|

|

The R.E.A. Range

During the course of the present review, I'll take the opportunity to conduct a close examination and test of a representative example of this manufacturer's work in the form of the R.E.A. Series 2000 2.5 cc glow-plug motor of 1955. For reasons which are unclear, information in the English-language modelling media about engines from the pioneering and classic eras in France appears to be in relatively short supply. Very few tests of French model engines ever appeared in British modelling magazines, while the various engine-related articles in those magazines rarely mentioned motors from La Belle France. This is a great pity, because the history of model engine development in that country is every bit as interesting as that of parallel efforts in other countries. Indeed, the commercial manufacture of model engines in France actually preceded that in the United States, making France a true pioneering nation in this field. I view this article as an opportunity to pay long-overdue tribute to the many noteworthy French achievements in the realm of model engine design and manufacture. Another very good reason for any model engine enthusiast to take an interest in French designs is the unquestionable fact that in general their quality was of the very highest order. The products of pioneering French manufacturers such as Rebous, Peugeot, R.E.A., Micron, Fulgur, Airplan, Allouchéry, DELMO, Maraget-Météore and Bosmorin (to name just a few) were all built to the very highest standards - no early British-style “garden shed” or American "slag engine" offerings here! It appears that a standard of quality was established early on which any competing manufacturer would have to meet if he was to stay in business. The general excellence of the early French model diesels in particular was such that some of them exerted a strong influence upon British and American designers during the early post-war period. Having made the above statements, honesty compels me to freely acknowledge the fact that I possess very little first-hand information regarding French model engines despite owning a number of examples from different manufacturers. Engines from that country were not imported into Britain in commercial quantities during the period when I was cutting my modelling teeth there, nor were French engines the subject of much commentary in the contemporary English-language modelling media. The same generally holds true for other English-speaking nations. My French friend and colleague Christian Farcy has commented that the main reason why French engines never made much of a mark outside France is that French manufacturers tended to confine their thinking to "French market" rather than "global market". Put another way, they "thought small". Their products certainly had sufficient merit to support overseas marketing efforts, but they didn't know how to pursue such initiatives, nor did they take the trouble to find out. Their focus on the domestic market greatly limited their market scope and hence their production potential. Micron did make some efforts during the early 1970's, but it was a case of too little, too late. That said, a few French engines did somehow manage to find their way into the hands of modellers in other countries. This was even true of some countries which then lay behind the formidable Iron Curtain of the Cold War era. My valued late Hungarian friend and colleague Ferenc "Somi" Somogyi informed me that a number of French engines from makers such as Micron, DELMO and R.E.A. showed up in Hungary during the period 1949 - 1952, being in fact the first quality engines from the West to see service in that country. A number of examples of the Micron 5 cc fixed-compression diesel also ended up in the USA through various channels.

Like every other model engine reference work of my personal acquaintance. Maeght's book is by no means free from error. Even so, no-one having even a peripheral interest in the fascinating history of model engine development and manufacture in general, and in France in particular, can afford to be without a copy. Although now long out of print, the book remained readily available both through Amazon France and eBay France, which is how I obtained my copy. A check confirmed that the book remained available as of mid 2016 from both sources. However, it wasn't cheap – typically you’d pay somewhere around 80 euros (US$90.00) for a clean copy. Well worth it, though – what price knowledge?? There’s no other comparable publication. In a very real sense, this is the French equivalent of the late Tim Dannels’ invaluable “American Model Engine Encyclopedia”. I can pay it no higher compliment. I'm unable to comment on the book's availability as of 2024. I freely acknowledge having drawn extensively upon this outstanding work when carrying out the research for this article. I have also used a number of illustrations from the book, all of which are acknowledged in the captions. My very sincere thanks to Adrien Maeght and his colleagues! Another indespensable source of information on French engines is Michel Rosanoff's ever-engaging "Retroplane forum" website. Although presented in French, the information on this forum may easily be rendered into comprehensible English using current translation software. Many high quality images of very rare French engines appear on this site, along with a good deal of information and related images about engines from other countries. I have frequently consulted Michel’s outstanding work during the preparation of various articles on French model engines, including this one. I have also periodically used images extracted from the forum with Michel’s kind permission. A visit is highly recommended! I'd also like to acknowledge the invaluable assistance rendered by French reader Christian Farcy. As we shall see, marine engines were a particular area of interest for the manufacturer of the R.E.A. range. Chris is the only model engine aficionado of my acquaintance who specializes in marine engines as opposed to the far more usual aero models. He was kind enough to provide information on a number of the marine engines and accessories supplied by the R.E.A. company over the years. Many thanks, Chris!! Now, before we dive into the details of the R.E.A. engines, it’s well worth spending a little time reviewing the hitherto poorly-documented history of model engine development in France. Accordingly, let’s begin at the beginning …………… Background

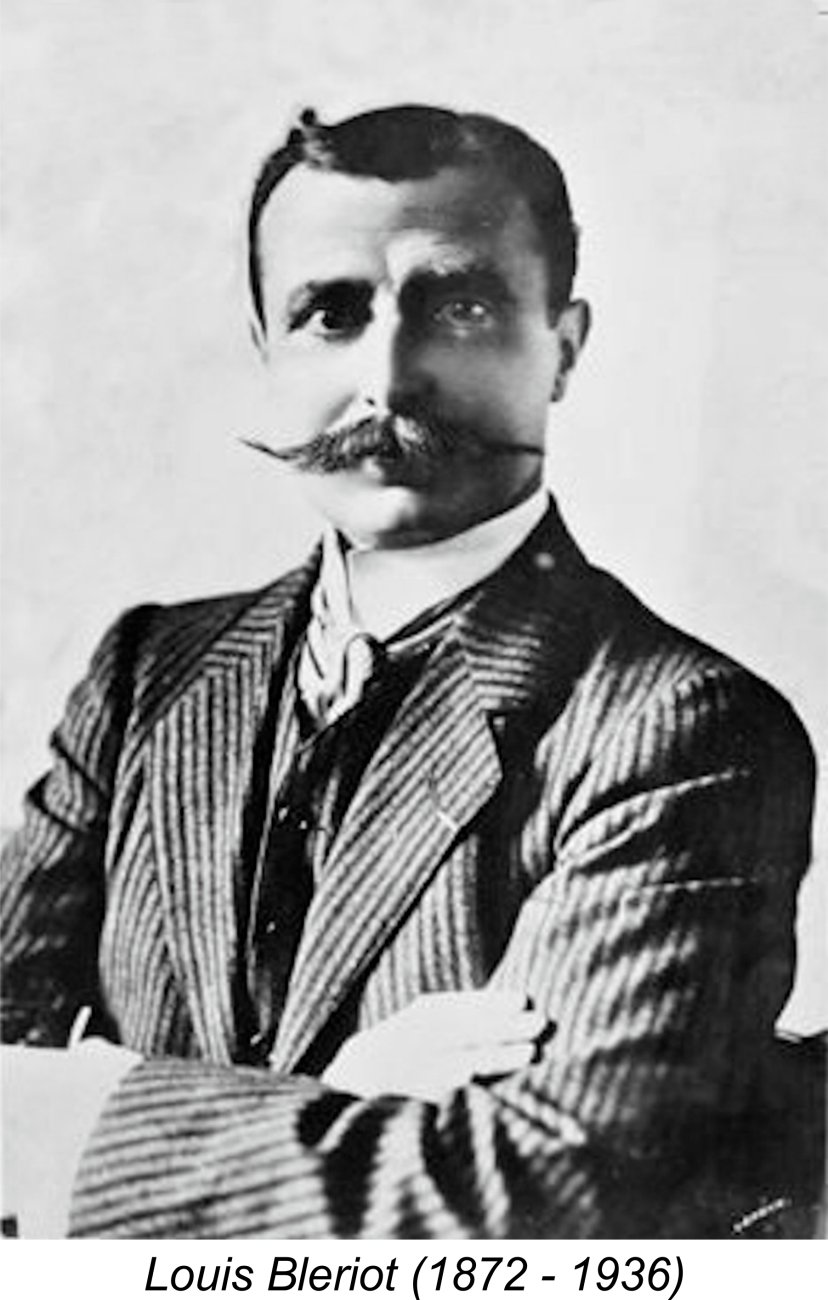

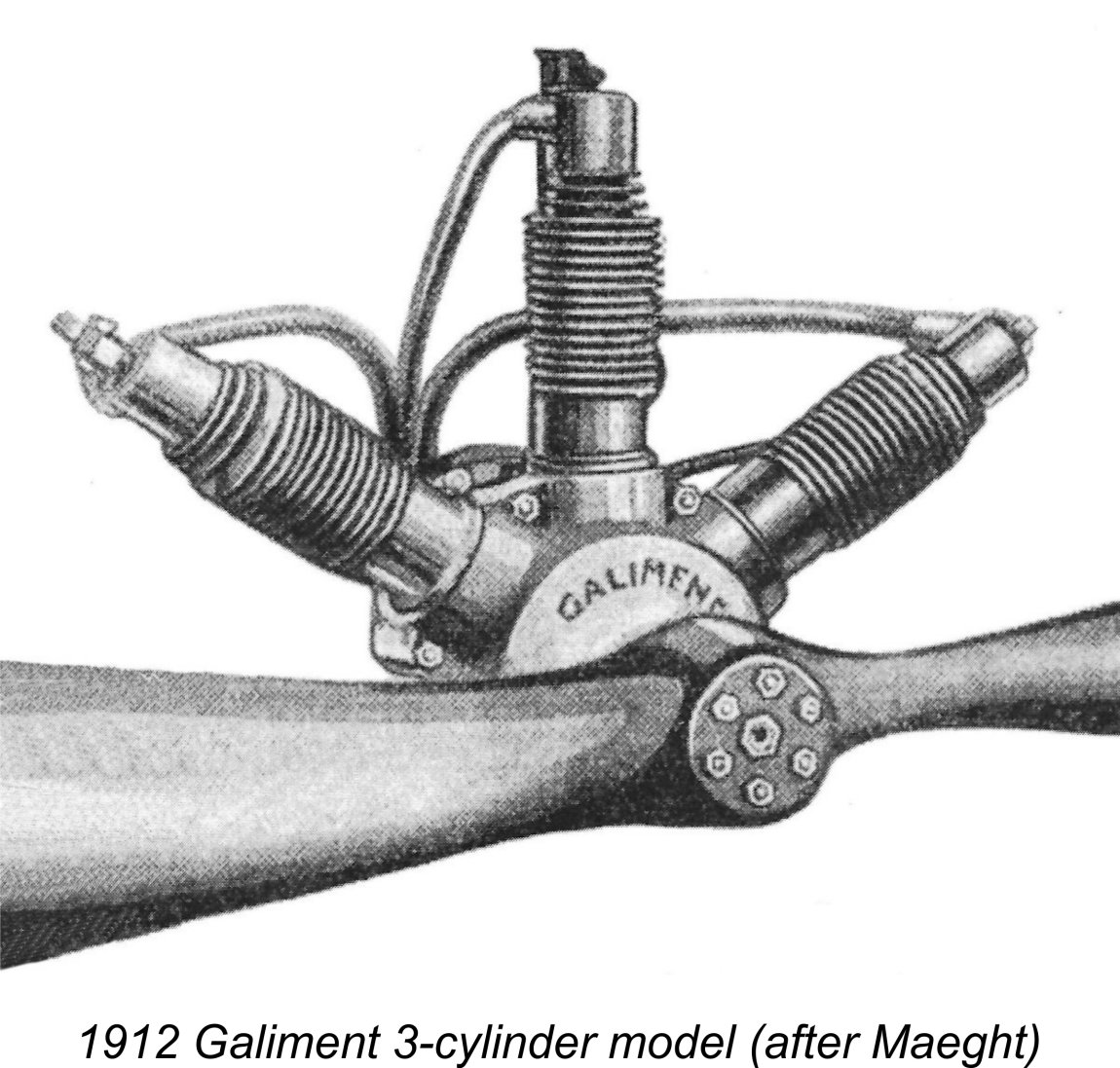

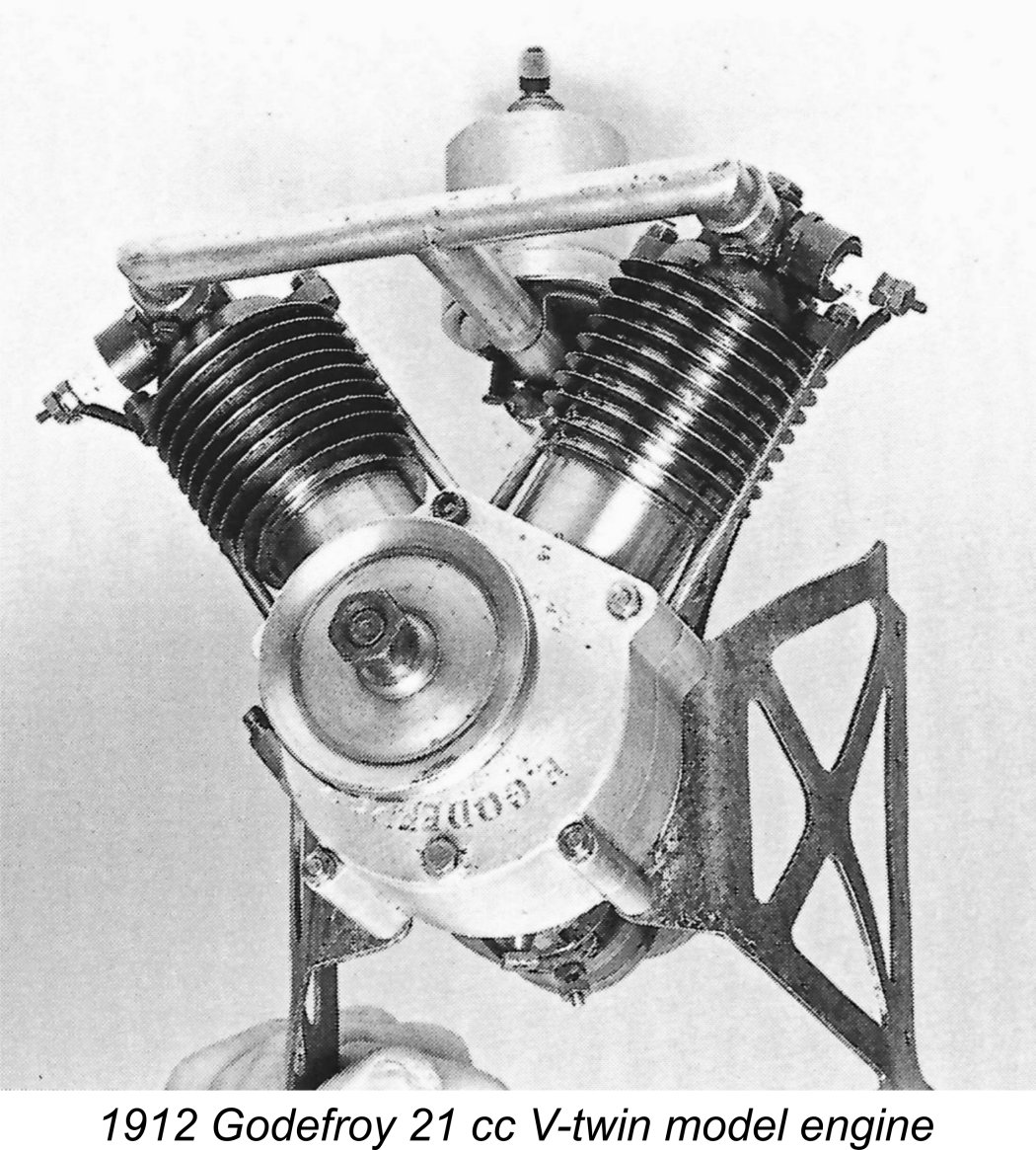

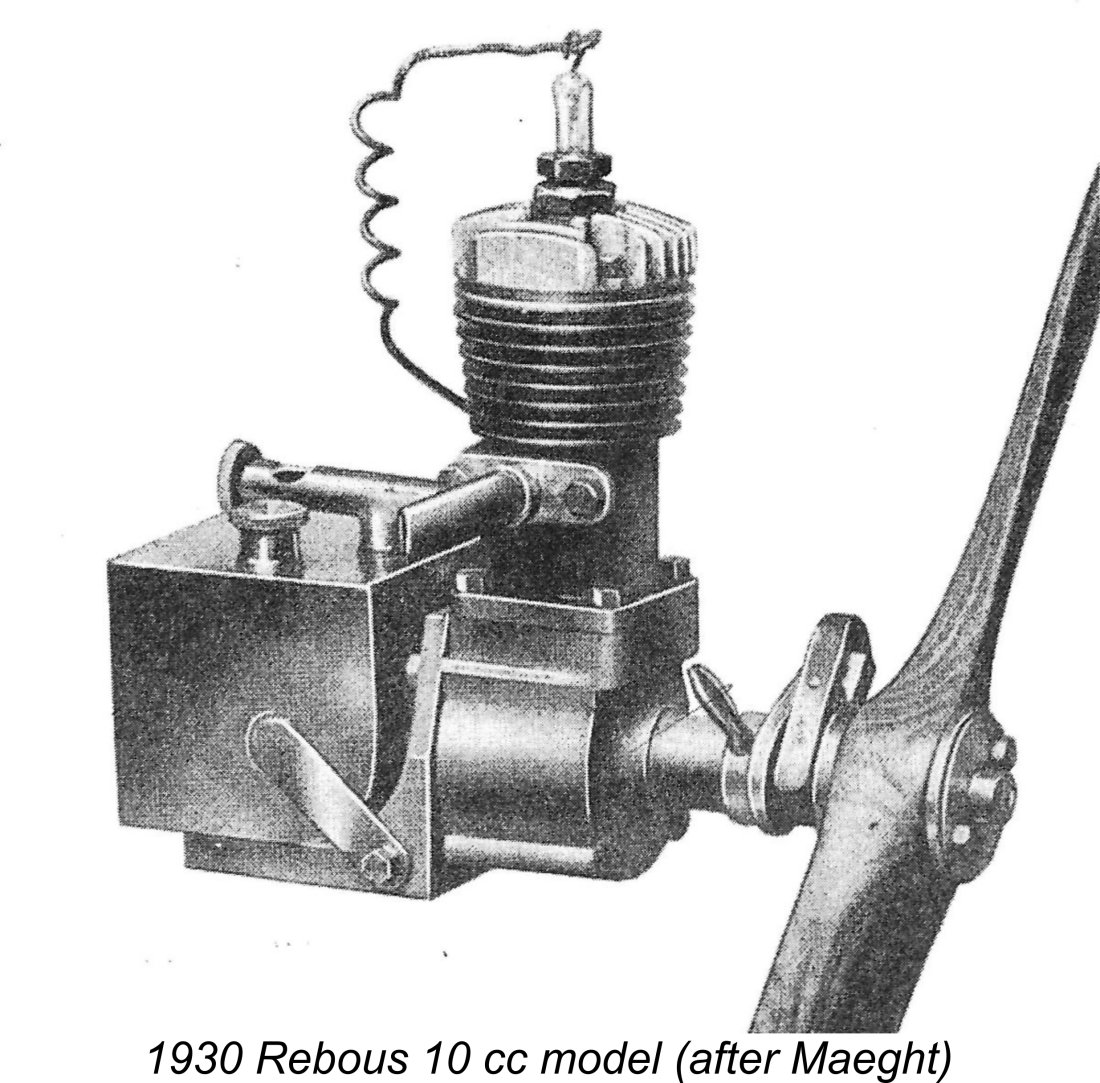

Logically enough, Blériot himself saw research in the model aviation field as offering an excellent low-cost opportunity to gain further insights into the design of full-scale aircraft. Accordingly, he engaged in a number of model-scale experiments in support of his rapidly expanding full-sized aircraft manufacturing business. One manufacturer which was inspired by Blériot's experiments was Radiguet & Massiot, a respected company which had been established in the 1850's to manufacture and market a variety of scientific products in the areas of In 1911 (two years after Blériot’s historic achievement), Radiguet & Massiot introduced an opposed twin-cylinder two-stroke engine of 16 cc displacement which was specifically intended for model aircraft use. This may have been the first model aero engine to be commercially produced in France - indeed, one of the first such engines produced anywhere. Radiguet & Massiot were soon joined by the Galiment company, who introduced a series of one, two and three-cylinder four-stroke model aero engines in 1912. The Godefroy brothers soon joined in the fun, producing a very fine V-twin four-stroke model of 21 cc displacement in 1912. This design proved to be very successful. At this stage, French model engine designers were clearly well ahead of their competitors in most other countries. This However, there was an ominously dark storm cloud looming on the horizon in the form of World War 1, a tragic and (in hindsight) completely unnecessary conflict which engulfed Europe in general and France in particular beginning on July 28th, 1914 and dragging on until November 11th, 1918 at the cost of millions of French and Allied lives, to say nothing of the cost to the Germans and their allies. Combined with the equal devastation of the 1919 worldwide influenza epidemic, the human and economic impact of this conflict gave rise to conditions in which the resumption of model engine manufacture was the last thing on anyone’s mind. A very few model engines were made in France by talented amateur enthusiasts during the 1920’s, but for the most part these were model boat powerplants. Power aeromodelling stagnated throughout much of this period. It was not until 1930 that commercial manufacture of model aero engines resumed in France, with both Rebous and Fameaux commencing the commercial manufacture of model aero engines on a relatively small scale. The French power aeromodelling movement began to make a slow recovery from that point onwards. Oddly enough, it was a political event that really set the stage for the full recovery of the French model engine The Popular Front was an alliance of left-wing movements which included the French Communist Party, the French section of the Workers’ International (SFIO) and the French Radical-Socialist Party. A similar coalition called the Frente Popular had won office in Spain in February 1936, and now the French followed suit. The Popular Front won the May 1936 French Legislative Election, resulting in the formation of a Government initially headed by SFIO leader Léon Blum and composed exclusively of Radical-Socialist and SFIO ministers. Blum's government implemented a range of social reforms. Among these was the adoption of a policy of “democratisation” of all forms of motorised sport, including power aeromodelling. Hitherto these activities had been viewed as the exclusive purview of the wealthy and aristocratic members of society, but the new policy changed this completely. Particular emphasis was placed upon air sports, with financial incentives being offered to young people from all walks of life to take flying lessons and become licensed pilots. This led to an immediate proliferation of both full-sized and model flying clubs throughout the country.

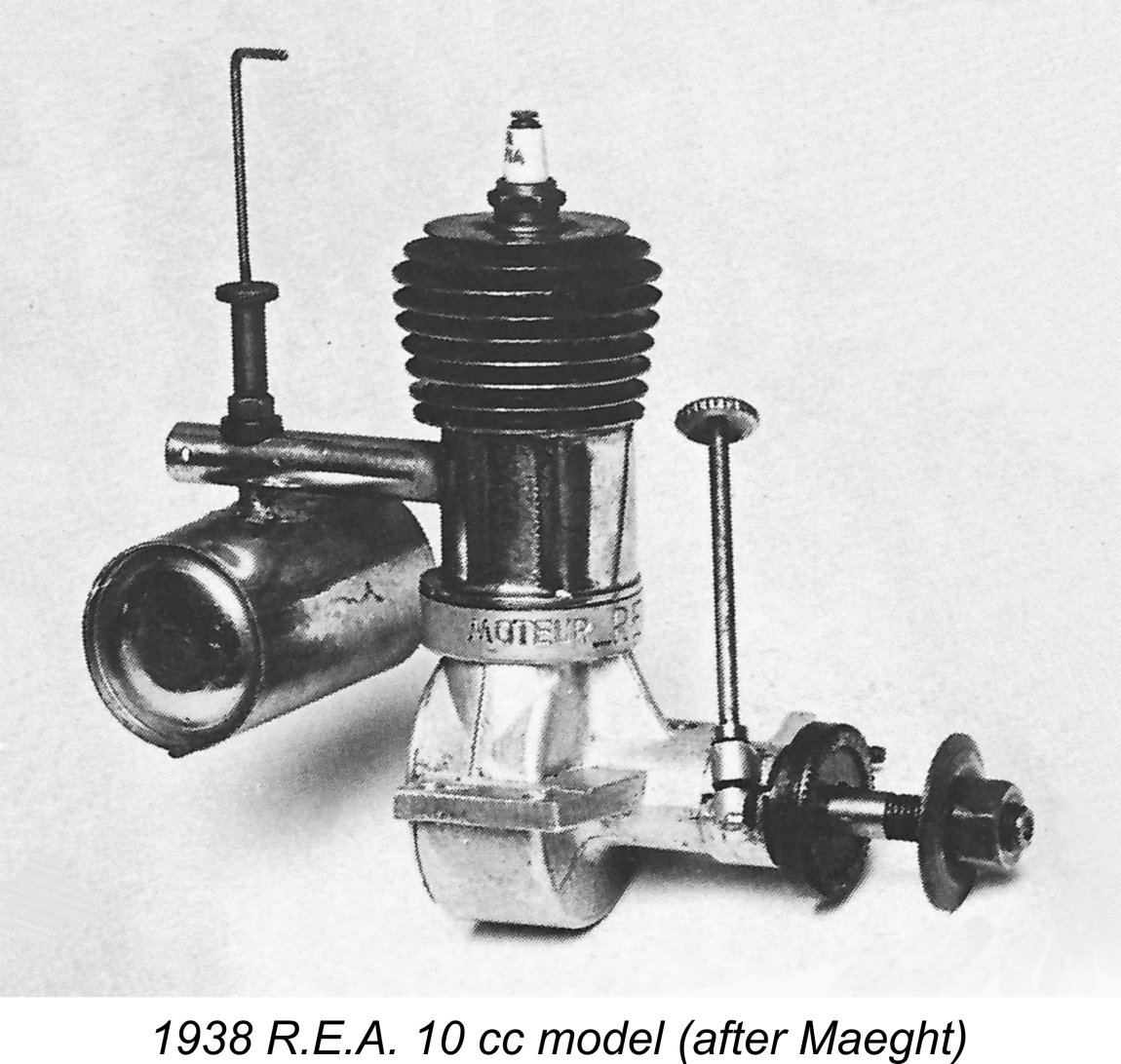

Another French industrial organization which followed a similar pathway was the Train company, whose main business was the supply of full-scale motorcycle engines under contract to others. In 1937-38, encouraged by the rising popularity of aeromodelling in France, they manufactured a small number of 3 cc engines for aeromodelling use. As with Peugeot, these engines were constructed by the firm’s trainee machinists to give them valuable precision machining experience. Naturally, the rising interest in aeromodelling provided an incentive for others to get in on the act. The Rebous company had somehow managed to survive through the 1930’s, and now they felt able to expand their activities, The growing political instability in Europe brought about by the aggressive moves of Adolph Hitler's Nazi Germany and General Francisco Franco's right wing totalitarian faction in Spain led to ever-increasing fragmentation among the Popular Front membership arising from disagreements regarding appropriate responses. By 1938 the coalition had begun to crumble. Nevertheless, the shot in the arm which it had given to the aeromodelling movement undoubtedly had a lasting effect. In particular, the arrival on the scene of new model engine manufacturers continued unabated. 1938 saw the entry into the French model engine market of an amazing number of newcomers, including Artus-Borde, Astus, Ceko, Radium, Stab and our main subject manufacturer, R.E.A. Thus by 1938 there were no fewer than ten firms engaged in the commercial manufacture of model engines in France. Even at this stage, this was a highly competitive business in which both performance and quality would count when it came to generating sales. From this point onwards, we'll focus upon just one of the ten French firms involved in the model engine business as of 1938 - the R.E.A. company. The R.E.A. Company - the Early Years

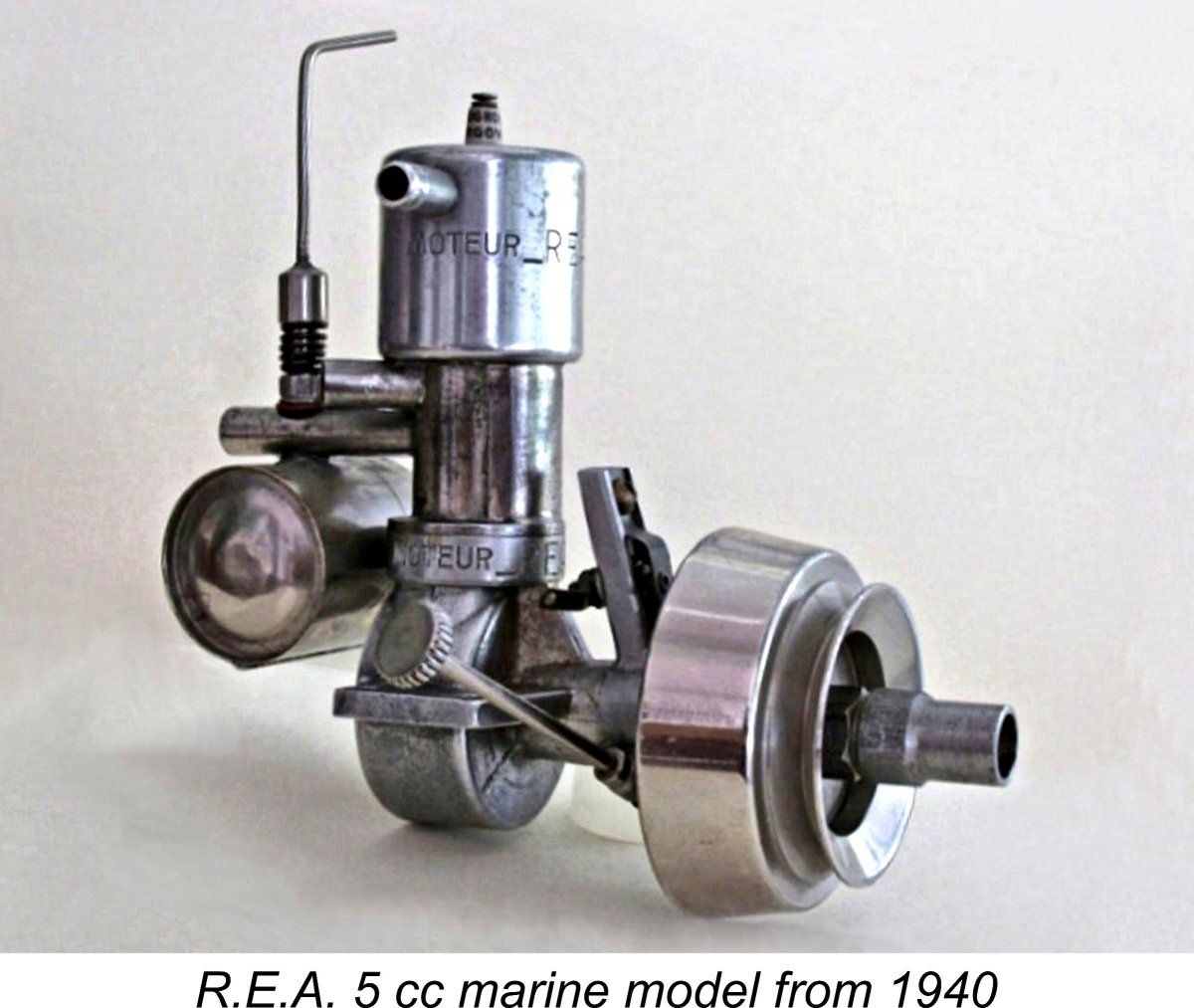

The R.E.A. engines were manufactured between 1938 and 1963. They were sold exclusively through “La Source des Inventions” in Paris, being in effect a “house brand” for that company. “La Source” was one of Paris’s oldest and most famous scientific supply houses, having opened its doors in 1907. It was located on Strasbourg Boulevard in Paris. Generations of young people with scientific minds dreamed of owning some of the products sold by this company - I know for sure that I would have been one of them if I had been growing up in Paris at the time in question! Model engines were among the early products sold by “La Source”, with steam engines being offered from 1908 onwards. These were joined by compressed air engines in 1920 and finally by petrol engines in 1938. Among the first petrol engines offered by “La Source” in 1938 was the first design by Arnoux and his colleagues, the initial version of the R.E.A. 10 cc spark ignition model. This was essentially a very competently-designed and well-made copy of the Brown Junior from America. It was joined in the same year by the first version of a very similarly-designed 5 cc model. A marine version of the 5 cc unit followed in 1940.

Production of the R.E.A. engines continued up to the June 14th, 1940 occupation of Paris by German forces, a situation which was to continue for the next four years pending the liberation of Paris by Allied forces on August 25th, 1944. The extent (if any) to which R.E.A. production continued during this unhappy period is now unclear. Certainly, the German occupation of Paris appears to have curtailed further development of these engines, since no new models seem to have materialized. However, that of itself does not necessarily imply that all production ceased. A market for model engines undoubtedly existed during the occupation, as witness the introduction of new designs from no fewer than eight different manufacturers during 1943 alone. This makes it appear quite possible that Arnoux and his associates continued to manufacture their existing models during the wartime period.

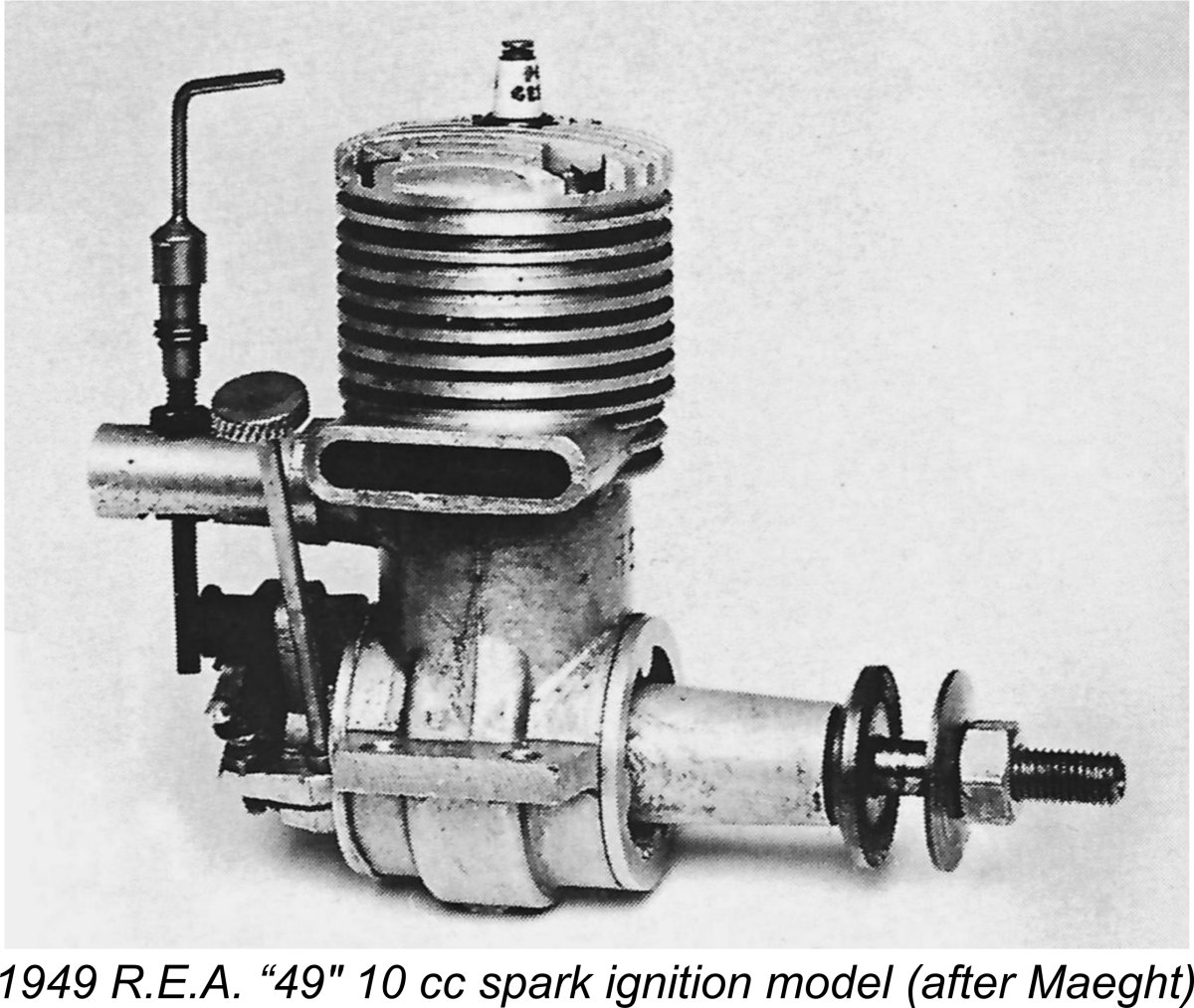

The design of these engines presented a rather odd mixture of old and new! The cylinder used cross-flow loop scavenging, which was a feature of many of the world's most successful competition engines at the time. The engines also employed short-stroke working geometry, bore and stroke being 24 mm and 22 mm respectively for a displacement of 9.95 cc (0.607 cuin.). To offset this appearance of modernity, both models featured side-port induction, an arrangement which was then rapidly falling out of fashion. The engines were clearly designed for slogging power and torque production rather than all-out speed. The makers claimed an output of 0.65 CV (0.64 BHP) @ 10,000 RPM for both versions of the engine. Weights of the spark ignition and glow-plug variants were 12.70 ounces (360 gm) and 11.48 ounces (325 gm) respectively.

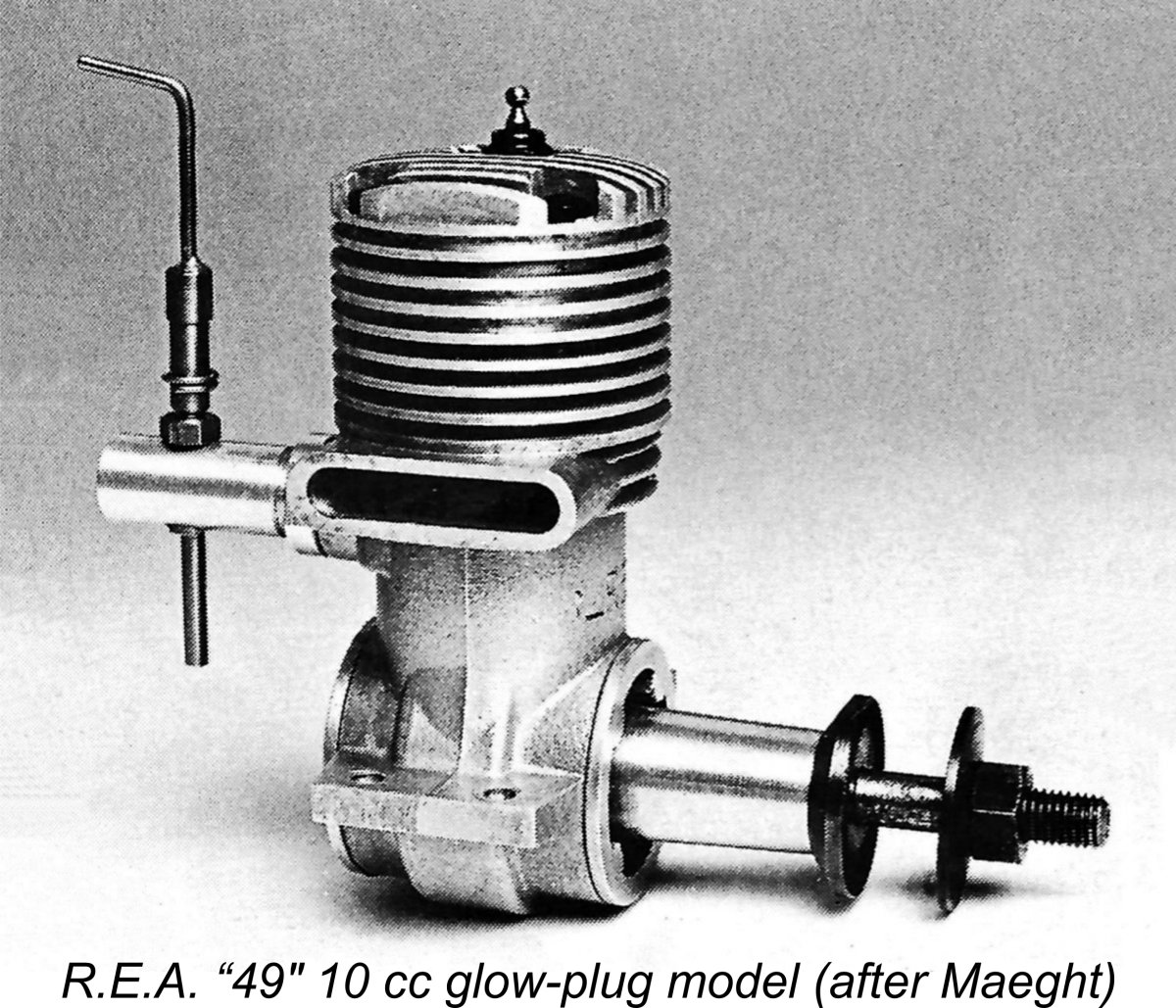

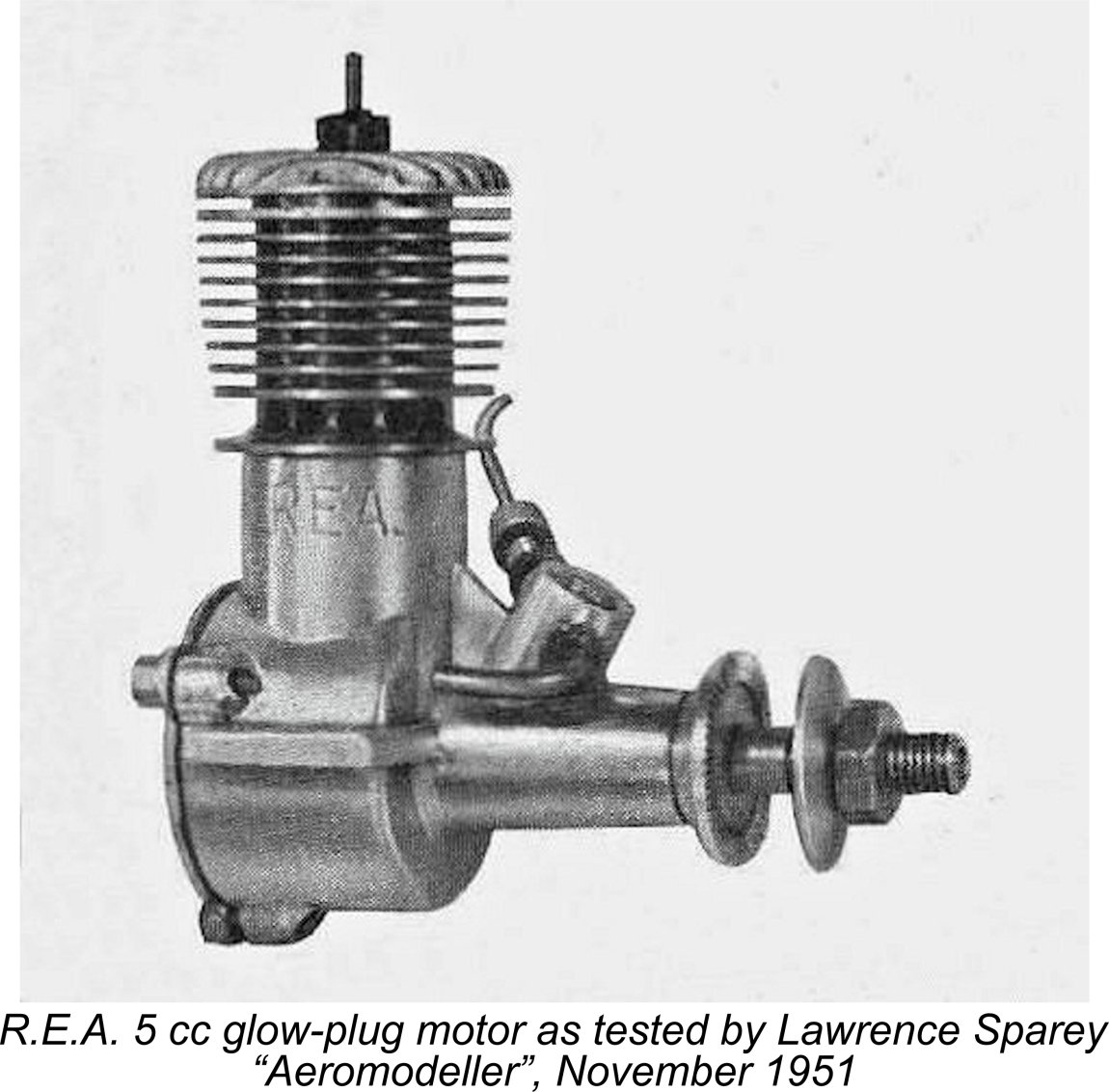

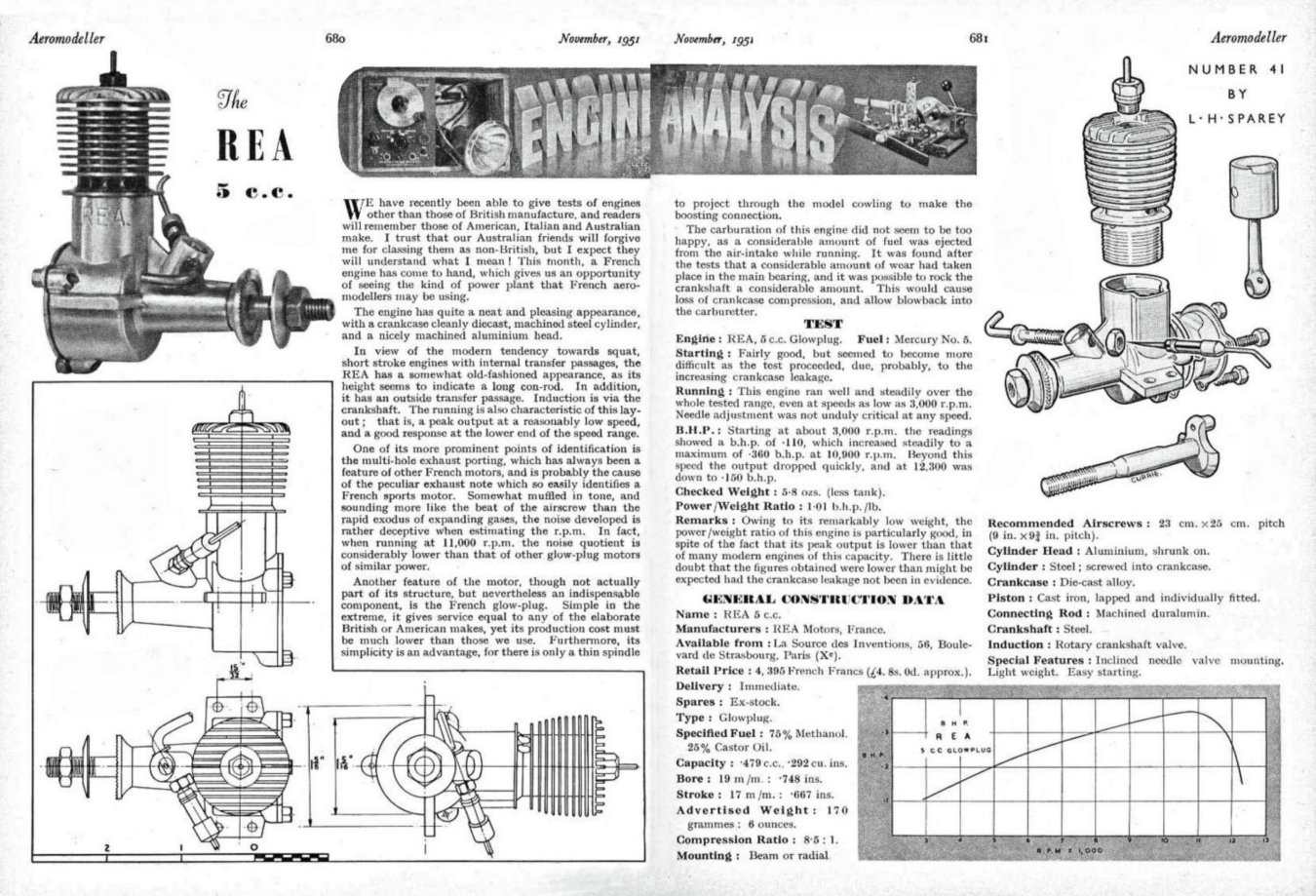

By 1951, these units had been joined (or perhaps replaced) by a 5 cc crankshaft front rotary valve (FRV) glow-plug model of completely different design. It's quite possible that a spark ignition version of the new model was also produced, but Adrien Maeght does not mention any such model in his previously-referenced book. That said, the manufacturers appear to have had a special fondness for spark ignition, continuing to produce such models for their beloved marine applications at least up to 1955. Hence they may well have made some examples of their new 5 cc model using spark ignition. It's actually noteworthy that as far as I'm aware, R.E.A. never produced a single diesel. Since the 5 cc glow-plug design of 1951 is one of the better-documented R.E.A. products, I'll spend a little time describing it in some detail. The 1951 R.E.A. 5 cc Glow-plug Model

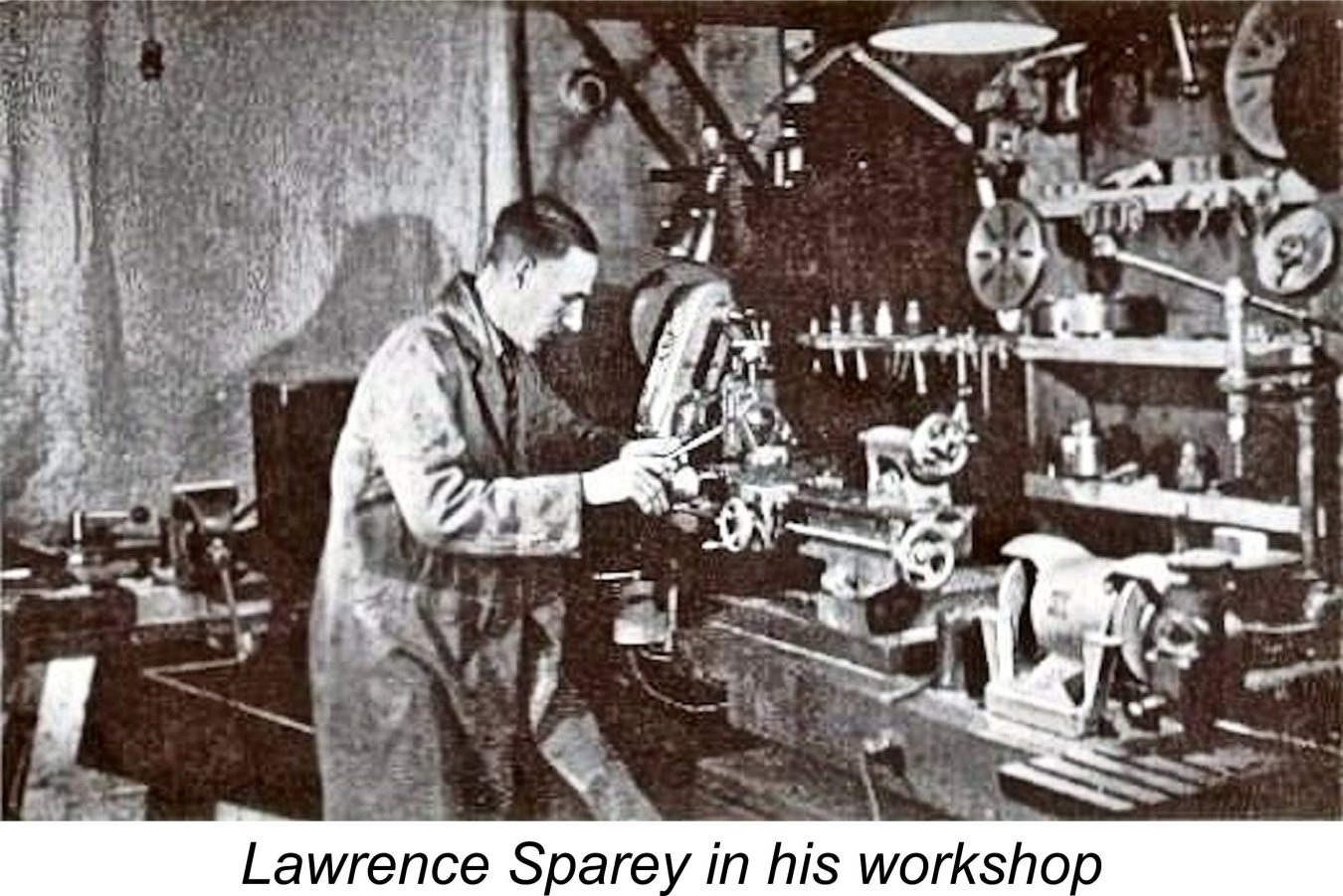

The new model featured a completely redesigned crankcase casting which did not incorporate an exhaust stack and cooling fins. The cylinder was machined with integrally-formed cooling fins. It was externally threaded at its base to allow it to be screwed into the top of the crankcase. Both transfer and exhaust ports consisted of rows of drilled holes, much like the earlier British Yulon models. Scavenging continued to follow the cross-flow loop configuration. In order for the transfer ports to align correctly with the bypass passage which was cast into the crankcase on the left side, it was necessary to ensure that the cylinder was correctly aligned when tightened down in its installation thread. This was presumably accomplished by fitting and marking the cylinder prior to the addition of the drilled transfer and exhaust ports, which could then be created in the appropriate locations to ensure their correct alignment upon final assembly. A similar approach was employed by the Anchor Motor Co. of Chester, England in the production of the AMCO .87 diesel with its screw-in cylinder. We Anglophones are greatly indebted to the redoubtable Lawrence H. Sparey for much of our knowledge of this engine. Sparey somehow obtained access to an example in mid 1951, subsequently conducting a full test of the engine. His report was published in the November 1951 issue of "Aeromodeller" magazine.

Sparey praised the engine's neat and uncluttered appearance along with its unusually low measured weight of only 5.8 ounces (164 gm). He reported that the engine ran "well and steadily over the whole tested range". Response to the needle valve was characterized as being "not unduly critical at any speed". So far, so good........ but Sparey also commented that although starting was "fairly good", it seemed to become "more difficult as the test proceeded". Sparey attributed this rather unusual observation to the reported fact that during the test the engine developed "a considerable amount of wear" in the main bearing, to the point where "it was possible to rock the crankshaft a considerable amount". Sparey felt that the progressive starting dificulties as well as the engine's relatively low peaking speed and power output were likely due mainly to gas leakage through the main bearing and consequent blow-back in the induction venturi. The very short sealing length at the rear of the crankshaft journal resulting from the rearward location of the induction port in the shaft would certainly exacerbate any such problem. Now, I don't doubt for one minute that Sparey reported exactly what he found. If rapid main bearing wear was a chronic fault of the engine, it would undoubtedly represent a serious criticism which should have been recorded. However, Sparey gave this particular game away by stating for the record that he had tested the engine at speeds down to 3,000 RPM! The power curve that he included with the test report confirmed this by reporting figures covering the speed range from 3,000 RPM up to over 12,000 RPM. This is another case in which Sparey clearly demonstrated one of his great failings as a tester, upon which I've commented in connection with other reviews. This was his seeming inability to keep pace with emerging model engine design trends and technologies. In particular, he clearly failed to grasp the fact that glow-plug ignition timing is optimized to within relatively narrow limits by a combination of compression ratio, fuel mixture composition and plug heat range. While the effect of engine speed on element temperature doubtless plays a role in establishing the timing, it has far less primary influence than the other three factors. This is because glow-plug ignition is actually far more dependent upon a catalytic reaction between the methanol in the fuel and the platinum glow-plug element than it is upon the thermal initiation of combustion by the element temperature alone. Initiation of this catalytic reaction requires that a certain element temperature be achieved, which is why the plug has to be electrically lit for starting. However, once this catalytic reaction is initiated, it becomes self-sustaining and will continue more or less regardless of the actual ongoing element temperature. This is why R/C glow-plug engines continue to run at low throttle openings and why un-throttled engines continue to run on very rich mixtures, in both cases with the plug barely glowing. A higher element temperature will certainly speed up the ignition process somewhat, which is why plugs having different heat ranges can produce measurably different results in the same engine. However, there are limits to the effectiveness of changing the element temperature in this way - once initiated, the catalytic reaction will take place regardless. Consequently, the timing of a glow-plug engine having a set compression ratio and using a given fuel and plug is relatively (although not of course completely) independent of the engine speed when fully leaned out, and the operator can do little to change it apart from using either a hotter or colder plug, a richer mixture (thus sacrificing power) or a less “hot” fuel (ditto). I've discussed these parameters in detail in my separate article on glow plug heat ratings. To sum up, once the parameters of compression ratio, fuel composition and plug heat range have been established for a given glow-plug engine, the leaned-out ignition timing will only be perfectly matched to a relatively narrow range of speeds. At speeds below this range the timing will be too far advanced, while at higher speeds it will become excessively retarded. The latter condition will not harm the engine, but the former situation certainly can! The only way to keep such an engine happy is to run it at or near the speed at which the various factors combine to optimize the leaned-out ignition timing.

None of this should be interpreted as a disparagement of the memory of Sparey, who deservedly commands our respect as a prominent figure in early post-WW2 model engine history. As a pioneer of model diesel technology in Britain; as a tireless advocate of home construction of model engines; and as a diligent and consciencious model engine tester and commentator, Sparey had few contemporary rivals. It's just that he seems to have been a bit slow to adapt to emerging technologies such as glow-plug ignition. Despite this issue, Sparey managed to extract a reported peak output of 0.360 BHP @ 10,900 RPM. This may not sound very impressive to us today, but it was pretty good going by 1951 standards for a 5 cc sports engine weighing only 5.8 ounces (164 gm). Sparey said so very clearly, stating that thanks to the engine's unusually low weight "the power/weight ratio of this engine is particularly good". If the main bearing wear issue had not reared its ugly head, there seems to be little doubt that the R.E.A. would have improved somewhat upon this figure. For comparison, Peter Chinn's test of the far porkier 7.75 ounce (220 gm) FROG 500 in the May 1950 issue of "Model Aircraft" reported an output of 0.370 BHP @ 12,000 RPM. Clearly the R.E.A. was well in the hunt ............ Further Developments

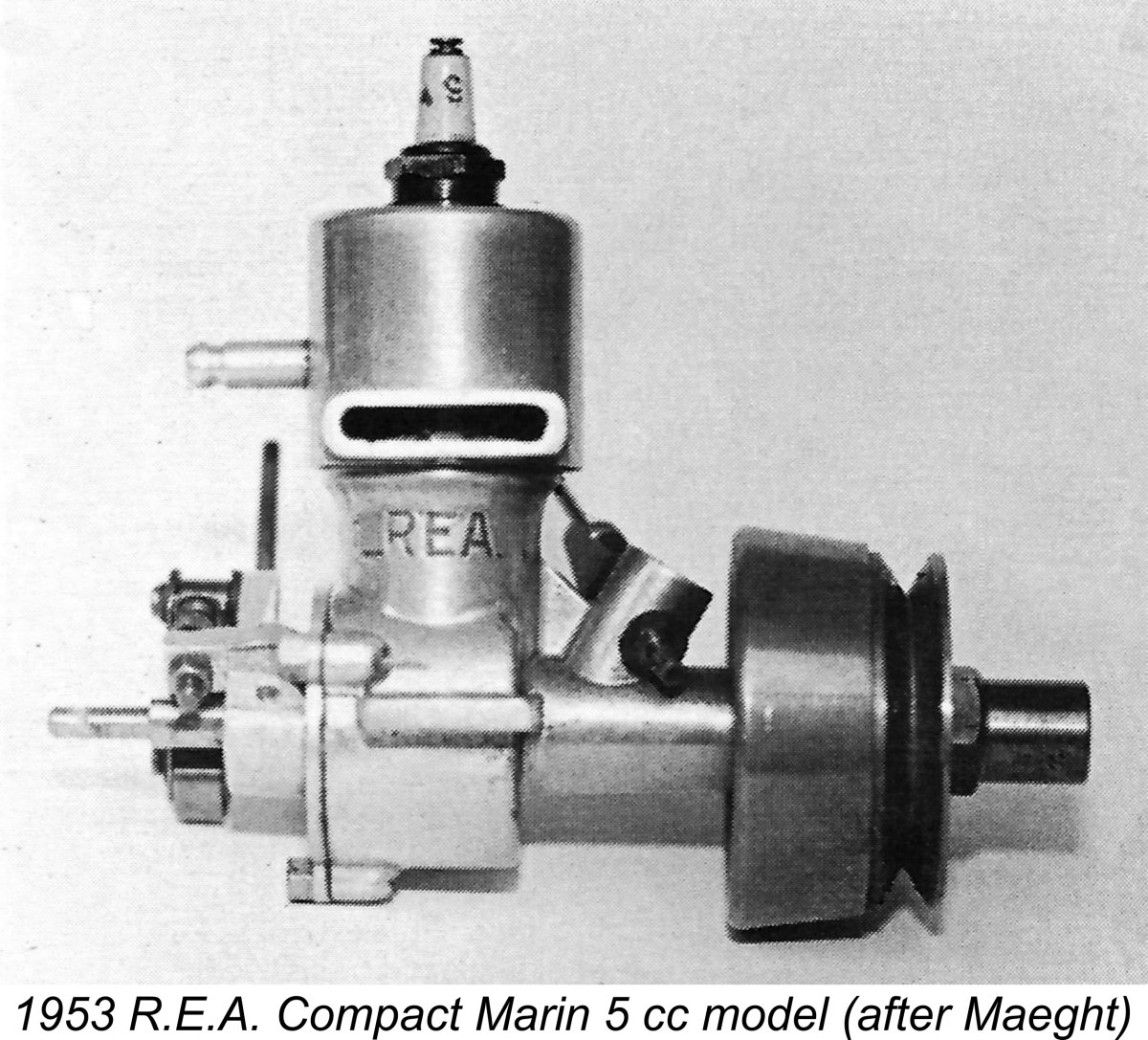

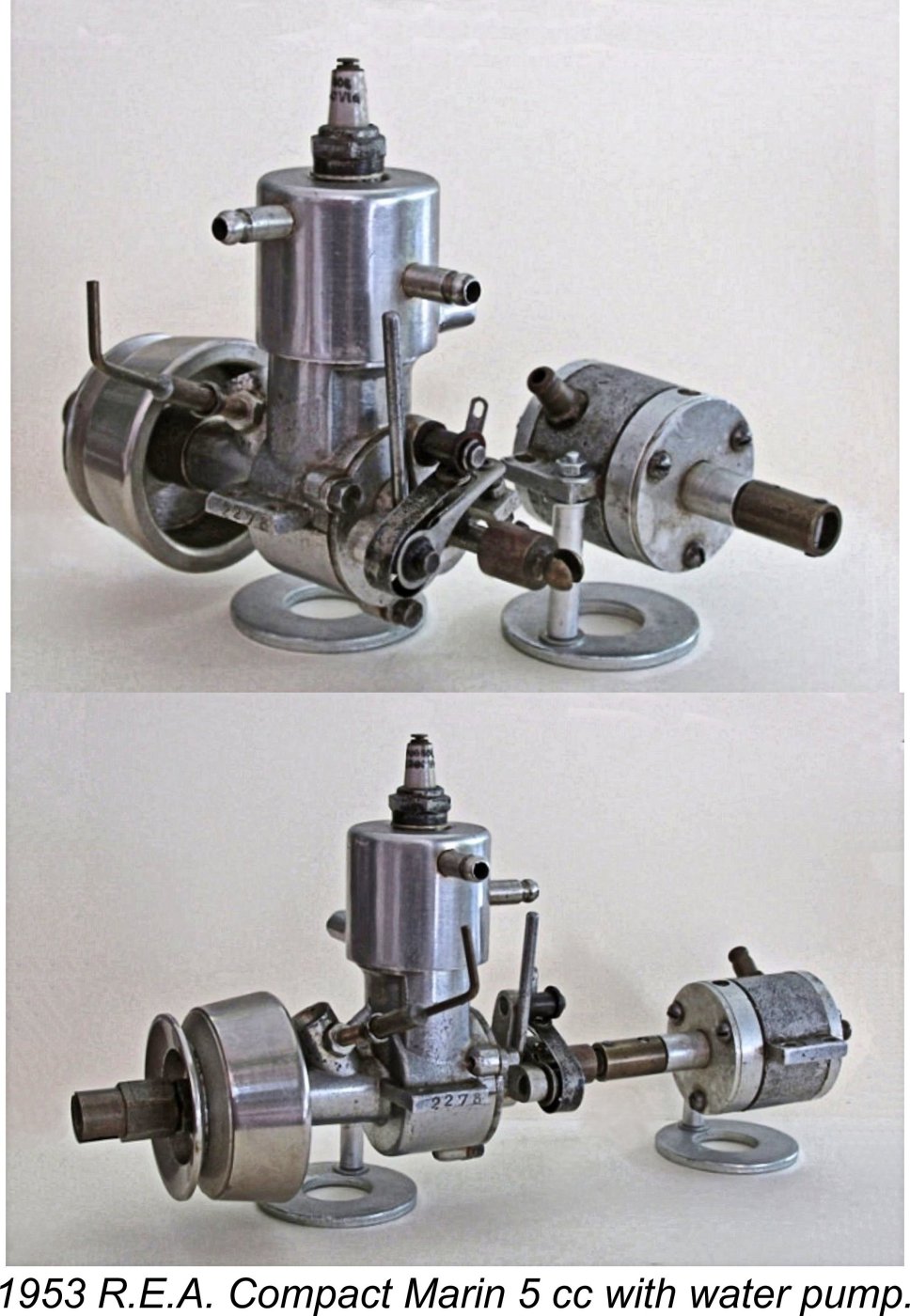

Interestingly enough, the Compact Marin continued to employ spark ignition, presumably because many model boat enthusiasts still favoured this form of ignition given the superior engine control and lower fuel costs which it afforded. The latter was an important factor given the very long runs typical of model boat operation. Moreover, in a model boat context the weight of the ignition support equipment was far less of a factor than it was for model aircraft applications. The Compact Marin also retained the backplate-mounted timer which had first appeared on the "49" 10 cc spark ignition model.

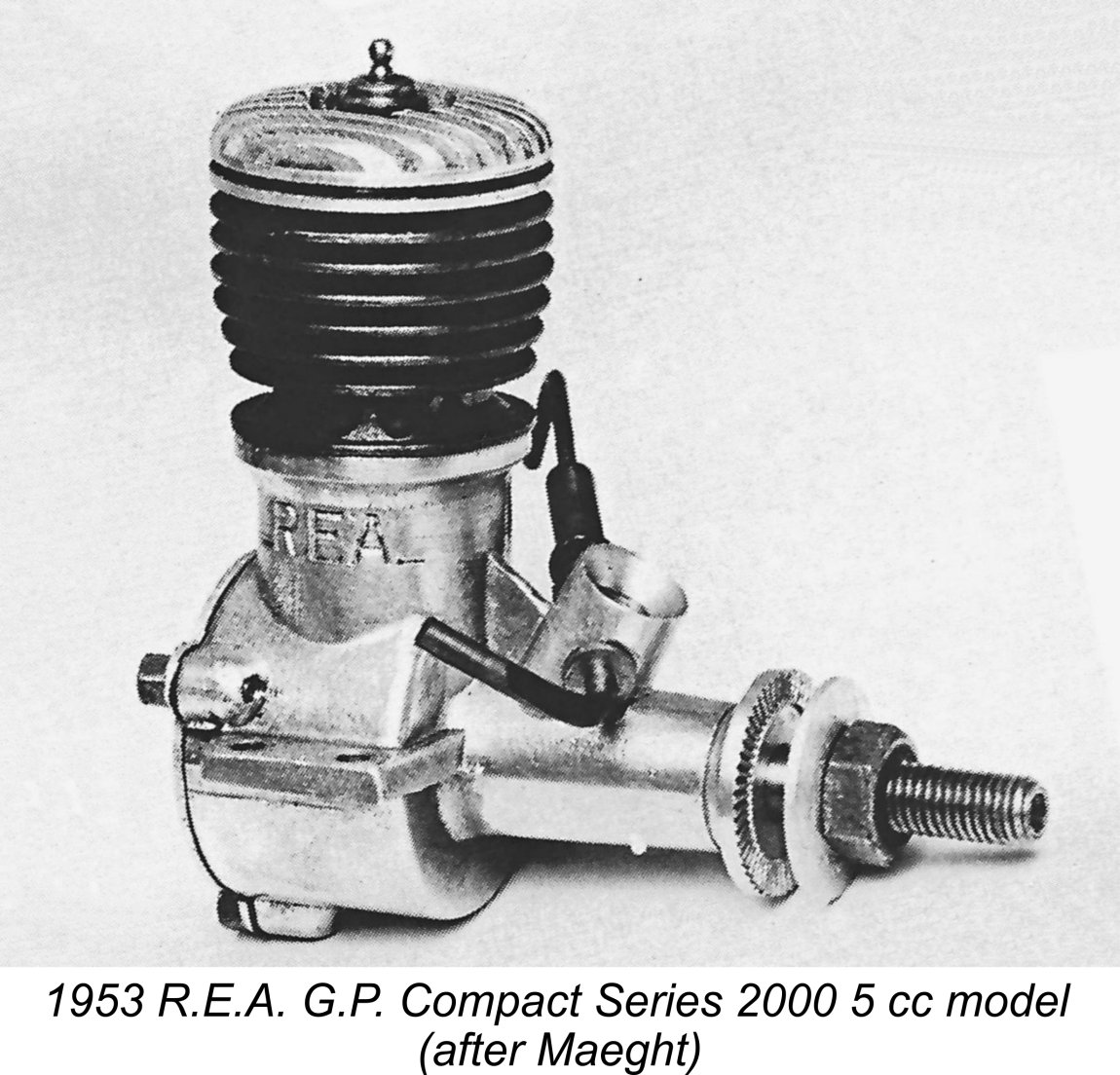

Jumping ahead a little, a slightly revised second model of this engine was released in 1955. This was actually a relatively minor update, the addition of an exhaust manifold being the main observable difference (although there may well have been internal changes as well). Remarkably, spark ignition was still featured on this revised variant, although a glow-plug version was offered as well. The spark ignition variant of this model was to prove to be the final such design to emerge from the R.E.A. workshops. Returning now to 1953, a revised version of the R.E.A. 5 cc glow-plug aero unit described earlier was also released in that year. This was marketed as the R.E.A. G.P. Compact Series 2000 5 cc model. The significance of the Series 2000 designation is unclear at this time.

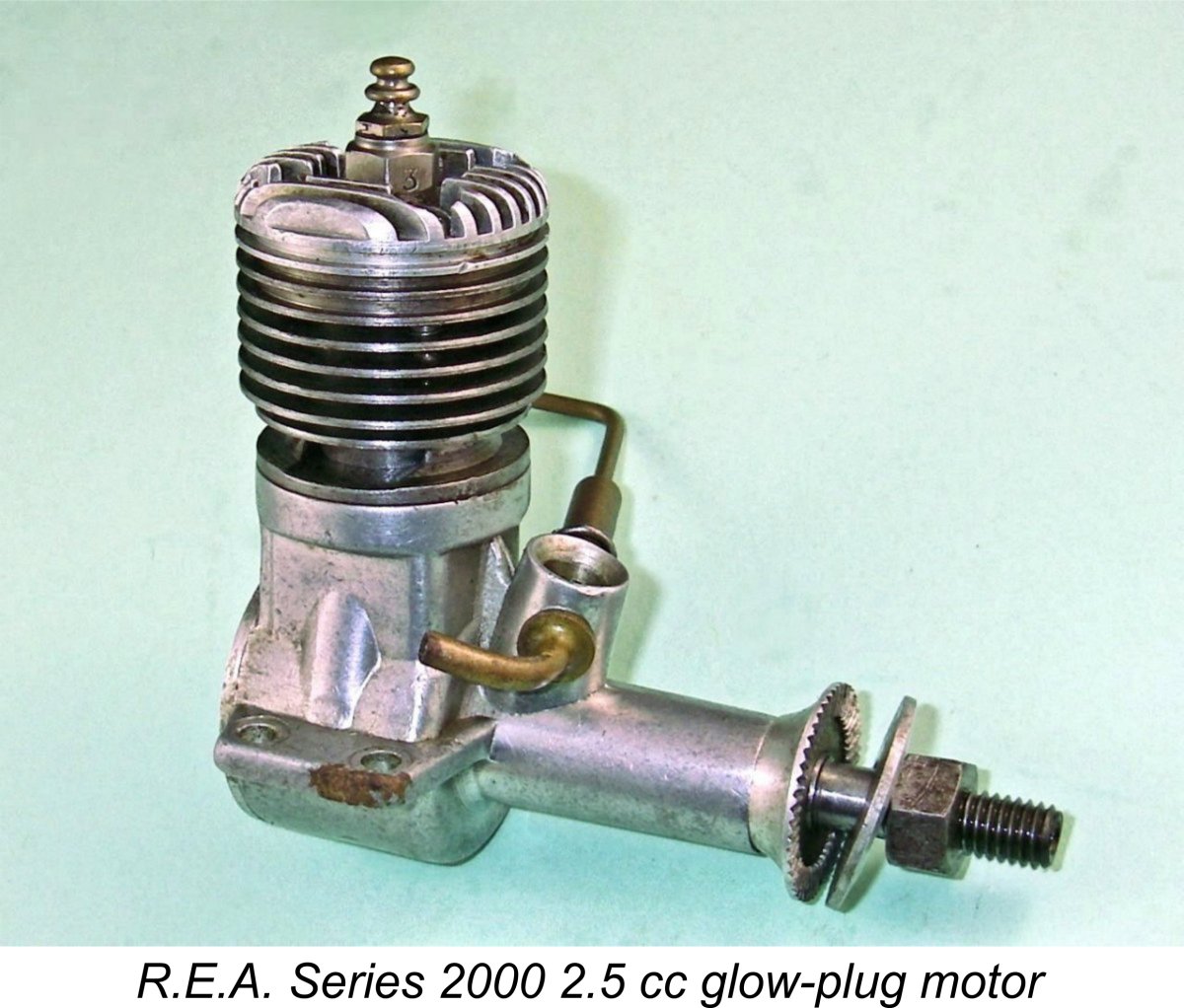

The switch back to long-stroke geometry makes perfect sense when we consider that these engines were all about torque at moderate speeds rather than all-out performance. The revised model would likely do an even better job of swinging a largish prop than its short-stroke predecessor. The manufacturer's reported claim of 0.365 CV (Cheval Vapeur - 0.360 BHP) at unspecified rpm for this model agrees exactly with Lawrence Sparey's previously-noted peak output figure for the earlier short-stroke version of the engine. Indeed, it seems possible that the manufacturers were using Sparey's independent report as their underlying reference in making this claim. In 1955 the 5 cc G.P. Compact Series 2000 model was joined by a smaller companion of very similar design. This was the 2.5 cc G.P. Series 2000 model. I'm fortunate enough to have a fine example of this model on hand for examination and test. This being the case, let's get right to it! The R.E.A. 2.5 cc G.P. Series 2000 Described

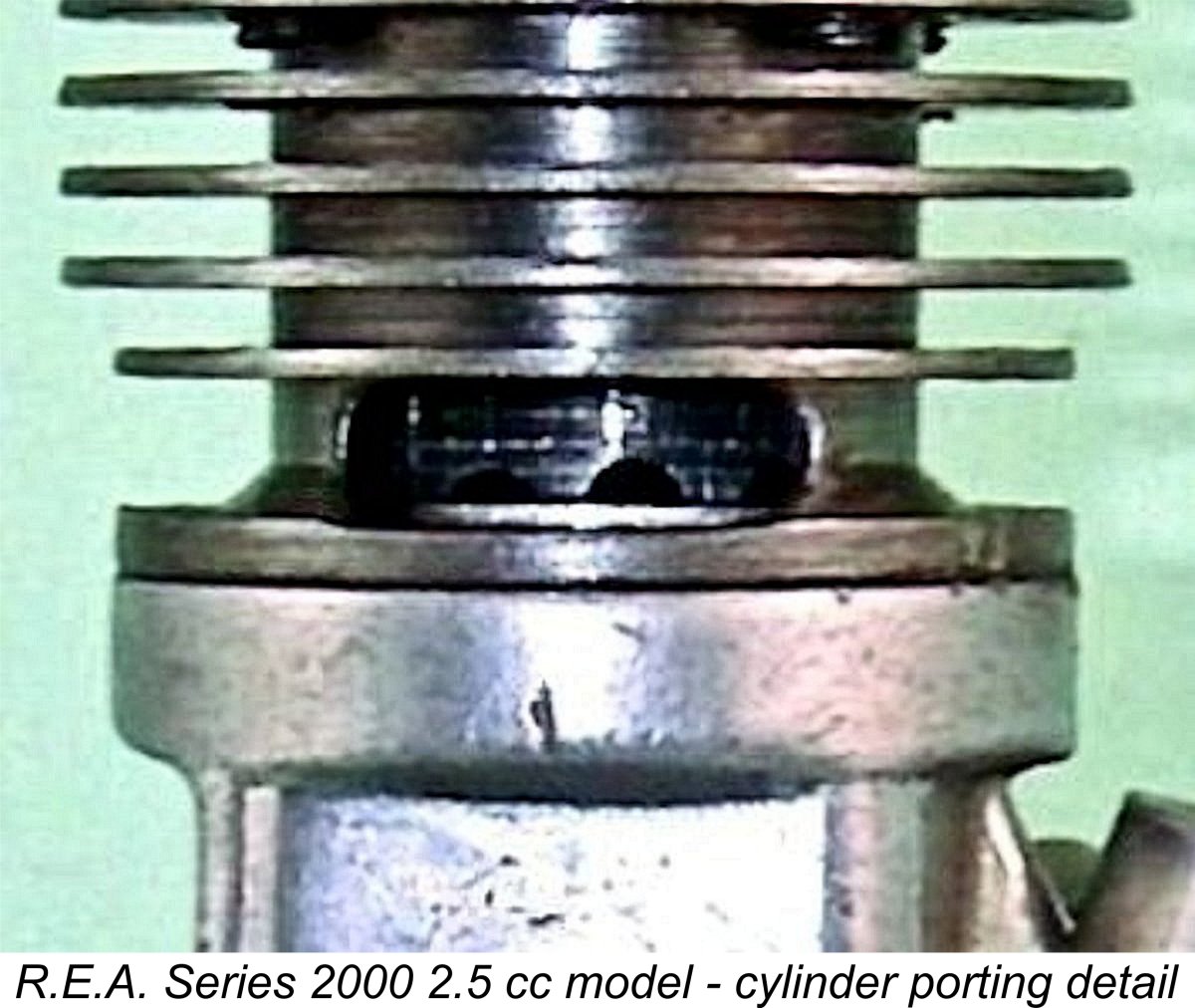

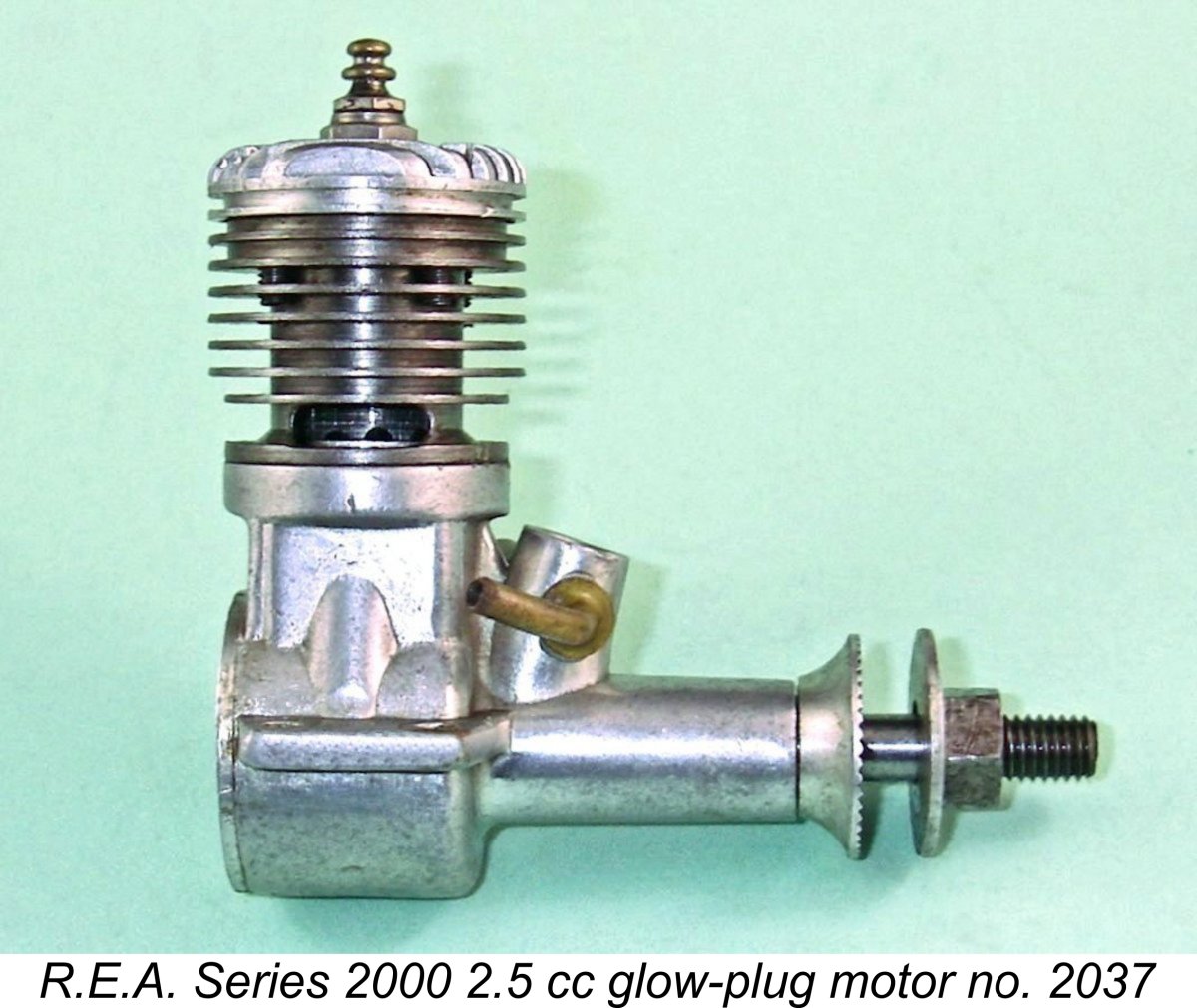

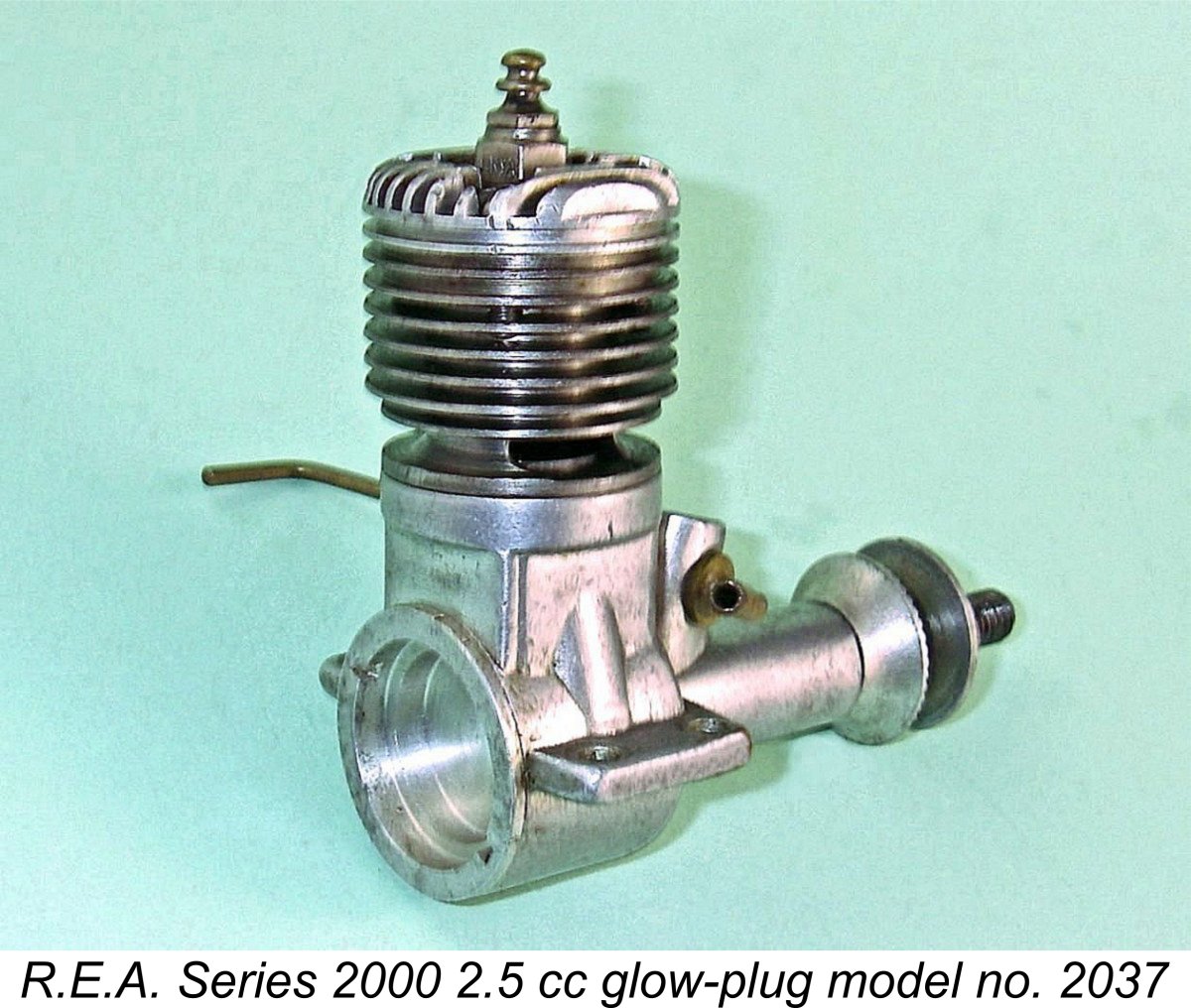

Like its 5 cc companion in the R.E.A. Series 2000 range, the 2.5 cc model is a long-stroke FRV engine which employs cross-flow loop scavenging. Bore and stroke are 14 mm and 16 mm respectively for a displacement of 2.46 cc (0.150 cuin.). The engine is commendably light in weight at a checked 126 gm (4.44 ounces). Volumetrically measured compression ratio is 8:1. The most obvious fundamental design change is the fact that the exhaust port is no longer formed as a row of drilled holes. While that arrangement was easy to produce and resulted in unusually low noise levels (as noted by Sparey in his 1951 test) due to the progressive exhaust port opening to which it gave rise, it was far less efficient than a single rectangular aperture. The exhaust port in the 2.5 cc model was formed by end-milling, resulting in an elongated oval "race-track" configuration with rounded ends.

An arc-shaped step is machined into the piston crown on the transfer side, serving the function of a baffle by directing the incoming gas upwards. This step is machined to a larger radius than the cylinder bore so that it tapers off progressively to nothing at the ends. The depth of the step is such that the transfer ports overlap the exhaust ports to a very significant extent in terms of their opening period. As with its 5 cc companion in the range, the steel cylinder of this model is externally threaded below the installation flange, allowing it to be screwed into the upper crankcase. The porting arrangements clearly require that the screw-in cylinder be oriented with the exhaust on the right side and the transfers on the left to match the bypass. Presumably a trial assembly allowed the cylinder to be marked for correct location of the ports. Dismantling of this engine is not recommended - restoring the correct cylinder orientation might be challenging!

As I mentioned earlier, this is an engine which should not be dismantled unnecessarily! This being the case, I can't provide a lot of detail regarding the engine's internal structure. I can confirm that the con-rod is a turned aluminium alloy component and that the main journal diameter is 9 mm, a pretty conservative figure for a sports glow-plug engine of this displacement. The induction port is a circular drilled hole, thus creating no sharp corners to act as stress-raisers. This port opens fairly early at 35 degrees after bottom dead centre, but closes even earlier at only 15 degrees after top dead centre for a total induction period of 160 degrees. The closure figure seems to be more or less coordinated with the sub-piston induction period noted above - the designer was clearly relying on that feature to permit an early closure of the rotary valve, with a consequent increase in the operating base compression ratio.

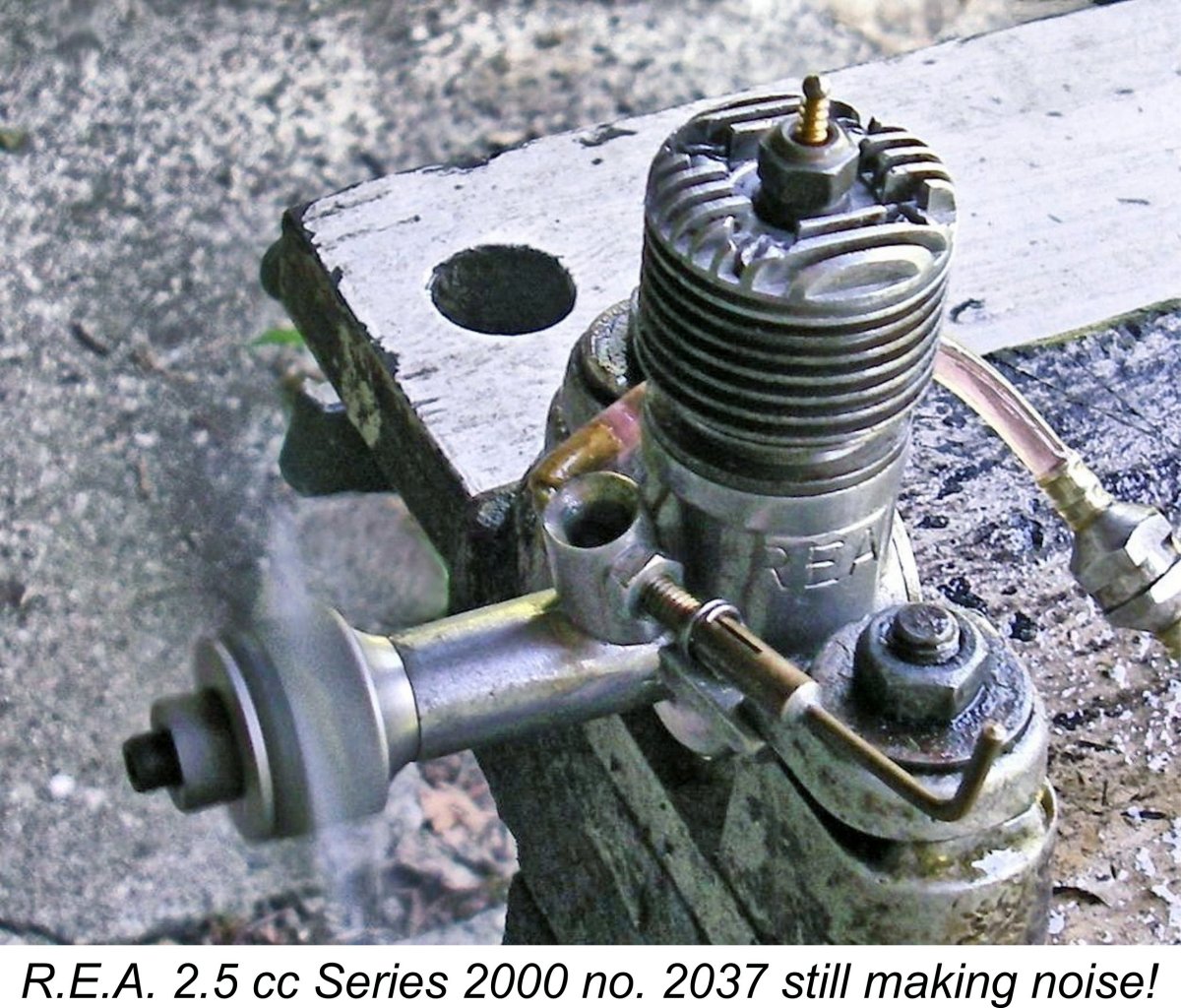

This example of the engine bears the serial number 2037. This indicates that it was the 37th engine built in the 2000 series of 1955. It also confirms that it is the actual example illustrated in Mike Clanford’s A-Z book on page 166, although Clanford incorrectly dates it to 1950. While it is undoubtedly extremely useful, Clanford's book is often unreliable when it comes to certain basic facts! It would be nice to get some more serial numbers so that some kind of credible estimate of production figures might be derived. Any volunteers out there?!? The quality of the engine's construction is very high, particularly where it counts. The unit makes no pretensions to flashy appearance, but all working fits are beyond reproach. In particular, there's no detectable play either in the rod bearings or the main crankshaft bearing despite the considerable use which this example appears to have experienced. Full marks to M. Arnoux and his associates!! OK, so we have here a very well-made unit of relatively conservative design. How does it run?!? Let's find out ........... The R.E.A. Series 2000 2.5 cc Model on Test T When discussing power output claims for model engines originating from certain Continental countries (including but not limited to France, Germany, Czechoslovakia, Hungary and Italy), we are confronted with the fact that manufacturers in those nations routinely cited their claimed power outputs in metric horsepower or Chevaux Vapeur (abbreviated to CV). We already encountered this in connection with the manufacturer's power output claim for the Series 2000 5 cc model. The figures for BHP and CV are very close - 1 BHP is equal to 1.01427772651 CV. Still, it's necessary to watch the units when reviewing power output claims from France and a number of other Continental sources. According to Adrien Maeght's book, the R.E.A. company claimed an output of 0.2 CV @ 9,000 RPM for the Series 2000 2.5 cc model. This converts to a claim of 0.197 BHP @ 9,000 RPM. Before anyone sneers at these figures, it's worth noting that an output of 0.197 BHP on straight methanol/castor oil fuel with no nitro was by no means a dismal figure for a plain-bearing 2.5 cc sports motor in 1955 - many British and Continental diesels of the period struggled to reach such a figure. Moreover, few of them could manage an output of this magnitude at a speed of only 9,000 RPM. We seem to be looking here at an engine that is all about torque at low speeds - unusual for a glow-plug engine, to say the least. We would normally look to a diesel for any application requiring high levels of low-speed torque.

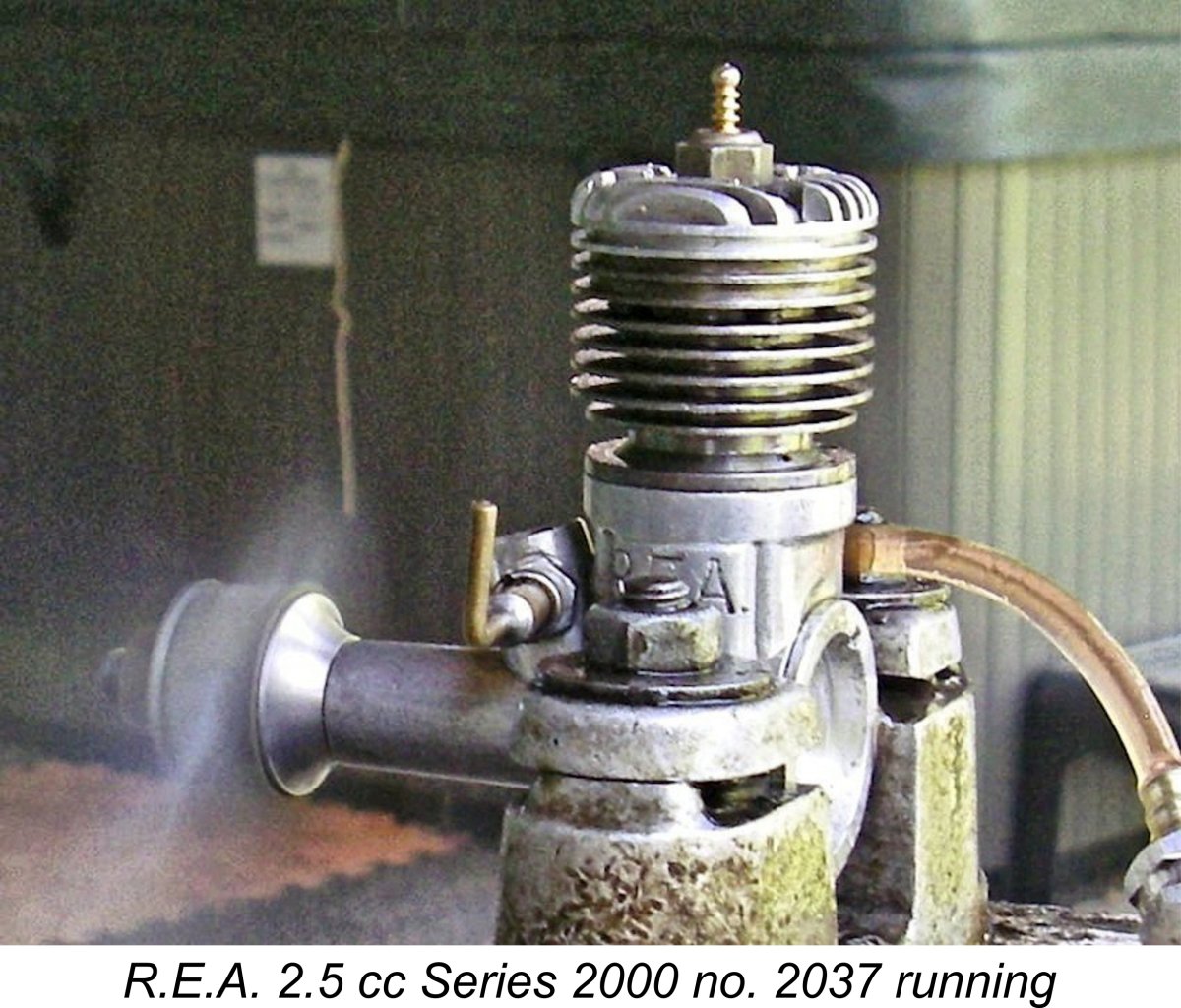

Acccordingly, I elected to conduct this test using a fuel containing only 5% nitro - the least-nitrated fuel which I had on hand. I also began by assuming that the manufacturer's claimed peaking speed might well be accurate. Reference to the established coefficients for my standard set of APC test props implied that an APC 10x4 might allow the engine to reach the cited peaking speed of 9,000 RPM or thereabouts. That said, I was mindful of the previously-noted fact that thanks to the relatively narrow range over which the ignition in a glow-plug engine will be perfectly timed, it's far better to err on the side of too light a load than too heavy. I therefore decided to begin with an APC 9x4 prop, which should theoretically be good for something over 10,000 RPM if the manufacturer's claims were anywhere near correct. At least there seemed little chance of harming the engine using such a load. As previously mentioned, this example of the R.E.A. 2.5 cc Series 2000 model appeared to have received a fair bit of use in the past. Accordingly, I decided to treat it as a used engine which required no running-in apart from a few shake-down runs on a slightly rich mixture. While preparing for this test, I noticed that the base (crankcase) compression seemed a bit insecure. A solvent immersion leak test showed that the backplate seal was leaking quite badly. Upon removal of the backplate (using the correct tool!), I found that there was no gasket. I made and fitted a suitable gasket, then re-assembled the engine. Happiness restored - the transfer ports now popped healthily when the engine was turned over without a plug. I'm certain that the engine was supplied with a gasket and that some previous owner had removed the backplate and omitted to re-use or replace the gasket. Always a point worth checking ..........

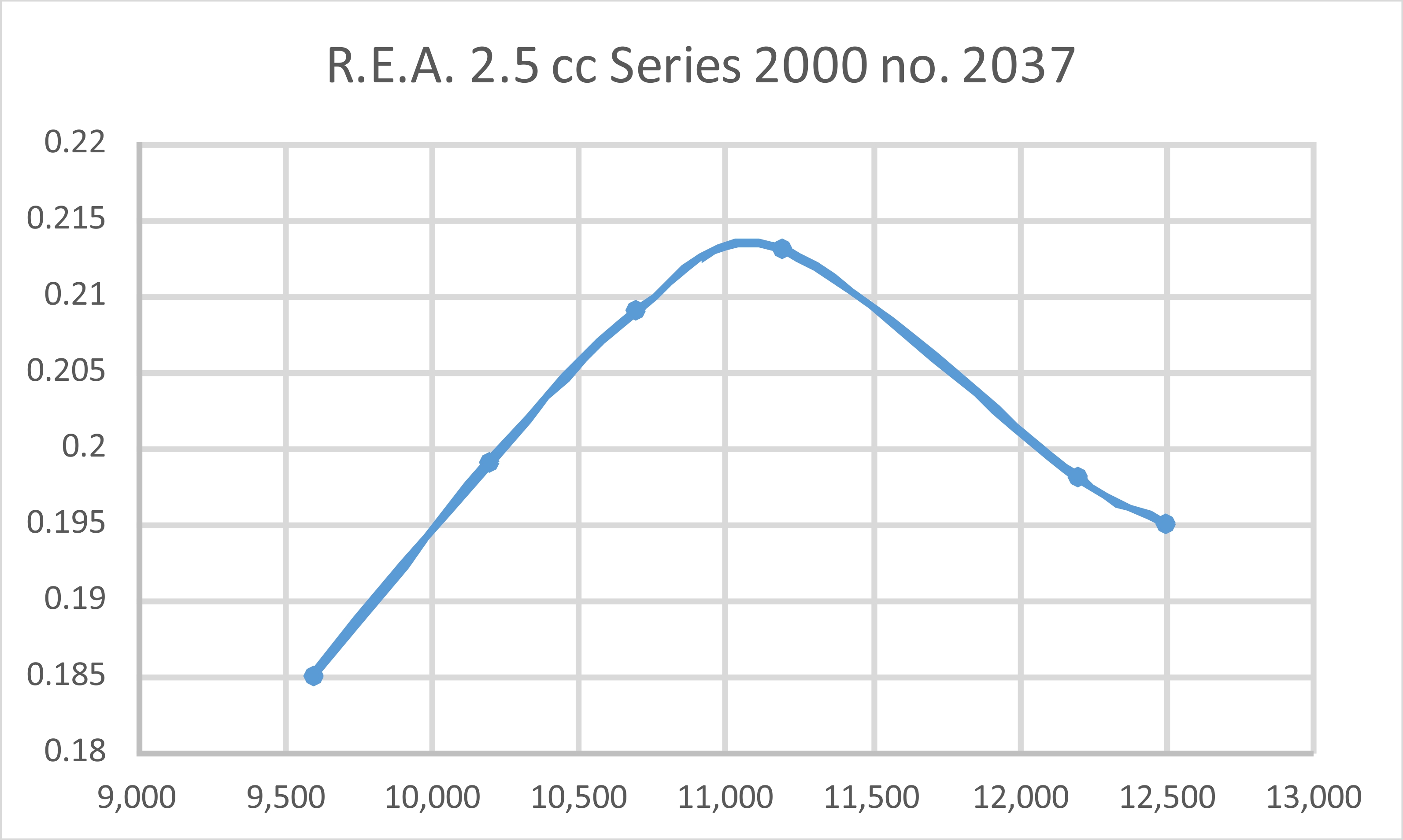

My earlier prediction that the engine should turn an APC 9x4 at a little over 10,000 RPM proved to be spot-on. The figure actually achieved with this prop was 10,200 RPM. I then tried an APC 8x7, which has a slighly higher power absorption coefficient, hence pulling speeds down a little from the 9x4. The actual power output indicated by the 9,600 RPM at which that prop was turned was less than that implied at 10,200 RPM by the 9x4, indicating that the power peak undoubtedly lay above 9,600 RPM. I therefore confined my further testing to faster props than the 9x4 and 8x7 items already tried. As the speeds climbed with successively faster props, I began to notice that at the higher speeds around what proved to be the measured peak, the engine picked up some 400-500 RPM on a given prop after warming up fully in two-stroke mode. This would normally be taken as an indication of a compression ratio that was too low, although the measured 8:1 geometric ratio is well within normal limits for a sports glow-plug motor. That said, the fact remains that the achievement of maximum revs on a given prop operating at around the peak required that the engine be fully warmed up. With that caveat, the engine performed extremely well, running smoothly and consistently with no mis-firing and no tendency to nip up or sag. The figures obtained on test are shown in the following table, together with the derived power curve.

These figures reflect a very creditable performance indeed for a 1955 plain-bearing sports glow-plug motor of 2.5 cc displacement. The engine appears to develop around 0.215 BHP @ 11,100 RPM, figures which many contemporary plain bearing sports diesels of the period had trouble matching. Interestingly enough, the measured output is a little higher than that cited by Maeght, and at a significantly elevated peaking speed. The 5% nitro probably contributed to this - Maeght's figures were most likely based on the use of straight fuel.

In terms of the flatness of its power curve, the engine is developing in excess of 0.200 BHP (93% of its peak) at all speeds between 10,300 and 12,100 RPM - a very useful spread which would allow a range of different props to be used effectively for different purposes. A "fast" 9x4 would probably do well in a free-flight application, while for control-line purposes a "fat" 8x6 would probably be ideal. The engine came through the test with flying colours, appearing to be ready and willing to do a lot more running if desired. The Fox glow-plug survived the entire test with no problems. Summarizing, an extremely well-made engine which was a pleasure to test and which gave a remarkably good account of itself by the standards of its day. Full marks once again to M. Arnoux and his colleagues! Swansong - the 2.5 cc G.P. Marin Model At the present time, I have no way of estimating the scale of the R.E.A. company's output. Given the fact that the engines were marketed exclusively by a single outlet, “La Source des Inventions” in Paris, it seems likely that production figures for this range were relatively small. However, that's as far as I can go for the moment. The Compact Marin Series 2000 5 cc glow-plug model was still listed in the 1963/64 catalogue from “La Source des Inventions”, as was the previously-described 2.5 cc glow-plug aero model (albeit by then referred to as the R.E.A. 2.5 Sport model rather than by the earlier Series 2000 designation. I don't have any definite knowledge regarding how long the various other models described above remained in production.

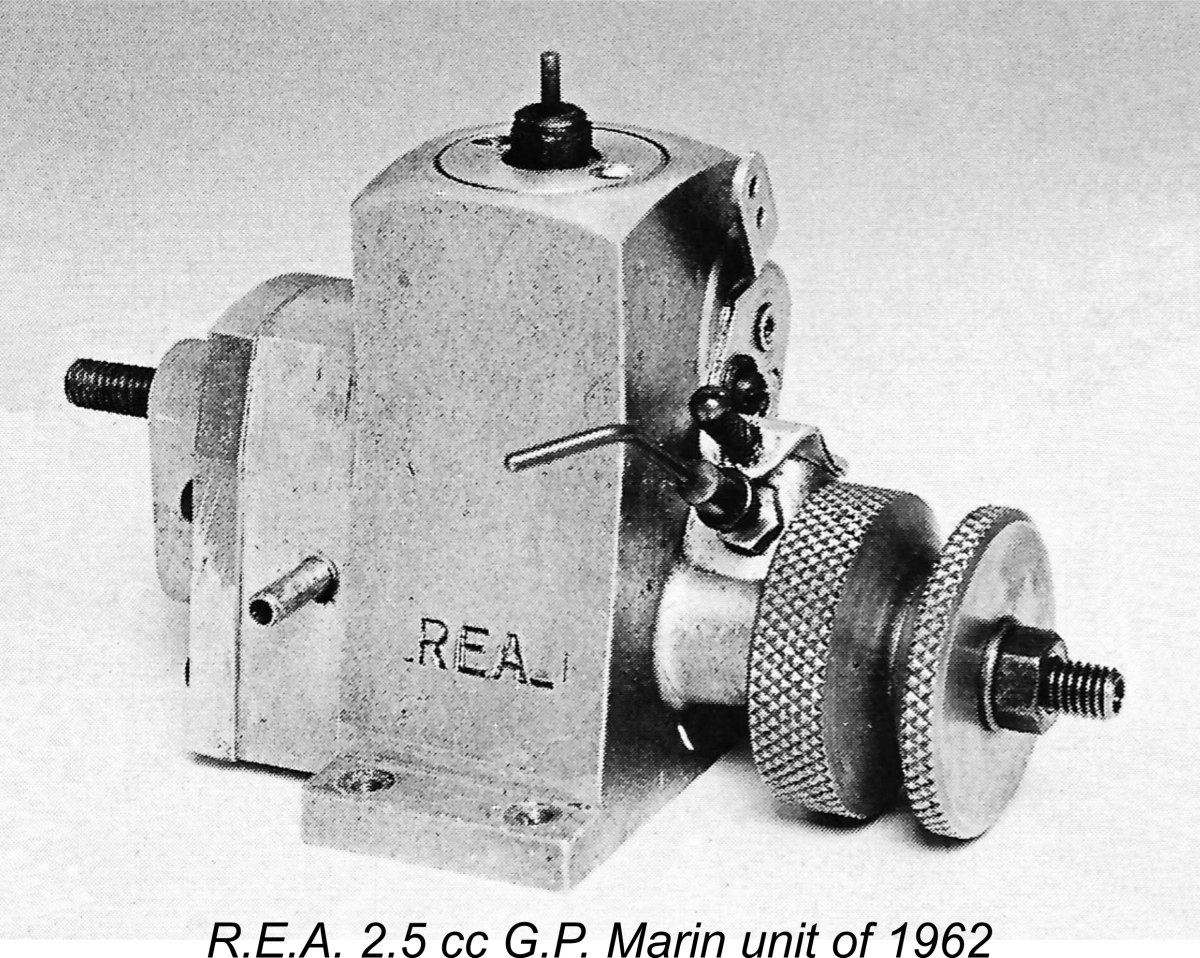

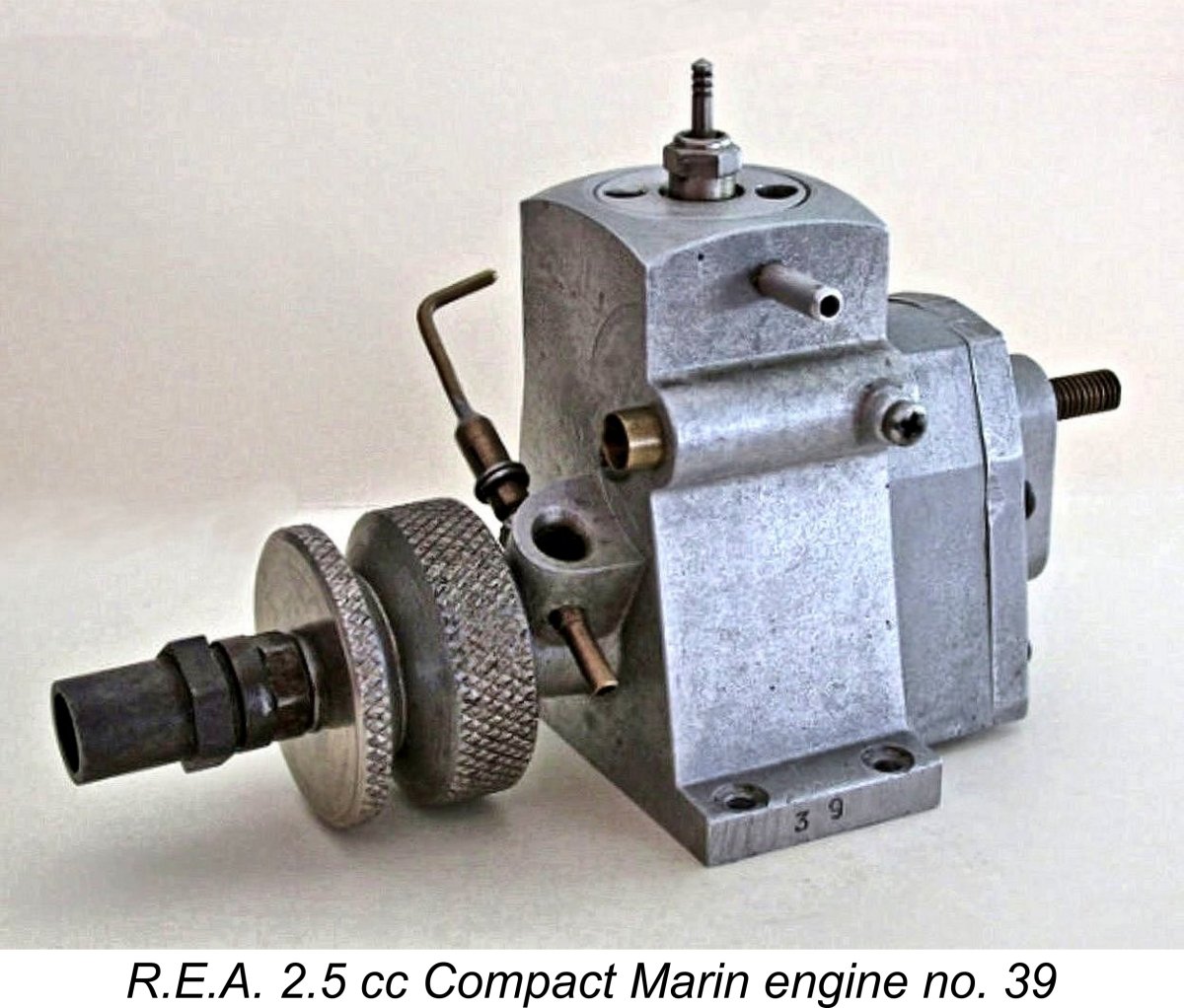

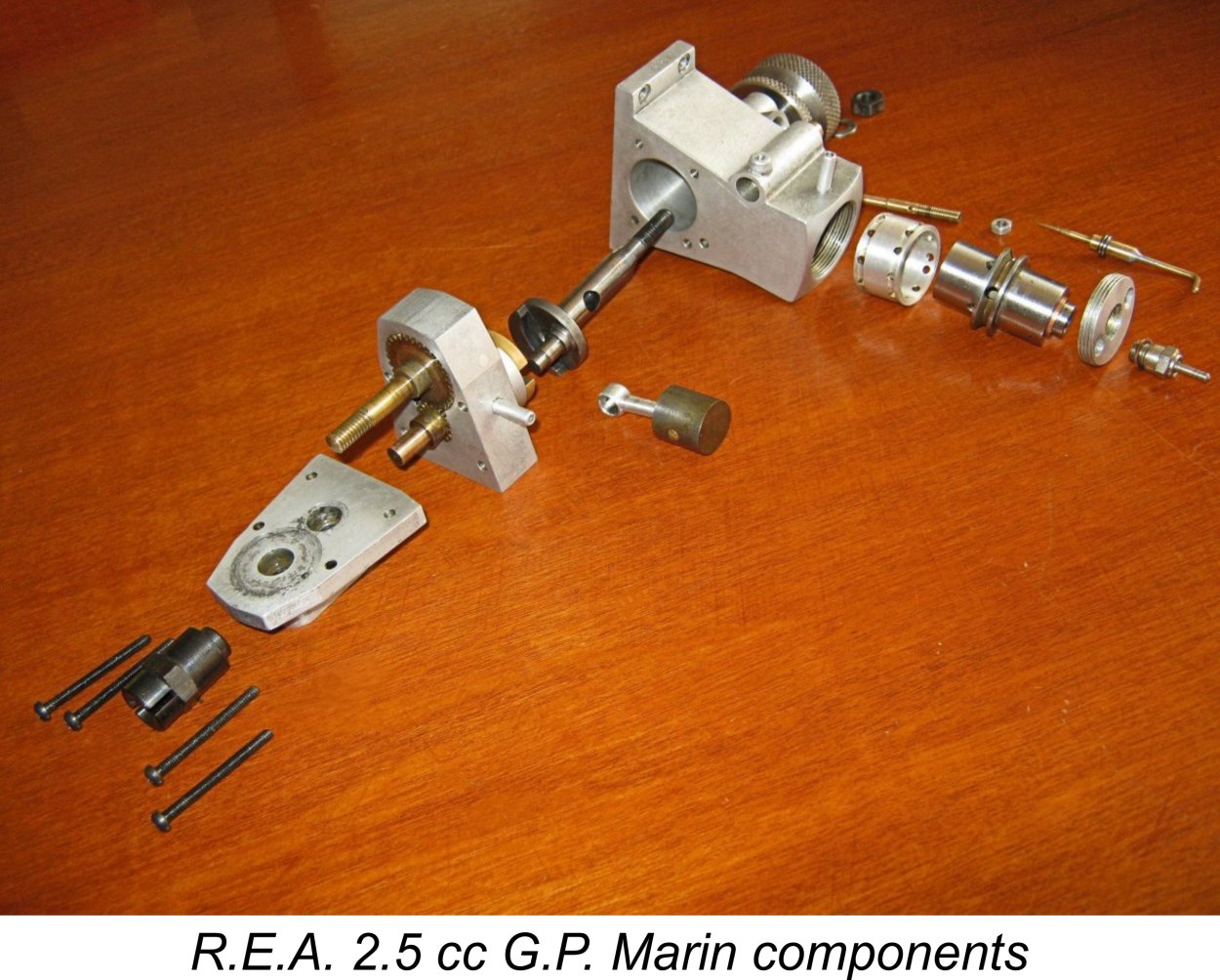

The R.E.A. G.P Marin was perhaps unique in the history of model marine engine design. It was clearly designed from the ground up as a marine unit, with no thought of an aero version being offered. Clearly, R.E.A.'s interest in marine engines had by no means abated! The accompanying image extracted from Adrien Maeght's outstanding book shows the engine's main features. At its heart, it was a crankshaft front rotary valve (FRV) design with an R/C throttle fitted. The working components were all housed inside a massive monobloc casing. The other image reproduced here showing engine number 39 confirms Maeght's statement that there was also an early variant of this unit which did not include a Bore and stroke of this very unusual engine were 15 mm and 14 mm respectively for a displacement of 2.48 cc (0.151 cuin.). Given the fact that this engine was intended for the high-torque application of model boat propulsion, it seems a little odd that R.E.A. didn't stick with the long-stroke geometry established previously with the 2.5 cc G.P. Series 2000 model descibed earlier. Not surprisingly in view of its complexity, including both gears and a flywheel, the engine weighed a very healthy 520 gm (18.3 ounces). An interesting and unusual feature was the fact that there were two power take-off points, one at each end. Chris Farcy has confirmed that the offset rear shaft was geared down at a 2:1 ratio using spur gears to provide a low-speed high-torque option when using this engine. The gearbox also had the function of keeping the rear shaft rotating in the conventional direction when viewed from that end. I've covered a similarly-equipped marine engine from a completely different source in the shape of the VT-12 "Seal Baby" manufactured in Hungary by the Vella Brothers. However, that wasn't the end of the gearbox's function! It also acted as a self-priming gear pump to supply cooling water to the engine when in operation. The designers seemingly retained their belief that this was a more dependable means of supplying cooling water than the old standby water scoop method. According to the information in the 1963/64 catlogue of “La Source des Inventions”, this pump could deliver some 20 litres (5.3 Imp. gallons) of cooling water per hour at 9,000 RPM.

The cooling water appears to have been in direct contact with the outer surface of the upper cylinder. This was made possible through the use of an alloy sleeve which was a close fit in the upper bore of the main casing. This sleeve had a larger inside diameter than the outside diameter of the upper cylinder, thus creating an annular water space around the upper cylinder. Water access to and from this annular space was provided by rings of holes at top and bottom with external communicating channels joining the members of each ring of holes. The alloy sleeve also served the function of transmitting the hold-down force from the screw-in cylinder head down to the cylinder port ring. It would appear that a water seal was secured at the top through the use of a (presumably) resilient washer of considerable thickness. Intriguing........... but it worked! Chris Farcy has drawn our attention to the fact that a YouTube video of one of these engines running may be accessed through this link, while the starting process is also recorded here on YouTube. With all of its complexities as well as its general design features, this engine was clearly not a racing unit. The manufacturer claimed an output of 0.20 CV (0.197 BHP) @ 9,000 RPM for this model. The engine's purpose appears to have been to power model cabin cruisers, runabouts, scale models, etc. It must have been a very expensive engine to produce, a factor which was reflected in its basic selling price of 110 francs (approximately US$24) in the 1963/64 calalog from “La Source des Inventions”. By comparison, the larger but less sophisticated 5 cc Compact Marin unit sold for only 80 francs. This likely explains why only a handful appear to have been manufactured. The only serial number of which I'm aware is engine number 39 illustrated above. It seems highly unlikely that the number produced reached three figures. Sadly, the G.P Marin 2.5 cc model proved to be the swan-song of the R.E.A. model engine manufacturing venture. Adrien Maeght tells us that all R.E.A. manufacture ceased in 1963. Still, the manufacturer had survived over a period of 25 years, producing some very interesting and well-made model engines in the process. So hats off to Raymond-Edmond-Arnoux for a noteworthy contribution to the manufacture of model engines in France!! _________________________________ Article © Adrian C. Duncan, Coquitlam, BC, Canada First published October 2016 |

||

| |

The following article was this web-site's first-ever overview of a French model engine range - the R.E.A. engines from Paris. I've subsequently added articles about the

The following article was this web-site's first-ever overview of a French model engine range - the R.E.A. engines from Paris. I've subsequently added articles about the  Fortunately, an excellent reference source is available to anyone having an interest in the subject of French model engines. This is the invaluable

Fortunately, an excellent reference source is available to anyone having an interest in the subject of French model engines. This is the invaluable  The 1909 achievement of pioneering French aviator Louis Blériot in making the first heavier-than-air flight across the English Channel sparked a tremendous upsurge of interest in aviation in France. Both full-scale and model aviation gained tremendously in popularity as a result of Blériot's courageous effort.

The 1909 achievement of pioneering French aviator Louis Blériot in making the first heavier-than-air flight across the English Channel sparked a tremendous upsurge of interest in aviation in France. Both full-scale and model aviation gained tremendously in popularity as a result of Blériot's courageous effort.

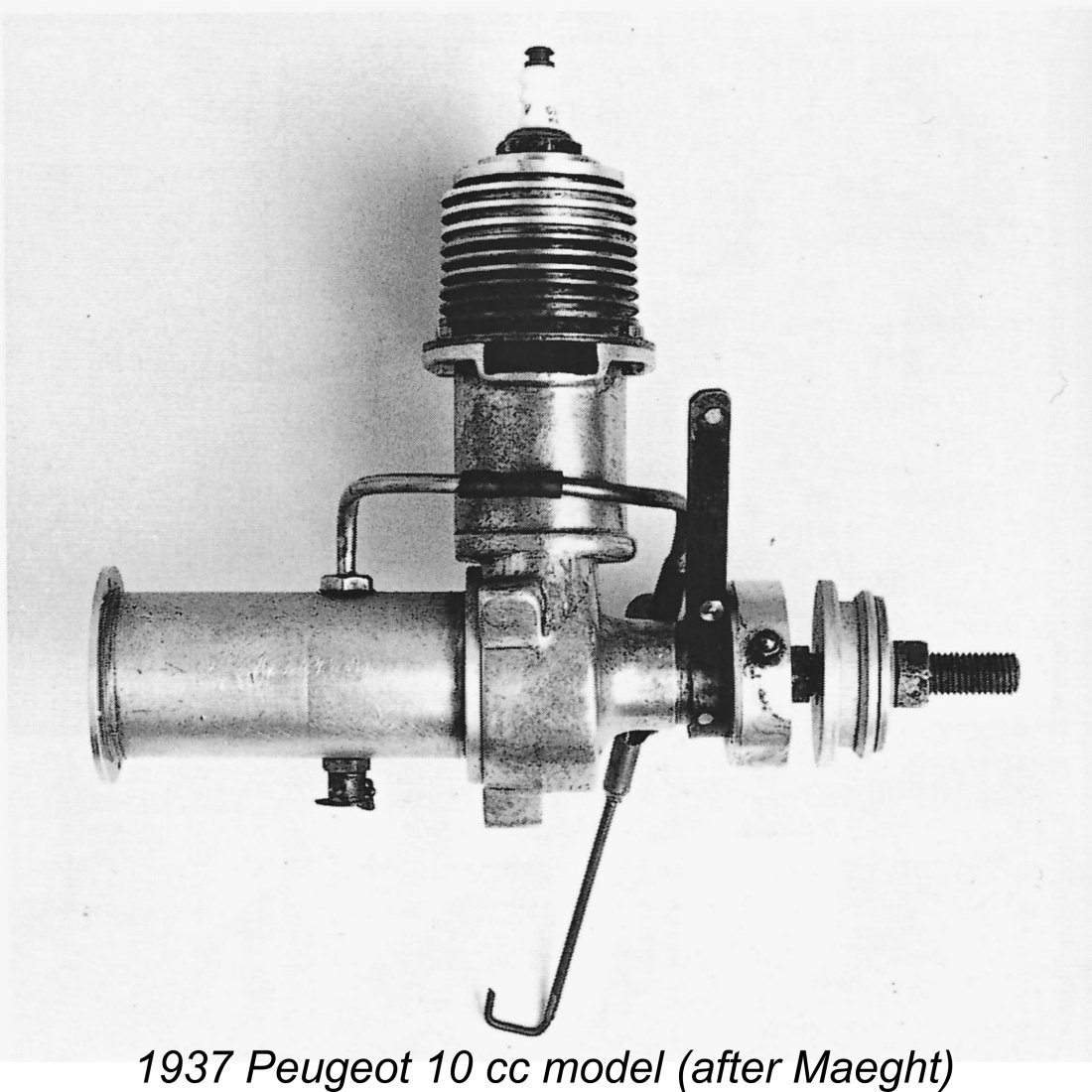

To take just one example, a model flying club was started by employees of the Peugeot automobile factory, which went so far as to manufacture about 100 examples of a fine 10 cc model petrol (gasoline) engine for the use of those employees. This engine was designed by Peugeot engineers at their Issy-les-Moulineaux factory and constructed during 1937-38 by the company’s apprentice mechanics at the Peugeot training facility in Sochaux as part of their training. The engines were very well-made and extremely successful. Indeed, on November 20

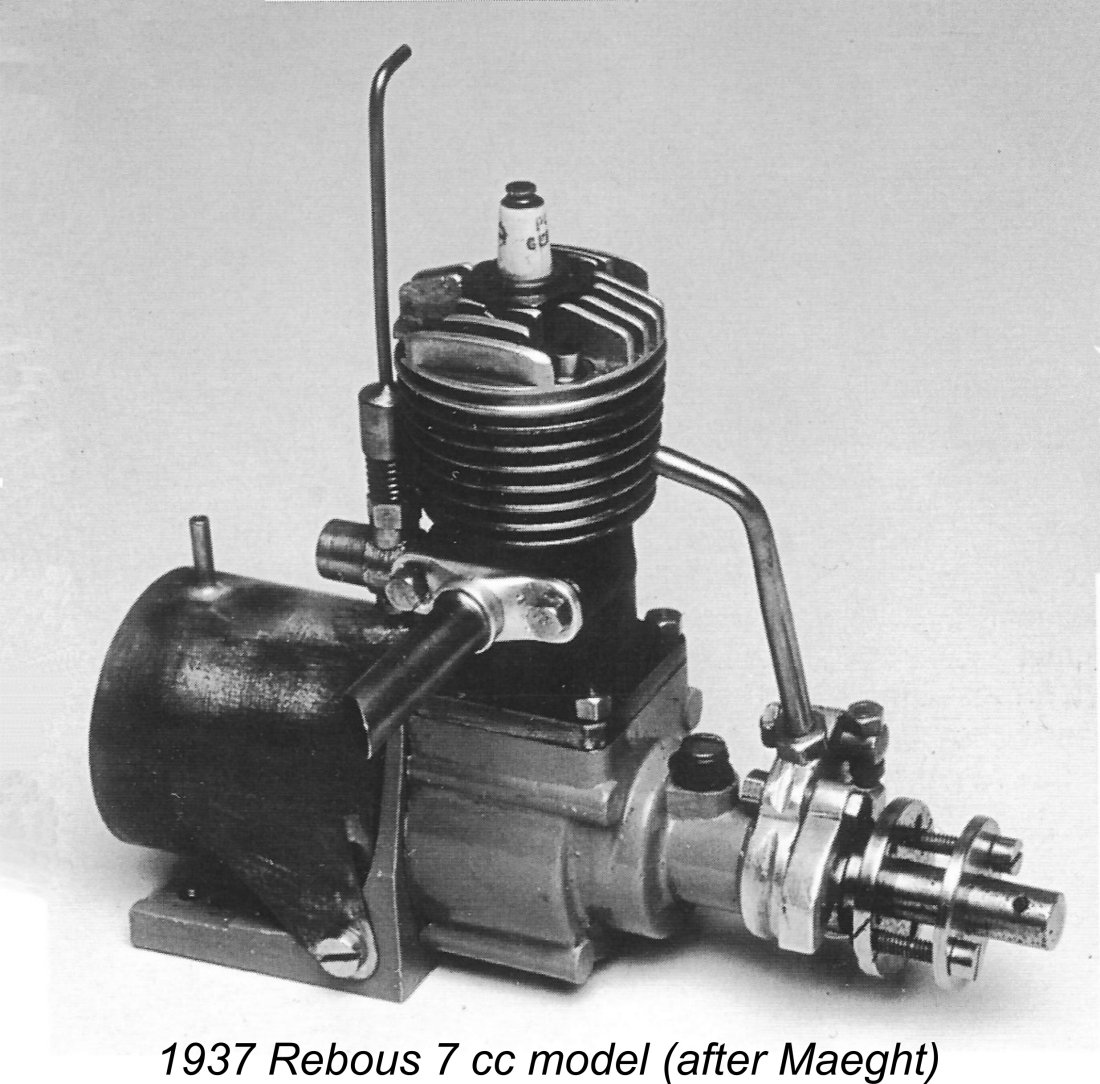

To take just one example, a model flying club was started by employees of the Peugeot automobile factory, which went so far as to manufacture about 100 examples of a fine 10 cc model petrol (gasoline) engine for the use of those employees. This engine was designed by Peugeot engineers at their Issy-les-Moulineaux factory and constructed during 1937-38 by the company’s apprentice mechanics at the Peugeot training facility in Sochaux as part of their training. The engines were very well-made and extremely successful. Indeed, on November 20 introducing a new 7 cc model in 1937. They were joined by the Terrot company with their 5 cc model in the same year.

introducing a new 7 cc model in 1937. They were joined by the Terrot company with their 5 cc model in the same year. The R.E.A. engines were built in relatively small numbers by Raymond Edmond Arnoux, or perhaps by three individuals having the surnames Raymond, Edmond and Arnoux - Maeght is not clear on this point. If any reader can provide clarity on this matter, please speak up!!

The R.E.A. engines were built in relatively small numbers by Raymond Edmond Arnoux, or perhaps by three individuals having the surnames Raymond, Edmond and Arnoux - Maeght is not clear on this point. If any reader can provide clarity on this matter, please speak up!!  It would appear that Arnoux and his associates had a special fondness for model boats, since the R.E.A. range included a wide variety of marine models throughout the production life of the company. A number of the marine engines and related accessories displayed a considerable degree of innovation, as we shall see in due course.

It would appear that Arnoux and his associates had a special fondness for model boats, since the R.E.A. range included a wide variety of marine models throughout the production life of the company. A number of the marine engines and related accessories displayed a considerable degree of innovation, as we shall see in due course. Whether or not it had been curtailed during the occupation, production undoubtedly resumed after the war. 1949 saw the introduction of a second generation 10 cc (0.61 cuin.) design, which was somewhat confusingly known as the R.E.A. "49" model to record the year of its introduction rather than its displacement. Reflecting the changing times, this was offered in both spark and glow-plug ignition versions.

Whether or not it had been curtailed during the occupation, production undoubtedly resumed after the war. 1949 saw the introduction of a second generation 10 cc (0.61 cuin.) design, which was somewhat confusingly known as the R.E.A. "49" model to record the year of its introduction rather than its displacement. Reflecting the changing times, this was offered in both spark and glow-plug ignition versions.  The spark ignition version of this engine was highly unusual in that the timer was driven by a subsidiary shaft mounted in the backplate and driven by the crankpin. Why advantage was not taken of this feature to incorporate some form of disc valve induction is not immediately clear. The glow-plug version of the engine in particular could easily have used this form of induction, since the rear of that model was unencumbered by the timer.

The spark ignition version of this engine was highly unusual in that the timer was driven by a subsidiary shaft mounted in the backplate and driven by the crankpin. Why advantage was not taken of this feature to incorporate some form of disc valve induction is not immediately clear. The glow-plug version of the engine in particular could easily have used this form of induction, since the rear of that model was unencumbered by the timer. The 1951 R.E.A. 5 cc glow-plug model was a cross-flow loop scavenged FRV unit of considerably more up-to-date design than its larger "49" predecessors. The main functional improvement which this unit embodied was the switch from sideport to crankshaft front rotary valve (FRV) induction. Short-stroke internal geometry was retained, bore and stroke being 19 mm and 17 mm respectively for a displacement of 4.82 cc (0.294 cuin.).

The 1951 R.E.A. 5 cc glow-plug model was a cross-flow loop scavenged FRV unit of considerably more up-to-date design than its larger "49" predecessors. The main functional improvement which this unit embodied was the switch from sideport to crankshaft front rotary valve (FRV) induction. Short-stroke internal geometry was retained, bore and stroke being 19 mm and 17 mm respectively for a displacement of 4.82 cc (0.294 cuin.).

If Sparey had understood the above points, there's no way that he would have considered running this or any other glow-plug motor at speeds as low as 3,000 RPM! Operation at such speeds would inevitably result in the engine being subject to severe pre-ignition, placing greatly elevated stresses on all of the working components, very much including the main bearing. Like all glow-plug motors, the R.E.A. was undoubtedly timed for operation at or around its peaking speed, which in this instance was around 11,000 RPM. Indeed, a major reason for the engine peaking at that speed was undoubtedly the fact that the ignition timing was optimized at that speed. Try setting your diesel compression screw or spark ignition timer for the correct timing at 11,000 RPM and then loading the engine down to run leaned out at 3,000 RPM without reducing compression or retarding the timer......... that in effect is what Sparey was doing, seemingly without realizing it. There can be little doubt that this was the cause of the rapid main bearing wear.

If Sparey had understood the above points, there's no way that he would have considered running this or any other glow-plug motor at speeds as low as 3,000 RPM! Operation at such speeds would inevitably result in the engine being subject to severe pre-ignition, placing greatly elevated stresses on all of the working components, very much including the main bearing. Like all glow-plug motors, the R.E.A. was undoubtedly timed for operation at or around its peaking speed, which in this instance was around 11,000 RPM. Indeed, a major reason for the engine peaking at that speed was undoubtedly the fact that the ignition timing was optimized at that speed. Try setting your diesel compression screw or spark ignition timer for the correct timing at 11,000 RPM and then loading the engine down to run leaned out at 3,000 RPM without reducing compression or retarding the timer......... that in effect is what Sparey was doing, seemingly without realizing it. There can be little doubt that this was the cause of the rapid main bearing wear. 1953 saw the introduction of one of the most famous R.E.A. models - the 5 cc Compact Marin design. This was of course intended exclusively for model boat use, a field in which the manufacturers clearly retained a strong interest throughout their career as model engine manufacturers.

1953 saw the introduction of one of the most famous R.E.A. models - the 5 cc Compact Marin design. This was of course intended exclusively for model boat use, a field in which the manufacturers clearly retained a strong interest throughout their career as model engine manufacturers.  It was in the context of this model that one of R.E.A.'s most fascinating accessories appeared. This was a small centrifugal water pump which was designed to be driven by the engine's rear power take-off shaft It's not absolutely clear what specific advantages were claimed for this unit - the more usual approach of arranging for water cooling of the engine through the use of a water scoop placed in the water-screw slipstream was generally more than adequate in my own direct experience (yes, I was a model boater once!). I suppose that the use of the pump would have maintained cooling water flow even at low speeds. It could also have been used to power scale accessories like fire hoses, water cannons, etc.

It was in the context of this model that one of R.E.A.'s most fascinating accessories appeared. This was a small centrifugal water pump which was designed to be driven by the engine's rear power take-off shaft It's not absolutely clear what specific advantages were claimed for this unit - the more usual approach of arranging for water cooling of the engine through the use of a water scoop placed in the water-screw slipstream was generally more than adequate in my own direct experience (yes, I was a model boater once!). I suppose that the use of the pump would have maintained cooling water flow even at low speeds. It could also have been used to power scale accessories like fire hoses, water cannons, etc.  Externally, the engine appeared relatively little changed from the unit tested by Sparey in 1951. However, there was at least one significant internal change. This was the revision of the engine's bore and stroke dimensions to return it to long-stroke working geometry. According to Maeght, the revised model had bore and stroke measurements of 18 mm and 19.5 mm respectively for a displacement of 4.96 cc (0.303 cuin.). There may well have been other internal changes which would only become apparent upon direct examination.

Externally, the engine appeared relatively little changed from the unit tested by Sparey in 1951. However, there was at least one significant internal change. This was the revision of the engine's bore and stroke dimensions to return it to long-stroke working geometry. According to Maeght, the revised model had bore and stroke measurements of 18 mm and 19.5 mm respectively for a displacement of 4.96 cc (0.303 cuin.). There may well have been other internal changes which would only become apparent upon direct examination.  The engine which forms the subject of the following analysis appears at first glance to be little more than a scaled-down version of the Series 2000 5 cc model described above. However, in reality it is a somewhat different design, presenting a number of features which set it apart.

The engine which forms the subject of the following analysis appears at first glance to be little more than a scaled-down version of the Series 2000 5 cc model described above. However, in reality it is a somewhat different design, presenting a number of features which set it apart. Perhaps a little oddly given the revised method of forming the exhaust port, the transfer ports continued to be formed by drilling. There are three upwardly-angled drilled holes placed directly opposite the single exhaust aperture. These are fed by a bypass passage of modest dimensions cast in the main crankcase. This passage interrupts the female cylinder installation threads on the bypass side.

Perhaps a little oddly given the revised method of forming the exhaust port, the transfer ports continued to be formed by drilling. There are three upwardly-angled drilled holes placed directly opposite the single exhaust aperture. These are fed by a bypass passage of modest dimensions cast in the main crankcase. This passage interrupts the female cylinder installation threads on the bypass side.  Port timing is relatively conservative, as we might expect with a long-stroke unit. The exhaust opens at 115 degrees after top dead centre, giving a total exhaust period of 130 degrees. The transfer ports overlap the exhaust to a considerable degree, opening at 125 degrees after top dead centre for a total transfer period of 110 degrees. There is a short period of supplementary sub-piston induction extending for around 12 degrees each side of top dead centre for a total sub-piston induction period of some 24 degrees.

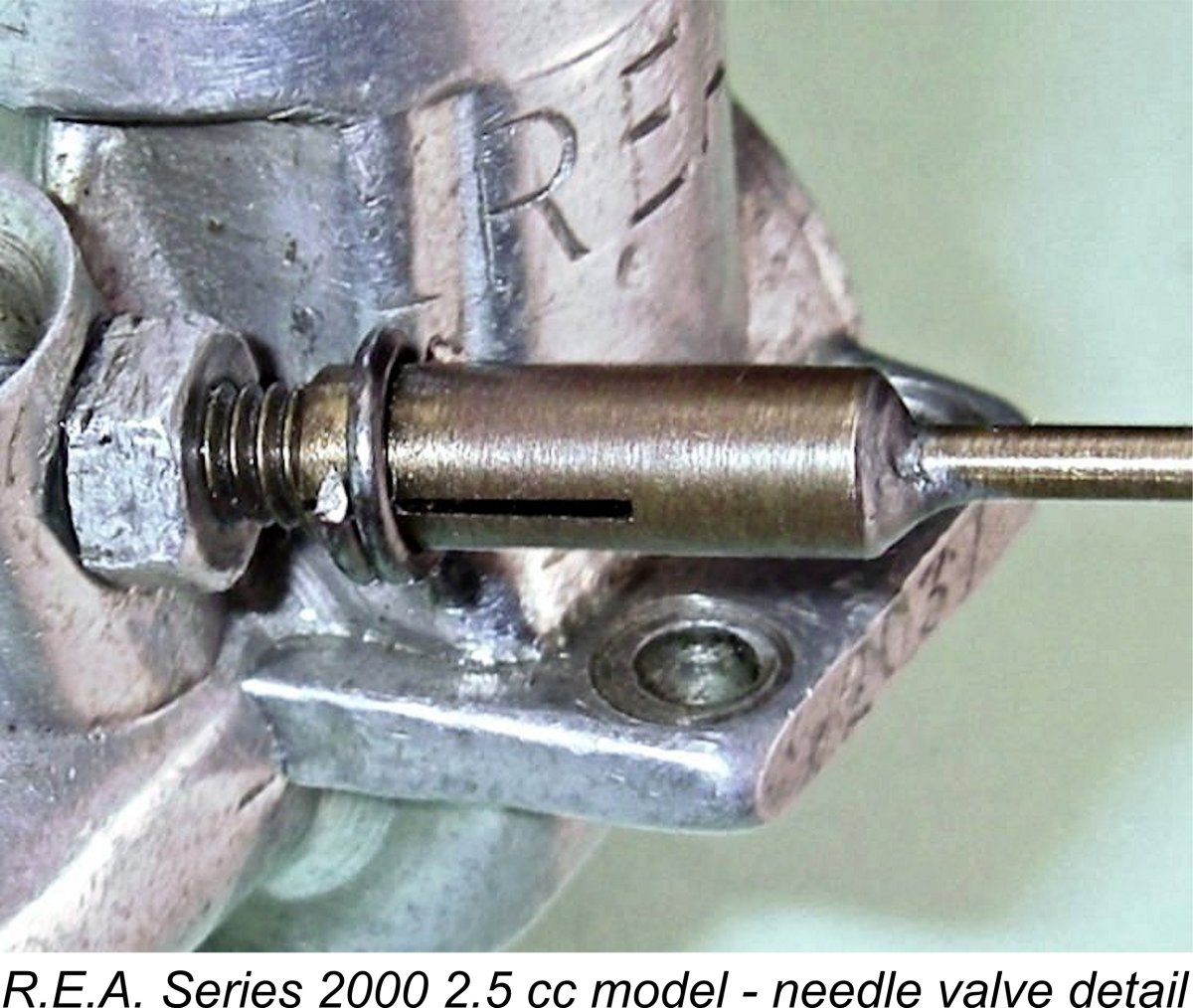

Port timing is relatively conservative, as we might expect with a long-stroke unit. The exhaust opens at 115 degrees after top dead centre, giving a total exhaust period of 130 degrees. The transfer ports overlap the exhaust to a considerable degree, opening at 125 degrees after top dead centre for a total transfer period of 110 degrees. There is a short period of supplementary sub-piston induction extending for around 12 degrees each side of top dead centre for a total sub-piston induction period of some 24 degrees.  In all other respects, the R.E.A. Series 2000 2.5 cc model is a more or less conventional plain-bearing FRV unit of its era. Its only other noteworthy feature is the needle valve assembly. The delivery end of the spraybar is neatly bent backwards to facilitate a nice straight run for the fuel tubing. The needle itself is tensioned by a split thimble in the usual manner, but the two halves of the split section are themselves tensioned against the spraybar's external thread by means of a quite strong coil spring. This is a clever idea, since it will maintain good tension at all times while also taking up any wear which might occur. A very similar design had been previously employed by the Micron company as far back as 1943.

In all other respects, the R.E.A. Series 2000 2.5 cc model is a more or less conventional plain-bearing FRV unit of its era. Its only other noteworthy feature is the needle valve assembly. The delivery end of the spraybar is neatly bent backwards to facilitate a nice straight run for the fuel tubing. The needle itself is tensioned by a split thimble in the usual manner, but the two halves of the split section are themselves tensioned against the spraybar's external thread by means of a quite strong coil spring. This is a clever idea, since it will maintain good tension at all times while also taking up any wear which might occur. A very similar design had been previously employed by the Micron company as far back as 1943.  he above description should hopefully have made it quite clear that the R.E.A. 2.5 cc Series 2000 model was not by any means designed with high performance in mind. Rather, it appears to have been planned expressly to produce the kind of dependable "slogging" power output which was highly valued by sport-flying enthusiasts as opposed to all-out competition participants.

he above description should hopefully have made it quite clear that the R.E.A. 2.5 cc Series 2000 model was not by any means designed with high performance in mind. Rather, it appears to have been planned expressly to produce the kind of dependable "slogging" power output which was highly valued by sport-flying enthusiasts as opposed to all-out competition participants.  In his 1951 test report on the original 5 cc R.E.A. model, Lawrence Sparey reported that the fuel specified by the manufacturer for that model was a straight 75/25% methanol/castor oil mix. This comes as no surprise given the cost and supply difficulties associated with nitromethane in Europe at the time. Few if any contemporary sport fliers would be prepared to spend significant sums of hard-earned cash on nitromethane - they would prefer to use engines which did not require that refinement in their fuel. It seems safe to asume that the 2.5 cc version of the Series 2000 line-up would have been designed for a similar low or no-nitro fuel.

In his 1951 test report on the original 5 cc R.E.A. model, Lawrence Sparey reported that the fuel specified by the manufacturer for that model was a straight 75/25% methanol/castor oil mix. This comes as no surprise given the cost and supply difficulties associated with nitromethane in Europe at the time. Few if any contemporary sport fliers would be prepared to spend significant sums of hard-earned cash on nitromethane - they would prefer to use engines which did not require that refinement in their fuel. It seems safe to asume that the 2.5 cc version of the Series 2000 line-up would have been designed for a similar low or no-nitro fuel.  With that sorted, the engine appeared to be all ready for testing. So into the stand it went, and the testing got underway. The engine endeared itself to me right away by proving to be an extremely easy starter. It liked a slightly rich needle for starting, and a port prime appeared to be an essential prerequisite. Apart from that, the R.E.A. was very willing to start and run, requiring only a few lazy flicks after priming. Upon firing up, it quickly settled down into a smooth four-cycle mode of running which was easily adjusted to give smooth two-stroking. Response to the needle was smooth and progressive, making the establishment of the optimum setting very straightforward indeed.

With that sorted, the engine appeared to be all ready for testing. So into the stand it went, and the testing got underway. The engine endeared itself to me right away by proving to be an extremely easy starter. It liked a slightly rich needle for starting, and a port prime appeared to be an essential prerequisite. Apart from that, the R.E.A. was very willing to start and run, requiring only a few lazy flicks after priming. Upon firing up, it quickly settled down into a smooth four-cycle mode of running which was easily adjusted to give smooth two-stroking. Response to the needle was smooth and progressive, making the establishment of the optimum setting very straightforward indeed.

Perhaps the two most noteworthy characteristics are the relatively low speed (for a glow-plug motor) at which peak power is developed and the notable flatness of the peak. Both of these characteristics are more typical of diesels than they are of glows. The low peaking speed of only 11,100 RPM coupled with a highly acceptable peak output reflects above-average low-end torque development for a 2.5 cc plain-bearing glow-plug motor dating from 1955. This is of course a highly desirable characteristic of any sports engine.

Perhaps the two most noteworthy characteristics are the relatively low speed (for a glow-plug motor) at which peak power is developed and the notable flatness of the peak. Both of these characteristics are more typical of diesels than they are of glows. The low peaking speed of only 11,100 RPM coupled with a highly acceptable peak output reflects above-average low-end torque development for a 2.5 cc plain-bearing glow-plug motor dating from 1955. This is of course a highly desirable characteristic of any sports engine.  Regardless, there appears to be no doubt that production of at least some R.E.A. models continued into 1963. Indeed, 1962 saw the release of what must surely be the company's crowning achievement as model engine designers. This was their highly individualistic 2.5cc glow-plug marine engine designated the 2.5 cc G.P. Marin. With its monobloc construction, geared rear drive shaft and built-in water pump, this was surely one of the most unusual yet eminently practical marine units ever manufactured.

Regardless, there appears to be no doubt that production of at least some R.E.A. models continued into 1963. Indeed, 1962 saw the release of what must surely be the company's crowning achievement as model engine designers. This was their highly individualistic 2.5cc glow-plug marine engine designated the 2.5 cc G.P. Marin. With its monobloc construction, geared rear drive shaft and built-in water pump, this was surely one of the most unusual yet eminently practical marine units ever manufactured.  throttle. Of course, an exhaust throttle could readily be applied to such an engine. The exhaust pipe was reversible, allowing exhaust gasses to be led away from the engine in either direction depending on which power take-off was used.

throttle. Of course, an exhaust throttle could readily be applied to such an engine. The exhaust pipe was reversible, allowing exhaust gasses to be led away from the engine in either direction depending on which power take-off was used. Examination of the accompanying image of the engine's components reveals a few more very interesting details. The cylinder was a radially-ported drop-in component which was secured by the screw-in cylinder head. It seems that a blind bore was used to facilitate this assembly. The bypass passage appears to have been the annular space formed between the lower cylinder outer wall and the larger-diameter inner wall of the casing, an approach which was employed in many engines of the classic era.

Examination of the accompanying image of the engine's components reveals a few more very interesting details. The cylinder was a radially-ported drop-in component which was secured by the screw-in cylinder head. It seems that a blind bore was used to facilitate this assembly. The bypass passage appears to have been the annular space formed between the lower cylinder outer wall and the larger-diameter inner wall of the casing, an approach which was employed in many engines of the classic era.