|

|

Connecticut Curios - the Gilbert Thunderhead Engines

All kidding aside, I may as well come clean and admit that this is one of those reviews which I undertake from time to time purely for my own interest and pleasure, spurred on in this case both by plain old curiosity and by a sense of an injustice to be righted. I say this because the subjects of the article, the Gilbert glow-plug engines of the early 1960’s, are almost universally ignored by present-day model engine enthusiasts and collectors. It’s only the more eccentric aficionados like me who take any interest. This unjustified lack of appreciation is something which I hope I can change to some extent through the publication of this article. To be honest, I’m not entirely sure why these units command so little attention and respect. True, they were over-manufactured in the hundreds of thousands, consequently still surviving today in as-new condition in extremely large numbers. As a result, they are completely lacking in any semblance of a “rarity” cachet. In addition, they are most definitely budget-category sports engines rather than performance powerhouses. Even so, these engine possess a widely under-appreciated combination of unusual design characteristics and a top-drawer pedigree which one would think would draw more attention to them. They’re also highly practical classics to actually use, being far better made than many people realize in addition to having levels of performance which belie their seemingly retrograde design.

Moreover, the engines combined the side-port induction system with a screw-in cylinder. This was a highly original concept which required some very clear “out of the box” thinking to realise. The end result was one of the most free-breathing sideport induction systems developed anywhere at any time. The Gilbert engines have been covered previously in an excellent article by Bob Pelfrey which appeared in September 2005 in issue no. 173 of Tim Dannels’ indispensable “Engine Collector’s Journal" (ECJ). I’ve made frequent reference to that article in developing my own text. My sincere thanks to both Bob and Tim! Like all model engine ranges, the Gilbert marque has its own background story which is by no means devoid of interest. In order to fully appreciate that story, it’s necessary first to trace the history of the company which instigated the production of these engines - the A. C. Gilbert Company. Background - the A.C. Gilbert Company

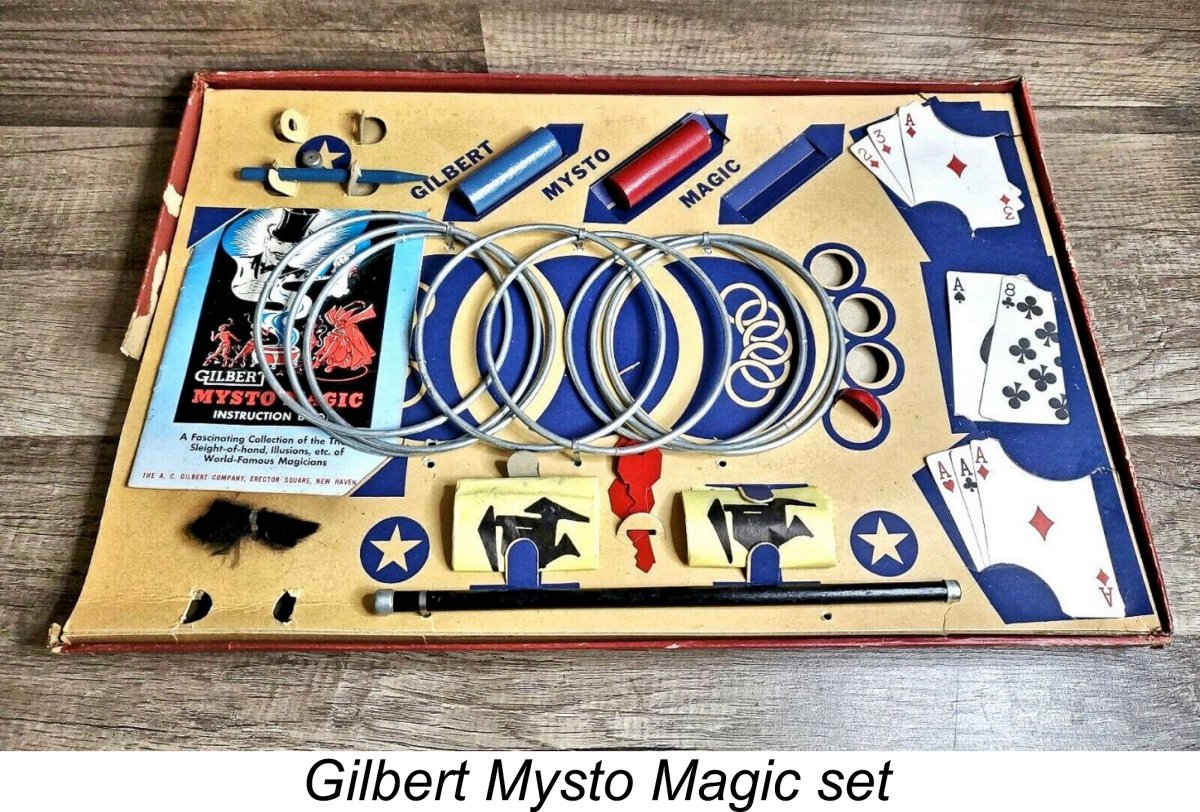

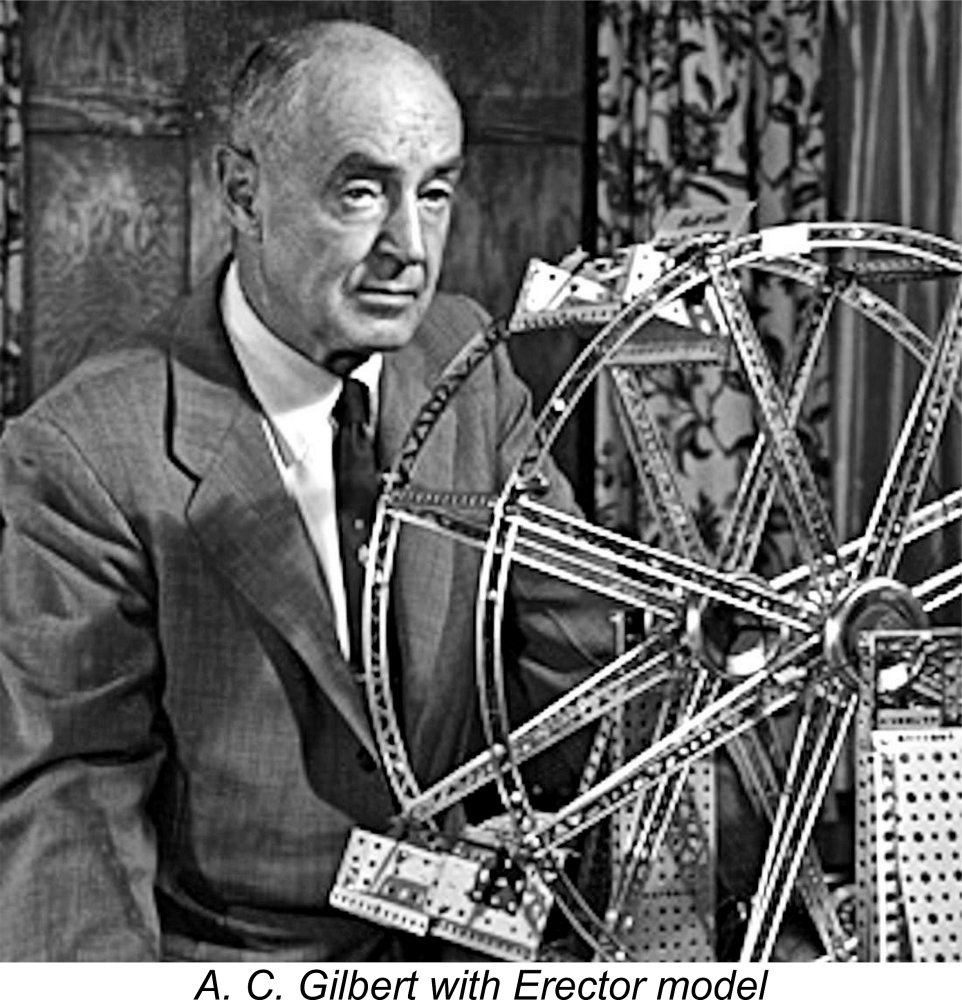

As if this wasn’t enough, Gilbert also earned a degree in sports medicine from the Yale Medical School in New Haven, Connecticut, to which he transferred from Pacific in 1903, necessarly relocating to New Haven in the process. He paid his way through college in part by working as a magician. He was always known both to family and friends as just plain “A.C.”, eschewing the use of his given name. Gilbert was far more interested in becoming established in business on the basis of his own inventions than in pursuing a medical career. In 1907 at the age of only 23 years this led him to join with his friend John Petrie in establishing the Mysto Manufacturing Company in Westville, Connecticut (an upscale west-side suburb of New Haven) to produce and market high-quality The Mysto company struggled somewhat during its first few years. The breakout came in 1913 when Gilbert introduced the first of the Erector construction sets for which he was to become famous. Contrary to Gilbert’s own claims, this was not his own invention. Frank Hornby of Liverpool, England had created the first Meccano construction sets as early as 1898, patenting the concept in 1901. It appears that Gilbert became aware of Hornby’s very successful and extremely popular invention while competing and training in England prior to the 1908 London Olympics. After working through the production challenges, he introduced essentially the same system to the North American market under the Erector label. In doing so, he clearly drew very heavily on Hornby’s invention, although he never admitted that very obvious fact. The means by which he evaded Hornby's patent remain unclear.

Whatever the ethics involved with the Meccano-Erector connection, from that point the business took off. The growing scale of operations quickly prompted a move from Westville to more suitable premises at 123 Fox Street in the Fair Haven district of eastern New Haven. At the outset, the Erector sets were marketed by the Mysto Manufacturing Company, as shown in the attached advertisement from the November 21st 1915 issue of “Sunday Magazine”. However, Gilbert had already parted ways with his partner John Petrie by that time, subsequently changing the corporate name to the A. C. Gilbert Company in 1916. Despite this change, production of the Mysto magicians’ equipment continued by that name alongside that of the Erector sets. At the same time, Gilbert relocated the company's operations once more from Fox Street to far larger premises at the nearby intersection of Blatchley Avenue and Peck Street, still in the Fair Haven district of eastern New Haven. The company was to remain at this location for the next half-century until its final closure. The Peck Street complex in which many of the company's products were manufactured still exists today (2021), being known as Erector Square. It now serves a variety of non-industrial uses. One of Gilbert’s more noteworthy business accomplishments was his successful 1918 campaign against the US government’s idea that toy-making should cease in order to allow the industry's facilities to be turned over to war production - at the time, America was deeply embroiled in WW1, the outcome of which was then still very much in doubt. This episode earned him the popular contemporary media title of “The Man who Saved Christmas”. It was the subject of a 2002 TV movie of the same title, in which Gilbert was very capably portrayed by Jason Alexander. Unfortunately, the movie took a number of significant liberties with the true facts, including sanitizing Gilbert’s character, ignoring the Meccano connection, omitting any mention of his original partner John Petrie, playing up a close relationship with a brother whom he later fired, omitting his two daughters and his elder brother entirely and featuring a son who wasn’t even born in 1918! However, the movie remains highly entertaining, undoubtedly capturing the spirit of the event.

In the latter half of the 1930s, the Gilbert company continued to expand, producing household products and small appliances including mixers, desk fans, milk shake machines, toasters, stoves with ovens, and washers. However, Gilbert’s first love was always toys. In 1938 he purchased the struggling “American Flyer” line of model trains, re-designing the entire product line to feature 1:64 scale trains running on three-rail S gauge track but retaining the “American Flyer” brand name. At the same time, Gilbert introduced a line of HO trains, which were primarily marketed under the brand name “Gilbert HO”.

By this time the Gilbert company had become by far the largest employer in New Haven, employing more than 5000 workers in three shifts at its Fair Haven manufacturing facility from the early 1930’s to the late 1950’s. After the war ended, Gilbert went back to producing toys, introducing model trains running on two-rail S gauge track in 1946. Other products followed, including a line of science-oriented items such as home laboratory kits, microscopes and telescopes. One of Gilbert's science kits, the Atomic Energy Lab of 1950-51, included a Geiger counter and several genuine radioactive samples - try that one today! A. C. Gilbert nominally retired in 1954, turning over the reins to his 35 year old son Al (1919 - 1964) and publishing his autobiography “The Man who Lives in Paradise”. It is from this book that much of Gilbert’s “legend” originates - basically, he created it himself and no-one bothered to check! Suffice it to say that he wasn’t quite the saint that he made himself out to be...................

A major problem for the company at this time was the fact that the interests and aspirations of American youth were entering a period of profound change. The advent of TV distracted them from hobby activities, while the beginnings of the Space Race diverted attention away from traditional toys like trains and Erector sets towards more futuristic pursuits. The Gilbert company was slow to pick up on these trends and respond to them appropriately. The end result was that their product lines began to stagnate, causing them to fall increasingly behind the steadily evolving products of other manufacturers. Basically, the company had lost both its edge and its way ahead. A. C. Gilbert died in January 1961 at age 76, having accumulated over 150 patents during his lifetime. This left Al Gilbert finally in charge in his own right. However, things had reached a rather dire point by then, with the company losing money every year and being forced to enter into a period of downsizing. It was at around this time that some bright spark on the company’s staff noted the tailor-made fit between the “American Flyer” name which had long been applied to the company's model trains and the then-vibrant Ready-To-Fly (RTF) model airplane business. A decision was taken that the A. C. Gilbert company would enter the RTF model airplane field in competition with the likes of Wen-Mac, Cox and Aurora with their own “American Flyer” range. It’s clear that from the outset they intended to do so using their own engines. Development and Manufacture of the Gilbert Engines

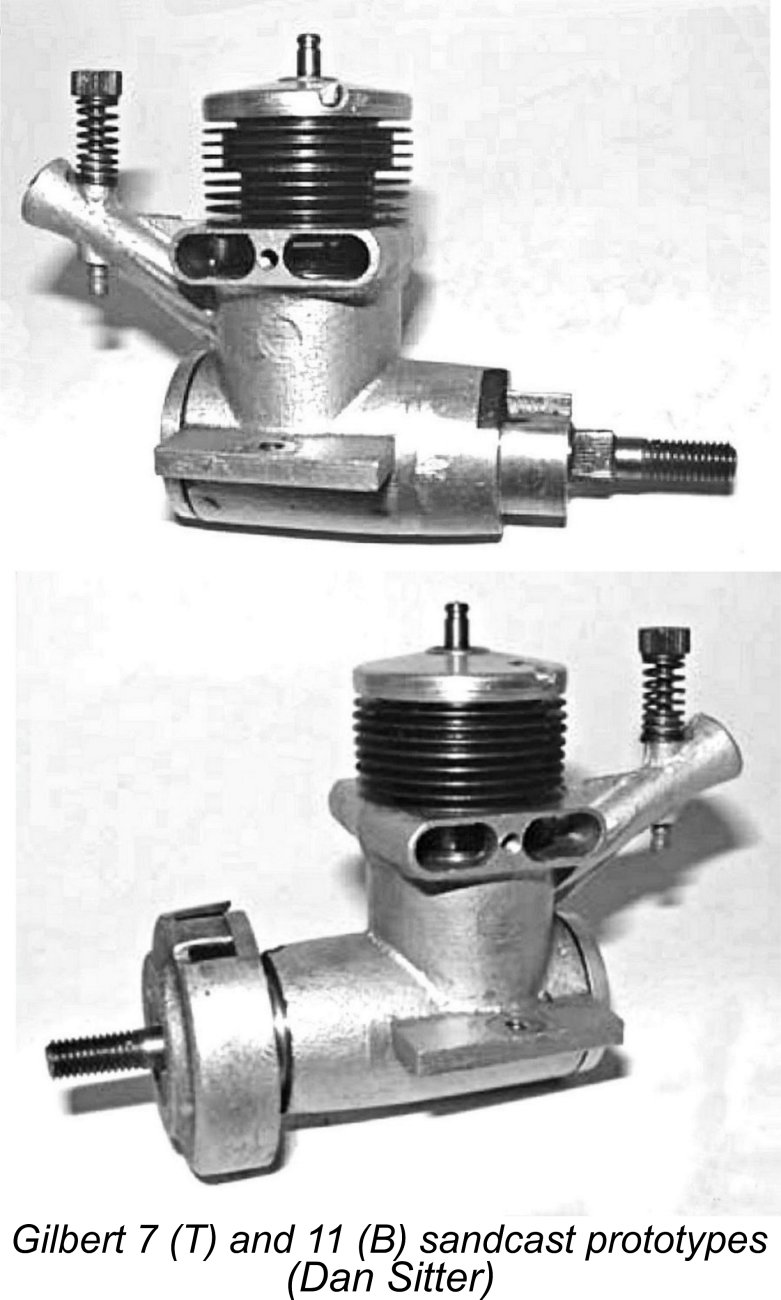

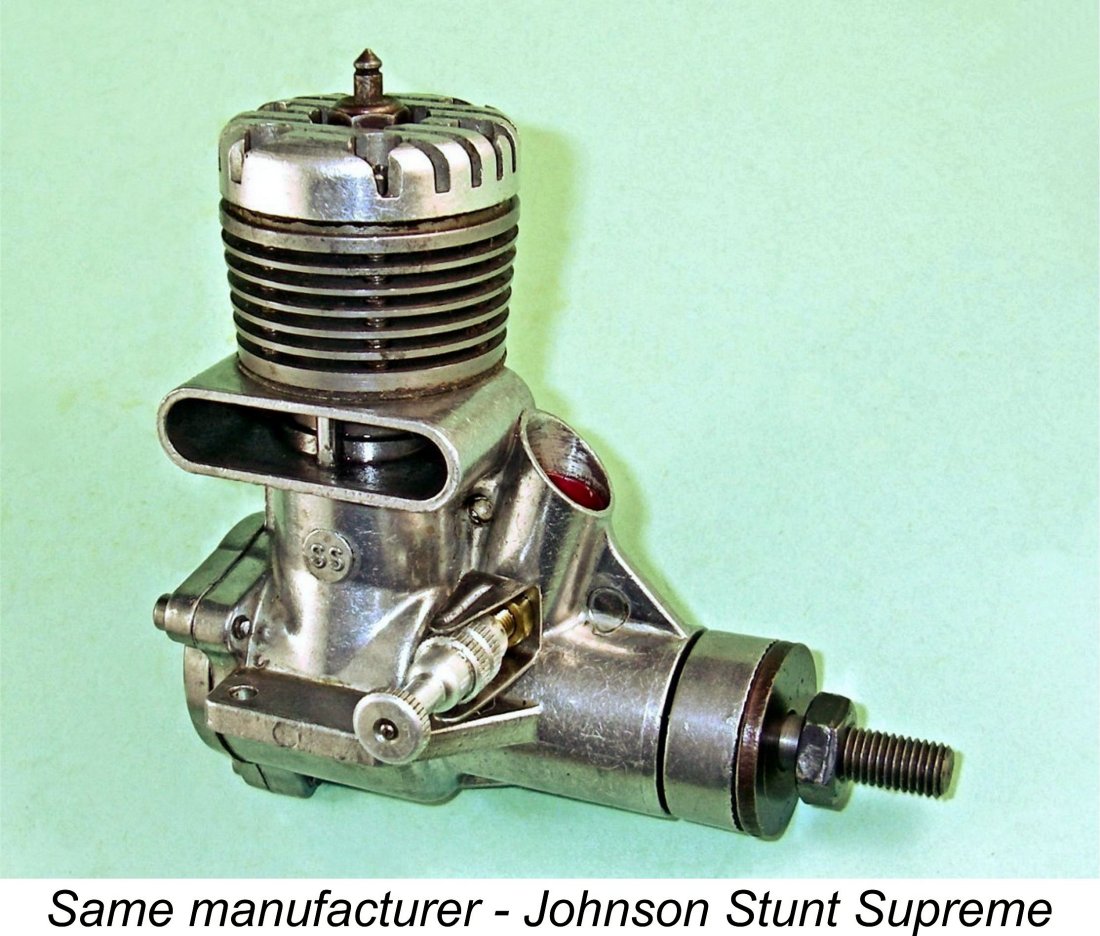

The Gilbert engines were designed by Hi Johnson and Bob Holland, who was then working for Johnson following the latter's takeover of the Holland Hornet line. Design input also came from Clarence Lee and Duke Fox. The majority of the actual RTF models were designed by Bill Effinger of Berkeley Models fame. No lack of applicable expertise here! The original prototype engines were produced using sand-castings. These prototypes were sent to Clarence Lee for his review and approval, which was evidently forthcoming. Once the design had been found to pass muster, pressure dies were created to allow series production to commence. The intended use of the engines in RTF applications was made clear from the outset by the fact that the beam mounting lugs on both models lacked the usual four clearance holes to accept the mounting fasteners. Instead, each lug had a single tapped hole which could be used to secure the engine in an RTF model with a pair of machine screws inserted from below. If the engine was to be used in regular "hobby" service with the fasteners inserted from above in the usual way, it would be necessary to drill out these holes to clear the fasteners or perhaps even to go all the way and drill four new clearance holes in the convertional locations. There was ample space to do this. It's very clear from the character of the design which emerged that the specification provided by Gilbert included requirements that the engines had to be both very The handling qualities of the engines will be discussed below - suffice it to say for now that the requirement for easy starting was fully met. The steeply downdraft angle of the induction tube was doubtless dictated by the need to facilitate access to the needle valve in a typical RTF installation. Even so, the needle was well protected against crash damage. It’s unclear why side-port induction was chosen to be a key design feature of the Gilbert engines. However, that decision completely explains Duke Fox’s involvement, which doubtless stemmed from his previous experience with side-port glow-plug engines through the development and production of his surprisingly good 1.6 cc Fox Rocket .09 model of 1959. This unusual side-port Chinn confounded all expectations based on the engine’s side-port induction by finding an excellent “sports” output of 0.112 BHP at the remarkably high speed (for a side-port) of 14,000 rpm, using a fuel containing 20% nitro. He also found the engine to be remarkably easy to start, with first-flick starts being the order of the day throughout his testing. It was doubtless Fox’s achievement of these characteristics that drew attention to the potential use of side-port induction in the Gilbert RTF engines, also leading to Duke Fox’s involvement in an advisory capacity. Apart from his input to the design, Fox also produced the glow heads for the Gilbert engines at his main factory in Fort Smith, Arkansas, since he was already set up to do so from his Rocket .09 venture.

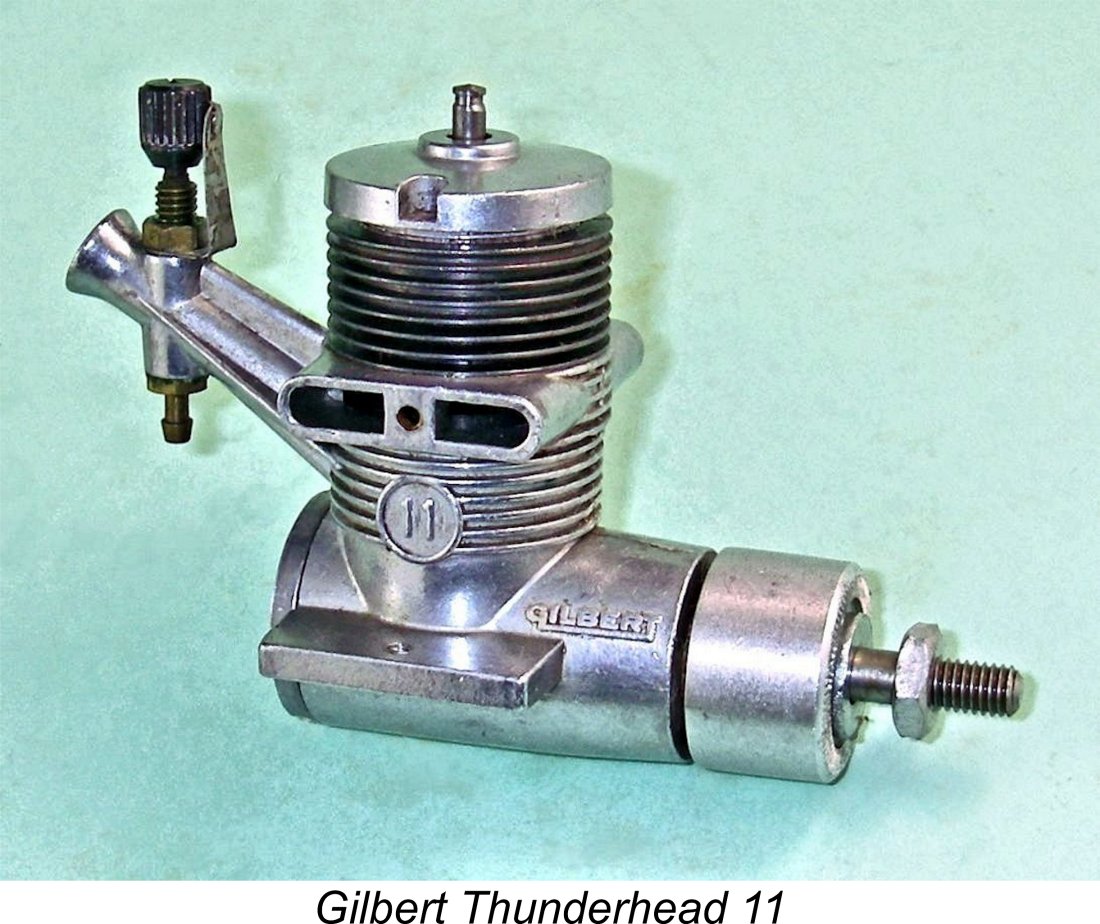

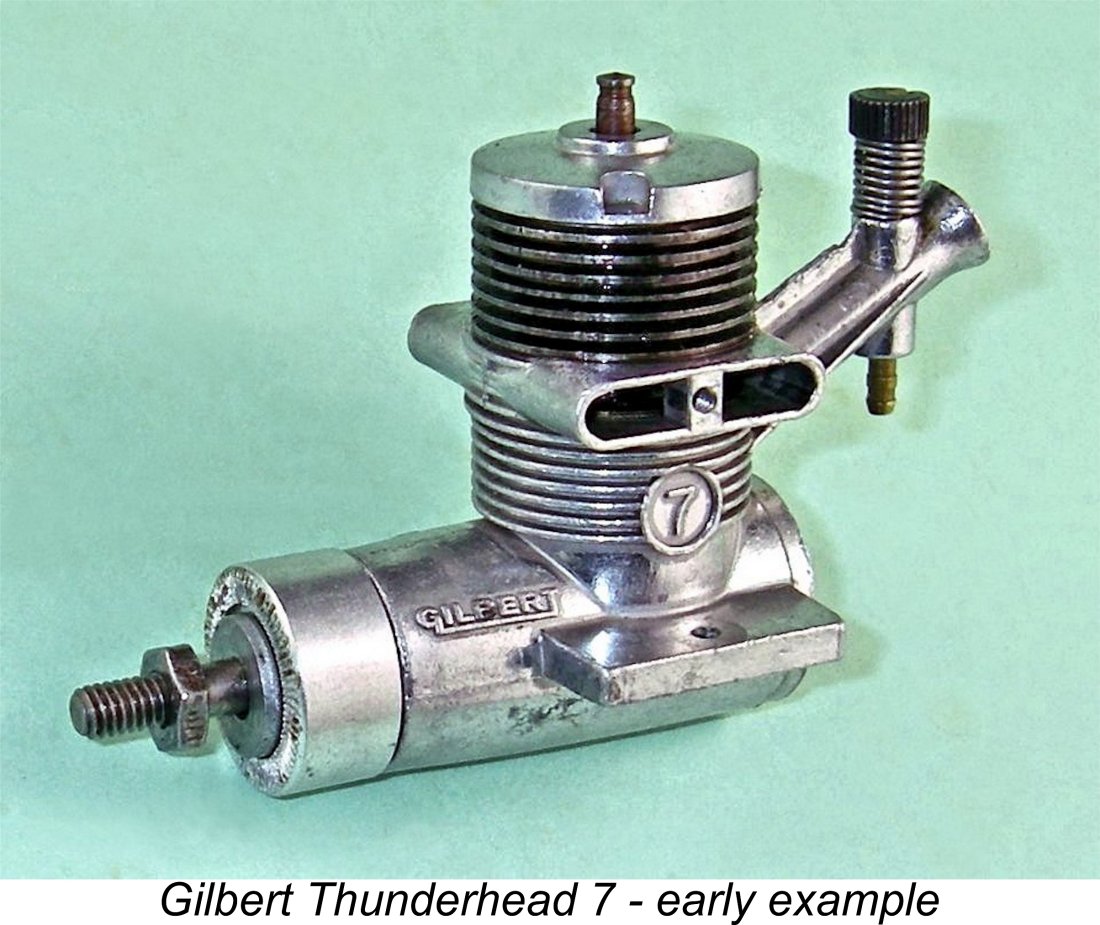

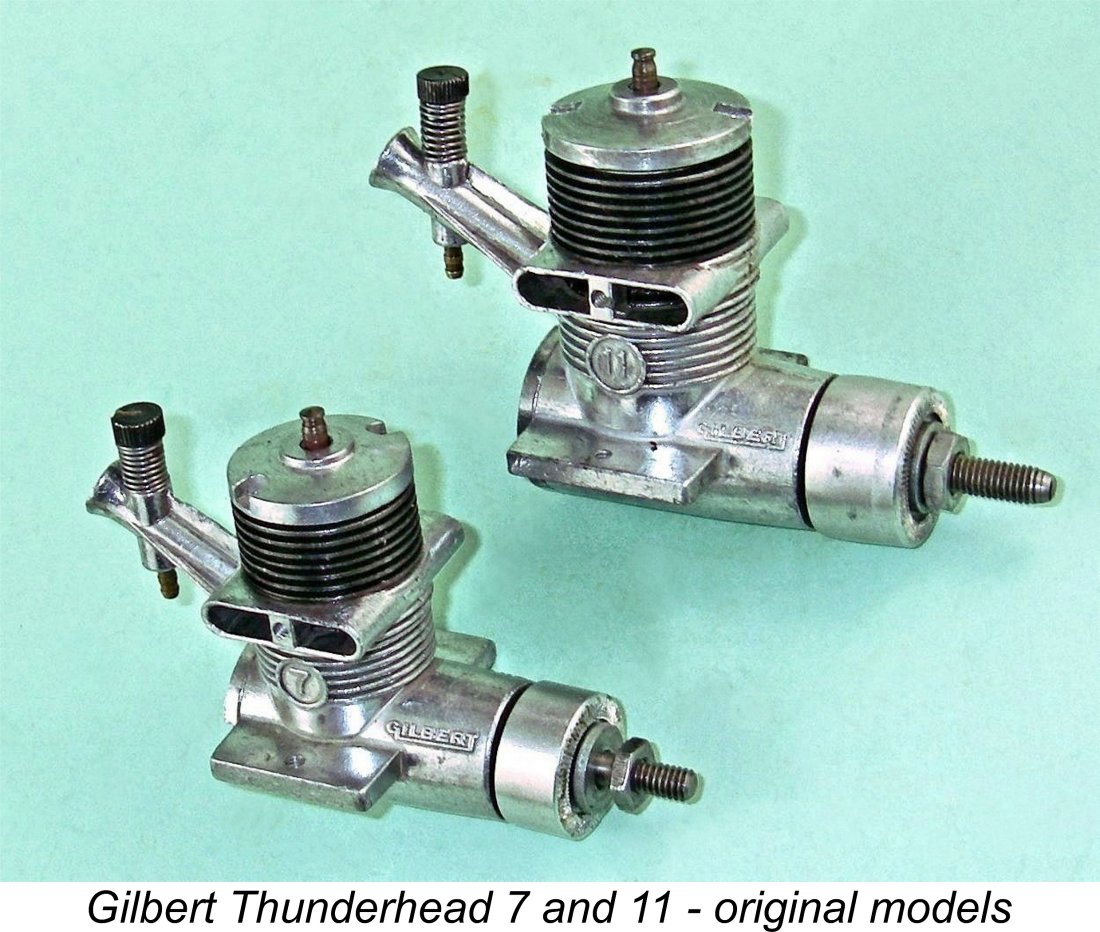

The engines appeared in two nominal displacements - 0.074 cuin. and 0.110 cuin. I say "nominal" because both of these figures are wide open to question - see further discussion below. Regardless, the two models were marketed respectively as the Gilbert Thunderhead 7 and 11 models. Production at Dynamic Models commenced in the latter part of 1961, and the engines were officially unveiled in the “World of Transportation” section of the Gilbert company’s 1962 catalogue.

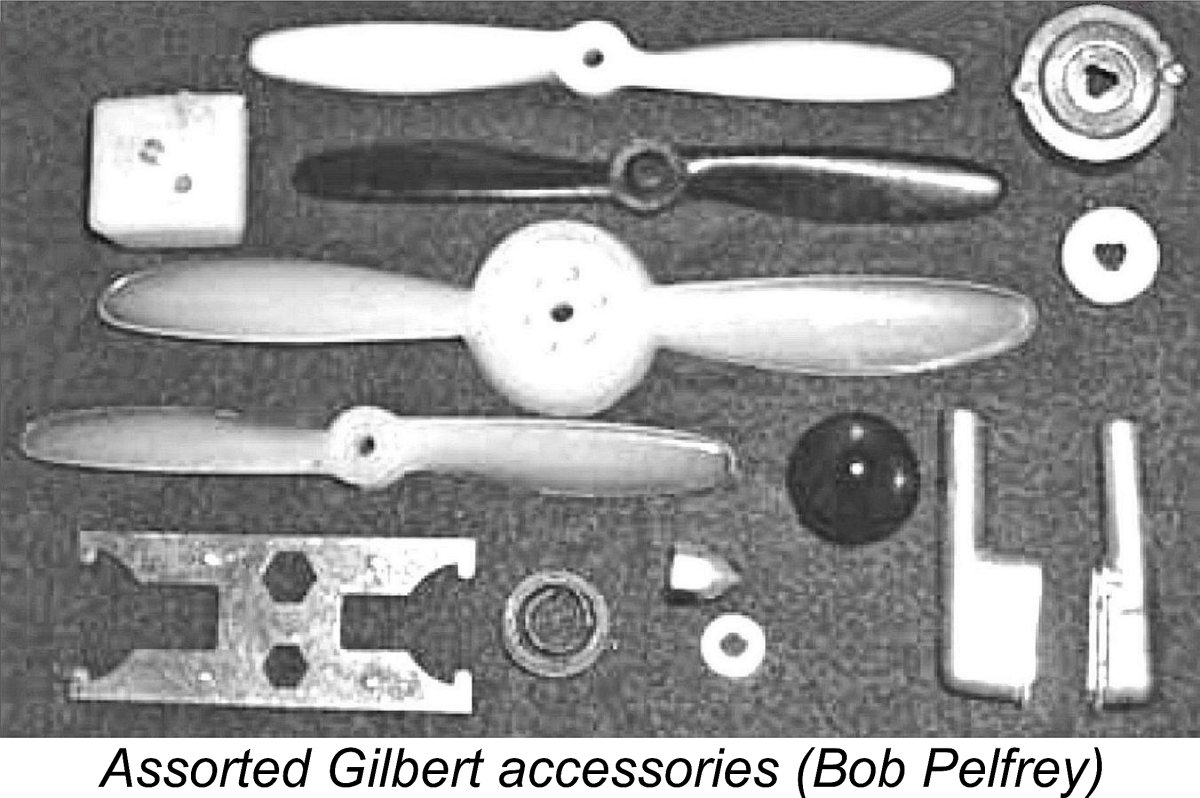

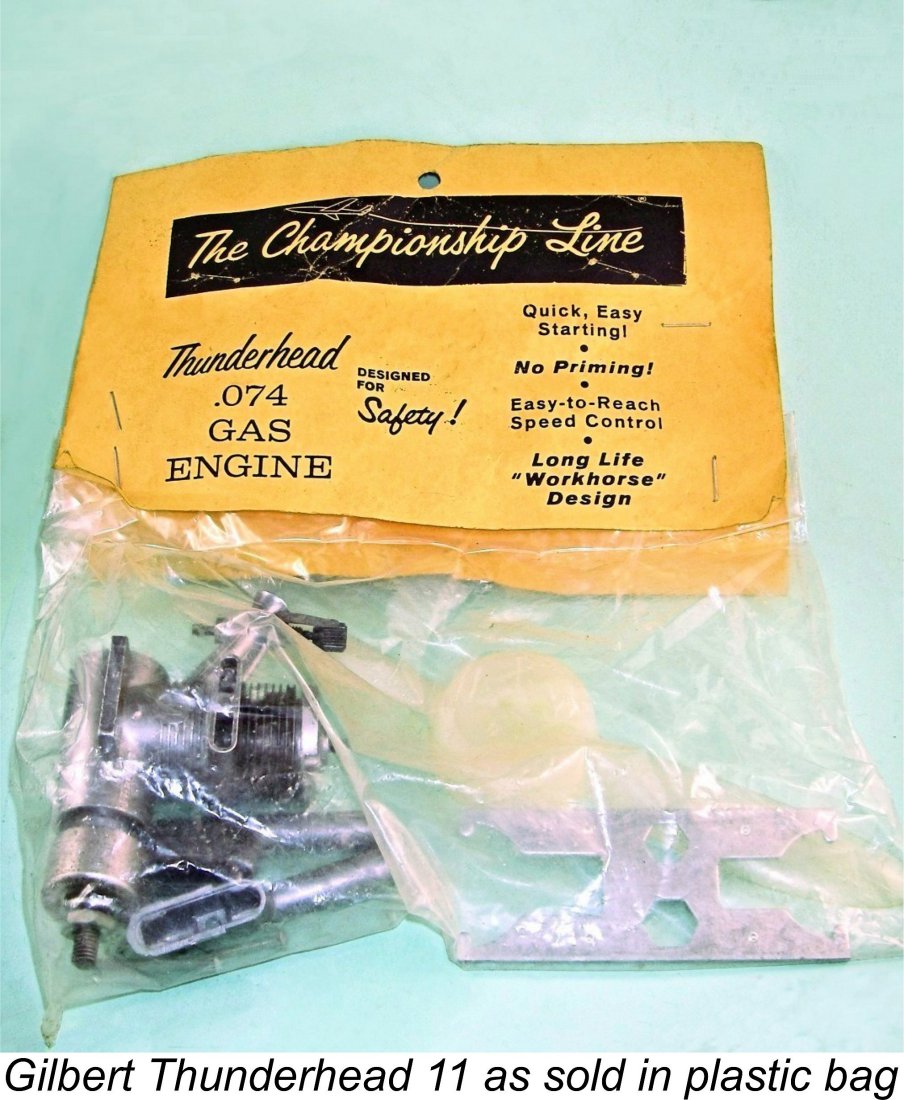

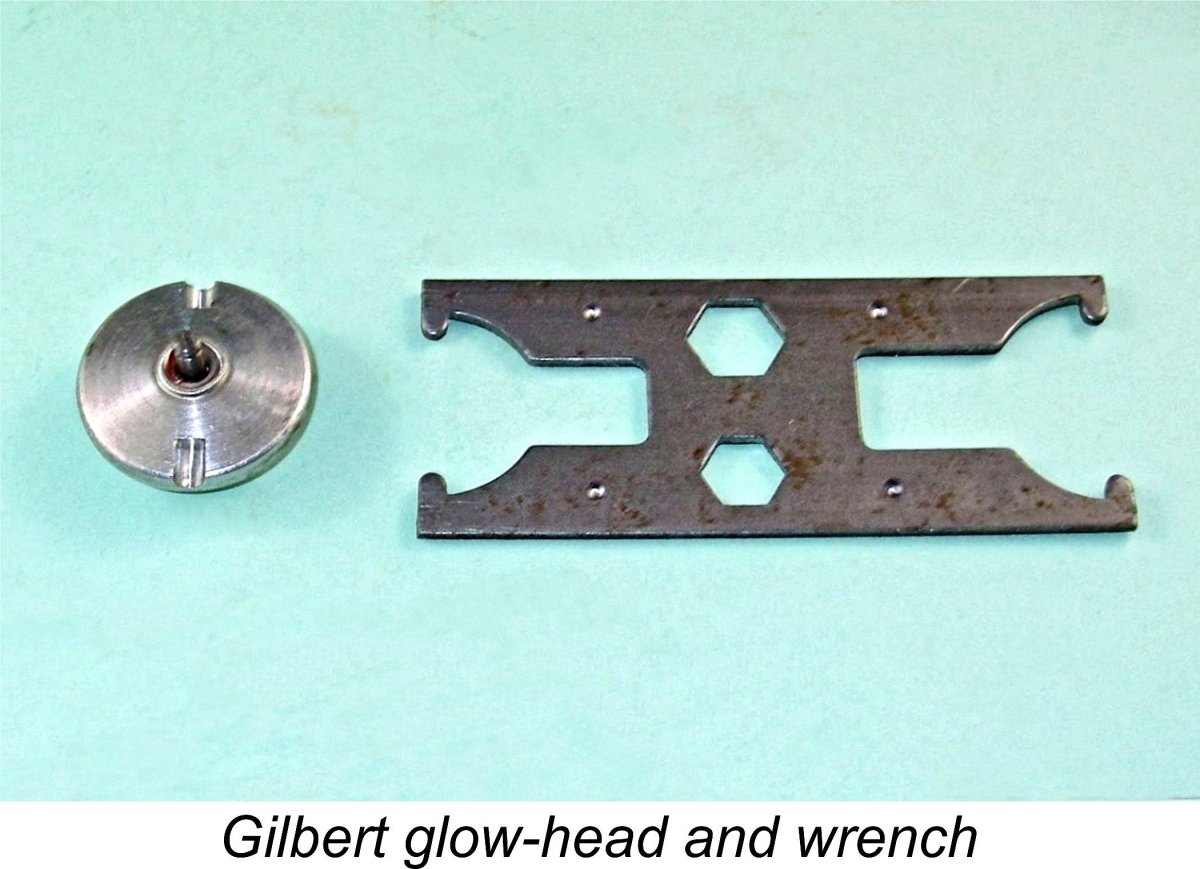

In addition to the many examples installed in RTF models, Gilbert sold individual “hobby” engines packaged in plastic bags with an instruction sheet plus a variety of accessories. These included spare glow heads, universal wrenches, matching airscrews, nylon fuel tanks, several different muffler styles and spring starters (to a design by Bill Effinger which he patented in 1963). All of the cases were notched on both sides of the main bearing housing at the front to allow the engagement of the starter spring, even on those examples that weren’t fitted with starters.

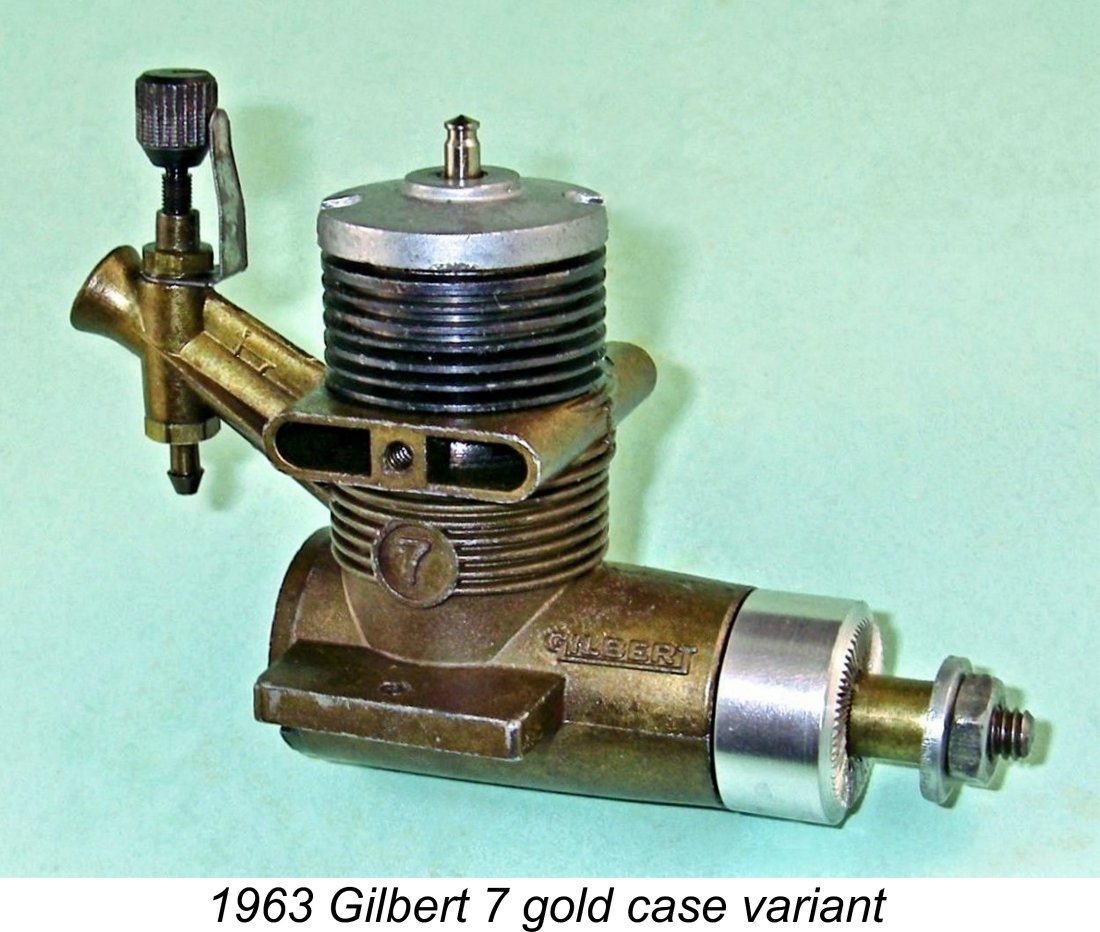

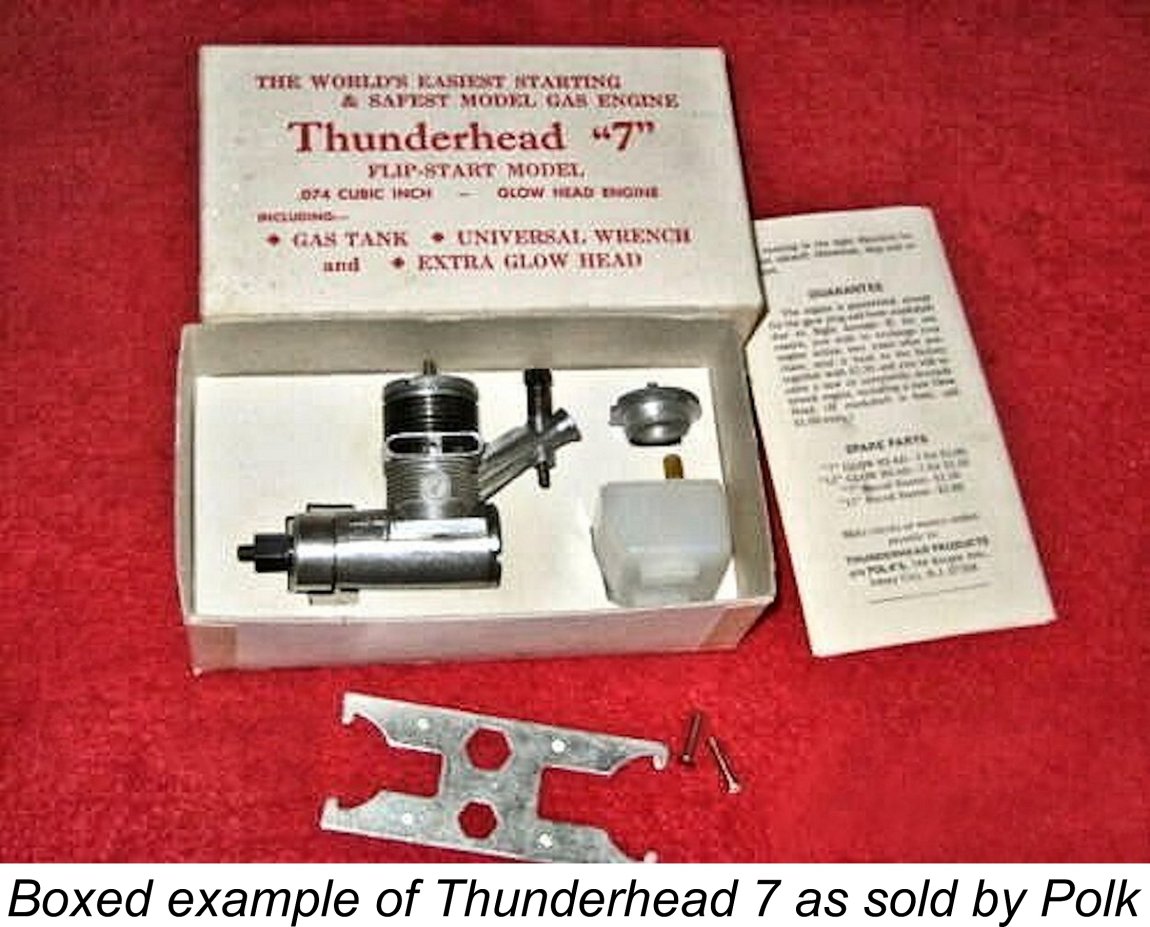

Unfortunately, it turned out that Dynamic were unable to produce the more widely-used .07 model at a rate which met Gilbert's expectations. This led to the creation of new dies and the transfer of the manufacturing of the .07 model to Gilbert’s own New Haven, Connecticut plant. However, all of the .11 models continued to be made at Dynamic. Bob Pelfrey reported that the .07 engines made by Gilbert are readily distinguishable from those produced by Dynamic. The Gilbert-made units have an additional starter spring notch at the very front of the main bearing in the 12 o’clock position. They also have the later three-piece needle valve set-up using separate components which screw independently into an expanded installation In 1963, a series of examples of both the .07 and .11 models were produced with “gold” coloured crankcases. There was a rumour that this was done in recognition of the 50th anniversary of the A. C. Gilbert Company, but the date is wrong. It’s actually far more likely (albeit unproven) that it was done to mark the 50th anniversary of the introduction of the Erector sets - the date is right for that. Or perhaps it was merely a cosmetic change intended to boost already-flagging sales. Regardless of the reason, casting alloys generally don’t anodize well, so the “gold” colour may well have been produced by other means. Certainly, experience shows that it quickly fades to a rather unattractive muddy brown colour. Despite what appears to have been a genuine effort to produce RTF models and engines of above-average quality, events proved that the Gilbert “American Flyer” Al stayed on as Chairman of the Board (a purely nominal position), but sadly died in 1964 of a brain tumor at age 45. He only outlived his father by three years. He was thus spared from seeing the end of the company upon which the fortunes of his family had rested for so long. Jack Wrather proved to be the wrong man to resuscitate the company, viewing it as just one minor element among his many business investments. He appears to have paid relatively little attention to its resuscitation, while those efforts that he did make to revive the company all failed. In late 1963 he reached an agreement with a toy inventor and promoter named Marvin Glass whereby Gilbert would buy Glass’s inventions and promote them on TV. Unfortunately, the assassination of President John F. Kennedy on November 22nd, 1963 At the same time, the Quaker Oats Company agreed to sell A. C. Gilbert's products on consignment. However, they failed miserably, returning a disastrous backlog of unsold merchandise to the company. Simultaneously, Wrather put both time and money into a proposed alliance with Pepsi Cola to jointly promote their products on TV. However, this effort too never came to fruition. The outcome was inevitable - by 1967, the A. C. Gilbert Company was history after 51 years in business by that name. Stephen D. Goldberg of the University of New Haven has written a compelling analysis of the reasons why the A. C. Gilbert Company failed to maintain its standing in the marketplace, only outliving its founder by a few years. It seems that the company provides a textbook case study of the reasons why less than 30% of family-owned companies make it to second-generation ownership, while only around 10% survive into third-generation ownership. Well worth reading if you have the time - interesting stuff! As of 1965, two years before the end, it had already become clear that the Gilbert model airplane venture was doomed to fail. Production had ceased altogether in 1964 and the remaining model aircraft assets (including the engines) were sold off, most of them ending up with Polk’s Modelcraft Hobbies of New York.

Polk thus acquired an extremely large inventory of completed engines and unassembled components, running well into the multiple tens of thousands. These engines were subsequently sold by Polk in a variety of packaging, both boxes and plastic bags. The price was $5.00 a crack. In all cases, the engines sold by Polk included their own Polk instruction sheet and guarantee. In addition, they were apparently all accompanied by a combination wrench, a nylon fuel tank and a spare glow However, it appears that the completed engines had been assembled using castor oil lubricant as a preservative. Over time, this hardened through polymerization into the castor gum that all collectors know and love! It's a superb long-term preservative, but the engines become totally seized up given enough time. The resulting need to unfreeze and clean each and every engine caused Polk to deem it economically impracticable to continue to market them. I know from personal experience that dismantling a really well gummed-up example of one of these units can present quite a challenge! As a result, large numbers of new un-run Thunderheads apparently languished in Polk’s warehouse for years. Eventually Polk began to move them along in bulk to parties having an interest in selling them as The supply of the Thunderhead units appears to have been strangely sporadic in the present millennium. The engines appear for a while in considerable numbers and then disappear once more. When they re-appear, they are generally being sold by different individuals. It seems that the presumably diminishing remaining stocks are periodically changing hands en masse and being released for sale in batches. There’s no way of knowing how long this will last. All that can be said is that new or as-new examples still appear frequently on eBay and elsewhere at very reasonable prices. Having traced the production and marketing history of the Gilbert Thunderhead engines, it’s now time to take a look at the engines themselves. The Gilbert Thunderhead 7 and 11 Models - Description

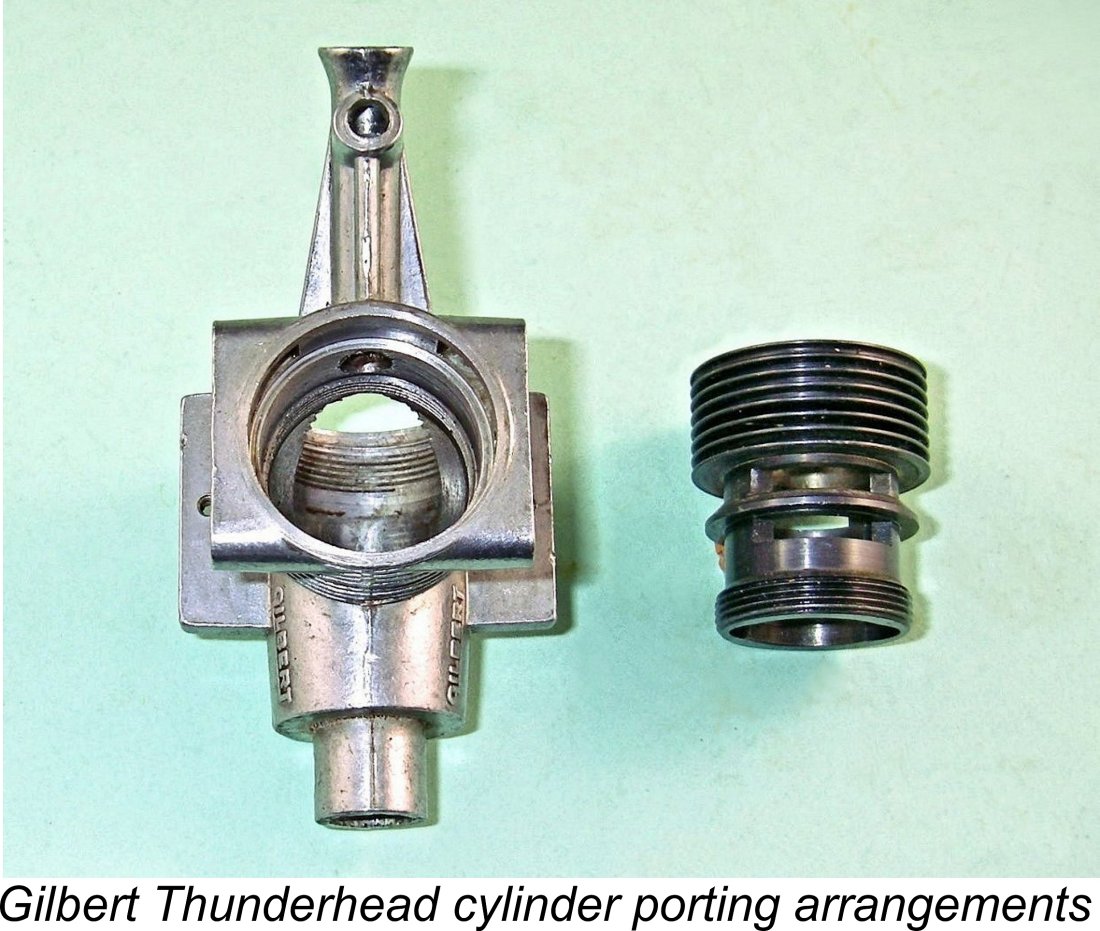

Given their distinct displacements, the working dimensions of the two models are necessarily different. However, this is an area in which there has been considerable confusion in the past. In his "Global Engine Review" published in the 1963 "American Modeler Annual", Peter Chinn gave bore and stroke figures of 0.472 in. (11.99 mm) and 0.400 in. (10.16 mm) respectively for the Gilbert 7, yielding a correctly-stated calculated displacement of 0.070 cuin. (1.147 cc) exactly. In their 1963 "Plans Handbook" listing of the world's model engines, "Aeromodeller" gave the same figures. This being the case, it's rather odd to have to report that the manufacturers themselves invariably referred to the Gilbert Thunderhead 7 as having a displacement of 0.074 cuin. (1.213 cc). Things get even weirder with the Gilbert Thunderhead 11, since Chinn cited the bore and stroke of that model as 0.582 in. (14.78 mm) and 0.450 in. (11.43 mm) respectively. Fair enough, but these figures yield a calculated displacement of 0.1197 cuin. (1.961 cc) as opposed to the figure quoted by Chinn in the same table of only 0.1097 cuin. (1.798 cc)! Go figure ..........Chinn clearly didn't! Once again, "Aeromodeller" quoted the same inconsistent numbers. The manufacturers always cited the displacement of this engine as being 0.110 cuin. exactly. So what's the true story? Only one way to find out - measure them up! When I did so, I found that the Gilbert Thunderhead 7 has actual bore and stroke dimensions of almost precisely those cited by Peter Chinn. Consequently, that model does indeed have a displacement of 0.070 cuin.(1.147 cc) as opposed to the 0.074 cuin. (1.213 cc) figure invariably cited by the manufacturer. I can think of no reasonable explanation for the discrepancy. The Thunderhead 11 model also measures up at Chinn's bore and stroke figures almost exactly. So my calculated displacement of 0.1197 cuin. (1.961 cc) is correct, making the Gilbert Thunderhead .11 a .12 in reality! Perhaps a case of the manufacturers inflating the engine's specific output by under-stating its true displacement - there are precedents. I've no idea how Chinn managed to get his incorrect displacement from those numbers. Possibly an uncaught editorial error?!? Or perhaps he merely took the manufacturer's word for it without checking the calculation. Thanks to their very substantial steel cylinders and sturdy crankshafts, both models are relatively heavy for plain bearing glow-plug units of their respective displacements. The Gilbert 7 weighs in at 2.68 ounces (76 gm), while the larger Gilbert 11 (as I will continue to call it despite the displacement discrepancy) tips my scales at a checked 3.60 ounces (102 gm). Once again Chinn blotted his copybook by quoting inaccurate figures of 1.6 ounces and 3.3 ounces respectively for the 7 and 11 models. "Aeromodeller" came closer on this factor, citing the weight of the Gilbert 7 as 2.6 ounces (near enough) while repeating Chinn's incorrect weight of 3.3 ounces for the Gilbert 11. I suspect that the first digit of Chinn's published figure for the Gilbert 7 was an uncaught editorial error. OK, end of the controversial bit! Generally speaking, the Gilbert engines are fairly typical smaller-displacement American glow-plug motors of their day, using a screw-in blued mild steel cylinder with thin integrally-machined cooling fins; a glow-head with integral element; a hardened steel piston and conrod; The very sturdy crankcase is a relatively complex pressure die-casting in some form of high-quality light alloy. It incorporates the steeply downdraft induction tube in unit along with the main bearing housing and the two exhaust stacks, one on each side. The stacks are provided with drilled and tapped central bosses to facilitate the fitting of the optional mufflers which were available for these engines. Because a screw-in cylinder is used, the designer had to figure out a way of arranging for the side-port induction system to function regardless of the orientation in which the cylinder ended up when tightened. It’s clear that Duke Fox took a hand here, because the system is basically that which he had used successfully in 1959 for his Fox Rocket .09 model. Indeed, one look at a Gilbert 11 alongside a Fox Rocket .09 makes the direct design relationship quite unmistakable. They may wear different clothes, but underneath they're virtually the same design.

This very ingenious arrangement provides an unusually open induction pathway by side-port standards, and one which is essentially unaffected by the orientation of the screw-in cylinder once it is sufficiently tightened. The overall result must surely be one of the most free-breathing side-port induction systems ever created. Well done, Duke Fox! Hopefully the attached image will clarify this description. The problem of how to provide transfer ports which do not communicate with the induction gallery is solved very simply by the creation of twin internally-machined bypass/transfer flutes in the relatively thick lower cylinder wall, one on each side of the cylinder between the twin exhaust ports. In effect, this is the Cox TD two-port bypass/transfer system, the effectiveness of which had been amply demonstrated by the early 1960's. The transfers overlap the exhaust ports to a significant degree. The Gilbert engines are effectively side-port Cox TD's! The effective functioning of the system is very much dependent on the sealing qualities of the cylinder installation threads. Since there's no location seat at this point, those threads cannot be sealed with a gasket even though they have to maintain separation between the lower crankcase and the induction gallery which is open to the atmosphere at all times. For this reason, they are cut to a very snug fit between the male and female threads. The construction is clearly effective - crankcase compression in these engines is outstanding. In fact, the crankcase volume is unusually small, resulting in quite high transfer driving pressures.

Like the Cox ball-and-socket joints, the Gilbert's small-end rod bearing can be re-set using an easily-made tool. One of my examples of the Gilbert 11 had an excessively loose rod about which I had to do something. I made the required tool by using a suitable centre drill to create a 60 degree tapered socket in the end of a length of steel rod and then creating a linear slot on one side a little wider than the conrod diameter at the ball end to allow the rod to lie over at an angle whiile the tapered tool is used with a hammer to tighten the bearing, rotating the tool slightly between blows. The tool, which is illustrated here, worked perfectly. The one-piece steel crankshaft has a heavily counterbalanced full-disc crankweb. It is very well supported in an integrally-cast unbushed front housing of substantial dimensions. Its lubrication is provided for by a vertical oilway cut into the upper front face of the crankcase. The fit is a little on the slack side, but that is not atypical of American small glow motor practise. As stated earlier, crankcase compression is more than adequate. In that regard, it's noteworthy that the shaft is solid throughout - the manufacturers resisted the temptation to drill it out to reduce weight. In this way, they minimized the working crankcase volume - a highly desirable objective.

At the rear, a conventional screw-in backplate is employed. A variety of needle valve assemblies were used, all in conjunction with an externally-threaded steel needle. The earliest models used a pressed-in spraybar with a coil spring for tension, but this was soon replaced by a transverse two-jet spraybar secured by a nut with a leaf spring “clicker” for tension. When Gilbert took over the manufacture of the .07 model, they introduced a third type of assembly featuring separate needle carrier and fuel jet components which screwed in from opposite sides. The latter two assemblies are both illustrated in the component view included earlier.

The .07 models produced by Gilbert with the separate screw-in needle carrier and fuel jet components also featured larger needle valve installation bosses as well as heavier stiffening webs on the top and bottom of the intake venturi tube. This revised configuration was also carried over to the .11 models still being made by Dynamic. Apart from the previously-mentioned spring starters, another optional accessory was a twin muffler set. This came in two distinct When Polk’s Modelcraft Hobbies took over the marketing function in 1965, they generally sold the engines with an extra glow head, a nylon fuel tank and a custom head wrench. They also included their own instruction sheets and their own guarantee. They offered the engines both with and without starters.

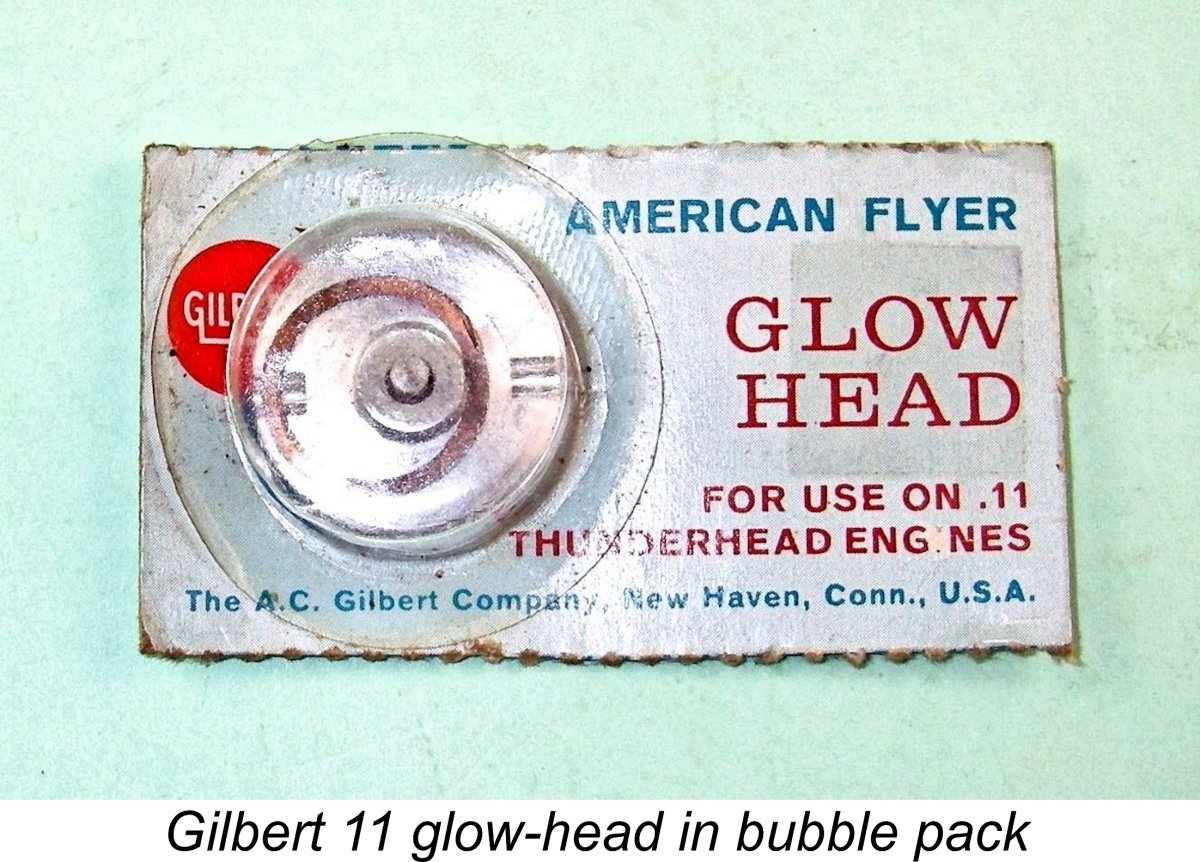

What I assume to be the later version follows the Cox pattern rather than the Fox design, as seen at the right in the image. This variant is machined all over as opposed to being cast. The combustion chamber is now hemispherical and the steel terminal post is now inserted from the top, being crimped in place once installed. This gives a far "cleaner" combustion chamber, albeit of quite different shape and yielding a lower compression ratio. In addition, the two indentations for the head wrench are now machined using a horizontal end mill rather than being cast. This makes it appear very likely, albeit presently unproven, that the manufacture of the Gilbert 11 glow heads had been taken up by someone other than Fox at some point. However, the heads themselves continued to be sold as Gilbert American Flyer components in bubble packs as illustrated below. Note that the head in this unopened pack is of the second (later) type. I have several other identical examples still in their bubble packs.

Up to this point in time, I've seen no evidence to suggest that the heads for the Gilbert 7 model were ever switched to the second type - all the heads that I've ever seen either installed on engines or as spares have been Fox-style components. If any reader has evidence to the contrary, please get in touch! It will be recalled that Fox made the original glow-heads for both Gilbert models. Perhaps as a result, the heads for the Fox Rocket .09 and the Fox .10 both fit the Gilbert .11 cylinders, and vice versa. Not owning a Fox .07, I haven’t been able to check to see whether or not a Fox .07 glow head fits the Gilbert .07 cylinder, but it seems possible. Can any kind reader check for me?!? Interestingly enough, the heads for the original Cox .15 models also fit the Gilbert .11 cylinder! For me, this makes Cox by far the most likely suspect for being the manufacturer of the revised Gilbert 11 heads - since Dynamic manufactured the Gilbert 11 engines all along, a switch to a local Los Angeles-area glow head manufacturer for that model would make perfect sense. In effect, the later Gilbert 11 heads were simply restyled Cox Olympic or Sportsman .15 components. Can any reader confirm this supposition?!? There have been a number of reports to the effect that the glow-heads supplied for these engines were somewhat variable in quality. We've seen that the heads for the Gilbert 11 certainly varied in terms of combustion chamber configuration and hence compression ratio. Some of them were reportedly too “cold”, Quite apart from any such issues, the supply of original replacement glow heads for these engines is obviously strictly finite. The user comments which appear below suggest that many owners expect to keep their engines going by simply drilling and tapping a burned-out head to take a standard ¼-32 glow-plug. Unfortunately, there's a major impediment to the direct application of this method to the earlier glow heads manufactured by Fox. As with other Fox glow heads, the element is mounted in a separate steel carrier which is inserted from below into a recess in the head, being located on a shoulder with a non-metallic washer to ensure a seal. The problem is that in the case of both .07 and .11 glow heads, this carrier has an outside diameter of 0.250 in.

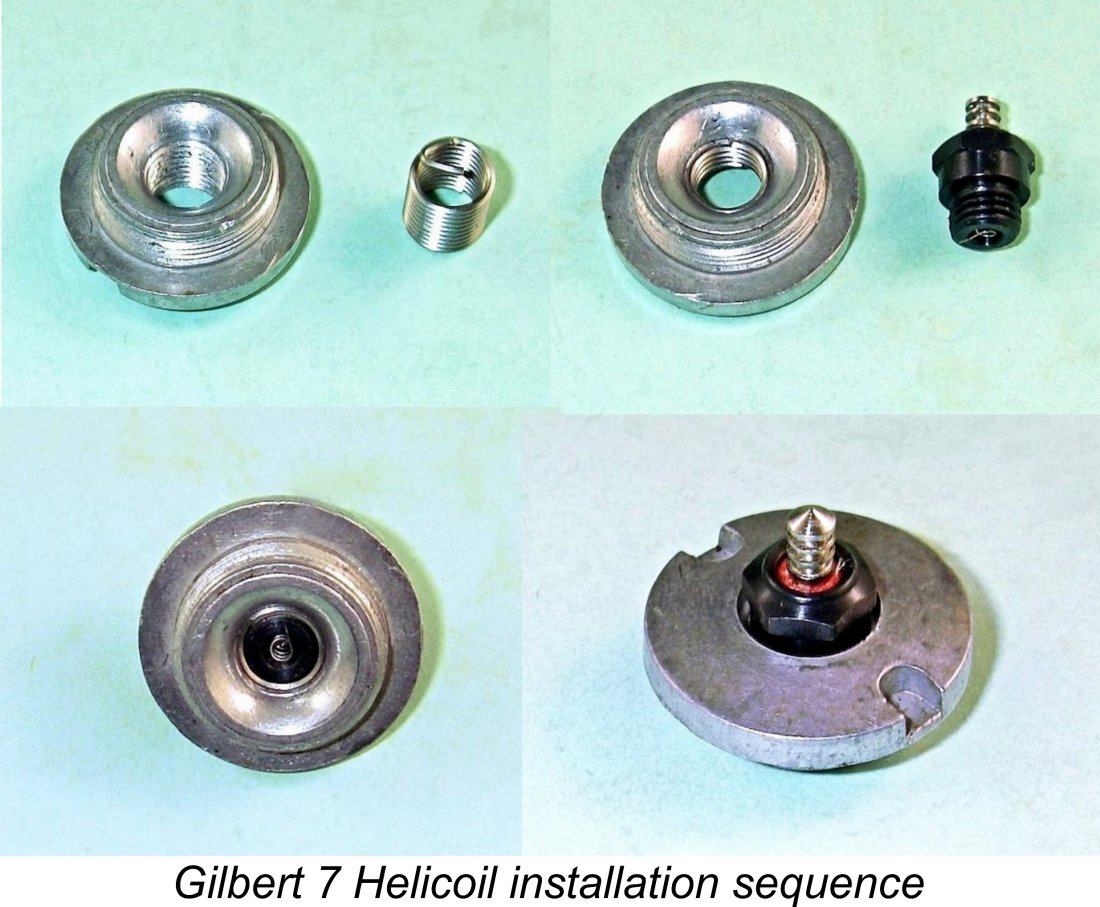

You can get around this by installing a ¼-32 Helicoil thread insert, which requires the preliminary drilling of a 6.5 mm (0.256 in.) diameter hole for installation - just over the size of the existing hole. The sequence is shown at the left. With a short-reach plug fitted, it's a nice-looking conversion which closely replicates the original head with its steel element carrier. However, it's an added complication which may put some people off. A limitation which is less amenable to resolution is the fact that the ¼ in. (6.35 mm) dia. hole is considerably in excess of the 5 mm diameter required to provide communication between the element of a Turbo glow-plug and the combustion chamber. Consequently, a standard Fox-type Gilbert glow head cannot be modified to accept a Turbo glow-plug. Of course, if you have a burned-out Gilbert 11 glow head of the second (Cox) type, either type of plug can be accomodated. You have to turn the protruding crimp off the top of the head and then push the central terminal out upwards away from the combustion chamber - the opposite of the Fox arrangement. Once that's done, it's a perfectly straightforward task to create a glow-plug installation hole to suit either type of standard plug. I have little doubt that the use of a Turbo plug would give the best results. My good mate Maris Dislers has written a very informative article on this subject which may be found elsewhere on this website.

A commercially-available option for the Gilbert 11 is the Turbo head made by Kamtechnik for the earlier Cox .15 engines - it fits the Gilbert perfectly. However, my own checks have suggested that the compression ratio with this head fitted will be too high for efficient operation at the design speeds of the rest of the engine. This is doubtless due to the Gilbert's domed piston crown as opposed to the flat crown of the Cox models. I would expect that it would be necessary to turn out some metal from the interior of the Kamtechnik head to enlarge the combustion chamber somewhat, taking care to stay well clear of the beautifully-machined Turbo plug socket. A frequently-encountered problem with both Thunderhead models is that of the entire cylinder unscrewing when one attempts to remove the glow-head. This is particularly likely to occur if you try to remove the head from a hot engine. The heat expands the light alloy head differetially to tighten it against its female installation thread in the steel cylinder, while that same heat causes the female cylinder installation threads in the alloy crankcase to expand away from the steel cylinder, hence loosening the fit.

The re-installation is quite straightforward - just screw the cylinder home with your fingers (avoiding crossed threads) and then install the head in the normal way. Tightening the head also tightens the cylinder. Of course, circumstances can arise when you actually need to remove the cylinder - a requirement to re-set the conrod ball-and-socket connection would be an example. In such cases, Sod's Law of Mechanical Perversity ensures that the head invariably comes off on its own, leaving the cylinder in place! AAAARRRRGGGGHHHH!@?! This situation is complicated by the fact that no provision is made in the form of accessible flats to apply a wrench to the cylinder. Please don't modify the cylinder or use a set of vice grips, even protected in some manner! I've seen far too many examples of these and other similarly-designed engines with graunched or filed cooling fins and/or distorted cylinders. The first thing to try in such a case is simply to give the engine a fast run to get it really hot, immediately after which the cylinder will often come out with the head still in place as mentioned earlier. If running the engine is not possible, an alternative is to heat the entire unit in an oven. Not too hot - you're not trying to cook it! just enough to create some differential expansion between the alloy head and case and the steel cylinder - around 150 -200 degrees Celcius usually works. This should cause the head to become tighter and the cylinder base threads to become looser. It will also soften any castor oil residues that may be gumming things up. The cylinder will now often unscrew with the head still firmly in place. After letting it cool, you can remove the head if necessary in the manner described above. I've had very good success in the past using both of these approaches. If this fails, a method that almost invariably works is the approach advocated way back in 1947 by the makers of the excellent D-E diesel conversion heads for the Arden engines. Take a scrap of 3/4 in. thick hardwood, cut it to a square shape around 2 in. per side (less for the 7 model) and drill a hole through its centre that is a fairly tight push fit on the cylinder. Cut a slot though the centre of one side all the way into the hole. Warm the case and then insert the cylinder (with the warm engine still attached of course) into the hole in the wood. Grip the assembly in a vice with the slot uppermost between the jaws. Tighten the vice, which will of course clamp the wood very tightly but uniformly all around the cylinder. Finally, apply torque to the engine to break the thread loose. You can use a large crescent wrench placed across the exhaust stacks to get a good purchase on the engine without causing any damage. This approach is extremely effective and doesn't mar or distort the cylinder in any way. In fact, it works equally well for other engines having screw-in cylinders. A useful tip ............. Now that we’ve looked at what makes the Gilbert engines tick, it’s finally time to see how they run! This is the bit that I really enjoy………….although I’m a diesel man at heart, a whiff of burning nitro never comes amiss! The Gilbert Thunderhead Engines on Test

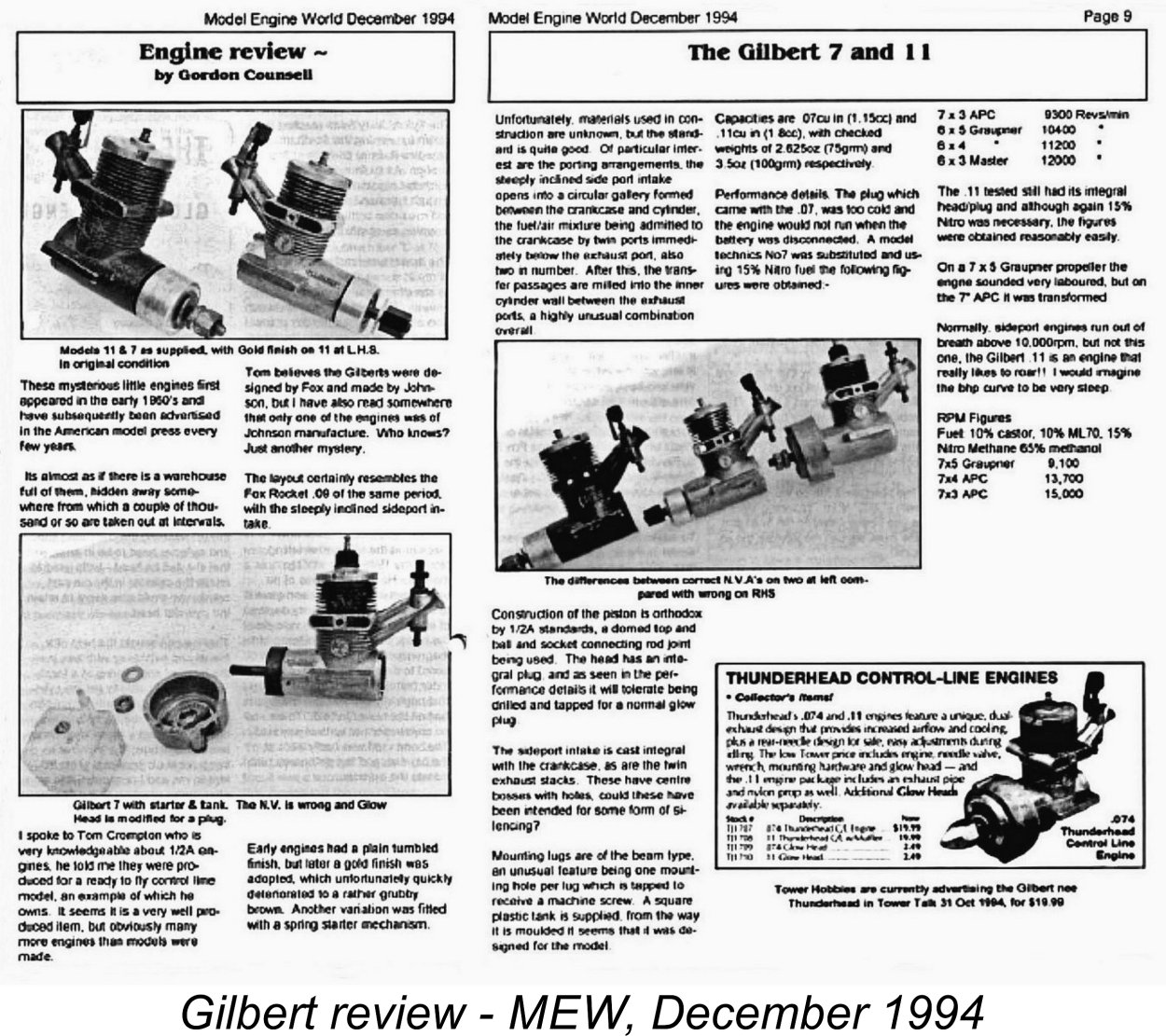

The first test formed part of an article by Gordon Counsell which appeared in the December 1994 issue of the now long-defunct “Model Engine World” (MEW) magazine. That article was based upon very limited historical research, thus not contributing much to our knowledge of the engines’ history while actually containing a few identifiable errors. However, it did include some comments on the engines’ performance. After describing their construction and commenting that the standard of manufacture of the Thunderheads was “quite good”, Gordon proceed to a summary of his testing of both models. Unfortunately, his test example of the .07 model was fitted with a glow head which had somehow been modified to accommodate a regular ¼-32 glow plug. Given the previously-noted fact that a standard head can't be directly modified to take such a plug, I presume that a Helicoil must have been installed as described earlier. Either that, or the head was an all-new owner-built component. It's a well-demonstrated fact that while such a conversion undoubtedly restores an engine to usefulness, it generally results in a very significant drop in performance compared with that obtained using the correct glow head with integral element. Read Maris Dislers’ article on glow head conversion to learn why. The initial challenge faced by Gordon was the fact that the ¼ in. plug which had somehow been fitted to the .07 model was too cold, resulting in the engine not continuing to run when the battery was disconnected. Since the test engine was modified to accept a standard glow-plug, a switch to a Model Technics no. 7 plug easily cured this problem. Using a fuel containing 15% nitro, Gordon obtained the following figures: APC 7x3 - 9,300 rpm Graupner 6x5 - 10,400 rpm Graupner 6x4 - 11,200 rpm Master 6x3 - 12,000 rpm Not much indication there of any spectacular output or willingness to rev out! To me, there appears to be little doubt that this was due to the use of a modified head as previously described. I’m sure that the engine would have done far better using an original glow head. Stay tuned ………… Switching to the larger .11 model, things went far better! This unit retained its original glow head, which almost certainly made a big difference. Gordon reported the following figures using the same 15% nitro fuel: Graupner 7x5 - 9,100 rpm APC 7x4 - 13,700 rpm APC 7x3 - 15,000 rpm These are very impressive numbers for a side-port engine of this displacement! The indication from the APC 7x4 is around 0.165 BHP at that speed, while the 7x3 number implies an output of around 0.147 BHP. The peak seems to lie somewhere between the two. So much for side-port engines not being willing to rev out ……....!

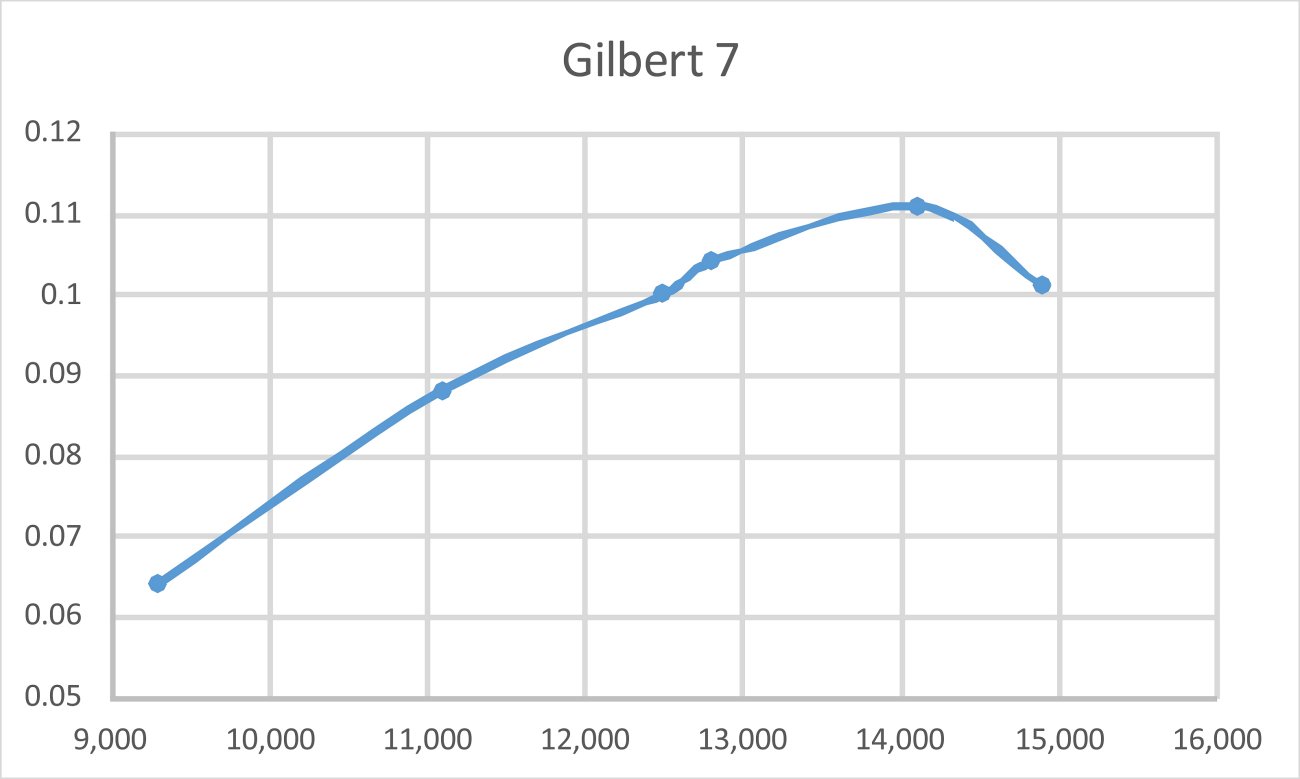

7x4 plastic - 10,500 rpm 7x3 wood - 13,000 rpm 6x4 wood - 14,500 rpm If that 6x4 wood prop was a Top Flite, the indicated output at that speed would be in the order of 0.085 BHP. Turning an APC 7x3 at 13,000 rpm requires the development of around 0.096 BHP. Indications are that the output of the Gilbert .07 was by no means inconsequential for an engine of its type, date and displacement! Roger’s figures for the .11 were far less impressive - indeed, they were not representative, since he tested that model on props which were clearly far too big. The only data even approaching any relevance was obtained with an 8x4 wood prop of unspecified brand, which was the lightest load that Roger tried. The engine turned that prop at 10,000 rpm, running very unsteadily while doing so. It’s likely that it was suffering from pre-ignition and was also operating below the minimum speed for consistent running dictated by its induction system - despite their side-port induction, these are clearly not low-speed engines! The manufacturers specifically recommended 7 in. dia. props for the .11 - undoubtedly an appropriate recommendation, but one that Roger didn’t follow. I have no idea why Roger loaded the poor little beastie up so much! I'd guess that a 7x4 or 7x5 would be far more like it, as witness Gordon Counsell’s results. Since it’s clear that several of the above test results were seriously compromised in some way, it was down to me to test the engines using original heads and appropriate airscrews. Happily, I retain a reasonably healthy stock of original Gilbert glow-heads, allowing me the luxury of being able to test both engines using their original ignition equipment without worrying too much about the possibility of blowing a plug. I elected to use a fuel containing 15% nitro and 25% castor oil, which would probably have been a typical brew used in these engines back in the day. I was mindful of the fact that motors like these having ball-and-socket conrod connections require at least 20% castor oil in the fuel - joints of this type give rise to extremely elevated unit working pressures between the ball and socket along with relatively elevated temperatures due to the direct connection with the centre of the piston crown. Synthetic oils are far less able than castor to adequately resist such a combination. Indeed, back in the ball-and-socket days, the warranties on Cox engines were specifically invalidated if the fuel used was not primarily castor-based. Leroy Cox knew what he was doing ............ First up was the smaller .07 model. Somewhat perversely, I decided to follow Roger Schroeder's example of ignoring the manufacturer's recommendations by beginning with an APC 7x5, although this was the heaviest load that I planned to use with this engine. Although my test example appeared to have done some previous running, I elected to treat it as a new engine by giving it a few slightly rich runs as a preliminary. Since steel-in- The little Gilbert proved to be an instant one- or two-flick starter following a couple of choked flicks and a small exhaust prime. Most of the time, it even started in the right direction, although a certain tendency to start backwards became increasingly marked with smaller and lighter props. Response to the needle was very positive, with the optimum setting being clearly defined. I put a little time on the engine on a rich needle and then tried leaning it out to see what it could do. It was immediately apparent that the Gilbert 7 wasn't at all happy on the 7x5 prop. It could only manage 9,300 rpm on that prop, with a certain tendency to hunt (i.e., display speed fluctuations while running). This was doubtless due to carburettor confusion arising from airflow reversals in the induction tube. A switch to a faster 7x4 produced an immediate improvement, although it turned out that the engine needed to be operated at speeds above 12,000 rpm to display its true colours. At such speeds, running became completely smooth and steady, while starting remained exceptionally good throughout. The measured performance on test was completely consistent with the figures reported earlier by Roger Schroeder. The following data tell the story.

These figures reflect an excellent performance, offering persuasive support for the figures reported by Roger Schroeder. My example appears to develop around 0.111 BHP @ 14,100 rpm. This was a higher-than-average figure among engines used in typical RTF models as of the early 1960's - indeed, it beat the reported outputs of most 1 cc diesels of the era. Taken together with its outstanding starting qualities and sturdy construction, the Gilbert Thunderhead 7 would clearly have made an excellent RTF powerplant as well as providing excellent service as a general-purpose sports hobby powerplant. Following the completion of this first round of testing, the glow head was removed for inspection and found to be still in perfect working order. There were no signs of any mechanical issues either. All in all, a most satisfactory introductory test session! Just for fun, I then tried my previously-illustrated ¼-32 Helicoiled head in place of the standard component. Using a few of the faster props and the same fuel, starting and running qualities were unaffected but performance was measurably down on the standard head, just as expected. The drop was in the order of 500 - 600 rpm or so - you'd notice the difference in actual service in the field, although the engine still handled and ran perfectly well. I have no idea why such conversions almost invariably produce inferior levels of performance, but there's a wealth of past experience to suggest that this is quite the usual thing. Stick to the original head as long as you can!! That said, the engine is perfectly useable with the Helicoiled head - it just doesn't rev up quite as enthusiastically. Perhaps matters could be improved somewhat by experimenting with plugs of different heat ratings. OK, time now to see if the larger Gilbert Thunderhead 11 could come up to the standard set by its smaller sibling! My test example of the Thunderhead 11 was selected at random from among half-a-dozen like-new examples that have somehow gravitated in my direction over the years, mostly as throw-in sweeteners with other engines in "package deals". Like its .07 companion, it was one of the earlier examples with the pressed-in spraybar and coil spring needle tensioning arrangement. As received, it was equipped with the earlier Fox-style glow head, as indeed are all of my other examples of that model. It had clearly done some previous running, but appeared to be in perfect mechanical and cosmetic condition. I decided that I would first test the engine as supplied with a Fox-style head and then try a few props around what proved to be the peak to see if a switch to the revised Cox-style head affected performance in any way. I had spare examples of both types of head, so I wasn't too worried about the possibility of a burn-out of either type.

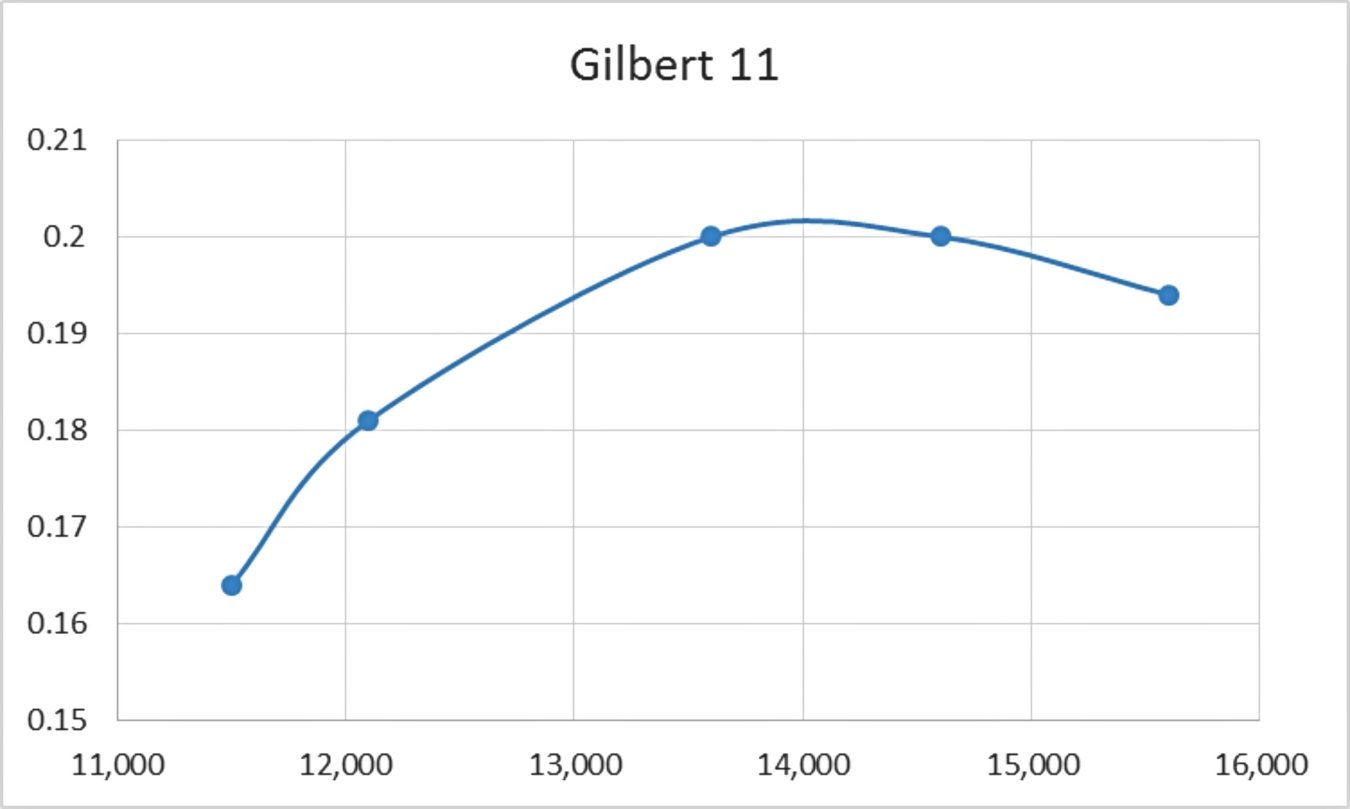

It turned out that the needle was a little too rich - the manufacturer's recommendation of 1½ turns was spot on for starting and slightly rich running. At that setting, the engine maintained its outstandingly easy starting throughout the test. The only issue was an increasing tendency to start backwards on the smaller props, but that was easily managed - just throw a small rag into the prop to stop the engine, and then try again without the prime! After a couple of slightly rich runs just to settle things down, I tried leaning out the mixture. Response to the needle was extremely good, making the establishment of the optimum setting a very straightforward matter. The Gilbert showed immediate signs of exceeding my performance expectations by turning the APC 8x4 prop at a smooth and steady 11,500 rpm. Encouraging .......... I then proceeded to test the engine on a series of lighter loads. Starting and running qualities remained extremely good throughout the test. Moreover, the promise of a better-than-anticipated performance was amply borne out. The following data tell the story.

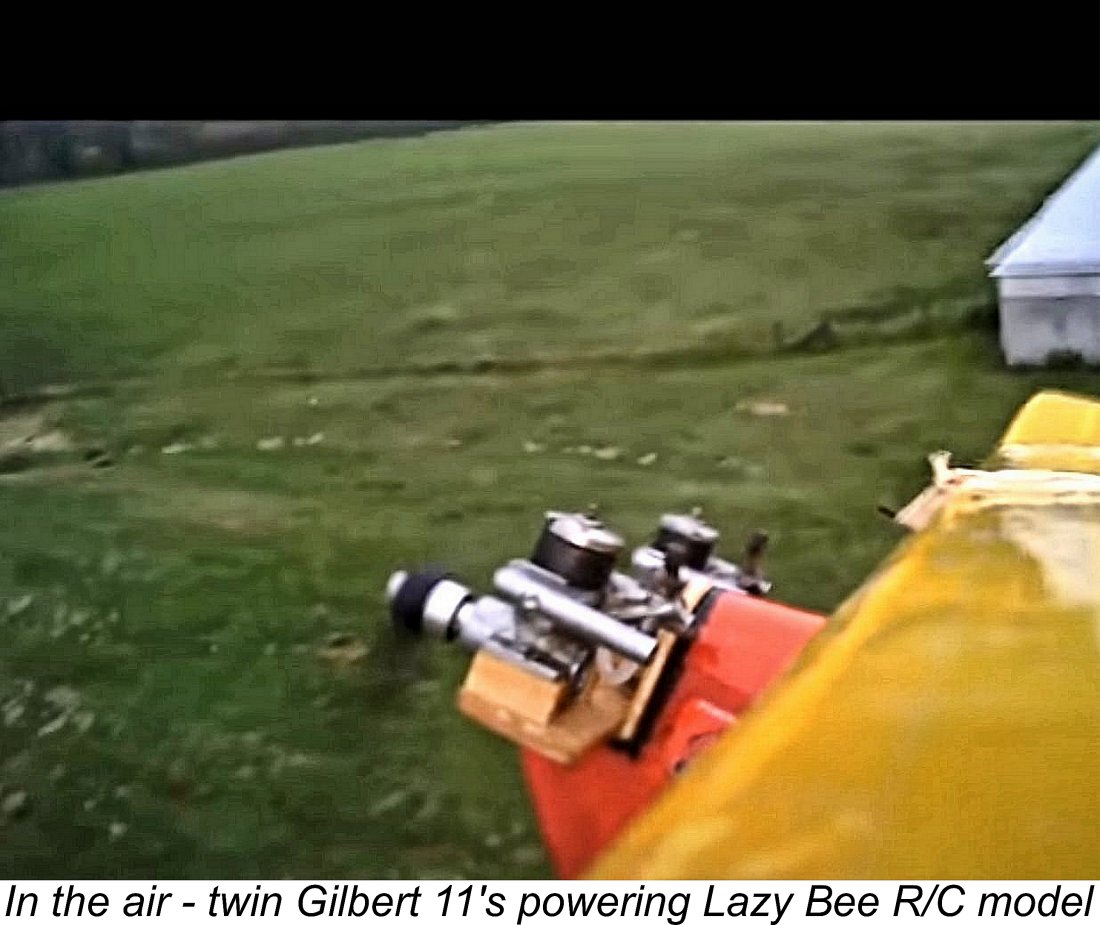

These are outstanding figures for an economy-grade side-port glow-plug motor of 1.96 cc displacement! In fact, I was so surprised at the speeds being recorded that I actually went back and ran the entire series again, obtaining almost exactly the same readings. Such figures make it apparent that the Gilbert Thunderhead 11 was arguably the most powerful engine ever to be used in the RTF models of the early 1960's. Coupled with its outstanding handling qualities and sturdy construction, it would have been an ideal RFT powerplant. Many of those models were somewhat underpowered in service, but that could not be said of a model powered by this unit! Indeed, I would have been happy to use one myself in hobby service back in the day. Just for fun, I also tried the engine using the nylon prop with integral spinner base with which many of the Gilbert Thunderhead 11 engines were supplied. This prop was clearly intended for use with the company's RTF models. It has a tip-to-tip blade diameter of 7 in. and appears to have a pitch of around 4 in. The Gilbert 11 turned it at an effortless 13,700 rpm - just a As planned at the outset, I next removed the Fox-style head, finding that it remained in perfect condition after a good deal of high-speed running. I replaced it with a Cox-style head of the second type described earlier in order to check a few of the faster props from the first series. As expected, the somewhat lower compression ratio was very detectable when flicking the engine over with the plug disconnected. The engine started and ran every bit as well as before, but was consistently some 200 - 300 rpm down from the earlier figures achieved with the same props. I would assume that the Fox plug's trumpet-shaped combustion chamber and higher compression ratio would account for this. Even so, the difference would be barely detectable in actual service in the field. At the conclusion of this relatively arduous test session, the engine was found to be still in perfect mechanical condition, all ready for more work. Rather to my own surprise, I was actually thoroughly impressed with it! Without question, it's the best-performing side-port engine of my personal acquaintance, also being extremely user-friendly. As a final comment, it's worth noting that the two engines peaked at almost exactly the same speeds - around 14,000 rpm. They also achieved very similar specific output figures - 96 BHP/litre and 103 BHP/litre for the 7 and 11 models respectively. Clearly the functional design worked equally well at both scales. User Impressions of the Gilbert RTF Models and Engines Although the Gilbert Thunderheads never appear to have been “adopted” either by contemporary "hobby" fliers or the later model engine aficionado community, both the engines and the RTF models that they powered nevertheless draw comment from time to time in the model engine media (such as it is!) and on various model forums. It’s interesting and perhaps somewhat unexpected to note that the comments are almost uniformly positive! Here’s a sample that I collected while researching this article.

Reviewing the above comments, it’s clear that people who actually tried the engines and models generally liked them very much. It appears that the final commentator never did so! It’s also evident that the American Flyer models were both well-made and durable. All in all, a nice collection of testimonials! Conclusion

The engines are constructed to more than acceptable standards of quality, bearing comparison with any of their contemporary mass-produced American commercial competitors in that respect. They also perform at levels which quite belie their seemingly old-tech operating system. I'm not 100% certain about this, but I believe it to be very likely that the Gilbert engines were the last-ever all-new side-port model engine designs to be mass-produced and marketed commercially anywhere in the world. If true, this gives them a very special status in the history of model engine design and manufacture worldwide. If anyone out there can point me to a later all-new commercial side-port design (leaving the many later side-port retros and replicas of earlier designs out of it), please get in touch! The ready availability and reasonable cost of these engines today makes them appear as very logical classic engines to use in present-day sport and retro flying. Their unusual appearance and design add to I‘ve actually found several on-line comments to the effect that until a few years ago at least there were a few R/C clubs that used the Gilbert engines for R/C combat and/or low-key control line combat too. They evidently created their own classes and rules to permit this. The relatively “disposable” character, sturdy construction and ready availability of the engines at low cost doubtless made such applications quite attractive. As-new examples appear regularly on eBay, generally selling for prices in the region of US$25-30. However, the prices vary quite a bit depending on the context - a pair of new examples (a 7 and an 11) in original Polk boxes with all accessories and instructions sold in early 2021 for US$135 each! But that's the exception which proves the rule - anyone having an interest should easily be able to find a nice reasonably-priced example to play with. Go ahead - these nice little classics are inexpensive FUN!! ______________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published September 2021 |

||

| |

The article which follows is one of those efforts which probably causes many of my readers to wonder if poor old Duncan is finally entering his dotage! WHY, I hear some of you asking, am I writing about such a mundane subject as this one? Guys, you're talking about the fellow who wrote at length about the

The article which follows is one of those efforts which probably causes many of my readers to wonder if poor old Duncan is finally entering his dotage! WHY, I hear some of you asking, am I writing about such a mundane subject as this one? Guys, you're talking about the fellow who wrote at length about the

At the time when it became involved with model engines, the A. C. Gilbert Company had already been in business for 45 years - even longer if one counts its direct predecessor organisation. The venture was established by

At the time when it became involved with model engines, the A. C. Gilbert Company had already been in business for 45 years - even longer if one counts its direct predecessor organisation. The venture was established by

Following the conclusion of WW1, the range of the company’s products continued to grow. A short-lived foray into the radio business was ended by legal action instigated by another firm, but the company introduced chemistry sets in 1922, followed by the 1929 acquisition of the competing American company which was producing licensed versions of Frank Hornby’s Meccano sets. The products of that company continued to be marketed until 1938 under the “American Meccano” name. In effect, Gilbert was competing with himself, although it didn't matter - he made money regardless of which brand was purchased!

Following the conclusion of WW1, the range of the company’s products continued to grow. A short-lived foray into the radio business was ended by legal action instigated by another firm, but the company introduced chemistry sets in 1922, followed by the 1929 acquisition of the competing American company which was producing licensed versions of Frank Hornby’s Meccano sets. The products of that company continued to be marketed until 1938 under the “American Meccano” name. In effect, Gilbert was competing with himself, although it didn't matter - he made money regardless of which brand was purchased!  During the period of America’s involvement in WW2 beginning in December 1941, virtually all American manufacturing operations of any size were converted to make some type of war materiel, no matter what they originally produced. The A. C. Gilbert Company was no different - by 1942 it was producing a range of equipment for military aircraft at its New Haven plant.

During the period of America’s involvement in WW2 beginning in December 1941, virtually all American manufacturing operations of any size were converted to make some type of war materiel, no matter what they originally produced. The A. C. Gilbert Company was no different - by 1942 it was producing a range of equipment for military aircraft at its New Haven plant. Despite his nominal retirement, A.C. was unable to really let go. He continued to exercise considerable influence over the company’s affairs, perhaps not to the company’s advantage. Certainly, it was at this point that the company’s fortunes began the progressive down-turn that was to end in its final 1967 demise. Al Gilbert had never had any real interest in the business, taking over reluctantly mainly to please his rather demanding father, whose continuing interference with Al’s attempts to run things certainly didn't help.

Despite his nominal retirement, A.C. was unable to really let go. He continued to exercise considerable influence over the company’s affairs, perhaps not to the company’s advantage. Certainly, it was at this point that the company’s fortunes began the progressive down-turn that was to end in its final 1967 demise. Al Gilbert had never had any real interest in the business, taking over reluctantly mainly to please his rather demanding father, whose continuing interference with Al’s attempts to run things certainly didn't help. It must be said to their credit that the Gilbert company management had the good sense to recognize the fact that they had no prior experience or expertise relating to the RTF model airplane field. Accordingly, in entering this market the company wisely retained the services of a talented group of individuals having the required knowledge and experience.

It must be said to their credit that the Gilbert company management had the good sense to recognize the fact that they had no prior experience or expertise relating to the RTF model airplane field. Accordingly, in entering this market the company wisely retained the services of a talented group of individuals having the required knowledge and experience.

The die-cast production Gilbert engines were manufactured at Hi Johnson’s Dynamic Models plant in Anaheim, California where the renowned Johnson and Holland Hornet engines were produced. It’s thus no surprise to find that in general they were constructed to quite a high standard - Hi Johnson certainly knew what he was doing, and he had very capable assistance from Bob Holland and Bill Effinger. Did I mention that the Gilbert units have a pedigree .......?!?

The die-cast production Gilbert engines were manufactured at Hi Johnson’s Dynamic Models plant in Anaheim, California where the renowned Johnson and Holland Hornet engines were produced. It’s thus no surprise to find that in general they were constructed to quite a high standard - Hi Johnson certainly knew what he was doing, and he had very capable assistance from Bob Holland and Bill Effinger. Did I mention that the Gilbert units have a pedigree .......?!?

The American Flyer RTF models and Thunderhead engines were promoted quite vigorously from the outset. In fact, it appears that the company may have seen this product line as representing a pathway to salvation given the progressive erosion of their market share in other areas. This is clearly implied by the fact that their 1962 catalogue begins with model airplanes, relegating the formerly dominant Erector Sets and American Flyer trains to dead last.

The American Flyer RTF models and Thunderhead engines were promoted quite vigorously from the outset. In fact, it appears that the company may have seen this product line as representing a pathway to salvation given the progressive erosion of their market share in other areas. This is clearly implied by the fact that their 1962 catalogue begins with model airplanes, relegating the formerly dominant Erector Sets and American Flyer trains to dead last.

collectibles. For example, you could buy new examples from Tower Hobbies during the mid 1990’s, although the asking price had risen to $19.99 by then, apparently on the basis of the engines being characterized as "collector's items". The attached advertisement from late 1994 reflects this marketing effort. Another individual who evidently acquired a few pallets of the engines was Pennsylvania resident Stephen Brown, who used to clean them up and sell them individually. He also offered glow heads for the engines.

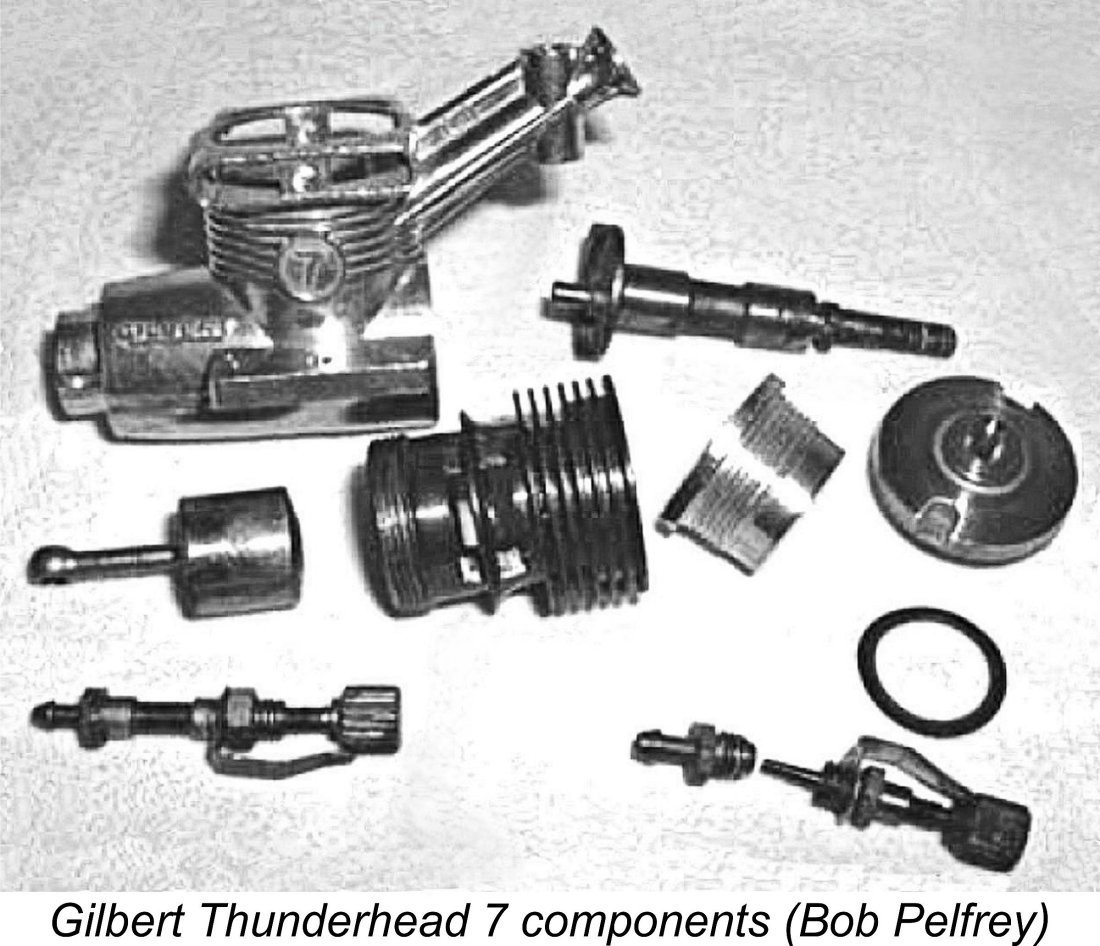

collectibles. For example, you could buy new examples from Tower Hobbies during the mid 1990’s, although the asking price had risen to $19.99 by then, apparently on the basis of the engines being characterized as "collector's items". The attached advertisement from late 1994 reflects this marketing effort. Another individual who evidently acquired a few pallets of the engines was Pennsylvania resident Stephen Brown, who used to clean them up and sell them individually. He also offered glow heads for the engines. The two distinct variants of the Gilbert Thunderhead engine are identical in design terms - only the operating dimensions and displacements are different. Accordingly, the following description applies to both models except where noted. The accompanying component view of a dismantled Gilbert Thunderhead 7 should clarify much of the following description - apart from its dimensions, the Thunderhead 11 model looks identical in all respects.

The two distinct variants of the Gilbert Thunderhead engine are identical in design terms - only the operating dimensions and displacements are different. Accordingly, the following description applies to both models except where noted. The accompanying component view of a dismantled Gilbert Thunderhead 7 should clarify much of the following description - apart from its dimensions, the Thunderhead 11 model looks identical in all respects.

At the front, another very clear sign of the Gilbert's Fox heritage is to be seen in the form of the arrangements for locking the prop driver to the shaft. Like several Fox models, including the side-port Rocket .09 from which the Gilbert engines were chiefly derived, the crankshaft is provided with three protruding dogs which engage with matching cut-outs in the prop driver to force it to turn as one with the shaft.

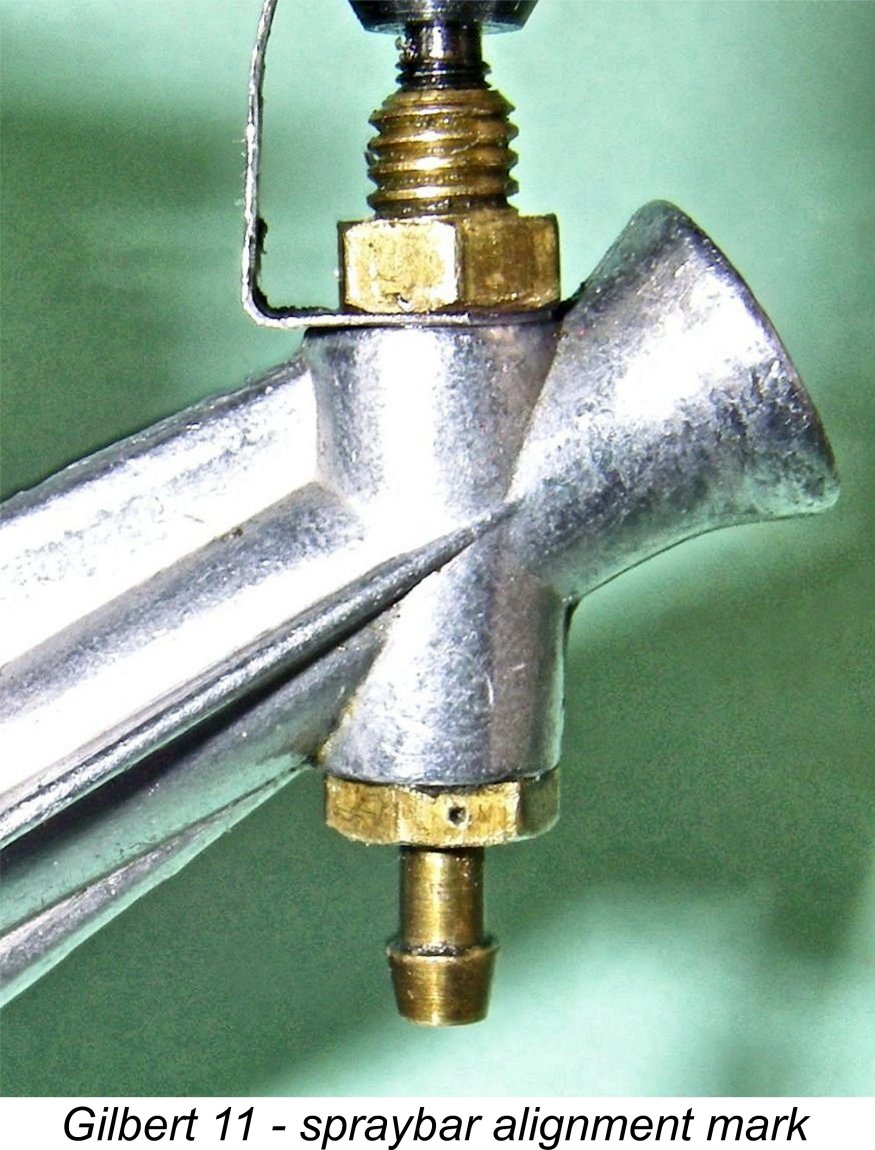

At the front, another very clear sign of the Gilbert's Fox heritage is to be seen in the form of the arrangements for locking the prop driver to the shaft. Like several Fox models, including the side-port Rocket .09 from which the Gilbert engines were chiefly derived, the crankshaft is provided with three protruding dogs which engage with matching cut-outs in the prop driver to force it to turn as one with the shaft.  An interesting detail which seems to have been overlooked previously relates to the second type of needle valve assembly. The spraybar has two jet holes spaced 180 degrees apart - a pretty standard arrangement. For best results in terms of suction, these holes need to be placed at either side of the induction tract facing the walls, so that they can take best advantage of the point at which maximum incoming air velocity and hence maximum suction and atomization are achieved. To assist in confirming that this orientation is achieved when the spraybar is tightened, a tiny punch mark is added to the appproriate facet of the spraybar's hexagonal location shoulder above the fuel nipple. If the spraybar is correctly oriented, this mark should appear at one or the other side of the intake tube as shown in the accompanying illustration. A very thoughtful touch - I've often added such marks myself to other similarly-equipped engines.

An interesting detail which seems to have been overlooked previously relates to the second type of needle valve assembly. The spraybar has two jet holes spaced 180 degrees apart - a pretty standard arrangement. For best results in terms of suction, these holes need to be placed at either side of the induction tract facing the walls, so that they can take best advantage of the point at which maximum incoming air velocity and hence maximum suction and atomization are achieved. To assist in confirming that this orientation is achieved when the spraybar is tightened, a tiny punch mark is added to the appproriate facet of the spraybar's hexagonal location shoulder above the fuel nipple. If the spraybar is correctly oriented, this mark should appear at one or the other side of the intake tube as shown in the accompanying illustration. A very thoughtful touch - I've often added such marks myself to other similarly-equipped engines.

One hitherto-unreported fact across which I stumbled during the course of my research for this article was the existence of two quite distinct types of glow-head for the Gilbert 11. What I assume to be the earliest version is seen at the left in the accompanying composite image. It is based upon a standard Fox-style steel insert which is pressed into the head itself from below. The combustion chamber has an efficient-looking curved trumpet shape to it. The two indentations on the top to accommodate the head wrench are neatly cast into the component.

One hitherto-unreported fact across which I stumbled during the course of my research for this article was the existence of two quite distinct types of glow-head for the Gilbert 11. What I assume to be the earliest version is seen at the left in the accompanying composite image. It is based upon a standard Fox-style steel insert which is pressed into the head itself from below. The combustion chamber has an efficient-looking curved trumpet shape to it. The two indentations on the top to accommodate the head wrench are neatly cast into the component.

As far as I’m able to determine, only two tests of these engines were ever published. Unfortunately, for various reasons neither of them represented valid assessments of both models.

As far as I’m able to determine, only two tests of these engines were ever published. Unfortunately, for various reasons neither of them represented valid assessments of both models. At Bob Pelfrey’s request, the late Roger Schroeder subsequently also ran some tests on the Gilbert engines for ECJ Issue no. 173. Roger commented that both engines were very easy to start following an exhaust prime. It appears that Roger must have tested the .07 with an original head, because his example revved out far better than the one tested by Gordon Counsell. He obtained the following figures using an unspecified fuel formula:

At Bob Pelfrey’s request, the late Roger Schroeder subsequently also ran some tests on the Gilbert engines for ECJ Issue no. 173. Roger commented that both engines were very easy to start following an exhaust prime. It appears that Roger must have tested the .07 with an original head, because his example revved out far better than the one tested by Gordon Counsell. He obtained the following figures using an unspecified fuel formula: steel piston/cylinder combinations don't benefit from the multiple heat cycles necessary for proper

steel piston/cylinder combinations don't benefit from the multiple heat cycles necessary for proper

I began with an APC 8x4 prop fitted - the heaviest load that I planned to use. After opening the needle two turns, I applied two choked flicks followed by a small exhaust prime. With the plug lit, the engine recommended itself to me immediately by starting on the second flick in the right direction after a layoff of who knew how many years!

I began with an APC 8x4 prop fitted - the heaviest load that I planned to use. After opening the needle two turns, I applied two choked flicks followed by a small exhaust prime. With the plug lit, the engine recommended itself to me immediately by starting on the second flick in the right direction after a layoff of who knew how many years!

I realize that considerable variations in performance are to be expected with economy-grade mass-produced engines, especially those with screw-in cylinders and consequently variable cylinder port orientations. I admit that my example may be a "good 'un", but the fact that it performed at this level, even allowing for the 15% nitro in the fuel, is extremely impressive in terms of demonstrating the potential of the design. The data suggest an output of around 0.202 BHP @ 14,000 rpm from this particular example.

I realize that considerable variations in performance are to be expected with economy-grade mass-produced engines, especially those with screw-in cylinders and consequently variable cylinder port orientations. I admit that my example may be a "good 'un", but the fact that it performed at this level, even allowing for the 15% nitro in the fuel, is extremely impressive in terms of demonstrating the potential of the design. The data suggest an output of around 0.202 BHP @ 14,000 rpm from this particular example.

The Gilbert Thunderhead engines are undoubtedly a little “different”! Quite apart from their adherence to side-port induction and their highly individualistic cylinder porting design, they are a rather rare commodity in being genuine classics which remain quite readily and affordably available in New or Like New condition, 60 years on. Basically, they appeared in 1961 and never went away!

The Gilbert Thunderhead engines are undoubtedly a little “different”! Quite apart from their adherence to side-port induction and their highly individualistic cylinder porting design, they are a rather rare commodity in being genuine classics which remain quite readily and affordably available in New or Like New condition, 60 years on. Basically, they appeared in 1961 and never went away!