|

|

Brooklyn's Best - The Mite .099 Diesel by Adrian Duncan with Maris Dislers

However, during the preceding two years the American model engine manufacturing industry produced an amazing and widely under-appreciated variety of model diesel designs, many of which possessed considerable merit. Among these may be included the Drone, Micro, Speed Demon, Vivell, Air-O and C.I.E. diesels, all of which were excellent products by any standard. Several companies also made diesel conversion heads for the famous Arden spark ignition units. In addition, there were other diesels which undoubtedly reached the prototype stage but progressed little if any further, including proposed designs from Edco, Thermite, AHC, DeLong, Kencraft, Queen Bee and Strato (the latter two in Canada).

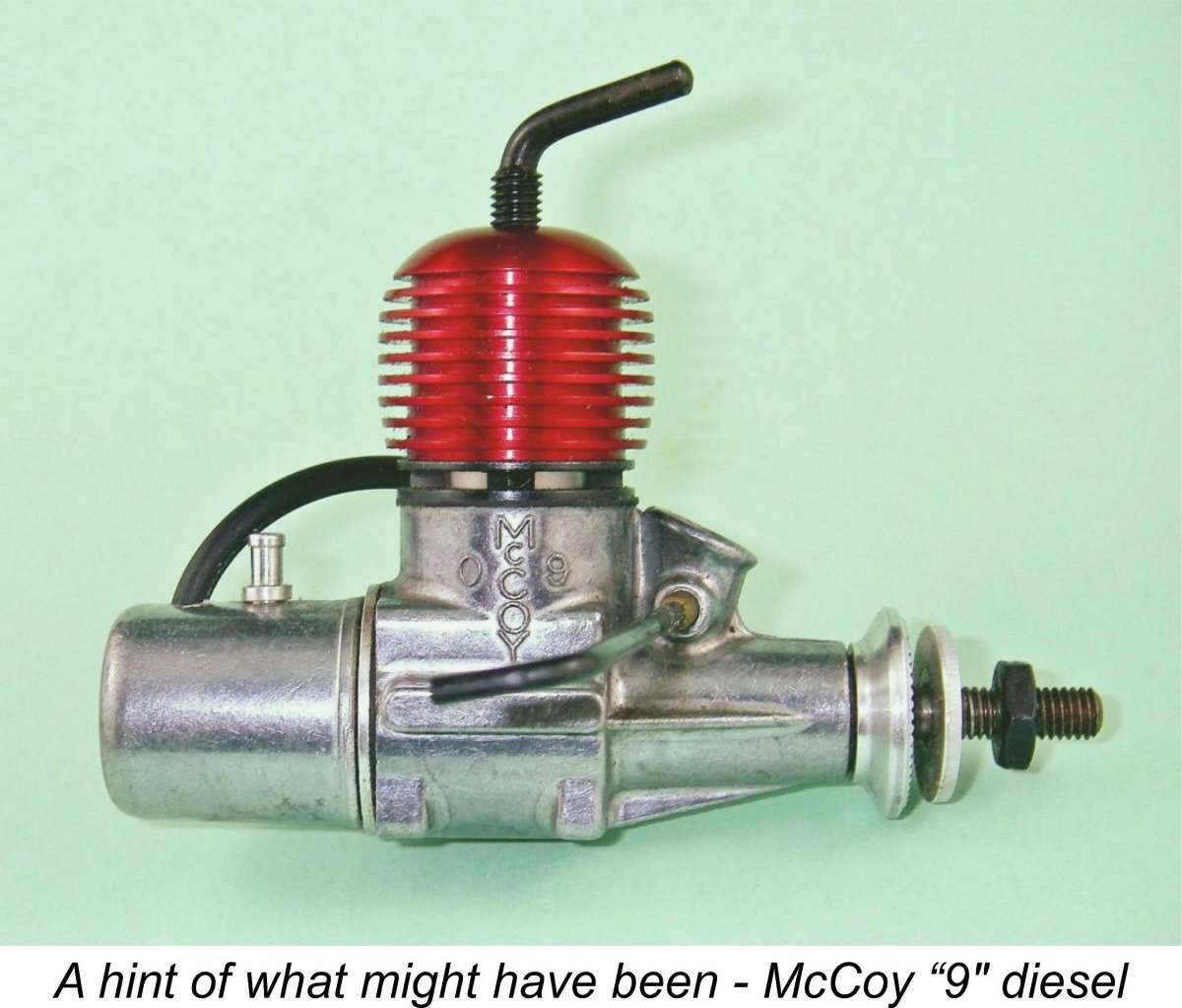

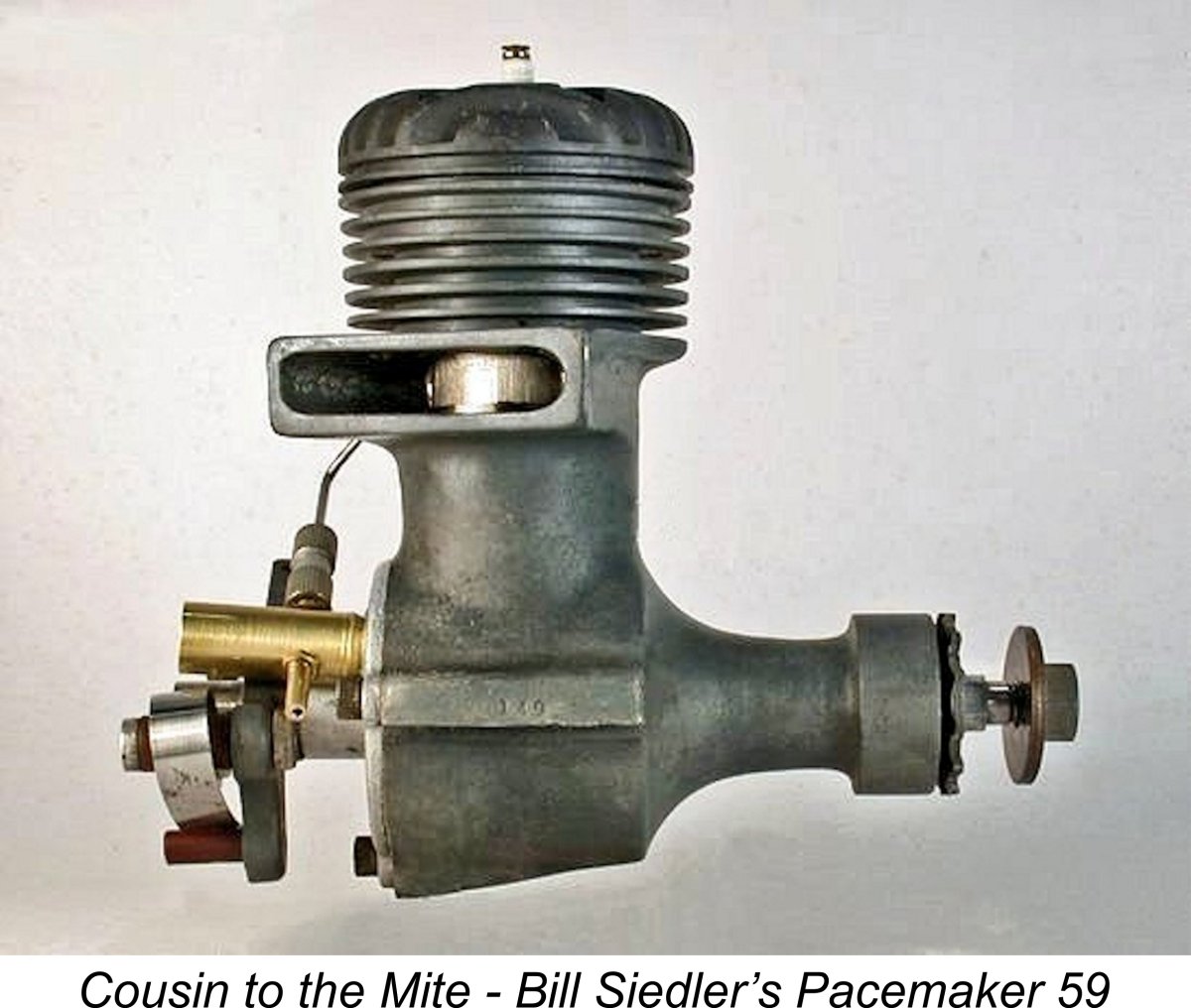

It’s a little-known fact that Gotham didn’t stop with the Deezil – they also advertised a diesel conversion kit for the Pacemaker 59 design which they seemingly took over from Bill Seidler of Brooklyn, New York in 1947. It’s unclear whether or not any of these kits were actually sold - I’m not presently aware of any surviving examples of this conversion. However, please remember the name of Bill Seidler, since he will re-appear later in this story. The above listing makes it clear that the number of North American manufacturers involved for better or worse with the development of model diesels during 1946 - The truly outstanding McCoy “9” .099 cuin. diesel of late 1954 provided a hint of the kind of quality and performance that we might have seen from American manufacturers if the arrival of the glow-plug in late 1947 had not derailed their diesel development programs so comprehensively just as they were getting into their stride. Another noteworthy American diesel which made its appearance during the above-mentioned pre-glowplug period was the Mite .099 cuin. model from Brooklyn, New York. It is this engine which forms the central subject of this article.

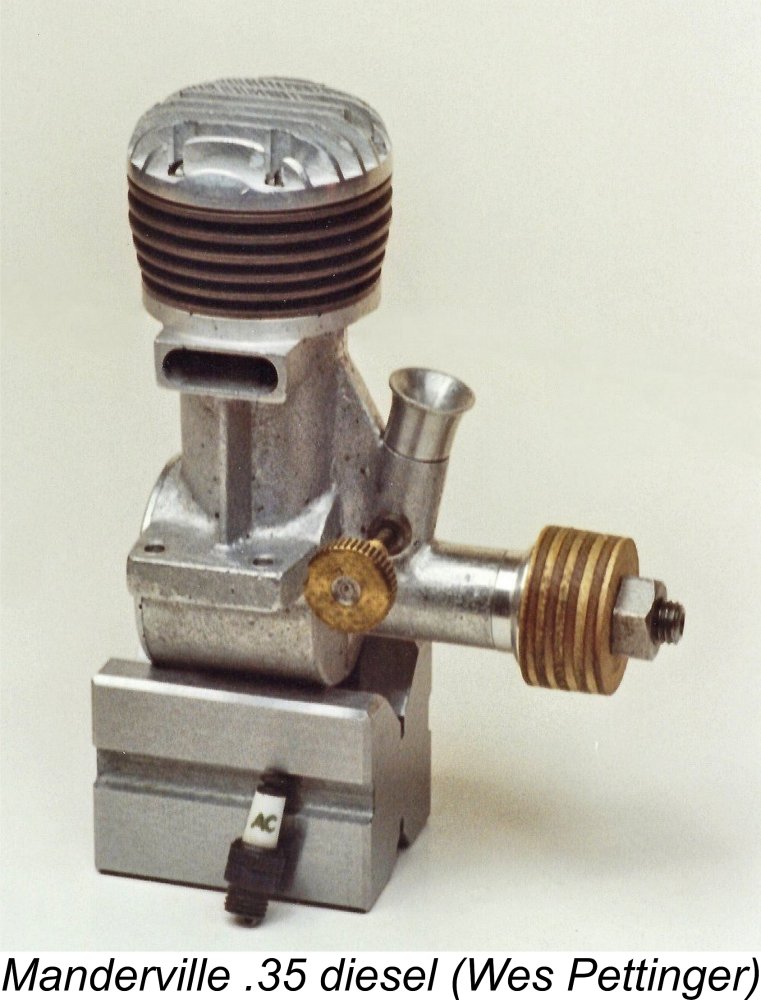

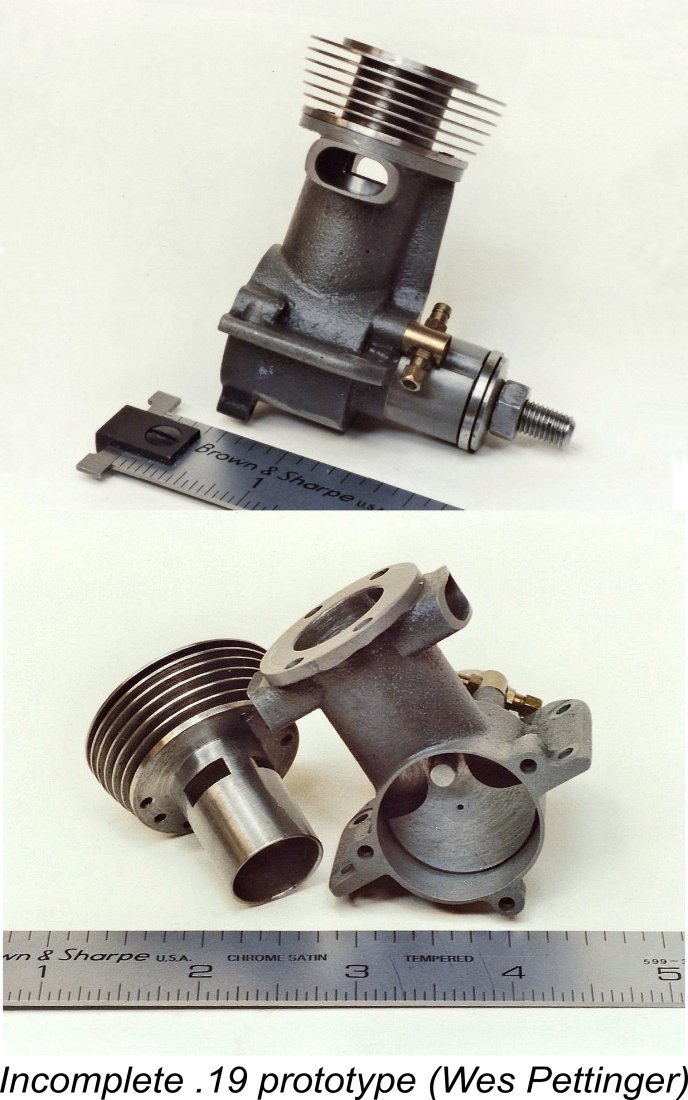

Fortuitously enough, the March 2017 issue of “AeroModeller” magazine included a retrospective review of the engine by Don Howie of Australia. It turned out that my good mate Maris Dislers had been involved with the bench testing aspect of that review, placing him in a position to provide some valuable comments on the engine’s operating characteristics and fuel preferences. Thanks, mate! Maris did some more digging on my behalf, coming up with a few additional sources of information. The late Gus Munich contributed an article on the Mite to MECA Bulletin no. 82 for March 1985. The broader work of Mite designer Howard Manderville was subsequently covered in an article by Wes Pettinger which appeared in MECA Bulletin no. 97 for August-December 1995. I was fortunate enough to establish contact with Wes in 2022, finding that he was happy to assist in any way possible. A number of the additional images attached to this revised version of the article were kindly provided by Wes. Maris also found that former Mite employee Norm Rosenstock had set down his modelling memoirs, which had fortuitously been preserved. His reminiscences included recollections of his time spent working on the Mite engines. David Janson referred to Norm’s memoirs quite freely in preparing his own Article no. 52 mentioned earlier. So things turned out to be not quite as bleak as they had appeared at one point! Armed with the information gleaned from the above sources as well as my own observations, I’ll now attempt to summarize what there is to say about this unexpectedly interesting little engine. I’ll begin by tracing its design and production history. The Mite .099 Diesel – Design and Production History

One of the more prominent among these personal imports was the French Micron fixed-compression diesel of 4.99 cc displacement, examples of which had begun to appear on American flying fields by 1946. It was this very successful engine which inspired the design of the famous Drone Diesel which enjoyed a period of almost unrivalled success in America during 1947 and 1948 before being submerged by the rising glow-plug tide.

In addition to his stand-out efforts with spark ignition hydroplane engines, Manderville experimented at some length with diesel technology, producing a number of superbly-made diesel prototypes. These included a cute little 0.017 cuin. (0.278 cc) fixed compression

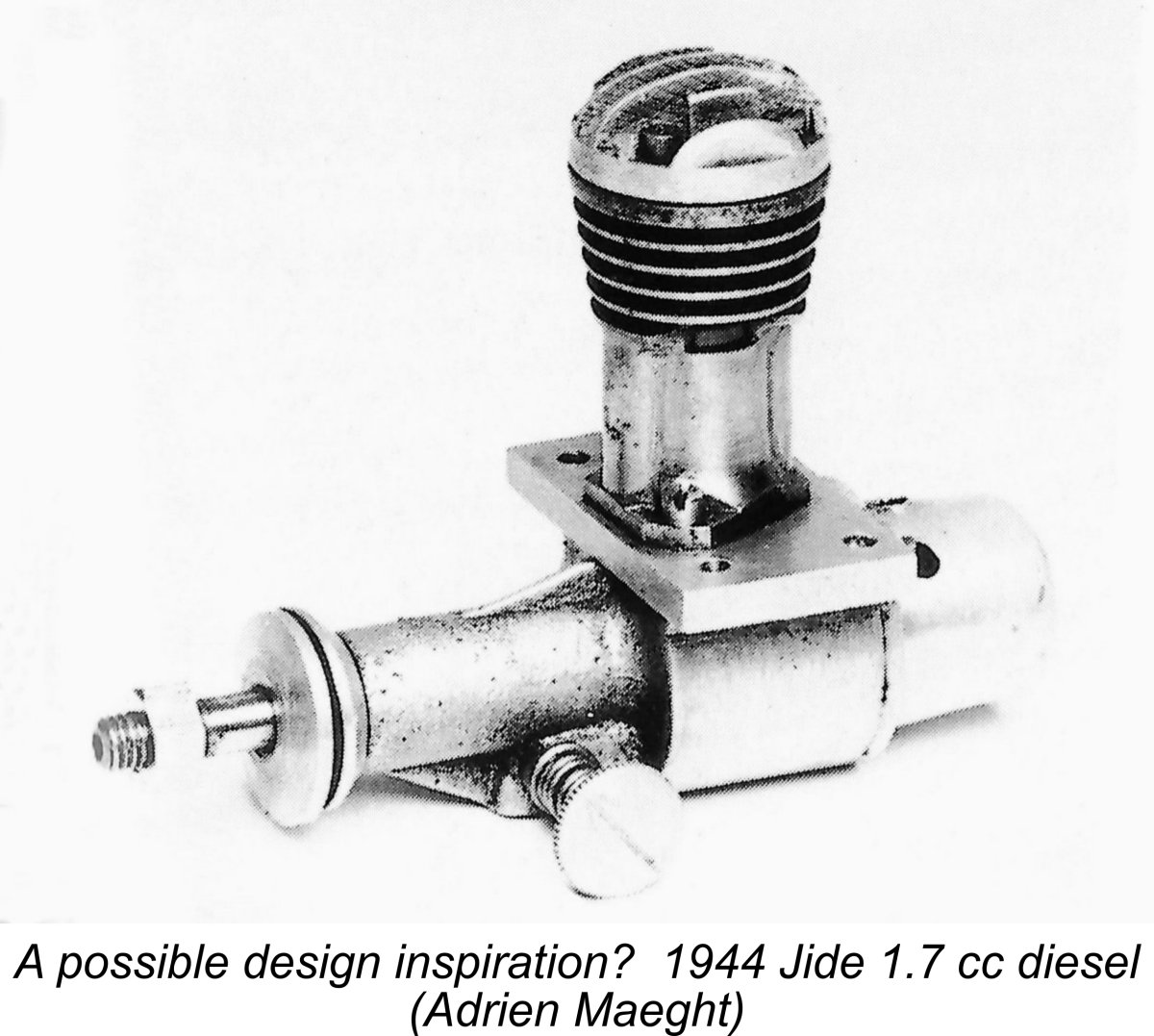

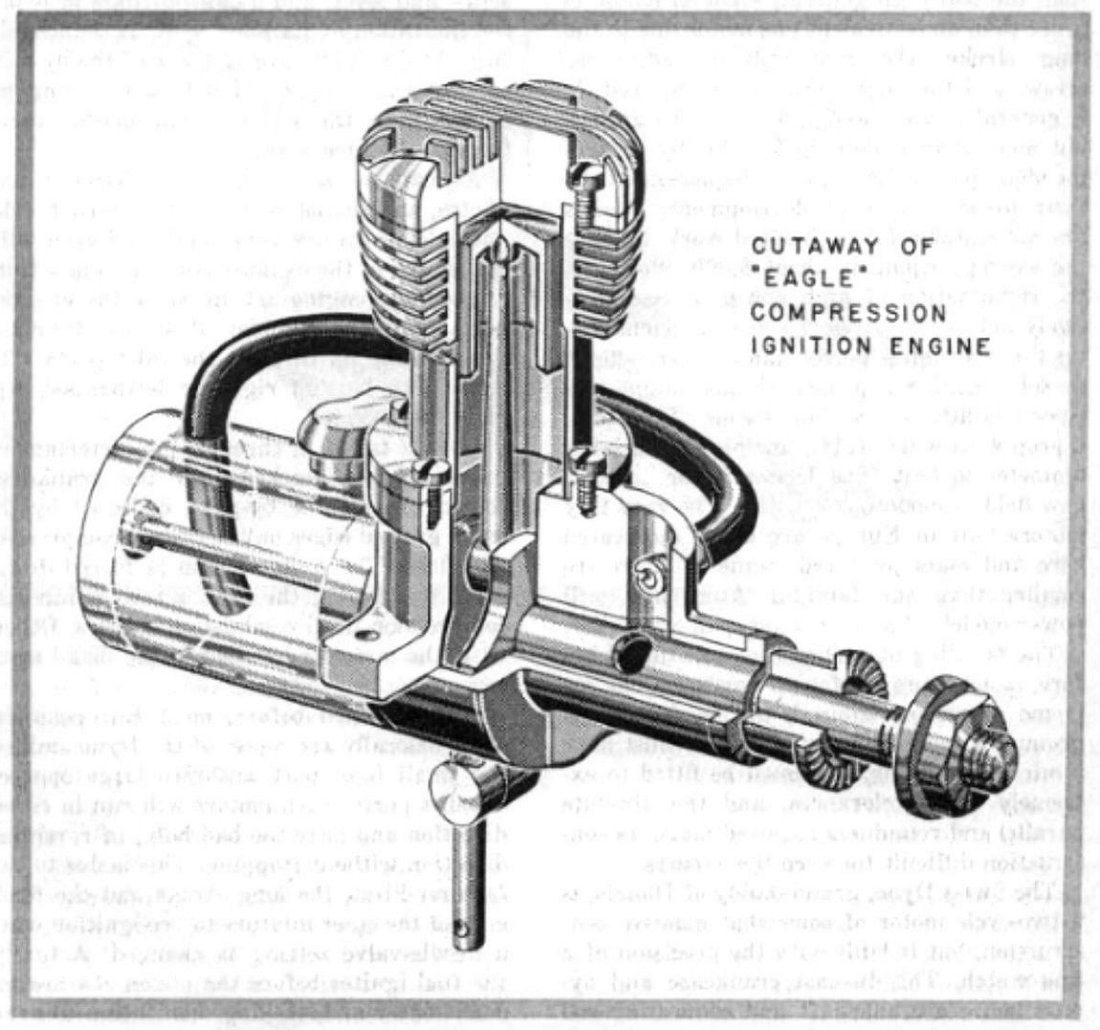

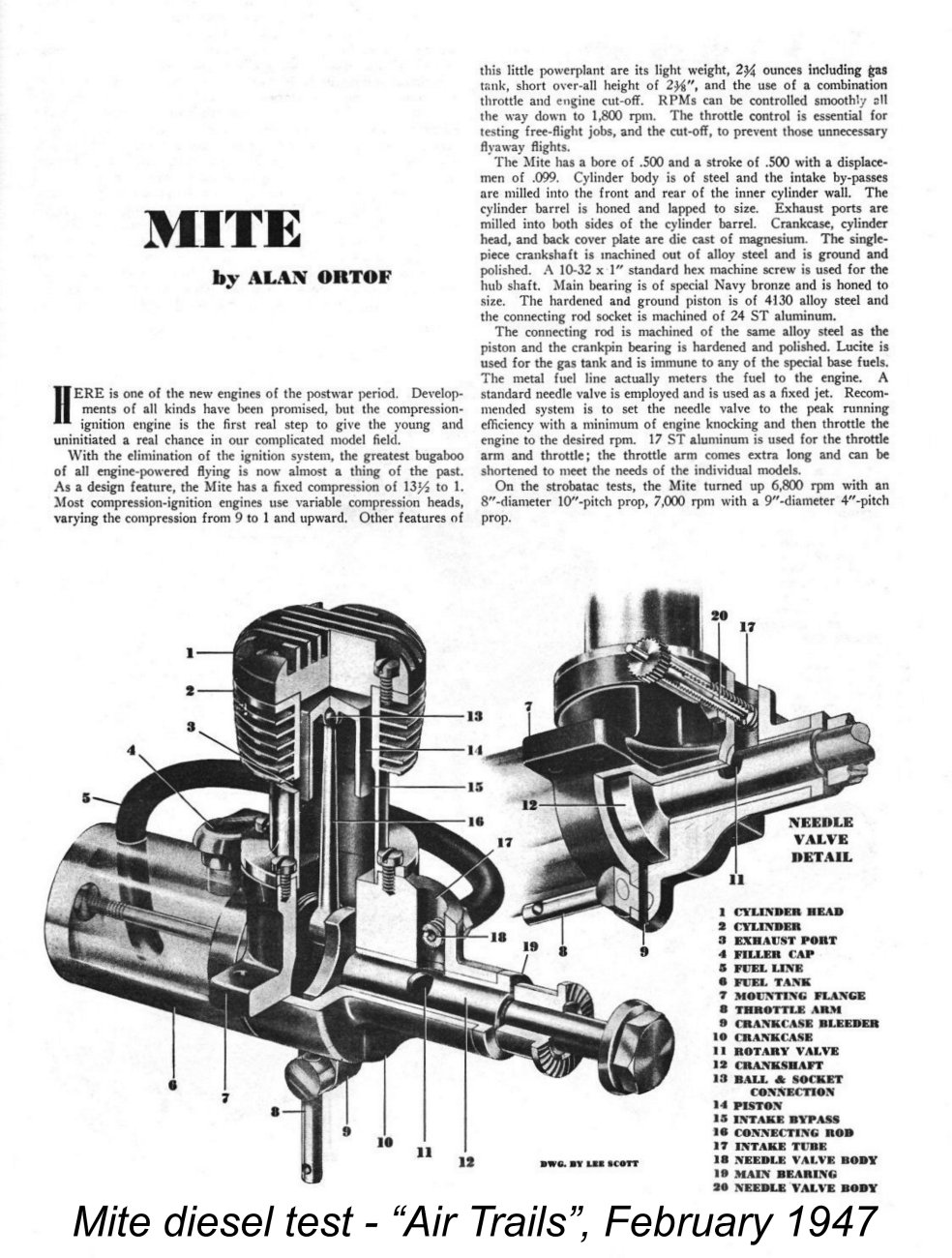

Presumably the design relied upon crankcase pressure to keep the disc valve in contact with its seat during operation - a number of other disc valve designs employed this principle. Wes confirmed The first advertisement for the production version of the Mite appeared in the February 1947 issue of "Model Airplane News" (MAN). Allowing for Editorial lead time, this confirms that the engine must have been in existence as of December 1946 at the latest. The fact that a published test of the engine appeared in the February 1947 issue of “Air Trails” (see below) adds support to this view. This in turn implies that the development of the Manderville design which became the Mite actually began in early to mid 1946. This fits well with the previously-noted unproven idea that an example of the Jidé 1.7 cc model bought back to The first production examples of the Mite .099 were marketed by the Eagle Manufacturing Co. of Brooklyn, New York. This company was owned by Walt Schroeder, who was later to go on to become the Editor of “Model Airplane News” during the 1950’s. The core business of the Eagle company was kit manufacture – the Mite diesel appears to have been marketed as a sideline, perhaps as a favour to Manderville.

Interestingly, it appears that this presumably early version of the engine had a threaded crankshaft with nut-and-washer prop attachment instead of the hollow tapped shaft and prop bolt used later. I've never encountered an example of the Mite which was so equipped - has anyone else?!? The engine was certainly in existence as of August 1946, at least in prototype form, since examples were demonstrated by Walt Schroeder at the 1946 Witchita Nationals held in late August 1946, a fact recorded in "Air Trails". The date of the Mite's marketplace entry in quantity is somewhat clouded, but a test of the engine appeared in the February 1947 issue of “Air Trails” (see below). This proves beyond doubt that the commercial rendition of the Mite must have been in existence as of late 1946. This makes it indisputably one of the earliest American diesels.

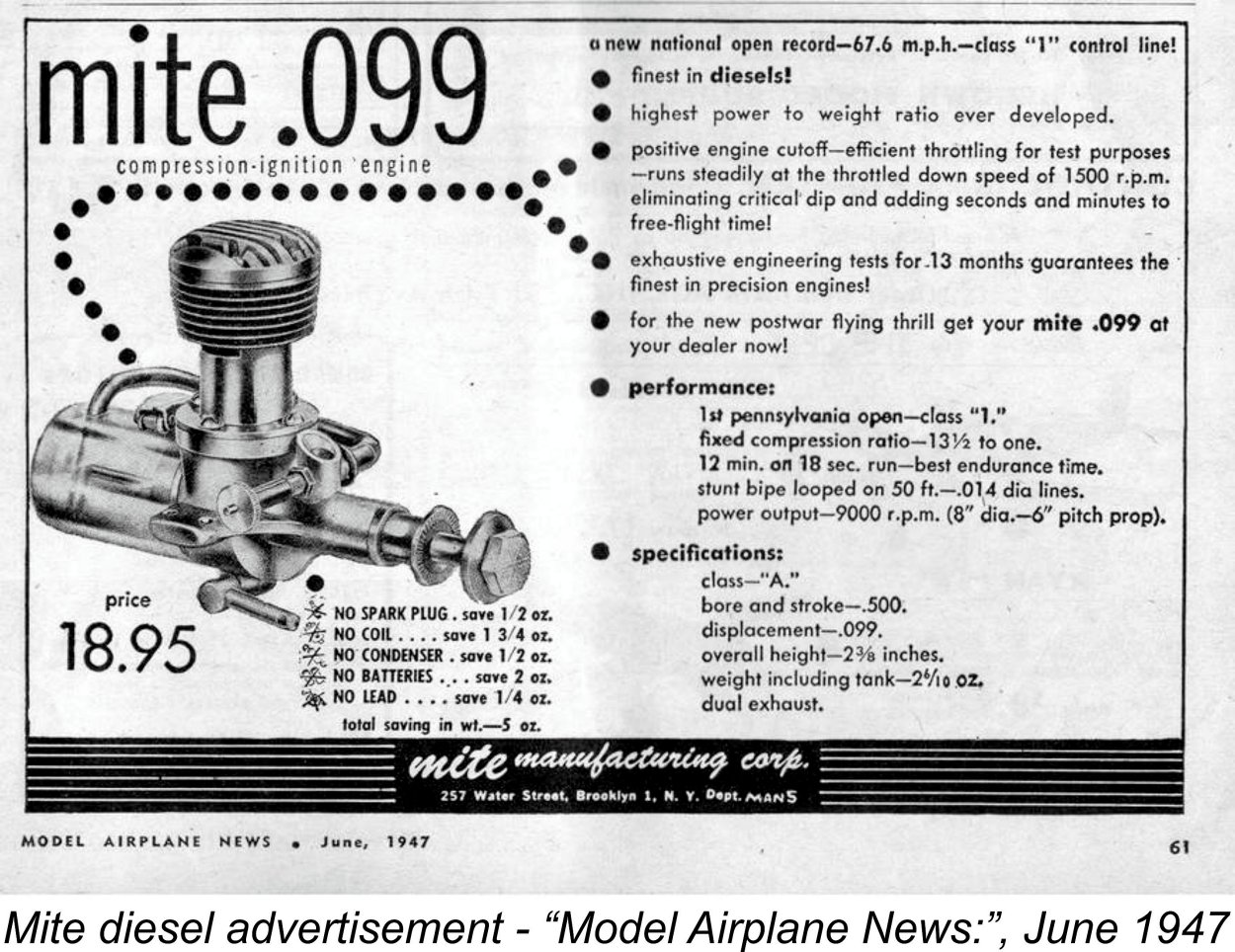

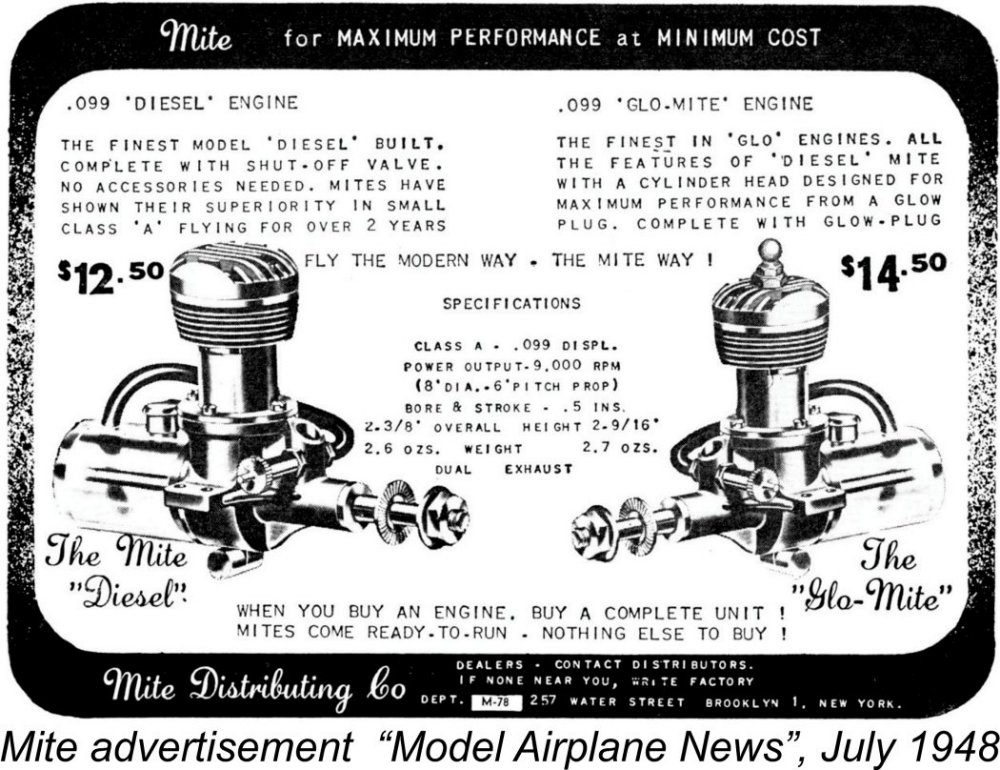

Another individual who became associated with the Mite project at around this time was the previously-mentioned Bill Seidler of Brooklyn, New York. Bill was already an experienced model engine manufacturer, having previously developed and marketed the excellent Pacemaker 59 spark ignition engine in 1946 prior to the appearance of the Mite. It’s not Bill was undoubtedly a close associate of Mite marketing guru Walt Schroeder. This connection was confirmed in the article by Jack Bayha entitled “Diesels Grow Up” which appeared in the December 1947 issue of “Model Airplane News”. That article cited Howard Manderville as the original designer of the Mite, but credited Bill Seidler and Walt Schroeder with its commercial production and further development. An advertisement which appeared in the June 1947 issue of “Model Airplane News” confirms that the new company had been established by May 1947 at the latest, and probably earlier. The selling price of the engine at that time was $18.95 – actually a fairly high price for an engine of this displacement. At the same time, most competing models sold for less, including the Atom at $15.50, the Arden 099 PB at $12.50, the Arden 099 BB at $15.50, and the C.I.E. 10 diesel at $16.50. It's unclear how long the Mite company maintained that introductory price, but they surely can't have done so for long. That having been said, the Mite may have continued to sell on merit for quite some time despite its higher price. Every old-timer with whom I've been in contact or whose writing I've read has remembered the Mite with great affection! Be that as it may, the advertising record shows that by April 1948 the price of the Mite had dropped to a far more competitive $12.50. The text of the Mite advertisements makes reference to an AMA Class 1 control-line speed record of 67.6 MPH which had evidently been established by the Mite – pretty fair going if accurate! This feat was independently confirmed in several contemporary articles about the engine.

When preparing his previously-mentioned article on the Mite diesel, David Janson was able to call upon the reminiscences of well-know old-time model flier Norman Rosenstock, who had worked for the Mite company during his early career. Norman was both a machinist and a modelling enthusiast, thus being well qualified to work in the model engine manufacturing field. Norman recalled his struggles with securing the correct piston/cylinder fits. Apparently the components were not made in the usual way as individually-fitted sets – instead, cylinders and pistons were finished separately to specified limits. The inevitable microscopic variations were accommodated by test-fitting pistons to cylinders at random in order to find a combination that fitted correctly by trial and error. This approach was not entirely successful - a good proportion of the Mites that survive today have somewhat slack piston/cylinder fits by diesel standards. Norman also recalled the challenge of individually test-running each engine before delivery. He recalled personally testing some 3,800 examples, suggesting that more than one tester was involved. It seems that this test-running was taken quite seriously – head gaskets of differing thicknesses were available to allow the compression ratio to be adjusted based on each engine’s test performance. Clearly, experience must have counted for a great deal in this process. The fuel used in this testing and recommended by the manufacturers was a rather unusual mixture of 50% ether and 50% heavy mineral oil. This blend was a direct result of the designer's decision to set the engine's fixed compression ratio at only 13.5 to 1 - very low indeed for a compression ignition engine. Anyone who has read my article on fixed compression diesel operation will understand that the very high oil content was required in this instance to raise the effective operating compression ratio to workable levels. It's a bit of a puzzle why such a low compression ratio was chosen.......... The high oil content also helped to compensate for the rather slack piston/cylinder fits with which a fair number of Mites were afflicted.

The Mite attracted a certain amount of attention from the US modelling media during 1947. Apart from the February 1947 test in “Air Trails” (see below), it was included in a number of subsequent articles, including “Care and Feeding of Diesels” by Jack Bayha (“Model Airplane News”, June 1947), “New Power Units” by Edward G. Ingram (“Model Airplane News”, August 1947), “The Development of Diesels” by Jim Noonan (“Air Trails”, September 1947) and “Diesels Grow Up” by Jack Bayha (“Model Airplane News”, December 1947). Bayha and Noonan were both Mite users who expressed a very high opinion of the engine’s performance characteristics based upon their own direct experiences with it. Sadly, that inclusion in Bayha’s December 1947 article was the engine’s final media appearance of which I can find a record. Ray Arden’s introduction of the commercial miniature glow-plug in November 1947 evidently killed off the Mite in very short order, along with most other American diesels. It appears that the engine faded into the background rather precipitately, since it was not mentioned in the article by Edward G. Ingram which appeared under the title “Model Motors for 1948” in the January 1948 issue of “Model Airplane News” despite the fact that other diesel models were included. The only classic American diesel to survive for some time into the glow-plug era was the ball-bearing Drone, which lingered on into 1949 before following its American diesel contemporaries into total eclipse. Interestingly enough, the Mite diesel was still on offer from America's Hobby Center (AHC) as of July 1950 along with the Air-O and Micro diesels, both of which had gone out of production long before that time. It's evident that AHC was selling off New Old Stock - this listing cannot be taken as evidence of continued production.

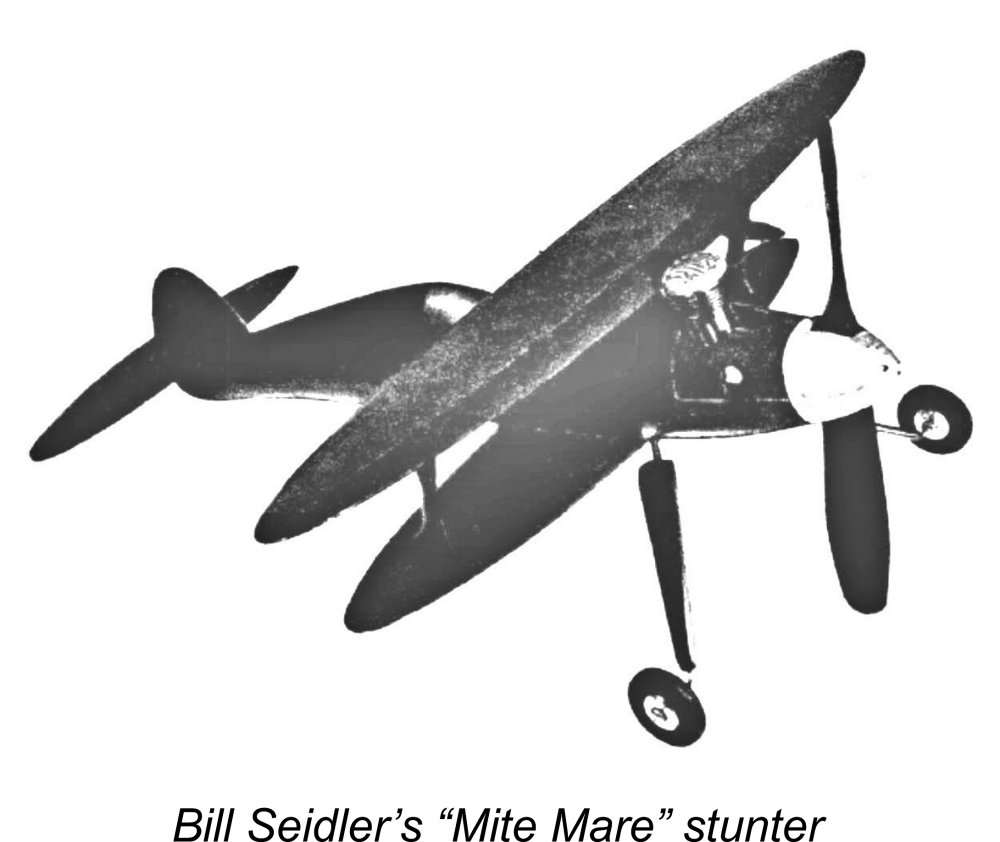

Although by no means definitive, there is a strong suggestion here that the renamed company was no longer involved with actual manufacturing other than the creation of the glow-plug conversions, which were probably based upon existing diesel units. Under the new company name, they continued to advertise both diesel and glow-plug models throughout much of 1948. However, I've been unable so far to find a company advertisement from 1949. Bill Seidler contributed by publishing the plans for a small biplane stunt control-line model called the “Mite Mare” in the June 1948 issue of MAN. Sadly, none of this was sufficient to save the marque. "America's Hobby Center" (AHC) advertised the Mite and Glo-Mite through to April 1949, after which there was an advertising hiatus. Norman Rosenstock recalled that the Mite name, designs, components and goodwill were all sold at this point to an outfit called the Mercury Model Co., also of Brooklyn. This transfer was recorded in the "What's New?" column in the June 1949 issue of "Flying Models", which also stated that new Mites were expected to be available "shortly". The new owners reportedly assembled the remaining components into glow-plug models, selling them off over an extended period of time ending in the late 1950’s. They never advertised these engines themselves, relying instead upon word of mouth and direct communication with New York area model clubs to generate sales. The price of these units dipped to as low as $6 in the final days of availability. A few diesel Mites evidently remained unsold at the time of the ownership transfer. Having evidently acquired stocks of both models, AHC resumed their advertising of the Glo-Mite in July 1949, with the Mite diesel joining the Glo-Mite in September 1949 - evidently AHC had acquired all remaining stocks of the Mite diesel. They continued to list the Glo-Mite until October 1950, after which the only examples still available were evidently those being marketed by Mercury Model Co. The final AHC advertisement for the Mite diesel appeared in May 1951, at which point their stocks were evidently exhausted. Thereafter, only the Glo-Mite remained available from Mercury. Now that we’ve traced the manufacturing history of the Mite diesel, it’s time to take a closer look at the engine itself. The Mite .099 Diesel – Description

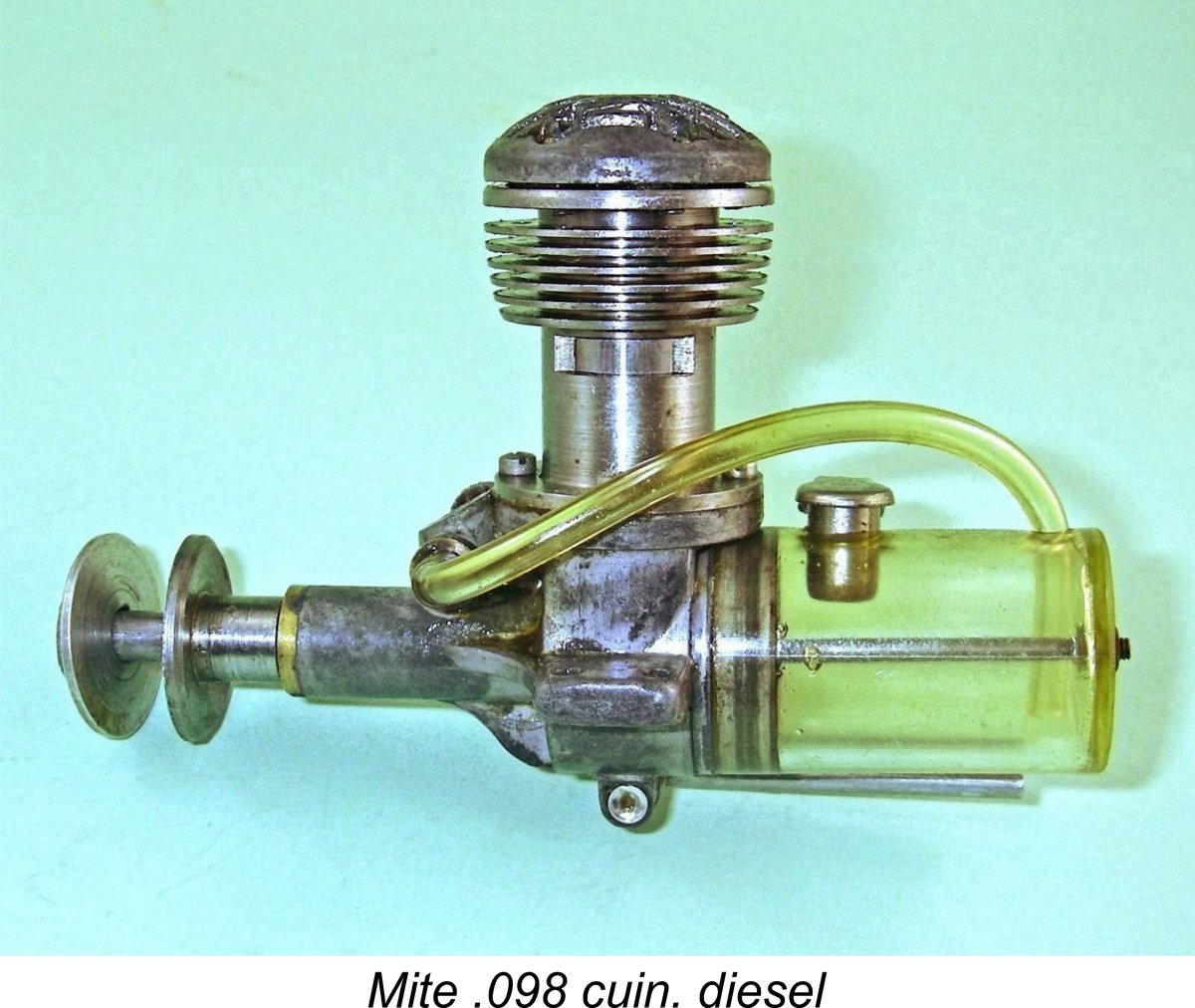

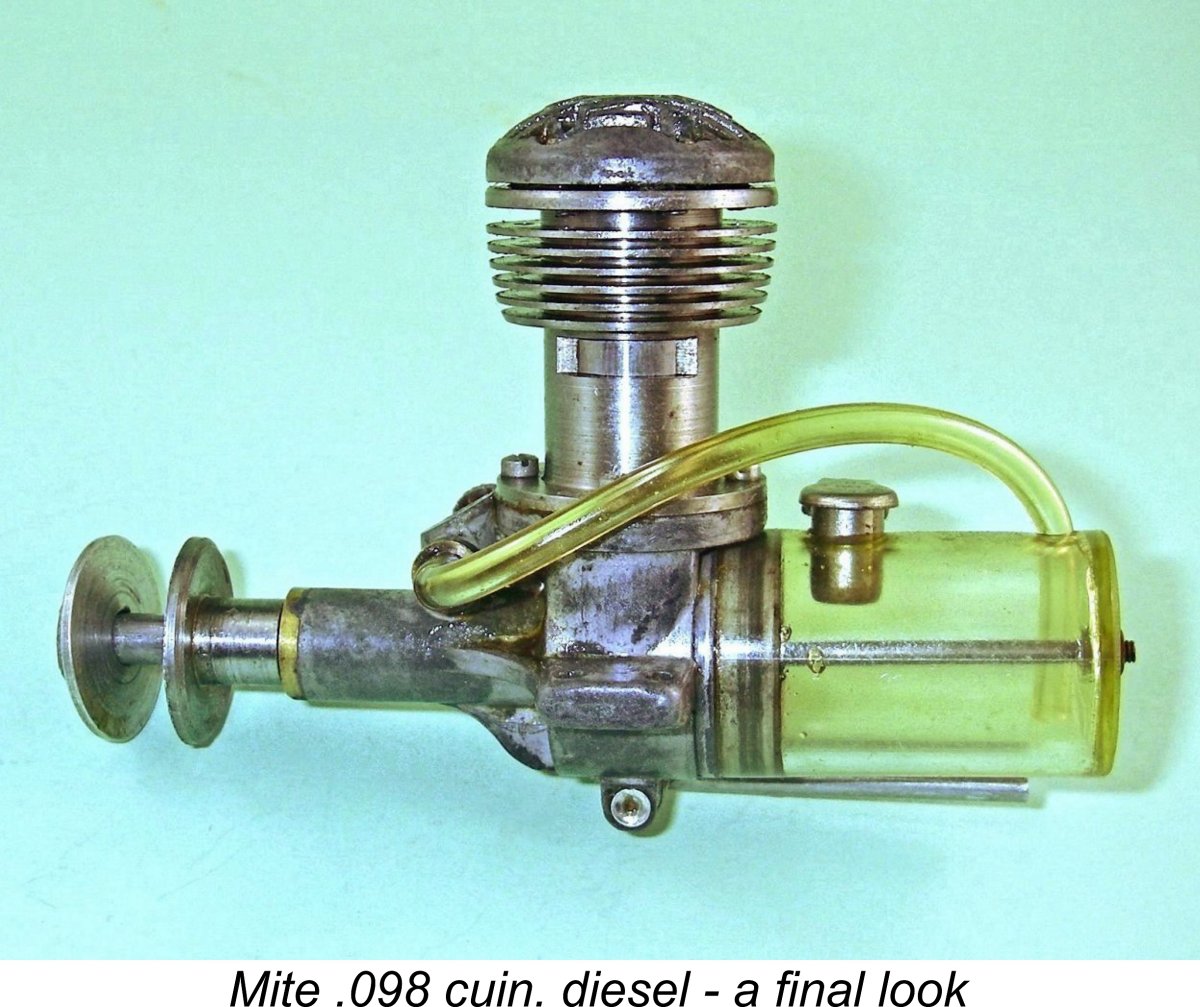

All castings used (crankcase, backplate and cylinder head) were cleanly pressure die-cast in magnesium alloy. The steel cylinder had integrally-formed cooling fins. The finned magnesium alloy head was secured using six 2-56 screws which matched threaded holes in the upper cylinder flange. The cylinder was attached to the crankcase using four more 2-56 screws which passed through the cylinder’s base flange to engage with tapped holes in the upper crankcase casting. Take great care when tightening these small screws – easily stripped! Cylinder porting was essentially identical to that used later by Cox. Two rectangular exhaust ports were milled into opposite sides of the cylinder, while transfer was provided for by the creation of two internal transfer flutes located between the exhaust ports. Port timing was relatively conservative, with the exhaust opening at around 130 degrees after top dead centre (ATDC) and the transfers opening some 15 degrees later at 145 degrees ATDC. This gave exhaust and transfer periods of 100 degrees and 70 degrees respectively – probably ideal for the kind of speeds quoted by the various contemporary writers on the engine, especially given the generous port areas provided. The thin-walled lightweight piston was also of steel. A steel-in-steel piston/cylinder combination can prove quite troublesome if not perfectly fitted initially – running-in wear is likely to be minimal. This probably explains the manufacturer’s policy of making the components separately and then test-fitting them until a matching combination was found by trial and error. The fit of my own example is absolutely perfect, but the one tested by Don Howie and Maris Dislers (see below) was apparently fitted somewhat too loosely. I've heard from others that this is a not-uncommon issue with these engines.

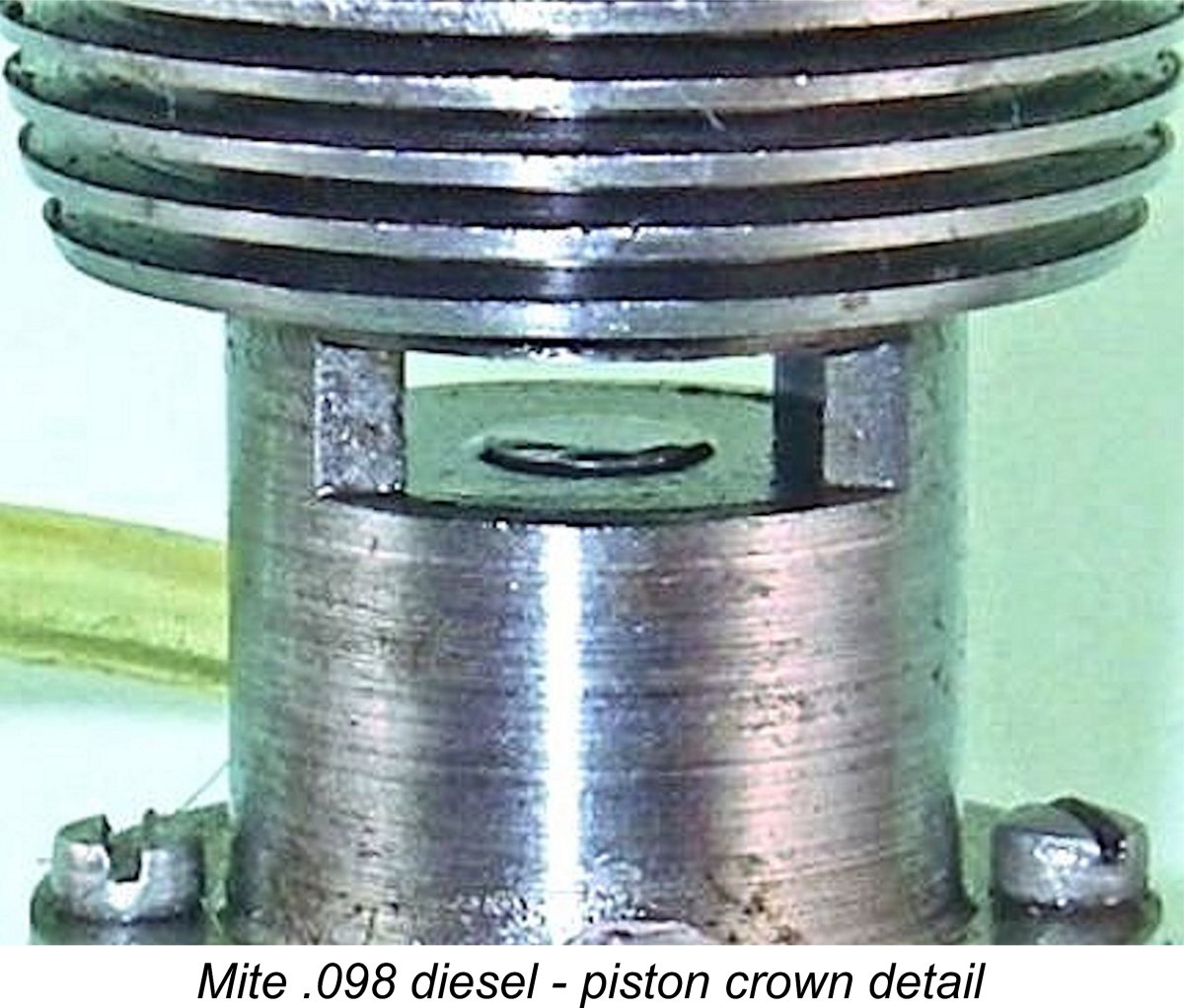

The spherical upper end of the steel conrod was installed in a socket made of high-strength aluminium alloy. The presence of a swaged cap in the centre of the piston crown confirms that the aluminium socket was located by an integral socket pin which passed through a hole in the piston crown and was then swaged in place to retain the socket. The reciprocating weight of this assembly would logically appear to be relatively low, along with a smaller-than-usual piston interior volume which would increase crankcase compression. Moving on downwards, the engine used a one-piece crankshaft of alloy steel having a crankdisc which was counterbalanced through the provision of crescent-shaped cutaways on each side of the crankpin. This shaft was supported by a naval bronze bushing which was pressed into the main bearing housing from the front. Measured main journal diameter was a rather skinny 0.250 in. (6.35 mm), which is rather on the small side for a diesel engine of this displacement. Having elected not to dismantle my example of the engine, I can’t report on the diameter of the internal gas passage. I just hope that it’s not too large! Like the cylinder port timing, the engine’s induction arrangements were also very much on the conservative side. The drilled circular induction port opens at 50 degrees after bottom dead centre (ABDC). Fair enough, but it closes at only ten degrees ATDC for a total induction period of some 140 degrees. There is also a The intake was cast in unit with the main crankcase. A conventional spraybar-type needle valve assembly was used, with a split thimble to provide needle tension. Right up front, we come to one feature of the Mite which deservedly comes in for a fair amount of criticism. The tiny very steep self-releasing taper provided to "lock" the steel prop driver to the shaft is a joke. Experience with running the engine shows that it is quite incapable of consistently holding the prop firm against starting loads. Both Maris and I had endless trouble with the prop coming loose, particularly during cold starting. A far longer taper at a shallower angle would have worked a great deal better. That having been said, Maris has speculated that the very "slippy" prop driver fixture may have been intentionally designed into the engine to prevent damage from inexperienced users trying to fip a well-flooded engine. This is certainly a possibility, although in practical terms the aggravation that it causes doesn't seem to be an acceptable price to pay for such protection. The fact that the need to really tighten the prop on these engines was a recognized issue is amply demonstrated by the appearance of an article by Ray Rusher entitled "Installing Props on Model Engines" which appeared in the December 1949 issue of MAN. The Mite was cited as an engine requiring careful attention to this issue. The author described the old "chopstick in the ports" method of preventing the shaft from turning while tightening the prop. When all else fails, this system actually works - I've used it myself when really pushed!

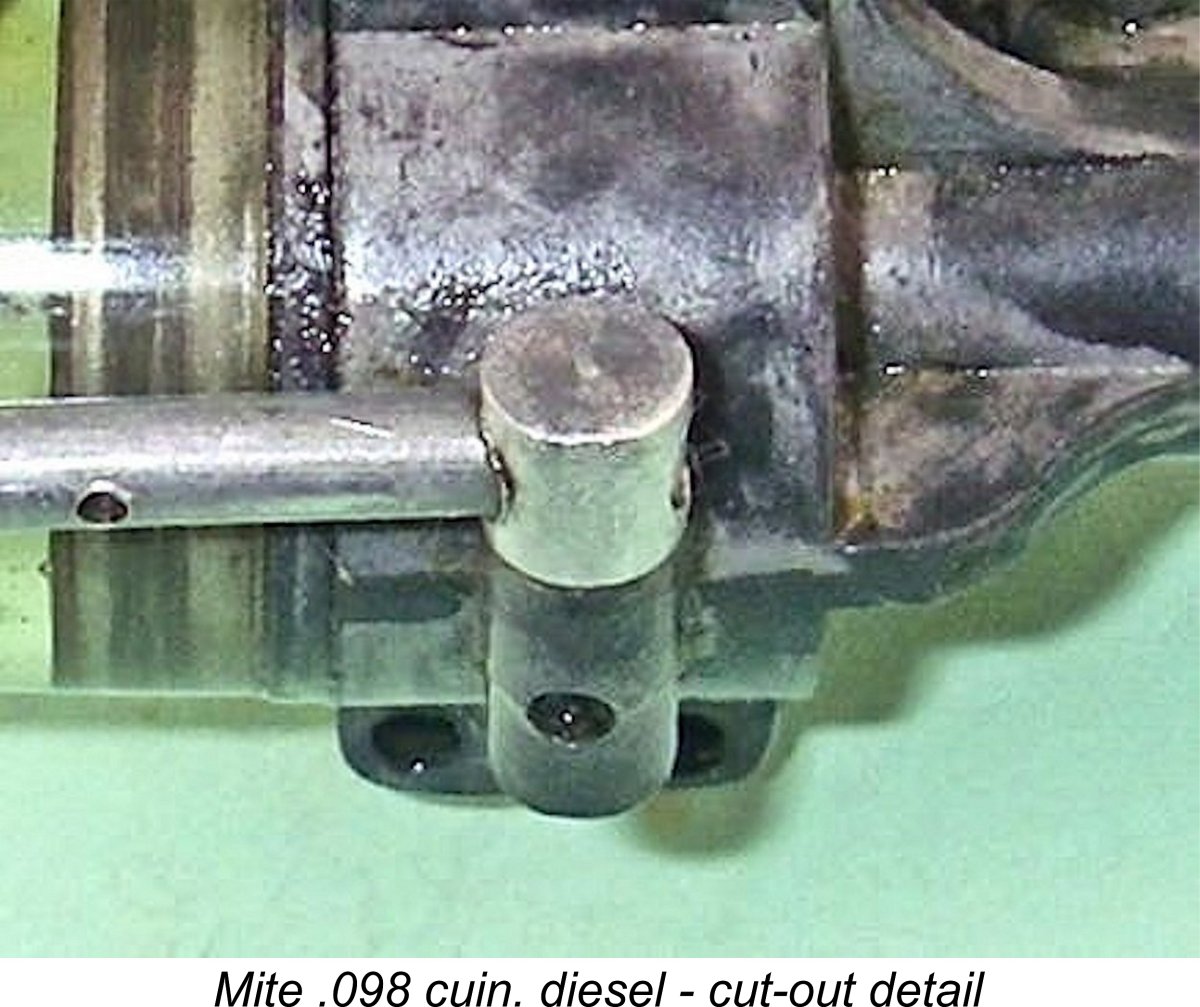

At the rear, the crankcase is sealed by a die-cast screw-in backplate of magnesium alloy. This includes a central boss which accommodates a thin stud for retention of the Lucite plastic fuel tank. The tank is equipped with a Gits cap for filling. The final noteworthy feature is the so-called “throttle lever”. In fact, this is nothing more than an air bleed which passes vertically through a boss cast onto the bottom of the crankcase. It’s opened and closed by a lateral shaft which has a hole drilled transversely though it. A lever of light alloy is provided to activate this system by rotating the transverse shaft. When the arm is pointed straight back, the transverse hole in the shaft is aligned with the air bleed hole into the crankcase, allowing the engine’s crankcase compression to escape. When it is aligned straight down, the bleed aperture is closed, allowing the engine to run normally. The amount of bleed can of course be varied depending on the setting of the lever between the two extremes. Although touted as a throttle, this actually looks more like a simple air-bleed cut-off arrangement to me. Certainly something whose claims to effectiveness warrant testing. Let’s get to that aspect of the matter right away! The Mite Diesel on Test

The report was mainly concerned with a detailed description of the engine’s structural features, which were then quite out of the rut and hence of considerable interest to Ortof's readers. Performance information was confined to a comment on the operation of the cut-out plus a few speeds measured on specific props. There were no observations on the engine’s handling or running qualities. The cut-out was reported to be effective as a throttle in bringing the engine down to an idle speed of 1,800 RPM. It also functioned as a cut-out when fully opened. Reported prop speeds were 6,800 RPM on an 8x10 of unspecified make and 7,000 RPM on a 9x4 ditto. I must say that I’m a bit suspicious regarding these figures – the 9x4 should by rights be a lot faster than the 8x10. Perhaps the 8x10 was a speed “toothpick”. Naturally, I have no idea of the power absorption coefficients of these two props. All I can say is that if the 9x4 were a present-day APC, the reported speed of 7,000 RPM would imply an output of around 0.064 BHP. The manufacturers published their own contemporary claim, which was reported in the article by Edward G. Ingram entitled “New Power Units” which appeared in the August 1947 issue of “Model Airplane News”. The claim was made that the Mite would turn an 8x6 prop at a quite impressive 9,000 RPM. It must be said that this seems rather inconsistent with the speed of 7,000 RPM reported by Alan Ortof for the 9x4, which one would expect to turn at a speed not greatly different from that of an 8x6. It also implies a level of performance which appears at first sight to be rather hard to accept – as an example, a speed of 9000 RPM on an APC 8x6 (a relatively "fast" prop of that size) would imply an output of around 0.127 BHP at that speed, which I for one found extremely difficult to believe. But once again, read on .......... After a lapse of over half a century, another test of the Mite diesel finally appeared in the pages of “AeroModeller” magazine. The fact that this test appeared in the March 2017 issue of the magazine just as I was beginning to plan the present article was extremely fortuitous, since it greatly informed my own proposed testing efforts to be described below. The report appeared as part of Don Howie’s very interesting article entitled “For Old Time’s Sake”, which presented Don’s commentary upon a number of facets of old-time modelling.

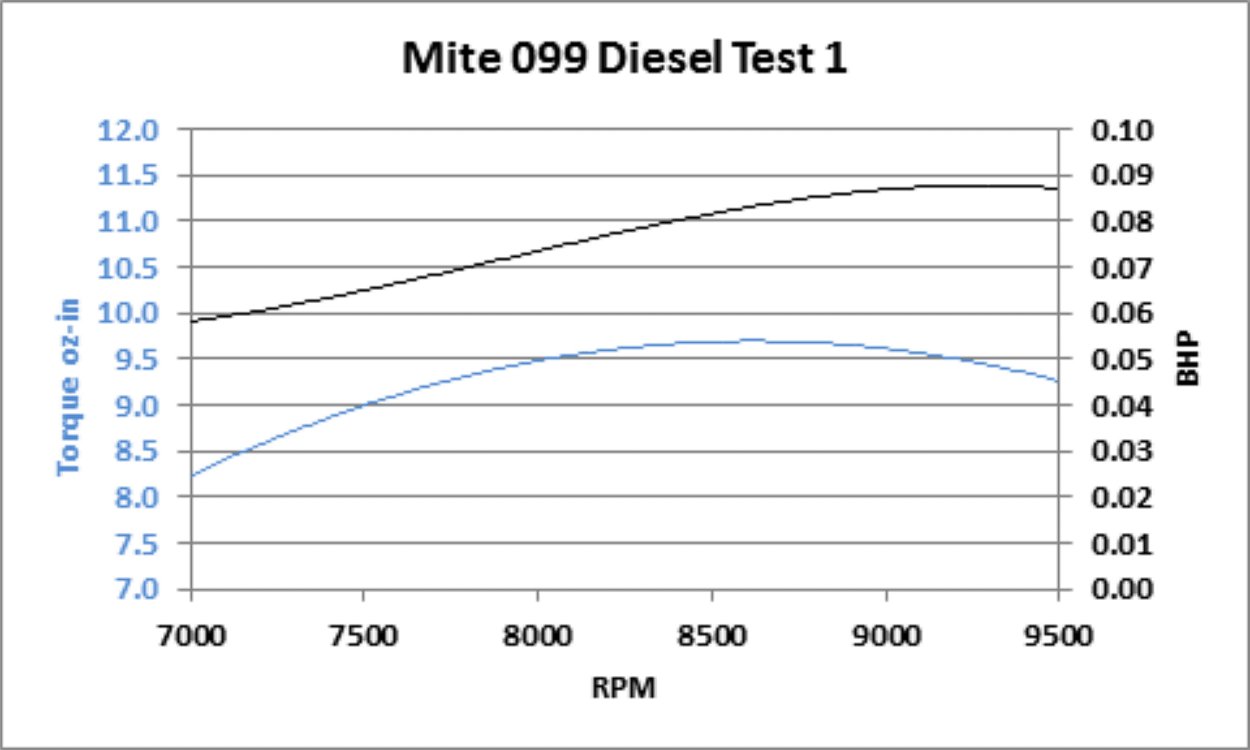

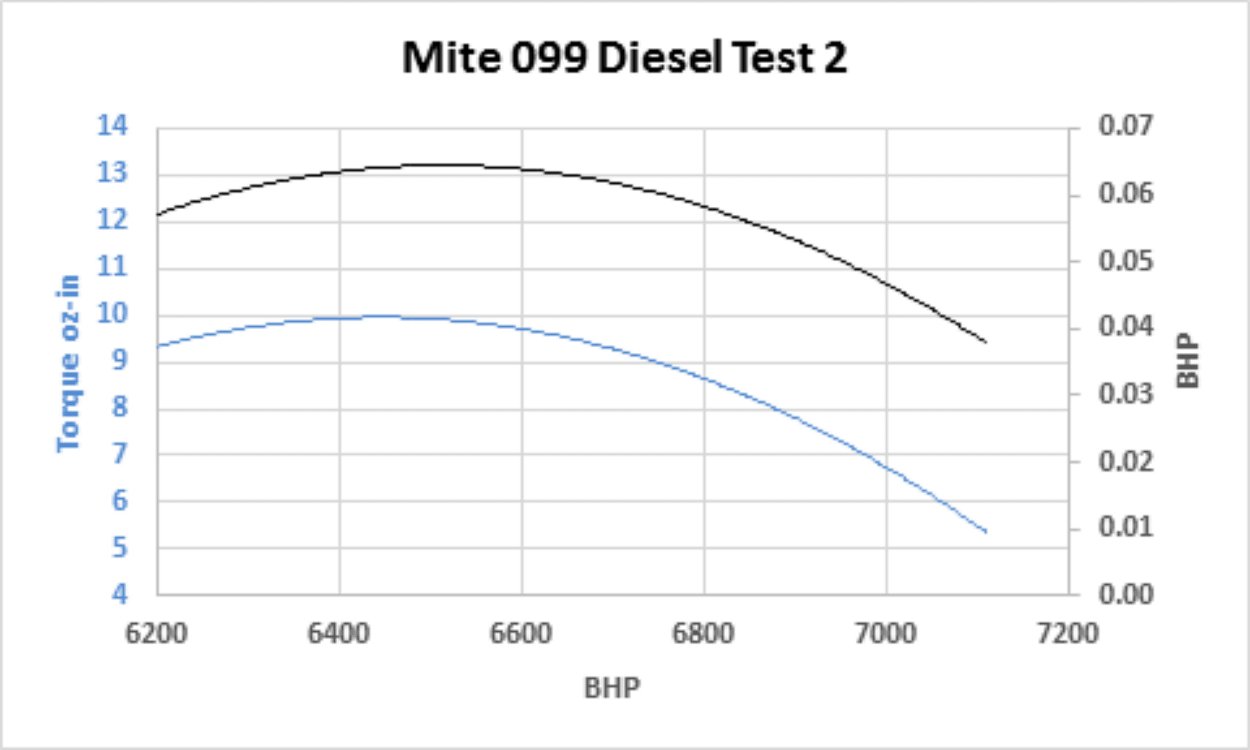

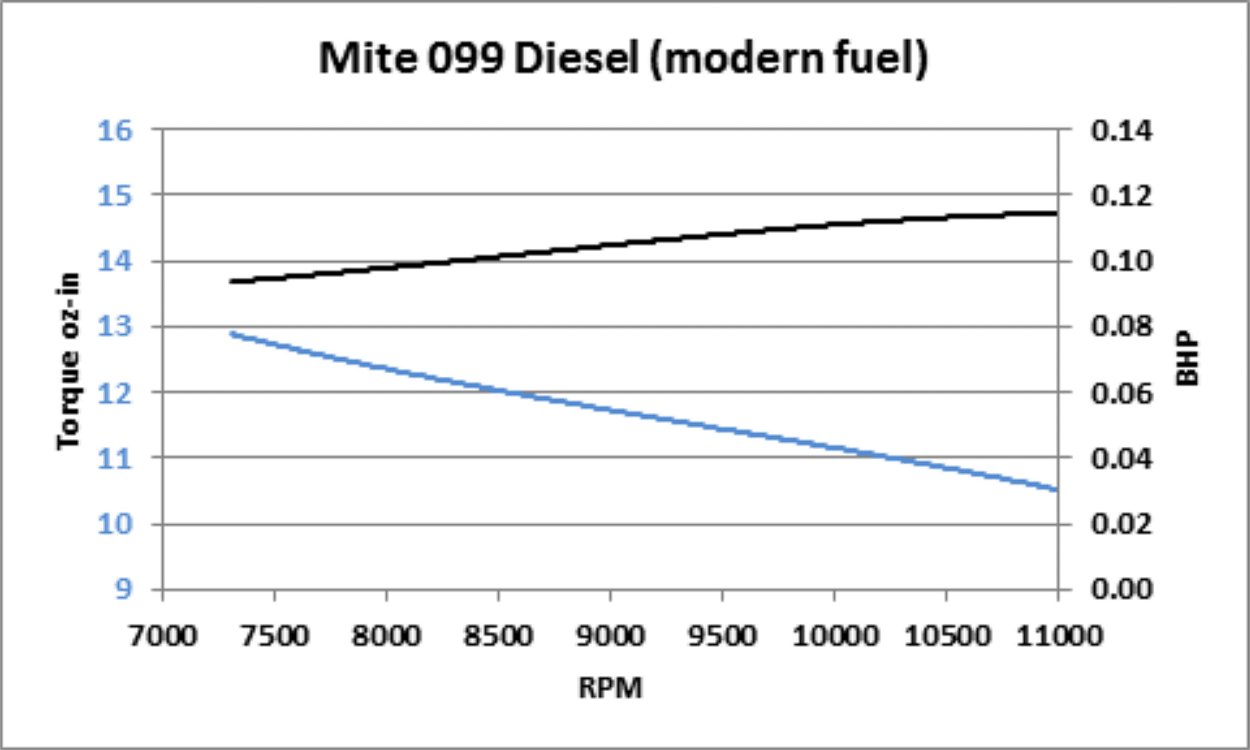

Not too impressive! Attention then switched to an example owned by Don Howie himself. Maris Dislers assisted with these latter tests, using a castor oil-based fuel. The first problem encountered was the fact that, despite being in new and unused condition, the piston/cylinder fit was rather on the slack side by diesel standards. It was found to be necessary for starting to administer a straight castor oil prime followed by a small fuel prime – the old Owat procedure! However, once it was running the engine reportedly seemed happy enough. This second example was tested using a fuel consisting of 40% kerosene, 30% ether, 30% castor oil and 1½% ignition improver added to the overall mix. Using this fuel, the results obtained were far more impressive. The engine managed 7,800 RPM on the APC 9x4 (0.088 BHP), 8,700 RPM on a Graupner Super 8x5, 9,400 RPM on the 8½x4 Bolly Clubman and 10,000 RPM on an 8x4 APC (0.109 BHP). Quite impressive results by late 1946 .099 cuin. diesel standards, and offering strong support for the previously-cited performance of the Mite as reported by Edward Ingram in the August 1947 issue of "Model Airplane News". A few years after the initial publication of this article in 2019, Maris decided to have another go at testing the Mite in both diesel and glow-plug forms. I can do no better than turn the pen over to Maris at this point to allow him to share his updated findings with us. The Mite .099 Diesel Retested by Maris Dislers Welcome to the world of fixed ignition timing! A different experience to the old spark ignition motors, regular variable compression diesels and the more-or-less self-adjusting glowplug engines (yet to come). For a diesel, a fixed compression ratio defines performance and handling more than any other factor. The compression seal (piston to cylinder fit) also has a direct bearing on effective gas pressure at the point of ignition. The high oil content in the specified Mite fuel (50% ether and 50% heavy mineral oil) is very necessary to create a liquid compression ring, given the relatively easy piston/cylinder clearance dictated by pairing a steel piston with a steel cylinder. That clearance varies from one Mite to the next. One of the available test engines proved useless but did yield a head for glowplug tests. I had two examples of the Mite available for testing. Unfortunately, one of them proved to have a piston/cylinder fit which was too loose to allow the engine to be operated. All testing was therefore done with the other example, which had an adequate piston/cylinder fit. The other one could usefully serve to provide any required spare parts. In preparation for this new round of testing using the recommended Mite fuel mixture, I checked the geometric compression ratio. This was carefully set at the factory close to the design 13.5 to 1 value. Calculating from the measured stroke, the necessary head to piston clearance at top dead centre is almost exactly 1 mm or .040 in. With a standard 0.3mm cylinder base gasket, and one 0.15mm copper head shim, it was close, and there’s not much leeway. Starting preliminaries were found to be one choked turn with a full fuel line and 1-2 drops onto the piston crown. The engine then started easily - a pleasure to fire up, in fact. Once running, the Mite drinks like a fish (explaining its generous fuel tank volume) so that the required mixture needle setting was way more open than I expected. Optimum RPM is achieved when the needle is set a little on the rich side of popping-white-smoke-lean. Vibration levels are low. Once on top of the starting procedure, it becomes a matter of trying different propellers to find the best running speed/load combination to suit the ignition timing established by the fixed compression. An excessive load causes sagging to a stop, at markedly reduced RPM. Excessively light loads produce an obvious misfire that cannot be cured with a richer mixture. This required approach is the big departure from normal practice - you have to match the load to the ignition timing instead of the other way round. Tinkering with shim thicknesses to increase the compression ratio for better high-speed running won’t get you very far, because the engine then can’t be started, as the previously-criticised prop driver comes loose from the pre-ignition pop. Set up next day for a couple more check runs, the engine was found to be completely useless - stiff to turn over and pre-igniting due to the residual oil. The only remedy was flushing with solvent. The crankcase vent proved to be very useful for that process. A related problem with the Mite was hot restarts. The ether content quickly evaporates from the prime, leaving behind a quite significant amount of oil. Subsequent primes and failed starts add more oil until the engine knocks and the loosening prop driver bugaboo returns. Priming with straight ether (automotive starting fluid) may help to get around this problem. Also, once cylinder heat had spread further down into the spraybar after a run, the incoming fuel could subsequently boil, causing a vapour lock in the fuel line junction and erratic mixture feed. You might surmise that running the Mite was not all beer and skittles! The Mite’s air bleed valve reputedly permits throttling down to 1,500 RPM. In his review, Charlie Bruce managed a rough-running 6,000 rpm, down from 7,500 rpm. The device is best used as a shut-off device, but it needs almost the full 90 degrees of rotation to really open the vent for full effect. The arrangement is unsuited to models with enclosed fuselage noses when set in the downward, closed position. I folded mine back, plugged the vent with a small piece of wood and ignored it. The Glo-Mite on Test by Maris Dislers In his review of the Mite, David Janson related that Glo-Mites used the original diesel head, modified to accept an Arden glowplug. This reportedly “resulted in blown heads, as the small 2-56 screws were just unable to hold them on”. There's a grain of truth there, methinks, but in my experience the six head screws are quite adequate. The weakness is in the four screws securing the cylinder to the magnesium crankcase, particularly the rearmost, which is cut shorter to clear the back plate sealing flange. Add to this the difficulty of tightening the round-head screws at an awkward angle with a flat-blade screwdriver, which tend to come loose during running if not snugged up tight. This requirement risks overdoing it, causing a stripped thread. Alternative Allen head screws carefully cut to length for maximum thread engagement would be well worth the effort. My available glowplug head is a somewhat dodgy home conversion – a shortened spigot with a short-reach glowplug seemed about right. The compression ratio when assembled with a single head shim was around 10:1. The Glo-Mite proved to be very easy to start using the same technique as the diesel. It ran smoothly with larger propellers, and its broad response to mixture adjustment gave ample warning when going lean. An erratic misfire crept in at higher speeds and could not be eliminated despite making very precise needle adjustment, trying different glow plugs and adding more nitro. A K&B 1S glow plug was about the best, while fuel with a 10% nitromethane content seemed to be a reasonable choice. Performance analysis The Mite diesel supports the contemporary wisdom that model diesel engines perform best at low speeds. The advertised 9,000 rpm with an 8x6 propeller only seems possible with a good example, and even then only under optimum weather conditions. To illustrate the point, I'm presenting data from two testing sessions of the same engine and fuel mix. Test 1 (from memory) took place in warm-hot weather, while Test 2 was undertaken at around 20 degrees C (68F). In addition, barometric pressure and humidity were almost certainly different. Conditions during Test 1 allowed the Mite to turn lighter loads without misfiring, so that its relatively modern design elements were put to good use. Not so during Test 2, when heavier propeller loads were required for useful smooth running. The results achieved during the two tests were as follows:

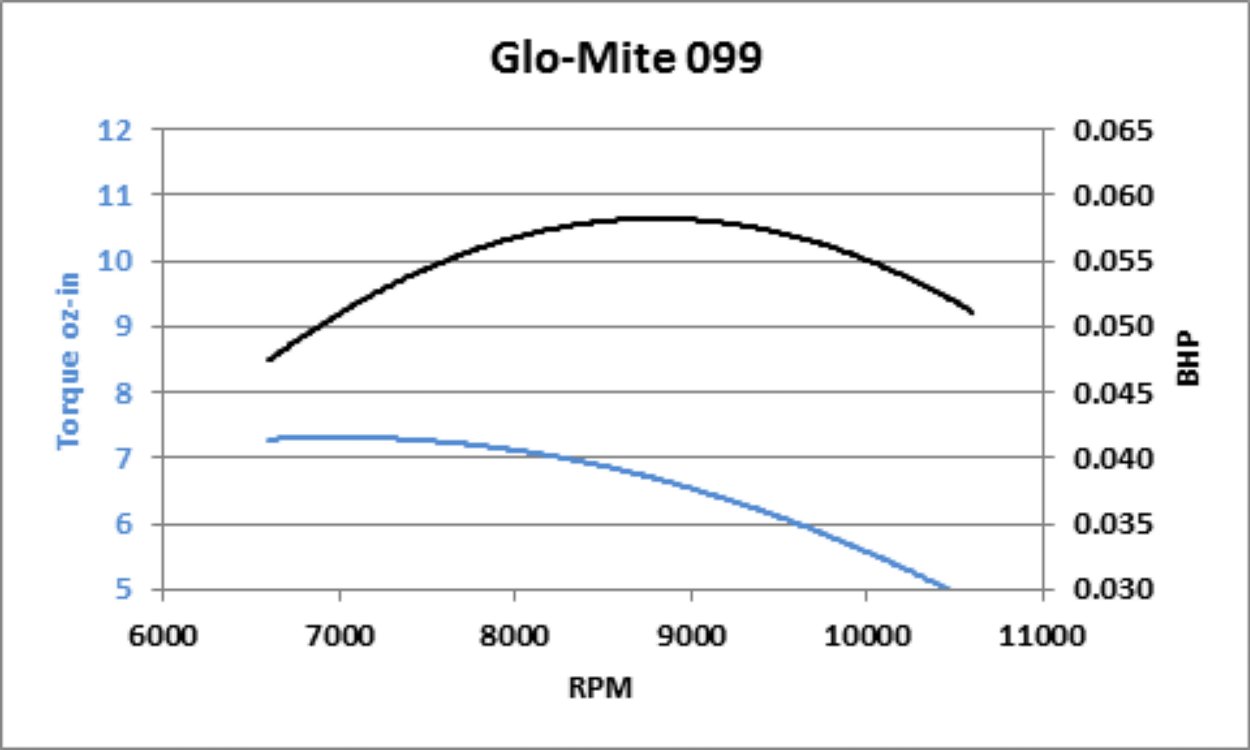

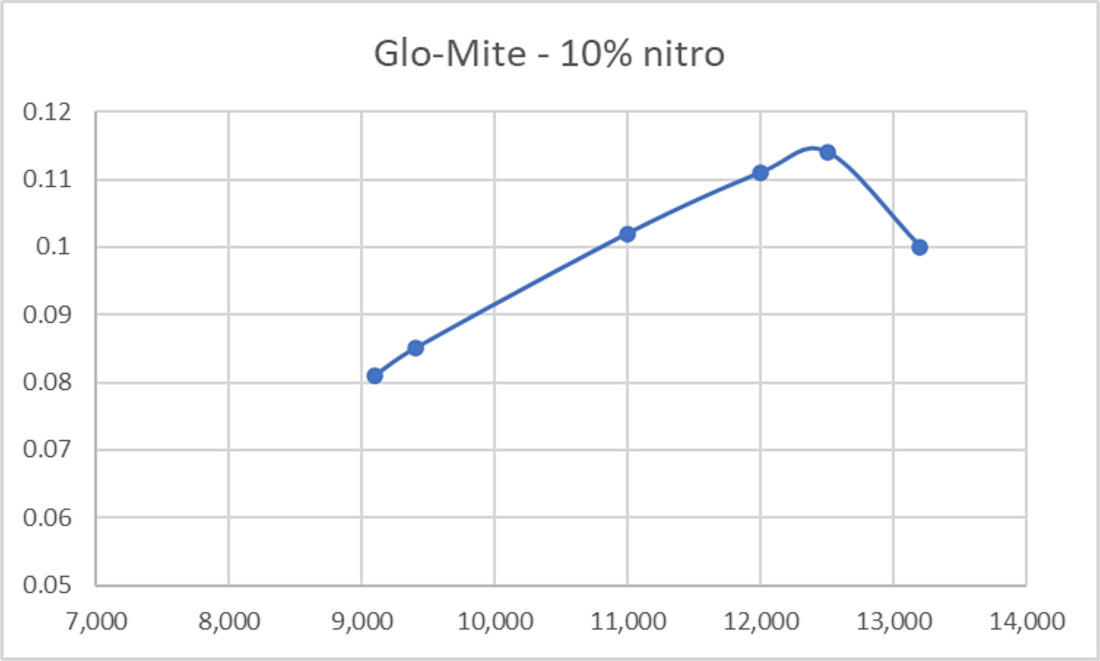

Performance curves from Test 1 are a little uncertain owing to data limitations, but the actual power output obtainable from a Mite diesel running on the recommended fuel could evidently be anywhere between .06 BHP and .09 BHP at somewhere between 6,500 and 9,000 rpm. A great deal clearly depends upon the operating conditions. In general, the lower numbers seem more likely. The decent maximum torque of 9 – 9.7 oz-in closely aligns with peak power, for resolute flight performance. This is a perfectly reasonable performance for an 099 engine in 1947, unencumbered by ignition equipment weight. The Glo-Mite’s best features were its easy starting and handling. It was happiest running at higher speeds with lighter loads, although (like the diesel) top-end speeds were hampered by a misfire which couldn't be eliminated. The data obtained during the test were as follows:

My “homespun” Glo-Mite's peak output was almost .06 BHP at a little under 9,000 rpm. Maximum torque was 7.3 oz-in at around 7,000 RPM. Charlie Bruce’s spot readings of 7,000 rpm with a Top Flite 8x6 and 8,000 with a Graupner 8x4 for his Glo-Mite seem a little less energetic. The advertised 9,000 rpm with an 8x6 propeller appears to be a seemingly unattainable carry-over from the diesel claims. For the sake of completeness, here are some other available test rpm numbers: Mite 099 Diesel Unspecified 8x10 - 6,800 RPM (Alan Ortof) Glo-Mite 099 8x6 Top Flite - 7,000 RPM (Charlie Bruce) Experiments Only a few years later, two important advances in model diesel fuel technology could have made a big difference to the operation of the Mite diesel. The major developments were improved compression sealing with castor oil lubricant and good combustion at moderate compression ratios obtained by “doping” the fuel with alkyl nitrate ignition improver. To explore the Mite’s potential, I tried it with a typical modern fuel containing 25% castor oil, 30% ether, 45% kerosene, plus 1.5% ignition improver. The results obtained were as follows:

Using this fuel, the engine developed significantly higher torque and a worthwhile power boost due to effective running at higher speeds. Fitting a smaller spraybar (increasing effective choke area to 4 mm2) and upping ignition improver to 2% (acting as a chemical compression adjusting screw) added a further 600 – 800 rpm, delivering .14 BHP at around 11,500 RPM. This is right in line with a good equivalent European or Australian diesel from the 1950s. In a similar revisionist vein, Stan Pilgrim made a few rational modifications to his Glo-Mite. He shortened the piston skirt to give 65 degrees of sub-piston induction (SPI), also increasing the compression ratio to around 9.5:1. He added some counterbalancing to the crankweb, eased the shaft fit in the main bearing and opened the head centre a little with a ball-nosed cutter. His spot checks with an APC 7x4 propeller showed 11,250 rpm (.092 BHP and 8.2 oz-in torque), while an APC 7x3 prop was spun at 13,350 rpm (.104 BHP and 7.9 oz-in torque) using 5% nitromethane fuel. Admittedly, both of these exercises are revisionary “if onlys”, but they do demonstrate that the Mite 099 had “good bones”. Incidentally, my colleagues and I noted detail differences in piston/cylinder sets between our two available Mites, both of which are genuine ex-factory units. The usable one has no SPI, while the other has 63 degrees SPI. Stan’s tweak to extend induction duration is therefore quite in keeping with an apparent factory modification to at least some Mites. A real pity that ours could not be appraised. Even in the mid-1940s, fixed compression for model diesels was clearly a dead-end feature, avoided by most and only successfully applied to a few engines with larger swept volumes. M. Durand wisely switched to variable compression for his second series Jidé 8 1.7cc diesel. Had the Mite gang chanced upon that one as their (highly likely) inspiration, instead of the first model, history would have recorded a much more successful, pleasant handling engine, delivering power and flexibility to rival the Arden 099. I hope that the above test data may prove useful or at least interesting! Now back to Adrian................ Adrian's Personal Experiences My very sincere thanks to Maris for sharing the above information and insights with us! Of course, this is quite revisionist stuff, particularly Maris's results achieved using ignition improver, which was not contemplated by the manufacturers of the Mite. In defence of the Mite's designers, the use of ignition improvers was poorly understood in 1946, even in Europe. It's to be doubted that any of their contemporaries anywhere had a much better understanding of fuels for small model diesels. Even so, their design was potentially quite capable of keeping up with an Arden .099 on spark ignition, using the original fuel formula on the right day. The advertising gives the impression that competing successfully with the Arden was exactly what the Mite was designed to do! The incorporation of variable compression would have gone a long way towards ensuring that every Mite .099 would achieve good results in all weather conditions and with a reasonable range of propellers. Turning now to my own example, I had to look way back in the model engine log that I’ve kept since the 1970’s to find a record of my previous experience with this engine. My example appears almost new and is certainly unmounted. Unlike Don Howie’s engine, it has a perfect piston/cylinder fit. I acquired it way back in May 1981 from a now-unrecalled source, probably a MECA swap meet (no eBay back then!).

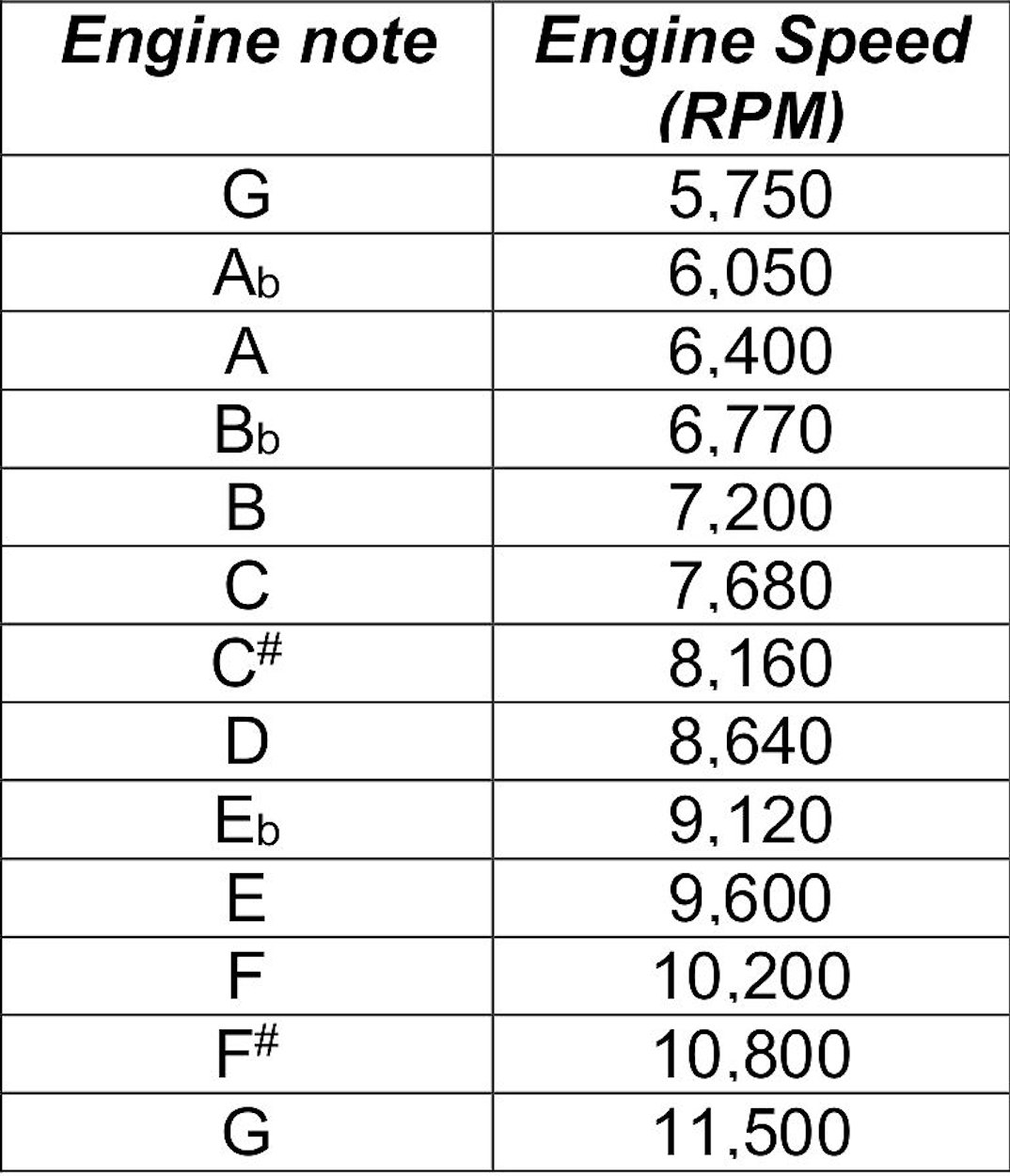

I still use a harmonica today to estimate airborne RPM from the centre of the circle. If you have a good musical ear for matching notes and detecting the quarter-tones, this method actually gives pretty good results to within a few hundred RPM. In case anyone's interested, I've attached a table of note/speed equivalents. When you get to the octave above any given note, simply double the indicated speed. The two G's in the table at the left give an example of this principle. I found that the lightest load on which the engine would run smoothly using the maker’s recommended 50/50 fuel was an 8x8 Top Flite wood prop, which just happens to be the flight prop recommended by the manufacturer. Running on that prop was extremely smooth and consistent. On an 8x6 I found that the engine would run OK but showed unmistakable signs of under-compression using the maker’s fuel mix. I was sure that a bit of kerosene and ignition improver would have extended the engine’s upper speed range by generating more heat, but I never tried it back then. Maris's previously-reported test results have clearly demonstrated the effectiveness of this approach. I recorded the fact that the Mite would hit a G note exactly on the 8x8 Top Flite wood prop that I was using. Reference to the above table shows that this equates to 5,750 RPM – not actually a bad figure for a diesel of this displacement on that rather parasitic airscrew. If that prop were an APC 8x8 (which it isn’t), this would represent an output of around 0.048 BHP. The old Top Flite wood prop probably drew more power, implying a somewhat higher output than this at that speed. The engine got well past 6,000 RPM on the 8x6, but had developed an under-compression misfire which of course could not be cured. One point which I did note in relation to these long-ago tests was the issue of the prop mounting system. I commented earlier upon the inadequacy of the design, mainly due to the configuration of the taper used to locate the prop driver. My long-ago notes record the fact that I had endless trouble with the prop coming loose during starting. Maris Dislers confirmed that he and Don Howie had similar problems. I tried to get around these problems by making up a threaded stud which would screw into the female thread in the front of the crankshaft to full thread depth. I could then use a conventional nut and washer for prop retention. It was my feeling that this would allow the prop to be more securely fastened than was possible with the standard prop bolt. It would also be far kinder to the internal thread in the crankshaft. Sadly, this measure didn't resolve the problem. The grip of the prop driver on the shaft is insufficient to prevent the shaft from turning inside the prop hub and prop driver when trying to really tighten the prop. Because of this, the work that I did in making the replacement stud was of relatively little use in tightening the prop, although it was undoubtedly far kinder to the internal thread of the crankshaft. The engine maintained its habit of backfiring the prop loose. Aggravating, to say the least ....... Reading my notes from all those years ago, I decided that the test results obtained by Maris will have to suffice to inform this article. I have less frustrating ways to spend my time than fighting with a recalcitrant prop driver! Rearguard Action - the Glo-Mite

The problem with this variant was the fact that even with the extra combustion chamber volume represented by the glow plug cavity, the resulting compression ratio was still too high for glow-plug operation. According to David Janson, the consequent pre-ignition resulted in the engines blowing their head seals with monotonous regularity. Can't have been very kind to the working components either ......

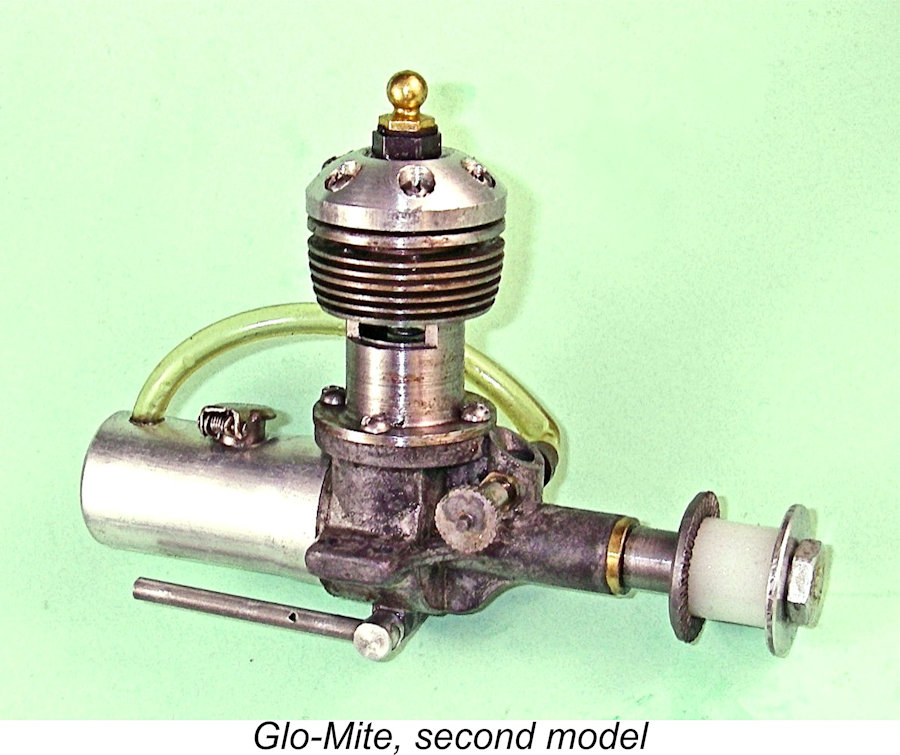

I noted earlier that the name of the company which marketed this variant was changed from the earlier Mite Manufacturing Co. to Mite Distributing Co., although the address remained the same - 257 Water Street, Brooklyn 1, New York, USA. The advertising trail proves that this company name change had unquestionably been implemented by mid 1948. Although by no means definitive, there is a strong suggestion here that the renamed company was no longer involved with actual manufacturing. It seems possible, and perhaps even likely, that the Glo-Mites were simply conversions of already-existing unsold diesel models. A major problem which continued to plague the Mite was its higher price relative to its major competitors. And things were only getting worse - Arden must have knocked the stuffing out of the Mite venture in mid 1949 by reducing the price of their .099 BB glow-plug model to only $8.75. The more or less concurrent appearance of the $7.95 McCoy .098 glow-plug model did absolutely nothing to help. By December 1949 the price of the diesel Mite remained fixed at $12.50, but the Glo-Mite had been reduced to only $7.95, presumably to compete with the Arden and McCoy glow-plug models as well as address the threat from the OK Cub .099. As already recorded, the introduction of the Glo-Mite fell short of allowing the company to remain in operation. In 1950 the entire Mite project was taken over the Mercury Model Co., also of Brooklyn, who spent the next ten years selling off the remaining Mite physical assets. The last examples were sold off in the late 1950’s at a price of only $6.00. The Second Model Glo-Mite on Test

An examination of this engine was quite revealing. The revised cylinder head yielded a measured compression ratio of around 8 to 1 - far more conducive to successful glow-plug operation. In addition, the piston had been shortened to create a sub-piston induction period of around 46 degrees (23 deg. each side of TDC). This change alone might be expected to produce a far more lively runner. In all other respects, the engine appeared to be identical to its diesel progenitor. The Glo-Mite instructions recommended the use of an 8x4 prop for free flight and a 7x6 for control line. Based upon the results of Maris's testing, both of these prop sizes would over-prop the engine to a degree. There was no specific fuel recommendation - any fuel which was commercially available at the time was said to be suitable.

The engine proved to be an instant starter provided an exhaust prime was administered as a preliminary. The instructions actually mentioned this requirement. Response to the needle was all that could be desired, while the control held its settings perfectly. Having established a fairly fast rich setting, I put on 20 minutes' running time. At the end of this, the engine felt absolutely perfect. I could see no point in continuing the break-in, so I switched to testing mode using a fuel containing 10% nitro as recommended by Maris. The Glo-Mite continued to start and run perfectly throughout - it was a real pleasure to test! The far lower starting torque and reduced tendency to backfire combined to more or less eliminate the problems with the prop driver coming loose. Running actually improved at the higher speeds, while vibration levels remained well within acceptable limits at all times. The following data were collected:

As can be seen, the factory second model Glo-Mite outperformed Maris's home-grown version by a very substantial margin. On the 10% nitro fuel, it developed around 0.114 BHP @ 12,500 RPM, actually topping the original diesel model for good measure. There's little doubt in my mind that the sub-piston induction contributed significantly to this result, as did the 10% nitro.

All in all, the Glo-Mite proved to be a user-friendly engine with a very competitive performance by 1949 standards. What prevented it from achieving higher levels of commercial acceptance was almost certainly its higher-than-average price. Those purchasers from the late 1950's who acquired their engines at only $6.00 undubtedly got value for their money! Conclusion Over the years, a certain amount of folklore has attached itself to the Mite diesel. For one thing, it’s generally been referred to as having appeared in 1947. In reality, the facts that examples were demonstrated at the August 1946 Witchita Nationals and that a media test of the engine was completed and published by February 1947 makes it all but certain that the Mite actually made its debut in mid to late 1946 after a development period which began in early 1946.

The other view of the Mite which seems to have acquired some credibility in the minds of many model engine aficionados is that it was a somewhat over-rated performer. I hope that Maris Dislers has dispelled this view quite comprehensively through his test results reported in this article. The Glo-Mite was certainly well up to par with the other .099 glow-plug models available in 1949. Perhaps the Mite's most important legacy was the influence which it clearly exerted over Leroy Cox when designing his iconic Cox ½A engines during the 1950's. The cylinder porting and ball-and-socket conrod configuration of the Mite were carried over wholesale to the Cox designs, as was the all-steel piston/cylinder combination. A very significant legacy indeed! While a variable compression head plus a redesigned prop mounting system might have worked wonders for the little Mite, the fact remains that it was a very impressive performer indeed by late 1946 standards. Viewed as a direct contemporary of the highly-regarded Mills 1.3 Mk. 1 Series 2 which appeared almost simultaneously in Britain, there’s no contest – the Mite was simply streets ahead in terms of both its technical design and its level of performance. In addition, the Glo-Mite simply buried contemporary British glow-plug engines of similar displacement such as the FROG 160 and the Allbon Arrow. So hats off to Howard Manderville and his associates Walt Schroeder, Bill Seidel and Norm Rosenstock! Together they produced a genuine American classic which is well worth remembering! ______________________ Article © Adrian C. Duncan, Coquitlam, BC, Canada First published June 2019 Revised December 2022 Second revision June 2023 - addition of Glo-Mite test

|

||

| |

Here I'll collaborate once again with my good mate Maris Dislers to take a close look at the Mite .099 diesel, one of the often-overlooked and somewhat under-valued American diesels dating from the brief period during 1946-1947 when American manufacturers and modellers alike were taking a serious interest in model diesels. This phase was not destined to last – Ray Arden’s introduction of the commercial miniature glow-plug in November 1947 very quickly swept all further consideration of diesels off the table as American manufacturers and modellers immediately gravitated en masse to the new form of ignition.

Here I'll collaborate once again with my good mate Maris Dislers to take a close look at the Mite .099 diesel, one of the often-overlooked and somewhat under-valued American diesels dating from the brief period during 1946-1947 when American manufacturers and modellers alike were taking a serious interest in model diesels. This phase was not destined to last – Ray Arden’s introduction of the commercial miniature glow-plug in November 1947 very quickly swept all further consideration of diesels off the table as American manufacturers and modellers immediately gravitated en masse to the new form of ignition. We must also recall the notorious efforts of the Gotham Hobby company of New York who did the diesel cause in America a great disservice by taking over what had been a perfectly sound product in the form of the original 1947

We must also recall the notorious efforts of the Gotham Hobby company of New York who did the diesel cause in America a great disservice by taking over what had been a perfectly sound product in the form of the original 1947  1947 at least equalled and possibly exceeded the number of their contemporary counterparts in the diesel stronghold of Britain. Given this fact, it’s really easy to find oneself wishing that Ray Arden had been a year or two later in perfecting and marketing the commercial miniature glow-plug – given a few more years to take root, diesels might well have gained as much acceptance in America as they did in the rest of the world, and American manufacturers might have continued to carry the diesel torch for quite a while with very positive results.

1947 at least equalled and possibly exceeded the number of their contemporary counterparts in the diesel stronghold of Britain. Given this fact, it’s really easy to find oneself wishing that Ray Arden had been a year or two later in perfecting and marketing the commercial miniature glow-plug – given a few more years to take root, diesels might well have gained as much acceptance in America as they did in the rest of the world, and American manufacturers might have continued to carry the diesel torch for quite a while with very positive results.  When researching the Mite story, I began as always by going to my valued and much-missed late friend and mentor Tim Dannels for advice regarding source material. Somewhat to my astonishment, Tim replied that this is one of the few American engines which has never been covered in any detail in the pages of Tim’s invaluable “

When researching the Mite story, I began as always by going to my valued and much-missed late friend and mentor Tim Dannels for advice regarding source material. Somewhat to my astonishment, Tim replied that this is one of the few American engines which has never been covered in any detail in the pages of Tim’s invaluable “ As of 1945, when aeromodelling activity resumed in the USA following the conclusion of WW2, spark ignition engines remained dominant in American aeromodelling. The model compression ignition technology which had been steadily evolving in Europe since 1938 was still virtually unknown in America. However, this began to change shortly after the conclusion of WW2, when returning US servicemen started bringing European diesels back home with them in increasing numbers.

As of 1945, when aeromodelling activity resumed in the USA following the conclusion of WW2, spark ignition engines remained dominant in American aeromodelling. The model compression ignition technology which had been steadily evolving in Europe since 1938 was still virtually unknown in America. However, this began to change shortly after the conclusion of WW2, when returning US servicemen started bringing European diesels back home with them in increasing numbers. Although there is presently no firm evidence for this, it’s possible that our main subject, the Mite .099 cuin. diesel, was also inspired by a similar personal importation from Europe. Reference to Adrien Maeght's outstanding book ”

Although there is presently no firm evidence for this, it’s possible that our main subject, the Mite .099 cuin. diesel, was also inspired by a similar personal importation from Europe. Reference to Adrien Maeght's outstanding book ”

Being an eastern USA production, the Mite naturally found the majority of its purchasers in its geographic area of manufacture. Relatively little usage and related commentary is on record which might help to gauge its acceptance out west. A number of these engines undoubtedly did find their way to the west coast, and there are a handful of "testimonials" about those Mites, mostly expressing reservations about power and dependability over the engines’ lives.

Being an eastern USA production, the Mite naturally found the majority of its purchasers in its geographic area of manufacture. Relatively little usage and related commentary is on record which might help to gauge its acceptance out west. A number of these engines undoubtedly did find their way to the west coast, and there are a handful of "testimonials" about those Mites, mostly expressing reservations about power and dependability over the engines’ lives.

As usual, we’ll start with a few vital statistics. The Mite was a plain bearing fixed compression crankshaft front rotary valve (FRV) compression ignition ("diesel") engine utilizing reverse flow scavenging. Bore and stroke were both 0.500 inches (12.70 mm) for an actual calculated displacement of 0.098 cuin. (1.61 cc). The engine weighed a checked 2.96 ounces (84 gm) complete with tank and fuel tubing, a figure somewhat in excess of the weight of 2.75 ounces cited by “Air Trails” tester Alan Ortof but still not out of line for an engine of its displacement. The fixed compression ratio was set at 13.5 to 1 – a very marginally low figure for a diesel.

As usual, we’ll start with a few vital statistics. The Mite was a plain bearing fixed compression crankshaft front rotary valve (FRV) compression ignition ("diesel") engine utilizing reverse flow scavenging. Bore and stroke were both 0.500 inches (12.70 mm) for an actual calculated displacement of 0.098 cuin. (1.61 cc). The engine weighed a checked 2.96 ounces (84 gm) complete with tank and fuel tubing, a figure somewhat in excess of the weight of 2.75 ounces cited by “Air Trails” tester Alan Ortof but still not out of line for an engine of its displacement. The fixed compression ratio was set at 13.5 to 1 – a very marginally low figure for a diesel. With the fore-and-aft transfer flutes used in the design, it was obviously necessary to ensure that the wrist pin could not move fore or aft out of its bosses to foul the transfers. The Mite designer got around this very simply by eliminating the wrist pin altogether! The upper conrod bearing was a ball and socket combination – another feature which Cox was later to adopt. In the case of the Mite, this feature was probably adopted from the earlier Arden designs.

With the fore-and-aft transfer flutes used in the design, it was obviously necessary to ensure that the wrist pin could not move fore or aft out of its bosses to foul the transfers. The Mite designer got around this very simply by eliminating the wrist pin altogether! The upper conrod bearing was a ball and socket combination – another feature which Cox was later to adopt. In the case of the Mite, this feature was probably adopted from the earlier Arden designs.

The Mite diesel has been the subject of two previously-published tests over the years. The first was the aforementioned report in the February 1947 issue of “Air Trails”. The author of this report was Alan Ortof.

The Mite diesel has been the subject of two previously-published tests over the years. The first was the aforementioned report in the February 1947 issue of “Air Trails”. The author of this report was Alan Ortof. My good mate Maris Dislers was involved in the reported testing and was most willing to share his experiences with me. He confirmed that two examples of the Mite were tested for Don’s article. One was owned by Bill Britcher. Bill’s engine was tested at his home using a 3-part fuel mixture consisting of ether, kerosene and synthetic oil. Using this fuel, the engine was found to suffer from a chronic misfire when running, probably (in my own opinion) at least partially due to the use of synthetic oil at a proportion which was too low in any case. The best that it could manage was 5,600 RPM on an 8½x4 Bolly Clubman prop and 5,300 RPM on an APC 9x4 (around 0.028 BHP).

My good mate Maris Dislers was involved in the reported testing and was most willing to share his experiences with me. He confirmed that two examples of the Mite were tested for Don’s article. One was owned by Bill Britcher. Bill’s engine was tested at his home using a 3-part fuel mixture consisting of ether, kerosene and synthetic oil. Using this fuel, the engine was found to suffer from a chronic misfire when running, probably (in my own opinion) at least partially due to the use of synthetic oil at a proportion which was too low in any case. The best that it could manage was 5,600 RPM on an 8½x4 Bolly Clubman prop and 5,300 RPM on an APC 9x4 (around 0.028 BHP). Test 1:

Test 1: Test 2:

Test 2: Glo-Mite test:

Glo-Mite test: Diesel Mite - modern fuel

Diesel Mite - modern fuel Curiosity had led me to run the Mite on a number of occasions over the two months following its acquisition, during which time I put some 45 minutes of running time on it with no mechanical problems. I had no tachometer in those far-off days, using the old “match the note to the piano” approach to measuring speeds. In the field, I used a harmonica – far more portable than my Mum’s concert grand!

Curiosity had led me to run the Mite on a number of occasions over the two months following its acquisition, during which time I put some 45 minutes of running time on it with no mechanical problems. I had no tachometer in those far-off days, using the old “match the note to the piano” approach to measuring speeds. In the field, I used a harmonica – far more portable than my Mum’s concert grand!  Since Maris included some testing of his home-brewed version of the Glo-Mite, I thought that I should include a little history of this variant. I noted earlier that a serious effort was made in mid 1948 to produce and promote a glow-plug version of the Mite to stem the rising tide that was then submerging the diesel Mite. By July 1948 the diesel and glow-plug versions of the engine were being advertised together, as seen in the attached advertisement from that month's issue of "Model Airplane News". Note that this is one of the advertisements which claims that the diesel Mites had been "showing their superiority" for "over 2 years" as of the date of the advertisement!

Since Maris included some testing of his home-brewed version of the Glo-Mite, I thought that I should include a little history of this variant. I noted earlier that a serious effort was made in mid 1948 to produce and promote a glow-plug version of the Mite to stem the rising tide that was then submerging the diesel Mite. By July 1948 the diesel and glow-plug versions of the engine were being advertised together, as seen in the attached advertisement from that month's issue of "Model Airplane News". Note that this is one of the advertisements which claims that the diesel Mites had been "showing their superiority" for "over 2 years" as of the date of the advertisement!

A few years after the publication of this article in 2019, I was lucky enough to acquire a pristine NIB example of the second version of the Glo-Mite. This example was complete with its box and papers, seemingly being unrun apart from its factory test (assuming that such tests were still being conducted by this time). It was fitted with an unused Arden glow-plug, which was apparently standard equipment for this engine, also sporting a stamped metal tank.

A few years after the publication of this article in 2019, I was lucky enough to acquire a pristine NIB example of the second version of the Glo-Mite. This example was complete with its box and papers, seemingly being unrun apart from its factory test (assuming that such tests were still being conducted by this time). It was fitted with an unused Arden glow-plug, which was apparently standard equipment for this engine, also sporting a stamped metal tank.

Maris analysed my data using his own protocols and compared the Mite's performance with that of an

Maris analysed my data using his own protocols and compared the Mite's performance with that of an  This undoubtedly adds credibility to the otherwise somewhat shaky contemporary media claim that the Mite was the “first” American diesel. However, we can now see that although the development of the Mite did indeed commence at a very early date (possibly preceded only by the prototype

This undoubtedly adds credibility to the otherwise somewhat shaky contemporary media claim that the Mite was the “first” American diesel. However, we can now see that although the development of the Mite did indeed commence at a very early date (possibly preceded only by the prototype