|

|

The 1956 Super Tigre G.20 S on Test

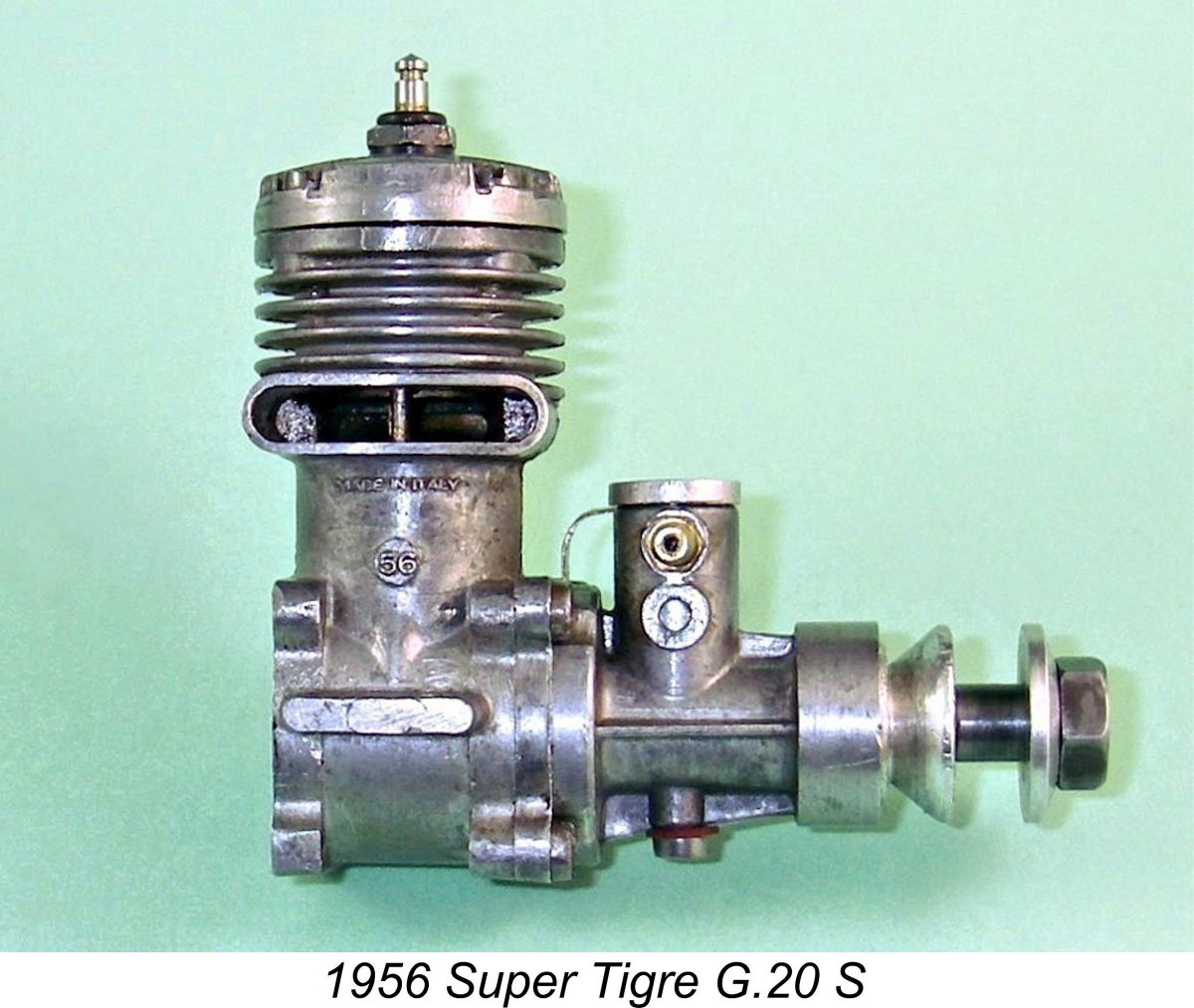

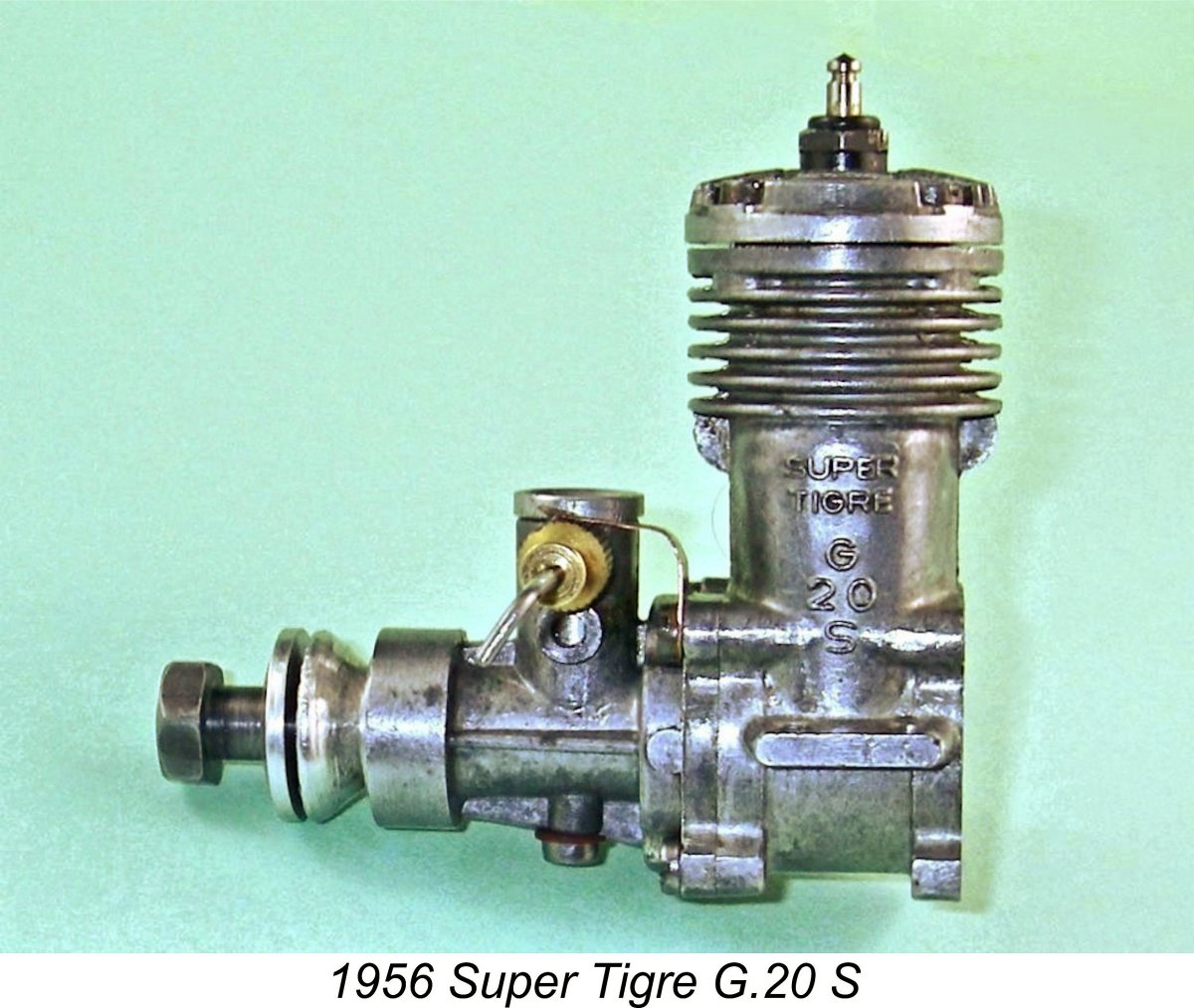

Having a well-used and cosmetically beaten-up but still all-original and mechanically sound example of the 1956 model on hand thanks to the kindness of my valued Danish friend Luis Petersen, I was in a position to remedy this omission by testing the engine myself. As will soon become apparent, the engine did itself proud! To place the engine’s performance in context, it’s worth summarizing the course of development which led up to the appearance of this model. Further details A significant weakness of the original G.20 that was never corrected prior to the 1957 introduction of the G.20 V version was its remarkably skimpy mounting lugs. The engine's layout was such that there was a greater than usual overhang between the prop and the lugs, which would give rise to elevated impact loadings during a crash (wot - me crash?!? Never....!!). The lugs did not take advantage of the full available length of the main crankcase casting, being set to the rear of the case and terminating well short of the front of the casting. They were also made relatively thin. These lugs would not do well in a hard crash. This version of the engine was tested by Lawrence H. Sparey (“Aeromodeller”, April 1951), who reported a peak output of 0.24 BHP @ 14,000 RPM, figures which closely approximated the manufacturer’s claim of 0.25 BHP @ 15,500 RPM. He characterized these figures as “exceptional”, which they undoubtedly were by then-prevailing standards. It’s important for context to note that Sparey’s figures were obtained using a commercial low-nitro fuel (Mercury no. 5). A high-nitro fuel would undoubtedly have improved these numbers substantially. Thereafter, the engine was the subject of more or less continuous development, with revised features being added more or less on an ad-hoc basis as Garofali developed them. Little attempt was made to keep track of all the changes through revisions to the model designations, the result being that many minor variants of these engines may be encountered under the same model designation. I’ll do my best to summarize the main changes, with the proviso that I don’t have all of the information by any means.

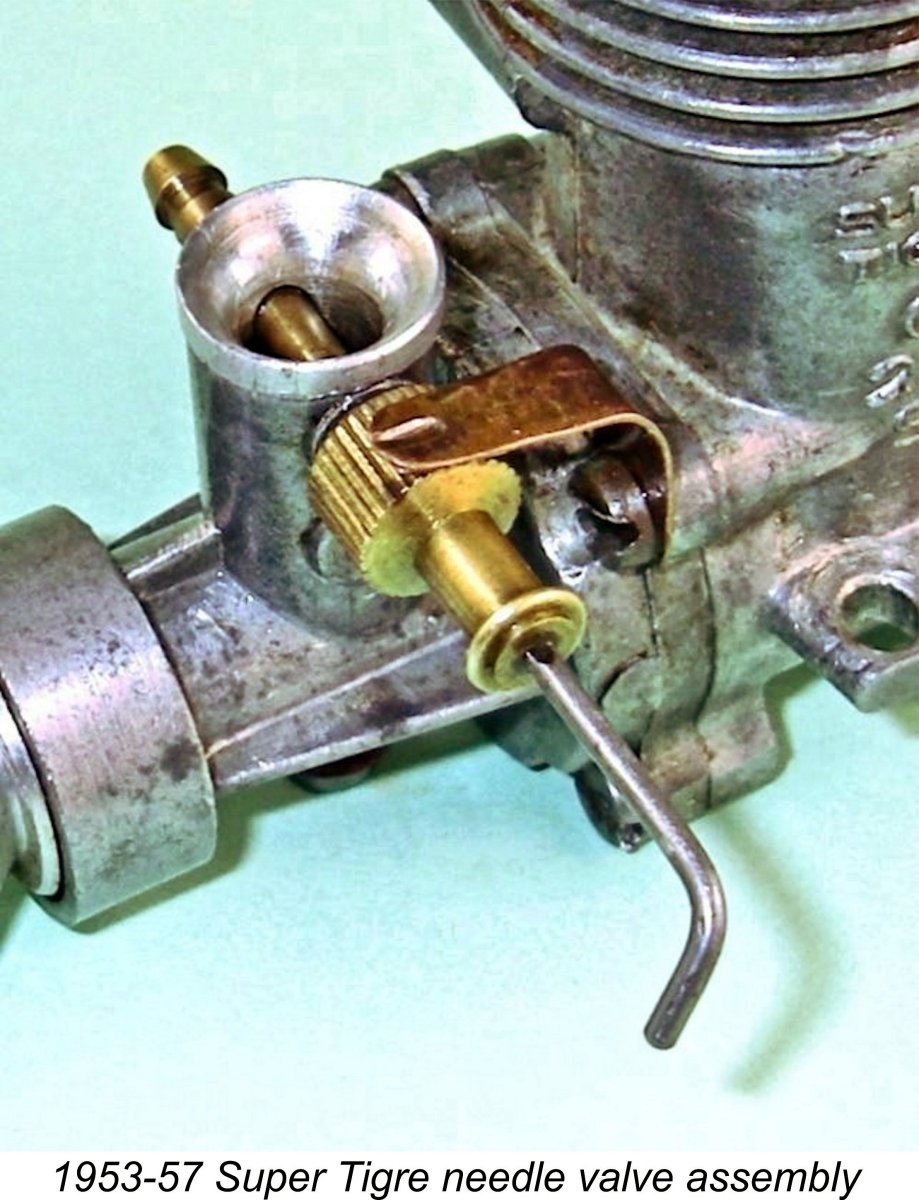

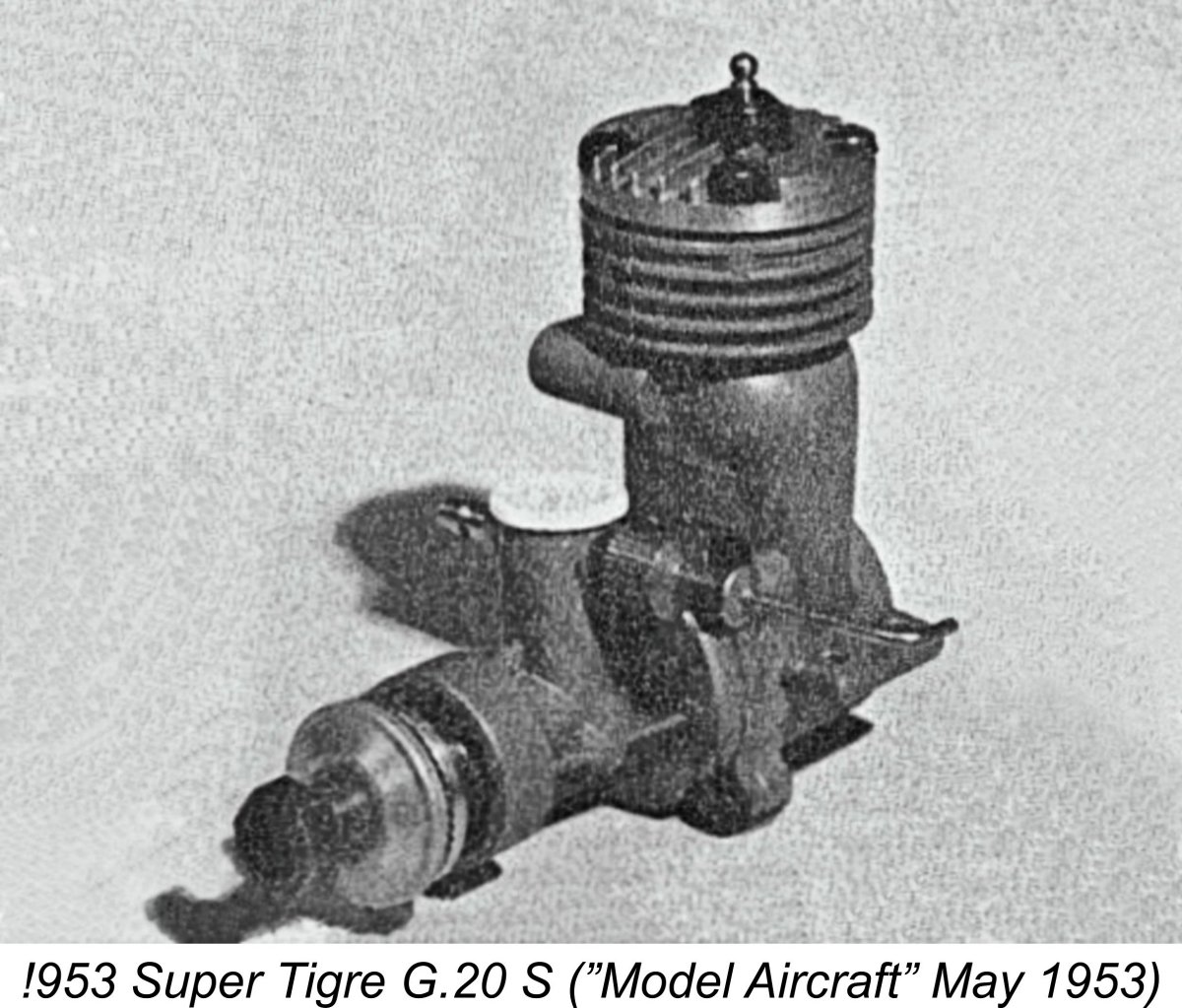

The head used on both versions of this model continued to be a plain unfinned component with the plug offset towards the bypass side of the cylinder. It provided a 10:1 compression ratio in the “Speed” variant, while the "Sport" model had to make do with a compression ratio of only 8.5:1. The twin ball-race "Speed" version of this engine was tested by Ron Warring, who had taken over from Sparey as the resident engine tester for “Aeromodeller”. The tested example is illustrated at the right. Warring's report was published in the November 1952 issue of “Aeromodeller”. Despite some difficulties arising from a seemingly poor compression seal provided by the two piston rings (which presumably required some more bedding in), Warring extracted a peak output of 0.26 For 1953 a revised cylinder head was introduced on both "Speed" and "Sport" models of the G.20. This was a finned die-cast component which retained the offset location of the plug towards the bypass side of the cylinder. The same compression ratios were retained. A completely redesigned needle valve was also introduced at this time. The former split thimble component was replaced by Super Tigre’s highly individualistic thimble design having a large-diameter serrated barrel which was tensioned by a bronze leaf spring secured using one of the four front housing attachment screws. The thimble was internally threaded to match the spraybar, while the inner end of the barrel was recessed to clear the spraybar installation nut. Extremely neat, and it worked very well indeed. This assembly was used on the G.20 and the companion 5 cc G.21 for the next four years. The 1953 “Speed” variant of the G.20 (the G.20 S) was the subject of a test by Peter Chinn which appeared in the May 1953 issue of “Model Aircraft”. Using a fuel containing 25% nitromethane, Chinn reported a peakoutput of 0.25 BHP @ 15,200 RPM. This figure actually seems a little low to me. It's certainly somewhat shy of the manufacturer’s highly credible claim of 0.29 BHP @ 16,500 RPM, presumably using Regardless, Chinn summarized the engine as being “the fastest 2.5 cc engine yet tested”. To underscore this comment, Amato Prati of Bologna used one of these engines later in 1953 to establish a new Italian National 2.5 cc speed record of 161 km/hr (100.04 mph). In 1954, designer Garofali introduced a further modified version of the G.20 S which utilized a lapped cast iron baffle piston in place of the ringed light alloy component used up to that point. This engine was referred to as the G.20 S “Lappato”. The result was a considerable performance improvement. Amato Prati (now a Super Tigre employee) used a stock example of the new lapped piston variant in his “Speed King” model to record a speed of 190.47 km/h (118.36 mph) at the 1954 Giornate Aeromodellistiche Ambrosiane meeting held in Milan, thus establishing a new FAI World Speed Record for the 2.5 cc class. Now up to this point in time the G.20 had not been a contender for World Control Line Speed Championship honours. The annual competition for this title had been established in 1951, with trophies being awarded in 2.5 cc, 5 cc and 10 cc displacement categories. The same three classes were run at the 1952 meeting as well. Oddly enough, no official Super Tigre entries appeared at either meeting to test the merits of the G.20 For 1953, when the G.20 S might have been ready to challenge the world, a decision was taken that the control-line speed World Championships would thenceforth be contested in a single displacement category. Inexplicably, the 1953 Championship meeting held at Milan, Italy, was restricted to the least well-supported class, the 10 cc category. Consequently, only Britain, France and Sweden sent representatives to compete against the powerful Italian team. Obviously, there was no scope here for the G.20 S. Instead, Jaures Garofali quickly came up with an all-new Super Tigre 10 cc design, the rear drum valve G.24. This brand-new engine achieved a very creditable fourth place in its very first International appearance. The G.20’s championship prospects did not improve in 1954. For that year, the 5 cc category was designated as the World Championship class. Although a 2.5 cc event was run at the same meeting, this was not accorded World Championship status. This being the case, one wonders why they ran it at all! In view of its “secondary “ status, Garofali elected not to send any of the new lapped-piston G.20 S “Lappato” units to Wright's speed was a remarkable achievement for that particular powerplant. It would have been just good enough to win the following year's 2.5 cc World Championship event, of which more below. The window of opportunity for Garofali to display the merits of his G.20 S “Lappato” against all comers finally opened with the announcement by the FAI that from 1955 onwards the World Control Line Speed Championships would be contested exclusively in the 2.5 cc class. This was a much-appreciated decision, since it ended the uncertainty created by the annual switches between Championship categories, thus providing both model builders and competition engine manufacturers with a clear focus for further development.

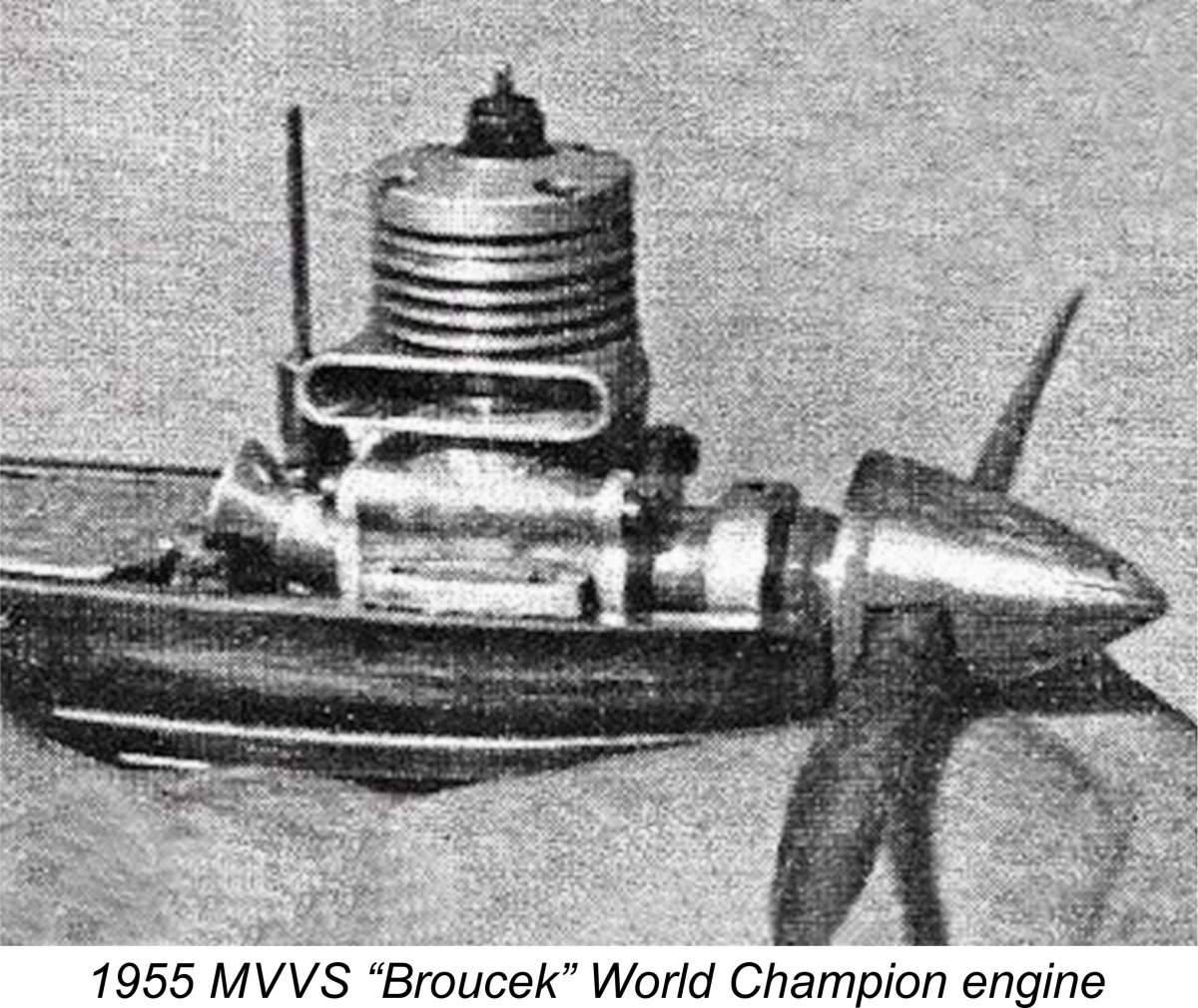

The new piston featured a large skirt port on the bypass side which registered at bottom dead centre with a matching port cut through the lower cylinder wall. This improved gas access to the bypass while also improving piston cooling and reducing reciprocating weight. The intake stubs on the front housings now sported twin sets of transverse holes, one above the other, to allow for the fitting of either a conventional spraybar (as commercially supplied) or a two-piece racing-style setup with a separate surface jet and needle carrier threaded into opposite sides of a matching alloy venturi insert. Alternative venturi inserts were available to suit the two systems. The inserts were now made from aluminium alloy instead of the plastic formerly used. Unfortunately for the Italians, this meeting coincided with the emergence of a new threat from the other side of the Iron Curtain in the form of the State-sponsored MVVS tool-room specials from Czechoslovakia (as Czechia was then). Garofali’s showcase ambitions almost succeeded, but the top prize eluded him by a narrow margin. MVVS chief designer Josef Sladký won the individual title with a speed of 179.11 km.hr (111.30 mph) using one of the MVVS one-off powerplants, the rear disc valve SK-25 “Broucek” model. Amato Prati came in a close second with his G.20 S powered model at a speed of 176.05 km/hr (109.39 mph), closely followed by his fellow Italian team members S. Monti and C. Cappi.

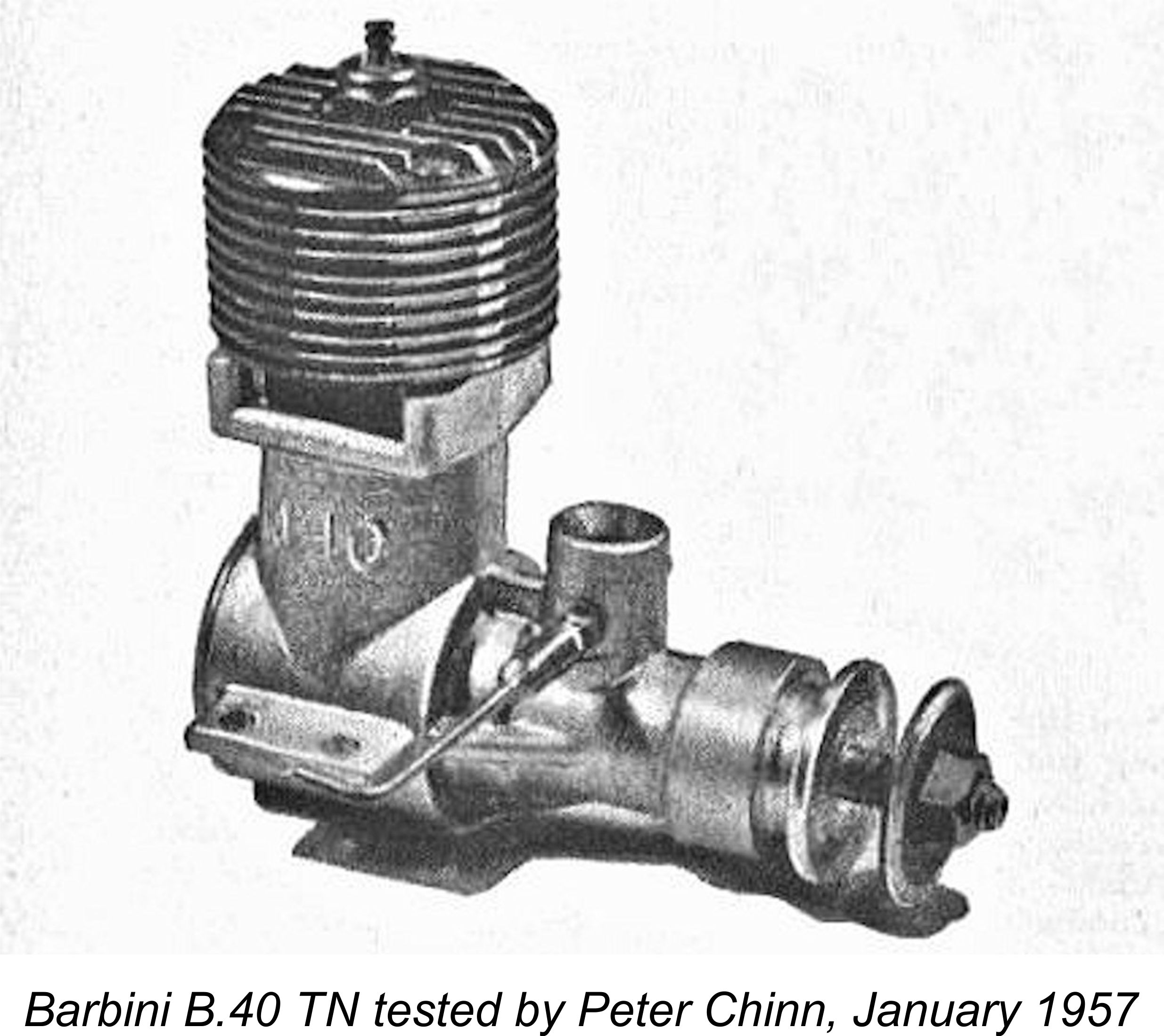

Sladký’s success signalled the beginning of what might be termed the “works team” or “special” era in International control-line speed. Thenceforth there were in effect two distinct tiers of competitors – those using well-prepared examples of commercially-available engines and those using non-commercial individually-made “specials”, many of which were State-sponsored like the MVVS units. Events were to prove that the “specials” generally ruled the roost, with the commercial engines competing in what amounted to a separate category. As a commercial manufacturer having his eye on the international market, Garofali naturally remained true to the second category, choosing to compete using well-prepared examples of his own commercial products. In that context, 1956 must have shaped up as a perfect year for Garofali to showcase his G.20 S, particularly since the Given the fact that the Barbini B.40 was one of only two then-current racing engines to retain reverse-flow scavenging (the other being the Webra 2.5R) as well as featuring long-stroke internal geometry, Garofali probably did not anticipate much competition from that quarter. However, he was undoubtedly expecting some stiff opposition from the various tool-room specials from Czechoslovakia and elsewhere. Accordingly, he did not stand pat with his 1955 design – something better would be needed. The lesson of Paris 1955 had been well learned!

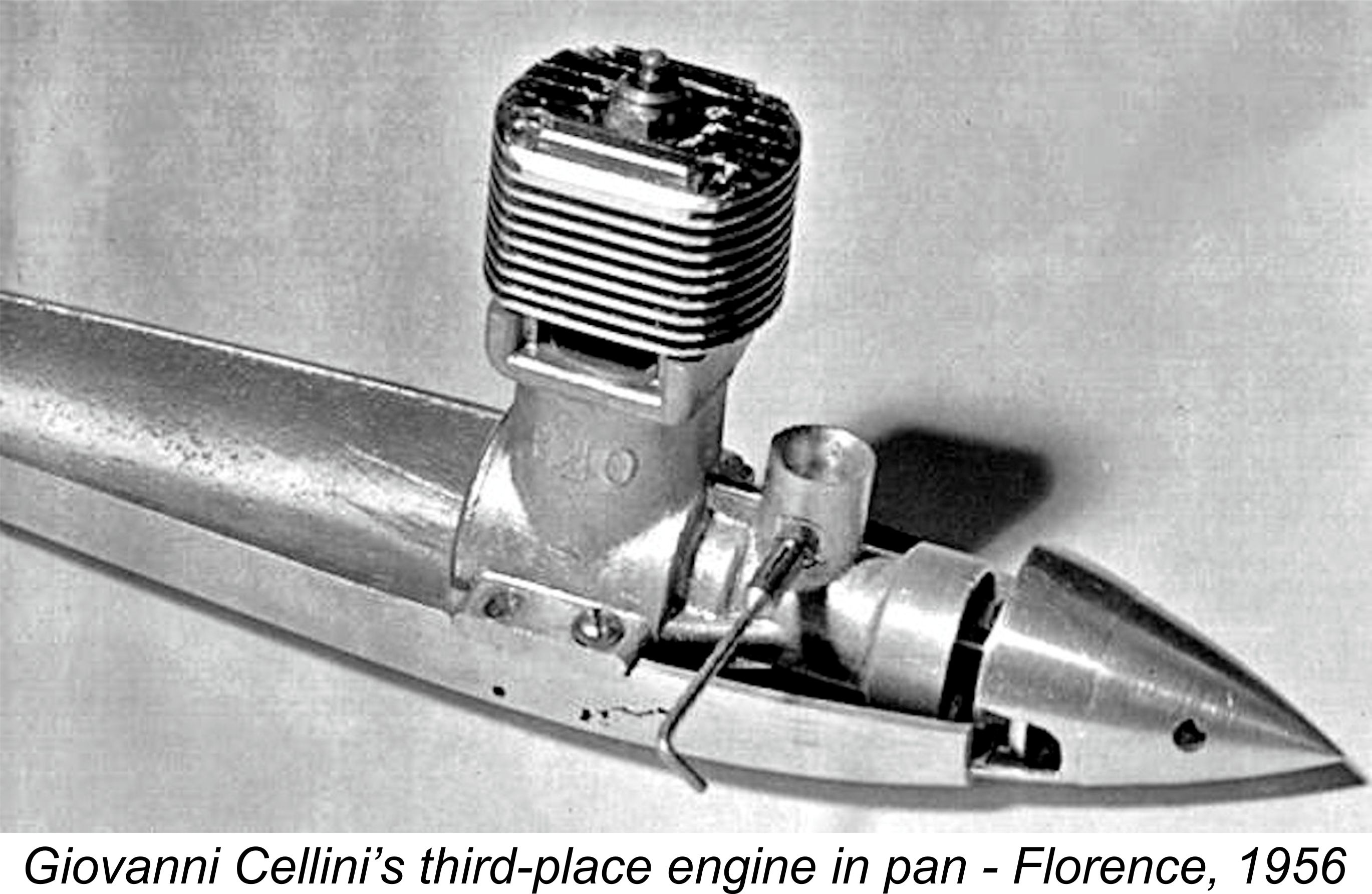

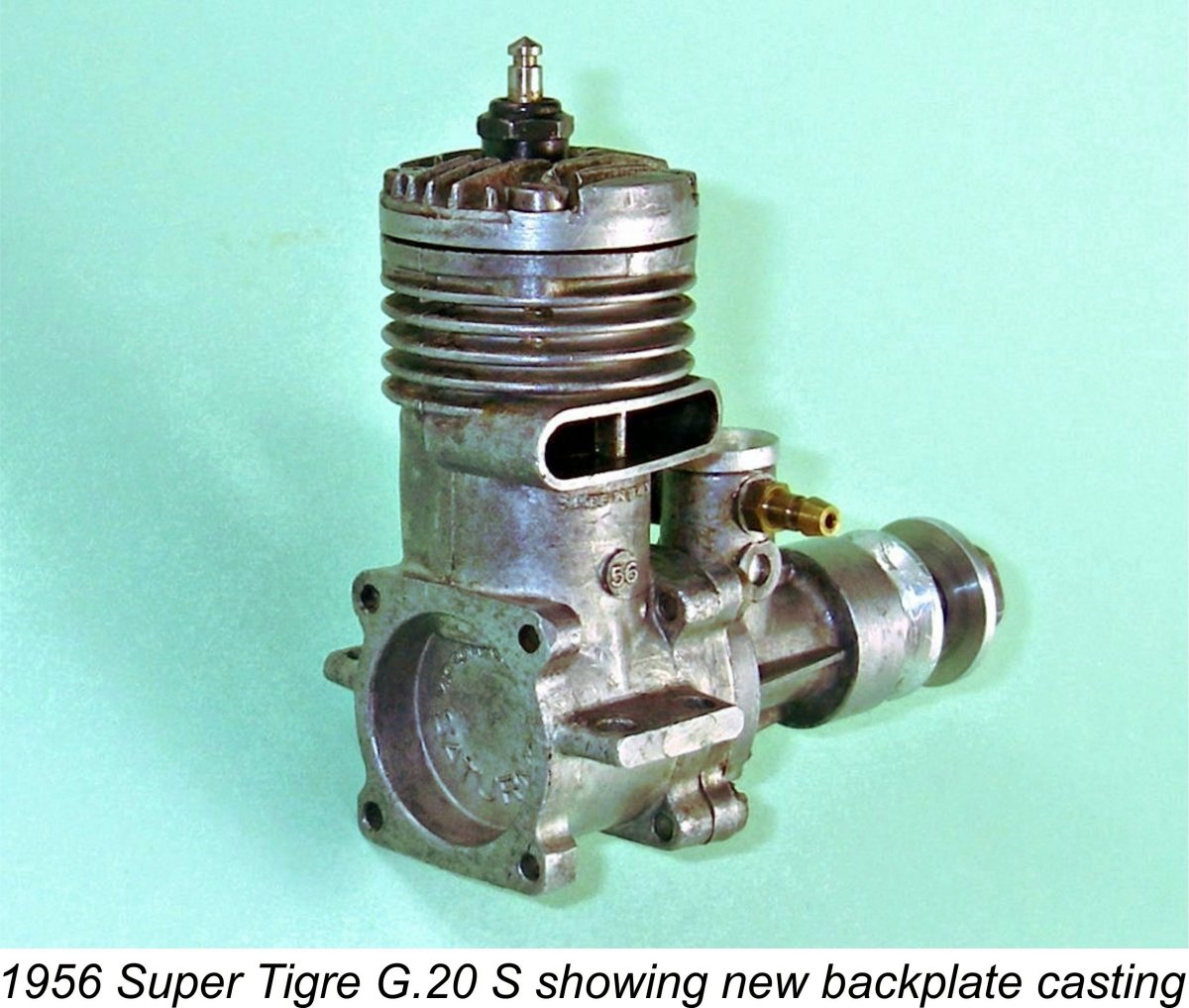

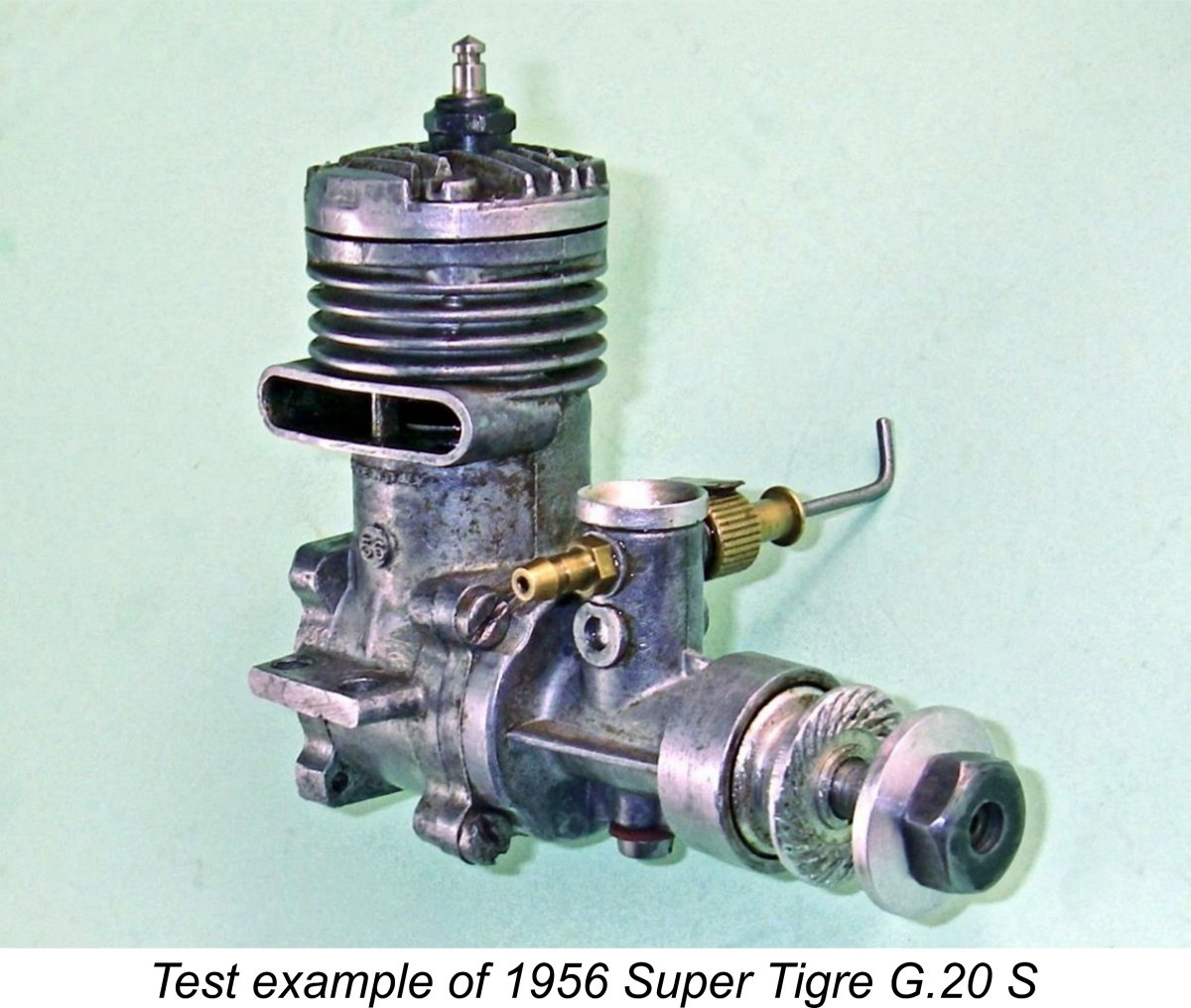

However, this was not good enough for Garofali given the standard of opposition that he expected at the Florence meeting - he continued to develop improvements to the G.20 S. By the time that Chinn's test of the 1955 model appeared, Garofali's efforts had resulted in the early 1956 appearance of a further refined model of the engine. It is this model which is the subject of the test which will be summarized below. The revised 1956 model was readily distinguishable from its predecessor by the fact that while the crankcase casting The year of introduction of the revised case was clearly indicated by the numbers "56" cast in relief onto the right hand side of the upper crankcase below the exhaust stack, as seen in several of the accompanying illustrations. The commercial version of the revised model retained the unique needle valve assembly which had been introduced in 1953, although the optional two-piece racing assembly could also be fitted. The engine also maintained the offset location of the plug towards the bypass side. However, there were a number of further internal tweaks. Unfortunately this model also perpetuated one of the engine's real design weaknesses - its very flimsy mounting lugs which were mentioned earlier. It would have been easy to amend the 1956 die to create lugs which extented all the way forward to the front of the casting. However, the lugs still terminated well short of that point. They could also have been made substantially thicker. Regardless, this new model was not long in proving its worth for all to see. At the 1956 Criterium of Europe meeting at Brussels, Belgium, held on April 30th - May 1st, which was in effect a tune-up for the later World Championship meet, J. Battlo of Spain used his new 1956 G.20 S to achieve a speed of 202.0 km/hr (125.5 mph) to narrowly defeat Britain's future World Champion Ray "Gadget" Gibbs with his Carter-powered "Nipper". And there was even more to come - on May 20th, 1956, another well-known Italian speed flier, A Marconi, used Given the above successes as well as the years of effort which had gone into the development of the 1956 version of the Super Tigre G.20 S, Garofali’s hopes must have run high for a good result at Florence. However, things did not go his way at all at the meeting. Using a well-prepared but surprisingly close-to-stock Barbini B.40 TN, Giovanni Barbini’s colleague Giovanni Cellini finished in third place with a speed of exactly 200 km/hr (124.28 mph). Only the one-off tool-room “specials” of Miclos Vitkovics of Hungary (BRMV To add insult to injury, Gibbs subsequently established a new 2.5 cc FAI World Record speed of 225 km/hr (139.81 mph) at the same meeting using thinner lines than those permitted in FAI competition. He thereby rubbed salt in the wound by eclipsing Marconi's previously-noted Super Tigre mark from earlier in the year. It was undoubtedly the disappointment of this result that led Garofali to go right back to the drawing board for 1957 to produce a comprehensively revised and even more powerful version of the G.20 called the G.20 V. That model is described in my companion article to be found elsewhere on this website. The 1956 G.20 S model thus became the final variant of the “original” G.20 from 1950. So what kind of an engine was the 1956 G.20 S which came up short at Florence? Let’s check it out! The 1956 Super Tigre G.20 S on Test

I don't know the full details of the engine's internal arrangements since I've never torn down this well-settled unit beyond removing the front cover. However, it generally follows the structural arrangement of its predecessors in having a lapped cast iron baffle piston operating in a drop-in steel cylinder liner and driving the steel crankshaft through a forged light alloy conrod. Bore and stroke of this model remain unchanged at 15 mm and 14 mm respectively for a displacement of 2.47 cc (0.151 cuin.). The engine weighs a commendably light 126 gm (4.44 ounces). The piston is provided with the previously-described large circular skirt port on the transfer side which had been introduced in the 1955 model. In addition to the integrally-cast backplate, albeit now with four "eyes" at the corners, the finned head retains the offset plug location towards the bypass side which was a feature of all the G.20 models up to this point in time. The unique Super Tigre needle valve introduced in 1953 is also retained. However, this was to be the last G.20 variant to retain these latter three features. The 3 mm diameter spraybar is waisted to 2.5 mm across the jet hole section which traverses the venturi throat. Together with a 6 mm diameter venturi, the use of Maris Dislers' very useful choke area calculator tells us that this provides an effective choke area of 13.720 mm with an effective minimum operating speed on suction feed of 11,387 RPM. These are clearly well-chosen dimensions. The crankshaft rotary valve used in this model is extremely efficient. The induction port in the shaft is an elongated rectangular opening with straight sides, giving very rapid opening and closing as well as an unusually large area. Timing is quite radical, with the port opening early and closing late for a total induction period of around 210 degrees. Definitely a high speed setup!

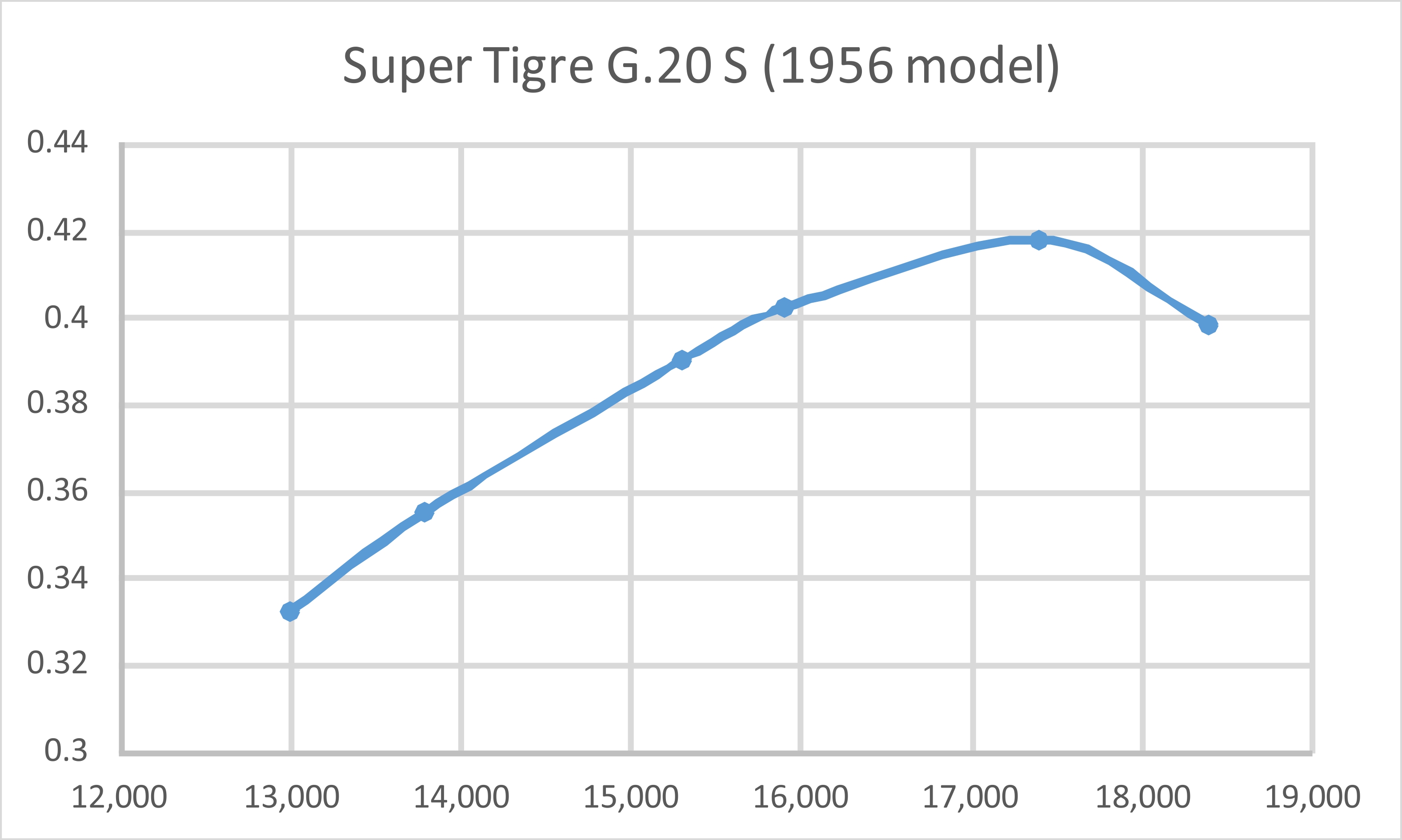

To get it settled down after its long period of inactivity, I gave the engine a few slightly rich runs on an 8x4 APC prop using an oily fuel containing 15% nitro. A considerable amount of brown goop came out of the front bearing, but this soon cleared right up. I tried the engine leaned out on this prop and fuel, getting a speed reading of 14,100 RPM. Quite promising! The engine’s needle response proved to be excellent, making the establishment of the optimum setting very straightforward. Once established, the needle held its setting very well indeed. Then it was time to start probing for the engine’s best performance. I used a fuel containing 30% nitro for this phase, since it was ultimate performance that I was after. I also fitted a cold plug to guard against pre-ignition. On this fuel and plug, the speed on the 8x4 jumped all the way up to 15,300 RPM. This engine clearly likes its nitro – the more, the better!! Things continued to go really well as the test proceeded. Running was absolutely smooth at all speeds, and settings remained easy to establish and maintain. No mechanical issues of any kind presented themselves during the test apart from a little detectable wear in the rod bearings which was already there before I started and got no worse during the test. Although quite well used, the piston/cylinder fit in this example remains excellent – probably close to the optimum based on my own long experience. Starting was a one or two flick chore almost every time. The prop/RPM figures and power curve shown below tell the story:

The two WB props are cut-down APC 8x6 and 9x4 items created and calibrated to fill gaps in my test set of APC props. As can be seen, they filled in very nicely at the bottom end in this test.

Of course, this example may also have been modified by a previous owner - I didn't tear it down sufficiently to check this point. As an example, the waisting of the spraybar may well be an owner modification - I don't know. Regardless, this test represents a very strong statement indeed regarding the engine's potential. Looking at this performance, it’s really hard to see how the Barbini B.40 TN managed to beat the 1956 G.20 S at Florence – published figures for that model were nowhere near those that I measured for this particular example of the Super Tigre. Of course, different examples of the same engine can perform very differently. Moreover, success in control line speed is not just about engine performance – you have to use the available performance to best advantage. That said, there’s little doubt that the 1956 Super Tigre G.20 S was the most powerful 2.5 cc racing glow-plug motor then available to the general public. Quite an achievement by Jaures Garofali! The Sequel

To add insult to injury, the top commercial engine (in sixth place) was once again the pesky Barbini B.40 TN, which finished ahead of all the Super Tigres. Josef Sladký’s winning speed of 216 km/hr (134.2 mph) using a prototype of what was to become the MVVS 2.5R-58 totally eclipsed the best Super Tigre speed of 198 km/hr (123 mph) which gave eighth place to the ever-persistent but doubtless frustrated Amato Prati behind Renzo Grandesso’s sixth place Barbini B.40 TN speed of 206 km/hr (128 mph). As far as I can determine, this was the highest official speed ever recorded by a 2.5 cc reverse flow scavenged powerplant. My own separately-reported testing of a production example of the MVVS 2.5R-58 yielded a peak output of 0.470 BHP @ The G.20 V returned in 1958, only to fall victim this time to the newly-introduced MOKI S-1 from Hungary, which took the first two places and was followed by three MVVS entries. Garofali had to wait until 1959 for his moment in the spotlight, when the further improved Super Tigre G.20 V’s finally broke through, with Ugo Rossi winning at a very creditable speed of 222 km/hr (137.95 mph) and brother Cesare placing third at 210 km/hr (130.49 mph). This was an outstanding result in the face of the ongoing presence of the MOKI specials, which were relegated to second and fourth places. The result was somewhat tempered by the fact that MVVS did not seriously contest this event, evidently due to their concurrent focus upon the commencement of limited series production of some of their designs, including the MVVS 2.5R-58. As 1960 rolled around, the ten year old Super Tigre G.20 was completely transformed into the radically redesigned and even more powerful G.20/15V. But that’s another story which I’ve recounted elsewhere. Meanwhile, I hope you’ve enjoyed this look at one of the truly great commercial racing engines of the 1950’s. Hats off to Jaures Garofali – ben fatto!! ___________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published October 2017 |

||

| |

This is the second in what I hope will develop into a series of tests on classic racing engines of the 1950’s which began with my earlier test of the

This is the second in what I hope will develop into a series of tests on classic racing engines of the 1950’s which began with my earlier test of the  One variant of the engine which was never tested, at least in the English-language modelling media, was the final version of the “original” Super Tigre G.20 which was released in 1956 as the last in a long line of "S" variants of that original design. It was the final model to retain the integrally-cast backplate and offset plug location of its predecessors. The variant which followed in 1957 was the much-improved

One variant of the engine which was never tested, at least in the English-language modelling media, was the final version of the “original” Super Tigre G.20 which was released in 1956 as the last in a long line of "S" variants of that original design. It was the final model to retain the integrally-cast backplate and offset plug location of its predecessors. The variant which followed in 1957 was the much-improved

compete in the 2.5 cc class. Had he done so, he would probably have fared quite well, since the 2.5 cc non-championship class was won by Britain’s Pete Wright using an

compete in the 2.5 cc class. Had he done so, he would probably have fared quite well, since the 2.5 cc non-championship class was won by Britain’s Pete Wright using an  The first event to be run under the new displacement rule took place on July 2

The first event to be run under the new displacement rule took place on July 2 Together with G. Gottarelli’s sixth place finish behind Mir Zatočil’s fifth-placed MVVS, this was easily enough to give Italy the team title. However, the fact that the individual title had eluded them cannot have sat well with Signor Garofali!

Together with G. Gottarelli’s sixth place finish behind Mir Zatočil’s fifth-placed MVVS, this was easily enough to give Italy the team title. However, the fact that the individual title had eluded them cannot have sat well with Signor Garofali!

The 1955 model as used at Paris (illustrated at the right) was the subject of a published

The 1955 model as used at Paris (illustrated at the right) was the subject of a published

My illustrated test example is a well-used former competition motor which has a filed exhaust stack, like many engines which have been used in competition. However, it is otherwise mechanically sound and in completely original condition. It was a very gracious gift from my valued Danish friend Luis Petersen, to whom my very sincere thanks are due.

My illustrated test example is a well-used former competition motor which has a filed exhaust stack, like many engines which have been used in competition. However, it is otherwise mechanically sound and in completely original condition. It was a very gracious gift from my valued Danish friend Luis Petersen, to whom my very sincere thanks are due. Although it had not been run for many years, the Super Tigre turned over freely and looked and felt right at home once mounted in the test stand. The initial start was a bit of a challenge because it turned out that I’d set the needle considerably too rich. Once I got that sorted, the engine proved to be an extremely easy starter provided a small port prime was administered as a preliminary. I noticed immediately that until speeds got up past the 13,000 RPM mark there was considerable blow-back through the intake. This of course was a consequence of the relatively late closure of the induction port. This is not an engine to be operated at the lower speeds!

Although it had not been run for many years, the Super Tigre turned over freely and looked and felt right at home once mounted in the test stand. The initial start was a bit of a challenge because it turned out that I’d set the needle considerably too rich. Once I got that sorted, the engine proved to be an extremely easy starter provided a small port prime was administered as a preliminary. I noticed immediately that until speeds got up past the 13,000 RPM mark there was considerable blow-back through the intake. This of course was a consequence of the relatively late closure of the induction port. This is not an engine to be operated at the lower speeds!

The implied peak output of 0.418 BHP @ 17,400 RPM is an outstanding performance for a commercial 1956 engine of this displacement. It’s considerably better than any of the published figures reported earlier. Mind you, no other published tester used a 30% nitro fuel, besides which the very “experienced” test engine was doubtless far better freed up than those tested by Peter Chinn and Ron Warring. Moreover, it was the “improved” model which was never tested by others to my knowledge. Seemingly Garofali had tweaked this engine to very good effect!

The implied peak output of 0.418 BHP @ 17,400 RPM is an outstanding performance for a commercial 1956 engine of this displacement. It’s considerably better than any of the published figures reported earlier. Mind you, no other published tester used a 30% nitro fuel, besides which the very “experienced” test engine was doubtless far better freed up than those tested by Peter Chinn and Ron Warring. Moreover, it was the “improved” model which was never tested by others to my knowledge. Seemingly Garofali had tweaked this engine to very good effect! We saw earlier that his defeat at Florence in 1956 inspired Garofali to undertake the development of a significantly improved version of the G.20 S, which appeared in 1957 as the

We saw earlier that his defeat at Florence in 1956 inspired Garofali to undertake the development of a significantly improved version of the G.20 S, which appeared in 1957 as the