|

|

The Vella Brothers VT engines

A number of other Hungarian model engine ranges from the classic era were also mentioned in that article, although nothing of substance was then known about them outside of their native Hungary. Among these were the Proton and Meteor engines as well as the earlier GyM series. I had heard of these engines, but was unable at that time to present any information on them beyond confirming the mere fact of their existence. All of this changed dramatically later in 2011 when I heard from Hungarian resident Ferenc Somogyi (in Hungarian naming order, Somogyi Ferenc), an 82 year old retired mechanical engineer (in 2011) who was generally addressed by his English-speaking colleagues as Francis (an English rendering of Ferenc) but was known to his family and Hungarian friends by his nickname of Somi. I was honoured to have Somi's permission to address him in this manner. Accordingly, at his request I’ve referred to him as Somi throughout this article. After reading the original article on MEN in its revised form, Somi was kind enough to contact me directly to provide a great deal of additional data and photographic material in addition to correcting a number of errors, some of them significant. It was immediately apparent that the scope of the new information provided by Somi was such that a complete re-write of the article would be an absolute necessity. The original intention had been to replace the article on MEN with a further revised text, but the tragic passing of Ron Chernich and the subsequent freezing of the MEN site has precluded this. Hence I have elected to publish the revised material here.

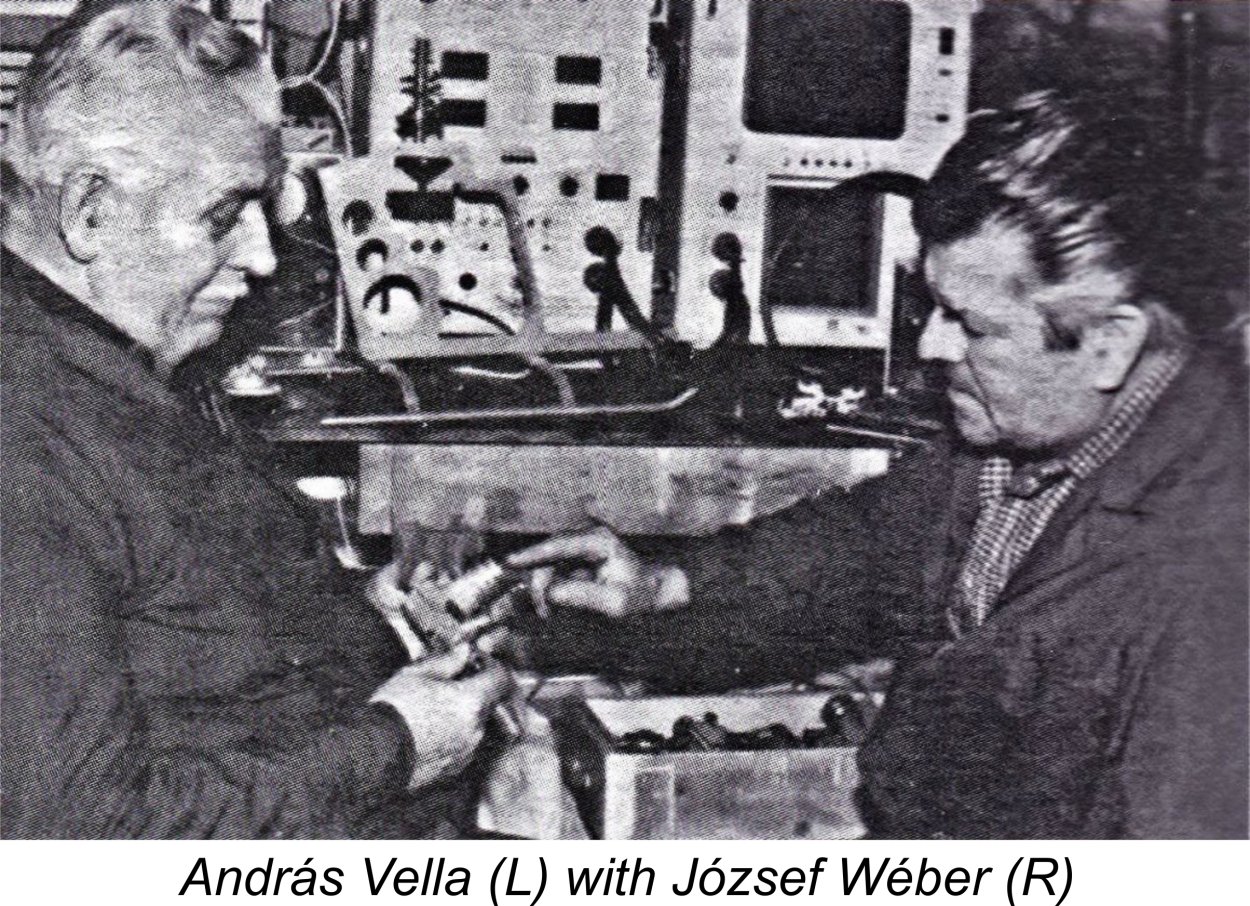

This is the kind of contact that model engine historians like me dream about - there could be few individuals in a better position to comment upon our present subject. Many thanks indeed, my friend!! When I began to revise the original 2011 article in light of Somi's comments, I quickly realized that I was facing an impossible task in terms of keeping the material within the original bounds of a single article about a number of contemporary Hungarian model engine ranges from the "classic" era. In order to keep things readable, it would clearly be necessary to break the original format up into a series of stand-alone articles about the specific model engine ranges for which a mass of detailed first-hand information was now available. Since the history of the MOKI enterprise clearly warranted an article all to itself, such an article duly appeared on this site in Februiary of 2015. That article was in fact primarily authored by Somi himself. It was followed in May 2015 by a companion piece on the subject of the Alag range, which was soon joined by a further article covering the Proton engines. The present article on the VT range first appeared in January 2016, while the story of commercial model engine production in Hungary during the "classic" era was completed by the September 2016 appearance of an in-depth review of the FOK series. An event that seems to happen with encouraging regularity these days is the receipt of additional information following the original publication of an article. Such contacts invariably result from some knowledgeable individual reading the published text, noting areas in which errors or omissions are apparent and taking the time and trouble to contact me regarding those issues. In the present instance, in late 2016 I was delighted to hear from András Vella (b. 1955), the son of the younger Vella brother Géza, who is a long-time resident of the United States and is still on deck at age 88, living in New Mexico. Between them, András and his father Géza (who was the younger of the two original Vella brothers by 12 years) have provided a number of key corrections and additions which have greatly contributed to this article's scope and authenticity. I'm immensely grateful to both of them. Now, on with our study of the VT marque ............. Background This section of the article will contain a good deal of material which has appeared previously in the companion articles about the MOKI, Alag and Proton ranges. This material is reprised here purely to relieve the new reader of the need to search other articles for background information. Readers who are already familiar with this background material are invited to skip to the following section of this article. For the rest of you, read on ..........

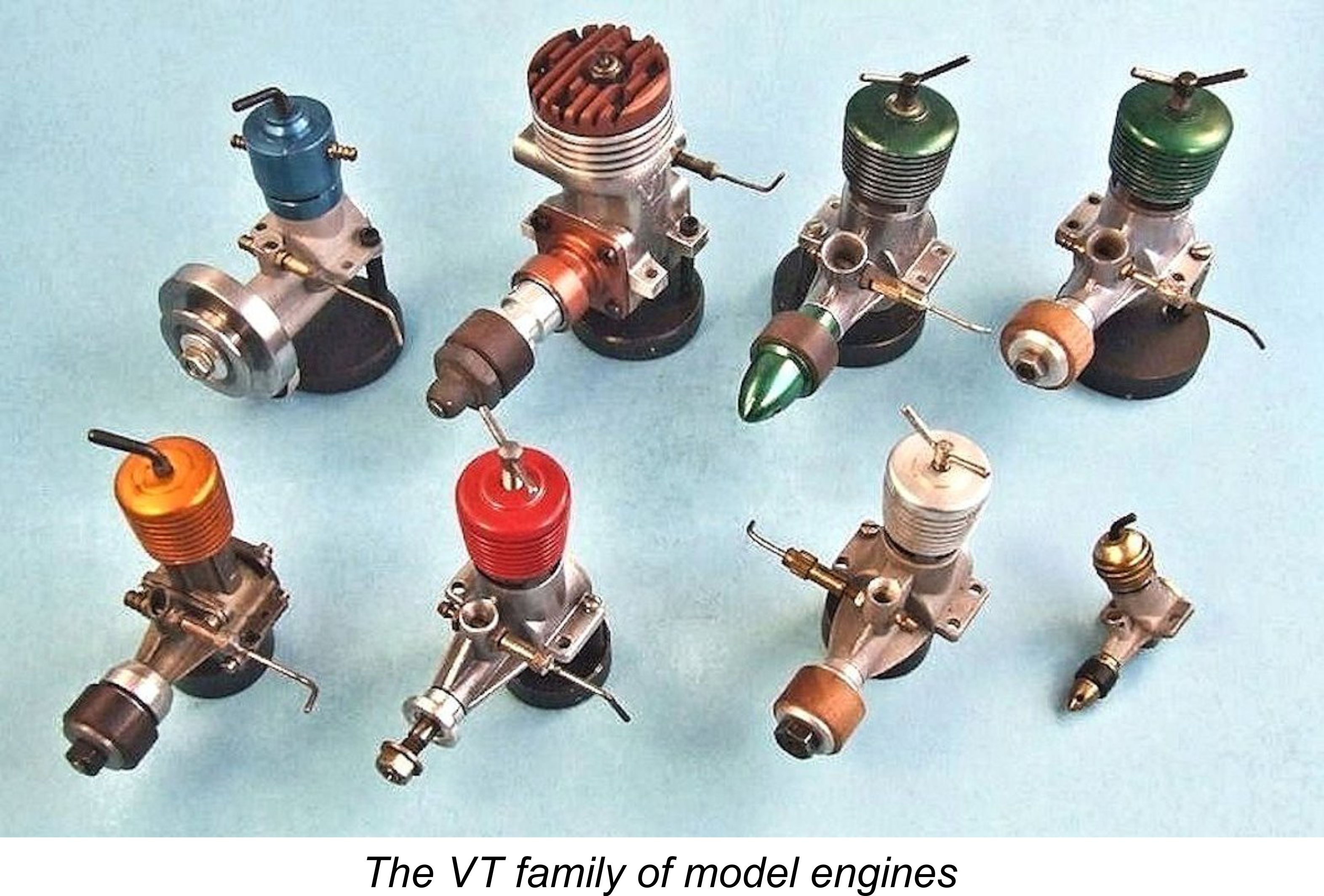

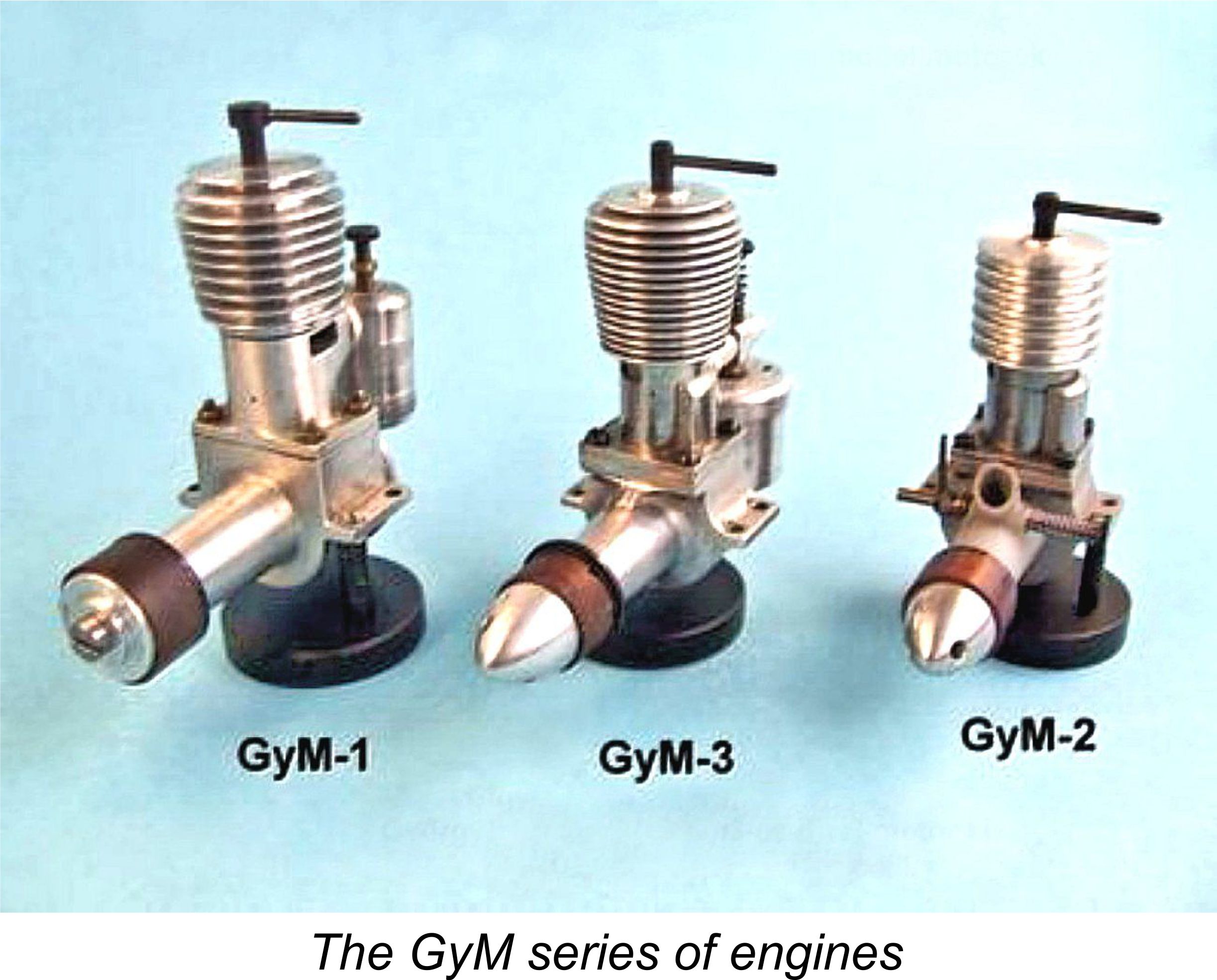

However, as time went on the Hungarians became increasingly disenchanted with the direction that the war was taking, accordingly attempting to negotiate secretly on their own account with Britain and the USA. The German discovery of this initiative led to the country being occupied by the Nazis in March 1944. This occupation lasted until April of 1945, when the invading Russians finally assumed control of the country. Further negotiations between the Allied powers subsequently led to the February 1st, 1946 supplanting of the Kingdom of Hungary by the Second Republic of Hungary (Magyar Köztársaság) which was governed by the Hungarian Communist Party under close Russian supervision. The imposition of this change in government did not proceed smoothly - it took until August 1949 for the country to finally become stabilized as the Hungarian People’s Republic (Magyar Népköztársaság), a Communist state which was administered by the Socialist Workers’ Party, still under dominating Soviet influence. The Hungarian People’s Republic was destined to survive until October 23rd, 1989, at which Despite the turmoil of the early post-war period, the sport of aeromodelling had quickly gained ground following the end of WW2. Indeed, aeromodelling had somehow managed to continue during the wartime period - our valued informant Ferenc "Somi" Somogyi became involved with the hobby in 1944 at the age of 15 years, as the attached image shows. The early post-war head of the Hungarian Modelling Department was the supremely well-qualified György Benedek (1921-2004), who was internationally known for his very successful “B” aerofoil design for free-flight models. However, Mr. Benedek was forced out of his post for political reasons when the Communists finally established firm control of the country in 1949. His expert leadership was replaced by uninformed Communist political appointees, a move which did nothing to help the Hungarian modelling movement to improve its standards. It’s worth noting in passing that after the Hungarian Returning now to the early 1950’s, Somi tells us that contemporary Hungarian modellers faced a serious problem – a chronic lack of suitable model powerplants. A few Czechoslovakian and Soviet engines were apparently in circulation, but both the quality and performance of these units were generally sub-standard at this time. Compounding this issue was the fact that Hungary was then suffering from a chronic shortage of hard currency, which made the importation of engines from outsde the country next to impossible. This The first model engine to enter series production in Hungary, albeit on a very small scale, was the GyM 1 sideport diesel of 5 cc displacement, which first appeared in 1950. This engine was designed by the late Györgyfalvy Dezső (d. 2010) and made in a very small series by a single individual whose name is now lost, working in a tiny workshop with minimal machine tooling. Revised models soon followed in the shape of the GyM-2 and GyM-3 variants. The inclusion of a three-view drawing of the GyM-3 which appeared in the 1951 edition of “Aeromodeller Annual” proves that these three models were all in existence by the latter part of 1951. Although it was doubtless very much appreciated, the production of the GyM engines was so small that it did little to relieve the chronic shortage of engines faced by Hungarian modellers. This made it inevitable that furth In 1953 such an effort emerged on the part of an entity known as the Szegedi Vas és Fémipari Szövetkezet (Szeged Iron and Metallurgical Co-operative). This manufacturing venture was located in Szeged, a town situated in southern Hungary. I've covered the activities of this manufacturer in my separate article on its Proton range which first appeared in 1954. It's worth mentioning in passing that the designer of the Proton engines was none other than our valued Hungarian informant Ferenc "Somi" Somogyi! While Somi was working on the development of the Proton series of engines, others were not standing aside from the challenge of increasing Hungarian model engine production. Even with the addition of the various engines manufactured by the Szeged Co-Operative, the demand for model engines among Hungarian modellers still far outstripped supply. This made it inevitable that others would make efforts to become involved in model engine manufacture in Hungary. One such initiative came from the government of the At around the same time in early 1955 a similar venture was independently initiated by the Budapest-based Vella brothers András (1916-1999) and Géza (1928-2017), who embarked upon the manufacture of model engines under their own initials of VT (standing for Vella Testverek, or Vella Brothers). This range forms the main subject of the present article. According, from this point onwards I'll focus exclusively on the products of the Vella Brothers, mentioning other ranges only where their history intersects that of my main subject. Marketing Initiatives

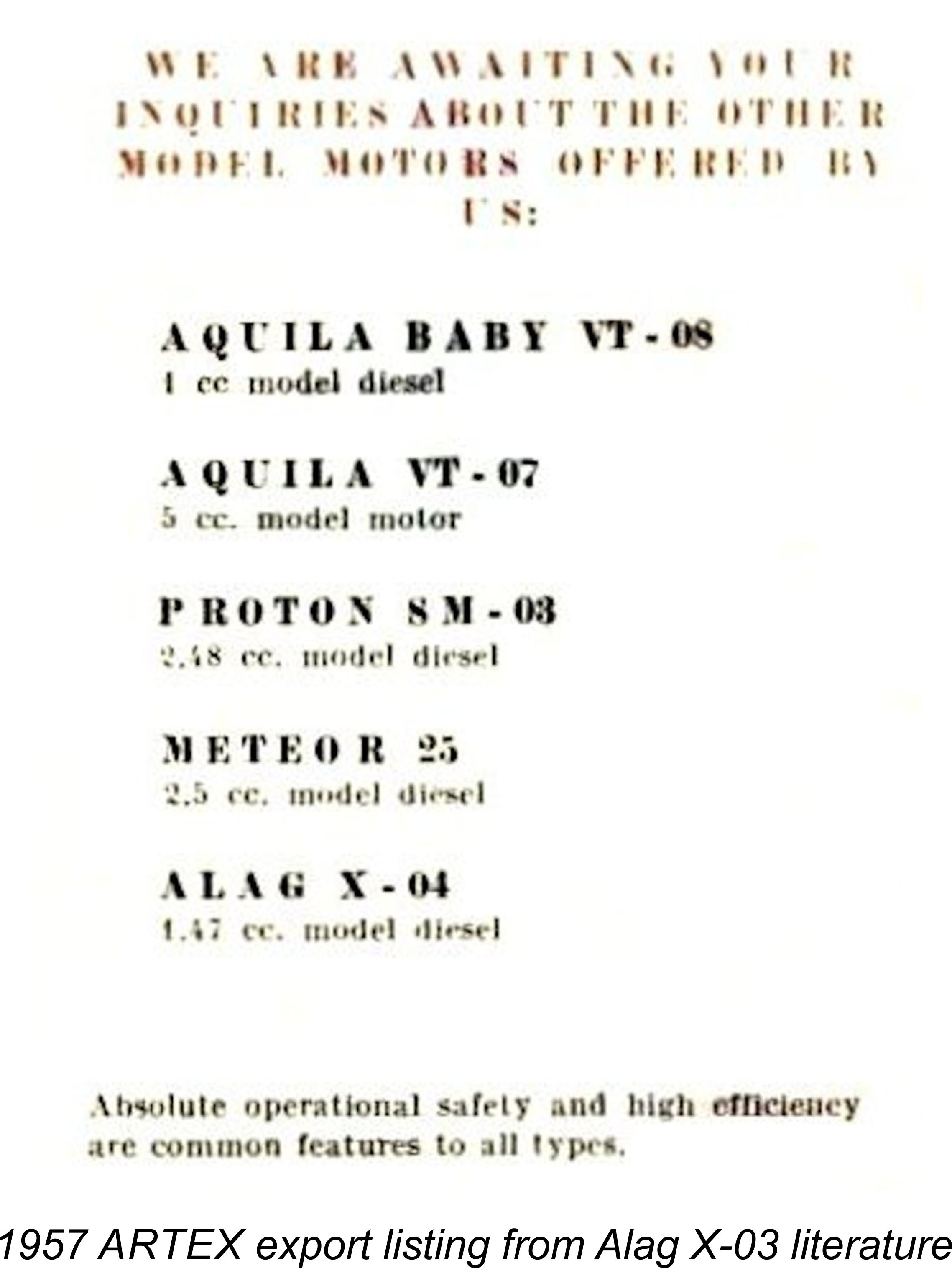

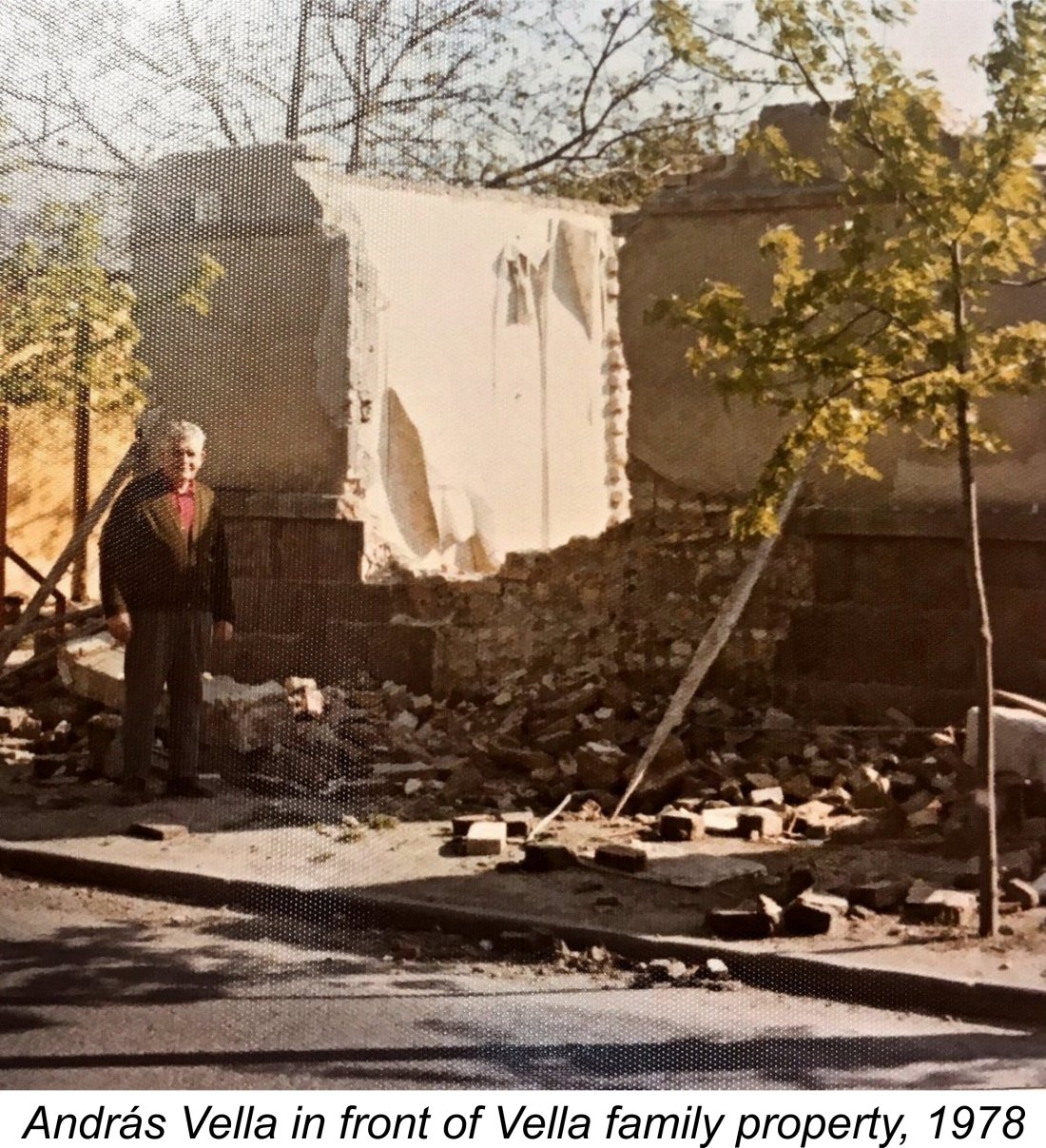

Recognizing this, the government of the day decided to make a real effort to generate sales interest in countries other than Hungary, including those in the West on the other side of the Iron Curtain. This initiative was by no means confined to the model engine industry. The new export drive was largely driven by the previously-mentioned shortage of hard currency in Hungary at the time along with the recognition that the only way to generate such currency was the development of export markets for Hungarian goods. The seriousness with which this goal was pursued is underscored by the fact that the export of Hungarian model engines was added to the portfolio of a Budapest-based international trading organization known as ARTEX which had been established some time previously for the express purpose of developing export markets for a range of Hungarian products. Although the Alag and VT engines were initially sold mainly on By mid 1957 the list of engines being offered to Western markets by ARTEX included the Proton SM-03 2.5 cc diesel, the 2.5 cc Meteor 25 sideport diesel, the 2.5 cc Alag X-03 diesel, the 1.5 cc Alag X-04 diesel, the VT-08 "Aquila Baby" 1 cc diesel and the VT-07 5 cc racing glow-plug motor (incorrectly characterized as an Aquila product). Some of these offerings never made any real impression on the International market, while others became quite widely known. We will examine the VT products on this list in later sections of the present article. ARTEX was successful in securing distribution agreements with wholesalers in a number of Western countries. Chief among these were Britain (initially RipMax and later Relum Ltd.), Germany (the Engel company), Australia (Bill Evans of Eden Distributors Pty. Ltd.), South Africa and Scandinavia (Bertil Beckman & Co. of Stockholm, Sweden). A substantial number of engines were sold in those markets as a result of ARTEX's activities. The overall effect of these initiatives was the significant expansion of the sales potential of commercial Hungarian model engines. The increased production levels which this permitted doubtless had a very positive effect upon unit manufacturing costs, allowing the engines to be sold outside Hungary at quite competitive prices. The Vella brothers were certainly among those who benefitted from this situation. Let's return now to 1955 and look at the development of the VT range which became an important part of ARTEX's model engine portfolio. VT Production Commences According to Somi, who knew them both personally, the Vella brothers were talented machinists who had a small workshop on Csepel, a large island in the Danube in the Budapest area. They had no modern machine tools, but they were well-trained and highly experienced toolmakers and craftsmen who knew how to use what they had to the best advantage. They had assistants both in the design and manufacture of the VT engines. András Vella, the son of the younger Vella brother Géza, tells us that the VT workshop was located in a residential neighborhood on Csepel, which is the 21st precinct of Budapest. The family had a double lot, and the factory building was in the back. The front right side of the double parcel was occupied by the old Vella home built years earlier by the father of the two Vella brothers. This residence was subsequently expanded further along the double parcel to provide accomodation for multiple families. Consequently, my informant András Vella the younger (b. 1955) spent his first 14 years actually growing up on the factory property.

Somi tells us that the Vella Brothers received a considerable amount of assistance from a gentleman named István Gombócz. He was a noted competitor in both the control-line speed and team racing categories. After graduating with a degree in economics, he worked for some years in the ARTEX organization. He then transferred to the Hungarian Modelling Department, eventually rising to the position of deputy to Rezső Beck at the Hungarian Association of Modellers. During all of this activity, he somehow found time to provide technical assistance to the Vella Brothers, particularly by making them aware of the technical solutions being applied by manufacturers in the West to a range of design issues. Through his position with ARTEX, he also helped them with the export of their products. His language skills were of value to them in corresponding with customers outside Hungary. The multiplicity of names under which the Vella Brothers subsequently produced and exported different engine lines confirms Somi's statement that they routinely operated as contract manufacturers for others in addition to turning out their own VT line. They certainly did so in the case of the Engel Rebell and BX ranges, of which more below in due course. The concurrent use of different trade-names on otherwise-identical examples of their various product lines makes it a challenge to keep track of their activities at any given time. According to members of the Vella family with whom I've been in contact, the manufacturing activities of the VT enterprise were by no means confined to model engine production. A wide assortment of other model-related items was also produced, including a range of rubber tyres for model aircraft wheels. As might be supposed from the multiplicity of their product lines, the Vella Brothers were very successful manufacturers. According to András Vella, the son of the younger Vella brother Géza, the older brother András was the firm's business manager, having a notable talent in that area. His brother Géza (who was the younger of the two by 12 years) was a certified Master Machinist, accordingly being in charge of the actual production, although András also worked in that field when not engaged in dealing with business matters. At its peak in the late 1950's, the firm employed a total of over 20 workers in addition to the Vella brothers themselves. This brings us to the first of several long-standing errors regarding the activities of the Vella Brothers. It has long been generally known that the manufacture of the Alag engines by AKKÜ at Dunakeszi ceased at some point in 1957. However, manufacture of the Alag range continued past that year, albeit by a different manufacturer. Earlier commentators (including the normally-reliable Peter Chinn) have incorrectly credited the Vella Brothers with taking over the manufacture of the Alag range at that point. Given the brothers' demonstrated willingness to manufacture engines for others under different names, this belief appeared quite credible.

This organization continued the production of the Alag X-series diesel models, also developing and manufacturing the 5 cc Alag Y-02 and 2.5 cc Alag Y-03 racing glow-plug engines. The fact that Gyula Krizsma had stepped into the designer’s role for the Alag range was doubtless of great value in connection with the development of the two new Alag glow-plug models. Krizsma was a busy man at this time, since he was also closely involved with the design and production of the Krizsma Rekord K-8 and K-9 diesels at the Hungarian National Defence Association Accessory Supply Company (MHS Felszerelési és Ellátó Vállalat), continuing in this role until he moved over to MOKI in 1960, as related elsewhere. In a similar vein, the second long-standing error requiring correction is the widespread impression reinforced by Peter Chinn among others that the Vella Brothers also produced a line of engines under the Aquila trade-name. This statement too is in error. The main basis for this long-held belief was the existence of the previously-mentioned Aquila Baby 1 cc diesel (of which more below), which was exported to Western markets for some years in the mid to late 1950’s, becoming quite well-known as a result. However, we have seen that this engine was actually identified on the case as a VT product, creating the impression that the name “Aquila Baby” was in fact simply the name of the model rather than the name of a line of engines. This is consistent with the fact that the marine version of this engine was called the “Seal Baby” (again, more info below) which was also designated as a VT product, both on the case and in the packaging. The erroneous belief that the Aquila name applied to a range as opposed to a specific model was unfortunately encouraged by the fact that the previously-pictured 1957 listing of the engines then being offered by ARTEX included a model designated as the Aquila VT-07 5 cc racing glowplug motor (of which more below in its place). However, our friend Somi confirmed that the “Aquila Baby” and similar designations such as "Seal Baby" were indeed names applied to the particular engines as opposed to reflecting a distinct trade name per se. The engines all formed part of the VT range - there never was an Aquila range as such. The Aquila name was presumably attached to the VT-07 glow-plug unit through a misunderstanding on the part of someone at ARTEX. Or perhaps the Vella brothers did have some initial notion of adopting the Aquila trade-name but subsequently dropped the idea.

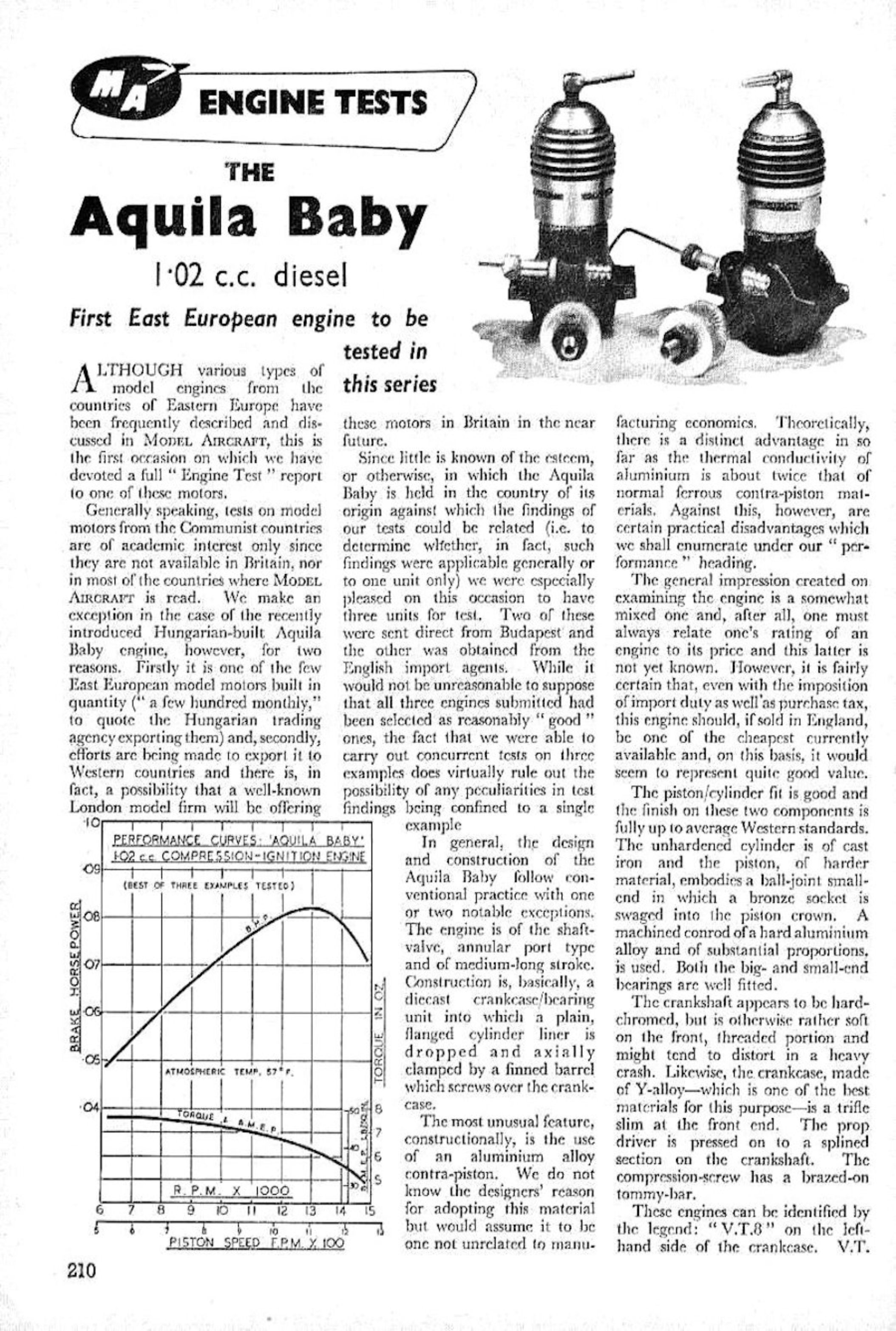

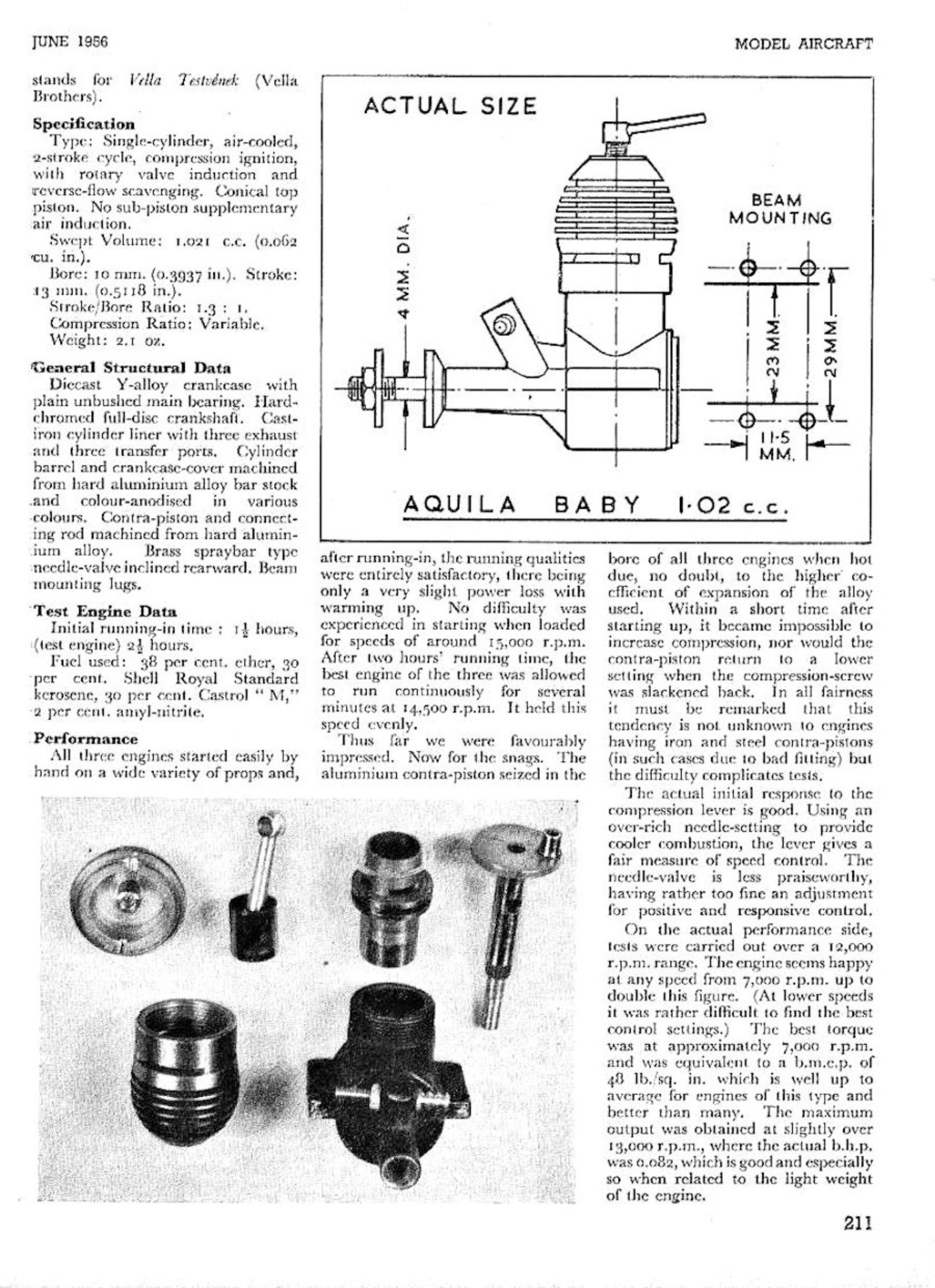

One of ARTEX's earliest export customers was Ripmax Ltd. of Camden Town, London, England, who became their British agents in 1956. Since Ripmax were naturally keen to increase the visibility of their new Hungarian model engine lines, one of their first promotional moves was to send a sample of the 1 cc VT-08 "Aquila Baby" to the most respected and widely-read model engine commentator in England at the time, Peter Chinn, who described the engine in his "Accent on Power" column in the April 1956 issue of "Model Aircraft". This was followed by the publication of a test report on the engine in the June 1956 issue of “Model Aircraft”. More of this below. This was the first test of a Hungarian model engine to appear in the English-language modelling media. Prior to the appearance of this test, it’s likely that few if any modellers in Britain and other Western countries were even aware that model engines were being commercially manufactured in Hungary. Having taken an overview look at the early development of the Hungarian model engine manufacturing industry and the entry of the Vella Brothers into that industry, let’s examine a representative sample of the engines which emerged from their workshop during this period. There may well have been other models, and I'd be most openly grateful for any information from readers who are able to expand our shared knowledge of this subject. The VT-08 Aquila Baby

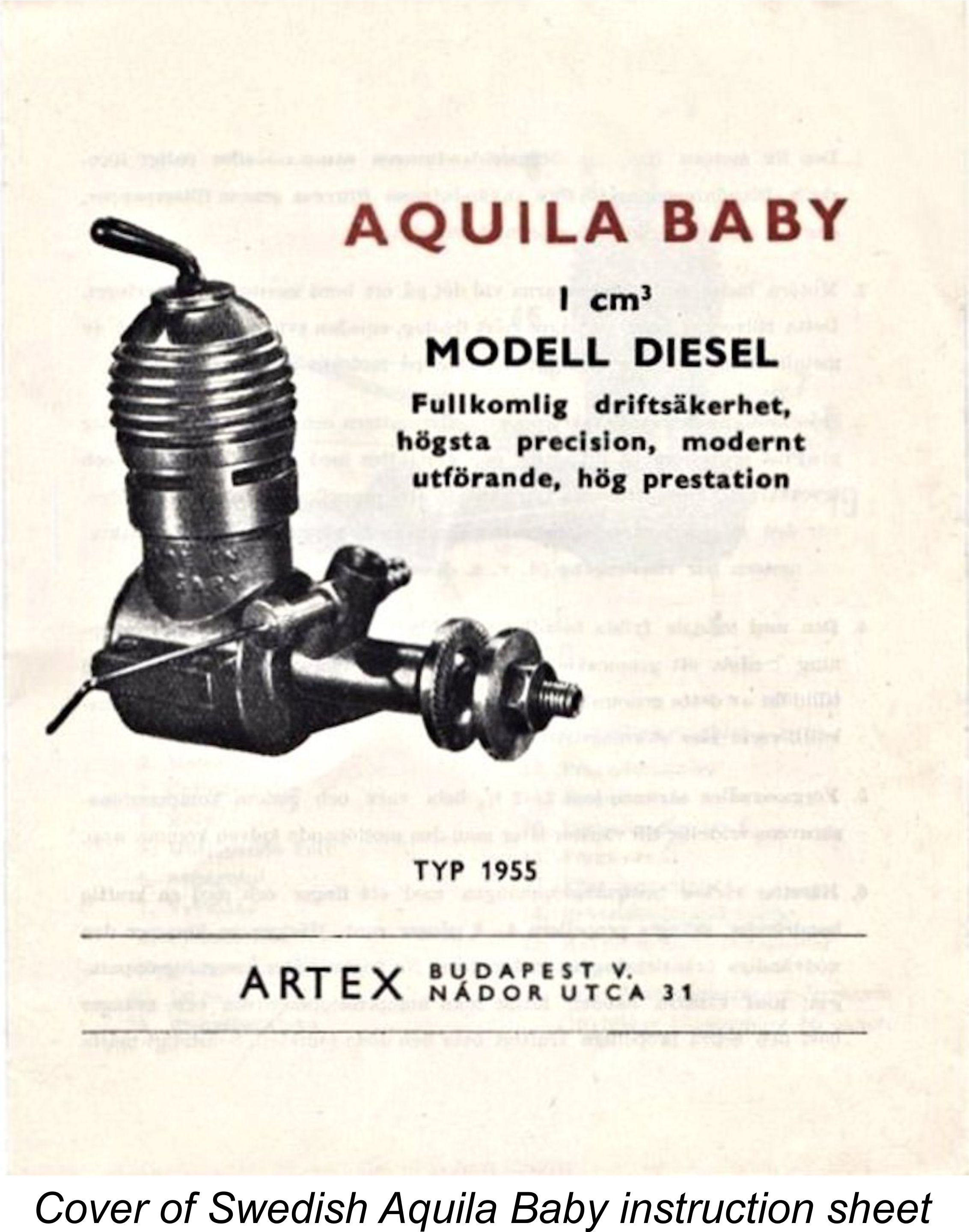

As already mentioned, the Aquila Baby was introduced by the Vella brothers in 1955 - this date is confirmed by the Swedish-language Aquila Baby instruction leaflet which was pictured earlier. The leaflet in question was printed in 1956 but the cover clearly confirms that the engine with which it was associated was a 1955 model Aquila Baby. The Aquila Baby was a more or less conventional radially-ported plain bearing crankshaft rotary valve diesel which nonetheless exhibited a few then-uncommon design features. Somewhat unusually by 1956 standards, it was an exaggeratedly long-stroke design having a bore and stroke of 10 mm and 13 mm respectively for a slightly odd-ball displacement of 1.02 cc (0.062 cu. in.). Despite its long-stroke internal geometry, the engine was quite neat and compact in appearance, weighing in at a relatively light 60 gm (2.1 ounces). It was supplied with a range of different colours applied to the cooling jackets, prop drivers and backplates - I have a second "bones" example which has gold-anodized components. As noted earlier, this model was the subject of a test report by Peter Chinn which was published in the June 1956 issue of “Model Aircraft”. This was in fact Chinn’s first-ever published test of an Iron Curtain engine from any source. Chinn had been provided with no less than three examples of the engine for test from two separate sources, and all of these apparently ran OK.

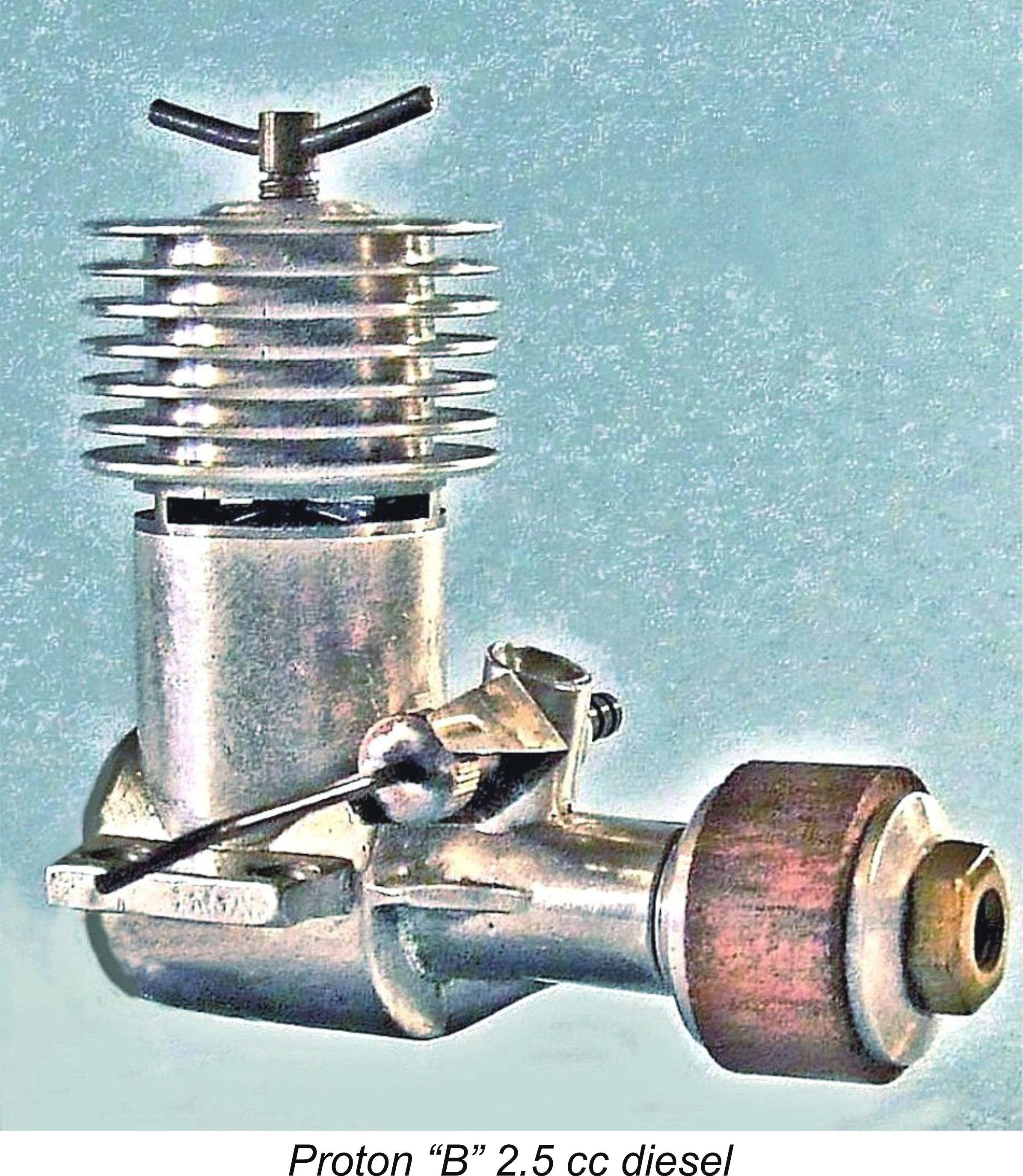

Chinn was understandably less than complimentary about the engine’s use of an aluminium alloy contra piston, since the differential expansion of this item in relation to the cast iron cylinder resulted in its seizing solid in the bore once the engine warmed up, with a consequent inability to make any further compression adjustments. He also expressed a concern that the minimally-braced crankcase casting might have been made a little too “thin” at the front end for adequate strength. Despite these criticisms, Chinn found the Aquila Baby to be a quite acceptable performer overall. Power was fairly average by then-current standards – measured output was 0.082 BHP at 13,100 rpm, at a time when the better British, Italian, Scandinavian and German 1 cc diesels were approaching or beating the 0.10 BHP figure. However, Chinn commented quite rightly that this was a good performance for an engine of such light weight. He noted the easy starting of the engine, also stating that all key fits and finishes were very good. He did however recognize the possibility that he might have received some “selected” better-than-average examples to test…………. It appears that the manufacturers were paying close attention, since they quickly responded to at least two of Chinn’s comments. A refined version of the engine soon appeared, featuring a main casting having considerably more substantial bracing for the main bearing. In addition, the forward-angled intake venturi was replaced by a well-braced vertical component. It is one of these variants that is illustrated here. Another change that was evidently made as a result of Chinn's comments was a switch to a cast iron contra piston, which greatly improved the engine's handling qualities. In addition, the original two-piece compression screw was replaced by a one-piece component, presumably for cost reasons. Reportedly, there was also a variant that had the needle valve angled back on the right-hand side of the engine (looking forward in the direction of flight). Bore and stroke of these models remained unchanged, as did the main mechanical design features. Chinn stated very clearly that the early examples of the Aquila Baby tested by him were identified through having the legend “VT 8” cast onto the left side of the crankcase. Moreover, the illustrated later variant from my own collection is similarly identified. Evidently the Vella Brothers wanted their initials to be This still leaves us a little puzzled as to why a 1.02 cc engine was identified as the “VT 8”! The fact that a later development of the 1 cc VT model was designated the VT-12 seems to confirm that the numerals in the name were not related in any way to the displacement of the engines. Nor were they apparently related to the order in which the various models appeared - if they had been, where are the VT-01 through VT-06 models?!? More than a little confusing, but there it is and we’re stuck with it! András Vella, the son of the younger Vella brother Géza, quizzed his father on this point. As far as Géza could recall sixty years on, there was no particular pattern to the numbers applied to the various models. In Géza's words, "the numbers were what they were"! As far as he could recall, there were never any VT-01, VT-02 or VT-03 models - he wasn't sure why! Somi tells us that in an effort to increase the market range of the VT-08 outside Hungary, ARTEX arranged for the production of a couple of ready-to-fly models which were fitted with Aquilla Baby engines. The two models in question were named the "Kakadu" and the "Kolibri". A number of them were reportedly sold in Western countries. It appears that the Aquila Baby remained in production for some 5 years or so. During that period, production figures seem to have been comparatively high by 1950's Hungarian standards - in his very interesting 1980 Czech-language book “Modelářské Motory” (Model Engines), Jiří Kalina reported that the engine was produced in “relatively large numbers”. Somi informs us that the number produced was in fact around 10,000 units. The implied average production rate of some 170 units monthly at a time when a number of other models were being manufactured simultaneously confirms that the Vella Brothers were able to make very good use of such production facilities as were available to them. The Early VT Racing Engines During the mid-1950's, one issue which challenged Hungarian modellers was an almost complete lack of access to racing engines which could be used by prospective competitors to gain the experience necessary to compete at the highest levels. This issue was by no means confined to Hungary - both the Czechs and Russians suffered from a similar problem. The result was that relatively few modellers in those countries In other articles, I've looked at the various initiatives taken by the Russians and Czechs to address this issue. The Russians began their own program of making "consumer-grade" racing engines more widely available through the 1957 introduction of the vastly under-rated Super Tigre-based 5 cc MD-5 Kometa, which was later joined by a 2.5 cc MVVS-influenced model called the MD-2.5 Moscow. Both models are the subjects of separate articles which appear elsewhere on this web-site. At around the same time, the Czechs introduced the Vltavan line of racing engines which were based upon the tool-room specials then being constructed in minimal quantities by the MVVS workshops. The MVVS engines, the Vltavan 2.5 cc model and the Vltavan 5 cc unit have all been covered in separate articles which are to be found on this website.

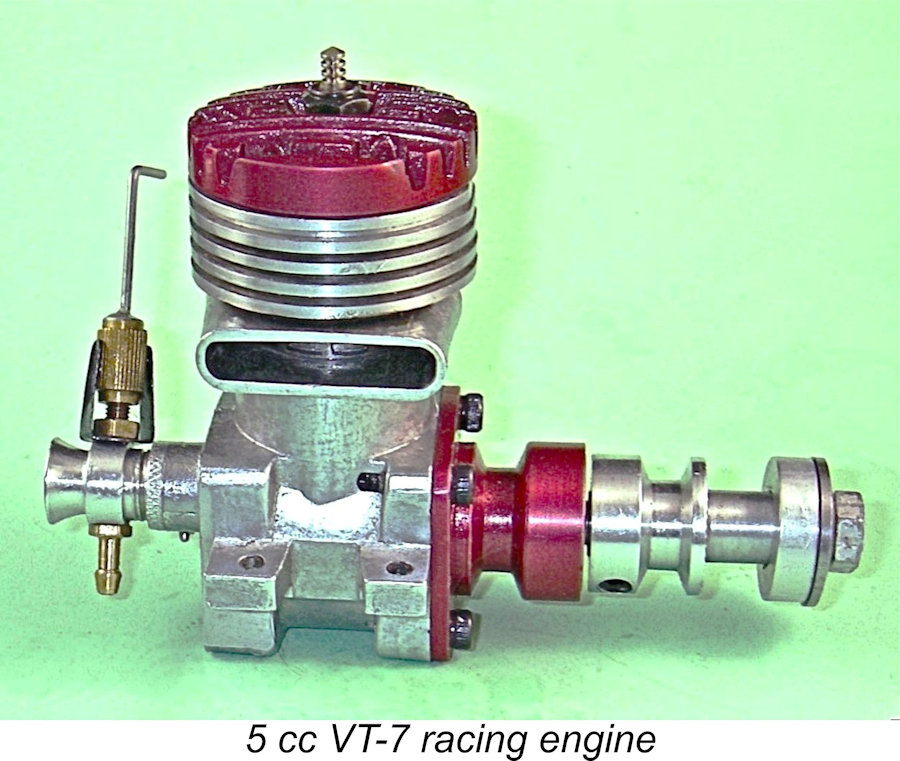

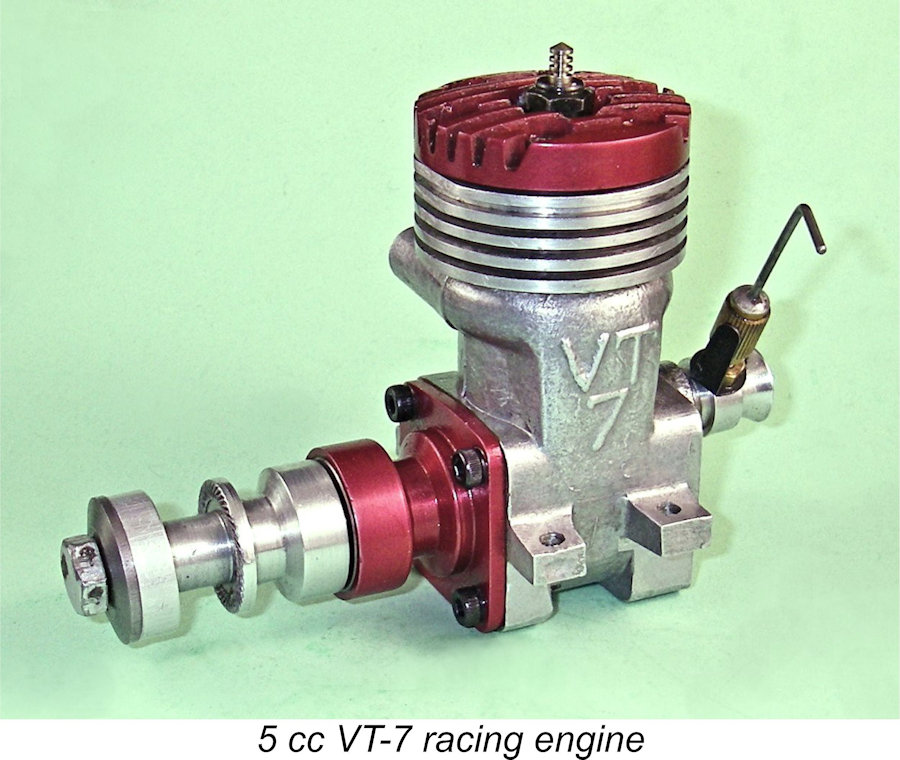

The VT-07 was a basically conventional 5 cc racing glow-plug motor of its day. It followed the classic racing engine pattern established by the Hornet and McCoy models from the USA, The VT-07 was undeniably rather handsome, featuring a red-anodized head and front bearing housing, although the red anodizing appears to have been somewhat prone to fading in service. Perhaps the most unusual feature was the mounting lug design, which consisted of four quite separate extrusions, one for each of the four mounting bolts. These extrusions were unusually thick, hence seemingly having adequate strength. My illustrated example of the VT-07 has been expertly overhauled by my valued mate Peter Valicek, who renewed the somewhat faded anodizing, replaced the piston rings and made a new disc valve and conrod. A few test runs following the engine's return from Peter's workshop showed considerable promise. When time and opportunity coincide, I hope to run a full test of this engine, the results of which will be added to this article. Based upon its specification I would expect the VT-07 to perform at a quite adequate level by contemporary standards to allow its users to at least gain valuable experience.

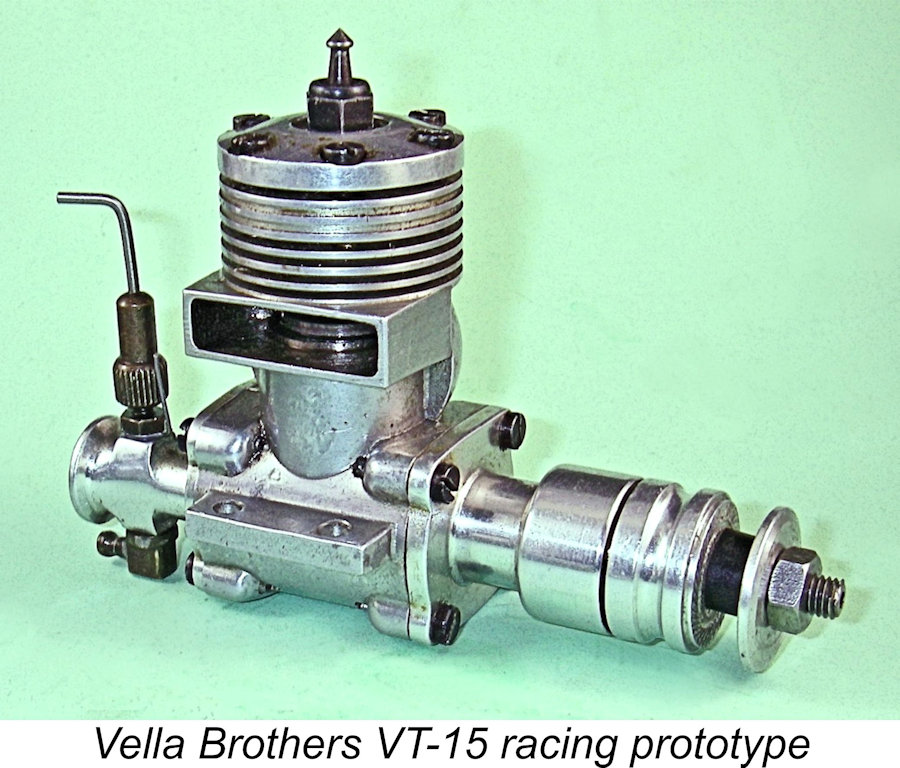

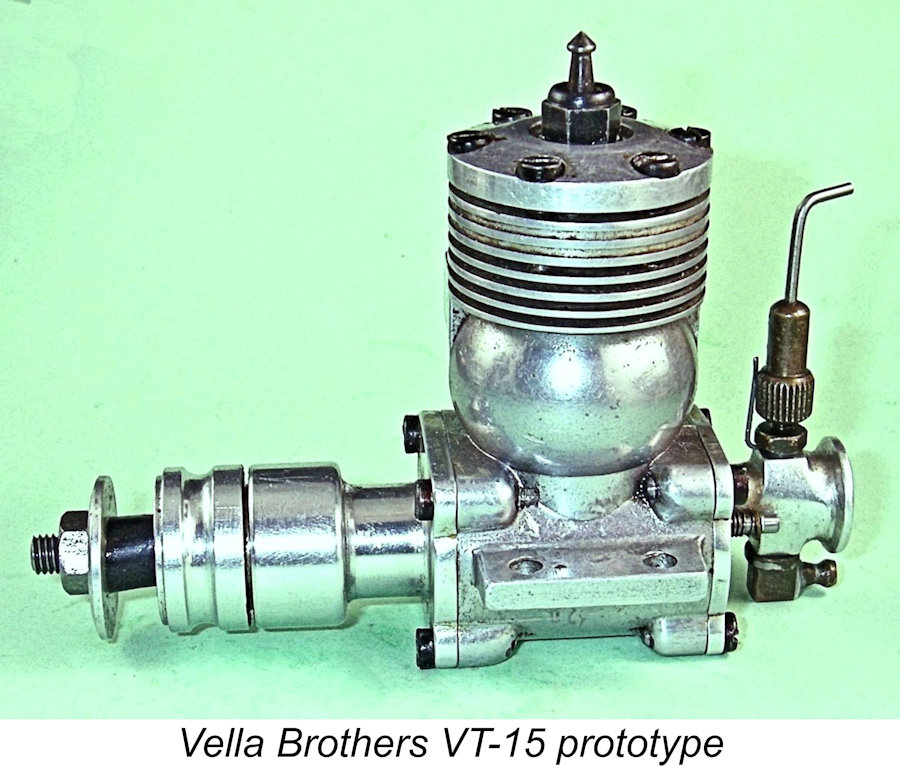

The image of the VT-15 seen at the right shows it to be a fairly typical Eastern European racing glow-plug unit of the latter part of the 1950's. It had a Dooling-style bulge bypass transfer system in conjunction with a twin ball-race crankshaft and RRV induction. I'm informed by members of the Vella family that the bore was chrome-plated, while the light alloy piston carried two steel rings rather than the usual cast iron components.

Somi confirmed that production figures for both of the VT racing models were very small. In his recollection, the engines never became truly competitive because then-current market conditions did not justify the ongoing development which would have been required to bring them up to the As mentioned earlier, the VT-07 and VT-15 were not the only racing engines to appear in Hungary at this time. We saw previously that during 1957 the manufacture of the Alag diesel series at the AKKÜ facility at Dunakeszi was terminated, with the ongoing manufacture of this range being transferred to the Preciziós KTSZ co-operative. This manufacturer immediately set about the design and production of a pair of Alag racing glow-plug motors designated the Alag Y-02 (5 cc) and Y-03 (2.5 cc) respectively. Both of these engines were designed by future MOKI chief and 1962 World Control-Line Speed Champion Gyula Krizsma, who used a prototype Alag Y-03 to place fourth at the 1957 World Control Line Speed Championship with a speed of 205 km/hr (127.381 mph). I've covered this story in my separate article about the Alag range.

It appears that both the VT and Alag racing engines had become essentially redundant as of 1960, since there is no evidence that production of either series continued beyond that year. The same appears to be true of the competing Vltavan models from Czechoslovakia (now the Czech Republic).

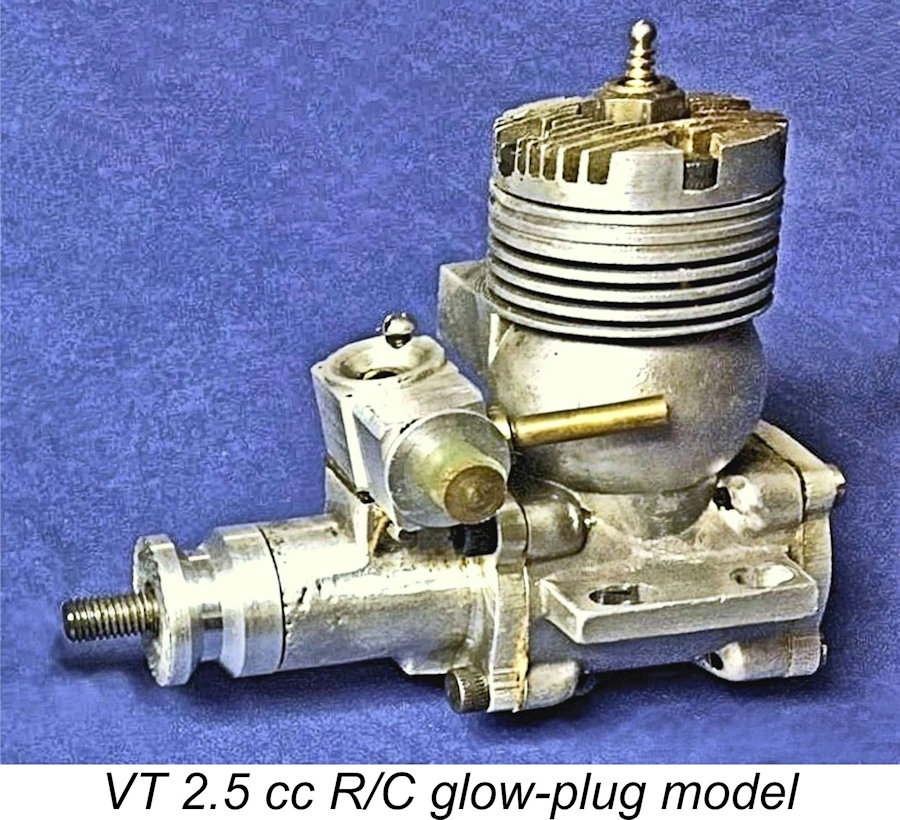

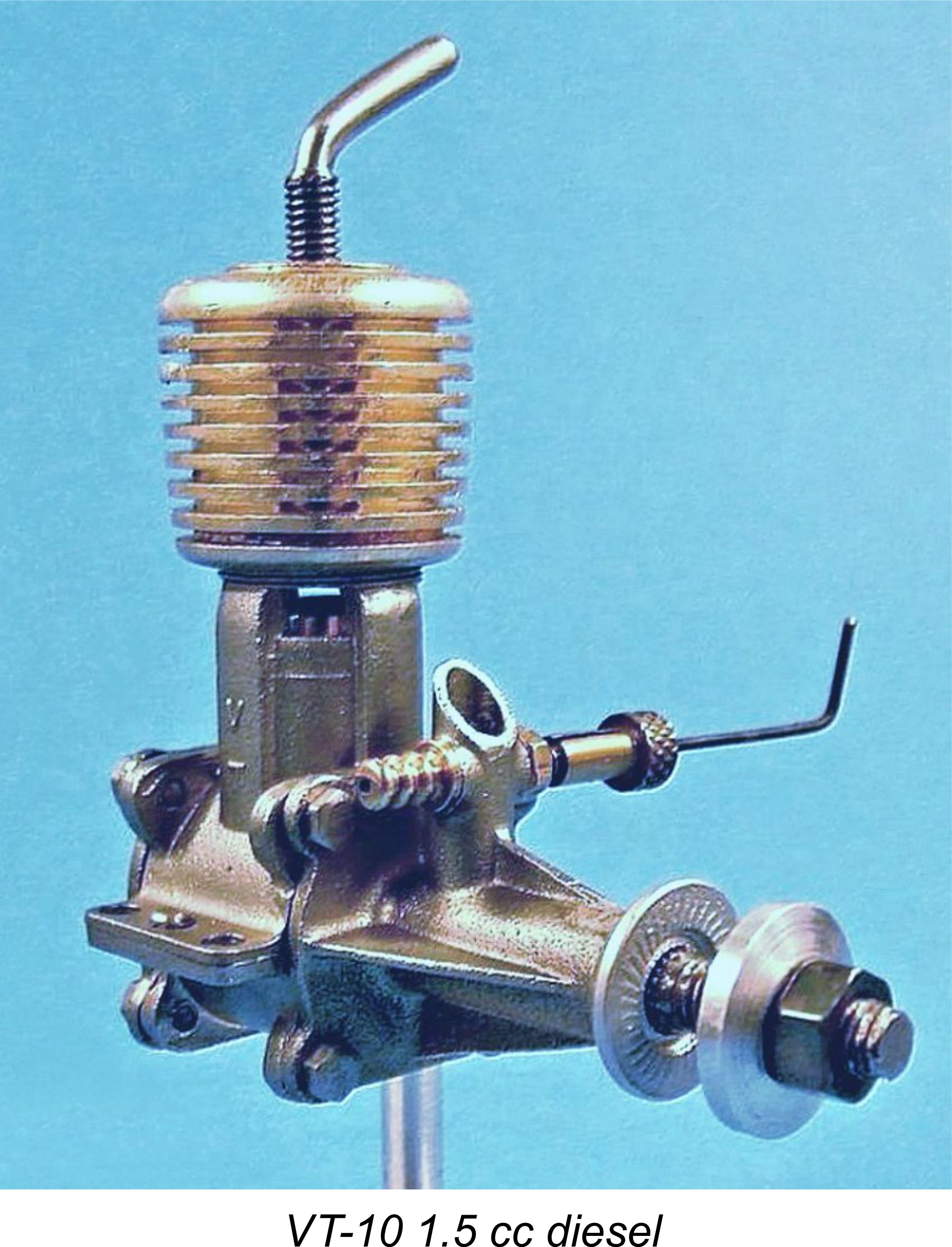

I should also mention that a very few examples of a seemingly-related Vella FRV 2.5 cc R/C glow-plug motor have shown up. This engine was based upon the same Dooling-style "bulge bypass" crankcase as my own lapped-piston VT-15 prototype racing unit described above. It featured a conventional backplate and a front housing which was arranged to accommodate an R/C throttle. I can find no evidence that this seemingly experimental design was ever produced commercially. Its dating is likewise unclear, although the surrounding circumstances suggest a date of around 1960-61. The Later VT Diesels As time went on, the VT-08 Aqila Baby was progressively joined by other diesel models which were sold under the VT label. These included the 1.5 cc VT-09, the diminutive little VT-11 of only 0.25 cc displacement, and a companion (or possibly a successor) to the VT-08 in the form of the 1 cc VT-12 of somewhat different design. The latter model also appeared in a fascinating marine variant called the "Seal Baby", of which more below in its place. There was also a VT-10 model of 1.5 cc displacement which was built to a very different design from the other diesels in the range. The marketing of an engine line bearing their own initials might be expected to act as an incentive for the Vella Brothers to strive for the best possible product, and it’s certainly true that the quality of the VT engines appears in general to be up to quite acceptable standards. All of my VT engines are very well made - the working fits match anything I‘ve seen from any other commercial European manufacturer of the period. Reports from other owners indicate that this is typical of the VT line as well as its Engel Rebell and BX offshoots (see below). It seems that the Vella brothers were making a sincere effort to maintain acceptable quality control standards. That said, a number of quality control issues which did somehow escape their notice have been reported from time to time. Although they share a number of common characteristics with their Alag contemporaries of similar displacement, the VT diesels are in fact quite distinct designs. For one thing, the porting of the VT engines differs substantially from that of the Alag models. The Webra-style transfer porting used in the Alags, with six internal flute bypass/transfer passages, had two drawbacks. Firstly, it was not possible to incorporate any overlap between the exhaust and transfer ports. This naturally restricted the transfer period, or alternatively forced a longer-than-desirable exhaust period, particularly in the case of a short-stroke design.

An issue which has been noted from time to time is an error in aligning these bypass/transfer flutes correctly between the exhaust ports. This could reach the point at which a direct connection between exhausts and transfer flutes was established, as exemplified in the accompanying image from Peter Valicek showing such an issue in a 1 cc VT-12 diesel. Obviously, this will greatly affect the engine's base pumping efficiency during operation, as well as promoting a considerable loss of fresh fuel mixture. The occurrence of such issues implies a less-than perfect quality control program. In addition, some of the earlier examples of these later diesels featured a steel circlip surrounding the piston, evidently with the intention of retaining the gudgeon pin within its bosses to prevent fouling of the bypass/transfer channels. An example will appear below in its place. Other manufacturers have subsequently used this idea (notably the early M.E. engines), but I can’t think of an earlier model engine range that displayed this feature. In some examples of the VT engines, the ends of the gudgeon pin were themselves grooved to accommodate the circlip. When discussing this concept with the late Ron Chernich, Ron's late fellow Motor Boy David Owen convinced Ron that this is a bad idea on engines such as the later VT diesels in which the transfer ports overlap the exhaust, as described earlier. The reason for David's opinion is that as the piston descends, the circlip groove will briefly connect transfer and exhaust ports well before the exhaust opens. During this period, the crankcase becomes open to the atmosphere, allowing the possibility for the higher-than-atmospheric crankcase pressure to vent some of the fresh charge via the exhaust, also reducing crankcase pressure. The duration of any such leakage will be small, and obviously such engines do still run. However, some negative effect upon performance will almost certainly result. In addition, the circlip goove tended to retain some particulates which would otherwise be expelled with the exhaust residues. Consequently, those particulates moved rapidly up and down in contact with the bore, potentially contributing to accelerated wear. Finally, the circlip tended to fail after some running time, to the point where it fouled the ports. These issues were evidently recognized by the Vella brothers, because the use of the circlip in their engines was abandoned at some point relatively early on. Let’s look at a few more examples of the diesel models produced under the Vella Brothers' VT brand-name. The VT-09

I'll comment on other models in this series in due course. For now, I'll focus on the 1.5 cc VT-09 as a representative example. We might perhaps expect to find that the design of this engine was influenced to some degree by that of the earlier Alag X-04. This is far from being the case - the two engines are in fact quite distinct designs, albeit sharing a common overall layout. The styling of the VT-09 is markedly different from that of the X-04, the overall result being that the VT engines appear somewhat bulkier than their Alag compatriots of similar displacement. In part, this appearance of added bulk is due to the fact that in contrast to the corresponding Alag X-04 model, the VT-09 is a long-stroke engine. It has bore and stroke measurements of 12.0 mm and 13.0 mm respectively for a displacement of 1.47 cc. Weight is 82 gm (2.9 ounces), up a little from the Alag X-04’s notably light weight of 71 gm but still a very reasonable figure for a 1.5 cc diesel of its day.

The amended transfer arrangements allowed the designer to significantly decrease the blowdown period by comparison with that to which the Alag model was restricted by its porting. The VT-09 has a measured exhaust period of some 150 degrees (75 degrees each side of bottom dead centre), identical to that used in the 2.5 cc Alag X-03. However, the revised porting arrangements made it possible to reduce the blowdown period to 15 degrees for a total transfer period of The venturi is cast integral with the crankcase, no insert being used. Otherwise, the VT-09 is basically similar to its Alag compatriot, with plain bearings, crankshaft rotary valve induction, a rather heavy cast iron piston, a cast iron contra-piston and a sturdy steel cylinder. Assembly too is identical, with all parts threading together directly without the use of bolts or screws. All of the external turned alloy components on my example of the VT-09 (jacket, backplate, prop driver, prop washer and spinner nut) are anodized candy-apple red. In fact, there appears to have been little consistency in the colours applied to the various VT models - it seems to be a function of whatever colour was in the anodizing bath when a given batch of components was ready to treatment. The illustrated example of the companion 1 cc VT-12 features blue anodized components, while the 2.5 cc model frequently featured pale green anodizing. The minute little VT-11 of only 0.25 cc displacement was usually anodized gold. All fits on my example of the VT-09 are beyond reproach and are a match for any of the engine’s commercial contemporaries regardless of source. This is reportedly typical of the VT engines. The Vella 2.5 - A Latter-Day Test

Maris noted a couple of interesting features. The crankcase of his example appears to be electroless nickel plated. This is an auto-catalytic chemical technique that deposits a nickel-phosphorus coating without the usual electric current requirement. Maris's example also carries a different designation from later VT products, bearing the identification markings "Vella 2.5" cast in relief onto the right-hand side of the crankcase. It is presumably an early example dating from the time prior to the general adoption of the VT identification protocol. Another feature indicative of an early date is the engine's use of an Maris's engine came from his fellow Aussie Steve Foster, who was given it while in high school in the late 1960’s. He only used it a few times, finding it very difficult to start, as did Maris when using his usual general purpose diesel fuel containing 25% castor oil. Experience has shown that even if compression seal is good over top dead centre, poor pumping effectiveness through the lower part of the stroke can cause starting troubles. A switch to Maris's usual free flight fuel comprising equal parts castor oil, ether and kerosene helped greatly, allowing performance testing to proceed.

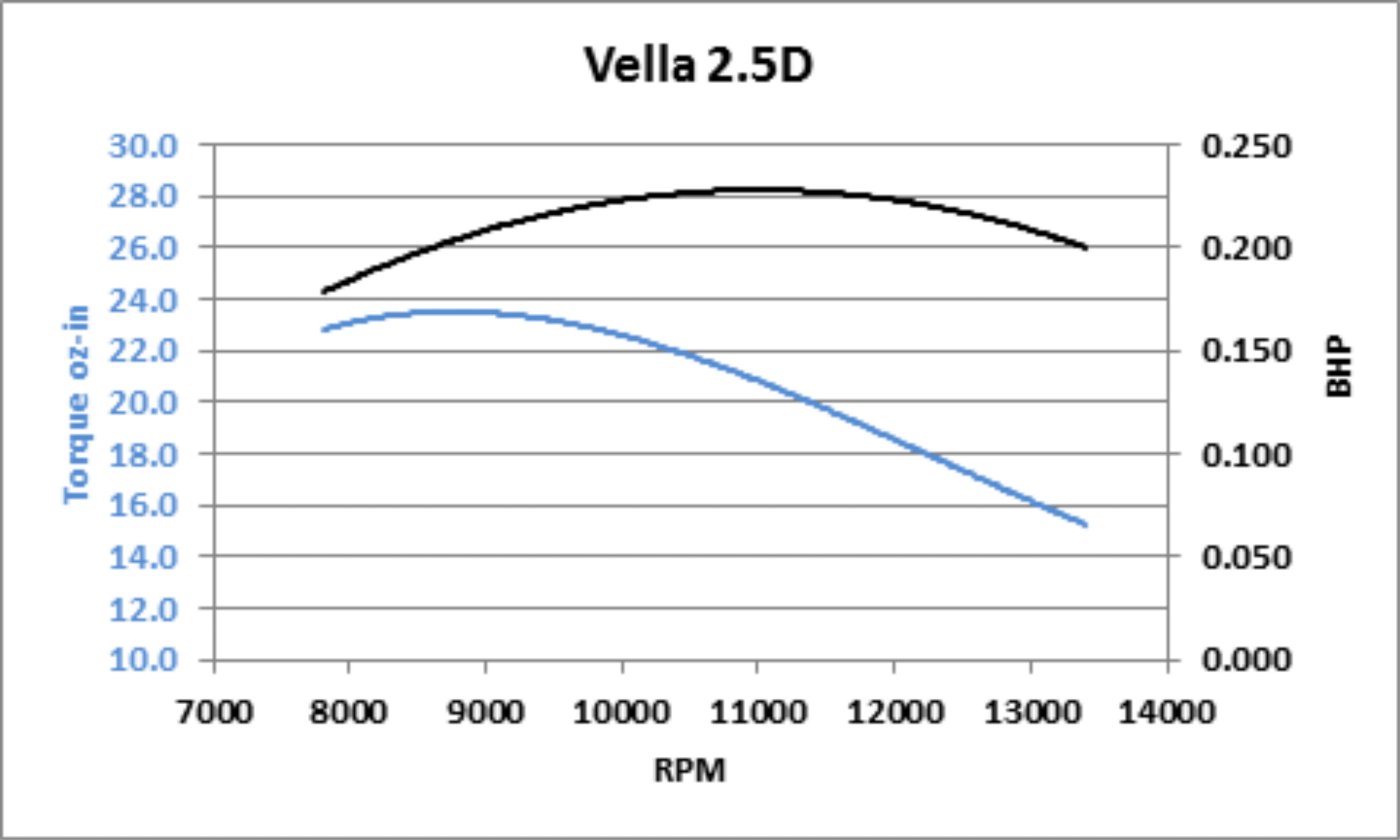

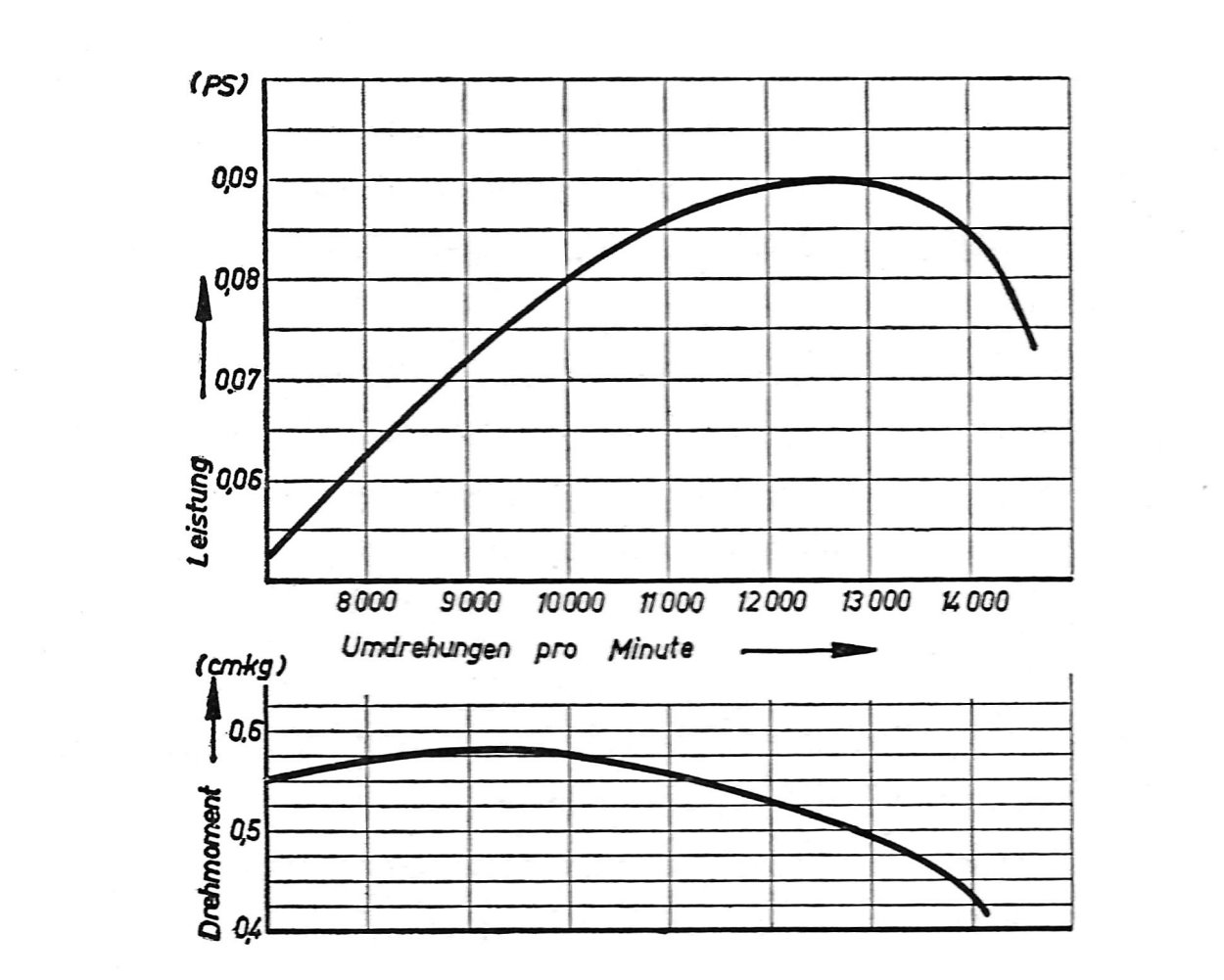

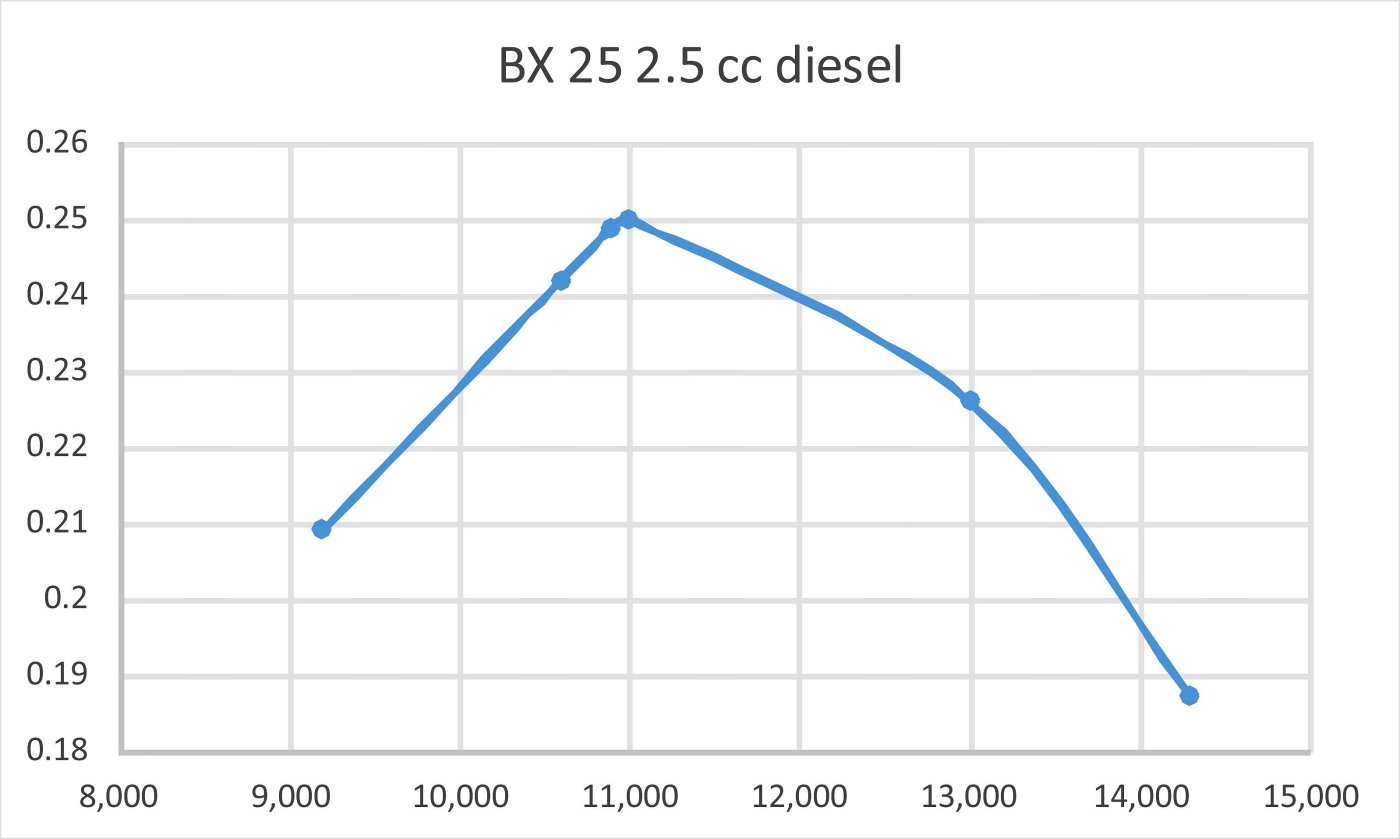

The standard spraybar is a slender 2.5 mm diameter through the 6 mm ID venturi, resulting in a very generous 13.9 mm2 effective choke area with somewhat marginal suction. According to Maris's very useful choke area calculator, the minimum speed at which the engine can be operated with adequate suction is 11,390 RPM, which is actually in excess of its peaking speed. It seems clear that it would work better for practical purposes with a slightly thicker spraybar. Regardless, this factor complicated starting since engine RPM would need to be fairly close to peak for the engine to catch on, irrespective of how far open the needle was set. Compounding that, there was a tendency to knock when starting at peak running compression setting. The approach finally settled on was to open the needle a lot (it’s almost impossible to balk this engine with a rich setting) prime the venturi and exhaust and back off compression by a quarter to half turn. The moment it fired, compression was then rapidly brought up and fine-tuned once the needle was wound in. It appeared to be no wonder that this particular engine reached Maris with only moderate previous use! The prop/RPM figures measured by Maris were as follows:

The performance measured by Maris for this engine essentially matched my own test results for the derivative BX-25 unit (see below), although Maris's example was clearly far harder to start and performed at a slightly lower level. It's possible that Maris's engine suffered from the previously-discussed effects of a misaligned bypass flute which allowed some short-circuiting between exhaust and transfer ports, with a corresponding loss of crankcase compression and associated loss of incoming mixture during operation. Maris reported that his test example was not very happy when lightly loaded, seeming to be at its best when turning relatively hefty propellers around the 9x6 size. Such a prop would doubtless speed up in the air to something approaching the engine's peak. The measured peak power of 0.23 BHP around 11,000 RPM is reasonable compared to other plain bearing “sport” diesels of the era. We might anticipate little or no loss of power but much improved flight consistency (and easier starts) with a 3.5 mm or even 4 mm spraybar diameter. The VT-10

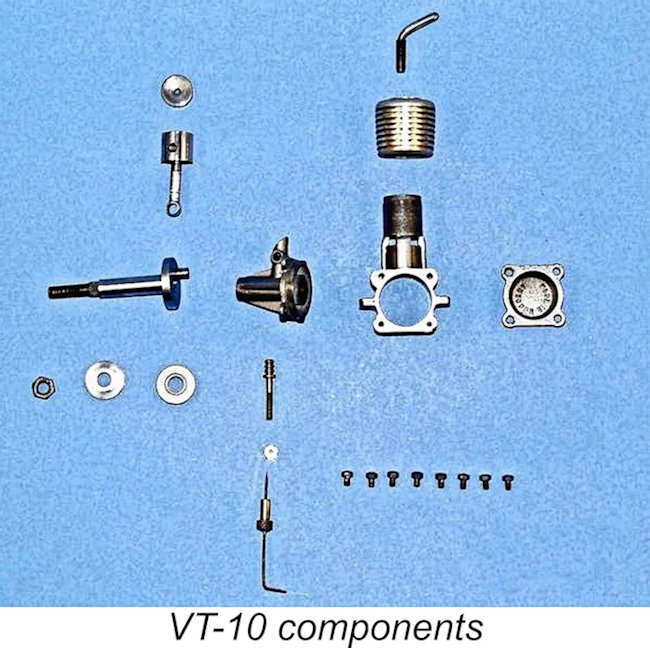

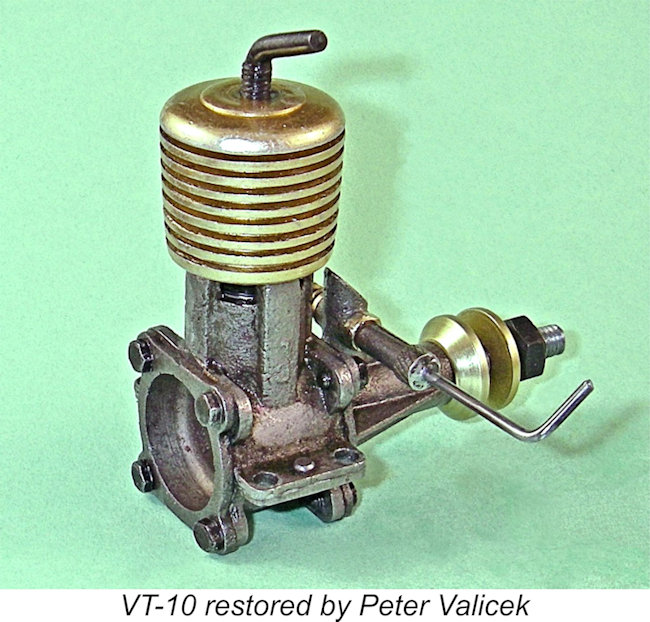

Whatever the fact of the matter, this is undoubtedly one of the rarest VT models. It was only thanks to the splendid co-operation of my valued friend Peter Valicek of the Netherlands that I was able to acquire a fine example of this engine following its expert restoration by Peter. In many ways, this is the most interesting and out-of-the-rut VT design of them all! This is because the upper half of the horizontally-split crankcase was formed in a single iron casting which incorporated the cylinder itself in unit! No cylinder liner was employed - instead, the piston and contra-piston operated in a bore machined directly into the main casting material. In Somi's view, the relatively few examples of this model that were made were most probably experimental prototypes constructed simply to test the concept both from production and operational standpoints. That said, it does appear that a small production series of these engines was manufactured. To my present knowledge, the only previous instance of a similar material selection was the manufacture of one or two iron-case examples of the GP 7.5 spark ignition model constructed in the late 1930's and early 1940's by the Italian-born Swedish manufacturer Giancarlo Pinotti. I've recounted the fascinating story of the Pinotti engines in a separate article on this web-site, including a test of an iron-case Pinotti GP 7.5.

Now it gets really weird! The crankcase is horizontally split across its centre-line, with the split centred upon the beam mounting lugs. The upper and lower halves are fastened together by rivets which pass vertically through the two mounting lugs. These arrangements are clearly visible in the images reproduced here. Th This form of construction in turn made the use of detachable front and rear housings unavoidable. Both front and rear covers are also formed in cast iron. They are each attached using four hex-head screws, more along racing engine lines than the arrangements usually applied to a sports diesel.

After expending a considerable amount of careful effort restoring this engine for me, Peter gave it a few runs. He found that it started very easily and ran well. However, he was mindful of the comments received from several friends to the effect that this design proved in service to have a serious Achilles Heel, namely a tendency for the main casting to develop cracks in service. This tendency is understandable given the fact that cast iron is well-known to be very strong in compression but relatively weak in tension and quite susceptible to cracking. The presence of the sharp corners of the exhaust ports would serve as tailor-made stress concentration points from which cracks could develop and propogate. Peter gathered that relatively few examples of this engine survive intact. I feel very fortunate - thanks, Peter! It's rather difficult to discern a rational motive for the Vella Brothers developing this design, especially given the fact that they had their VT-09 model on offer at around the same time. In my view, this supports Somi's suggestion that the VT-10 was more of an experimental venture than anything else. Its main effect would be to eliminate any use of aluminium alloy castings, but why this would be seen as desirable is a mystery. Its construction and the manufacturing processes involved were far more complex than those applicable to the VT-09. In addition, servicing was rendered extremely difficult or impossible - how would you extract the piston and contra-piston, rebore the engine if required and then install new components? The VT-11

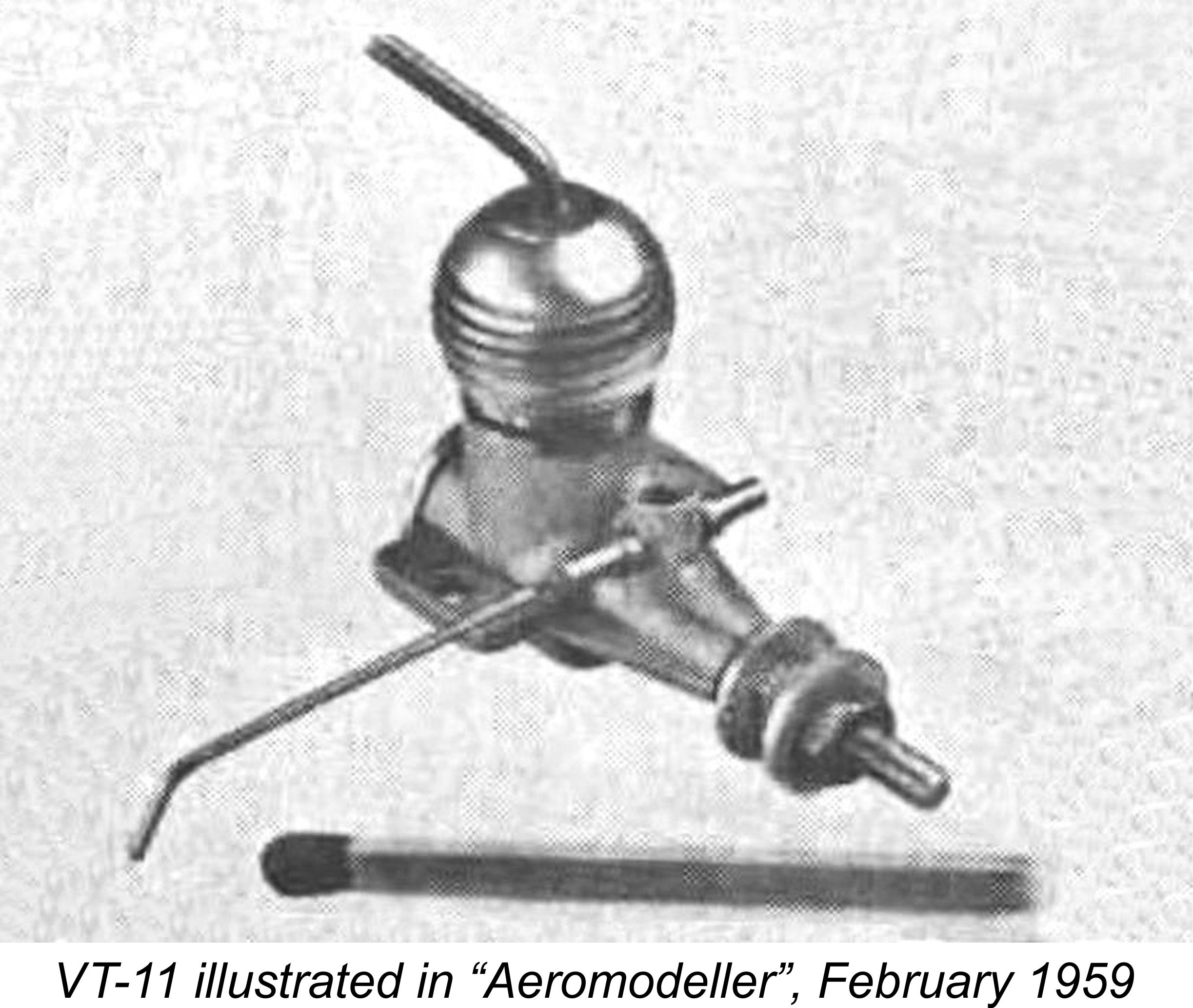

This very neat and compact little engine has bore and stroke measurements of 7 mm and 6.2 mm respectively for a displacement of 0.24 cc. Weight is a measly 18 gm (0.63 ounces). In terms of its design and construction it is very much a typical member of the Vella Brothers family, albeit with a few simplifications in deference to its tiny size. The same high standard of manufacture is once again in evidence in my example at least - the minute forged alloy con rod is particularly noteworthy. The cooling jacket, backplate and prop driver/washer are all anodized gold. The same system of porting as used on the larger VT engines is again employed, there being three internal flute-type transfer passages formed in the cylinder wall and located between the three exhaust ports so that a certain degree of overlap is present between the exhaust and transfer ports. Both the piston and contra-piston are of cast iron. Like the earlier VT-08 Aquil The intake is cast in unit with the crankcase and has no separate venturi insert, once again reflecting the design of the other VT models. Most unusually, the backplate does not screw into the rear of the crankcase as on the larger models but is actually a tight press-fit into the rear of the case! This unique set-up appears at first sight to be fraught with potential problems, but in practise works just fine on my example of this cute little motor. Apart from the pressed-in backplate, the most unusual feature of this engine is the needle valve assembly. A So how does it run?!? Very well indeed, as my own tests have shown! Compression seal on my example is excellent and starting is dead easy following standard procedures, the main imperative being to avoid flooding the engine, as with all sub-miniatures. Once running, the engine is extremely responsive to both controls. Consequently, an optimum setting is easily established – the ultra-fine 1 mm thread on the needle really helps here. I use a Cox 4½x2 prop for demonstration runs on this engine, and it turns this prop very happily at around 13,000 rpm (around 0.014 BHP) without missing a beat at any time. This is an excellent performance for such a small engine, and the VT-11 would undoubtedly fly a lightweight free-flight model very well on this prop. I actually suspect that for flying purposes (to which I’ve never put my example) this might be a bit less prop than desirable – I’d guess that the engine probably peaks at somewhere in the region of 13,500 rpm and that a trimmed 5x3 pulling the static revs down to 11,000 rpm or so might be a better bet for flying.

This example appeared to have had relatively little running when I acquired it. The running that it has since done has had little discernable effect upon the tight piston fit, no doubt due to the chrome-plated piston. I have no doubt that an example having a slightly looser piston fit would deliver an even better performance. In other respects, the engine is extremely well fitted, and I would objectively rate the general standard of manufacture of my specific example as above average. The VT-12 Seal Baby

The Seal Baby shared the 10 mm bore and 13 mm stroke of both the Aquila Baby and the VT-12 upon which it was broadly based. Its displacement was accordingly identical at 1.02 cc. It also used the same piston/cylinder assembly and backplate. However, that’s about all that it shared with its air-cooled companions! It exhibited a few quite unusual features, the most noteworthy of which was the provision of an under-slung parallel drive shaft which was driven by gearing at a quarter of crankshaft speed. The checked weight of the illustrated example is 185 gm (6.52 ounces), much of this being accounted for by the very heavy flywheel. This example is one of the later products from around 1959 – earlier versions like that shown in the 1958 Engel catalogue did not have the cast-in filler between the two shaft bearings beneath the induction tube. As mentioned earlier, the cylinder appears to be the same as that used on the Aquila Baby and its successor VT-12 aero version. Porting is quite conventional, three shallow sawn exhaust ports being used with three similar sawn transfer ports located underneath them. Mixture reaches the transfer ports through an annular space left between the outer cylinder wall and the crankcase casting, exactly like the arrangement used by Allen-Mercury, Davies Charlton and others. The contra piston is also the same as that used on the Aquila Baby, being made of aluminium alloy. One difference between this design and the aero models upon which it was based is the conrod, which is an alloy forging on the Seal Baby as opposed to the machined unit used on the original Aquila Baby model. The same ball and socket small end is however retained, being perfectly fitted with no detectable play.

The secondary shaft carries a large pressed-on gear made of a Tufnol-like material. This is driven by a small steel spur gear very neatly machined integrally with the main crankshaft behind the flywheel, the drive reduction ratio being 4:1. The drive to the water-screw can be taken either directly off the end of the crankshaft for high-speed operation using small water-screws or from the opposite end of the underslung reduction shaft for slower turning of a larger high-torque water-screw. A potentially useful pair of options! Regardless of the option chosen, the output rotation is in the conventional direction. The gear train ensures that the reduction shaft also operates in the conventional direction when the drive to the propeller is taken from that shaft at the rear of the motor. Lubrication of the underslung reduction shaft is very effectively arranged by the drilling of a small hole at the base of the main crankcase through to the bore of the reduction shaft bearing. The reduction shaft is thus continuously pressure-lubricated when the engine is running. This arrangement naturally means that the engine will not run with the reduction shaft removed, since the base compression seal is dependent upon the shaft being in place. The gear train is adequately lubricated simply by the excess oil which dribbles from the ends of the two bearings in the usual way. This is undeniably a quite innovative approach to the engineering of a model marine diesel. Although it can be used as a conventional marine diesel with direct drive off the

This example appears to have had little or no use. It has been gripped in a vice (fortunately without any substantial damage!) but has never been mounted using the mount holes drilled through the lugs. Once again, all fits are absolutely first-class. The engine starts easily and runs very smoothly when tested (using an airscrew on the main shaft as the load and a drip feed for cooling). The illustrated example still retains its sturdy two-piece plastic box and its very detailed English-language instruction leaflet (which was the same one that had been printed for the earlier 1958 model). This leaflet clearly confirms that the English-speaking world was a major target market, just as it was for the other VT and Alag models. The original needle valve assembly was missing when the engine was picked up years ago at a swap meet, and a non-standard matching unit is fitted in the photographs. Apart from this, the illustrated engine is complete and original. The Engel Rebell models

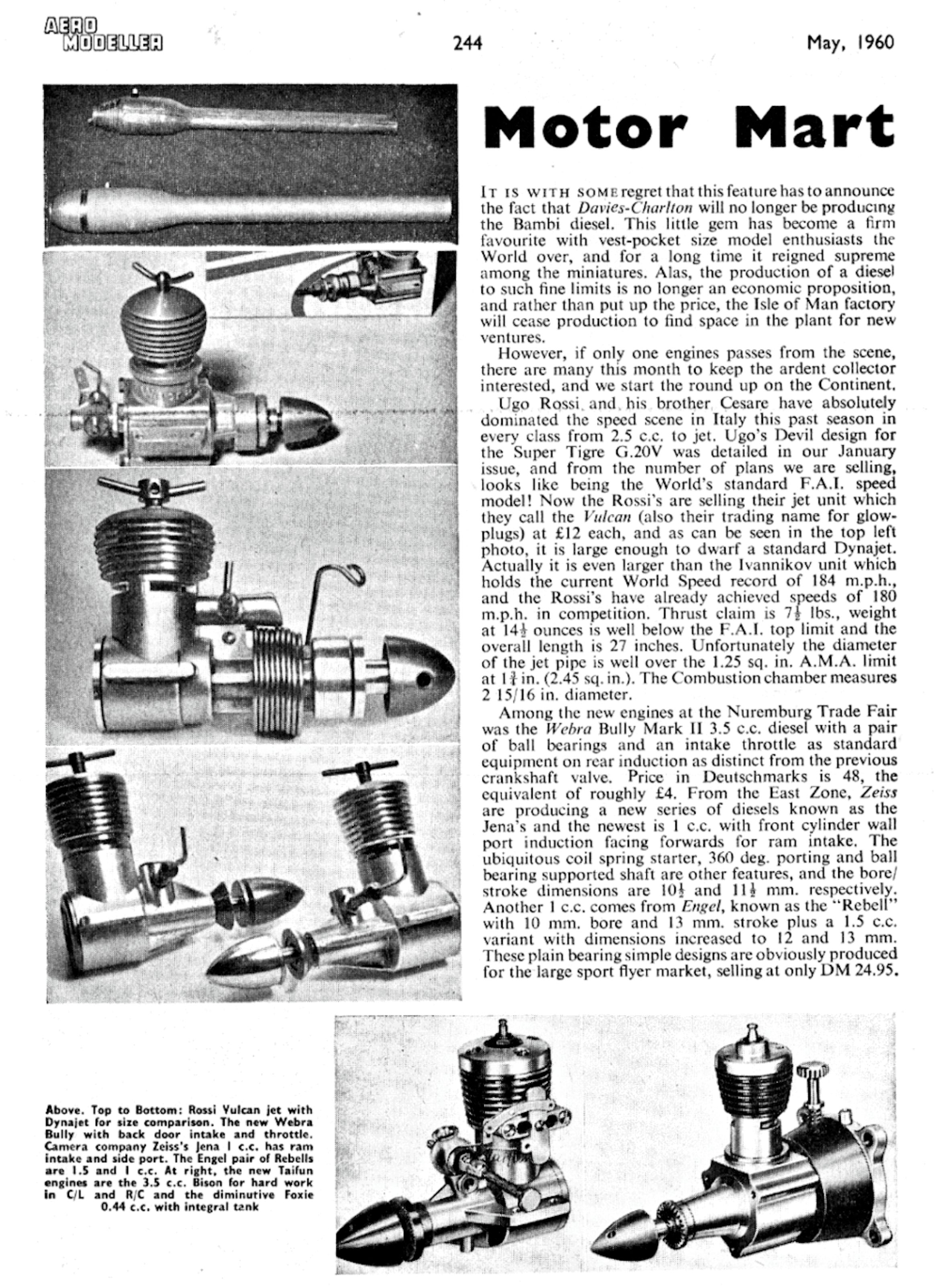

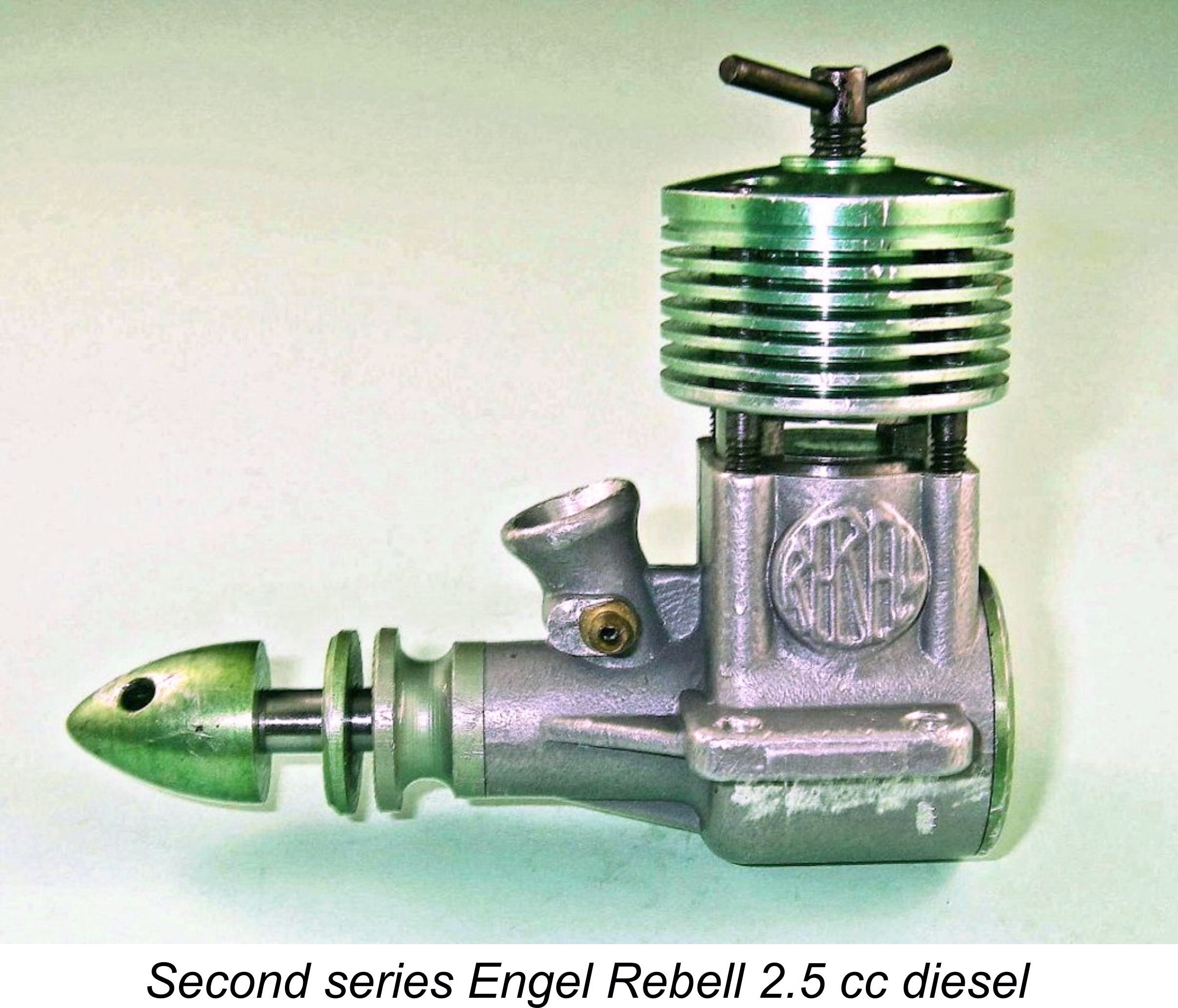

The Engel Rebell engines were first unveiled at the Nuremberg Trade Fair in February 1960, an event which was recorded in the “Motor Mart” feature of the May 1960 issue of “Aeromodeller” magazine reproduced at the left. Both 1 cc and 1.5 cc models were displayed at this event. The 1 cc model had a gold anodized head, a feature which was ultimately to give rise to trouble for the Vella brothers, as we shall see in due course. The published images of these engines that I’ve so far been able to find show that these engines were essentially identical to their VT relatives. Indeed, this appears to have been nothing more than a simple case of “badge engineering” for the purpose of giving the engines a recognizable identity in the German marketplace served by Engel. The VT engines continued to be marketed elsewhete under their own name.

It's interesting to note the fact that the Engel company appears to have downplayed the fact that the Engel Rebell engines were actually manufactured in Hungary! Peter Demuth's two-page discussion of these engines did not mention this fact at all, leaving readers with the impression that they were manufactured in Germany by or for Engel. A Final Fling - the BX engines

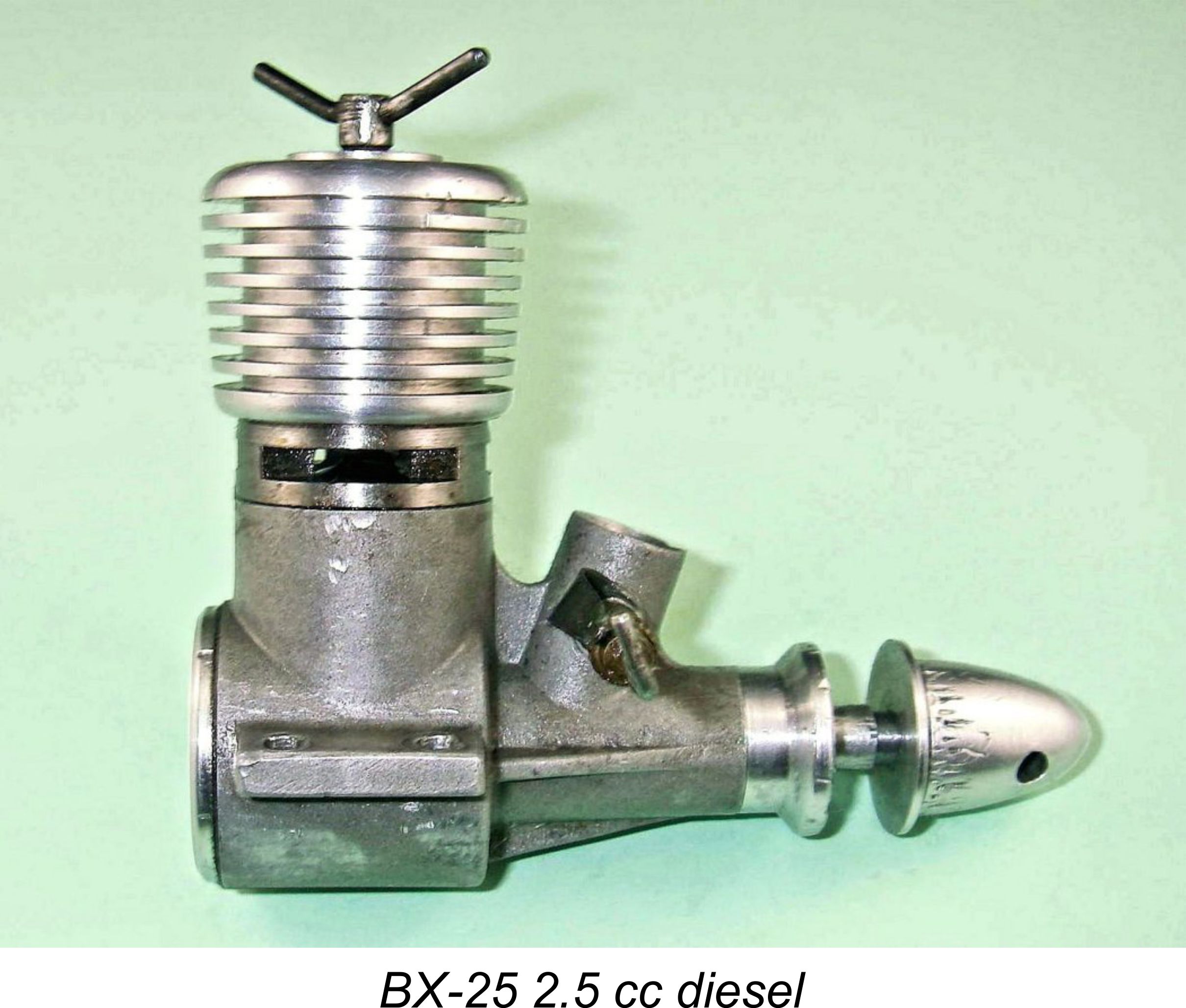

It appears that the agreement with Engel was confined to the German marketplace, leaving the Vella Brothers free to market the same designs in areas in which Engel was not active, although they naturally had to use a different brand-name. The BX engines were essentially identical to the corresponding VT and Engel Rebell models with a few cosmetic changes. They were also equally well-made. Somi tells us that the BX engines were marketed by Bertil Beckman & Co. of Stockholm, who imported them for sale under their own BX brand-name. ARTEX reportedly made a practise of accepting any such requests from customers in the hope of gaining further business. They had of course done so earlier in the case of the Engel Rebell models. The packaging in which the BX engines were supplied was reportedly identical to that used for the VT models such as the Seal Baby described earlier.

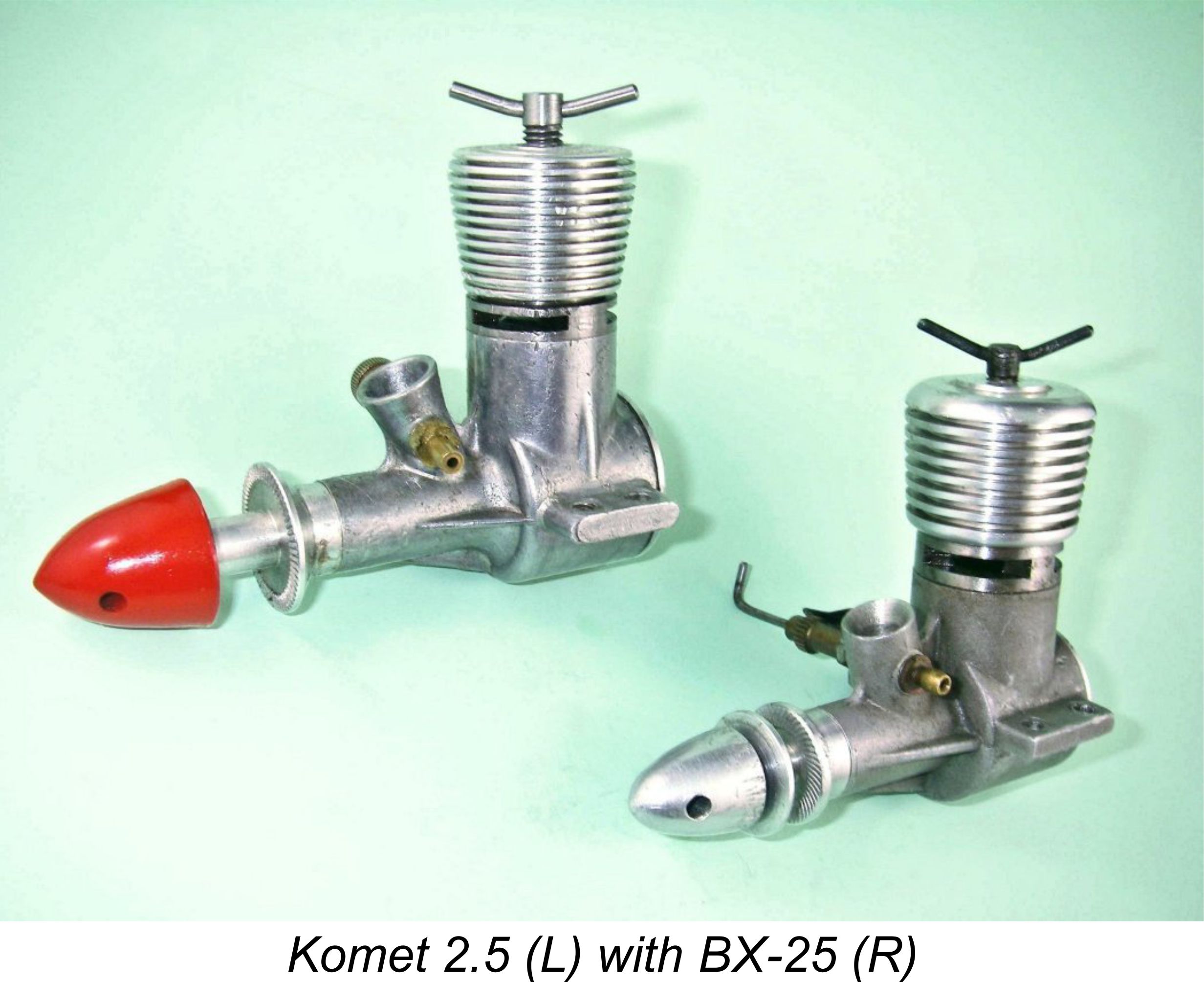

The view that their distribution was essentially confined to Scandinavia is supported by the fact that very few of the BX engines seem to have found their way into other parts of Europe or the West in general. As a result, the BX line has remained rather obscure up to the present day. I have not been able to find any reference to them in the contemporary English-language modelling media. Accordingly, what little I am able to present comes courtesy of a few good friends, in particular Lars Gustafsson of Sweden and my late and much-missed Australian mate David Owen. My sincere thanks to both! The BX engines were essentially identical to their VT equivalents except for the fact that the crankcase dies were slightly modified to eliminate the VT identification - the BX cases were unidentified. The other change was the elimination of the colour anodizing which was a feature of both the VT and Engel ranges - the BX engines used plain un-anodized components. They employed the revised porting which had appeared on the VT engines as described earlier, with three internal-flute transfer passages somewhat overlapping the exhaust. The BX models were sold in 1 cc, 1.5 cc and 2.5 cc displacements. Like their British Allen-Mercury cousins, they were designated by their metric displacements. David Owen had a BX-15 (1.5 cc) at one time, and thanks to some splendid co-operation from my Swedish mate Lars Gustafsson I have on hand a fine example of the BX-25 (2.5 cc) model. David reported that the smaller model was essentially identical in appearance to its larger relative (and to the VT-09 described earlier), so it will be sufficient for present purposes to describe the larger model.

In the case of the BX-25 (and presumably its VT and Engel equivalents) the timing flexibility secured by the above means was in fact used to decrease the exhaust period somewhat by comparison with the Alag X-03 whilst at the same time increasing the transfer period. The BX-25 has a measured total exhaust period of 144 degrees (72 degrees each side of bottom dead centre) compared to the 150 degrees used in the Alag. However, the revised porting allowed the overlap between the exhaust and transfer periods to be set to give a blowdown period of only 15 degrees, resulting in a extended transfer period of 114 degrees (57 degrees each side of bottom dead centre) compared with the 100 degree figure to which the Alag was confined by its design. This would do much to offset any adverse effects of the reduction in the number of transfer flutes, and starting might well be improved by the higher gas velocities generated by the smaller port area. In addition, the sub-piston induction of the Alag was almost (but not quite) completely eliminated in the BX design. All of this should theoretically result in an easy-starting engine having a somewhat more flexible performance and improved torque at lower and mid-range operating speeds. The forward-angled venturi is cast integral with the crankcase, no insert being used. In addition, the backplate is a screw-in item of turned alloy rather than the thermo-set plastic unit employed on the Alag X-03. Otherwise, the BX is basically similar to its Alag predecessor, with plain bearings, crankshaft rotary valve induction, a rather heavy cast iron piston, a cast iron contra-piston and a sturdy steel cylinder. Assembly too is identical, with all parts threading together directly without the use of bolts or screws. Bore and stroke of the 2.5 cc model are unchanged from the Alag at 15 mm and 13.9 mm respectively for an actual displacement of 2.46 cc. It seems to be a fairly safe assumption that the bore and stroke of the smaller BX-15 would have mirrored the figures of 12.0 mm and 13.0 mm quoted above for the VT-09 equivalent. The production of the BX engines seems to have been confined to a relatively short period from c. late 1959 to mid 1961, when the Vella Brothers ceased production. This being the case, they may legitimately be viewed as the “final” engine line to have been introduced by the Vella Brothers. There is no serial number on the illustrated example of the BX-25, but there is a curious symbol stamped beneath the left mounting lug. This takes the form of a capital “G” with a vertical line through the centre. I have no knowledge of the significance of this, and cannot say whether it is original or a later addition by a previous owner. We noted earlier that the different styling of the BX (and companion VT) engines from that of the earlier Alag engines resulted in these engines appearing somewhat bulkier than their Alag predecessors. Despite this appearance of increased bulk, the BX-25 rather surprisingly weighs in at only 128 gm (4.51 ounces), very little more than the Alag X-03. The mounting holes too are identically spaced, making the two engines directly interchangeable in the same model. It's hard to see this as being purely coincidental. In terms of performance, a 2008 test on the illustrated example of the BX-25 yielded the following results (with those reported elsewhere for the Alag X-03 repeated for comparison):

These tests were conducted many years ago at a time when I had not yet assembled my present set of test props. It's clear that the set which I was using at the time had a major torque absorption gap between the Taipan 9x4 and 8x4 props. I have since filled that gap with my present APC-based test set, but the above figures display a gaping void in the available data between 11,000 and 13,000 rpm. Unfortunately, the power peak clearly lies between those two figures. If one extrapolates the curves lying on the opposite sides of this gap, the implied peak output is in the region of 0.255 BHP @ 11,500 rpm. I should probably repeat this test sometime using my present test prop set.

That said, I suspect that in real terms the Alag would continue to outperform the BX at the top end even after the BX was fully freed up. However, the BX comes quite close to matching the performance of the Alag on the larger prop sizes which would more than likely be used in actual service. This being the case, well freed-up examples of the two engines would probably deliver very similar performances in the field. Moreover, both engines handled equally well. One point that seems worth mentioning - their common area of distribution and very similar design have resulted in the BX-25 being occasionally confused with the earlier and relatively rare Swedish-made Komet 2.5 cc model from the 1950’s. It is true that the two engines are very similar, but there are enough differences to make the identification quite simple. The attached comparison view should help to resolve any confusion. The red plastic spinner on the Komet is of little help since it is almost invariably missing from surviving examples! The End of the Line ……Temporarily!

As of August 1962, when “American Modeller” magazine published their very interesting article entitled “Iron Curtain Engines – Da? Nyet?” (un-attributed, but almost certainly authored at some time well prior to that date by Peter Chinn), the reference to the Vella Brothers products included the previously-noted incorrect statement that production of engines under the trade-names of Alag, Aquila and VT was then still continuing simultaneously at the Vella Brothers plant in Budapest. Interestingly, there was no mention of the BX engines - it appears that at the time these models escaped even Peter Chinn’s attention! The Engel Rebell versions also escaped notice. Total production of engines at that time was reported to be “a few hundred monthly”, implying a relatively small-scale manufacturing operation by Western standards. The 0.25 cc VT-11 described above was featured in the article as an example of the Vella Brothers products, being described as the smallest engine so far (at that time) produced behind the Iron Curtain. However, it appears that the information in that article was somewhat out of date, most likely due to the article having been written some time prior to its eventual publication. In reality, the production of engines by the Vella brothers had ceased by mid 1961. It was Somi's recollection from over a half-century ago that the event which precipitated the cessation of VT production at that time was the 1961 escape of the younger Vella brother Géza with his family to Italy by way of the former Yugoslavia. However, information received from none other than US resident András Vella, who is the son of Géza Vella and the nephew of András Vella the elder, has confirmed that Somi's recollection was not accurate as regards the dating. The real story behind the demise of the Vella Brothers model engine manufacturing operation is rather more complex as well as being a clear sign of the very challenging political climate in which the brothers had been operating.

One day in 1961 a government revenue officer showed up at the plant to check on the "gold" story. The officer was told that this report must be a joke or a misunderstanding, because gold is not hard enough for engine-related purposes. Samples were shown to the officer along with the explanation that the gold coloration was only a surface treatment not involving the use of real gold. However, this did not allay the government's suspicion that the company was doing far better than it was admitting and was somehow hiding its true level of economic activity. It appears that private companies like VT were generally viewed by the government as basically dishonest and as closet capitalists rather than committed supporters of the Communist state. The assumption was therefore made that the VT books must be under-reporting the company's true economic performance, resulting in a tax declaration that was substantially lower than it should have been. A massive tax bill was presented to the company, along with a series of fines for this supposed under-the-table activity. The level of economic activity upon which these charges were based was around ten times the true situation, leaving the company unable to pay from the actual proceeds of their model engine manufacturing activities. Consequently, they were forced to sell all of their workshop equipment to pay the bill, leaving them unable to continue in business past mid 1961. This absurd government action ended over 6 years of very successful business activity during which the Vella brothers had provided employment for upwards of twenty people and had made a meaningful contribution to the national economy, particularly in the export sector. Such stupidity takes some believing, but András assures me that this is exactly how his father recalls the event. The dating of this sorry incident is consistent with Peter Chinn’s later statement in his April 1964 review of the Hungarian-made FOK-25 to the effect that “production of the Alag and Aquila (VT) engines ceased about three years ago”, i.e., in early to mid 1961. In the case of the Alag engines, this was a couple of years too late, but the dating was accurate as far as the VT range was concerned. It's certainly true that by late 1962, when "American Modeler" published their first “Global Engine Review” in their 1963 “Annual” edition, there were no entries for any of the Vella Brothers engines, although some of their spin-off products such as the Engel Rebell models were still included, presumably on the basis of existing stocks held in Germany. András Vella the younger (son of the elder Géza Vella) tells us that the machines and tooling which the Vella brothers had utilized in the manufacture of the Engel Rebell engines and their VT and BX relatives was bought by an organization called Finommechanikai és Elektronikus Műszergyártó Szövetkezet (Precision Mechanical and Electrical Instrument Manufacturing Cooperative), which installed the equipment in a factory located in Salgótarján in northern Hungary. This factory was known as the Finommechanikai és Orvosi Készülékeket Gyártó KTSZ, generally known for short as FOK-GYEM. It was well equipped with the best machine tooling and other equipment available in Hungary at that time, including the former Vella brothers machinery and tooling. According to Géza Vella, the purchasers of the Vella brothers' eqipment paid only a fraction of its true value. It was this factor that forced the brothers to sell all of their equipment, leaving them with no means of continuing production at even the most minimal levels. This sorry debacle left the Vella brothers in need of fresh employment. From 1961 to 1969 both András and Géza Vella worked at various factories. Géza initially worked on machinery maintenance at a champagne bottling plant, while András worked during the same period at a motorcycle factory on Csepel. The younger András Vella (Géza's son) recalls his father having discussions with his brother András Senior during the mid 1960's regarding Uncle András's frustration with his employment at the time. Evidently Uncle András could see a great deal of potential for quality and performance improvements to the motorcycle engines which they were producing, but he couldn't get anyone to listen to him. It appeared that the Communist government's factory objectives were focused on mass production (regardless of quality) and job preservation rather than the pursuit of higher quality and greater efficiency. The younger András Vella tells us that in 1965, his Uncle András purchased a building located at Lake Velence, about 75 kilometers south of Budapest. He was joined there by his brother Géza, with whom he worked at the new location until 1969, returning home to Budapest on weekends. They designed and constructed an automatic machine which mass-produced various metal items such as high-heel metal caps, etc. The escape of Géza Vella and his family actually took place in the summer of 1969. Somi's recollection of the facts was essentially correct - he just got the date wrong. Géza escaped to Italy with his family by way of the former Yugoslavia in 1969, thereafter spending some time in several Italian refugee camps. According to his son András, who was 14 years old at the time of the escape, Géza had hoped to settle in Germany and resume his association with the Engel company, but it proved impossible to gain residential status in Germany at the time. The family eventually relocated to Chicago in the USA.

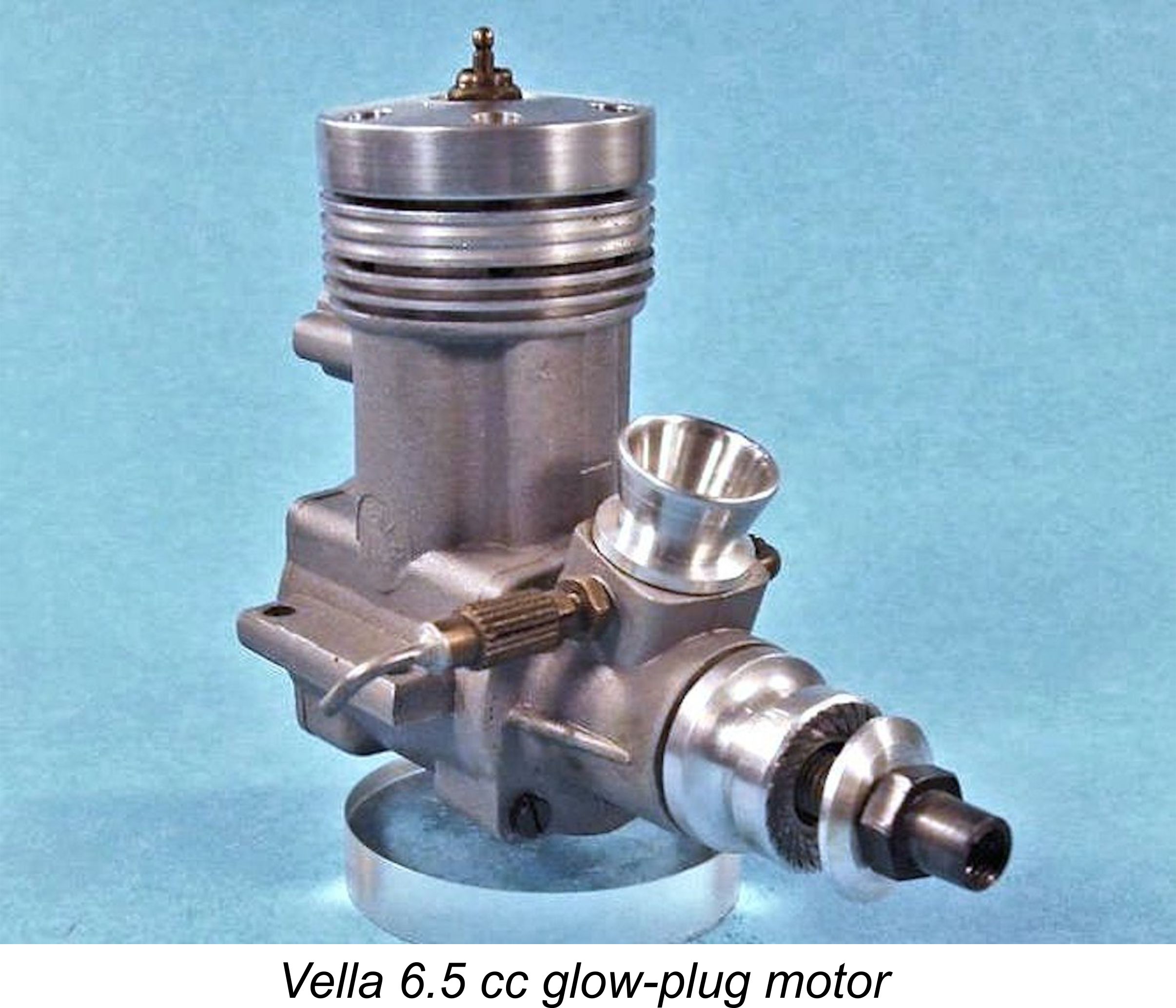

More recently, András was surprised to learn that his father and brother had been working together on a 6 cc (0.36 cuin.) R/C glow-plug engine as well as a twin cylinder "boxer" unit until only a few years ago, when Géza Senior suffered a medical setback. Evidently Géza Senior retained his passion for model aero engines lifelong, even if only as a hobby in later years. Apart from a brief visit to the USA in the summer of 1973 to see his brother Géza and family, András Vella the elder remained lifelong in Hungary until his death in 1999. In the late 1970's, the entire neighborhood of 5 city streets on Csepel in Returning now to 1961, the demise of the Vella Brothers operation initiated a brief period during which there were no “commercial” model engines produced in Hungary – such production as did take place was then being carried out on a very limited basis under the auspices of the state-sponsored MOKI Institute. This situation was remedied to a certain extent later in 1961 when the MOKI institute finally recognized that in order to remain in operation it would have to generate some cash flow from engine sales. Accordingly, the Institute embarked upon a policy of expanded production of a number of their more widely applicable designs. However, the number of engines produced by MOKI was still quite limited by normal commercial standards, hence falling well short of meeting demand. This situation was relieved in 1962, when the Engel model company from Germany, which had been previously involved with the Vella Brothers, invited bids from various manufacturers for the contract production of a revised range of diesel engines to be sold once more under their own Engel Rebell brand-name. Clearly they had been happy with the success of their previous arrangement with the Vella brothers, leading them to initiate a search for a replacement manufacturer.

These units were apparently sold mainly on the German domestic market, once more under the “Engel Rebell” designation. The best-known member of this series was the green-headed 2.5 cc version. The porting of these engines was completely different from that of the earlier VT designs. Two opposed exhaust ports were used along with two internal transfer flutes located fore and aft between them. In effect, this was the style of porting which had been popularized by Super Tigre, Barbini, Cox, Holland and others. The contract with Engel was apparently restricted to engines destined for markets in which the Engel company was active, and this evidently left ARTEX free to once again become active in promoting the wider sale of these engines to Western countries, which they did later in 1963. The engines produced for other markets were sold under the FOK designation which was of course derived from the manufacturer’s initials. However, they were to all intents and purposes identical to the Engel models. This made a lot of business sense – if the Engel company was not planning to promote sales of the engines in other marketplaces, there was no reason why the Hungarians should not be left free to do so for themselves.

The FOK engines were produced in 1 cc, 1.5 cc and 2.5 cc sizes. They were identified by their metric displacements as the FOK 10, 15 and 25 models respectively, a fact which may confuse people who are used to thinking of engine displacements in cubic inches. This very well-made range did achieve some commercial success in the sport diesel market for a period of time. Although there is currently only the scantiest of evidence for this, it appears possible that production of the FOK range may have outlasted the Hungarians’ contract with the Engel company. Somi tells us that FOK production continued until 1969. The FOK engines were well up to prevailing standards in terms of overall quality, generally matching the standards which had been established by the Vella Brothers with the VT and BX engines. They also performed very well indeed when viewed from a sport flying standpoint. In his published test of the FOK 25 ("Model Aircraft", April 1964), Peter Chinn praised the engine's performance highly, also stating his view that the FOK 25 was “a better-made engine than the earlier Alag, Aquila (VT) and Proton diesels”. Given the quality of those models, this was high praise indeed! I've covered the FOK story in detail in a separate article to be found on this website. Comeback

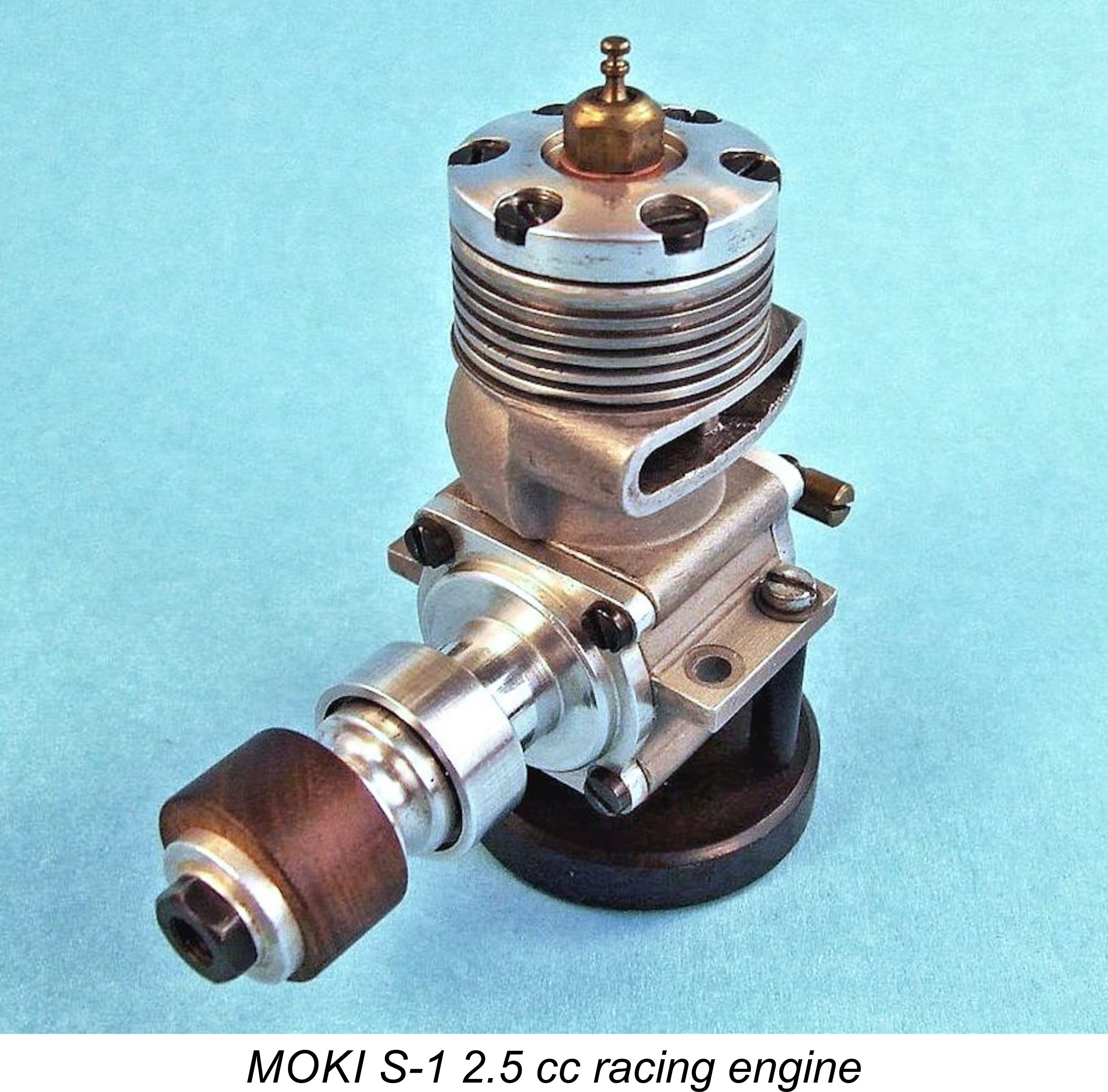

The engines were Somewhat later, András Vella acquired a partner named József Wéber, a talented Following the final demise of the Vella range, a new Hungarian manufacturer emerged in 1988 in the form of the Magyar Optikai Művek (Hungarian Optical Works) located in the western Hungarian city of Zalaegerszeg. This continued a long tradition of association between the optical and model engine industries which had begun decades previously with the Mamiya company in Japan and the Zeiss Optical company in East Germany. The engines produced by this company were exported to Western Europe under the trade names MOM or MMI. Although they were up-to-date designs which were very well made, they appear to have met with somewhat limited commercial success. Consequently, production ended in 1993. At that point, MOKI was left to carry on alone, as related elsewhere. Conclusion It should be clear from the above account that the Vella Brothers are richly deserving of our respect for the long line of excellent model engines which they manufactured over what eventually proved to be a thirty-year period. Based upon my own experiences with these engines, I can attest to the fact that they were well-made and dependable units which would give long and trouble-free service if treated with the care that all model engines deserve. The multiplicity of names under which the Vella Brothers products were sold has led to a degree of dilution of the apparent scope of their activities along with a consequent under-appreciation of the scale of their efforts. I hope that this article has done something to set the record straight and place the Vella Brothers where they belong - in the company of the more prolific and creative manufacturers of the Iron Curtain era in Central Europe. In this article I have deliberately omitted any consideration of the most famous model engine venture launched within Hungary - the MOKI Institute. The stellar accomplishments of that organization richly merited a separate article, which may be found here on this web-site. Factor in the accomplishments of the MOKI institution together with those of the Vella Brothers, the Alag and Proton manufacturers and the makers of the FOK and later Hungarian engines, and Hungary must be seen as a world leader in model engine development and manufacture! ___________________________________ Article first published January 2016 © Adrian C. Duncan, Coquitlam, BC, Canada Updated June 2023 - additional details of Vella racing engines Second update January 2026 - additional details of VT-10 model

|

||

| |

Long-time readers of my series of articles on model engine history which began to appear way back in October 2007 on the late Ron Chernich's now-frozen "

Long-time readers of my series of articles on model engine history which began to appear way back in October 2007 on the late Ron Chernich's now-frozen " It would be impossible to overstate our indebtedness to Somi, since he was actively involved in the Hungarian model engine industry at the time in question, thus having intimate first-hand knowledge of the designs and personalities involved. Regular readers will doubtless recall his excellent article on the history of the

It would be impossible to overstate our indebtedness to Somi, since he was actively involved in the Hungarian model engine industry at the time in question, thus having intimate first-hand knowledge of the designs and personalities involved. Regular readers will doubtless recall his excellent article on the history of the  Prior to the commencement of WW2, the Kingdom of Hungary (as the country was then known) was very much allied with the Axis powers in Europe, relying increasingly upon trade with Nazi Germany and Fascist Italy to pull itself out of the Great Depression of the 1930’s.

Prior to the commencement of WW2, the Kingdom of Hungary (as the country was then known) was very much allied with the Axis powers in Europe, relying increasingly upon trade with Nazi Germany and Fascist Italy to pull itself out of the Great Depression of the 1930’s. point the collapse of the Soviet Union coincided with the completion of an orderly transition to a Western-style democracy designated the Republic of Hungary. However, all of the engines to be covered in this article were produced during the Communist era.

point the collapse of the Soviet Union coincided with the completion of an orderly transition to a Western-style democracy designated the Republic of Hungary. However, all of the engines to be covered in this article were produced during the Communist era.  revolution of October-November 1956 this situation changed very much for the better. At that point in time, Rezső Beck (1928-2002) became the chief of what had now become the Hungarian Association of Modellers. Mr. Beck was a well-known post-war competitor in various categories of aeromodelling, subsequently becoming a very successful control-line speed flier in the 1950’s. Thanks to his professional knowledge and political influence, he was well able to guide the further development of Hungarian aeromodelling, also serving as the Hungarian representative on the FAI Aeromodelling Commission (CIAM).

revolution of October-November 1956 this situation changed very much for the better. At that point in time, Rezső Beck (1928-2002) became the chief of what had now become the Hungarian Association of Modellers. Mr. Beck was a well-known post-war competitor in various categories of aeromodelling, subsequently becoming a very successful control-line speed flier in the 1950’s. Thanks to his professional knowledge and political influence, he was well able to guide the further development of Hungarian aeromodelling, also serving as the Hungarian representative on the FAI Aeromodelling Commission (CIAM).  situation made it inevitable that efforts would be made to initiate the domestic development and manufacture of such engines.

situation made it inevitable that efforts would be made to initiate the domestic development and manufacture of such engines. er efforts would be made to increase the availability of model engines in the country.