|

|

The Vltavan 2.5 Racing Engine Reappraised

The Vltavan 2.5 has already been the subject of an article which may still be accessed on the late Ron Chernich’s wonderful but now frozen “Model Engine News” (MEN) web site. There’s also an article there on the larger Vltavan 5 cc model, which I plan to test in the future. While the earlier article on the Vltavan 2.5 did include a limited amount of test data, it fell well short of constituting a full test report on the engine. More problematically, it also included several incorrect statements which subsequent research has clarified. The present article is intended to remedy those deficiencies. Normally I would have simply added the more complete test data to be presented below to the existing article on MEN, along with all necessary corrections. However, the fact that my mate Ron unfortunately left us without providing the required access codes to his heavily encrypted site has resulted in that site becoming frozen. Hence I have no alternative other than to present this revised article here. Now, in order to fully understand the circumstances which led to the early 1957 appearance of the Vltavan 2.5 and its larger 5 cc companion, we have to go back a little in time to follow the history of the famous MVVS enterprise up to the point at which the Vltavan engines made their appearance. The MVVS Connection The story behind the Vltavan engines begins in 1953 when the Czechoslovakian state authorities decided that there was international prestige to be gained through Communist success in the field of model aircraft competition at the World Championship level. Aeromodelling was a far more mainstream hobby than it is today, attracting many enthusiasts of all ages and from all walks of life. Accordingly, such events were widely reported in the Western modelling media and were avidly read by many young and potentially impressionable people, adding to the perceived propaganda value of this concept. To further this aim, a state-sponsored model development centre was established at Brno. This facility was known as the Modelárského Výzkumného a Vývojového Strediska (Modelling Research & Development Centre), better recognized by its initials of MVVS. The express intention was the development of model aero engines which would power Czech modellers to the achievement of World Championship honors. Further details regarding the establishment of this facility may be found in my focused article on the classic MVVS engines which remains accessible on MEN.

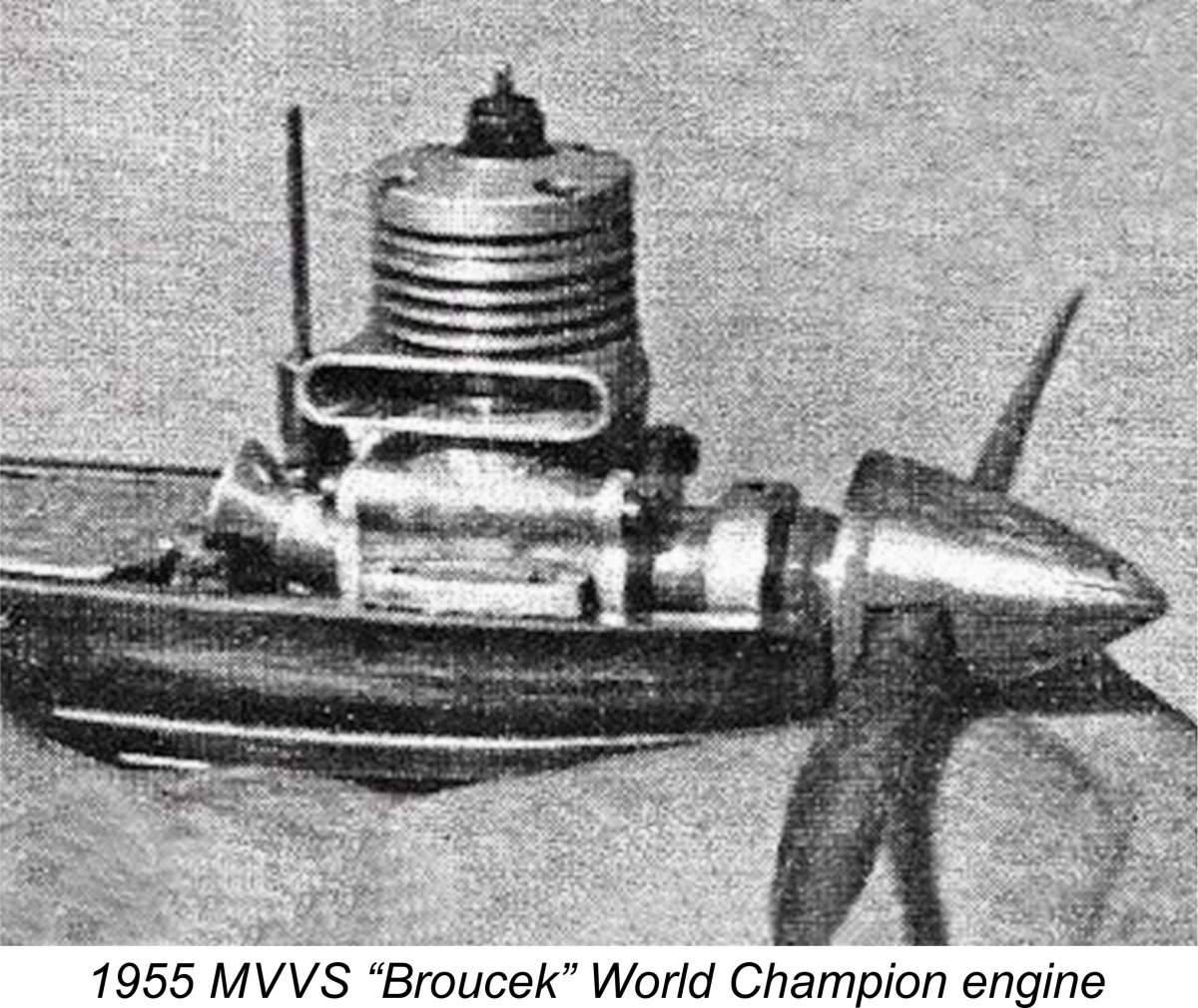

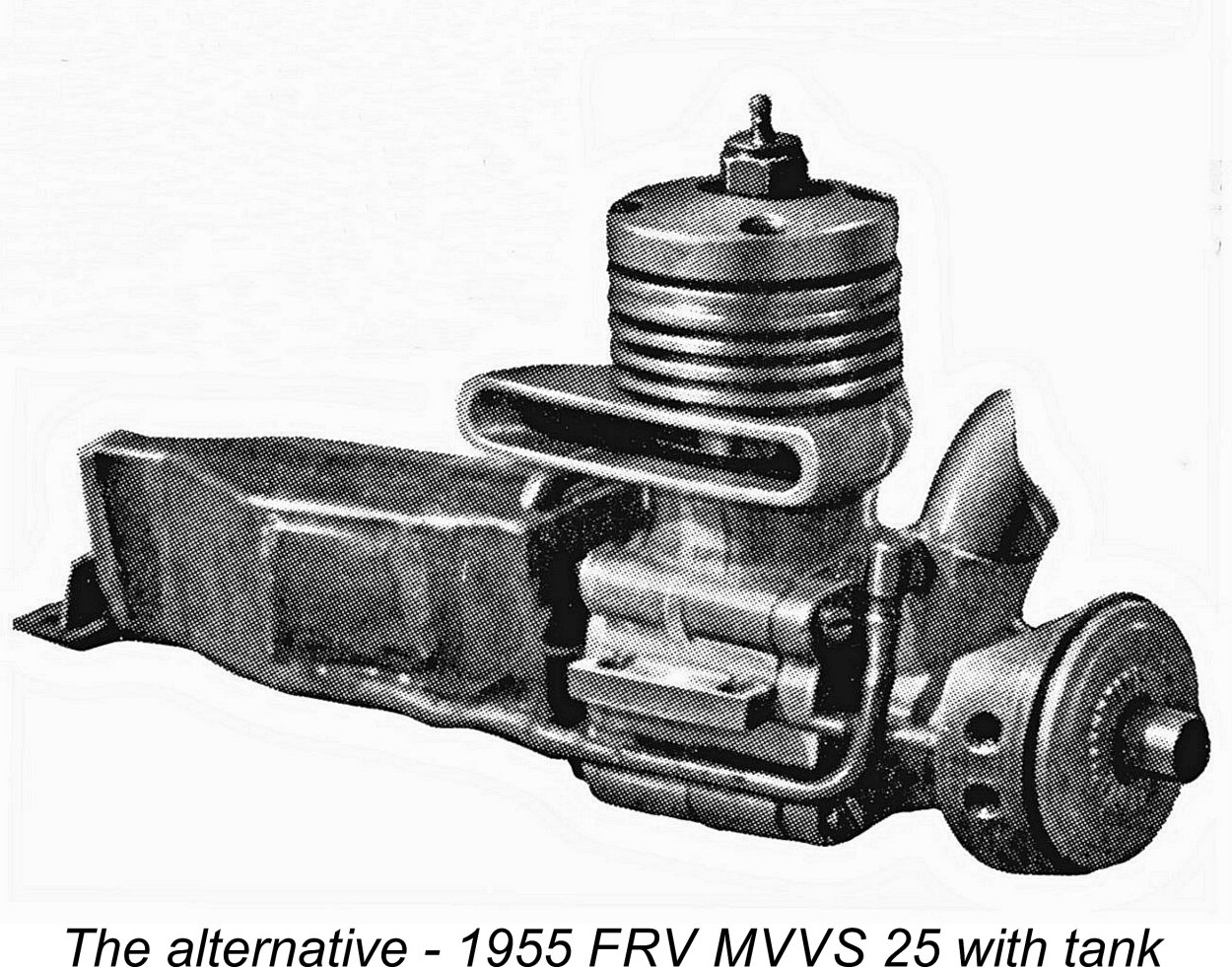

The engines that the Czech team members were using at this contest were in essence conventional racing motors of their time - cross-flow loop scavenging, lightweight ringed aluminum piston, twin ball-bearing shaft, oversized bypass passage, etc, etc. They appeared at the Paris meeting in several different configurations. The winning powerplant, the one-off SK-25 “Broucek” unit, featured disc rear rotary valve (RRV) induction, while the other Czech team members used crankshaft front rotary valve (FRV) variants of basically the same engine. At this stage, MVVS were clearly hedging their bets as far as induction was concerned. The FRV variants were designated the MVVS 25 models. While not matching the winning performance of the one-off SK-25 unit, they nonethless acquitted themselves well, finishing in fifth, eleventh and fourteenth places, performing well enough to secure the second place team finish for the Czechs to go along with Sladký's outright win.

The engines used by Sladký and his compatriots were individually built at the MVVS workshops to the very highest standards. It would clearly have been impossible to produce equivalent engines commercially at anything like a reasonable price, and no attempt was made at this time to do so, at least at the MVVS facility. However, a need quickly became apparent for the production of more affordable engines of generally similar design for the use of a larger spectrum of aspiring flyers in order for them to gain the experience necessary to challenge for positions on the Czech team. Accordingly, a decision was taken to establish a separate factory in Prague (very distant from Brno) for the purpose of manufacturing "consumer" versions of the 2.5 cc and 5 cc MVVS racing engines in sufficient quantities to make them more readily available to modellers in the Iron Curtain countries. This decision was acted upon in late 1956, and the Vltavan engines were born. Vltavan Production Commences Series production of both Vltavan 2.5 cc and 5 cc models seems to have commenced in early 1957. The design of the Vltavan 2.5 had its roots in that of Sladký's 1955 World Championship SK-25 motor which was illustrated earlier. That model had subsequently been further developed by MVVS co-designer Jaroslav Kocí, who had actually constructed the SK-25 unit in collaboration with Sladký (hence the initials SK in the engine’s designation). Kocí rebuilt one of the 1955 FRV engines in RRV form and won with it at the 2nd annual International People's Democratic States contest in Vrchlabi, Czechoslovakia in September 1955 at a speed of 179.9 km/hr (111.84 mph) - very close to Sladký's World Championship-winning speed of a few months earlier. Using the same engine, Kocí subsequently achieved a significantly higher speed of 203.53 km/hr (126.47 mph) on thinner lines to establish a new FAI 2.5 cc World Speed Record.

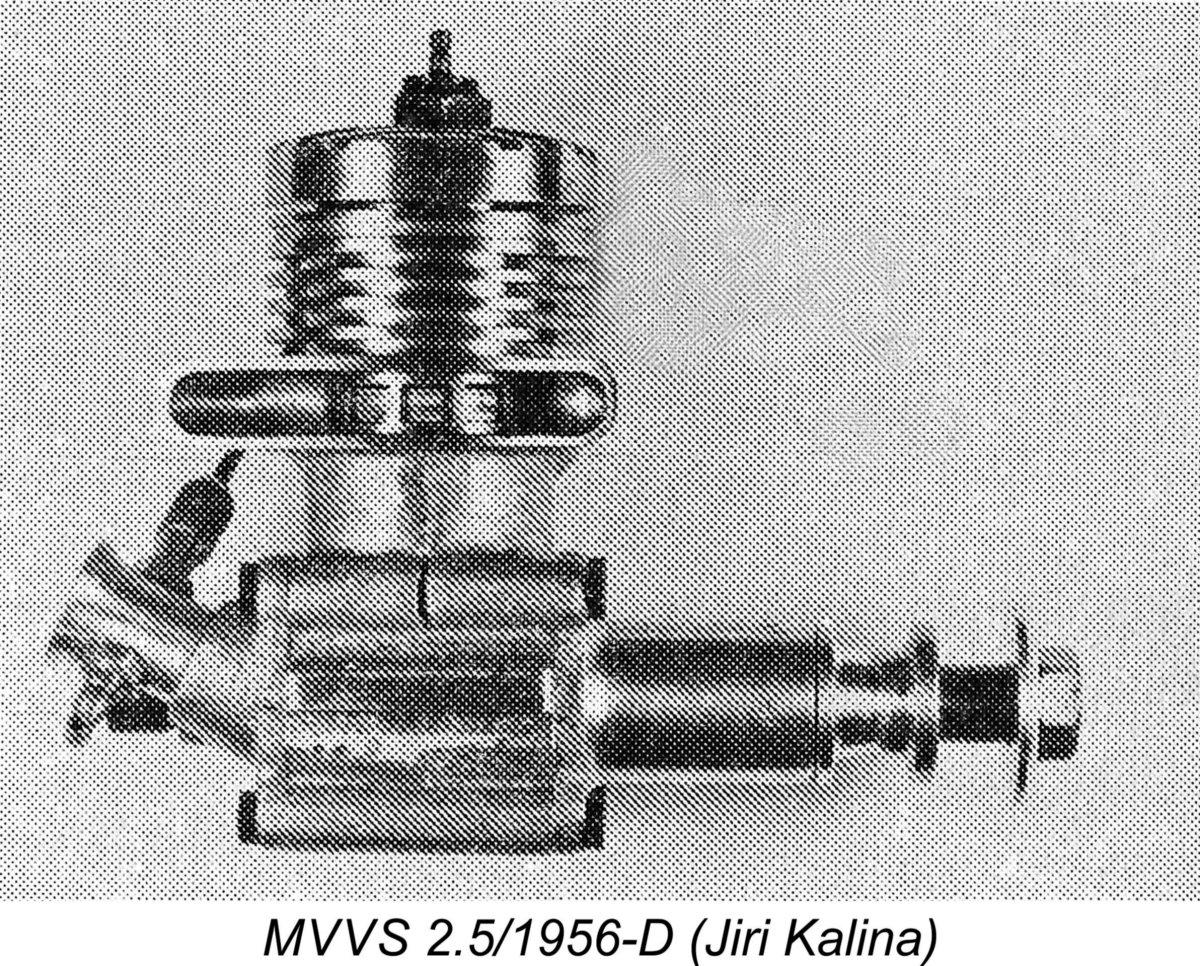

Sladký finished sixth on this occasion with a speed of 194 km/hr (120.5 mph), demonstrating that he had found something extra in the SK-25 since the previous year’s contest. However, the MVVS 2.5/1956-D had clearly kept pace, since two other Czech team members using that design tied Sladký’s speed, hence finishing in equal sixth place. In fact, the fastest MVVS speed at the meeting was 196 km/hr (121.8 mph) which earned a fourth place finish for Vaclav Smejkal using an example of the MVVS 2.5/1956-D. These combined results were easily enough to secure the team prize for the Czechs.

The facility at which the Vltavan engines were manufactured was known as the Praha-Modrany factory. The engines were named for the river Vltava, which flows northward through Prague. In effect, the Vltavan engines were "the engines from the banks of the Vltava"! Sort of like calling a line of engines made in Newcastle the "Tyne" series........... Information from behind the Iron Curtain was scanty and unreliable during the era in question. Contemporary reports from Czechoslovakia implied that an annual production target of 5,000 engines was planned, but the evidence suggests that such figures were never achieved or even approached. What can be said with certainty is that the highest serial number for a Vltavan 2.5 cc model which has come to my attention in many years of looking is 3142, seemingly confirming that at least that many were made in total. It seems doubtful that there were many more.

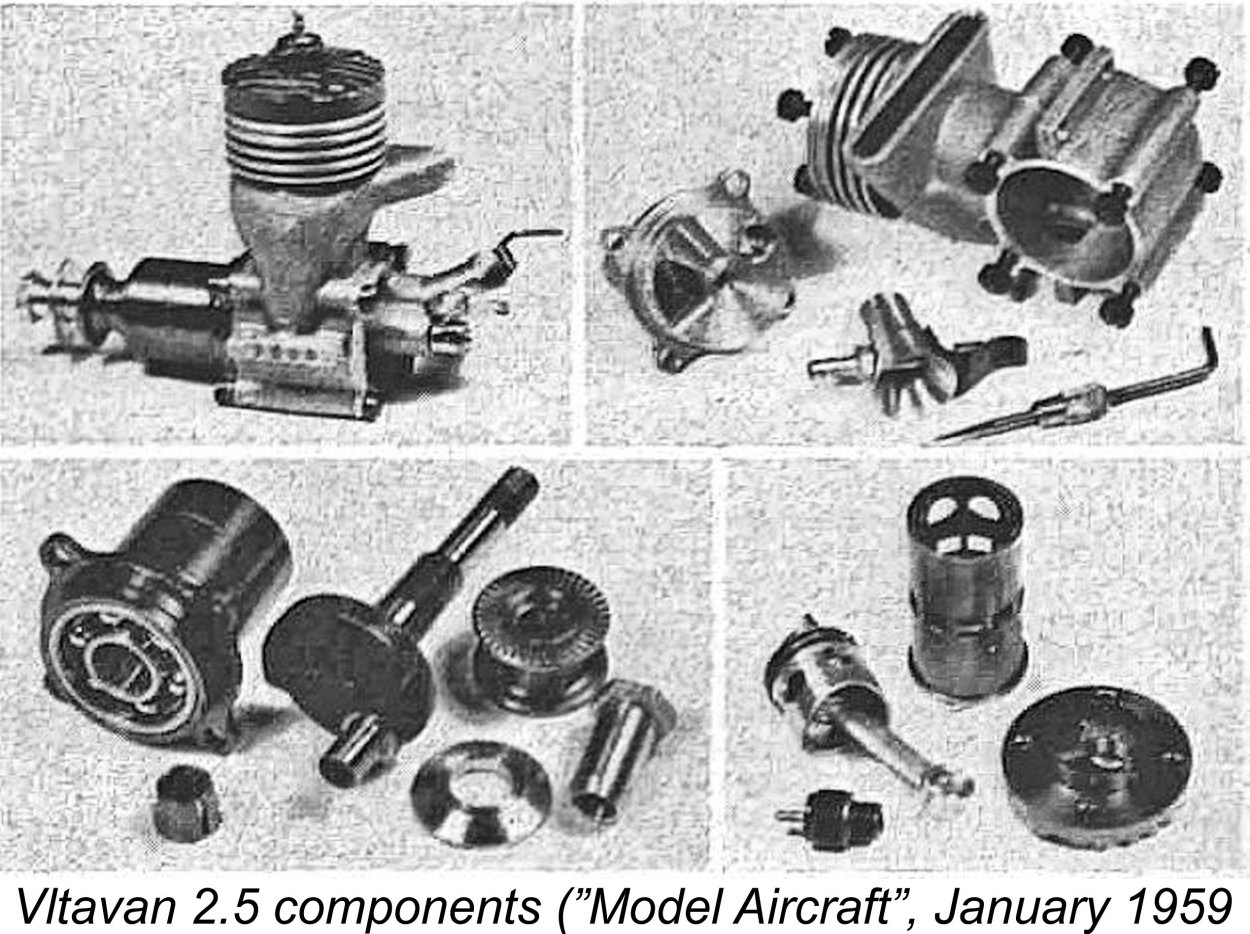

Another specimen found its way into the capable and well-informed hands of Peter Chinn in late 1958. The latter engine was loaned to Chinn by well-known British free-flight competitor Ron Draper, who had previously contrived to obtain an example of the companion 5 cc Vltavan model as well. Draper's example of the 2.5 cc Vltavan was illustrated in the “Latest Engine News” feature in the November 1958 issue of “Model Aircraft”, being more fully described in the “Latest Engine News” column of the January 1959 issue. The Vltavan 2.5 – Description

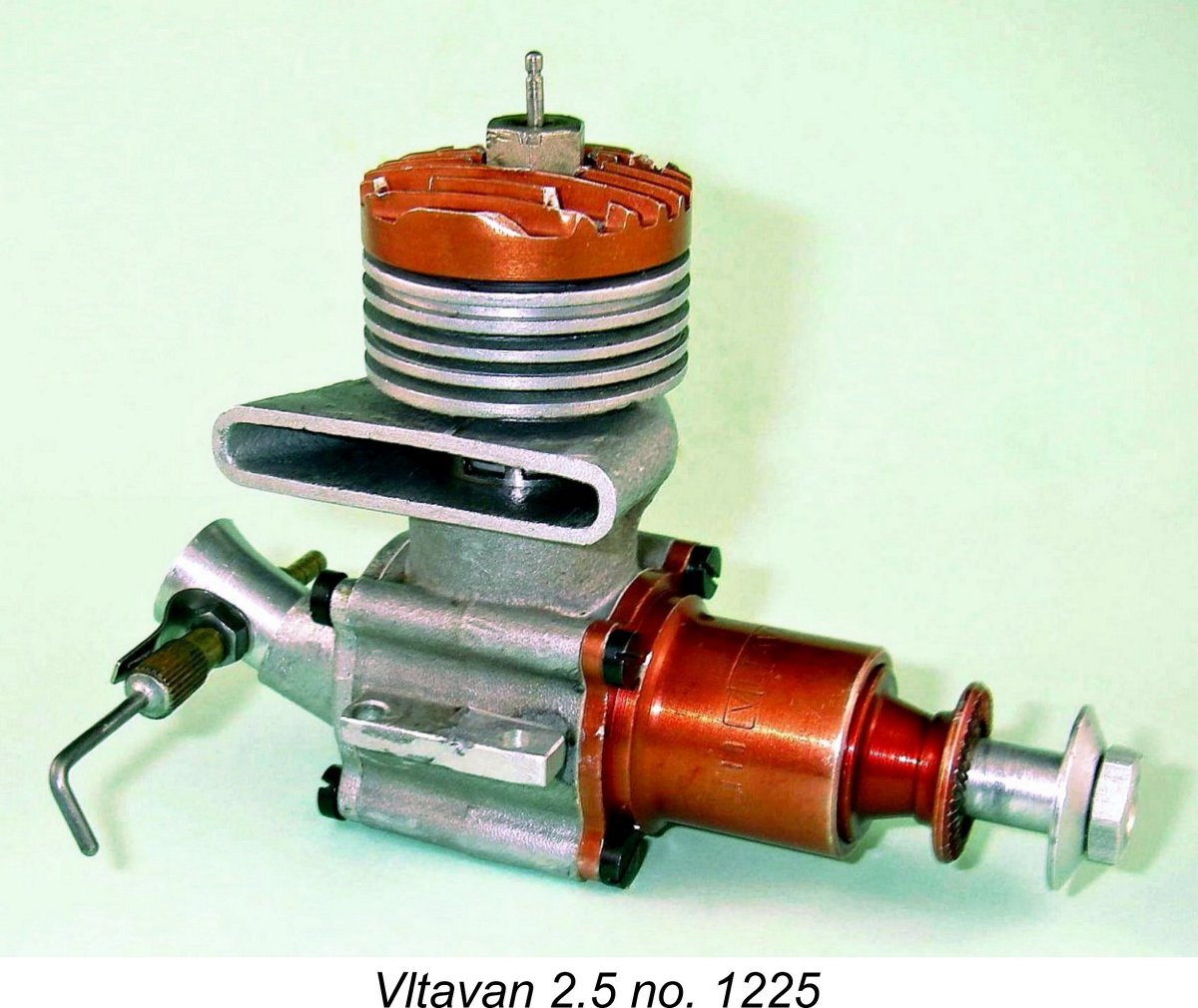

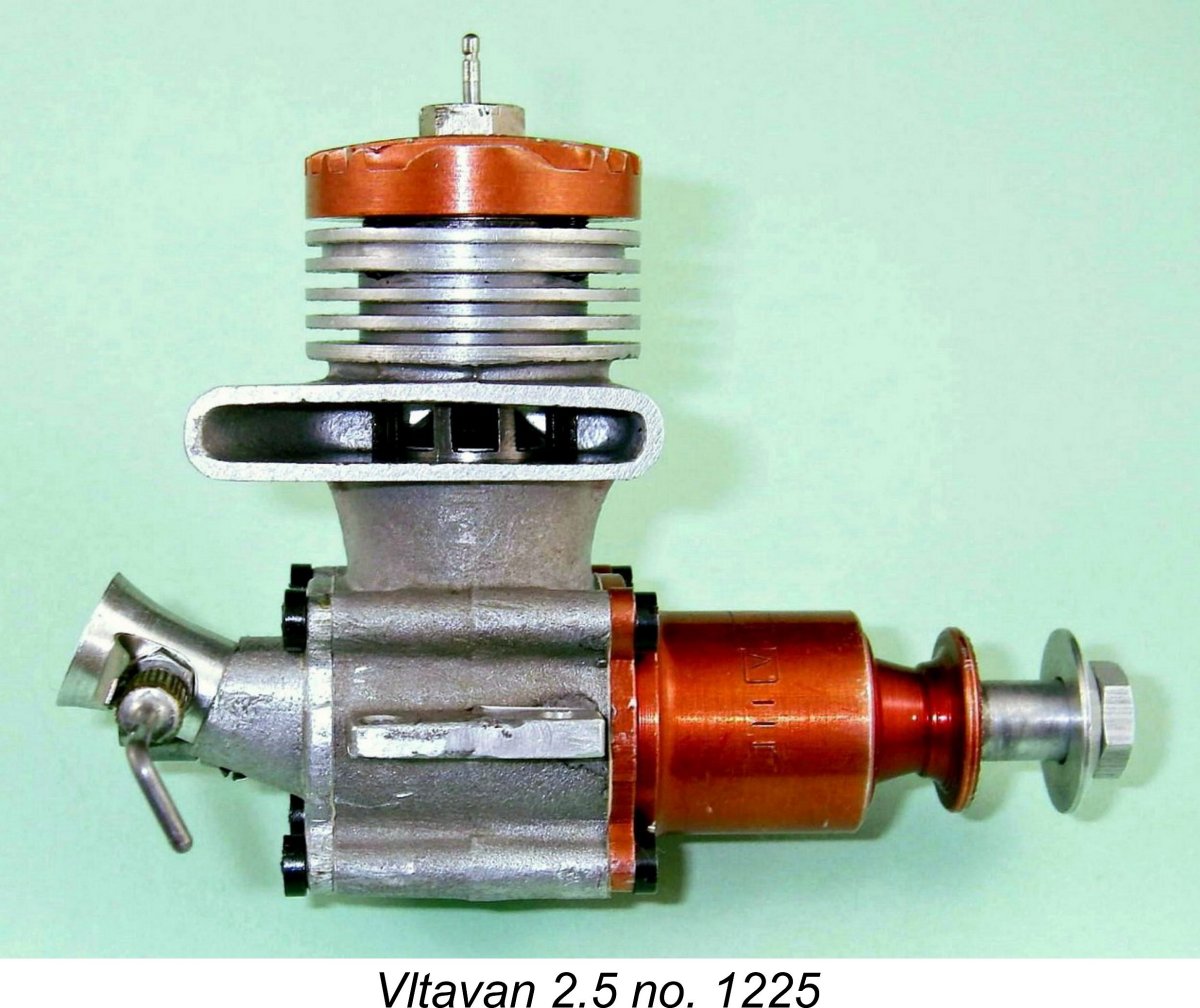

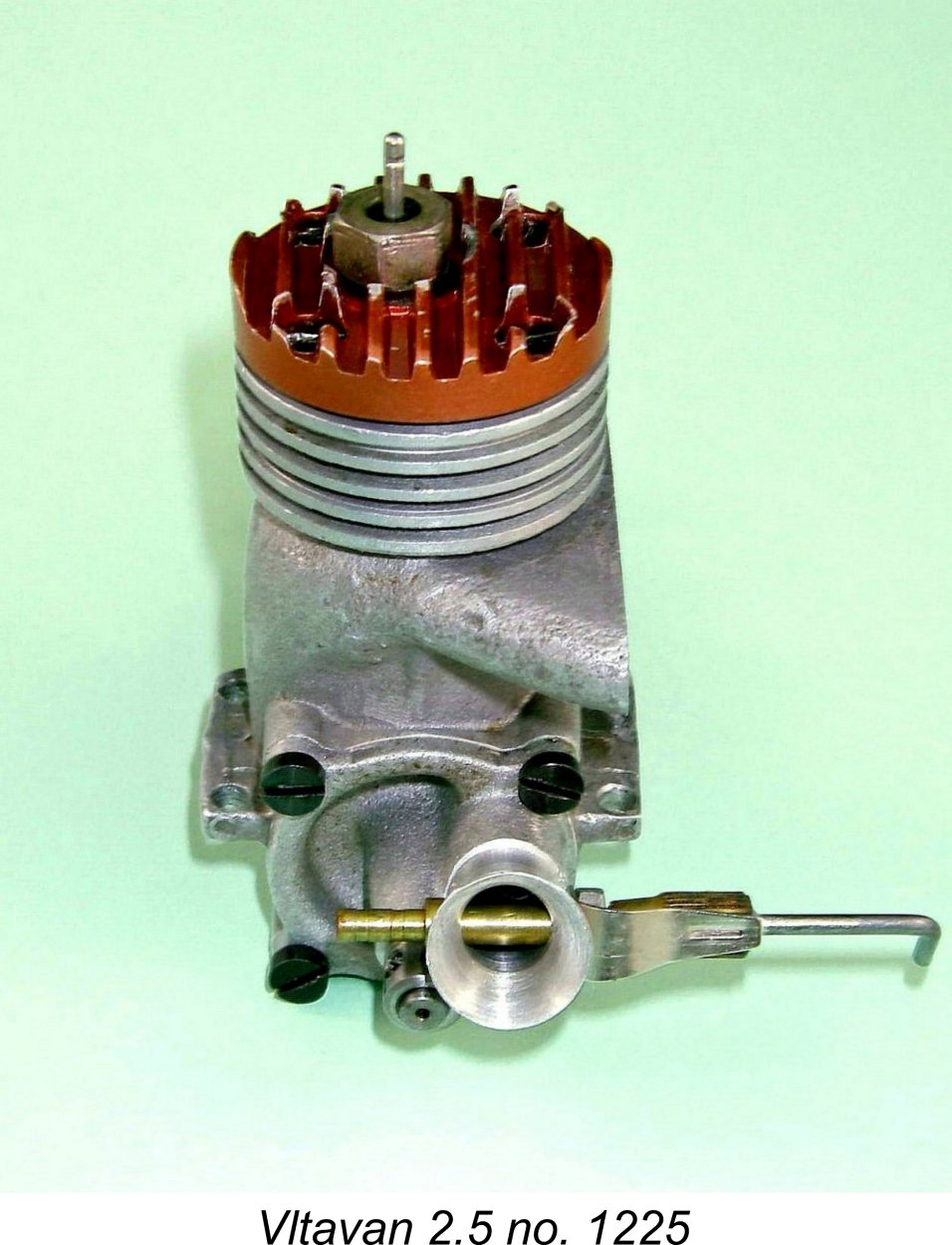

In most respects, the Vltavan 2.5 cc model is a completely typical racing motor of its day - cross-flow loop scavenging, twin ball-bearing shaft, large bypass passage, high-domed ringed aluminum piston, rotary disc valve, offset plug, etc. Measured geometric compression ratio is 8:1, implying an expectation that a high-nitro fuel would be used. The engine features the standard Continental bore and stroke of 15 mm by 14 mm for a displacement of 2.47 cc (.151 cuin.). It weighs a mere 4.2 ounces.

However, the effect of all this clever engineering is somewhat marred by the fact that the disc in the Vltavan is of cast aluminum alloy rather than some more durable material such as Interestingly, a standard transverse spray-bar type needle valve was employed in conjunction with a nicely-shaped venturi intake which was retained in place by a small grub screw. The spraybar diameter is 3 mm, while the venturi diameter is 6.5 mm. According to Maris Dislers' very useful Choke Area Calculator, this combination provides an effective choke area of 14.399 mm2 with a minimum operating speed of 11,951 rpm on suction feed. Obviously, we would normally expect the engine to be operated at far higher speeds than that. The used of a continuous transverse spraybar represents a significant reduction in the cross-sectional area of the venturi throat, but it does provide a very good level of suction for a racing motor. This was important given the fact that the Czechs were using metal chicken-hopper tanks with suction feed at the time. In any case, the spraybar could of course be thinned if desired to increase the effective venturi throat area. Alternatively, it could be eliminated altogether through the fitting of screw-in surface jet components along the McCoy and Dooling pattern. The generously-sized bypass passage is cast into the side of the crankcase opposite the exhaust in the usual way. It has a conventional point of entry at the lower end, but this was not enough for the MVVS designers - the piston features two large skirt ports which register with corresponding ports in the lower cylinder liner a la Dooling and in fact take up much of the piston skirt on that side. In effect, this is the Dooling system with the addition of an extra point of entry to the bypass at its lower end. Two potentially negative consequences arise from the use of this set-up. Firstly, the crankcase volume is rather larger than might be considered desirable. Secondly, the piston ports significantly reduce the skirt area on the transfer side, which has to resist the major lateral loading during the power stroke. Mechanically speaking, this is not an ideal arrangement - there simply isn't much skirt left to take those loadings! The presence of the swept-back exhaust stack precludes any possibility of assembling the engine the other way round. However, compromises are inevitable in matters of this nature when all-out performance is the sole imperative.

Quite apart from the above-mentioned skirt ports, the cast and machined piston is a work of art! It has two rings and an intricate domed baffle crown which conforms to a contoured combustion chamber shape formed in the cylinder head. The short-reach plug is well offset to the transfer side to accommodate these arrangements. The purpose of such an offset is to bring the ignition point closer to the partially-isolated pocket of mixture behind the piston baffle at top dead centre, thus accelerating its involvement in the combustion process. The gudgeon pin bosses are beautifully fitted to the pin itself, and the forged alloy rod is also very well made and fitted. The pin is equipped with aluminum end-pads. Reciprocating weight is minimal - a very good feature. The extremely generous cylinder ports consist of multiple square openings separated by thin pillars in the normal fashion when using a ringed piston. The purpose of these pillars is of course to prevent ring snag in the ports. One point worth noting is that if you ever run across an unmodified example of one of these engines, you’ll find that a standard glow-plug won't fit! The thread of the Czech glow-plugs for which the Vltavan heads were originally tapped was M6x0.75. This thread was used in the 1950's by MVVS in addition to Vltavan, presumably to accommodate the thread then in use on standard Czech glow-plugs. A quick calculation reveals this thread to be pretty close to the Western 1/4-32 glow-plug standard. Expressed in metric units, this latter thread would be 6.38 mm x 0.78 mm pitch, which is slightly larger but sufficiently close that a 1/4-32 tap will open out the metric thread very easily with no preparation, making the conversion to a standard plug very simple indeed. Any Vltavan (or vintage MVVS) engine that has been used by a modeller in the Western countries will generally be found to have been re-tapped in this manner. The illustrated example retains its original metric thread and Czech glow plug. If you wish to run an engine having a metric plug thread, a far better option from the standpoint of conservation is to use a M6x0.75 die to re-cut the threads on the desired standard plug. I've tried this myself with completely satisfactory results. All that is necessary is to ensure that the re-cut threads are correctly aligned to the plug body - easy to do if you have access to a lathe and a tail-stock die holder.

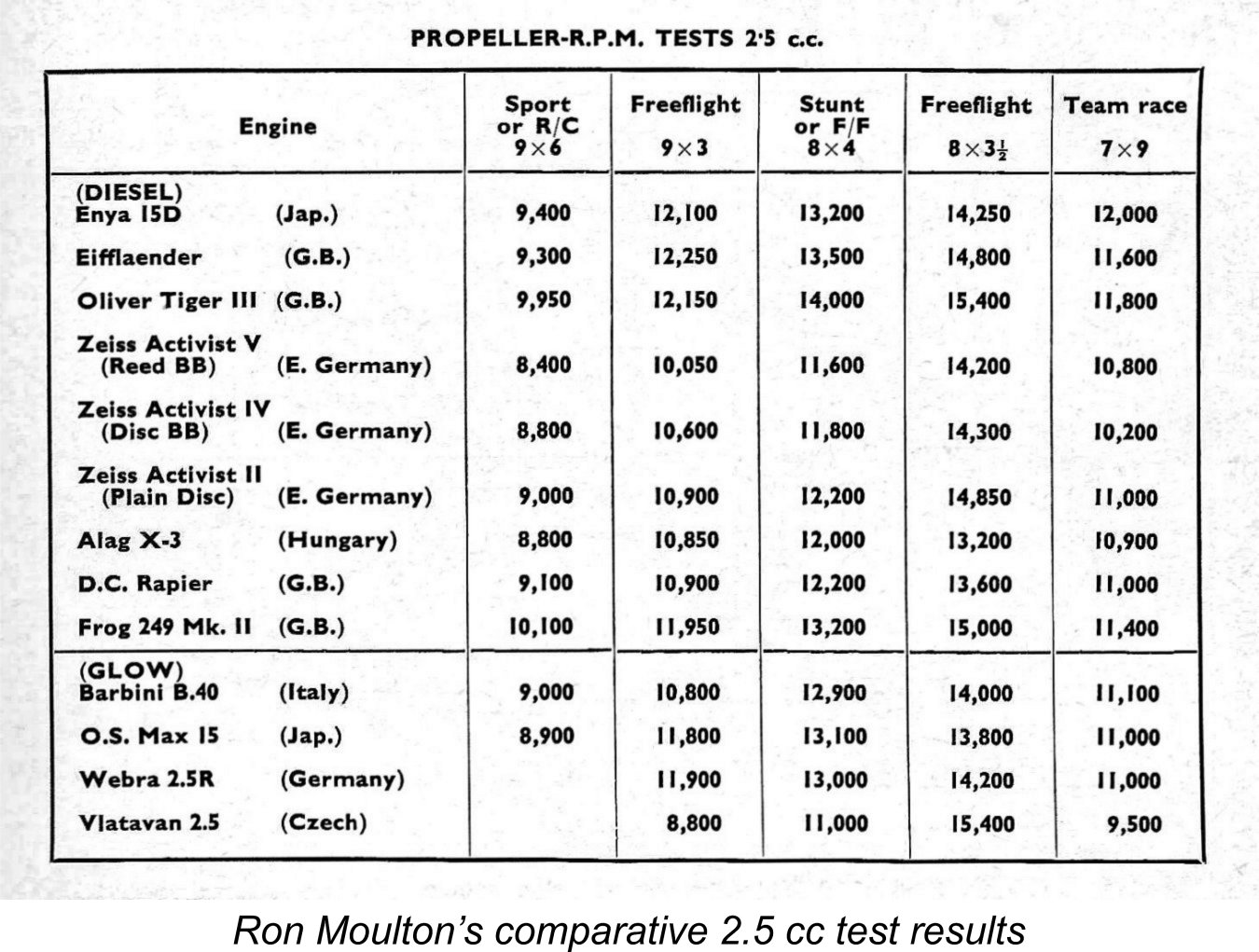

A significant issue with this engine is the fact that the mounting lugs are left "as cast" on both upper and lower surfaces. This would be OK if they were flat, but they're not - anyone planning to use one of these units in anger would have to set the case up in the milling machine and true up the underside of the lugs for mounting in a speed pan. And frankly, there's already a minimal amount of metal in the lugs—they could have been made a lot sturdier in my book. All that aside, how did the Vltavan perform? Let’s look over the contemporary evidence before running a present-day test. The Vltavan 2.5 – Performance Over the years, the Vltavan 2.5 has maintained a reputation for having been a considerably less-than-stellar performer by comparison with its MVVS progenitors as well as its other competitors. To what extent is this view justified? The only published contemporary "test" of the engine of which I'm currently aware appeared in the 1957 edition of "Aeromodeller Annual". The Vltavan was one of the engines included in a comparative performance evaluation of a number of then-contemporary 2.5 cc competition engines, both diesel and glow-plug. This comparison was conducted by the late Ron Moulton. The means by which Ron got hold of a Vltavan 2.5 so soon after production had commenced are unknown, but the tested example may well have been borrowed from British speed flier Pete Wright, who is known to have secured an example as of mid 1957, as mentioned earlier.

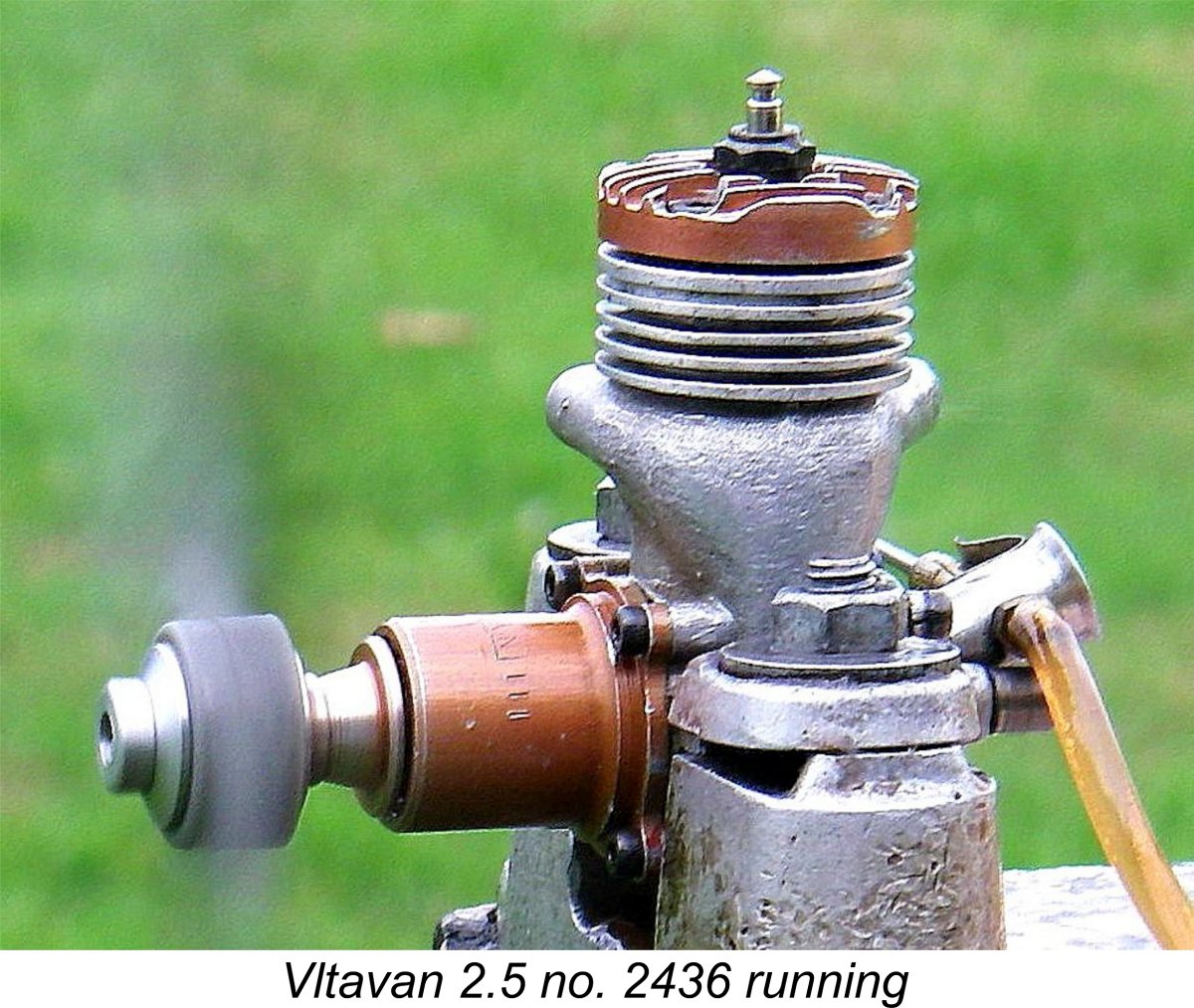

As one might expect from a racing glow-plug motor designed primarily for all-out speed work, the Vltavan was a very poor performer indeed on the larger airscrews, lagging well behind the other tested units. It's apparent from this that low-end torque was relatively minimal, as we might expect. Understandably, Moulton didn't even bother to try the engine on the 9x6. However, it's equally clear that torque was unusually well sustained at higher speeds. Consequently, on an 8x3½ prop typical of those used in competition free-flight applications at the time, the Vltavan pulled itself up to the top of the heap, turning this prop at a highly respectable 15,400 rpm. In this it was matched only by the Oliver Tiger Mk. III, although Ron commented that the Vltavan ran more steadily than the Ollie at this speed and appeared more than willing to go faster if desired. Published tests on the Mk. III Oliver by Ron Warring and Peter Chinn were quite consistent in finding an output for the Oliver of around 0.32 BHP at this speed. It seems safe to conclude that Moulton's test example of the Vltavan was developing a similar output in this range. However, the difference was that at 15,400 rpm the Oliver was already past its peak, whereas the Vltavan was clearly still working up to its peaking speed, with more yet to come. Moulton reported that the Vltavan turned a 6x9 speed prop at a quite creditable 14,000 static rpm, which would doubtless rev up to something approaching the engine's peak in the air. He commented that this latter figure matched those measured for "many reworked specials" on the same prop, also characterizing the engine as an easy starter. Overall, he was clearly most impressed with the Vltavan. Fair enough – it’s evident that by then-prevailing commercial 2.5 cc glow-plug standards the Vltavan was a relatively strong performer. However, none of the above information brings us any nearer to an accurate measurement of its peak performance capability. Only one way to do that – head for the test bench to burn a little nitro! The Vltavan 2.5 on Test I've never run the example pictured earlier (no. 1225) which appears to be pretty much unused and still has its 1950's-vintage metric thread Czechoslovakian plug installed. However, I had run two of my somewhat less pristine examples on a number of occasions in the past. Engine no. 663 had proved to be a good performer, although I didn’t take any prop-rpm readings on any of the occasions on which I ran it. The same went for engine no. 2436, although in that case I did have speed readings for a couple of props. I elected to use that example as my test subject on this occasion.

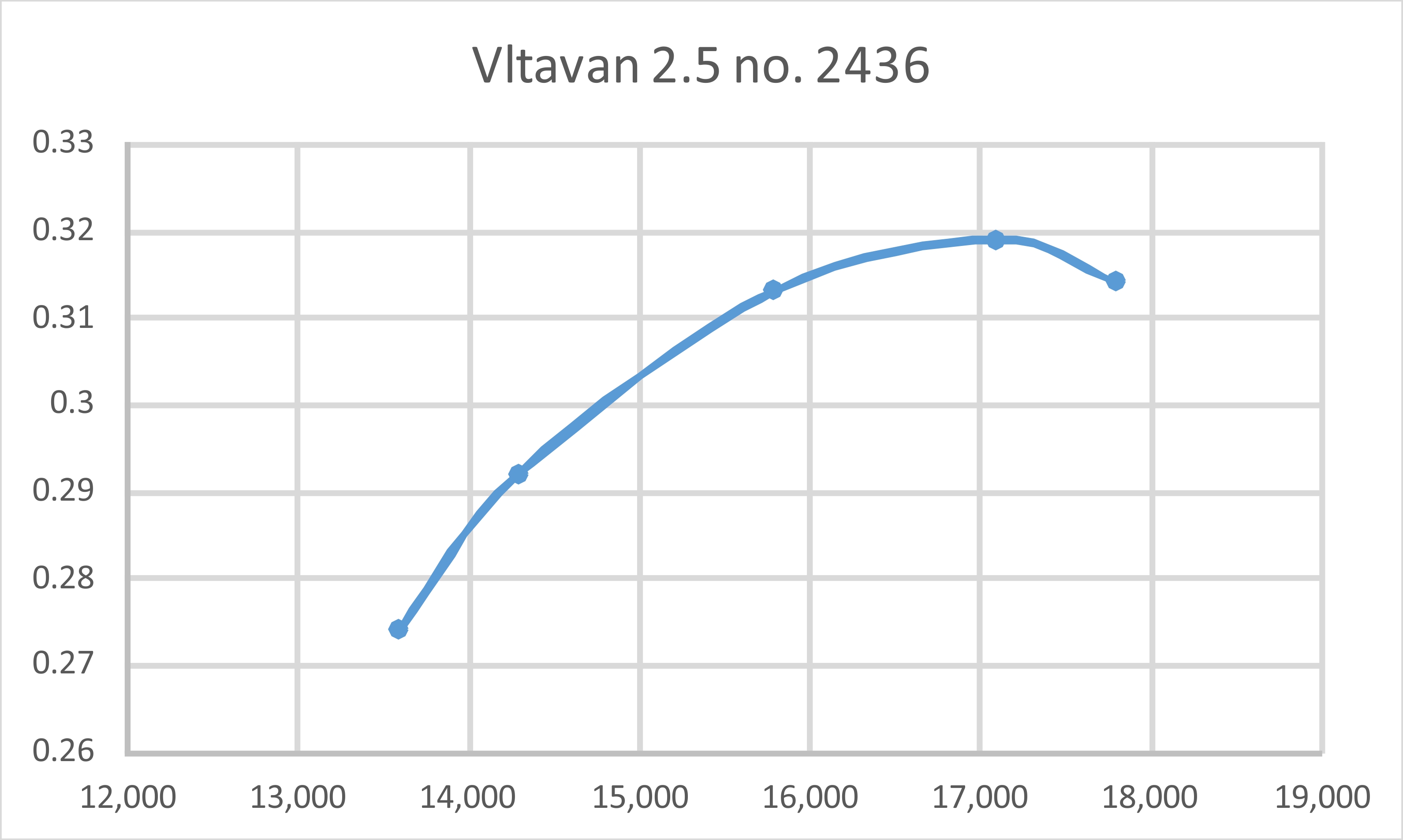

Using this combination, I found that hand-starting was perfectly straightforward using conventional methods. The engine appears to be well used, which doubtless explains the detectable wear in the con-rod bearings as well as the fact that the two piston rings did not seal perfectly despite giving the appearance of being well bedded in. However, there was more than ample compression for easy hand-starting if a healthy port prime was first administered. A few flicks invariably sufficed to produce a start. Once going, the engine ran extremely steadily with unusually low levels of vibration. It also needled very well indeed, with perfectly adequate suction. When leaned out, it maintained an absolutely steady exhaust note with no trace of sagging or nipping up. Indeed, it came through the test session with no signs of any mechanical issues developing, seemingly ready to run as long and as hard as desired. The excellent needle response made the establishment of the optimum settings very straightforward, and the engine would hold these settings without complaint for as long as required. I was encouraged by the fact that the Vltavan exactly duplicated the prop/rpm figures recorded during its previous running sessions. On this occasion, the following speed readings were recorded for the full suite of test airscrews:

As can be seen, the engine delivered a quite creditable performance by 1957 commercial glow-plug standards despite the wear resulting from previous use. The implied peak output of around 0.320 BHP @ 17,200 RPM is well in line with published test figures for other contemporary commercial 2.5 cc competition glow-plug engines and indeed many diesel engines of the period – in fact, it exceeds the majority of them. No doubt a carefully fettled and less well-used example could do even better than this, particularly if supplied with the higher-nitro fuels typically used in competition at the time.

Indeed, at the time of its release in early 1957 the Vltavan was almost certainly one of the most powerful commercially-available 2.5 cc racing glow-plug engines worldwide - as of 1957, the only competing commercial products that might have beaten it in standard over-the-counter form were the still-evolving Super Tigre G.20 models. Even then, I can see a number of readily-applicable modifications which would almost certainly improve the performance of the Vltavan considerably. The only references that I can find to a Vltavan 2.5 appearing in International competition were an official flight by Britain's Pete Wright at the previously-mentioned 1957 World Control Line Speed Championship meeting held at Mlada Boleslav in Czechoslovakia and the entry of Bengt Martinelli of Sweden at the 1958 Brussels Expo International event. After beginning his participation at the 1957 contest using a Barbini B.40 TN, Pete Wright switched to a Vltavan (probably obtained at the meeting given the location plus the fact that production had only recently commenced) after his Barbini expired. However, his speed of just over 161 km/hr (100 mph) was no threat to Josef Sladky's winning 216.0 km/hr (134.2 mph) figure using the latest MVVS prototype. Lack of adequate familiarity and preparation time may well have contributed to this rather lacklustre showing - the engine certainly had the potential to go considerably faster than that. At the 1958 Brussels meeting, Martinelli more or less matched Wright's 1957 speed with a mark of 163 km/hr. However, this speed was only good enough for 30th place behind the winning figure of 216 km/hr achieved by Imre Tóth of Hungary using the new MOKI S-1 powerplant. Conclusion

It didn't take long for the Czechs to recognize that the strategy of putting large numbers of increasingly uncompetitive and out-dated MVVS clones into the hands of ordinary modellers was not perhaps the best approach to the development of a broader talent pool. Indeed, it must have become apparent that if a way could be found to increase the availability of genuine MVVS engines, the modellers who were facing an uphill struggle trying to overcome the ever more apparent performance shortcomings of the Vltavan units would have far better equipment, enabling them to achieve higher standards of performance with a greatly reduced frustration factor. Accordingly, it was in 1958 that MVVS took the first steps towards becoming a major supplier of high-quality competition model aero engines to modellers in general rather than to a few selected Czech experts. They took on a number of extra workers at the centre and added more production equipment. Once this was done, several of their engines were put into small-scale production for wider distribution than had formerly been possible.

Still, as my own experiences and those of Ron Moulton show, the Vltavan 2.5 was a useful enough engine, with which an aspiring Czech speed flyer or free flight power buff could undoubtedly have gained valuable experience. In that context, the engine probably served its intended purpose quite well enough. It was certainly a far better performer than its "legend" suggests! _______________________________

Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published January 2018 |

||

| |

This will be yet another installment of my series of bench tests of some of the classic racing engines of the 1950’s. In previous articles, I’ve presented my own test data on such classics as the 1948

This will be yet another installment of my series of bench tests of some of the classic racing engines of the 1950’s. In previous articles, I’ve presented my own test data on such classics as the 1948

Given this latter success, it was hardly surprising that the MVVS design team took the decision to adopt RRV induction as their ongoing standard. Their competition glow-plug designs from 1956 onwards were to reflect this approach for some years to come. They contested the 1956 World Control Line Speed Championships held at Florence, Italy mostly using Kocí‘s modified version of the 1955 championship winner, which was known as the MVVS 2.5/1956-D. The one holdout was Josef Sladký, who stuck with the SK-25 “Broucek” unit which had been the previous year’s winner.

Given this latter success, it was hardly surprising that the MVVS design team took the decision to adopt RRV induction as their ongoing standard. Their competition glow-plug designs from 1956 onwards were to reflect this approach for some years to come. They contested the 1956 World Control Line Speed Championships held at Florence, Italy mostly using Kocí‘s modified version of the 1955 championship winner, which was known as the MVVS 2.5/1956-D. The one holdout was Josef Sladký, who stuck with the SK-25 “Broucek” unit which had been the previous year’s winner. The introduction of the Vltavan models was sufficiently delayed that advantage could be taken of the very latest design thinking emanating from MVVS as of late 1956. Accordingly, both of the Vltavan models sported RRV induction, just like the latest competition designs then emerging from the MVVS center. As the accompanying comparative images above and at the left will confirm, the Vltavan 2.5 was in fact pretty much a direct if somewhat simplified and less precise copy of the MVVS 2.5/1956-D design.

The introduction of the Vltavan models was sufficiently delayed that advantage could be taken of the very latest design thinking emanating from MVVS as of late 1956. Accordingly, both of the Vltavan models sported RRV induction, just like the latest competition designs then emerging from the MVVS center. As the accompanying comparative images above and at the left will confirm, the Vltavan 2.5 was in fact pretty much a direct if somewhat simplified and less precise copy of the MVVS 2.5/1956-D design.

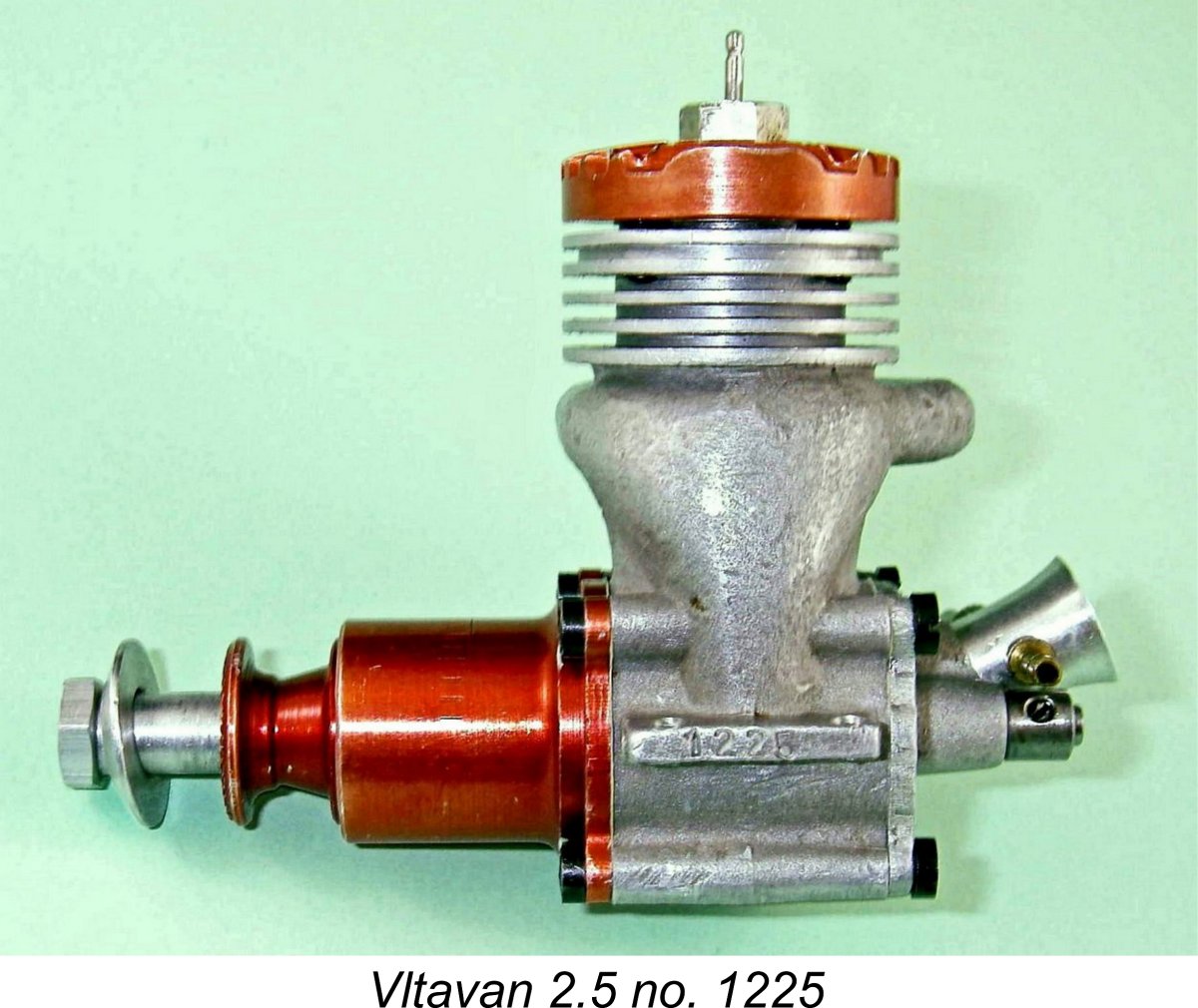

After one gets beyond the very attractive red anodizing on the head and front bearing housing (either a concession to "consumer appeal" or a party political message!), the first feature of the Vltavan that strikes one is the spectacular swept-back exhaust stack. This configuration originated with Sladký's 1955 World Championship motor and had been carried over to the MVVS 2.5/1956-D upon which the Vltavan was directly based.

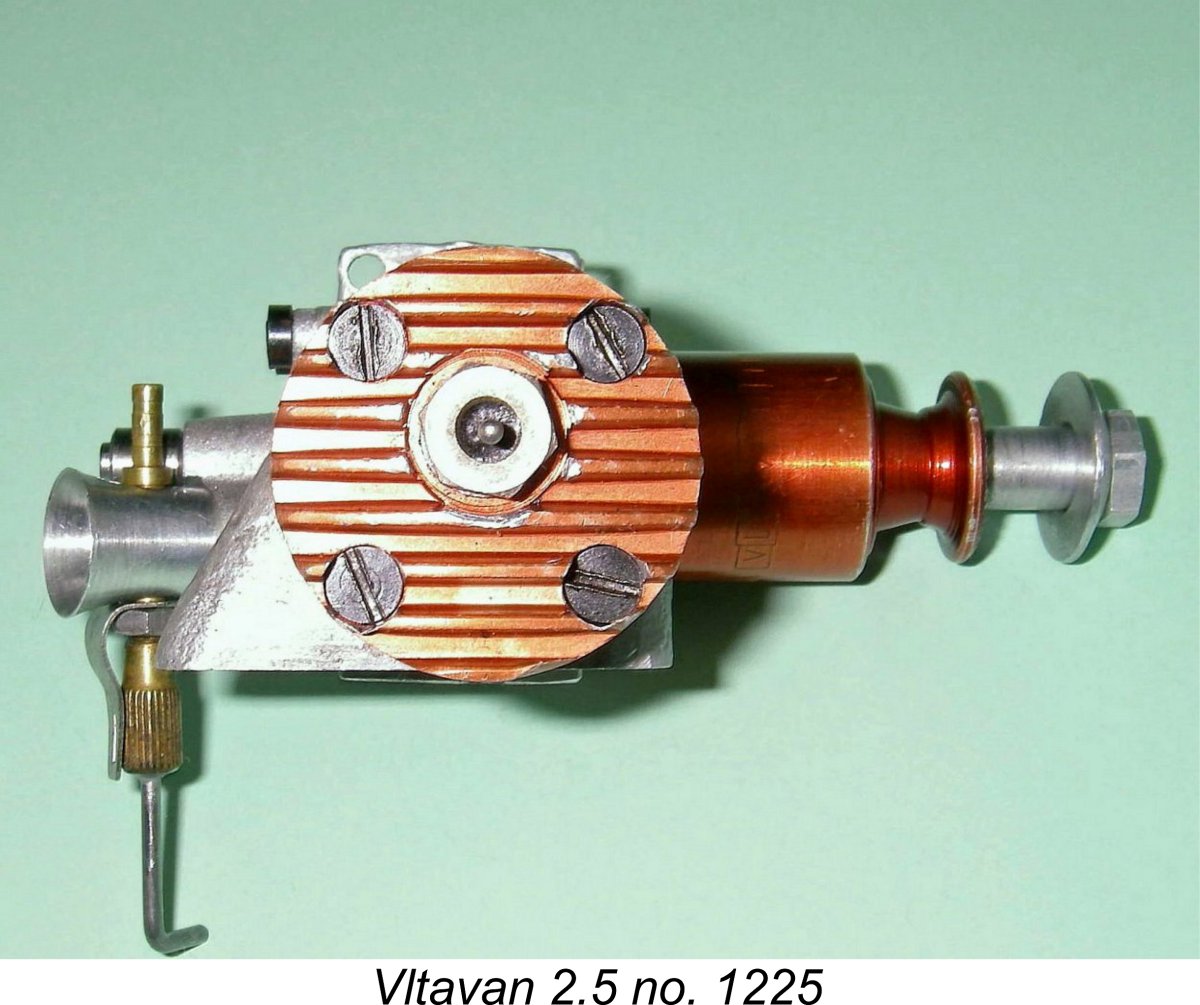

After one gets beyond the very attractive red anodizing on the head and front bearing housing (either a concession to "consumer appeal" or a party political message!), the first feature of the Vltavan that strikes one is the spectacular swept-back exhaust stack. This configuration originated with Sladký's 1955 World Championship motor and had been carried over to the MVVS 2.5/1956-D upon which the Vltavan was directly based. The attached images extracted from Peter Chinn's previously-mentioned January 1959 article in "Model Aircraft" should do much to clarify the engine's main design arrangement. The Vltavan's MVVS heritage is clearly reflected in the fact that it is very well engineered and displays some neat features. The design of the disc valve is particularly worthy of comment - it is extremely well mounted on a steel shaft of generous length which turns with the disc and runs in a close-fitting bearing in the centre of the backplate, being secured at the outer end by a steel collar and grub screw. This arrangement provides outstanding support for the rotary disc, maintaining a very accurate alignment with the face of the backplate. The disc shaft is drilled to allow adequate lubrication to reach the bearing.

The attached images extracted from Peter Chinn's previously-mentioned January 1959 article in "Model Aircraft" should do much to clarify the engine's main design arrangement. The Vltavan's MVVS heritage is clearly reflected in the fact that it is very well engineered and displays some neat features. The design of the disc valve is particularly worthy of comment - it is extremely well mounted on a steel shaft of generous length which turns with the disc and runs in a close-fitting bearing in the centre of the backplate, being secured at the outer end by a steel collar and grub screw. This arrangement provides outstanding support for the rotary disc, maintaining a very accurate alignment with the face of the backplate. The disc shaft is drilled to allow adequate lubrication to reach the bearing.

On the positive side, the presence of the piston ports has three clear benefits. One, they improve gas access to the bypass passage, which would otherwise be restricted by a rather narrow lower point of entry; two, they promote the flow of cool incoming mixture through the piston interior, thus improving piston cooling; and three, they doubtless enhance the lubrication of the more heavily-loaded transfer-side area of the cylinder wall. The very slight reduction in piston weight may also be viewed as a minor additional benefit - even a small reduction in reciprocating mass is a step in the right direction for a high-speed engine.

On the positive side, the presence of the piston ports has three clear benefits. One, they improve gas access to the bypass passage, which would otherwise be restricted by a rather narrow lower point of entry; two, they promote the flow of cool incoming mixture through the piston interior, thus improving piston cooling; and three, they doubtless enhance the lubrication of the more heavily-loaded transfer-side area of the cylinder wall. The very slight reduction in piston weight may also be viewed as a minor additional benefit - even a small reduction in reciprocating mass is a step in the right direction for a high-speed engine. Returning to our description of the Vltavan 2.5, the heavily counterbalanced crankshaft is very well supported in two ball bearings which appear to be of adequate if not spectacular quality. The prop mounting thread on the shaft of the pictured engine (serial number 1225) is a rather fine 5.0 mm by 0.5 mm pitch - not your everyday metric propshaft thread! An earlier example in my possession (number 663) also has this thread. By the time that they got to serial number 2436, the manufacturers had changed to a far more standard 5.0 mm by 0.8 mm pitch thread.

Returning to our description of the Vltavan 2.5, the heavily counterbalanced crankshaft is very well supported in two ball bearings which appear to be of adequate if not spectacular quality. The prop mounting thread on the shaft of the pictured engine (serial number 1225) is a rather fine 5.0 mm by 0.5 mm pitch - not your everyday metric propshaft thread! An earlier example in my possession (number 663) also has this thread. By the time that they got to serial number 2436, the manufacturers had changed to a far more standard 5.0 mm by 0.8 mm pitch thread. Each engine was tried on the same suite of standard test airscrews, while speeds were measured using the same equipment throughout. No actual power figures were reported, nor were the formulation(s) of the glow fuel(s) provided, but the results are nonetheless highly informative in that they do provide a direct performance comparison between the test engines.

Each engine was tried on the same suite of standard test airscrews, while speeds were measured using the same equipment throughout. No actual power figures were reported, nor were the formulation(s) of the glow fuel(s) provided, but the results are nonetheless highly informative in that they do provide a direct performance comparison between the test engines.  It’s a reasonable deduction that the engine was expressly intended for operation on a very high-nitro fuel, which was of course allowed in FAI-sanctioned international competitions when these engines were current. The Czechs are known to have used up to 45% nitro in their competition fuels. I couldn't go that far, but I did used a fuel containing 30% nitromethane along with a healthy dose of castor oil. I also fitted a cold plug for this series of tests to guard against pre-ignition.

It’s a reasonable deduction that the engine was expressly intended for operation on a very high-nitro fuel, which was of course allowed in FAI-sanctioned international competitions when these engines were current. The Czechs are known to have used up to 45% nitro in their competition fuels. I couldn't go that far, but I did used a fuel containing 30% nitromethane along with a healthy dose of castor oil. I also fitted a cold plug for this series of tests to guard against pre-ignition.

Based on this test in conjunction with Ron Moulton's results reported earlier, I have no hesitation in saying that while the Vltavan 2.5 did not perhaps come up to the performance levels of the individually-prepared MVVS factory originals, it undoubtedly did provide ample performance to allow aspiring Czech competitors to gain valuable contest experience. It would have made an excellent "clubman's" speed motor - certainly far better for that purpose than anything then commercially available in Britain, for example. It would probably also have acquitted itself well in free flight competition if fitted with an appropriate airscrew.

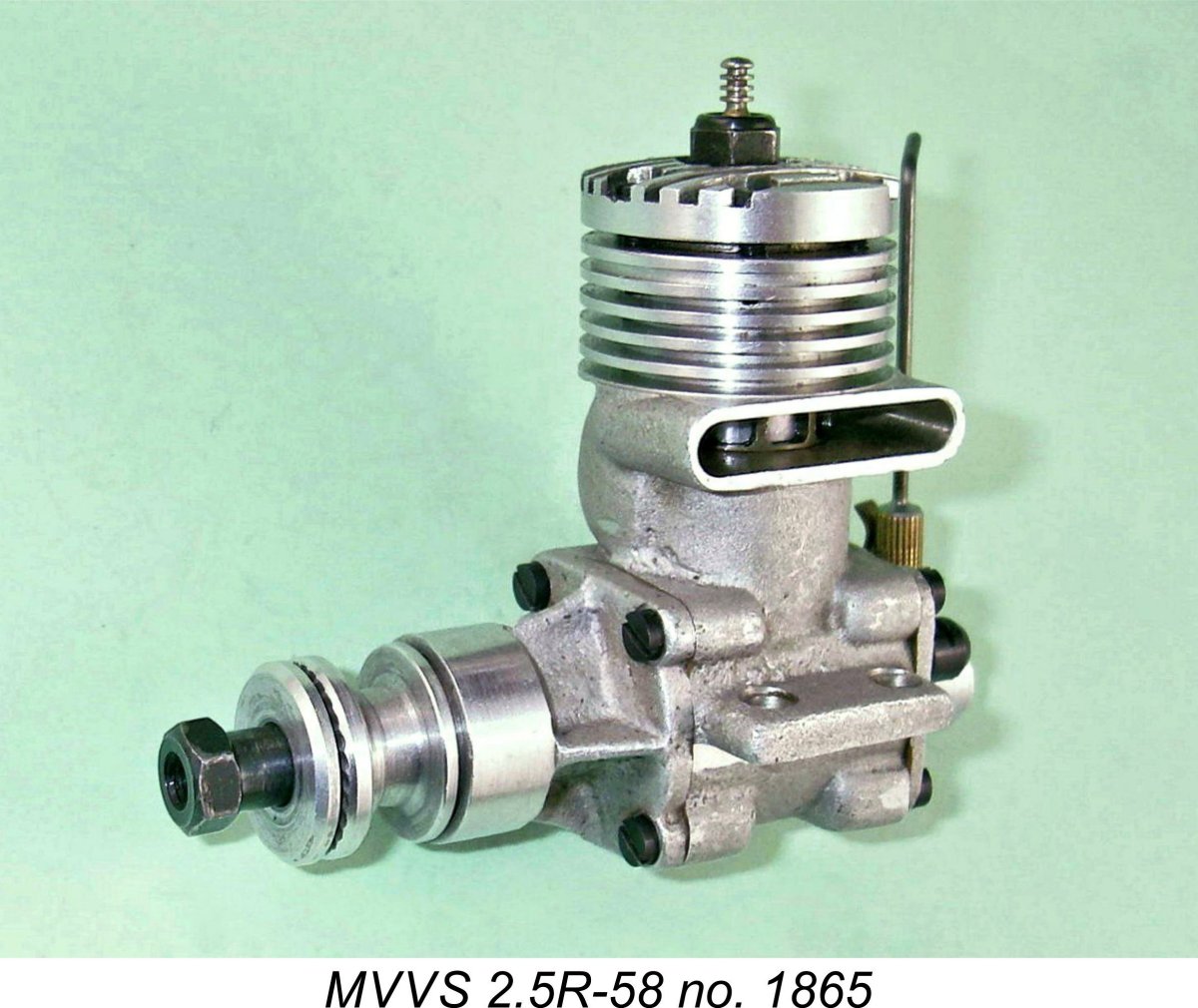

Based on this test in conjunction with Ron Moulton's results reported earlier, I have no hesitation in saying that while the Vltavan 2.5 did not perhaps come up to the performance levels of the individually-prepared MVVS factory originals, it undoubtedly did provide ample performance to allow aspiring Czech competitors to gain valuable contest experience. It would have made an excellent "clubman's" speed motor - certainly far better for that purpose than anything then commercially available in Britain, for example. It would probably also have acquitted itself well in free flight competition if fitted with an appropriate airscrew. By 1958 the MVVS Centre had further refined their 2.5 cc design to produce the outstanding 2.5R-58 model which has been the subject of a

By 1958 the MVVS Centre had further refined their 2.5 cc design to produce the outstanding 2.5R-58 model which has been the subject of a