|

|

Low-Profile Ukrainians - the POLET Engines

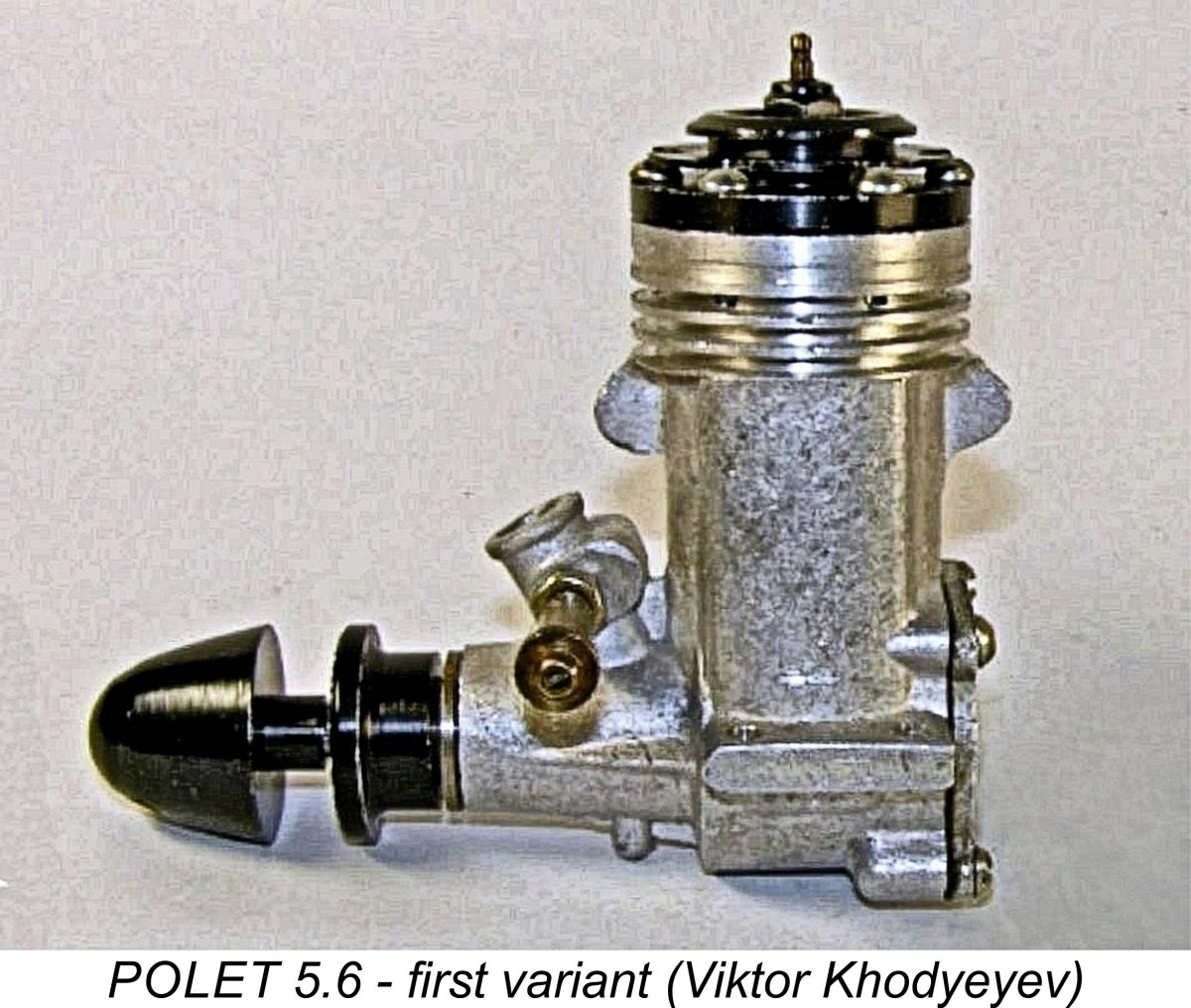

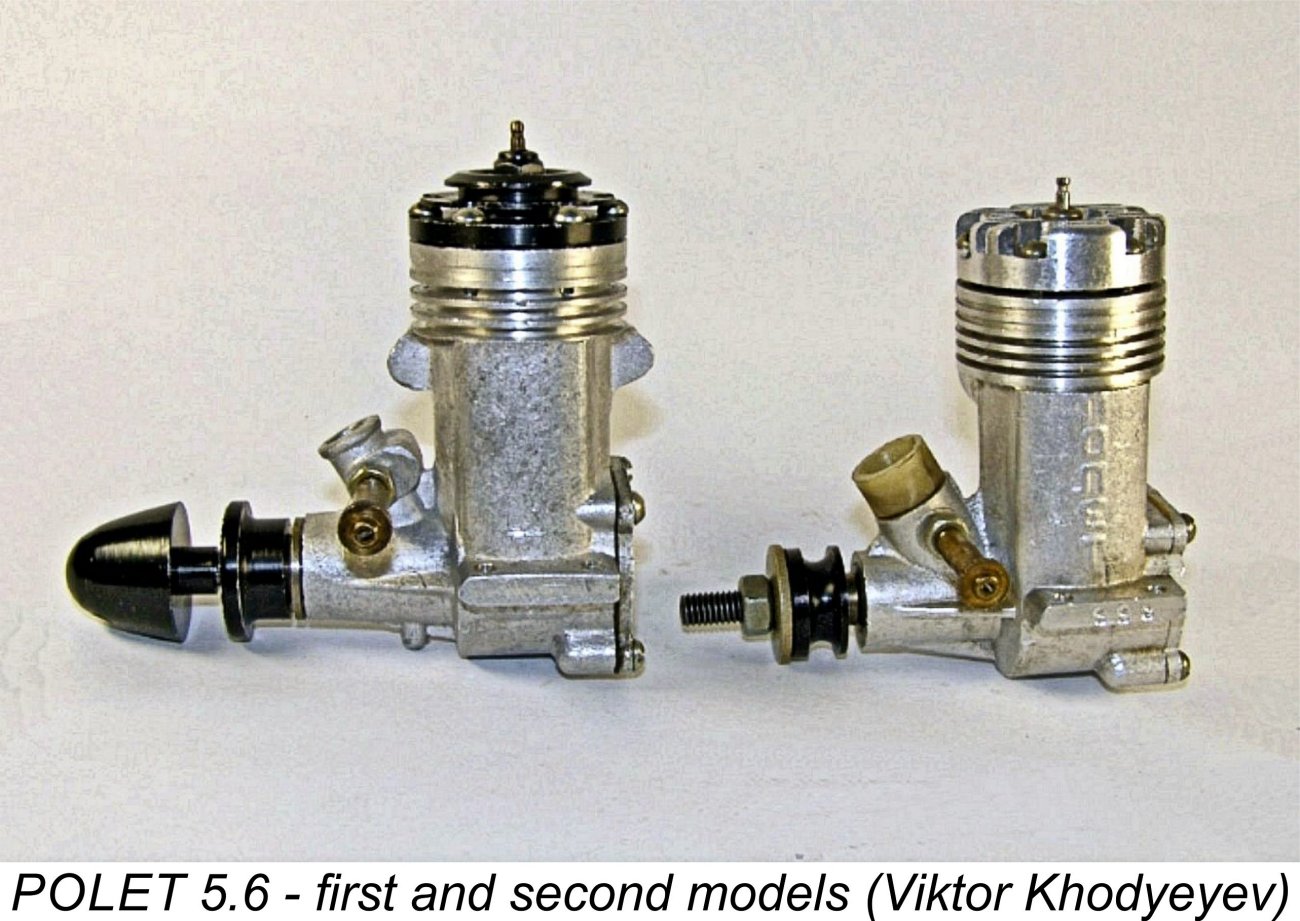

The only printed reference to the POLET engines which I’ve been able to find appeared in Viktor Khodyeyev’s very interesting but frustratingly incomplete 2014 German-language book “Modellmotoren Made in USSR”. Unfortunately, the research value of that reference is very much compromised by the fact that it includes very little historical or chronological background relating to the engines, focusing for the most part upon their structural characteristics. It thus provides very little information that cannot be ascertained from a direct examination of the engines covered. However, it does include a number of very informative images of the engines, some of which are reproduced here with my grateful acknowledgement. Unlike many contemporary Soviet products, the later variant of the POLET 5.6 appears to have made it out of its native USSR in at least moderate numbers. Examples show up fairly regularly on eBay, selling for relatively low prices for the most part. Unfortunately, a review of a number of eBay listings reveals that the sellers of these units appear to know very little about them, so no help there!

I’m fortunate enough to have examples of both the glow-plug and diesel variants on hand. This puts me in a position of being able to consider conducting bench tests of both units. But before I get into that, it’s worth spending a few moments clarifying the engine’s name. Some possible confusion arises from the fact that the Russian language is written in Cryllic characters rather than the Latin letters with which most of us are familiar. The engine’s name is written in Cryllic characters as ПOЛET. This is the name that appears on the boxes and on the engine itself. Reference to an on-line Russian pronunciation dictionary reveals that the word as written is pronounced more or less as “Pey - 0h - Let”. The normal rendition of POLET in Latin characters yields a pronunciation which is very close to correct. The Russian word ПOЛET means “flight” in English, but I have yet to see anyone refer to this engine as the “Flight 5.6”! Before getting onto the detailed analysis of the POLET 5.6, I’ll share what little I’ve been able to learn about the background to the development and manufacture of these engines. Background

This led to a perception among observers outside Russia that designers there were years behind their counterparts in other countries. This was simply not true - Russian designers were every bit as capable and knowledgeable as their Western rivals. It was simply that they were designing to different criteria. The inescapable result was that the Russians were relatively late starters in the high performance field. It was not until 1952 that designs which could fairly be classified as high performance competition models Although there were a few notable exceptions like the excellent 1955 MK-12S diesel designed by Oleg K. Gajevski and the equally good 1.5 cc MK-16K diesel from V. I. Petukhov, the majority of Russian engines in circulation during the 1950’s were highly derivative in design terms. Indeed, a number of them were straight clones of successful designs from elsewhere. Of course, this situation didn’t suit the Soviet political establishment at all! They were beginning to see success on the international contest field as a very good way to impress observers from elsewhere with the technical capabilities of the Communist regimes clustered behind the Iron Curtain under the USSR banner. However, success achieved using engines designed and manufactured west of the Curtain would contribute little to such a goal.

The technical development of aeromodelling in Russia was the responsibility of a para-military organization called DOSAAF, the primary goal of which was to support and encourage sporting activities which might prepare participants for later military service to the State. The Air Force connection brought both full-sized sport flying and model aviation into DOSAAF's portfolio. The organization operated a number of aircraft maintenance facilities throughout the USSR, including major plants in Moscow and Kiev. These plants could be tasked with the manufacture of model engines as the need dictated. DOSAAF resisted the temptation to follow the lead of their Czech and Hungarian compatriots. The Soviets had already estabished their own model technology development centre in Moscow way back in 1938 under the title (in English) of the Central Aircraft Modelling Laboratory (CAML). Among other tasks, this organization was responsble for providing support and technical assistance to modellers like Gajevski and Petukhov who were actively engaged in model engine development. DOSAAF saw no reason to expand CAML's mandate to have it produce very small numbers of "competition specials" for the use of leading Russian modellers - they felt that that was best left in the hands of the modellers themselves, with CAML's assistance as necessary. Instead, DOSAAF chose to focus on developing a pool of capable and experiences fliers who would use the home-grown world-beating engines to good effect once they were ready. To this end, they adopted an ongoing model engine production program based upon the large-scale manufacture and distribution Of course, there was an underlying logic driving this policy. At least the engines were made in Russia even if they were designed elsewhere, and half a loaf is far better than none! Moreover, the program made it possible to distribute "consumer grade" competition engines quite widely throughout Russian schools and model aero clubs, enabling students and club members to use them to gain invaluable hands-on experience. Meanwhile, the development of competitive all-Russian designs could proceed behind the scenes. By the time the engines were ready, their potential winning users would be ready also. The first sign that a switch to home-grown designs might be in the offing came in 1960 with the initial appearance of the RITM 2.46 cc team race diesel. Although its cylinder design paid tribute to that of the then all-conquering Oliver Tiger Mk. III, the rear drum valve RITM undeniably incorporated a good deal of The RITM was later put into large-scale production at Kiev beginning in 1962. Krasnoroutski went on to design further team race "specials", winning two World Team Race Championships and being accorded the coveted "Master of Sport" title no fewer than 3 times. He was also very much involved with the POLET project, as we shall see. As of the early 1960's, the Russians had also begun to show well in the international control line stunt category. However, in that category the fliers were well ahead of the engine designers, forcing them to use engines made elsewhere for the most part. It was inevitable that steps would eventually be taken to redress this situation. The POLET 5.6 cc glow-plug unit which forms our main subject was one manifestation of this process.

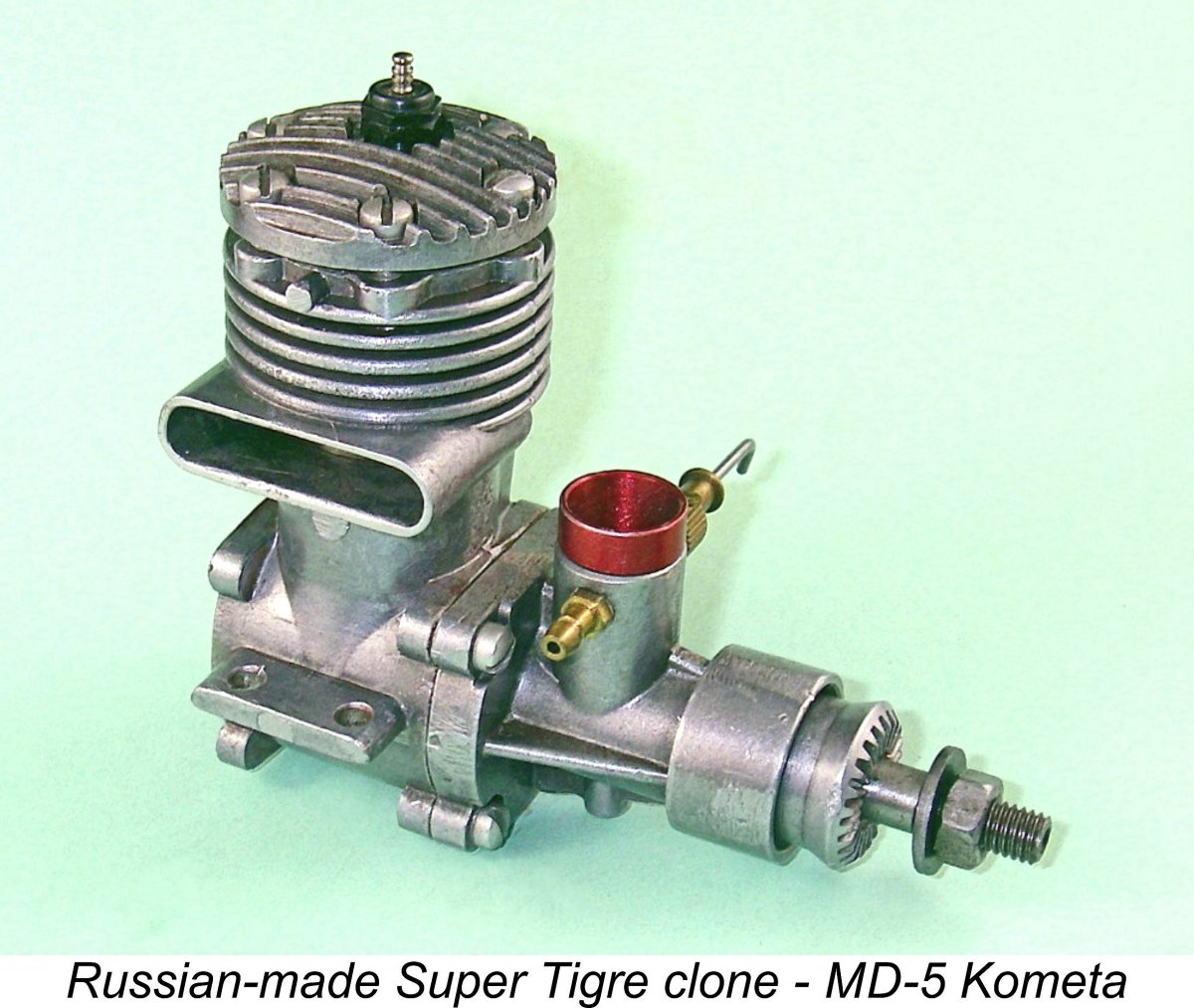

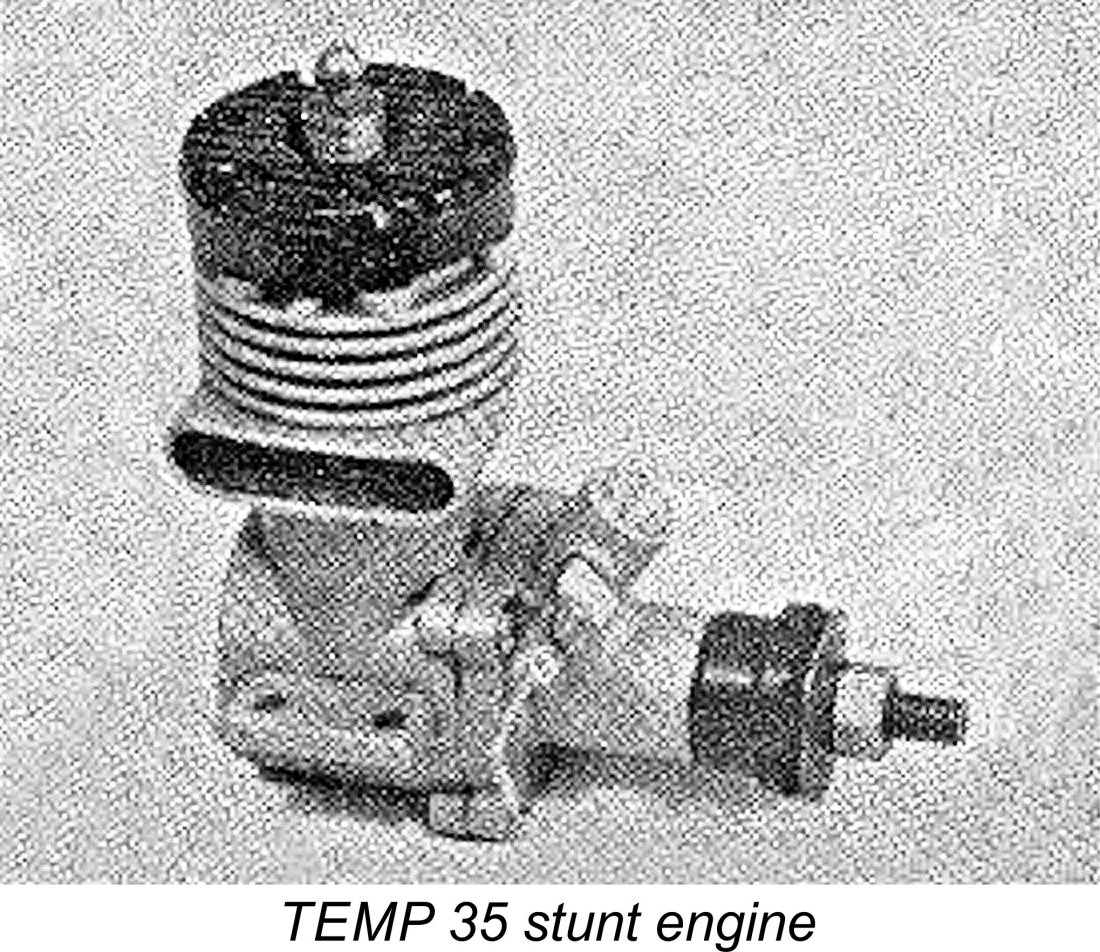

However, the use of the Kometa in this event was clearly no more than a stop-gap measure - a more focused design was clearly required. It appears from the available record that the initial Russian attempt to develop a "consumer grade" purpose-built stunt engine came in 1963, when a few examples of a unit called the TEMP 35 (Russian: TEMП) appeared at the 1963 Criterium of Europe meeting at Genk in Belgium. According to the brief write-up in the November 1963 issue of "Aeromodeller", the TEMP 35 was designed and produced in a short series by two un-named individuals from Kiev, one of whom was very likely Boris Krasnoroutski. The engine was a notably short-shaft design which reportedy performed very well indeed.

According to Viktor Khodyeyev, the POLET 5.6 cc glow-plug motor which appeared next was specifically designed as a “consumer grade” control line stunt motor, presumably based upon the same reasoning applied earlier to the development of Russian speed and team race engines. The idea was to get useable engines into the hands of Russian modellers in large numbers, thus allowing prospective competitors to gain the necessary model building and flying experience. This would create a very large pool of experienced fliers from among whom International representatives could be selected. There was nothing altruistic about this - the motives were largely political. The overriding goal was to enhance Russian prestige through success on the international contest field. Those who failed to make the grade would still have acquired skills and insights which could be directed towards service to the State in the aviation field. This highlights a major difference between the Russian approach to model engine development and that adopted in most Western countries. The manufacture of model engines in Russia was pretty much controlled by the State during the era under discussion. Consequently, decisions regarding which models to develop, to what standards and for what purposes were made by State officials (in this case, DOSAAF) rather than by the manufacturers themselves. All the latter had to do was produce the engines that they were told to make. By contrast, there was little or no State involvement in Western countries. While national prestige was certainly of interest, it was left to the individual model engine manufacturers to chart their own development courses with the primary goal of making money through engine sales to the public in competition with each other. Any international success achieved was a bonus which would presumably lead to enhanced sales. The Russians clearly recognized two quite distinct albeit related goals. These were a) the development of competitive powerplants, and b) the development of a sufficient pool of experienced competitors who could use those engines to best effect. The authorities quickly decided that the more experienced competitors at the international level could be relied upon to develop their own tool-room specials with which to compete. CAML was there to provide support to these individuals. As a result, Russian involvement in the fields of control line speed and team racing became increasingly dominated by individually constructed Russian “special” powerplants which were created by those who used them in competition. The State came to see its primary role as fostering the second of the two goals mentioned above - the development of a sufficient pool of talented and experienced competitors from which Russian representatives to international competitions could be drawn. To them, this meant ensuring the ready availability of “consumer grade” engines which could be supplied in large numbers at moderate cost to the school and club systems, allowing students and club members to gain the required experience. Get ‘em when they’re young …….. good policy!

Perhaps the most frustrating aspect of Viktor Khodyeyev’s previously cited book (the sole reference to the POLET engines that I’ve been able to find) is its almost complete lack of historical information on the engines covered, very much including their dates. The POLET entry is a case in point - there is absolutely no reference to the production dates and numbers of the engine. Moreover, the diesel version which unquestionably exists (see below) is not mentioned at all. Khodyeyev does tell us that the design of the engine was broadly based upon that of the Fox 35, with simplicity of construction being a key design goal. The engine was first mentioned in the English-language modelling media in Peter Chinn's "Latest Engine News" (LEN) column which appeared in the March 1968 issue of "Aero Modeller" magazine. In that article, Chinn stated that the engine was "destined for regular production this year (1968)", which seems to fix the POLET's introductory date pretty securely. Chinn credited Boris Krasnoroutski with the design. As 1970 approached, the stunt world was increasingly being taken over by larger and more technologically advanced powerplants than the venerable old Fox 35, which dated back to 1949 in its design essentials. It seems a little surprising that the forward-looking Krasnoroutski would have taken the Fox as his design inspiration at such a relatively late date - the writing was already on the wall by that time for that increasingly venerable design layout. His doing so must have been at the direction of his DOSAAF employers, who were evidently more concerned with production costs and figures than with technological progression.

However, 1000 engines does not constitute anything approaching “large numbers”, particularly by Russian standards. It thus appears that the serial numbering was started at engine number 1 when the second variant was introduced, probably in the early to mid 1970’s after the seemingly-unnumbered first version had been in production for some years. The “large numbers” doubtless relate to the total production figures for both variants combined. It would appear that the second version of the engine remained in production or at least on the market into the latter half of the 1970’s - I can’t be more definite than that. My valued Ukrainian informant Mykhailo Vasilik (lepondra on eBay) has confirmed that the POLET engines were indeed produced from the 1960's through the 1970's, but he couldn't be more definite than that. If any reader can inject some clarity into this dating question, please get in touch! Now, having summarized the background to the introduction of the POLET 5.6, it’s time to do what can be done to describe the engine. The POLET 5.6 - Description of First Variant

Bore and stroke of the engine were 20.5 mm and 17.7 mm respectively for a displacement of 5.84 cc (0.356 cuin.). This made it an unusually short-stroke engine for a stunt motor. This variant weighed in at 215 gm (7.59 ounces). The first variant of the engine differed in a few very obvious respects from its later and more familiar successor. The cylinder head was far less massive and sported a couple of turned concentric cooling fins instead of the fore-and-aft milled head fins used on the second variant. The prop driver was a more substantial component, while the prop was secured using a spinner nut instead of the plain nut-and-washer set used on the later version. The head, prop driver and spinner nut were all anodized black.

Another significant difference was the design of the intake venturi. That on the first model was cast in unit with the main crankcase in its entirety, with no separate venturi insert being employed. The venturi also incorporated an extruded section at the rear to allow the fitting of an offset surface jet spraybar if a more free-flowing intake tract was desired. A sub-variant of the same model appeared later with a larger-diameter intake stub which accomodated a black plastic venturi insert.

This model also included a pair of integrally-cast extrusions at the front and rear of the cylinder at exhaust level. This would appear to be an effort to facilitate the fitting of a muffler. Given the worldwide trend towards muffler use, the omission of this option on the second variant to be described next is difficult to understand. The crankcase of the first model bore no markings of any kind. Even the serial numbers applied to the second variant appear to have been omitted. Peter Chinn somehow obtained an example of this first model of the POLET in early 1970. He public shed an image of the engine in his LEN column in the February 1970 issue of "Aero Modeller", following this up with a commentary on the engine which was featured in his April 1970 LEN column. To say that he was unimpressed would be an understatement - his example was so poorly made that it could not be mounted securely due to lack of parallelism in the mounting lugs. Chinn stated that the same level of "rough-hewn workmanship" was evident elsewhere in addition. Evidently being unable to mount the engine for testing, he provided no performance figures. Lacking an example of this variant to examine, that’s about all that I can share with respect to this initial version of the POLET 5.6. Thankfully, I can now step onto firmer ground by describing the second variant, of which several examples are available for study and test. The POLET 5.6 - Description of Second Variant

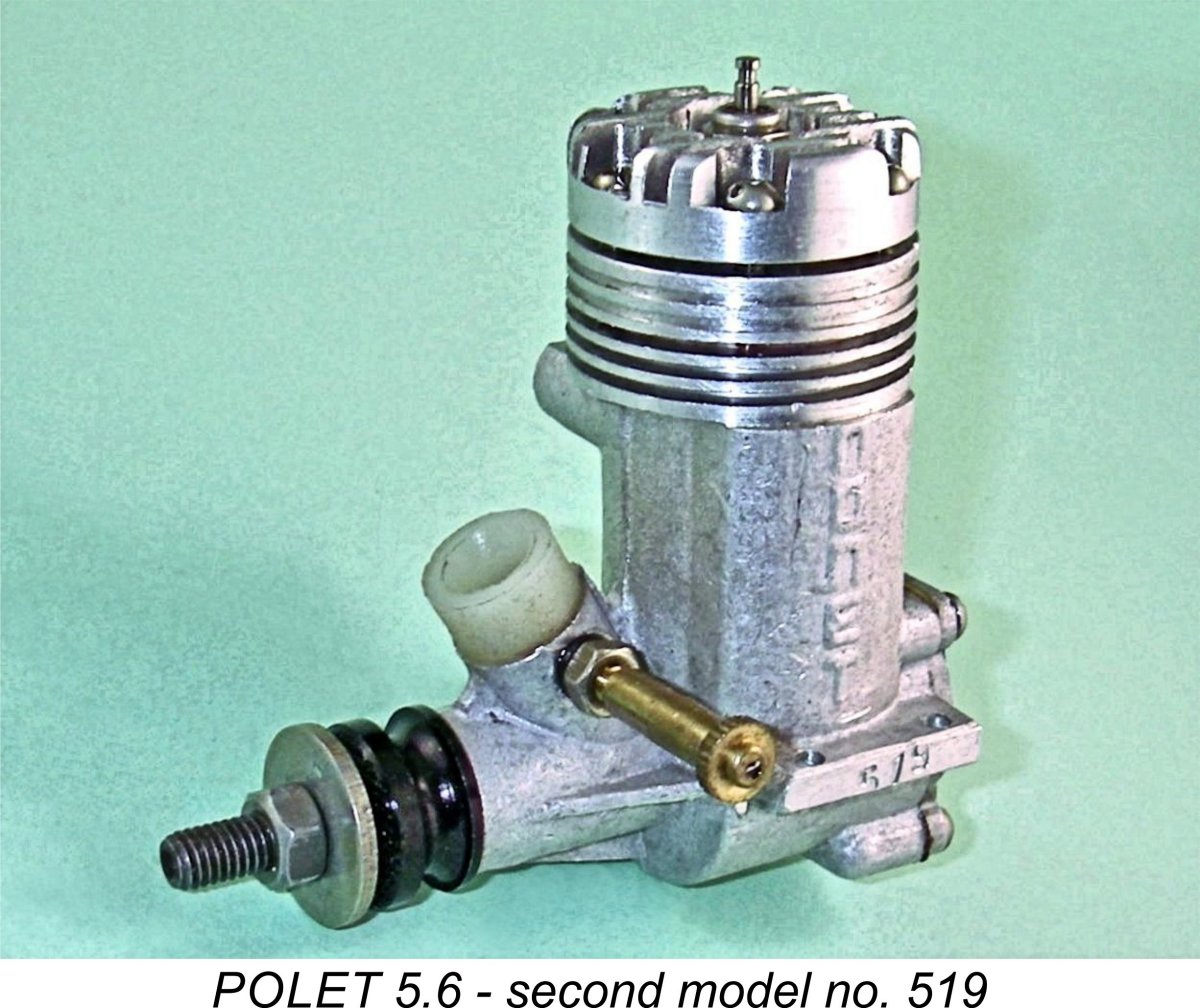

The fact that the matching-numbered papers with my Like-New-in-Box second model example no. 519 are factory date-stamped March 28th, 1975 suggests that the transition to this variant from the first model took place in 1974. I'd welcome the receipt of any confirmed data which could help to firm up the production dates for this engine. Beginning with a few figures, the instruction leaflet supplied with the POLET 5.6 cites unchanged bore and stroke measurements of 20.5 mm and 17.7 mm respectively for a calculated displacement of 5.84 cc (0.356 cuin.). As previously stated, this makes it an unusually short-stroke engine for a stunt motor.

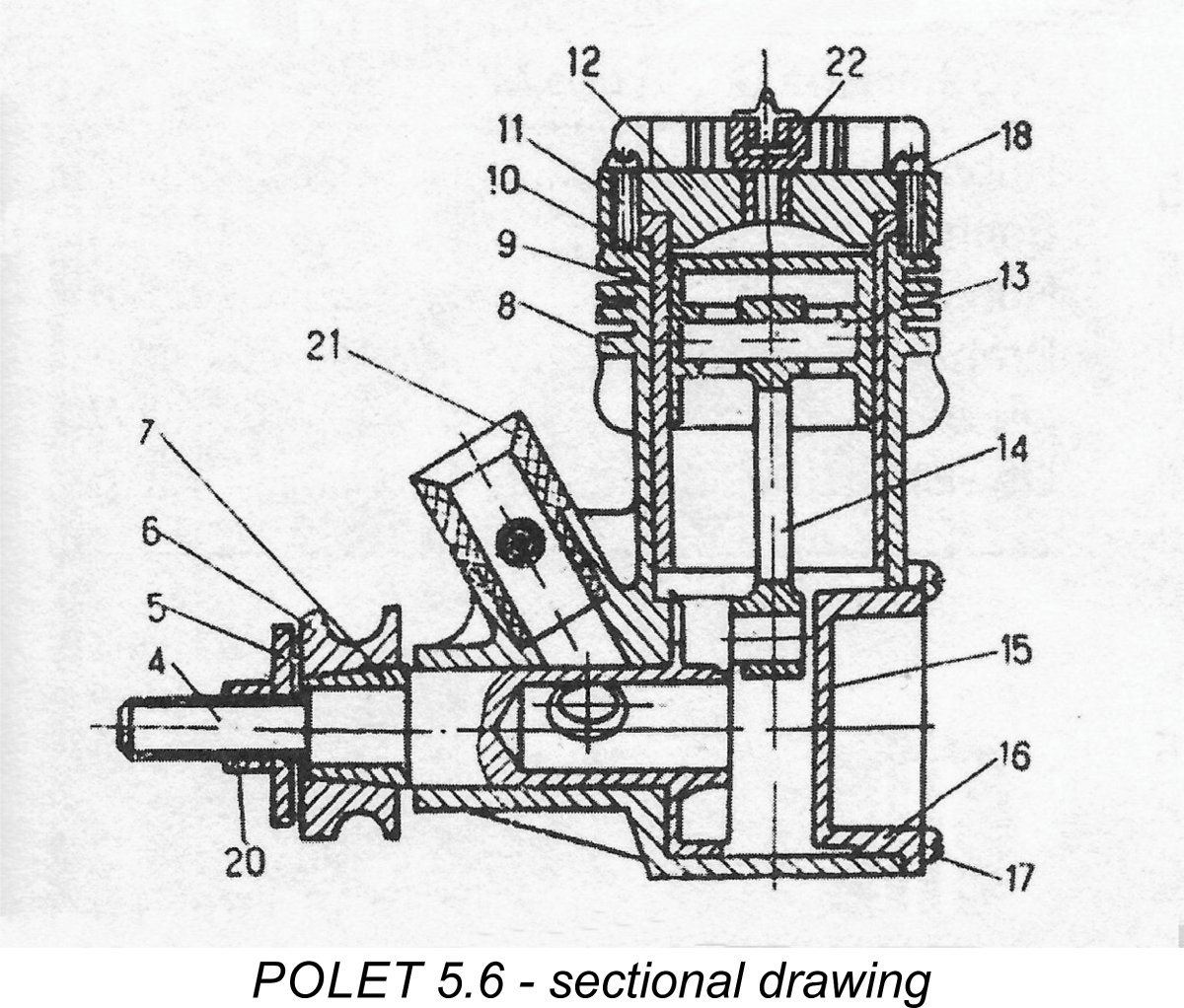

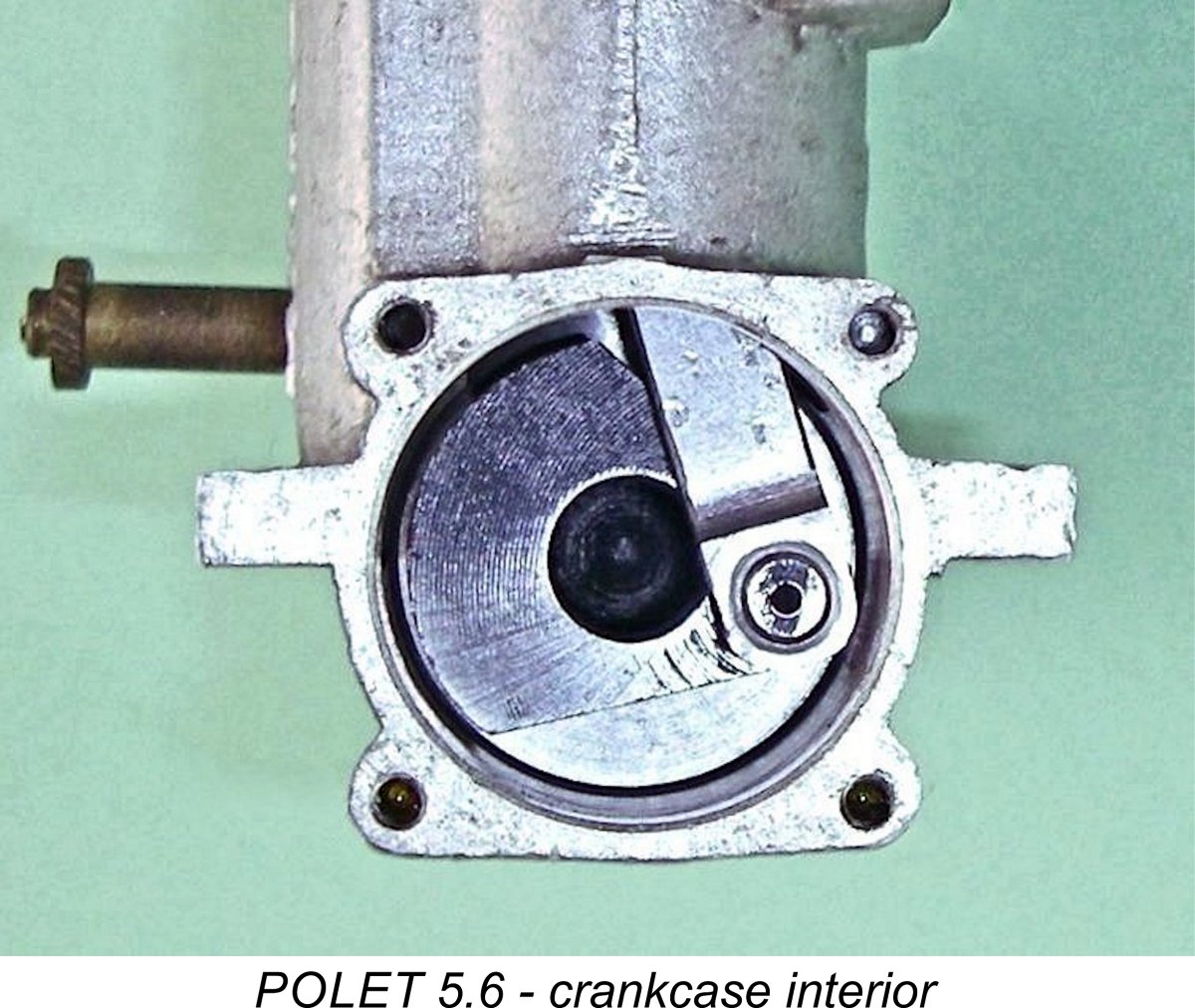

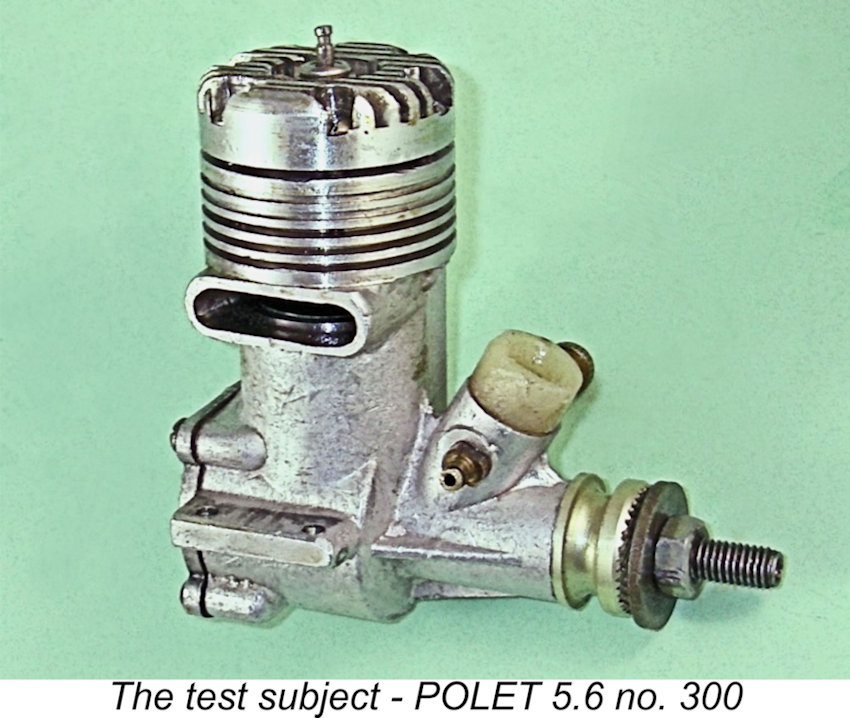

The engine is built up around a sturdy gravity die-cast crankcase which incorporates the main bearing and venturi base in unit. As stated earlier, the two fore-and-aft exhaust-level extrusions which appeared on the previous variant are omitted from the second model. The lower surfaces of the mounting lugs are milled parallel to encourage a really secure mounting - DOSAAF had evidently taken Peter Chinn's earlier criticism of the first model to heart! The name ”ПOЛET" (POLET) is cast in relief onto the bypass. The serial number is stamped onto the outer edge of the left-hand mounting lug. My illustrated LNIB engine bears the number 519. I also own LNIB engine no. 453 as well as used unboxed engine no. 300, of which much more below. A rather odd observation is that despite having looked for quite a few years, I have yet to encounter one of these engines with a four-digit serial number. The only other confirmed numbers which I've encountered are 331, 341 and 467.

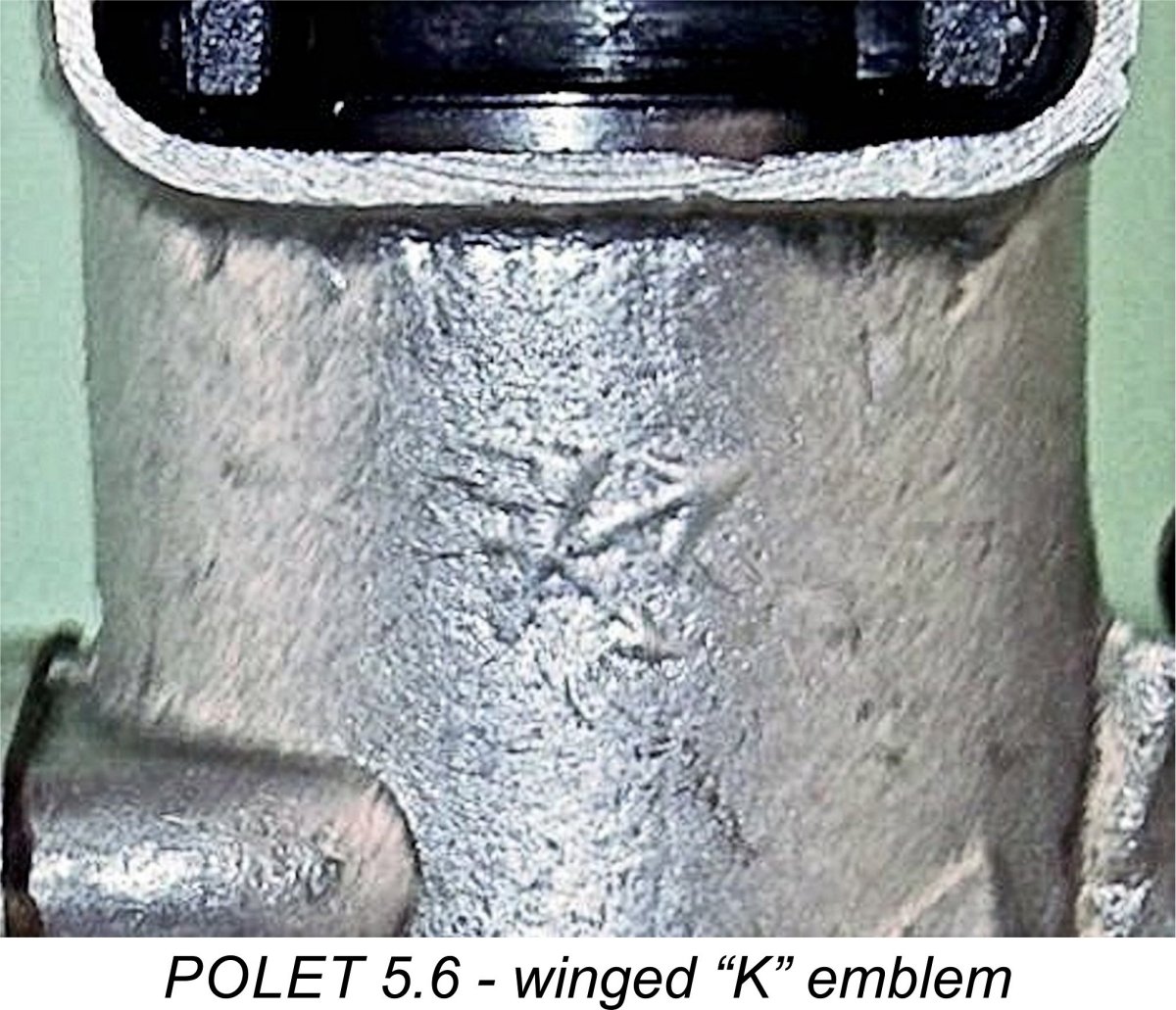

A cute little “winged K” emblem appears on the other side below the exhaust stack. According to information found in Jim Dunkin’s indispensable 2.5 cc model engine encyclopedia (page 316, engine I/D no. 499), this marking is the symbol for "КОНТУР ДОСААФ", which translates to “DOSAAF CONTOUR”. It appears to be in effect a DOSAAF trade mark claiming responsibility for the engine’s development. It appears on a number of different designs for which DOSAAF was responsible. My thanks to Maris Dislers for drawing my attention to this reference. The main bearing is unbushed, leaving the crankshaft journal supported directly in the crankcase casting material. The crankshaft is an excellent fit in its bearing. In typical Russian fashion of the day, little attempt has been made to “pretty up” the casting - the only concession to appearance is the fact that the un-fettled as-cast case has been silver-anodized. Despite the fact that it looks a little rough, the casting appears to be perfectly sound, and that’s what really counts.

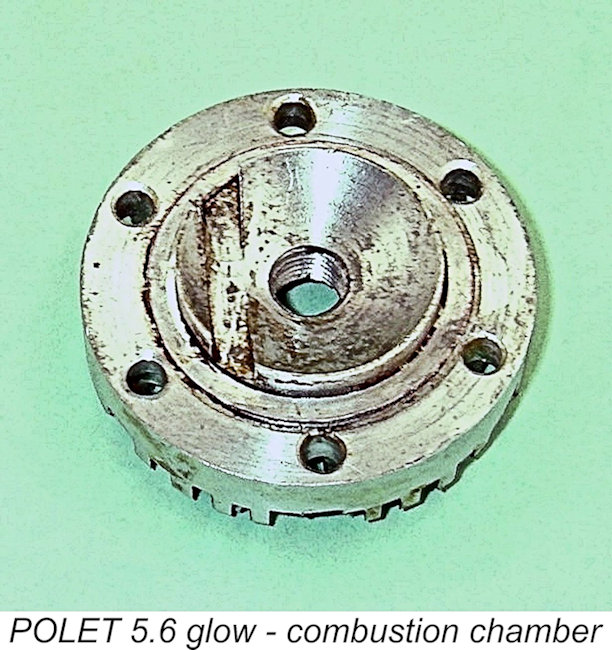

The head is secured using six slot-head machine screws of rather indifferent quality. It is centrally drilled and tapped to accept a standard ¼-32 long reach glow-plug. Oddly enough, the instruction leaflet cites a range of compression ratios from 6:1 to 7:1. The volumetrically measured compression ratio of my illustrated example splits the difference at 6.5:1. Presumably the figure could be adjusted between those limits by changing the head shimming. Even so, it’s clear that high speed operation was not envisaged for this engine. The hardened steel cylinder liner is very well finished both inside and out. It is notable for having a rather minimal wall thickness of only 1.75 mm. Both exhaust and transfer ports are cleanly-cut rectangular openings of generous dimensions. The cast iron baffle piston is lapped to a very nice if slightly tight fit in the liner. The cylinder port timing is even milder than that featured in the original version. The exhaust opens quite late at 120 degrees after top dead centre (ATDC) for a total exhaust period of only 120 degrees. The transfer port opens only 9 degrees later for a transfer period of 102 degrees. This is consistent with the manufacturer’s statement in the instruction leaflet that the engine was expected to operate in the vicinity of 9,500 rpm. The very large port areas should result in perfectly adequate scavenging at such moderate speeds, even with these relatively short exhaust and transfer periods. The goal here was clearly to go after good torque development at relatively low speeds.

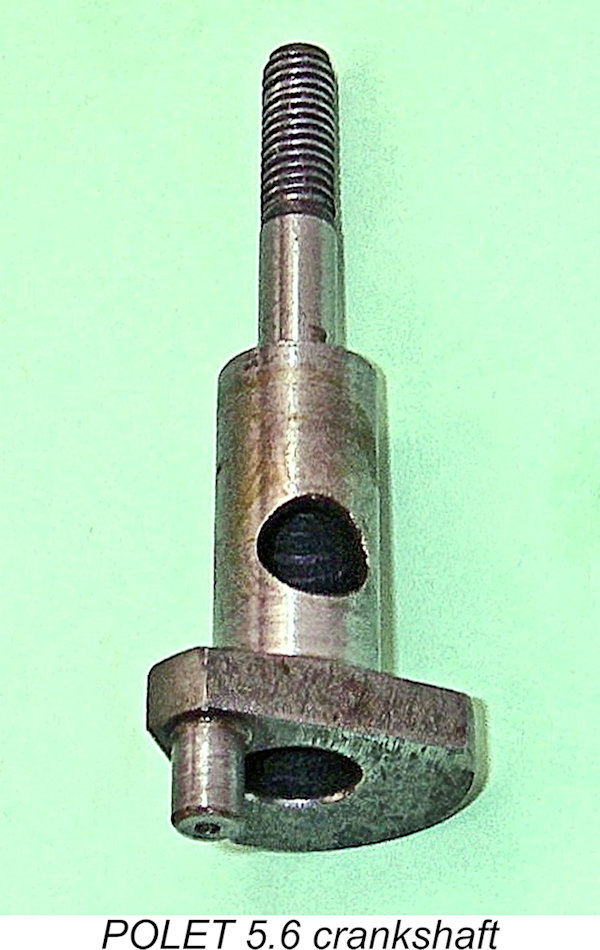

The main journal diameter is 12 mm, a seemingly more than adequate dimension. However, the internal gas passage is a monumental 9 mm in diameter, leaving a wall thickness of only 1.5 mm. This huge gas passage removes 56% of the cross sectional area of the shaft. Together with the stress-raiser created by the drilling of the necessary induction port through the shaft wall, I would judge this shaft to be somewhat marginal for long-term structural integrity. Much would depend on the quality of the steel and the care taken with the heat treatment. Like the rest of the engine’s design parameters, the induction timing is relatively mild, once again implying a design expectation that the engine would not be operated at high speed. However, it is a significant improvement over the induction timing applied to the original model. The induction cycle begins at 55 degrees after bottom dead centre (ABDC) - about the same as before - but ends some 43 degrees later at 30 degrees ATDC for a total induction period of 155 degrees - far more appropriate in my view. The early closure of the induction port combines with the relatively late opening of the transfer port to give a lengthy base compression period of 99 degrees. The resulting healthy “pop” as the transfer port opens is very apparent when the engine is flipped over without a plug! Again, this factor should promote good scavenging despite the late opening of the cylinder ports.

Finally, the rear of the crankcase is conventionally sealed with a backplate which is machined from a casting and secured with four machine screws. A fibre gasket is used to ensure a gas-tight seal. According to Viktor Khodyeyev, most examples of the POLET exhibited sub-standard workmanship, also vibrating excessively while in operation. To get the best out of one of these engines, most owners reportedly found it necessary to re-process certain components or even make replacements of superior quality. I can only say that while my own four examples (three glow and one diesel) may look a little rough externally and undoubtedly display a few fundamental design shortcomings, they seem to be constructed to generally acceptable standards where it counts - inside. How well they would hold up in service is quite another story……………….. It’s possible that the examples which were exported to other countries were “high-graded” by the manufacturer. So much for a capsule description of the POLET 5.6. Before moving to the testing phase of this investigation, we now need to look at a hitherto completely undocumented variant - the POLET 5.6 diesel. The POLET 5.6 Diesel Version

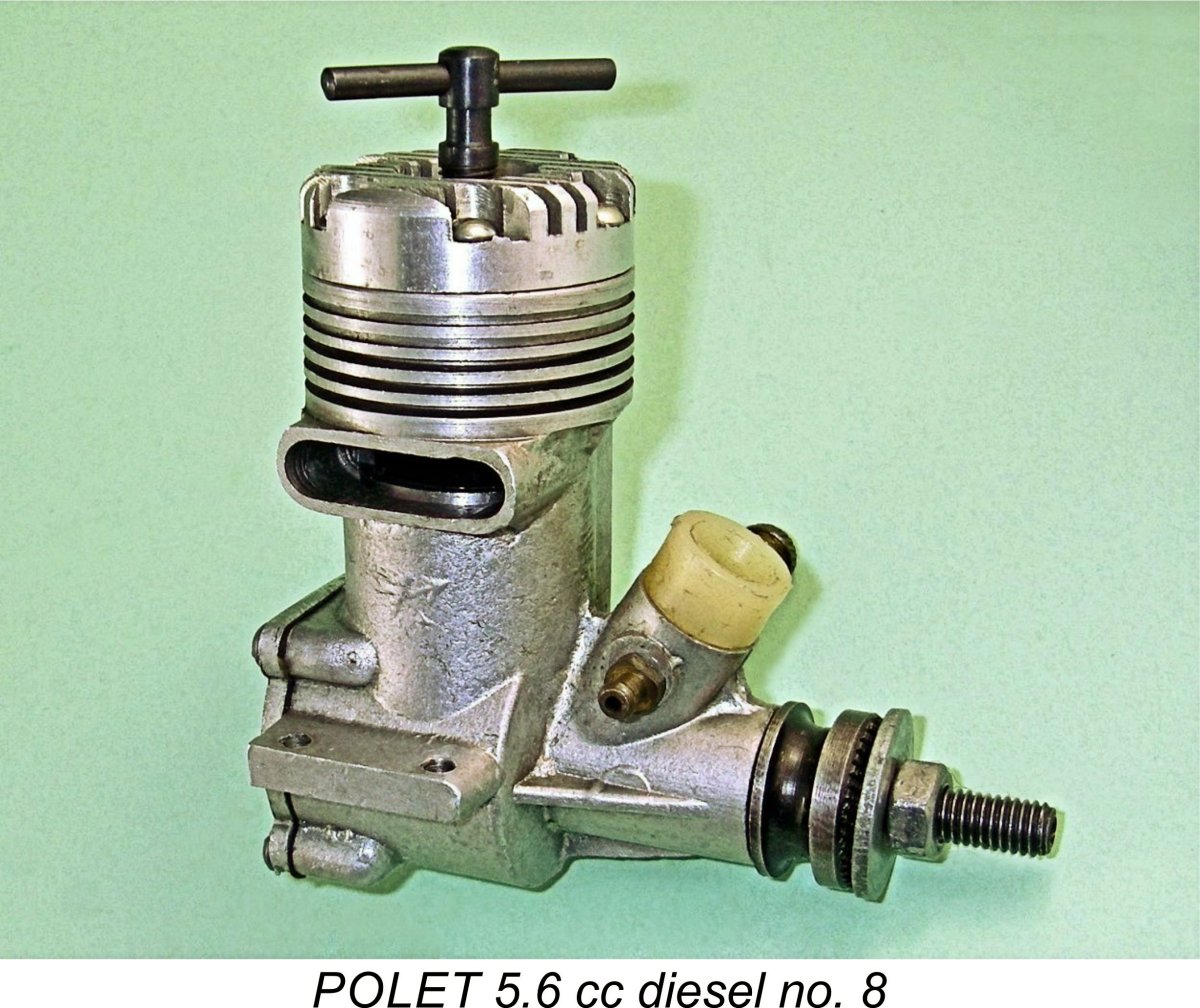

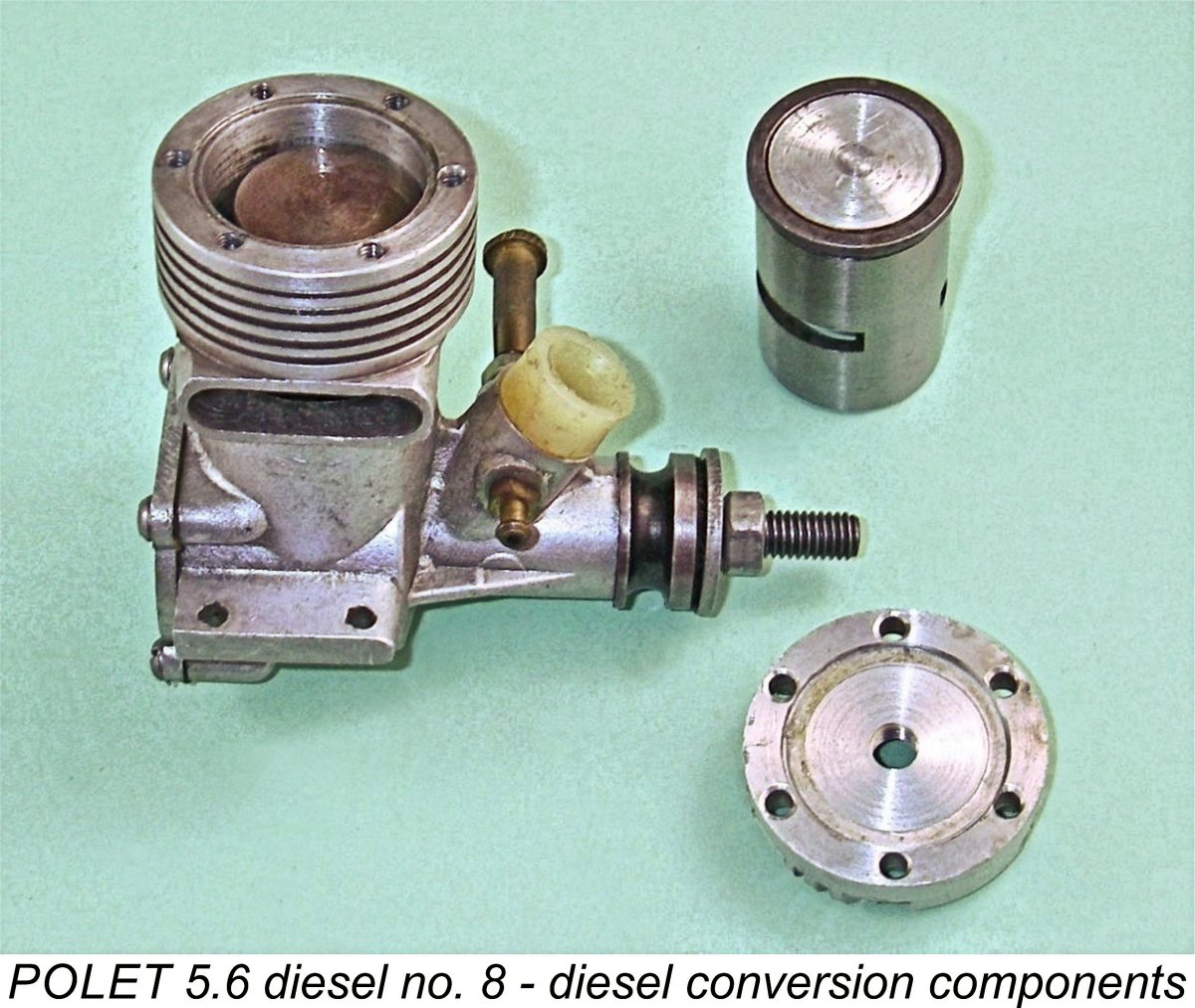

All I can say is that over the years I’ve very seldom been fooled by a home conversion - the “signature” of the home constructor is generally unmistakable to an experienced eye. After examining my example very closely indeed, I’m personally quite satisfied that it is an original factory production, albeit one which was turned out in very small numbers perhaps as an experiment. You’ll just have to trust me on this! The one reference to the diesel version of the POLET of which I'm presently aware is an article covering then-current Russian engines which appeared in 1977 in issue 3/1977 of the Czech model magazine "MODELÁŘ". Big thanks to Maris Dislers for spotting this one! The article confirmed the existence of diesel versions of several larger Russian engines, including the POLET, but suggested that these were higher-priced "custom" versions of the standard glow models. They may even have been produced by a party or parties other than the original manufacturers.

Mykhailo Vasilik has confirmed that the original variant of the POLET diesel was based on the first model glow. This unit featured a red-anodized head, prop driver and spinner nut. It also dispensed with the two fore-and-aft exhaust-level extrusions which appeared on the original glow-plug model described earlier. Presumably in other respects its construction largely followed that of the second diesel model to be described in the following paragraphs. The earlier description of the POLET 5.6 cc glow-plug model applies in Even with the above modification to the head, the amount of vertical space left to accommodate the contra piston at the top of the bore is pretty small. The engine uses a contra-piston of full bore diameter made from aluminium alloy - a very problematic material for this component due to its greater coefficient of thermal expansion than steel. This will inevitably cause it to seize in the bore when the engine is hot. Amazingly, this contra-piston has a thickness of only 3 mm - a very marginal figure indeed for a contra-piston of this diameter. It seems to provide a good seal, but it’s difficult to enthuse about the design.

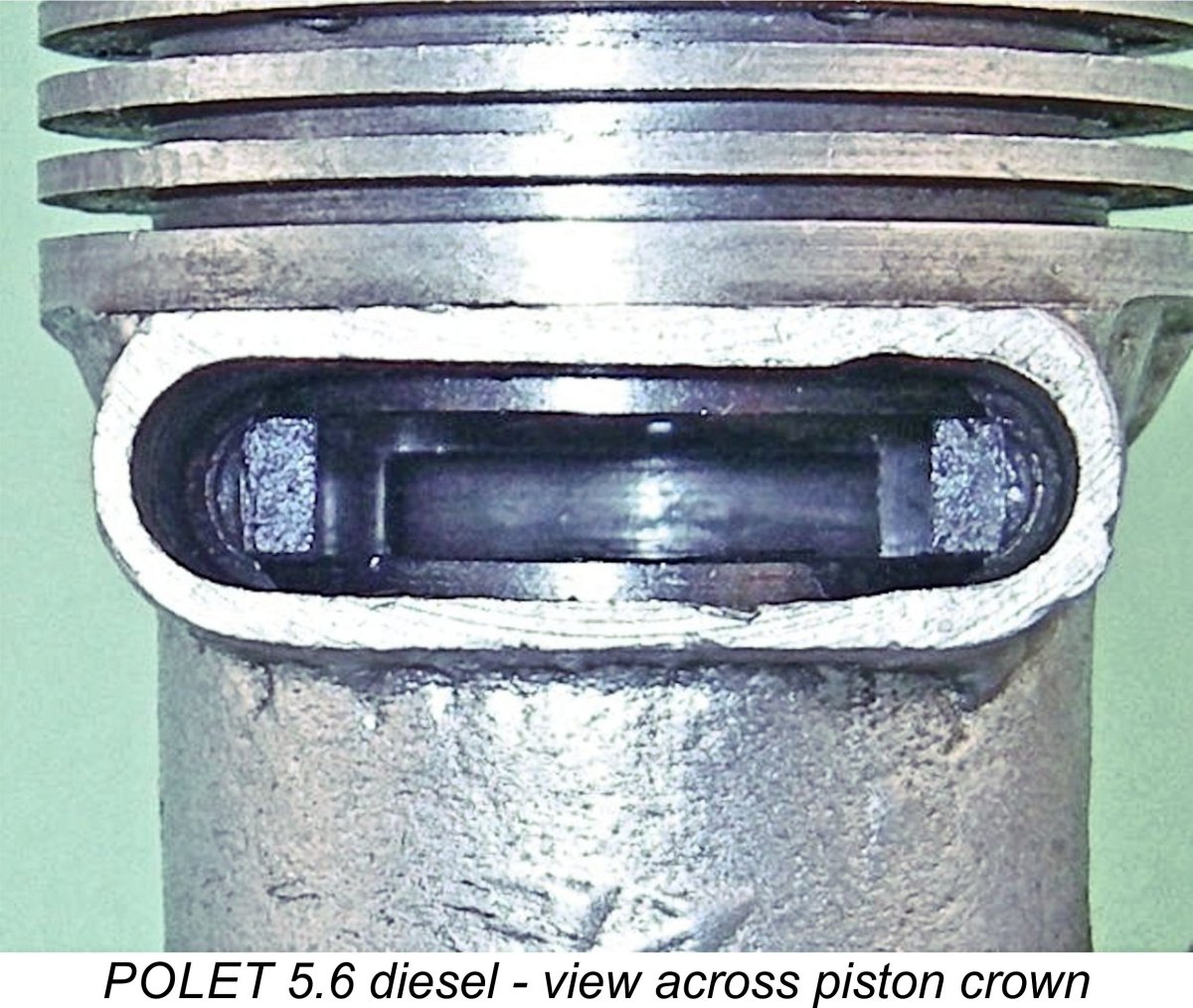

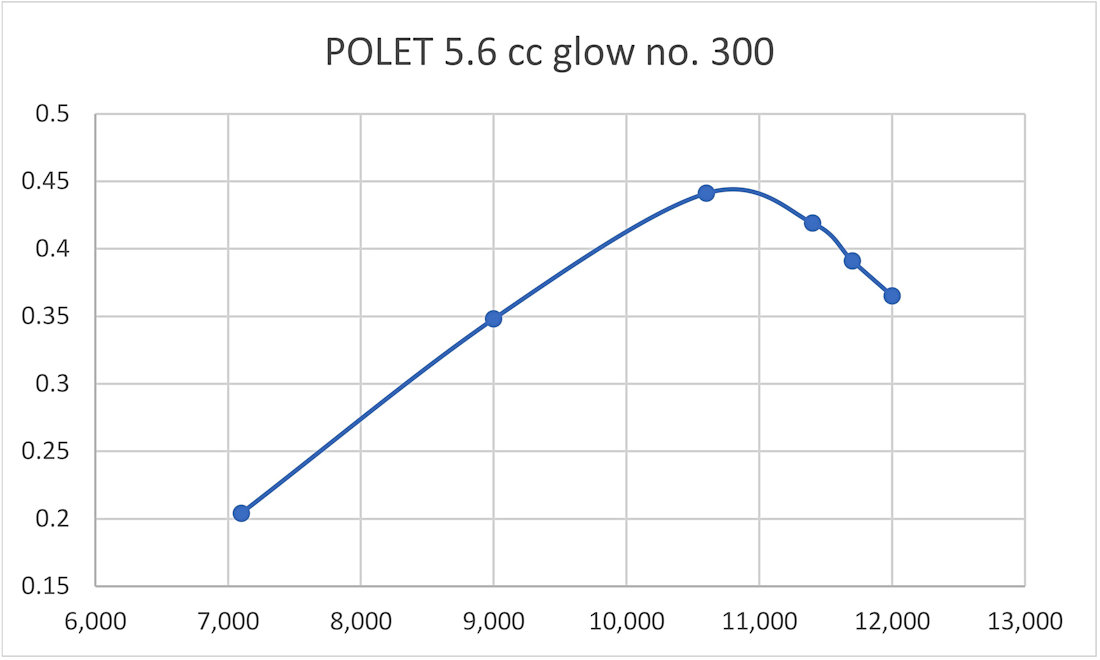

Oddly enough, the checked weight of the diesel version is only 210 gm (7.407 ounces) - 2 gm less than the glow! Apart from the elimination of the piston baffle and cylinder head installation spigot along with the glow-plug, I have no explanation for this rather unexpected fact. Four features of this variant give pause for serious reflection. First, the absence of the baffle means that the transfer port faces the exhaust directly across the flat piston crown with no intervening obstruction. I would expect short-circuiting of fresh incoming mixture to be pretty chronic with this engine. Second, the crankshaft is the same relatively undernourished component described earlier in connection with the glow-plug version. Thirdly, the unsupported length of the gudgeon pin is considerably in excess of what I would consider appropriate for a diesel of this displacement. I would expect the diesel to be even quicker to reveal any underlying weakness in these latter two components. Fourth and finally, the aluminium alloy contra-piston will undoubtedly seize solid in the bore when the engine gets hot. As with all such engines, the unit will effectively have to be operated as a fixed-compression diesel, albeit with the ability to make compression adjustments between runs while the engine is cold. All in all, this analysis promised interesting times ahead! On to the test bench! The POLET 5.6 cc Models on Test As far as I‘m aware, none of the POLET models were ever the subject of a published test in the English-language modelling media. The instruction leaflet cites an operating speed of 9,500 rpm without including a specific horsepower claim. According to Viktor Khodyeyev, the glow-plug version of the engine developed an output of 0.368 kw (0.493 BHP) @ 11,000 RPM, a claim which has a certain ring of credibility for a good example. This was supposedly achieved using the recommended fuel of 3 parts of methanol to 1 part of castor oil. Khodyeyev did not cite a reference for his performance claims.

My valued Ukrainian friend Mykhailo Vasilik, from whom I acquired this example, told me that the quality of these engines varied quite widely, with machining and assembly errors being encountered quite frequently. All I can say is that engine number 300 appeared to be essentially free from any such errors. It felt pretty good when oiled and turned over, with excellent compression and minimal play in the bearings, although the piston fit in the upper cylinder was undoubtedly a bit on the tight side. Even so, I was confident that it would start and run quite well - the questions were how fast and for how long! I was hoping not to answer the second question the hard way ………….. If the power output claim published by Khodyeyev was anywhere near valid, the POLET might be expected to turn an APC 10x6 airscrew at around 11,000 RPM. I decided to start proceedings with such a prop fitted. The fuel used was a 10% nitro brew with 5% added castor oil. I fitted a "hot" Fox glow-plug for this test.

Out of respect for the still-tight piston/cylinder fits, I elected to put 16 minutes of running on the engine in four-minute runs, keeping the needle a touch rich but leaning out briefly right at the end to put the components through complete heat cycles. At the end of this, the engine still felt a touch on the tight side, but I reckoned that I should be able to get some test figures if I continued to run it for the most part in four-stroke mode and kept the leaned-out bursts to a minimum at the end of each test run. The adopted procedure was to start the engine, let it run rich for 2 minutes and then lean out very briefly to get a maximum speed reading before stopping it by pinching off the fuel line. In this way, the break-in continued, complete with full-range heat cycles. Some vibration was definitely present, albeit less than I had been expecting. Running when leaned out was absolutely smooth and mis-free. I put the engine through its paces using a series of props which appeared to bracket the peak. The following data were recorded.

As can be seen, POLET 5.6 glow no. 300 appeared to develop around 0.442 BHP @ 10,800 RPM. While this falls short of the manufacturer's claimed 0.493 BHP @ 11,000 RPM, it does not do so by an outrageous amount. I have little doubt that if the engine was completely freed up, it would get reasonably close to the manufacturer's figures. Even as it is, the POLET certainly has the power to fly a vintage stunt model designed for .35 cuin. engines. The lovely 4/2 break tested by part-pinching the fuel line implies that it would actually be a perfectly satisfactory Old Time Stunt powerplant. Allowing for airborne pickup, the APC 10½x6 prop would appear to suit it admirably - there seems to be little point in propping it for airborne speeds over 11,000 RPM. The engine came through the test with no apparent signs of any mechanical issues or rapid bearing wear. I feel sure that this particular example would have served its user well over a reasonably long haul provided that the seemingly-vulnerable shaft and gudgeon pin held up.

There was also the reality that the aluminium alloy contra piston would cause compression settings to become frozen as the engine warmed up. With such a design, one has to operate the engine pretty much as a fixed compression unit, because any required changes in the setting which become apparent during operation have to be made with the engine cold or nearly so. If a change is indicated, the only way to proceed is to stop the engine, allow it to cool, change the compression setting by the estimated amount and then try again. This naturally involves a fair bit of trial and error, but eventually the optimum setting for the prop and fuel being used as well as the atmospheric conditions during the session can be established. A lot of experience in running diesels helps greatly. The final issue was the fact that the piston baffle had been omitted from the diesel version of the POLET, for the reasons discussed earlier. This would undoubtedly have a very detrimental effect on performance due to the inevitable short-circuiting of unburned fresh mixture out of the exhaust. Taking all of the above observations into account, I decided that there was little point in testing this variant. I'm sure that it would start and run, but there was no telling how well the seemingly over-stressed working components would continue to stand up, while the hassle of fighting with the aluminium contra-piston was definitely not a prospect to be viewed positively. In any case, the absence of the piston baffle more or less guaranteed that this variant would be at best a rather indifferent performer. If I ever change my mind, I will add any results to this article. Conclusion

The Russian political agenda placed success in well-publicised international competitions high on their list of priorities. Conequently, they saw value in making model engines widely available to young Russian citizens to enable them to gain the required hands-on experience without having to scrounge for a suitable powerplant. Given such an agenda, both the performance and appearance of the resulting "consumer-grade" engines were relatively unimportant - all they had to do was run well enough to support the model building and flying activities of aspiring competitors who were learning the ropes. The creation of world-beating "specials" was left to the experienced competitors themselves. It was only later when the Russians began to look for export markets that higher-quality engines such as the 1.5 cc MK-17 diesel and the KMD 2.5 team race diesel began to enter series production. At that point the Russians had joined the rest of the world's model engine manufacturers in competing for a share of the worldwide market. The POLET engines arrived right in the middle of the earlier era of mass production to encourage aspiring Soviet modellers. This explains their somewhat rough appearance and perhaps periodic lapses in quality. However, my examples were certainly well enough designed and constructed to serve their owners quite acceptably if prepared and handled with care. I hope you've enjoyed this look at a typical Soviet engine of a bygone era! I'd say that Boris Krasnoroutski carried out his assigned task well! __________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published August 2025 |

||

| |

In this article I’ll tackle one of the more challenging model engine reviews of my "career" as a model engine historian. I’ll be looking at the POLET engines from Kiev in Ukraine. I used the word "challenging" because very little authoritative information on these engines seems to be available. Even Jiří Kalina’s very useful and generally authoritative 1980 Czech-language book “

In this article I’ll tackle one of the more challenging model engine reviews of my "career" as a model engine historian. I’ll be looking at the POLET engines from Kiev in Ukraine. I used the word "challenging" because very little authoritative information on these engines seems to be available. Even Jiří Kalina’s very useful and generally authoritative 1980 Czech-language book “ The POLET model which is generally encountered is the second variant of the 5.84 cc glow-plug model which is usually referred to as the POLET 5.6 despite its true displacement (see below). What seems to be far less well-known is the fact that the same engine was also offered as a diesel. Even Viktor Khodyeyev missed this latter model, which seems to have been made in far smaller numbers than the glow-plug version. This may suggest that it wasn’t a success, for reasons which will be suggested as we proceed.

The POLET model which is generally encountered is the second variant of the 5.84 cc glow-plug model which is usually referred to as the POLET 5.6 despite its true displacement (see below). What seems to be far less well-known is the fact that the same engine was also offered as a diesel. Even Viktor Khodyeyev missed this latter model, which seems to have been made in far smaller numbers than the glow-plug version. This may suggest that it wasn’t a success, for reasons which will be suggested as we proceed.  As I’ve discussed in my overview of Russian model engine design and manufacturing which appears elsewhere on this website, the history of

As I’ve discussed in my overview of Russian model engine design and manufacturing which appears elsewhere on this website, the history of  began to appear in Russia, long after such engines had begun to appear in Western countries. This inevitably resulted in a fairly lengthy period during which the Russians were playing catch-up behind designers from elsewhere.

began to appear in Russia, long after such engines had begun to appear in Western countries. This inevitably resulted in a fairly lengthy period during which the Russians were playing catch-up behind designers from elsewhere. A number of aligned countries took very decisive steps towards developing home-grown engines with which selected modellers from among their citizens could achieve international success using engines from their homelands. These included the

A number of aligned countries took very decisive steps towards developing home-grown engines with which selected modellers from among their citizens could achieve international success using engines from their homelands. These included the  of what amounted to clones of well-known and successful competition engines from other countries on both sides of the Curtain. I’ve previously dealt with the

of what amounted to clones of well-known and successful competition engines from other countries on both sides of the Curtain. I’ve previously dealt with the  original thinking. It was designed by Boris Krasnoroutski, an up-and-coming young Ukrainian competitor who worked at the DOSAAF plant in Kiev. One of the RITM prototypes finished 7

original thinking. It was designed by Boris Krasnoroutski, an up-and-coming young Ukrainian competitor who worked at the DOSAAF plant in Kiev. One of the RITM prototypes finished 7

The POLET 5.6 was one manifestation of this policy. It was designed by none other than the previously-mentioned Boris Krasnoroutski, designer of the earlier RITM team race diesel. Like the RITM, it was manufactured at the DOSAAF facility in Kiev where Krasnoroutski was employed. The design was presumably commissioned by his DOSAAF employers.

The POLET 5.6 was one manifestation of this policy. It was designed by none other than the previously-mentioned Boris Krasnoroutski, designer of the earlier RITM team race diesel. Like the RITM, it was manufactured at the DOSAAF facility in Kiev where Krasnoroutski was employed. The design was presumably commissioned by his DOSAAF employers.  We are told that the POLET 5.6 was produced in very large numbers. This would be entirely typical for any “consumer-grade” Russian engine of the period. As far as the engine’s production life is concerned, all I have to go on is the fact that the papers with my Like-New-in-Box second model example no. 519 are factory date-stamped March 28

We are told that the POLET 5.6 was produced in very large numbers. This would be entirely typical for any “consumer-grade” Russian engine of the period. As far as the engine’s production life is concerned, all I have to go on is the fact that the papers with my Like-New-in-Box second model example no. 519 are factory date-stamped March 28 The production picture that we have of the POLET 5.6 is greatly complicated by the fact that the engine was produced in two quite distinct variants. The first variant appears to have made it out of the USSR in very small numbers, if at all. In many years of looking, I have yet to encounter an example either at first or second hand. Accordingly, all that I can share here is what little information can be gleaned from the few available images. We’re indebted to Viktor Khodyeyev for making these images available.

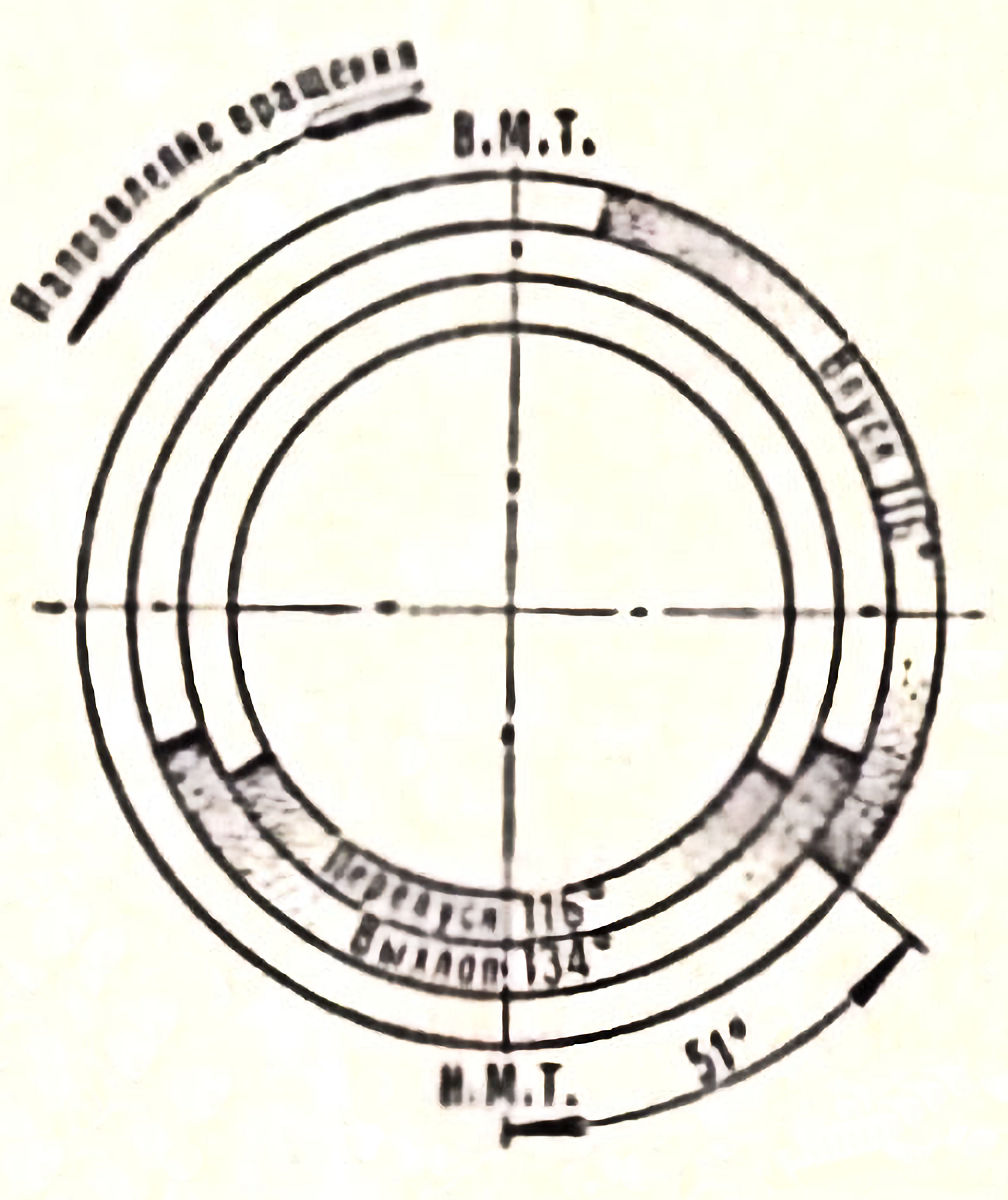

The production picture that we have of the POLET 5.6 is greatly complicated by the fact that the engine was produced in two quite distinct variants. The first variant appears to have made it out of the USSR in very small numbers, if at all. In many years of looking, I have yet to encounter an example either at first or second hand. Accordingly, all that I can share here is what little information can be gleaned from the few available images. We’re indebted to Viktor Khodyeyev for making these images available.  Perhaps the strangest feature of the first variant of the POLET 5.6 was its induction timing. My valued Ukrainian informant Mykhailo Vasilik sent along the attached scan of the published timing diagram for this engine. Exhaust and transfer periods were reported as 134 degrees and 116 degrees respectively - not unreasonable figures for a high-torque engine intended for operation at moderate speeds. However, the induction timing was reported as extending from 51 degrees ABDC to 13 degrees BTDC for a total induction period of only 116 degrees! I'm completely at a loss to explain the logic (if any!) behind these figures! Such an induction period would undoubtedly confine the engine to operation at relatively modest speeds.

Perhaps the strangest feature of the first variant of the POLET 5.6 was its induction timing. My valued Ukrainian informant Mykhailo Vasilik sent along the attached scan of the published timing diagram for this engine. Exhaust and transfer periods were reported as 134 degrees and 116 degrees respectively - not unreasonable figures for a high-torque engine intended for operation at moderate speeds. However, the induction timing was reported as extending from 51 degrees ABDC to 13 degrees BTDC for a total induction period of only 116 degrees! I'm completely at a loss to explain the logic (if any!) behind these figures! Such an induction period would undoubtedly confine the engine to operation at relatively modest speeds.

The gudgeon (wrist) pin is carried in a pair of piston bosses which I would rate as being excessively short. The consequent unsupported length of the wrist pin is considerable, which would give rise to significantly increased bending stresses on that hard-worked component during operation. The connecting rod is quite nicely machined from solid dural bar, having quite reasonable bearing lengths at both ends and being very well fitted to the gudgeon pin and crankpin. The big end bearing is bronze-bushed.

The gudgeon (wrist) pin is carried in a pair of piston bosses which I would rate as being excessively short. The consequent unsupported length of the wrist pin is considerable, which would give rise to significantly increased bending stresses on that hard-worked component during operation. The connecting rod is quite nicely machined from solid dural bar, having quite reasonable bearing lengths at both ends and being very well fitted to the gudgeon pin and crankpin. The big end bearing is bronze-bushed.  Perhaps the engine’s most notable internal feature is its crankshaft. This component is machined and finished to a standard which is perhaps best characteristized as "adequate"! It has a thick crankdisc from which segments have been cut away on opposite sides of the crankpin to create some counterbalance.

Perhaps the engine’s most notable internal feature is its crankshaft. This component is machined and finished to a standard which is perhaps best characteristized as "adequate"! It has a thick crankdisc from which segments have been cut away on opposite sides of the crankpin to create some counterbalance.  At the front, the prop driver on the second variant is mounted on a brass split collet. It actually appears to be the same component used on the later variant of the

At the front, the prop driver on the second variant is mounted on a brass split collet. It actually appears to be the same component used on the later variant of the  There will doubtless be some who will question the originality of this version of the POLET 5.6, suggesting that it is an owner conversion as opposed to a factory variant. It's true that this model has never been documented in any publication of which I’m aware, nor have I ever run across an example other than my own, which bears the serial number 8.

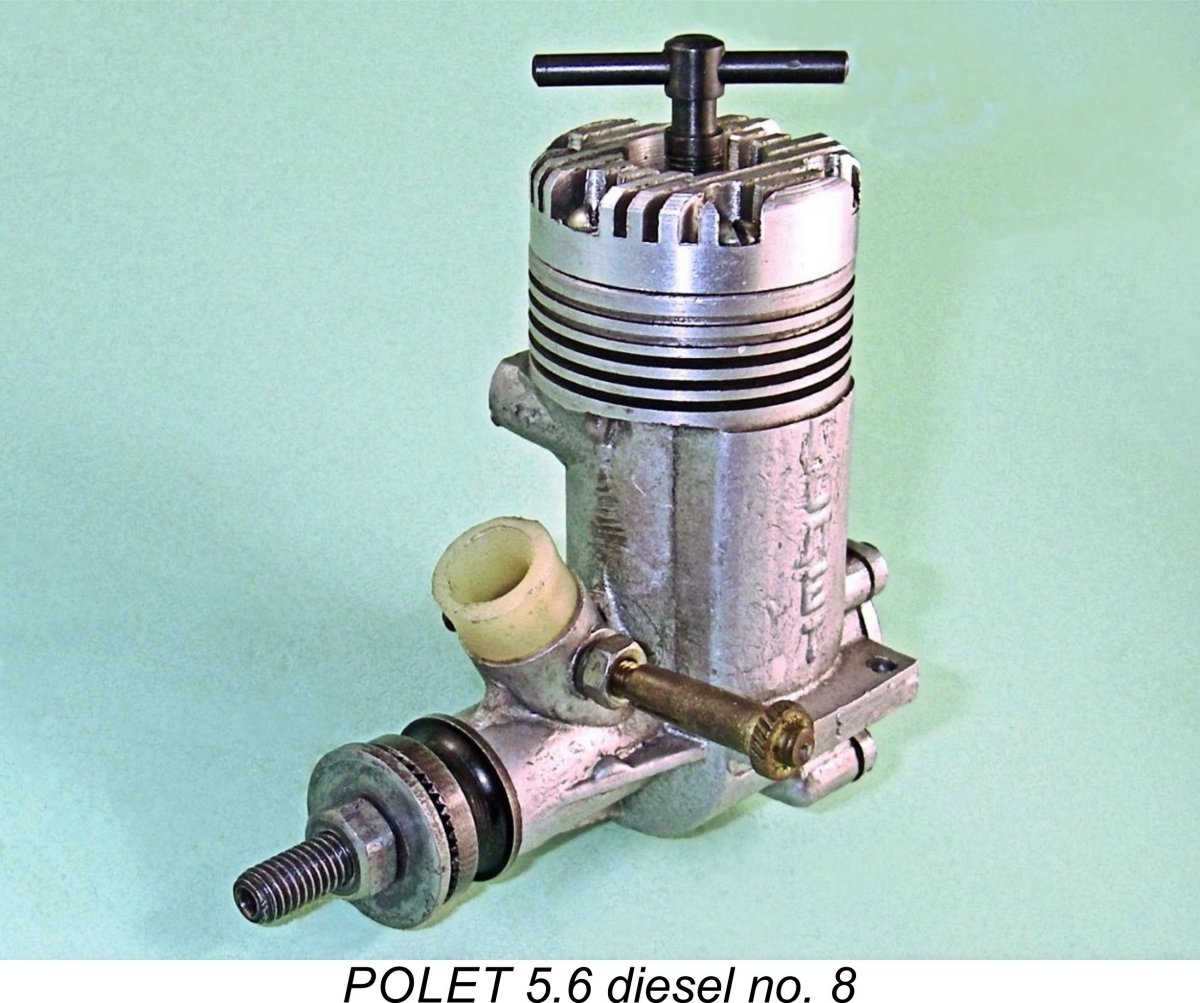

There will doubtless be some who will question the originality of this version of the POLET 5.6, suggesting that it is an owner conversion as opposed to a factory variant. It's true that this model has never been documented in any publication of which I’m aware, nor have I ever run across an example other than my own, which bears the serial number 8.

Apart from the comp screw and the general machining “signature”, what really convinces me that this is a factory conversion as opposed to an owner initiative is the piston. Because the radial orientation of the contra piston when installed cannot be guaranteed, it is not possible to provide the necessary slot for baffle clearance. The manufacturer dealt with this problem in the most direct way possible - he simply eliminated the baffle! The piston in my example shows no trace of any baffle removal operations, leading to the inevitable conclusion that it wasn’t removed - it was never there! The making of a well-fitted piston of different design definitely speaks to the direct involvement of the manufacturer in creating this conversion.

Apart from the comp screw and the general machining “signature”, what really convinces me that this is a factory conversion as opposed to an owner initiative is the piston. Because the radial orientation of the contra piston when installed cannot be guaranteed, it is not possible to provide the necessary slot for baffle clearance. The manufacturer dealt with this problem in the most direct way possible - he simply eliminated the baffle! The piston in my example shows no trace of any baffle removal operations, leading to the inevitable conclusion that it wasn’t removed - it was never there! The making of a well-fitted piston of different design definitely speaks to the direct involvement of the manufacturer in creating this conversion.  The absence of any authoritative test data left it down to me. I decided to begin with the glow-plug version, using unboxed engine number 300 as my test subject. This complete and original example appeared to have done some bench running, either at the factory or in the hands of a previous owner. The witness marks from the test stand clamps were clearly visible, as was the discoloration of the piston crown. However, the engine shows no visible signs of ever having been mounted in a model.

The absence of any authoritative test data left it down to me. I decided to begin with the glow-plug version, using unboxed engine number 300 as my test subject. This complete and original example appeared to have done some bench running, either at the factory or in the hands of a previous owner. The witness marks from the test stand clamps were clearly visible, as was the discoloration of the piston crown. However, the engine shows no visible signs of ever having been mounted in a model.  The POLET endeared itself to me by starting on the very first flick following the administration of an exhaust prime. I had guessed a bit on the rich side as far as the needle went, but this was soon sorted, with the engine settling down to a nice smooth four-stroke mode of running. This excellent starting persisted throughout the test - the engine was invariably a first or second flick starter.

The POLET endeared itself to me by starting on the very first flick following the administration of an exhaust prime. I had guessed a bit on the rich side as far as the needle went, but this was soon sorted, with the engine settling down to a nice smooth four-stroke mode of running. This excellent starting persisted throughout the test - the engine was invariably a first or second flick starter.

Turning now to the diesel variant, I will admit to having agonized at great length regarding the wisdom of testing this variant. The design of both the gudgeon pin and crankshaft appeared pretty marginal to withstand the elevated stresses imposed by diesel operation, especially in an engine of this displacement. The engine had clearly been mounted and had done some running in the past - the question was how much more it could take!

Turning now to the diesel variant, I will admit to having agonized at great length regarding the wisdom of testing this variant. The design of both the gudgeon pin and crankshaft appeared pretty marginal to withstand the elevated stresses imposed by diesel operation, especially in an engine of this displacement. The engine had clearly been mounted and had done some running in the past - the question was how much more it could take!  The POLET engines were very much products of their time and place. In design terms they were already obselete at the time of their introduction. However, we have to bear in mind that this was the Iron Curtain-era Soviet Union, where model engine production was controlled by the State on the basis of priorities which were very different from those in other countries.

The POLET engines were very much products of their time and place. In design terms they were already obselete at the time of their introduction. However, we have to bear in mind that this was the Iron Curtain-era Soviet Union, where model engine production was controlled by the State on the basis of priorities which were very different from those in other countries.