well cared for, remaining in widespread use for some years following their withdrawal from production. Moreover, they were generally retained by their owners even when supplanted by other more advanced models - no rubbish bin for these engines! Accordingly, a higher-than-usual proportion of the engines which were manufactured have survived for ¾ The difficulty and expense of obtaining the relatively scarce original Elfins led these fliers to investigate the replica route, creating a significant potential market for replica Elfin 249’s. The first manufacturer to attempt to tap into this pent-up demand was Dunham Engineering of 12 Lawns Ave., Orrell, Wigan. This firm was established by Alan Holmes Sr. together with his sons Alan Jr. and Barry. Together they produced a number of near-replicas of the radial-mount Elfin 249 between 1984 and 1987. Most of these were sold in the US for use by vintage fliers in that country. I’ve covered the activities of this company and the development of their Elfin replica in a

The difficulty and expense of obtaining the relatively scarce original Elfins led these fliers to investigate the replica route, creating a significant potential market for replica Elfin 249’s. The first manufacturer to attempt to tap into this pent-up demand was Dunham Engineering of 12 Lawns Ave., Orrell, Wigan. This firm was established by Alan Holmes Sr. together with his sons Alan Jr. and Barry. Together they produced a number of near-replicas of the radial-mount Elfin 249 between 1984 and 1987. Most of these were sold in the US for use by vintage fliers in that country. I’ve covered the activities of this company and the development of their Elfin replica in a

Bert Streigler recalled having sold some 200 examples of the Dunham Elfin during the period of his agency, which lasted until Dunham ended production in 1988. This left a considerable unfulfilled demand for replica Elfins, thus creating a further marketing opportunity.

Bert Streigler recalled having sold some 200 examples of the Dunham Elfin during the period of his agency, which lasted until Dunham ended production in 1988. This left a considerable unfulfilled demand for replica Elfins, thus creating a further marketing opportunity.  In support of his ambition, Targos approached former Australian Dunham distributor David Owen (since deceased) to ask if he had any examples left, notionally to serve as reference samples to guide Targos in setting up his own production. As it happened, David still had six unused New-in-Box examples on hand, although all of these were flawed in some way to an extent which rendered them un-saleable in David’s highly ethical view. David told Targos as much, but he was still interested. After some rather challenging negotiations, David ended up trading these engines to Targos for a box of spark plugs! David’s records showed that these six engines were sent to Targos on May 26

In support of his ambition, Targos approached former Australian Dunham distributor David Owen (since deceased) to ask if he had any examples left, notionally to serve as reference samples to guide Targos in setting up his own production. As it happened, David still had six unused New-in-Box examples on hand, although all of these were flawed in some way to an extent which rendered them un-saleable in David’s highly ethical view. David told Targos as much, but he was still interested. After some rather challenging negotiations, David ended up trading these engines to Targos for a box of spark plugs! David’s records showed that these six engines were sent to Targos on May 26 Of course, Gordon’s agreement to provide such very material assistance to Targos meant that the six Dunham Elfins supplied by David Owen were no longer of value as reference samples. It appears that Targos sold them on immediately as useable engines despite David Owen’s clearly-stated contrary opinion. Admittedly he may have fixed the issues that rendered the engines unsaleable in David's view - at this stage, we'll never know.

Of course, Gordon’s agreement to provide such very material assistance to Targos meant that the six Dunham Elfins supplied by David Owen were no longer of value as reference samples. It appears that Targos sold them on immediately as useable engines despite David Owen’s clearly-stated contrary opinion. Admittedly he may have fixed the issues that rendered the engines unsaleable in David's view - at this stage, we'll never know.  Since Bert remained the official American Dunham distributor of record right up to the cessation of production in 1988, it’s hard to see how Targos could have acquired his 1989 “stock” in any way other than that described above. After all, Targos’s involvement only commenced well after Dunham had terminated model engine production in 1988. Hence Targos could not have obtained his engines from the manufacturers.

Since Bert remained the official American Dunham distributor of record right up to the cessation of production in 1988, it’s hard to see how Targos could have acquired his 1989 “stock” in any way other than that described above. After all, Targos’s involvement only commenced well after Dunham had terminated model engine production in 1988. Hence Targos could not have obtained his engines from the manufacturers.  Whatever the truth of this matter, there’s no doubt that Targos applied the knowledge acquired both from Gordon Burford and from his examination of the Dunham Elfins provided by David Owen to press ahead with his plans for producing his own Elfin replica. He was doubtless well aware that a significant proportion of US vintage fliers fell into the third of the market categories discussed in the previous section. That is, they were attuned to competitive participation in events requiring the use of equipment having an old-time appearance without undue regard for absolute adherence to historical accuracy in terms of design, construction and performance. Fair enough - those holding divergent views are under no compulsion to take part …………….

Whatever the truth of this matter, there’s no doubt that Targos applied the knowledge acquired both from Gordon Burford and from his examination of the Dunham Elfins provided by David Owen to press ahead with his plans for producing his own Elfin replica. He was doubtless well aware that a significant proportion of US vintage fliers fell into the third of the market categories discussed in the previous section. That is, they were attuned to competitive participation in events requiring the use of equipment having an old-time appearance without undue regard for absolute adherence to historical accuracy in terms of design, construction and performance. Fair enough - those holding divergent views are under no compulsion to take part …………….  After considerable delays arising from teething troubles and production difficulties, the ARGO-Elfins finally began to appear on the marketplace in 1992. They were marketed as the “ARGO Elfin 2.49 cc diesel engine” - no mention of the word “replica”. The engine’s widespread replica identification evidently arose strictly from the use of the Elfin name. The manufacturer’s own statement regarding the engine’s purpose read as follows:

After considerable delays arising from teething troubles and production difficulties, the ARGO-Elfins finally began to appear on the marketplace in 1992. They were marketed as the “ARGO Elfin 2.49 cc diesel engine” - no mention of the word “replica”. The engine’s widespread replica identification evidently arose strictly from the use of the Elfin name. The manufacturer’s own statement regarding the engine’s purpose read as follows:  David Owen was kind enough to contact Larry directly to inquire about the full scope of his involvement with the ARGO project. Larry was able to confirm that he did indeed make the dies and arrange for the production of the investment castings for this engine. What is less well-known is the fact that Larry actually produced and assembled all the components for the first 25 examples, sending them as complete units to John Targos along with the rest of the castings.

David Owen was kind enough to contact Larry directly to inquire about the full scope of his involvement with the ARGO project. Larry was able to confirm that he did indeed make the dies and arrange for the production of the investment castings for this engine. What is less well-known is the fact that Larry actually produced and assembled all the components for the first 25 examples, sending them as complete units to John Targos along with the rest of the castings.  As always, a few vital statistics are in order at this point. The ARGO features measured bore and stroke measurements of 0.571 in. (14.50 mm) and 0.590 in. (15.00 mm) respectively for an actual displacement of 2.48 cc (0.151 cuin.) and a stroke-bore ratio of 1.035:1. The engine weighs in at 125 gm (4.41 ounces) - somewhat heavier than the original Elfin, which weighed only 113 gm (3.98 ounces), but still quite light for a diesel of this displacement.

As always, a few vital statistics are in order at this point. The ARGO features measured bore and stroke measurements of 0.571 in. (14.50 mm) and 0.590 in. (15.00 mm) respectively for an actual displacement of 2.48 cc (0.151 cuin.) and a stroke-bore ratio of 1.035:1. The engine weighs in at 125 gm (4.41 ounces) - somewhat heavier than the original Elfin, which weighed only 113 gm (3.98 ounces), but still quite light for a diesel of this displacement.  induction with updraft venturi is also retained, as is the screw-in cylinder with alloy screw-on cooling jacket. Like the original Elfin, the ARGO also features a single-arm compression lever, although the lever used on the ARGO is far longer than that employed in the original. Finally, like the Elfin original, the ARGO is arranged strictly for radial mounting.

induction with updraft venturi is also retained, as is the screw-in cylinder with alloy screw-on cooling jacket. Like the original Elfin, the ARGO also features a single-arm compression lever, although the lever used on the ARGO is far longer than that employed in the original. Finally, like the Elfin original, the ARGO is arranged strictly for radial mounting.  (but not exclusively) in the USA, who adhered to the third of our user categories discussed earlier. This was clearly the target market driving the development of this engine, and the servicing of this market is of course a perfectly legitimate motivation - no-one was compelled to buy the resulting product! Again, we have to bear this in mind when evaluating the results.

(but not exclusively) in the USA, who adhered to the third of our user categories discussed earlier. This was clearly the target market driving the development of this engine, and the servicing of this market is of course a perfectly legitimate motivation - no-one was compelled to buy the resulting product! Again, we have to bear this in mind when evaluating the results.

This being the case, I approached these tests with a completely open mind as regards performance expectations. It was my intention simply to evaluate the ARGO on its own merits with the goal of obtaining some hard data on its performance characteristics. However, just for fun I also decided to try both an original Elfin and my tweaked CS Elfin replica, which I knew ran very well indeed in the air following a complete overhaul and fettling by myself.

This being the case, I approached these tests with a completely open mind as regards performance expectations. It was my intention simply to evaluate the ARGO on its own merits with the goal of obtaining some hard data on its performance characteristics. However, just for fun I also decided to try both an original Elfin and my tweaked CS Elfin replica, which I knew ran very well indeed in the air following a complete overhaul and fettling by myself.  By contrast, the example of the ARGO that I elected to test (number A-133) gave the impression of being a very well-made unit which was all ready to go to work as received. Indeed, it had clearly received considerable use before it came into my hands. Despite this, it remained in first-class mechanical condition. I am advised by others that this is typical of the ARGO engines - all of them evidently appeared to be very well made throughout, including unused example no. A-144 and little-used engine no. J-169 which were also available for inspection when I was researching this article.