|

|

Fearless Fixed-Compression Diesel Operation

The chief barriers to one’s comfort when initially considering running such an engine are the inescapable fantasies of flooded engines which can’t be cleared at reduced compression; hard running and detonation due to over-compression which can’t be corrected; consequent bent rods, broken gudgeon (wrist) pins and sheared crankpins; etc., etc. It’s all too easy to conclude that these things could never have been a practical proposition, hence their early departure from the modelling scene. There have been lots of write-ups on how to start and run a conventional model diesel. However, I’m not aware of such a write-up for fixed-compression models by any previous writer. I now have a considerable amount of experience, some of which came the hard way, running such beasts! This being the case, I thought that it might be worthwhile passing on what little I’ve learned as a result. My sincere hope is that a few more of these intriguing old beasties may get the occasional successful test-bench outing and perhaps (gulp!) even some air-time as a result. My initial attempt to cover this topic appeared in 2007 on Ron Chernich's now-frozen "Model Engine News" (MEN) web-site. That article may still be found here. However, since the publication of that article my understanding of this subject has expanded as a result of further interactions with a wider range of engines of this type. As a result, I felt that an updated version of the article would make a useful addition to the present web-site. Here’s what works for me (which I’m sure is very far from being the last word on the subject!)………… Introduction

Ignition timing in any internal combustion engine is one of the more critical operating parameters. Ideally, ignition should be initiated just prior to the piston reaching top dead centre so that the greatly increased pressure created in the cylinder by the heating of the trapped gas following combustion may be fully developed in time for the descending piston to take full advantage of it during the power stroke. Within limits, the higher the speed, the greater the amount of ignition lead time or “advance” required. In a “true” diesel engine, the correct ignition timing is achieved by injecting the fuel into the combustion chamber at exactly the right moment for ignition to commence. The model “diesel” has no injector, hence being more properly referred to as a “compression ignition” engine as opposed to a true diesel. However, the term “diesel” is now so well entrenched in modelling circles that it would be futile to attempt to amend this undeniably convenient term at this stage! I certainly don’t intend to try ………… It is crucial to understand that the main function of the compression control in a conventional model diesel is not simply to set the compression ratio high enough to generate the heat necessary for ignition. While that is certainly a necessary prerequisite to the operation of a model diesel, the chief function of the compression control is to adjust the timing of the ignition once the engine is running, so that the best possible advantage is taken of the expansion of the heated gasses in the combustion chamber. The compression adjustment functions in this regard exactly like the timer arm in the old spark-ignition engines, taking over the timing function normally exercised in full-size “true” diesels by the injector. The higher the compression ratio, the earlier ignition will occur as the piston nears the top of the compression stroke and the greater the ignition “advance” will become. This is why higher compression settings are required for higher-speed operation of a particular model diesel engine. During the early years of model diesel engine development, a number of design issues which we would take for granted today were hotly debated. Among these was the need for some means of varying the compression, and hence the ignition timing, while the engine was running. Pretty much every model diesel engine introduced since 1950 has featured some means of varying the compression ratio with the engine running. This allows one to vary the ignition timing to suit different speeds and loads as well as accommodate different fuels and atmospheric conditions. The ability to reduce compression at will also assists in the clearance of a flooded engine by allowing one to burn off excess fuel by flicking over with the compression well backed off.

Another major factor which doubtless influenced such a design approach was the fact that model engines of the period in question were not expected to operate over a wide range of speeds. The compression levels required for starting might quite rationally be expected to be very similar, or even identical, to those required for running at the relatively low speeds expected of these units. Viewed from this standpoint, the use of fixed compression might well have appeared to be a perfectly reasonable proposition at the time in question. Of course, the fact that the ignition timing could not be advanced after starting by increasing compression more or less confined such engines to low speed operation. In the context of the times, however, this would not have appeared to be anything like as much of a limitation as it does to us today, since low operating speeds were all that anyone expected at the time. It was only when the typical operating speeds of model diesels extended into the five-figure bracket (which they did relatively early on) that the ability to fine-tune the ignition timing after starting became an obvious imperative.

However, very few of these hardy survivors ever get run!! Indeed, most diesel users today shudder at the idea of trying to run a diesel using fixed compression, tending to assume that the concept was a decided Now it must surely be obvious that these successes could not have been achieved if the fixed compression feature had limited the performance and utility of these engines to the extent that is often assumed by modern diesel users. Clearly, the owners of these engines somehow managed not only to overcome the limitations imposed by the fixed-compression feature but to extract contest-winning levels of performance from their engines. How?!? Well, mainly by having a very clear understanding of the challenges involved and approaching the task of making the engines work in light of that understanding. It is to assist present-day owners to arrive at a similar level of understanding that this little treatise has been written.

In the context of such a mindset, the operation and use of fixed compression diesels doesn't even make it to the starting line! Getting one of these critters to give its best is a challenge in its own right, make no mistake about it! However, it's a challenge that I for one have always very much enjoyed tackling. The sense of satisfaction and accomplishment that you get when that old motor first fires up against all expectations is something that you'll never derive from simply throwing a switch! Moreover, the looks on peoples' faces when they see the thing running without any visible means of ignition support are worth the effort in their own right! It's my hope that at least some of my readers may share my view of this as a challenge which is worth experiencing for its own sake, and that such individuals may persevere to the point where they are able to derive the considerable personal satisfaction that always comes from meeting and overcoming such a challenge. Believe me, the results are well worth the effort! Before proceeding any further, I wish to stress the fact that what follows is based purely upon my own experiences. Having no-one to advise me when a heady mix of extreme curiosity and underlying skepticism first led me to try running a few of my own fixed-compression diesels over three decades ago now, I had to learn everything the hard way from scratch, and it took a while! Moreover, I'm still learning! I have no doubt at all that others may have more practical approaches and clearer insights than I do. If so, I hope that this summary may encourage them to share their own experiences with the rest of us and set me straight where I’ve gone wrong. Basic Concepts To begin with, it’s important to understand the exact nature of the limitations with which we're dealing. That was doubtless the key to the impressive success of the original users of these engines during the early post-war pioneering era, and we need to follow in their footsteps. The key point to grasp right at the outset is that the use of fixed compression is by no means as limiting as it may appear. In fact, the sole limitation of so-called fixed compression is our inability to alter the compression ratio while the engine is running! We retain the ability to alter the compression ratio at will This is critically important! Every experienced model diesel user knows that a well run-in diesel with an appropriate load and suitable fuel for the intended application will usually start and run at the same compression setting as long as the load and fuel remain unchanged – it’s just a matter of letting it warm up before launching. I often spend an entire day flying without ever touching the compression setting of my engines once the optimum setting for the prevailing conditions has been found. In effect, that’s fixed-compression operation! Saves a lot of unnecessary wear on the contra piston ………….. But for this to work, the compression ratio has to be set right to start with. The primary requirement is that it has to be high enough to guarantee that the auto-ignition temperature of the fuel will be achieved during the hand-starting procedure. To ensure this, we have options with a fixed-compression engine just as we do with a unit that is fitted with a contra-piston. It’s just a bit more involved, that’s all. There are actually no fewer than three ways of varying the compression ratio of a so-called fixed-compression diesel:

So in reality we can readily adjust the compression ratio of our “fixed-compression” diesel! We can adjust the fixed compression ratio of the engine through mechanical intervention between runs. We can also temporarily increase compression during the starting procedure by using the oil priming technique noted above. Finally, we can make minor adjustments to the operating compression ratio by adjusting the oil content in the fuel. In fact, the sole limitation is that once the engine is running and warmed up on a given tankful of a given fuel, the effective operating compression ratio (and hence the ignition timing) will remain constant throughout the run. Since it should be readily apparent from the above discussion that the fuel mixture is critical for successful fixed-compression operation, it’s appropriate at this point to spend some time looking more closely at this piece of the overall equation. Fuel – the Key Ingredient As noted at the outset, the factor which sets model diesel engines apart from other types is the absence of any external ignition source. The principle of compression ignition depends on the fact that when a given mass of any gas such as a mixture of vaporized fuel and air is compressed in an adiabatic system (no exchange of heat between the system and its surroundings, a condition which is approached in a warmed-up engine), its temperature rises in direct proportion to its pressure. Glow-plug and spark-ignition engines use this principle to pre-heat the fuel mixture in the cylinder prior to ignition, thus promoting greater combustion efficiency. In the case of the model diesel, however, the fuel mixture is ignited solely by the heat generated by compression of the mixture trapped in the cylinder during the compression stroke. At a certain point during the compression of this mixture, the temperature reaches the auto-ignition point of the fuel mixture being used. This is the temperature at which combustion will be initiated spontaneously without any ignition source. Once combustion of the fuel mixture has been initiated, the same gas law that created the conditions for ignition to commence causes the pressure in the combustion chamber to rise dramatically with the increased temperature, at which point the power stroke can begin. The trick is to time these events appropriately for best performance. The fundamental base component of any practical model diesel engine fuel is diethyl ether, commonly referred to as just plain ether. At room temperature, this is a clear colourless liquid. There are a number of reasons for the use of ether in model diesel fuels:

Sounds pretty good, doesn’t it?!? However, here the advantages end. In other respects, ether is a bad diesel fuel! It has a decided tendency to detonate (i.e., to ignite explosively all at once rather than burn progressively). This imposes greatly increased shock stresses upon already-stressed engine components. Furthermore, either has a lower calorific value (the amount of energy released by burning a given amount) than other fuels such as kerosene and gasoline. In other words, you get less energy from burning a given amount of ether than you do from burning the same amount of other fuels. For the above reasons, modern fuels for model diesels tend to use only as much ether as required for good starting, and to make up the rest of the combustible content of the fuel with a high-energy smooth-burning constituent such as kerosene. However, we can turn some of the characteristics of ether to our advantage when looking at fixed-compression operation. One factor in model diesel operation that often gives rise to a need for a reduction in compression during running is that of over-heating. Since we can’t respond in this manner to any overheating issues with our fixed-compression diesel, we need to do everything that we can to prevent an overheating situation from arising in the first place. To keep temperatures under control, fixed-compression diesels of the pioneering era are generally best run on a fuel consisting of straight ether and mineral oil, with no power-enhancing additives such as kerosene (which burns far hotter than ether) or ignition improvers such as amyl nitrate. There are two reasons for this. The first and most obvious reason is the simple fact that ether has a substantially lower calorific value than kerosene. It thus has the advantage of generating significantly less heat in the cylinder through combustion. Of course, it also generates less power, but that’s a price that has to be paid for dependable operation. Secondly, ether has a significantly higher latent heat of vaporization than kerosene. This has the very beneficial effect of causing an all-ether fuel mixture to enter the working parts of the engine at a far lower temperature, doing much to promote cooling of those parts, most notably the piston. It actually seems to be a widely-unappreciated fact that so-called air-cooled two-stroke engines are in reality primarily fuel-cooled! When I was road-racing Bultaco air-cooled two-stroke motorcycles years ago, I always jetted for optimum operating temperatures rather than all-out horsepower. Get the operating temperature right, and you’ll have an engine which is both fast and dependable……to finish first, you first have to finish!! The dependability of my engines was legendary …………. It’s perfectly true that the relatively low calorific value of ether reduces the power potential of an all-ether fuel. However, the imperative is to prevent overheating. Fixed-compression diesels run very cool on an all-ether fuel, so there's little chance of the overheating problem occurring. The use of hot-burning fuels is definitely out – do not attempt to run a fixed-compression diesel on conventional modern diesel fuel!! If you do, the higher operating temperatures may well lead to pre-ignition and associated damage. I once got a clapped-out Drone that had been run on conventional diesel fuel (by the previous owner's admission) - the upper cylinder liner was a dark blue color, compression seal was shot and the rod was toast!

In his most interesting write-up on the Drone diesel which appeared in MECA Bulletin no. 71 in January 1981 (over forty years ago – how time flies!!), long-time Drone Diesel user Gus Munich recommended the use of medicinal mineral oil. I can only say that I’ve tried this, with very indifferent results. I’ve had far better luck with conventional mineral-base motor oil. Perhaps the 1940’s medicinal mineral oil recommended by Gus was a different substance from that sold in more recent years?!? The manufacturers of the Drone engine recommended “Heavy or Extra Heavy Mineral Oil (also known as Liquid Petrolatum)” or straight SAE 20 motor oil, with the addition of a little extra SAE 30 motor oil during break-in. There are some clear inconsistencies in these recommendations, and I can only repeat that the oils that I have noted above work very well in my extensive experience. I believe that the slightly thicker oil provides better wear protection at the high bearing stresses under which model diesel engines operate. As far as ether goes, the ready availability of this material is becoming increasingly compromised, largely because of its use as a solvent in the making of illicit drugs such as crystal meth, which has prompted a significant crack-down on its availability. As always, the legitimate users pay the price for the illegal activities of others ……… The most accessible source of ether at present is the automotive “starting fluid” available in aerosol cans from many automotive and heavy equipment supply stores. The better grades of this material have an ether content in the 60% plus range, with the bulk of the balance being heptane in most cases. Heptane is actually a member of the ether family in a chemical sense, although it has a somewhat higher self-ignition temperature as well as a higher caloric value. Its combustion characteristics are however far closer to those of ether than those of kerosene in that it tends to burn somewhat more “explosively” than kerosene. Accordingly, the presence of a proportion of heptane in the mix does not appear to greatly affect the performance of an ether-based diesel fuel as long as the ether predominates.

I’ve also had reasonable results with both Gunk Liquid Fire, which has a guaranteed ether content of at least 60%, and Kleen-Flo Kleen Start, which contains up to 70% ether. In both cases, much of the balance is heptane, with only a very small upper cylinder lubricant fraction which can be ignored when mixing. The resulting fuels ran a bit on the hot side, but starting and adjustment were quite straightforward. For more conventional variable-compression diesel fuels containing kerosene in addition to the ether and oil, you can use starting fluids having somewhat lower ether contents provided allowance is made for the non-ether component of the fluid. This means increasing the proportion of starting fluid in the mix above that which you would use if straight ether were being employed. For example, if you have a starting fluid which is only 50% ether, you have to use twice as much on a percentage basis as the fuel recipe calls for, reducing the kerosene content to make up for this. In this way, you make allowance for the presence of the non-ether component of the starting fluid. However, a 50% ether content is about the minimum that is useful for such purposes - below that, there's no room for any kerosene at all. Using this approach, you'll end up with a fuel having more or less the correct proportion of ether and oil, with the balance being a cocktail of kerosene and (usually) heptane. Such a fuel appears to work perfectly well for most purposes. However, we're talking here about fixed-compression fuels. In this situation, we really need to use a starting fluid containing at least 60% either, and preferable more. Generally speaking, the lower the ether content of your starting fluid, the hotter the engine will tend to run. Starting fluid is sold in aerosol spray cans, posing a challenge in extracting it for use as a fuel constituent. My own method of extraction is very simple and direct. Please note however that all I'm doing here is describing my own technique, which should not be taken as a recommendation to others. Specifically, I DO NOT CLAIM that this is necessarily a safe technique, nor do I recommend that anyone use it in preference to any other method of extraction (or none at all). ON THE CONTRARY, THIS TECHNIQUE IS OBJECTIVELY HAZARDOUS AND COULD LEAD TO SERIOUS INJURY OR EVEN DEATH. I can only report the fact that it has worked well for me so far, and I’m still here to prove it! Others may or may not wish to try this technique themselves – if so, it’s ENTIRELY at their own discretion and at their own risk. End of liability disclaimer……. I begin by holding the can upside down and pressing the spray button to open the valve. The pressure bleeds off while the liquid contents remain in place inside the can. This process needs to be repeated several times with a pause between attempts, since part of the content consists of dissolved gasses which take time to come out of the ether. You’ll notice how cold the can becomes due to the latent heat of vaporization of the pressurized fraction being extracted from the can and the surrounding air. That’s why ether helps so much to cool your engine. Once the pressure has been completely relieved to the point where repeated presses produce no more audible hissing, I then take a sharp-ended camping can-opener and cut a small hole in the base of the de-pressurized (and still inverted) aerosol can. This releases any remaining pressure in the system, although if I've carried out the earlier procedures properly there shouldn't be any residual pressure. I then cut a second slightly larger hole, through which the contents can then be drained into whatever container is to be used to store the ether or mix the fuel ingredients. Needless to say, I do all of this outdoors well away from any ignition source! In that context, a few more safety warnings seem appropriate at this point. Ether is extremely flammable, having a flash point of -40 degrees Celcius. The flash point of a liquid is the lowest temperature at which it can vaporize to form an ignitable mixture in air. The low figure for ether confirms that it can do this at any temperature at which it is likely to be used or stored as a component of model engine fuel. Moreover, it doesn't take much evaporated ether to reach that critical 2.8% lower limit at which it can explode. Accordingly, ether-based model diesel fuel should never be stored or handled anywhere near an external ignition source of any kind. In particular, it is highly unsafe to store ether or ether-based fuel in a refrigerator, since fridges are set at temperatures well above ether’s flash point of -40 deg. Celcius. This being the case, even a container that you believe to be sealed can release enough either to reach that critical 2.8% fraction at which it will explode if there's an ignition source. Unfortunately, fridges do have a potential ignition source in the form of the switch which activates the interior light when you open the fridge door. A few folks have learned this the hard way ………. Ether is extremely volatile, hence evaporating readily. Accordingly, model diesel fuel should always be kept in a well-sealed container except when being transferred to a field container or to the model. Ether is also highly reactive, hence being an excellent solvent. You’ll soon learn this if you try building a foam-core model for your diesel and fail to fuel-proof it properly – it’s the ether which will very efficiently dissolve your lovely foam core!! An often-overlooked characteristic of ether, but one which can kill the unwary, is the fact that it can form highly unstable and very explosive peroxides if exposed to light for any length of time. Both straight ether and mixed diesel fuel should therefore be stored solely in well-sealed metal containers in a cool dark location. The tendency to form peroxides is significantly reduced once the ether is in solution with the other ingredients of model diesel fuel, but the danger is still there regardless. OK, so we have our basic ingredients – ether and oil. How much oil should we use in our fuel mix?? Well, that depends, as we’ll see when we get onto the actual operational issues. Running Characteristics Wait a minute, I hear you say, we haven’t even got the engine started yet!! True – but in this instance (as so often in life) it will help us to get there if we first know where we’re going! So it’s now the appropriate time to talk a little about how these engines actually run. Their operating characteristics are very different indeed from those of a conventional diesel…………. Let’s assume for now that we have a fixed compression diesel set up in our test stand and have somehow got it going on an ether-based fuel as described above. We have no control over the compression once the engine is running, so the challenge facing us is to set the needle valve for best performance. Indeed, that’s the only control which we have available at this point.

Most likely our engine is running with a crackling exhaust note together with plenty of missing, puffs of white exhaust smoke and probably some sharp “knocking” indicative of detonation. In some ways it may look and sound like a conventional diesel that is running too rich and under-compressed. In reality, such a running condition with a fixed compression diesel running on straight ether indicates that it is running too lean!! You can turn the needle in quite a long way with the motor continuing to run like this. But there is a limit - if you keep going leaner, the lower explosive limit is finally reached in the cylinder and the engine stops without ever achieving a smooth-running state. OK, so much for going leaner – no cure for the erratic running there! What about going the other way?? Yup, that’s the ticket! The cure is to open the needle valve progressively until smooth running is obtained and the engine stops missing and throwing out those puffs of white smoke. At this point, Now, we know what indicates a too-lean condition. What about too rich?? Well, here’s one of the great challenges of fixed-compression operation! For the best power, best cooling and best lubrication, we want to put as much fuel through the engine as possible, right? So we should keep opening the needle until the engine shows signs of becoming too rich and slows down, right? Well ……… great in theory! Go ahead and slowly open the needle valve some more. The engine keeps right on running very smoothly, and possibly picks up a few revs. The wide explosive limits of our fuel mean that you can keep this up for a while. But now comes the problem - the first indication that the engine will give that it’s too rich is very simple and direct – it stops!! This happens with no warning whatsoever – you’re turning the needle very slowly to open it, and the thing simply cuts dead without missing a single warning beat! And of course, maximum power is found just prior to that occurring – the motor runs perfectly smoothly right up to the point of cutting out. AAARRRGGGH!! So to accommodate the inevitable changes in fuel draw which will take place under real operating conditions in a model, we need to set the needle somewhere in the middle of the smooth-running range. Fortunately, the wide explosive limits of ether mean that this is by no means critical, making a reliable setting easy to find. The trick is to make a couple of runs to establish and record the point at which missing begins to occur (bordering on too lean) and the point at which the engine cuts (too rich). The most dependable running setting is somewhere right in the middle. Starting Now that we know where we’re going, let’s see how we get there! We’ll begin by assuming that our engine is set up in a test stand with some suitable ether-based fuel in a tank with its top more or less at spraybar level and a suitable prop fitted. Before getting into the details, I may as well run my colors up to the masthead by coming right out and stating for the record that there has probably been more nonsense published on the topic of starting fixed-compression model diesels than almost any other subject relating to model diesels in general. In North America, most of this misinformation has unfortunately been directed towards America’s most significant contribution to the fixed-compression cause, the outstanding Drone 5 cc diesel. As a result of this misinformation, a well-established myth has grown up around the Drone and its fixed-compression relatives to the effect that they are “difficult” engines to start and operate. As we shall see in due course, nothing could be further from the truth provided the business of operating these engines is clearly understood and approached correctly from the outset. I’m well aware that in making such a statement I will have a fair measure of well-entrenched scepticism to deal with!! A few years back, I ran across a lengthy thread on a widely-read US R/C forum in which the Drone was discussed, mostly in very uncomplimentary terms which actually annoyed me very much! One poster claimed that the Drone simply would not start by hand but responded well to an electric starter (AAARRRGGGHHH!!! On a diesel?!?). Another claimed that the only way to start one was to pre-heat its cylinder with either a blow-torch (!!) or a car exhaust! Still another went even further – he stated quite categorically that it wouldn’t run at all and that most buyers consequently threw them out in disgust as useless boat anchors!

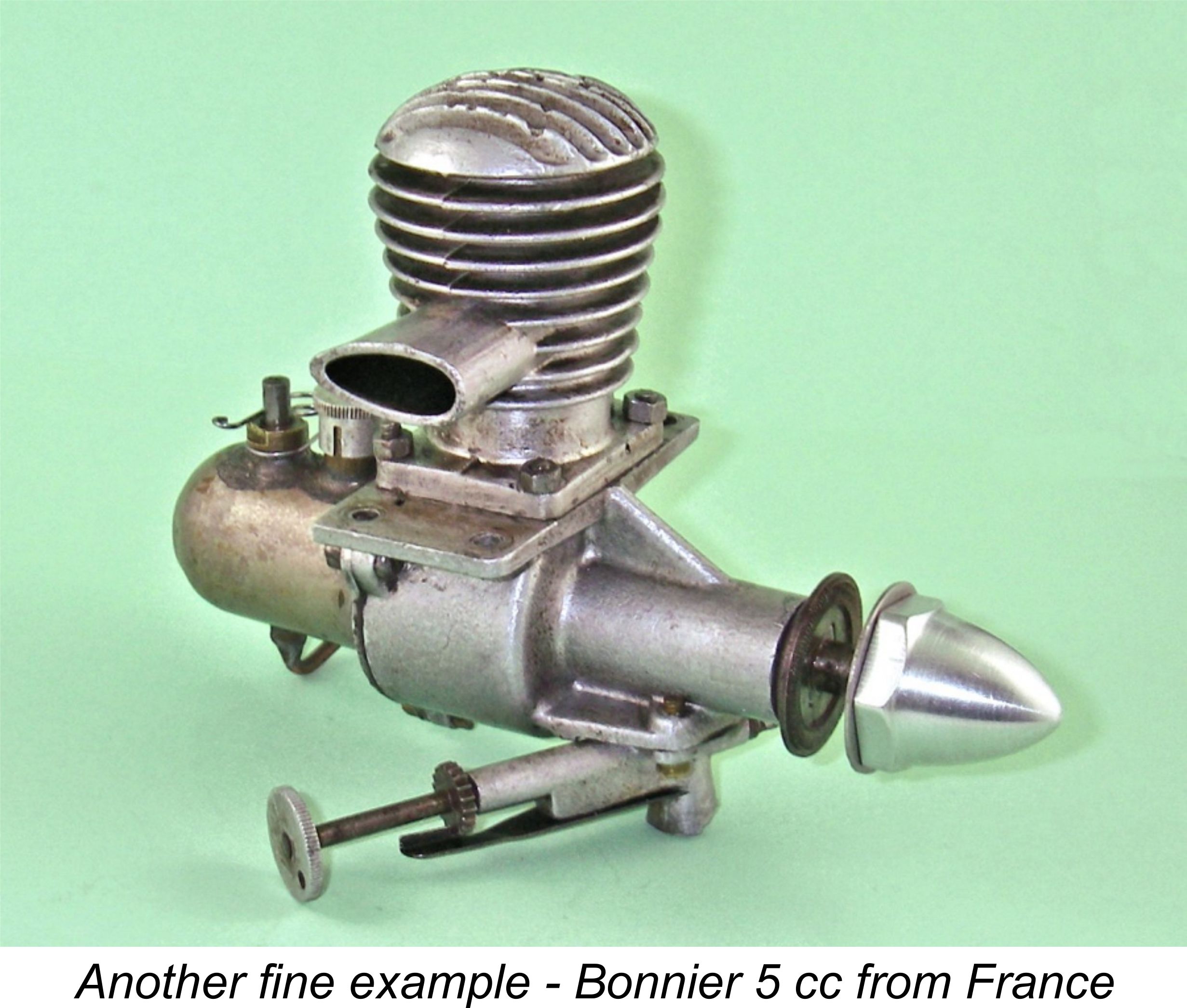

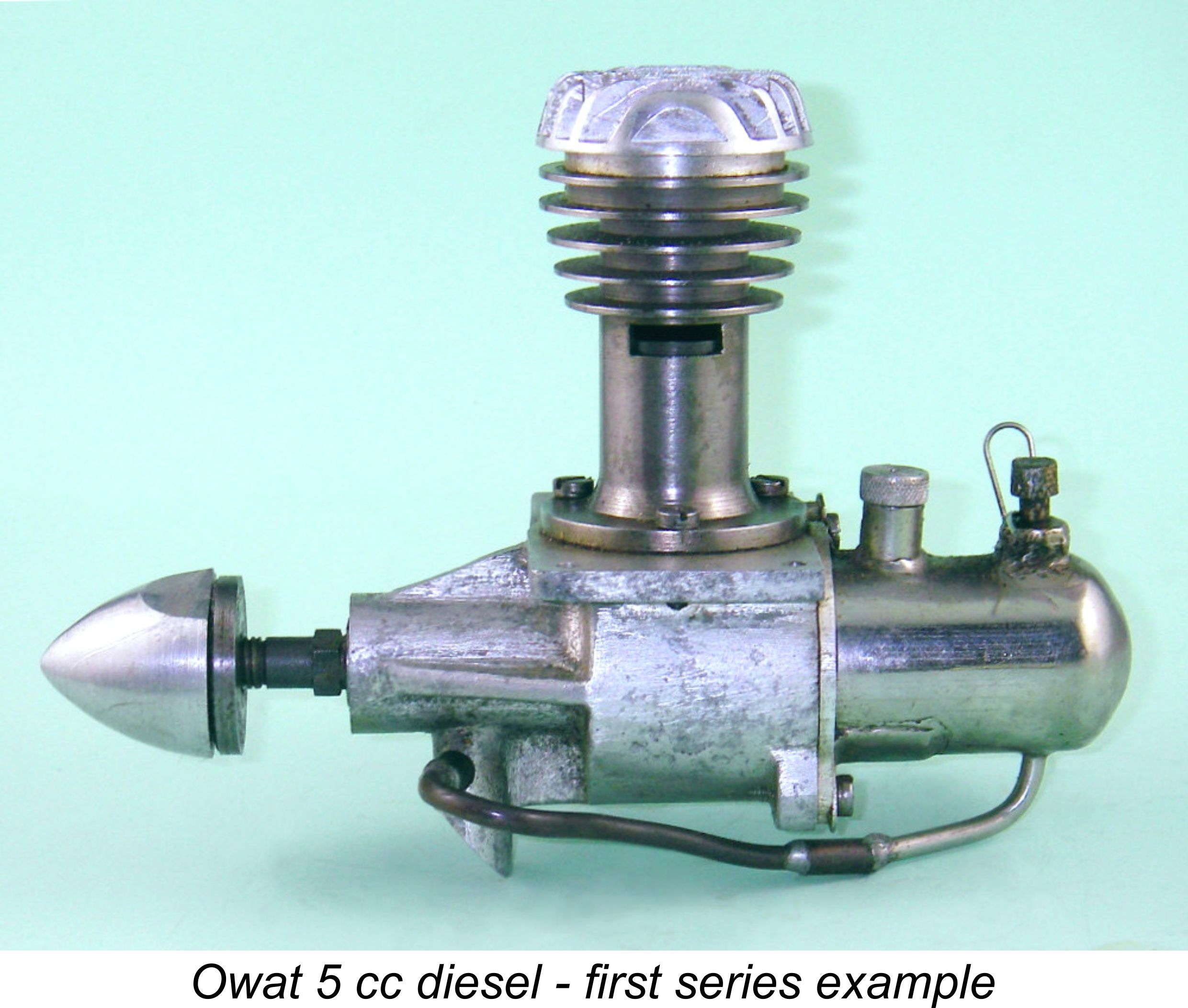

In reality, starting a well set-up fixed-compression diesel is almost absurdly easy if (and only if) the correct fuel and prop are used and the appropriate procedures are followed! Having owned numerous such engines, including examples of the Drone, Micron, Bonnier, Vivell, Mite and Owat models, and having run all of them and flown a few of them with no problems at all, I feel well qualified to say that! In making these statements, I’m in the best possible company - long-time Drone user and fellow enthusiast Gus Munich fully supported these views, as do the Drone's stellar contest record and uniformly positive media reviews. In his previously-cited 1981 MECA Bulletin article about the Drone, Gus recalled that stunt competitors during the Drone’s heyday were allocated three flights, the third of which followed no set schedule but instead was specifically designated as a “novelty flight” in which competitors could basically strut their stuff in any fashion that they chose. According to Gus, who was himself a participant, most winning fliers elected to put on a “two handed” display of formation stunt flying using two models at once. The Drone was greatly favoured for this event in large part because of what Gus characterised as its “easy instant sure start” which guaranteed that both models could be started simultaneously - not always possible with the spark ignition competition of the day! Reconcile that with the negative views noted above! The truth of course is that comments such as those appearing in the cited thread are complete and utter nonsense, as the stellar contest records of both the Drone and Micron fixed compression models surely confirm. So do the positive comments of users of the Owat fixed-compression model such as Col. C. E. Bowden. The negative comments appearing in this and other threads simply reflect the fact that the people making them were present-day R/C flyers who were umbilically tied to their electric starters and consequently lacked the “feel” and specialist flick required to start a diesel engine while also failing to understand the special needs of the particular engine that they were maligning. The nay-sayers also probably used the wrong fuel – fixed compression diesels absolutely need their special brew and don’t respond at all well to more conventional present-day diesel blends. In summary, we can feel completely confident that the task that we are about to attempt is by no means an impossible one, nay-sayers to the contrary! Let’s ignore them and get right on with it! To begin with, we know at the outset that we’re not going to be able to ease the task of clearing a flooded engine by the usual strategy of backing off on the compression and flicking until the thing fires and burns out the excess fuel. This leads directly to our first principle of good starting on a fixed-compression diesel – don’t let it get flooded!! The most critical point to remember in this context is that thanks to the very wide explosive limits of ether (all the way down to 2.8%, remember), it doesn’t take a lot of fuel in the cylinder to get one of these engines going. Glow-plug users in particular need to take note of this point. In the case of the Drone, I’ve found that turning the thing over with the intake finger-choked until the fuel line is full, then giving it one or two choked flicks (no more) usually gets enough fuel into the system for a start to be obtained with a few more energetic un-choked flicks. The ether is so volatile that the smallest amount of fuel getting into the crankcase sends a good whiff of ether vapor up into the cylinder, while the very wide explosive limits of ether mean that the actual amount that gets up there isn’t all that critical in any case - almost any amount of fuel will do. I’ve never at any time had to prime a Drone, and I don’t recommend it – a flooded engine is to be avoided at all costs! However, this is not true in the case of upright-mounted engines having an updraft intake like the Micron, Owat and Bonnier models. Experience shows that choking alone will not get sufficient fuel into the cylinder – once the fuel line is full, the excess fuel simply drips out of the intake under the influence of gravity. Such engines do require a small cylinder prime to be administered through the exhaust port. However, I do mean small – it’s all too easy to overdo this and flood the engine, in which case you have a problem!

If you do somehow manage to create an excessive build-up of oil in the crankcase and/or the cylinder head, the same spray can of starting fluid will stand your friend. As long as the engine can be flicked over, there’s hope! Close the needle valve (don’t want any more oil getting into a partially-flooded engine!), give the cylinder a small shot of starting fluid and then flick energetically until the engine fires and blows out the excess oil. Repeat until both the case and the head are clear, and then you can re-open the needle valve and start again with a clean slate! OK then, so much for priming and avoidance of flooding. What about the needle setting?? Well, that’s actually relatively non-critical for starting as long as it’s somewhere within the quite wide range over which the engine will keep running. The one essential thing is to ensure that we’re not trying to start with the needle set too rich, because we’ve seen that the engine won’t keep running at all in that condition and may tend to flood. I’ve found that it’s far better to start with the needle set a little leaner than the best running setting. That way, there’s far less chance of the engine “loading up” while starting, and smooth running is easily established by opening the needle once the engine starts. Of course, this is all very well when you know the needle setting for best running! If you don’t know that setting, it’s best to start from a fairly well-closed needle setting and work up. On a too-lean setting, the engine may fire, run erratically for a second with lots of white smoke, and then stop. If it does this, you simply open the needle a quarter turn and try again. Eventually, the engine will keep going, albeit running in the smoky hit-and-miss lean condition, and it’s then a simple matter of smoothing things out by opening the needle progressively until smooth running is obtained. Then open it a little more, and you should be in the pocket! It’s well worthwhile finding and recording the needle setting at which smooth running commences from the lean side of things and then finding the “maximum rich” setting at which the engine cuts out as described above. I find that if you set the needle right in the middle of that range, you’ll get pretty dependable running on the bench or in flight as long as the tank is appropriately located. For cold re-starting, simply close down the needle about half a turn from the running setting and follow the above procedure. Using this approach, you’ll find that fixed-compression diesels are extremely easy to start – my Drone, Owat and Micron fixed-compers are one or two flick starters every time under normal conditions. Scarcely surprising when you think about it – if an engine in good condition is set correctly and there’s fuel in the cylinder, it simply has to start because there’s nothing to prevent it from doing so! Of course, conditions sometimes aren’t normal............! The one thing that can adversely affect the starting of these engines is a very low ambient temperature. If the weather is down near the feezing point (as it often is during winter in my area), even a well set-up fixed compression diesel which is supplied with good fuel sometimes won’t even fire. Moreover, an engine that has a bit of wear in the piston/cylinder fit may need a bit of a helping hand.............. What to do in such a case? Well, before we turn to the blowtorch and set our model or test bench ablaze, here’s where the third of our previously-noted means of altering the compression ratio comes in very handy! We prime the engine with upper cylinder lubricant or straight lubricating oil rather than fuel. You can shoot a little ether in there from a spray can of starting fluid just to make sure that there’s ether in the upper cylinder, but the real key is to place a few drops of straight lubricant into the cylinder. An eye-dropper works well, as does an industrial syringe. The injected lubricant occupies some of the combustion chamber volume at top dead centre, thus increasing the compression ratio by displacing some of the gas mixture. You can easily feel this increase when you turn the engine over by hand, as you should always do after priming in order to ensure that you haven’t overdone it and set up a hydraulic lock. The key is not to overdo this procedure. That said, this technique can work wonders for the first start on a cold day! It can also be a life-saver when tackling an engine that is a bit worn.

The nearest present day equivalents that I’ve been able to find are Dura-Lube Upper Cylinder Lubricant and Marvel Mystery Oil, both of which are readily available in North America and work well. The fact that the upper cylinder lubricant contains a flammable solvent fraction (typically naphtha) seems to enhance its effectiveness. However, straight lubricating oil works fine too, although it’s a little easier to overdo things using this material. If you manage to get the engine flooded with either fuel or oil, you have little alternative other than to remove it from the stand and drain the excess oil out of it by way of the bypass and then the exhaust. The ether content evaporates very rapidly, but the excess oil has to be removed. A shot or two of straight ether from a spray can may help to flush a flooded engine. However, I repeat – if you follow the recommended steps, there’s very little chance of flooding the beast. OK, what about hot restarting?? My advice for most fixed-comp diesels is – don’t bother! Hot re-starting is not these engines’ strong suit – the detonation issue becomes very problematic and the engines pre-ignite and kick back fiercely, to the extent that stresses on the rod, gudgeon pin and crankpin must go through the roof. Best avoided - allowing near-complete cooling between runs is the only fix for this. The American Mite .099 diesel is an exception to this rule, to be discussed below.

This leads us directly to our final imperative, which is - DO NOT be tempted to use an electric starter at any time! These devices offer no feedback on the state of the engine – they simply turn it over against all resistance. If it happens to be flooded or excessively oiled-up, a bent rod or sheared crankpin are the inevitable result. When it comes to starting model diesels, there is simply no substitute for the direct feedback on the engine's condition that only your flicking finger can provide. You may get away with it for a while, but in the long term the use of an electric starter is a death sentence for any fixed-compression diesel, and indeed for most variable-compression models as well. My own favourite “flyer” example of the Drone is one for which I had to make a new crankshaft after the previous owner (by his own rueful admission) sheared off the original crankpin by using an electric starter. As I’ve stated earlier, these engines are such easy hand-starters that the use of an electric starter is completely unwarranted. Good thing, because I don’t even own such an accessory! Optimizing Performance So far, I've confined my remarks to some recommended approaches to getting a fixed-compression model diesel running on the test bench. For many owners, that would be a giant step in itself, and one which would generate a good deal of personal satisfaction if successfully accomplished. But what if, once having convinced yourself (as I did long ago) that these are perfectly reasonable engines to actually use, you wish to put that idea into practise by getting an old-time model together to put your engine back where it belongs - in the air?!? This notion brings us into a new realm of endeavour - optimizing the performance of the engine so that it will give of its best in the air. For anyone wishing to give this a try, let me assure you that it's a perfectly reasonable goal! It merely requires a somewhat different approach to that required when using a more modern variable-compression diesel. Anyone who uses “modern” diesel engines knows that once the engine is running, the thing to do is to adjust both the compression and the needle valve to optimize the ignition timing and fuel mixture respectively to give the best running on the particular load and fuel being used. The use of fixed compression doesn’t affect that as far as the needle valve is concerned. However, we can’t adjust the compression once the engine is running. That doesn’t alter the fact that there will always be an optimum ignition timing, and hence an optimum compression setting, for any compression ignition engine operating at a given speed under a given load once warmed up. In the case of our fixed-compression engine, the warmed-up ignition timing is essentially fixed for a given fuel mixture. However, the load, which governs the operating speed, is not fixed – we can change that simply by trimming or changing the airscrew being employed. Hence, the normal mode of operation of a model diesel engine has to be effectively reversed when running on fixed compression – rather than matching the ignition timing to the speed by varying the compression, we achieve the same objective by varying the applied load until the engine runs at the ideal speed dictated by the fixed compression ratio. The end result remains the same – we get the engine running as efficiently as possible with perfect ignition timing. The trick is to determine the operating speed for which the ignition timing is set at its optimum point by the fixed-compression head. To do this, one runs tests on a series of airscrews, noting the rpm and running characteristics achieved for each. One starts with a very large airscrew and then tests progressively smaller props until there are clear signs that the engine is reluctant to run any faster with the compression setting presently in place. On the oversized props, the engine will run smoothly but in a rather laboured fashion, possibly with some indications of detonation to spice things up. It may also sag somewhat as it warms up. These are clear symptoms of premature ignition or over-compression, about which nothing can be done on a fixed-compression engine. Operating under these conditions is very bad for the motor – internal stresses will be greatly magnified and damage may result. Do not run the engine for any length of time in this condition! Things will improve as the speed increases with smaller loads. At some point, the engine will run smoothly throughout the run with no sign of sagging and no trace of detonation. At this point, the engine is operating in harmony with its built-in ignition timing. Most fixed-compression diesels will operate in this happy condition over a range of 1000 - 1500 rpm, so there's plenty of latitude. If we keep on reducing the load, a point will be reached at which smooth running can no longer be achieved at any setting of the needle. The engine will misfire despite our best efforts to smooth it out using the needle valve. Trying an even smaller prop will result in little if any increase in speed. These are the familiar symptoms of retarded ignition or under-compression. The trick is to note and record the lowest speed at which the running becomes smooth and un-laboured and also the highest speed at which smooth running can be obtained. This gives us the range of operating speeds for which the fixed compression of the engine is optimized using that particular fuel. Using the test fuel, as long as we keep the engine within the identified speed range, all will be well and we will ensure smooth running and minimal internal stresses at all times. To minimize internal stresses on the engine, we should use a prop for bench running that allows the engine to operate at or near the upper limit. If the engine is to be flown, then it should ideally be operating in the air somewhere near the upper limit of the range to ensure that it is not lugging. All that is now necessary is to select a flight prop which will run in the air at or near that upper limit. Now if we really want to operate at a speed above that at which the symptoms of under-compression become apparent, we may have an option – reduce the thickness of the shim or gasket which provides the seal between the head and the cylinder liner. This will slightly lower the head and increase the geometric compression ratio. Our ability to do this is entirely dependent upon whether or not the gasket or shim that is already in place offers sufficient scope for thickness reduction. If it is already minimally thin, we’re out of luck! Of course, this can only be carried so far in any case – any increase in the fixed compression ratio will tend to render starting more problematic by encouraging more of a tendency for the engine to kick back. It will also encourage detonation of the ether-based fuel. Ultra-high compression ratios are incompatible with fixed compression operation! However, we may be able to extend the optimal operating speed range upwards a little using this approach. Conversely, if our engine shows signs of being over-compressed at our preferred speed, we may be able to improve matters by inserting a thicker shim or gasket between the head and the cylinder liner. This will raise the head slightly and reduce compression marginally. Once again, this can be overdone – at some point, starting will become compromised due to the reduced heat generated by the lower compression during flicking over to start. In addition, too thick a gasket may render the engine subject to gasket blow-out. The most convenient manner in which effective fine-tuning of the compression ratio and hence ignition timing can be achieved is by adjustment of the ether/oil mixture. This can be surprisingly effective. We noted earlier that an increase in the oil content of the fuel has the effect of increasing the operating compression ratio and advancing the ignition timing somewhat. So if we want to operate in a higher speed range than that indicated by the tests described above, the easy fix is simply to increase the percentage of oil in the fuel. Then run the tests again to establish the revised operating speed range. Naturally, changes in the oil content will be found to also affect fuel consumption. A technique which I’ve found helpful is to make up a few small batches of fuel having differing oil contents – say, 25%, 30% and 35% - and try the engine on each prop using the different fuel mixtures. If running improves on a given prop as the oil content rises, that says that the geometric compression ratio as set is on the low side for that operating speed – the extra oil compensates for this in the manner described earlier. In such a case, the geometric compression ratio may be increased by re-shimming the head as noted above. If the reverse is true and the engine runs harder as the oil content increases, geometric compression is on the high side for that speed. That says that the engine should be operated in flight at a higher speed than the one being tested or that the geometric compression ratio should be reduced by re-shimming as described above. However one goes about it, the key is to ensure that the engine operates in the air at a speed which is compatible with the built-in ignition timing. Like all model engines, the motor will pick up revs in the air. Therefore, it’s generally no use using a flight prop which allows the engine to run at its optimum condition on the bench – we want that condition to be reached in flight, not on the bench! Accordingly, once one has established the engine’s ideal operating speed by running a series of tests as described above, the trick is to use a flight prop that pulls the speed on the bench (or on the ground) down to some 1,000 – 1,200 rpm below the upper end of the speed range for optimum running conditions. If this is done, the engine can be relied upon to pick up speed in the air to the point where it is operating at or near its optimum condition during flight. It’s obvious from the above discussion that the selection of the airscrew can have a very significant bearing on flight performance. For the reasons discussed earlier, these are not high-revving engines – they’re all about high torque at low revs. To utilize that torque effectively, one should use a prop with plenty of blade area and a relatively high pitch. An 8 inch pitch seems to be the minimum advisable if a reasonable airspeed is to be realized. This all seems very complicated, no doubt, and there’s little question that the provision of some means of varying the compression is a godsend in that it eliminates the need for all this testing and tuning. But if one perseveres and establishes the optimum combination of geometric compression ratio, fuel mix and flight prop, the results can be impressive. Moreover, there’s a great deal of satisfaction to be gained from the knowledge that it was your own efforts that led to this happy result! My personal experiences with actually running and flying fixed compression diesels (notably the Drone) are that once you get things dialled in they are every bit as easy to use as their more modern counterparts and perform extremely dependably. Maintenance If the engine is kept scrupulously clean and is run on a fuel with at least 25% mineral oil of suitable quality and viscosity, these motors appear to run forever! There are no corrosive fuel residues to speak of since any residual ether quickly evaporates. The mineral oil does not gum up or bake on like castor oil. Wear rate is minimal, and all that is necessary is to use a good after-run oil to preserve the interior surfaces. I’ve found that air tool oil works very well for this purpose. It is just as well that this is so, because now we must touch on another Achilles Heel of the fixed compression diesel - they are more sensitive to wear of the major components than most other engines. Any wear which takes place in the rod bearings or the main bearing will have the effect of slightly lowering the position of the piston at top dead centre and hence of lowering the geometric compression ratio. Moreover, wear of the piston/cylinder fit can have an extremely adverse effect, since any leakage of compression past the piston is bound to affect starting to some degree. In both instances, our ability to adjust the engine to compensate for the effects of wear is limited as described earlier. For this reason among others, it is more than usually important that undue wear be avoided with these engines. They should be kept as free from dust or grit ingestion as possible – an air filter on the intake is probably a good idea. The engine should be wrapped in a plastic bag when not in use. Despite one’s best efforts, some degree of wear is inevitable over the long term if the engine is put to good use. As wear takes place, it may be found that an increase in the oil content of the fuel is necessary to re-establish the ideal operating compression ratio and/or restore the necessary piston seal. This has the added benefit of enhancing the lubrication of the engine, thus slowing the rate of further wear. Eventually, though, it will likely be necessary to remove a shim or gasket to lower the cylinder head to compensate. At the ultimate extreme, a rebore or a replacement of the main bearing bushing and/or the con-rod may be required. The other maintenance issue is the fuel. It is important to remember that ether is a hazardous substance in a number of ways. It is extremely volatile and inflammable, requiring storage in a tightly sealed container well away from any ignition source. Furthermore, if exposed to light and air for any length of time it can form peroxides which are highly unstable and can actually explode with minimal provocation. For this reason, both ether and mixed fuel should be stored in a cool, dark environment in an airtight container (a screw-cap metal can, for instance) well away from any ignition source. In that regard, never store an ether-based fuel in a refrigerator – the light switch is potentially an ignition source! The other inconvenient characteristic of ether is its extreme volatility, which leads it to evaporate at the slightest provocation. An ether/oil fuel which is stored for any length of time can lose a surprising proportion of its ether content unless stored under cool conditions in a very well-sealed contained. Even at the flying field during a day’s use, the ether content of such a fuel can drop significantly. My own preference is not to store such fuels for any length of time, but rather to make up fresh fuel each time I plan to do any fixed-compression running. That way, I can be sure of my oil content. A single can of starting fluid will make up plenty of fuel for a day’s flying or testing – these engines are pretty economical in terms of fuel consumption. I generally try to use up the entire batch at one session, thus eliminating the need to store any such fuel at all. If it is necessary to store some of this fuel, that’s OK as long as it is kept in a well-sealed airtight metal container in a cool, dark place well away from any ignition source. It will safely keep for quite a while under such conditions. Just for certainty, I make a practise of weighing my cans of left-over fuel prior to storage, weighing them again before the next session to assess how much (if any) ether has been lost to evaporation. In this way, I can keep track of any deterioration due to evaporation. Notes on Specific Engines Here are a few comments on some fixed-compression engines with which I have actual operating experience. More details regarding the engines themselves may be found in separate articles elsewhere.

The two models of the Drone are quite distinct – in fact, the only interchangeable parts are the prop driver and prop washer! The first model has a plain bearing crankshaft and was supplied with a fixed compression ratio of 18:1. This is on the low side for model diesel operation – high-speed diesels frequently require compression rations of up to 20:1 for optimum performance. However, the Drones are definitely not high-speed engines, so the compression ratio adopted is well matched to their normal operating speeds. I’ve found that the plain-bearing first model version of the Drone actually operates best on a 30% oil mixture. The plain bearing benefits from the application of the extra oil, since wear in this bearing is devoutly to be avoided given the previously-discussed effect which any such wear would have on the geometric compression ratio. This is in fact a well-documented problem with this model of the Drone, and there’s no easy fix – the bearing has to be re-bushed or a new shaft made. However, the bearing is very substantial and it will take tens of hours of running to wear the bearing to the point where a problem develops, as long as detonation is avoided and the oil content is of sufficient quantity and quality. The engine seems to run very smoothly in the 5,000 – 6,400 RPM range, but begins to struggle with under-compression above that range. One tester reportedly rated it at 8,400 RPM on a 9x4 wooden prop and 4,400 RPM on a 14x8. The 9x4 is definitely operating way past the engine’s peak, which is probably in the region of 6,200 RPM or so, and the 14x8 is unquestionably lugging the engine. I obtain around 6,300 RPM on the bench on a 12x6 APC prop, and would recommend that as a very suitable bench test prop for this engine. For control-line flying (for which these engines were primarily intended), one should aim for a ground speed of around 5,000 - 5,500 RPM or so. The makers recommended 10 to 12 inch diameter props for control-line stunt, with pitches ranging from 8 inches to 10 inches. The purpose-built Drone stunt prop for this engine was an 11x10, which would probably work very well if one can be found. The wood 11x10 item sold under the Zinger brand is a perfect match for the engine, since the Drone turns it at around 5,200 RPM on the bench. If you can’t find a Zinger 11x10, a slightly cut-down 12x8 should work fine. Or you may be able to cut down a larger prop of higher pitch. The trick is not to under-prop the engine and to use a high pitch for good airspeed at the relatively low revs which the engine will deliver. Such large props will shift a lot of air – you’ll be amazed at the static thrust developed! I don’t recommend running a Drone below 5,000 RPM under any circumstances – at lower speeds the condition of premature ignition sets in, with potential harm to the engine.

For these reasons, if you plan to do some serious fixed-compression running and/or flying, this is the motor with which to do it! In his previously-mentioned 1981 write-up, Gus Munich (whose all-time favourite engine this was) reported that he had a second model Drone which had over 500 running hours on it with no replacements! My own “flyer” second model Drone has around 25 hours in my hands, and who knows how many hours before that?!? It shows virtually no signs of wear. The second model Drone also has a slightly higher geometric compression ratio of 18.5:1, which allows it to keep running evenly at slightly higher speeds than the earlier version or alternatively allows the use of a fuel with a slightly lesser oil content – I generally use 25% oil in the fuel for my Mk. II Drones, as recommended by the manufacturers. The same prop sizes as for the first model generally work, but the engine turns them some 200-300 RPM faster. It may be found advantageous to trim the blades slightly to allow the second model motor to reach higher revs in the air. It probably peaks at around 6,500 RPM as supplied. Gus Munich recommended setting the engine a little lean for take-off and allowing centrifugal force to richen the mixture in flight to smooth out the running. Personally, I’ve found that the use of a well-located Uniflow or chicken-hopper tank eliminates any need for such measures since such tanks maintain a constant fuel head throughout the flight except insofar as manoeuvres may affect mixture. The trick is to locate the tank at or near the centre-line of the spraybar so that centrifugal force actually plays a minimal role in influencing fuel head relative to the spraybar. If anything, the tank should be a little inboard of the spraybar centre, since (as Gus rightly pointed out) it’s easier to adjust for a slight richening in flight than it is for a slight leaning-out. In a sidewinder mounting as used on a profile stunter (the recommended mounting position for the Drone), placing the tank in the usual position on the outside of the fuselage achieves this pretty well. The tank should also be tucked in as closely as possible behind the motor to minimize the effect of manoeuvres on the mixture. The motor should run smoothly throughout the flight using this approach, although it will start to run lean just before the tank runs out, thus giving you plenty of warning that the flight is about to end. If it crackles momentarily in manoeuvres, this is a symptom of momentary leaning-out. Nothing to worry about – it won’t stop and will pick up smoothly as soon as the momentary anomaly is passed. A slightly richer take-off setting may cure this as long as the setting stays within the rich-running limits of the engine. However, the opposite effect can also occur – the engine may suddenly cut out altogether if it is run too near the upper limit of fuel mixture richness and a temporary manoeuvre-induced fuel surge makes it go even richer. If this occurs, you’ll either have to adjust the fuel system or take off at a slightly leaner mixture. But the engine actually has pretty good suction, and troubles of this nature can generally be overcome by test-flying and appropriate adjustment. Once the system is fine-tuned, flying becomes smooth and trouble-free. The Drones can best be summed up as powerful and dependable engines which are one or two-flick starters and will run forever if well looked after. If you follow the above procedures, they can be run with complete confidence. For much more information on the Drone diesels, see my in-depth article which appears elsewhere on this website.

As a result, many thousands were manufactured in total, a significant number of which have survived down to the present day. Consequently, finding a nice example is by no means impossible even now. By “feel”, the Micron seems to have a very similar compression ratio to that of the Drone, although it has been reported as having a higher compression ratio of 20:1. All I can say is that its performance suggests otherwise – it definitely likes the lower speeds, appearing to peak at around 6000 RPM or so. Symptoms of under-compression begin to rear their ugly heads at around 6,300 RPM or thereabouts, so the engine simply won’t run much faster than that. The Micron does well on a 75/25 ether/oil fuel mixture, which was in fact the mix recommended by the manufacturer. Starting is very easy indeed using the procedures set out in the main text of this article. These engines were designed for free flight and as such were typically used with larger-diameter lower-pitch props than the Drone. A 14 inch diameter prop was specified, with pitches around the 6 inch range. I’ve never flown one of these engines, but can report that they start very easily and run flawlessly. I get just under 6,000 RPM on a 13x6 prop, which seems to be the ideal test prop for this engine since it probably duplicates airborne performance on a 14x6 airscrew, adding considerable credibility to the manufacturer’s recommendation. The thrust generated is amazing – despite the low revs, the large airscrew means that the thing moves a lot of air!!

I find that in practise the Owat starts easily and runs fine on the bench on a 75/25 ether/oil mixture, with a performance very similar to that of the Micron. Like the Micron, a 13x6 prop suits it very well on the bench. I’ve never flown one, though. A full examination and bench test of the Owat may be found here elsewhere on this web-site. The Owat was manufactured in far smaller numbers than either the Drone or the Micron, only remaining in limited production during the period 1946-1947. As a result, the chances of finding a good example are considerably less than those of running across a Drone or Micron.

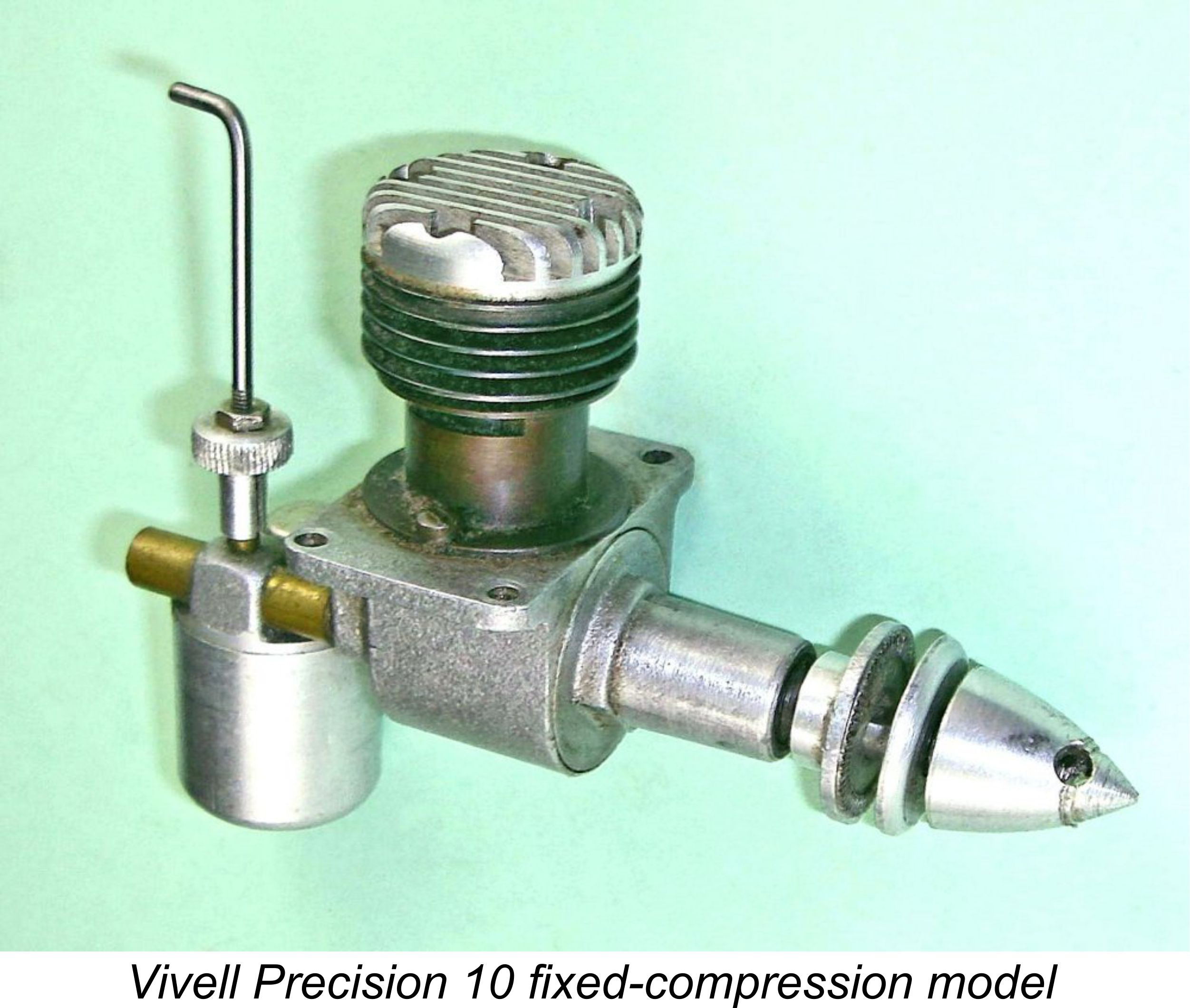

The makers appear to have recognized the implications of the low compression ratio employed, but their response to this recognition was somewhat unusual! Rather than taking the seemingly logical step of increasing the engine's fixed geometric compression ratio, they went instead to a recommended fuel mix of 50% oil, 50% ether! Experience shows that you really do have to use such a mix – with less oil, the effective operating compression ratio is simply too low for smooth running at any speed. This engine provides the most dramatic possible evidence of the effect upon an engine's operational compression ratio of adding more oil to the fuel. For starting, this engine is unusual in that you need to get a lot of fuel into the cylinder to reduce the unused space in the combustion chamber and generate enough heat for starting. Thanks to the very wide explosive limits of ether, you can get away with this. However, another problem rears its ugly head at this point – the method of mounting the prop driver on the shaft is highly unsatisfactory, with an absurdly small tapered shoulder against which the prop driver rests – more of a slip joint than an actual fixture! As a result, the prop tends to slip while starting the engine from cold. You have to really tighten it down, and even then it’s problematic. For this reason, the Mite is one fixed-compression diesel which is actually far easier to start when hot! There’s no tendency to detonate – the low compression ratio and high oil content jointly see to that! When hot, you just follow normal fixed-compression procedure as outlined above, and the engine re-starts very easily. As far as props go, I’ve found that an 8x8 prop is the lightest load on which the engine will run smoothly on the bench. Try an 8x6 and you get past the speed range at which the timing is optimized. The Mite turns an 8x8 at around 5,500 RPM on the bench. Naturally, it moves a fair bit of air while doing so, and would undoubtedly fly a small model very well. But it will not run smoothly above about 6,500 RPM on the standard 50% fuel mix, and it seems absurd to consider adding even more oil to such a mix. So I’d recommend an 8x8 as the ideal test and flight prop for this engine. Indeed, this prop size was recommended by several contemporary testers of the Mite. The castings on the Mite are all magnesium, so you have to follow the usual precautions to prevent corrosion while the engine is in storage. That said, the Mite is a neat little engine which runs well but would undoubtedly have benefited from being supplied with a higher compression ratio and a better method of mounting the prop driver. I also have a Vivell .099 fixed-compression diesel, but have never run it since I wish to preserve its New condition. It feels as if it has a rather low compression ratio as well, and I suspect that its running characteristics would not be unlike those for the Mite. I know from personal experience that the variable-compression version of the Vivell runs amazingly well for a diesel of its displacement and date, so there's no reason to suppose that the fixed-compression version would not also be a very stout performer. I also own an example of the Bonnier fixed compression diesel, a very well-made French contemporary of the Micron having very similar handling and performance characteristics. I haven’t bothered to include any commentary here because this engine is so rare that the chances of anyone finding one to try are very low. I just got lucky ………. an article on the Bonnier appears elsewhere on this web-site. Well, there it is! There’s no reason to fear setting up that old fixed-comper in the test stand and giving it a run! You’ll be as surprised as I was at how instantly they start and how well they do in fact run once everything is sorted out. Moreover, the contest records compiled by several of them will no longer seem quite so implausible! _______________________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published January 2015

|

| |

Researching my various articles involving the

Researching my various articles involving the  It scarcely needs to be said (but I’ll say it anyway!) that the fundamental operating principle of a model “diesel” engine is the ignition of the fuel solely by the heat generated through compression of the fuel mixture within the upper cylinder, with no additional ignition source being employed. In all other respects, the model “diesel” engine is a bog-standard two-stroke (and according to

It scarcely needs to be said (but I’ll say it anyway!) that the fundamental operating principle of a model “diesel” engine is the ignition of the fuel solely by the heat generated through compression of the fuel mixture within the upper cylinder, with no additional ignition source being employed. In all other respects, the model “diesel” engine is a bog-standard two-stroke (and according to  However, these advantages of variable compression were less than obvious to a number of designers in the mid and late 1940’s. Simplicity was seen as the major selling point of the diesel – no batteries, coils, timers or even any need for an external means of heating a glow-plug. The elimination of the contra-piston or equivalent was very much in keeping with this philosophy of extreme simplicity – one less control to mess about with!

However, these advantages of variable compression were less than obvious to a number of designers in the mid and late 1940’s. Simplicity was seen as the major selling point of the diesel – no batteries, coils, timers or even any need for an external means of heating a glow-plug. The elimination of the contra-piston or equivalent was very much in keeping with this philosophy of extreme simplicity – one less control to mess about with!  In keeping with such considerations, a substantial number of model diesel engines appeared on the market during these early years featuring fixed compression ratios which could not be varied while the engine was running. Well-known examples included the French Micron,

In keeping with such considerations, a substantial number of model diesel engines appeared on the market during these early years featuring fixed compression ratios which could not be varied while the engine was running. Well-known examples included the French Micron,  failure. Well, that’s true insofar as the concept of fixed compression did not survive the 1940’s in commercial terms, not reappearing until the 1980's with the prototype

failure. Well, that’s true insofar as the concept of fixed compression did not survive the 1940’s in commercial terms, not reappearing until the 1980's with the prototype  In tackling this topic, I recognize the inescapable fact that perhaps the greatest barrier to the present-day operation of fixed-compression diesels stems from the complete change in attitude towards the modelling hobby that has become prevalent among model fliers today. There has been a general adoption of the "instant gratification" mentality whereby the majority of present-day model fliers are no longer prepared (or in some cases able) to work for their flying pleasure. In the far-off days when these engines were current, modellers expected to have to work for their fun - indeed, performing that work was seen as being very much part of the fun! Not so today, when people are happy to buy complete electric-powered ARF models which come in a box and are ready to operate as soon as the ready-made components are assembled and the switch is thrown. No modelling involved.........The widespread move towards electric power is a further manifestation of this change in attitudes. The harsh reality which has to be accepted is that model flying has metamorphosized from a hobby into an activity - a very different thing!

In tackling this topic, I recognize the inescapable fact that perhaps the greatest barrier to the present-day operation of fixed-compression diesels stems from the complete change in attitude towards the modelling hobby that has become prevalent among model fliers today. There has been a general adoption of the "instant gratification" mentality whereby the majority of present-day model fliers are no longer prepared (or in some cases able) to work for their flying pleasure. In the far-off days when these engines were current, modellers expected to have to work for their fun - indeed, performing that work was seen as being very much part of the fun! Not so today, when people are happy to buy complete electric-powered ARF models which come in a box and are ready to operate as soon as the ready-made components are assembled and the switch is thrown. No modelling involved.........The widespread move towards electric power is a further manifestation of this change in attitudes. The harsh reality which has to be accepted is that model flying has metamorphosized from a hobby into an activity - a very different thing!

Apart from its low calorific value, the main limitation of ether as a diesel fuel is its previously-mentioned tendency to detonate rather than burn smoothly under auto-ignition conditions. However, salvation is at hand! For reasons which are unclear, the use of mineral oil in the fuel does much to counteract this tendency – in this respect, the more oil, the better! The point is that the oil content of the fuel does more than merely lubricate, seal and purge the engine – it also reduces the tendency of the ether to detonate. For some reason, castor oil does not seem to have this same “dampening” effect, so fixed compression diesels are definitely best run on mineral-based fuels. I’ve had excellent results using SAE 20-50 multi-grade mineral-based motor oil. I’ve also had highly satisfactory results using straight SAE 30 oil. You can buy mineral-based oils at most automotive supply stores. I’ve never tried the modern synthetic oils, and have no idea how they would work.

Apart from its low calorific value, the main limitation of ether as a diesel fuel is its previously-mentioned tendency to detonate rather than burn smoothly under auto-ignition conditions. However, salvation is at hand! For reasons which are unclear, the use of mineral oil in the fuel does much to counteract this tendency – in this respect, the more oil, the better! The point is that the oil content of the fuel does more than merely lubricate, seal and purge the engine – it also reduces the tendency of the ether to detonate. For some reason, castor oil does not seem to have this same “dampening” effect, so fixed compression diesels are definitely best run on mineral-based fuels. I’ve had excellent results using SAE 20-50 multi-grade mineral-based motor oil. I’ve also had highly satisfactory results using straight SAE 30 oil. You can buy mineral-based oils at most automotive supply stores. I’ve never tried the modern synthetic oils, and have no idea how they would work.  It’s important to realize that not all starting fluids are created equal! Some in fact (like the appropriately-named and doubtless effective Australian product “Start, Ya Bastard!”) have relatively low ether contents in the 25% range, making them unsuitable for our purpose. The best by far appears to be John Deere starting fluid, which is 80% ether by weight. A portion of the balance is an upper cylinder lubricant, which doesn‘t seem to upset things to any meaningful extent. Long experience shows that you can use John Deere starting fluid as a straight volume-for-volume replacement for pure ether in any model diesel fuel mix.

It’s important to realize that not all starting fluids are created equal! Some in fact (like the appropriately-named and doubtless effective Australian product “Start, Ya Bastard!”) have relatively low ether contents in the 25% range, making them unsuitable for our purpose. The best by far appears to be John Deere starting fluid, which is 80% ether by weight. A portion of the balance is an upper cylinder lubricant, which doesn‘t seem to upset things to any meaningful extent. Long experience shows that you can use John Deere starting fluid as a straight volume-for-volume replacement for pure ether in any model diesel fuel mix.  What does the needle valve do?? Basically, it adjusts the percentage of fuel vapour in the air which reaches the combustion chamber through the induction and transfer processes. We’ve already seen that ether will burn over an extraordinarily wide range of percentages of vapour (its explosive limits), so we can confidently expect that the engine will keep running in some fashion over a very wide range of needle settings. And in fact, that’s exactly what we find.

What does the needle valve do?? Basically, it adjusts the percentage of fuel vapour in the air which reaches the combustion chamber through the induction and transfer processes. We’ve already seen that ether will burn over an extraordinarily wide range of percentages of vapour (its explosive limits), so we can confidently expect that the engine will keep running in some fashion over a very wide range of needle settings. And in fact, that’s exactly what we find.  running becomes very smooth, with little if any detonation and little exhaust smoke. Nice!!

running becomes very smooth, with little if any detonation and little exhaust smoke. Nice!!  Now, if fixed-compression diesels (of which the much-maligned Drone is one of the finest examples) were really that unmanageable, how did they win all those high-profile contests and set all those records? Why, without exception, did both reviewers and users rave about how good they were? How did Leon Shulman manage to persuade 15,000 punters to buy the Drone?!? If all of those Drones were thrown out in disgust, why are there so many of them still in circulation today, over 70 years on - who raided the trash bins of America?? Finally, why did the makers of the Micron 5 cc fixed-compression model (the one that started it all in 1943) continue to manufacture the engine on the basis of an ongoing demand right up to 1959? Negative reputations travel fast if they’re well founded………… but positive reputations travel faster!