|

|

The Classic Super Tigre Engines

The need for an English-language article such as this is underscored by the fact that there’s a certain amount of misinformation out there with respect to the early models designed by Garofali. As is unfortunately so often the case, a major offender is Mike Clanford, whose very interesting “Pictorial A-Z of Vintage and Classic Model Airplane Engines” frequently proves to contain incorrect or misleading information. The early Super Tigres which appear on page 179 are either incorrectly/incompletely identified or wrongly dated (or, in one case, all three!). I’ve said many times that Mike Clanford deserves great credit for putting together this always-engaging and frequently useful book, but the correction of the errors which it contains is an ongoing task.

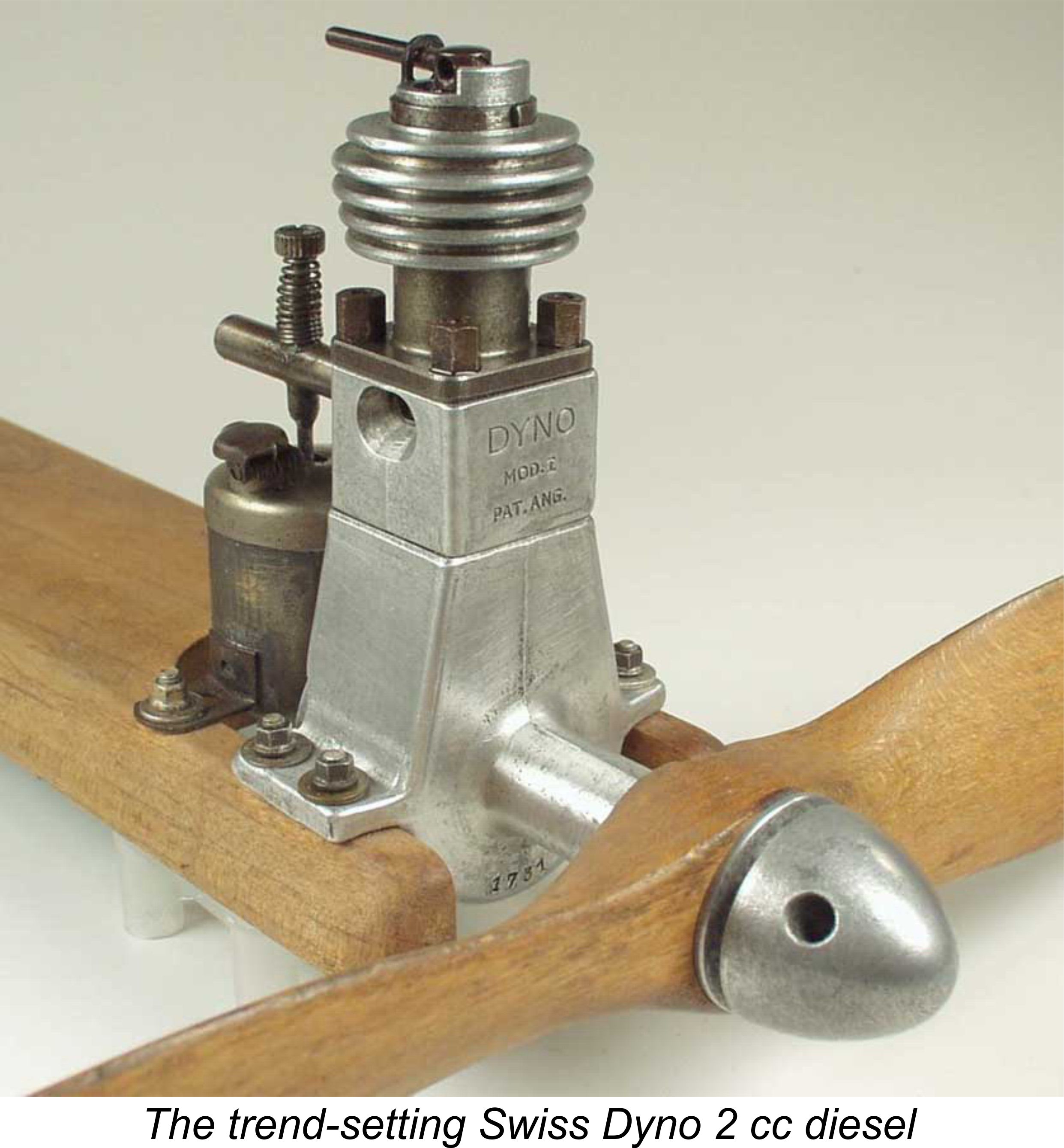

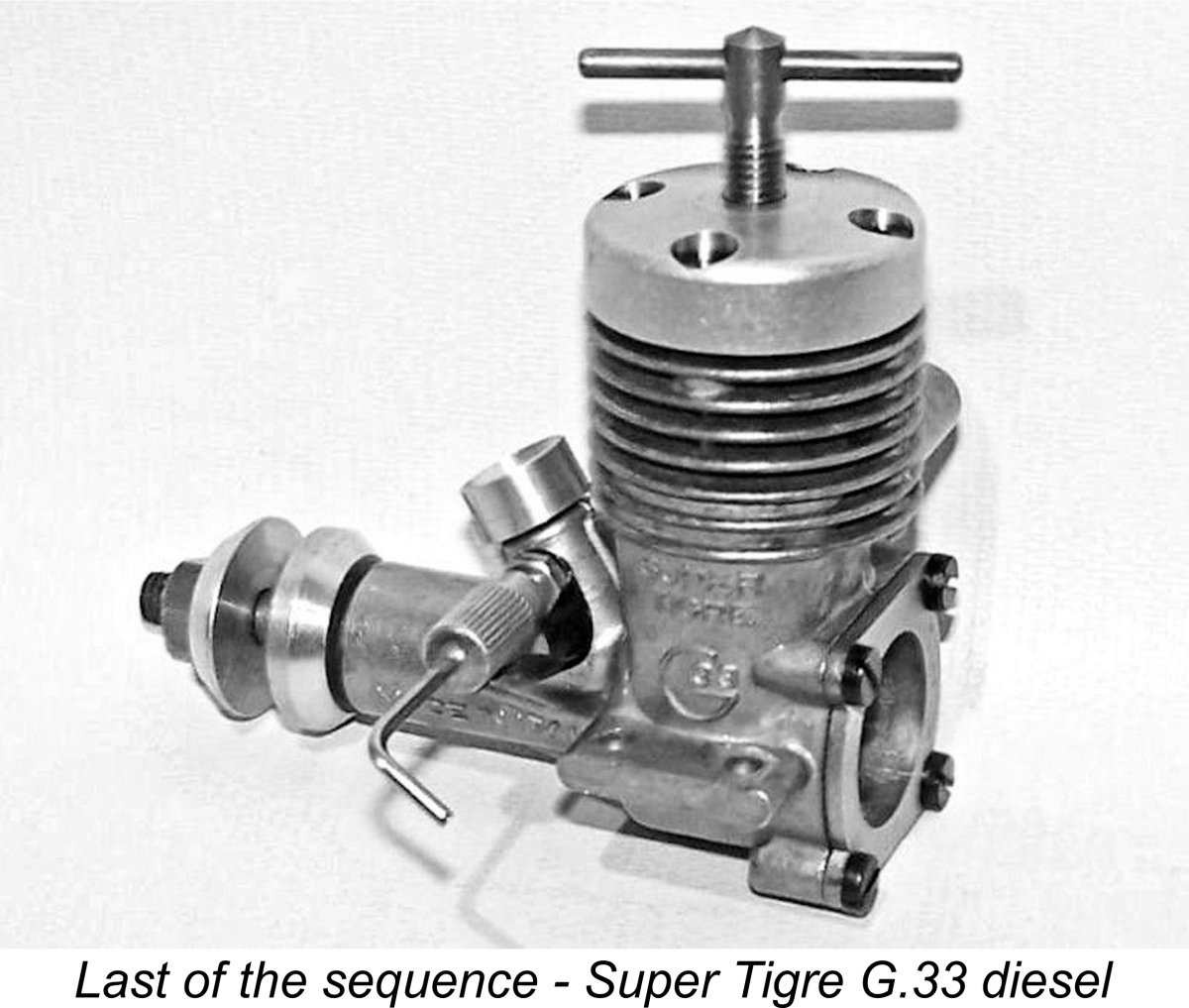

First and foremost among these is Salvi Angeloni of Lodi, Italy. Salvi published a most informative summary of the early years at Super Tigre in Issue 121 (February 1996) of the indispensable “Engine Collectors Journal” which was edited by my late valued friend Tim Dannels. I freely acknowledge my indebtedness to Salvi for much of the background information to follow. My task was also greatly facilitated by the fact that the very positive reputation which the Super Tigre engines quickly secured for themselves beyond the borders of Italy ensured that the international modelling media took a close interest in the range as it developed. From the early 1950’s onwards, the design revisions and all-new models which continually appeared from this very prolific manufacturer were regularly covered in the English-language modelling press, as were the competition results achieved. This of course did much to inform my first-hand research for this article. That said, I have to apologise for the poor quality of some of the images that I was forced to use. Not having direct access to examples of many of the engines discussed in what follows, I’ve had to cull images as and where I could do so. A number of them are scans of 60-70 year old faded and low-resolution magazine images which appeared in magazine articles or advertisements. I’ve used such images where no alternative presented itself, the theory being that some kind of image is surely far better than none at all when illustrating a discussion point. Finally, I must point out that the sheer scope and scale of the output of this extremely prolific manufacturer is such that a detailed review of each and every model would require numerous articles of this length. Not having the time to prepare such a mass of material, I have chosen instead to present nothing more than a referenced illustrated overview of the range. The intent here is primarily to provide basic information on the various models and on the dates and context of their respective appearances. At some future date, I may get around to running a few tests on specific models for which no published data appears to exist or for which available data are inconclusive. However, that will be for later. It was of course necessary to establish a boundary for this article - life's simply too short to cover the entire Super Tigre range from its beginnings up to the present day. I have chose to restrict this article to coverage of the entire series of engines which were designated by the initial G (for Garofali) and the number of each particular model in the design sequence, as opposed to a number representing the engine's displacement. This period covers the range from the very beginning up to the early 1960's, when the last engine to be so identified, the Super Tigre G.33, made its appearance. The rest of the Super Tigre story remains for others to tell. To assist readers who may be in a hurry to date their engines, I've included an Appendix at the end of this article which lists all the models discussed here along with their introductory dates and most notable features. Now, before getting down to the task at hand I’ll take some time to summarize the background to the very early post-WW2 appearance of the engines designed and manufactured by Jaures Garofali. Background The concept of the model compression ignition (aka somewhat incorrectly “diesel”) engine goes back way further than many of today’s model engine enthusiasts seem to realize. In the past, it has often been claimed that the Swiss Dyno 2 cc model of 1941 was the “first” commercial model diesel. While that may be true in terms of widespread acceptance and design influence, the concept actually dates back to December 17th, 1928, when the first patent for a model compression ignition engine was granted to one Ernst Thalheim, a resident of Switzerland.

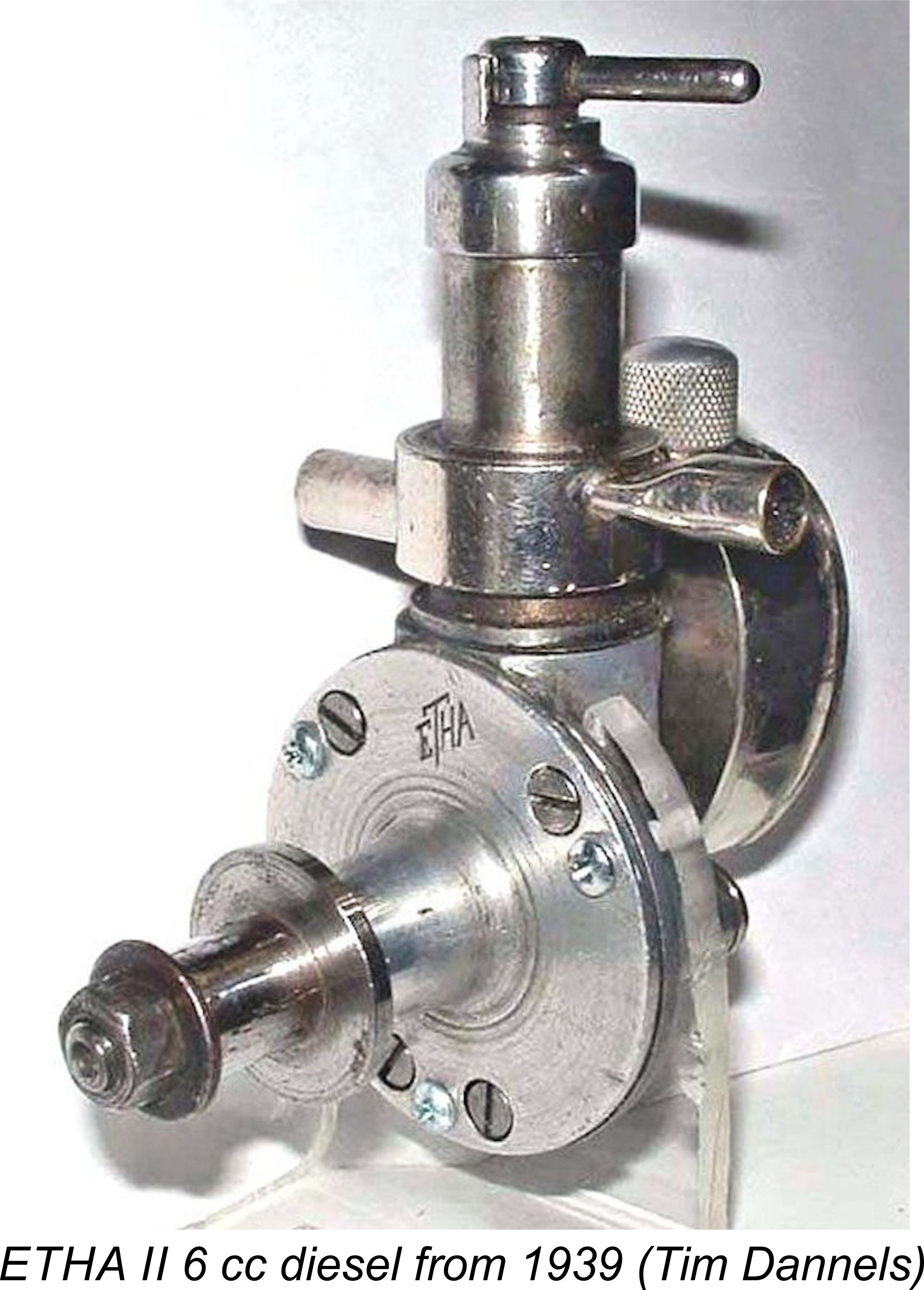

The ETHA engines were bulky, heavy and cumbersome. However, they were reportedly very competently constructed and ran well, thus proving the concept for all to see. This being the case, it was inevitable that others would follow Thalheim’s lead. The previously-mentioned Dyno 2 cc model manufactured in Alfligen, Switzerland by Klemenz-Schenk (whose primary business was the manufacture of bicycle lighting generators, hence the engine’s name) was one of the earliest spin-off products, being developed in 1940 and making its market debut in 1941. It was a considerable step forward from the ETHA designs, being both smaller and lighter as well as having a higher specific power output. As time went on, the Dyno became one of the most influential and widely-imitated early model diesel designs of them all.

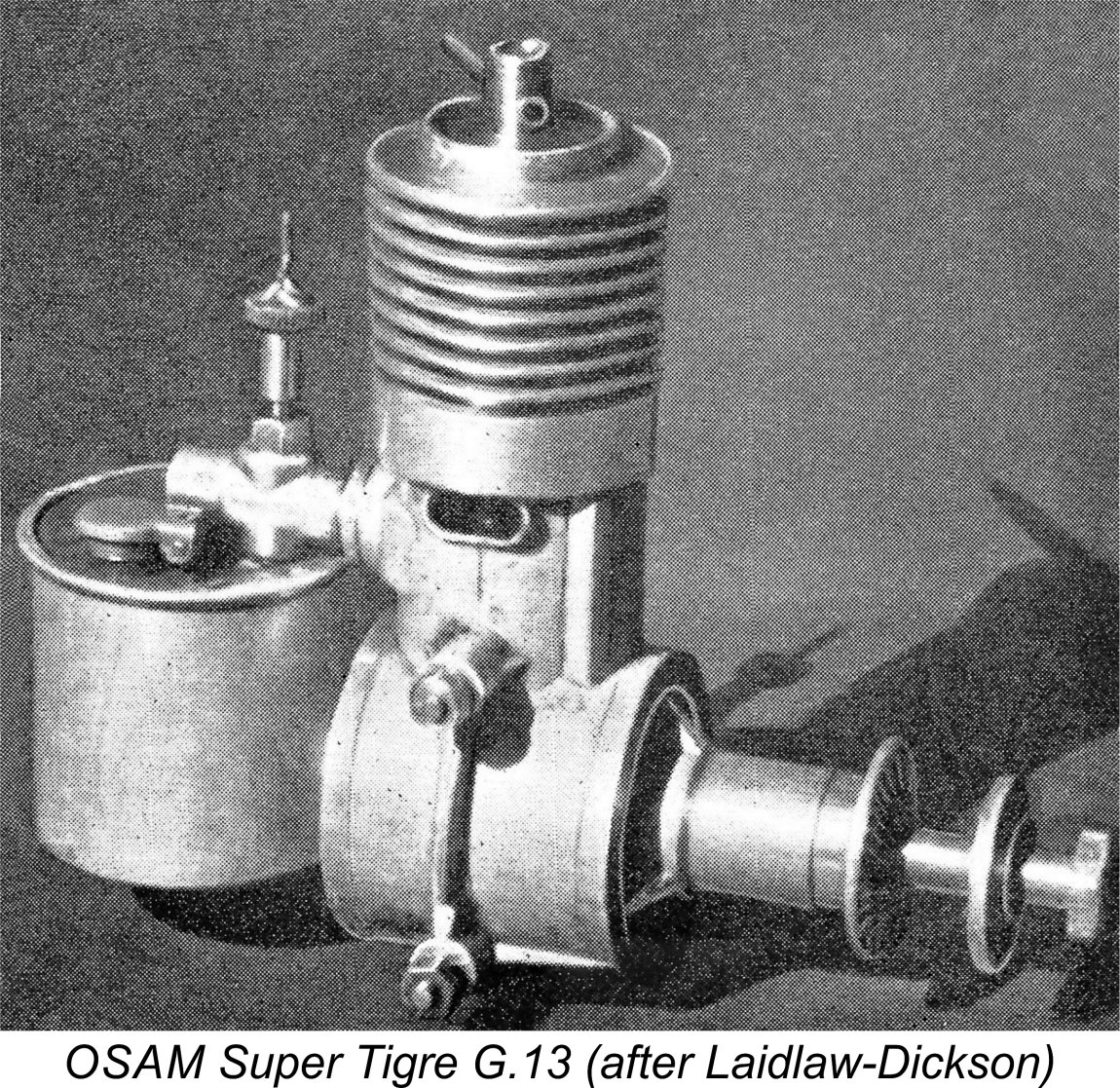

Italy thus became one of the first nations after Switzerland in which the development of the model diesel concept was seriously pursued. However, the fact that this pioneering activity took place at a time of international conflict prevented any details of the Italian developments in this field from becoming widely known outside of Italy. Among those involved with model engine development during the wartime period was Jaures Garofali, a native of Bologna who had been born in 1920. In 1937 after leaving school, the 17 year old Garofali teamed up with his friends Valerio Ciampolini and a certain Signor Betuzzi to found a company called OSAM, which stood for Officina Sperimentale Apparecchi Motori (Aircraft and Engines Experimental Workshop). From the outset, Jaures Garofali took the lead in the engine design field. It appears that the The OSAM team soon began to put this rudimentary equipment to use in producing the first model engine designs to emerge from Garofali’s drawing board. The very first Garofali-designed engine was the OSAM G.1, a 3.5 cc spark ignition engine. Only four or five of these units are known to have been built. Mention of this engine’s model designation brings up the important matter of the model identification system applied throughout the “classic” era to the series of engines under discussion here. From the outset, Garofali used a sequential numbering system to designate his early designs. The engines all bore the letter G (standing of course for the designer’s initial) followed by a number representing the position of that model within Garofali's own design sequence. Hence this numbering system bore no relation whatsoever to the displacement of the engines. This was to cause considerable confusion in some market areas, eventually forcing its abandonment. The numbering protocol just described was to last for some 25 years right up to the appearance of the G.33 in 1964. Even before that date, however, the model identification system was in the process of being changed to include a number equal to the displacement in cubic inches, doubtless to facilitate sales in foreign markets such as America where the cubic inch displacement standard was generally followed. Returning now to the late nineteen-thirties, further designs soon flowed from Garofali’s drawing board, including the G.2, G.3, G.4, G.5, G.6, G.7 and G.8 models. Salvi Angeloni tells us that most of these designs never got beyond the drawing board stage, remaining in the realm of “though experiments” or paper exercises. However, a few engines were apparently built from time to time to test the effectiveness of specific design features. This was a period during which Garofali was refining his understanding of model engine design without as yet entering the commercial manufacturing field. Italy’s entry into WW2 on June 10th, 1940 caused a complete change in Jaures Garofali’s situation. Still only 20 years old at the time, his technical expertise was already such that he was excused military duty, instead being assigned to an Italian air force base, where he worked for the balance of 1940 and the whole of 1941 on research projects involving the use of the Aerodynamic Research Vertical Wind Tunnel which was located at the base. This facility was directed by Garofali’s OSAM colleague Valerio Ciampolini, with whom Garofali continued to work closely during this period. It appears that neither Garofali nor Ciampolini allowed their involvement in the Italian war effort to diminish their enthusiasm for models, since it was during this period, supposedly in his spare time, that Garofali built the first examples of his G.9 design, a spark ignition engine of 6.83 cc displacement. It’s abundantly clear that at the very least Ciampolini must have turned a directorial blind eye to this non-military activity! Only three or four engines were alleged to have been made at this time. One of them ended up in the hands of the prominent Italian modeller G. Ridenti, a leading figure in the Italian model competition field. In 1942, Garofali was transferred to the Forli Aeronautical Academy located about 80 km south-east of Bologna. Here he worked alongside Warrant Officer A. Pagliani and a certain Signor Zambianchi. Presumably with their knowledge and concurrence, if not their actual help, Garofali produced a number of additional examples of the G-9. Reportedly around eight more examples were produced during this period. Garofali also found time to draw up the designs of three further spark ignition models, the G.10, G.11 and G.12. However, these latter designs were destined to remain on paper only. We saw earlier that a few examples of the Swiss Dyno-1 diesel had somehow reached Italy despite the ongoing conflict of WW2. In early 1943, one of these examples came to the attention of Jaures Garofali, who was able to take a long hard look at it. Although all of Garofali’s model engine design experience up to this point had been with spark ignition motors, he was immediately intrigued by the compression ignition concept, instantly recognizing its advantages in terms of dispensing with the parasitic weight of the ignition support system as well as its inherently superior reliability given the effective absence of anything to go wrong.

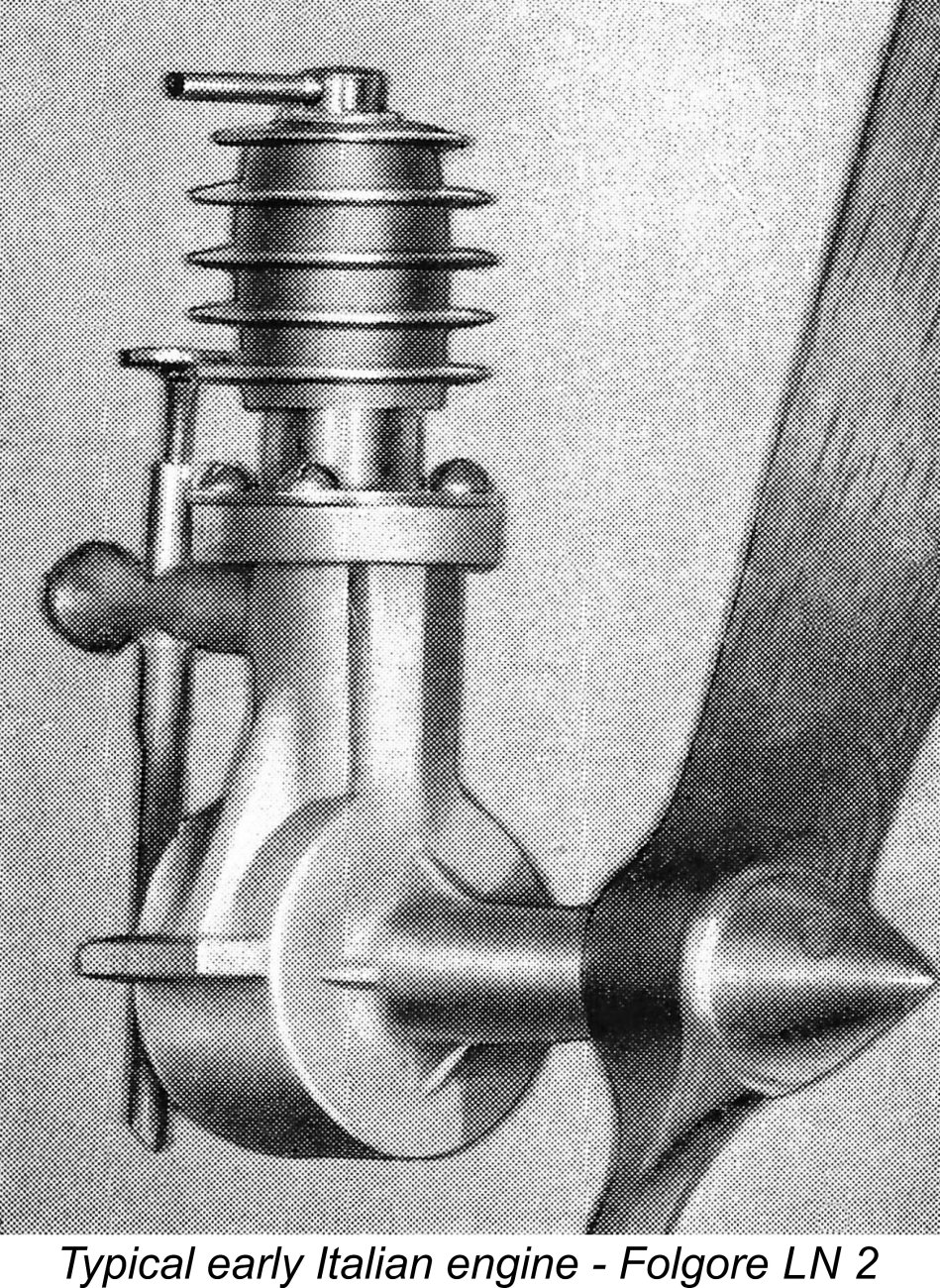

It’s unclear how many, if any, examples of the G.13 were constructed at Forli. However, a return to Bologna in September 1943 following Italy’s formal surrender to the Allies changed Garofali’s employment situation to the point where further model engine building work had to be deferred in favour of economic survival. It was clear that any large-scale commercial ventures involving such products would have to wait until the whole of Italy was finally liberated from Benito Mussolini’s fascist regime and forced out of the war altogether. This did not take place overnight – although Italy formally surrendered to the Allies by signing the Armistice of Cassibile on September 3rd, 1943 following the Allied invasion of Sicily, the Germans immediately responded by occupying the country and attacking Italian forces at a number of locations. Moreover, Mussolini was still at large. The ensuing fighting was some of the most bitter of the war, with very heavy casualties on both sides. It was not until April 27th, 1945 that the City of Milan in Northern Italy was finally liberated, with the Italian campaign being formally ended a few days later by the April 29th signing of the instrument of surrender by the leadership of the German Army’s Group C. In the interim, Garofali found work with a Bologna company that produced espresso coffee machines, very popular in Italy. During his free time, he continued working on the OSAM G.13, managing to produce a few more examples of the engine. However, much of Italy had ceased to be directly involved in the conflict as of the liberation of Rome on June 4th, 1944. Thereafter the ongoing fighting was largely confined to the northern half of the country. This left a sizeable number of Italian citizens free to resume some of their pre-war activities. Among these were a surprising number of individuals who had ambitions to Among these early Italian diesels were the Alfa 1 of 1.86 cc displacement, developed by a certain Signor Mancini; the Antares 4 cc design; the Atomatic 1 cc and 4 cc models from Rome, developed by Uberto Travagli; the 2 cc P.O.2 diesel from Bergamo; the Giglio 2 cc model from Florence, developed by Signor Grazzini; the MOVO D-2 developed in Milan by Stelio Frati, Ermenegildo Preti and Gian-Luigi della Torre; and the Folgore LN 2 of 1.99 cc displacement from Cremona. Several additional models originated in Turin in the form of the Elia 4.2 cc unit and the Helium B.6 and C.6 designs of 6 cc displacement. Italy must accordingly be seen as a real hotbed of early model diesel development – all of these engines had appeared on the Italian market well before the first British commercial diesels made their debuts in mid 1946, as indeed did our subject Super Tigre range, albeit under a different name at this stage. The OSAM Era

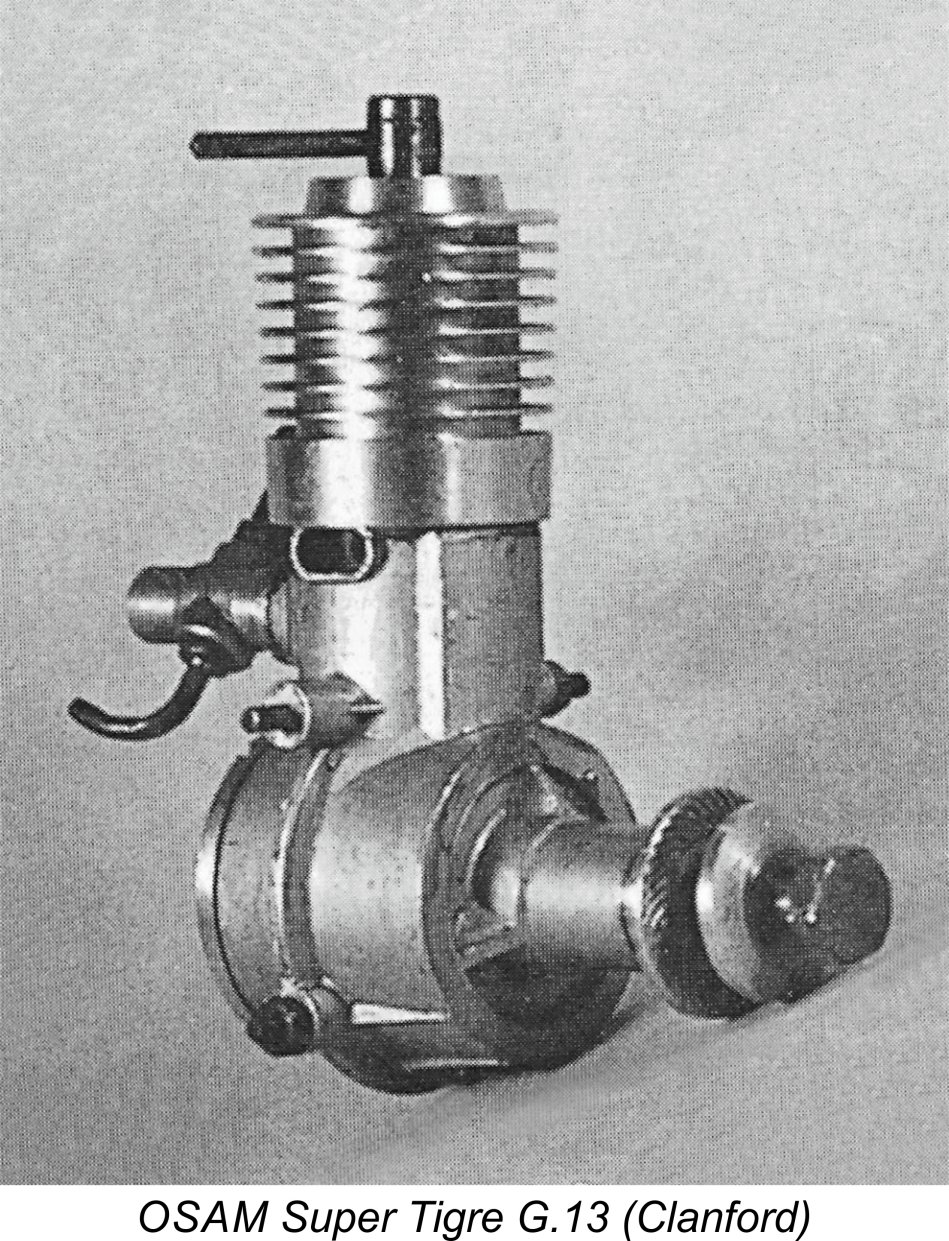

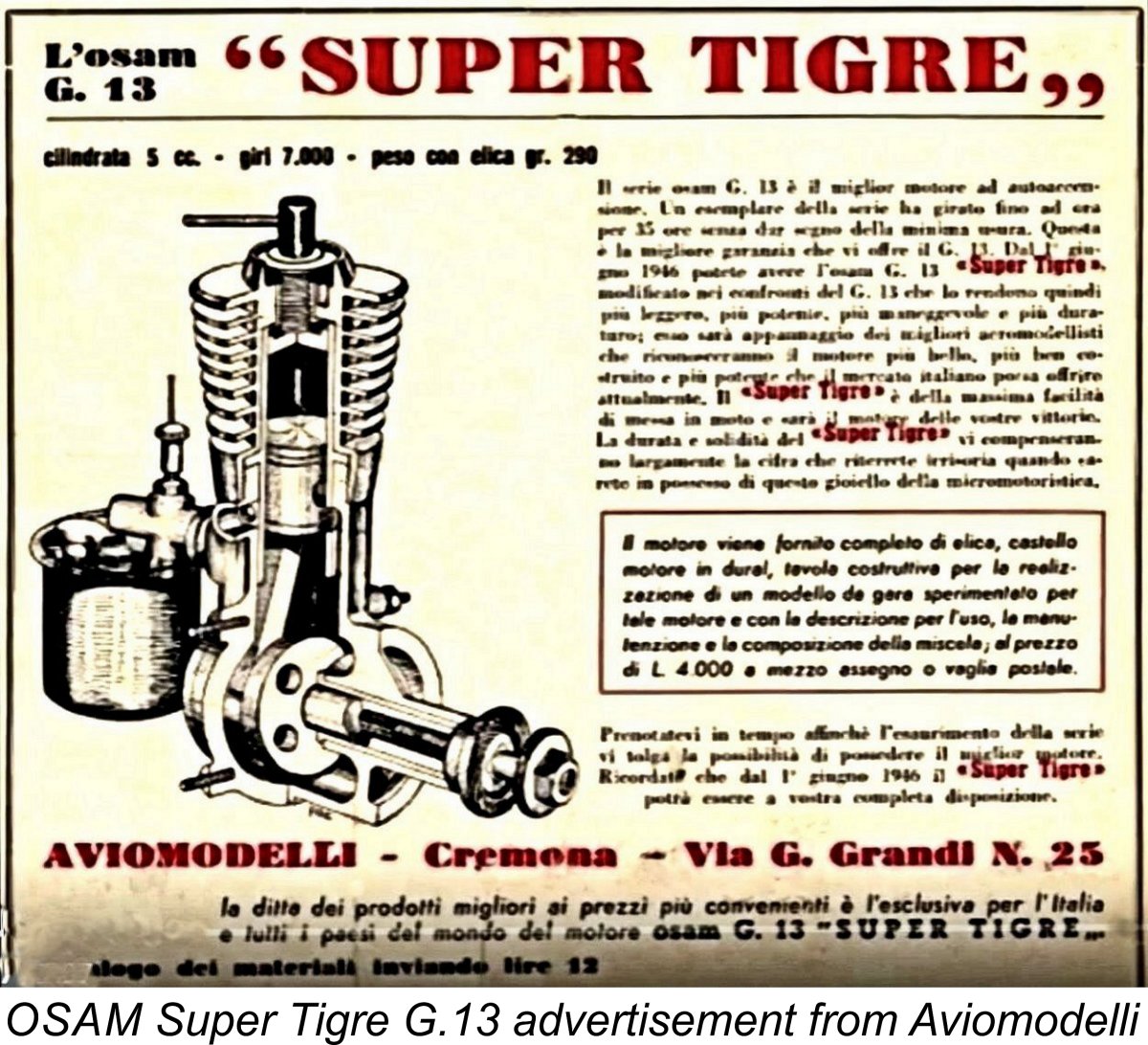

Although Garofali was still living and working in his native Bologna, the G.13 was advertised and sold exclusively at this stage by Signor A. Castellani’s Aviomodelli company of 25 Via G. Grandi in Cremona, some 150 km north-west of Bologna. This company also marketed the Folgore LN 2. Interestingly enough, the OSAM G.13 was advertised with the Super Tigre name prominently attached from the outset despite the fact that the emergence of Super Tigre as an independent Bologna-based manufacturer did not come about until 1949, as we shall see in due course. One of the 24 examples of the G.13 somehow found its way to England, presumably in the hands of a British participant in the Italian campaigns of WW2. This engine may actually have reached England in the hands of Peter Chinn, who served in Italy in 1944-45 and later recalled bringing back a number of pioneering Italian engines at the end of the war.

In reality, the G.13 was a 5.28 cc unit, as noted earlier. According to Laidlaw-Dickson, this model was cited by its designer as being particularly well-suited to control-line applications. A claim of 10,500 RPM on the manufacturer’s specially designed control-line airscrew was cited – if true, pretty good going for an engine of this type and displacement. The most unusual feature of the G.13 was its unique mounting arrangement. The crankcase was equipped with two bolts on a vertical axis on each side, as clearly seen in the attached illustrations. These bolts supposedly allowed easier changing of down and side thrust settings, thus facilitating the trimming of a free-flight power model. Against that, the system certainly presented a few structural challenges for the model builder! Another out-of-the-rut feature by diesel standards was the use of a ringed light alloy piston, which may be clearly seen in the above cut-away advertising image.

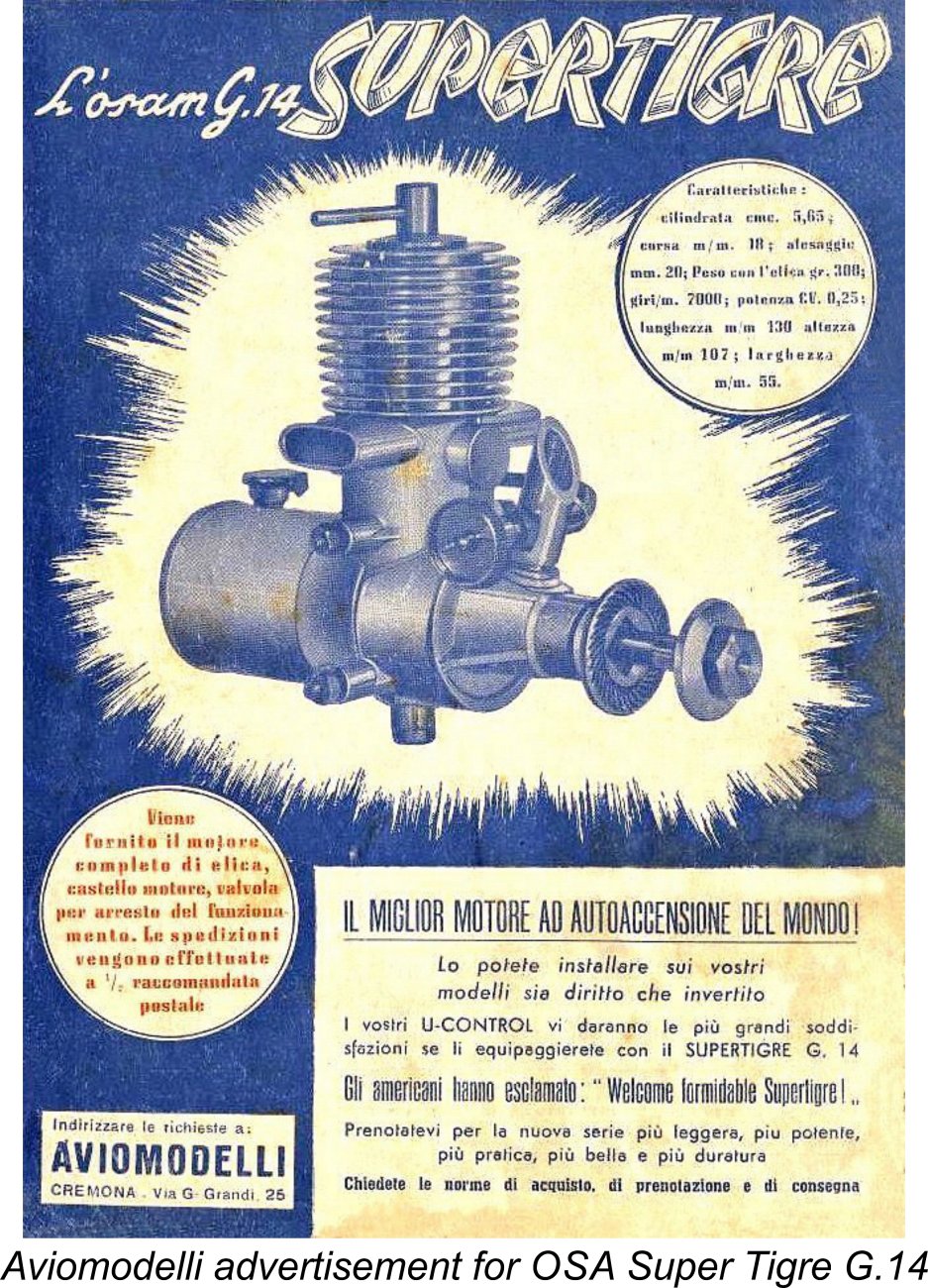

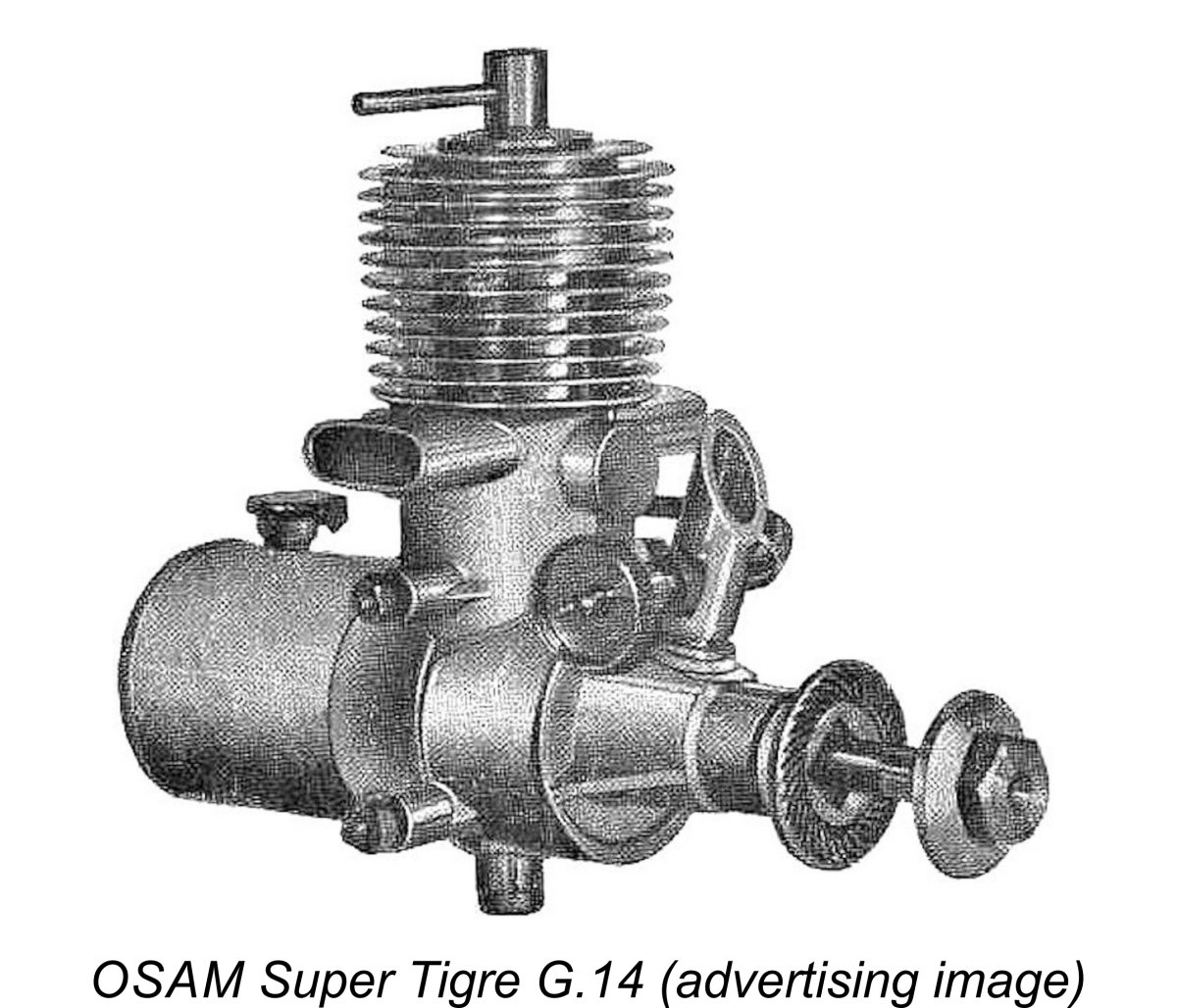

Under the terms of Garofali’s agreement with Aviomodelli, the 1946 OSAM G.14, was produced and marketed by that company. Like its predecessor, the OSAM G.14 was advertised all along with the Super Tigre name prominently associated with it. At this point in time it would appear that the name Super Tigre was seen as a catchy and hence easily-remembered marque identifier rather than the official trade-name which it finally became in 1949. The OSAM G.14 was a 5.65 cc diesel which abandoned the sideport induction system used on the G.13 in favour of FRV induction. It did however retain the unique mounting system involving two bolts on a vertical axis on each side. A significant departure from contemporary standards was the new model’s use of short-stroke internal geometry. Bore and stroke dimensions were 20.0 and 18.0 mm respectively. Weight with matching airscrew was cited as 300 gm (10.58 ounces). The manufacturer stated that the engine would turn this matching airscrew at some 7,000 RPM, at which speed an output of 0.25 CV (around 0.246 BHP) was claimed. This claim has a ring of credibility to it.

From this time onwards, the new designs produced by the partnership carried the GB designation (Garofali-Boreani) preceding the sequential design number. The numerical design sequence was however continued unbroken. The partners established their own production facilities in Bologna, allowing them to manufacture all future models themselves. However, they remained on cordial terms with Aviomodelli, who continued to promote and market their products. Incidentally, this latter company was still producing kits and accessories for the model builder as late as 1996 and possibly longer.

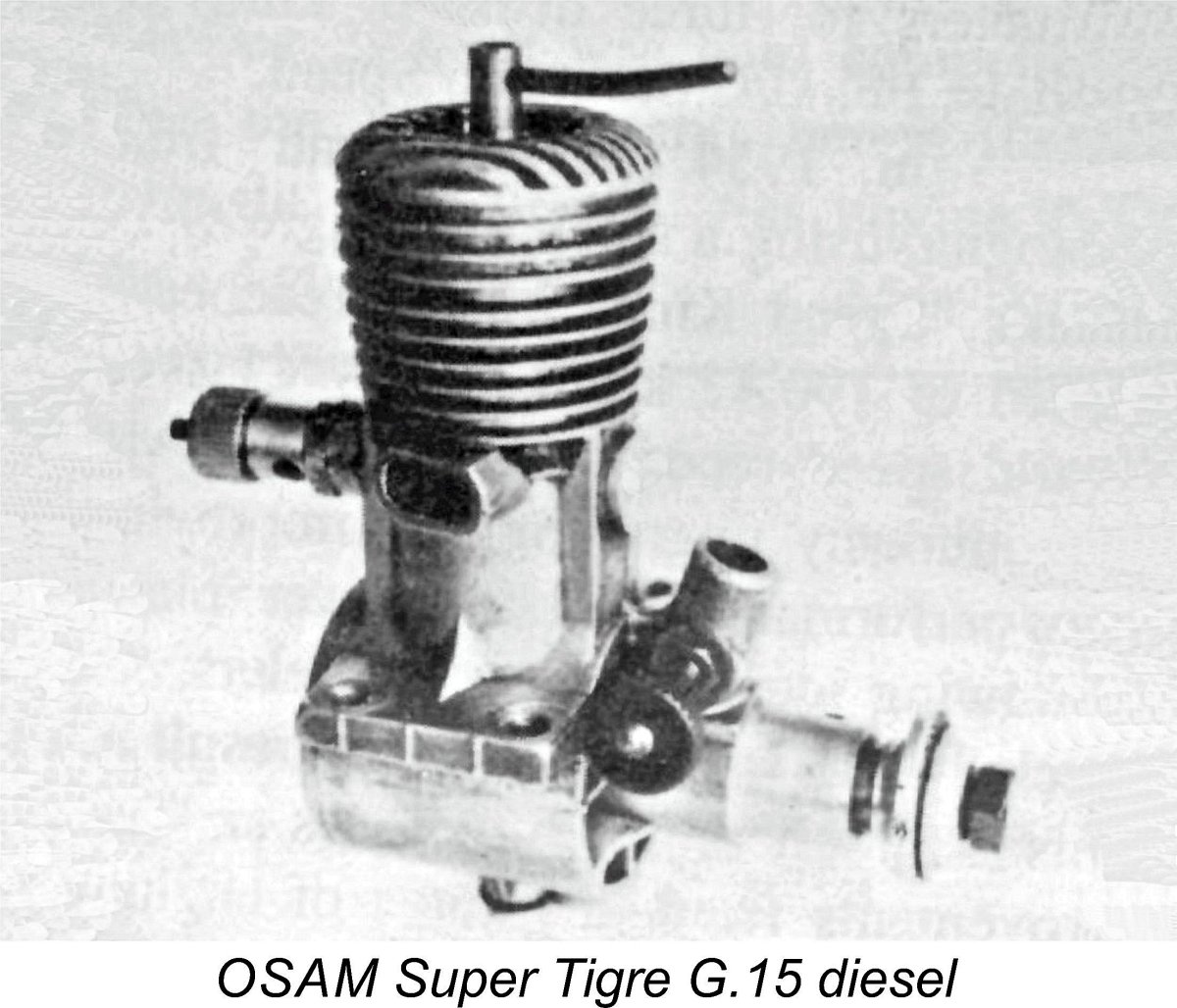

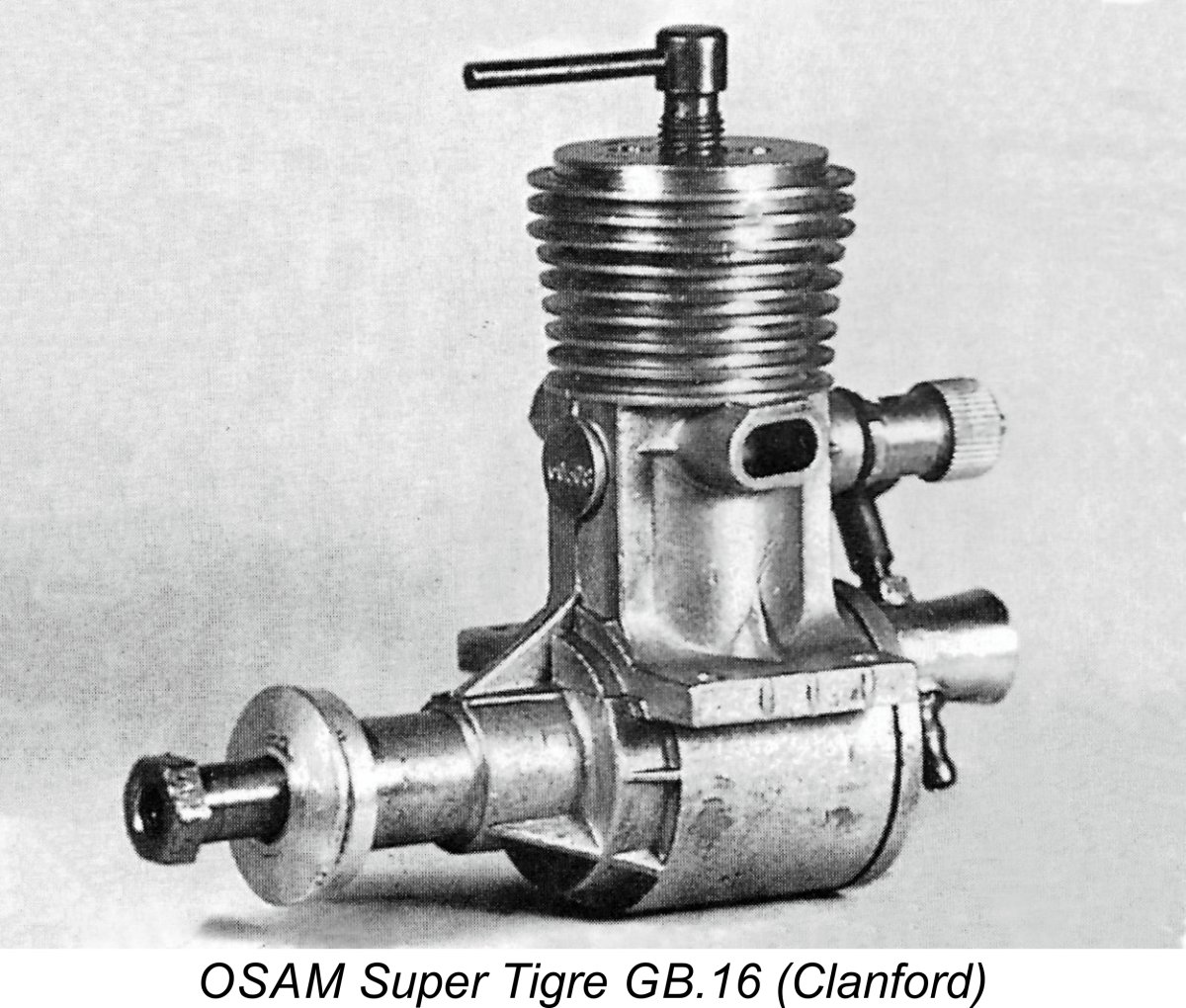

In early 1947, OSAM produced an engine at the request of Aviomodelli which the store sold as a “house brand” under the name of “Uragano.” This engine had the same 6.28 cc displacement as the GB-15 and was broadly similar in overall appearance. However there were more than enough detail differences in the castings to readily distinguish between them. 1947 also saw the introduction of perhaps the most famous and popular engine ever to appear under the OSAM name, the OSAM GB.16. This was a very powerful 5.65 cc diesel which incorporated the first disc rear rotary valve (RRV) induction system to appear from this manufacturer. It also featured a single ball-race at the rear of the crankshaft journal. This engine was particularly well received by the Italian modelling community, who found engines from the USA to be prohibitively The OSAM GB.16 appeared in three distinct variants, with around 1000 engines being manufactured in total. The Mk. I variant featured a black crankcase, very small exhaust stacks, a rear induction system which screwed into the rear of the crankcase, a cylinder which was held in position by a screw-on head and a cutout bleed valve at the rear of the upper crankcase. Only around 50 examples of this version were built. The Mk. II variant as illustrated at the left was very similar to the Mk. I apart from having a natural finish on the crankcase and slightly larger exhaust stacks. The bleed valve at the rear can be clearly seen in this image. The Mk. III variant appeared in 1948. It represented the addition of a number of improvements to the previous models, sporting significantly larger exhaust stacks having a rectangular section, longer mounting beams and a more practical rear rotary valve assembly which was now attached to the case by three screws instead of being screwed in. A cutout valve was not supplied with the last examples of these engines, probably due to the increasing use of the GB.16 in control line stunt and speed models. Instead, the cutout mounting boss was blanked off with an appropriately-threaded screw-in plug.

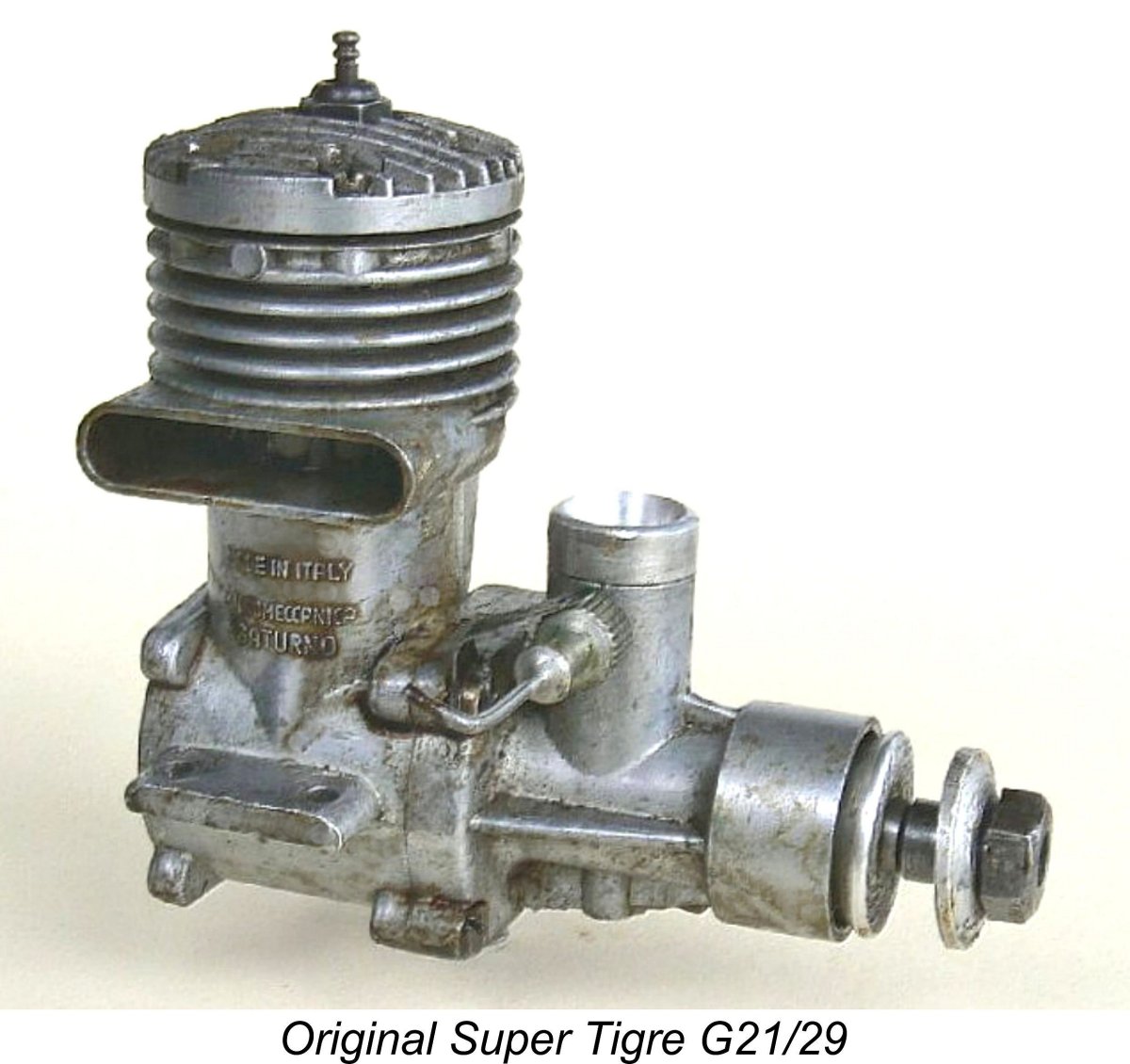

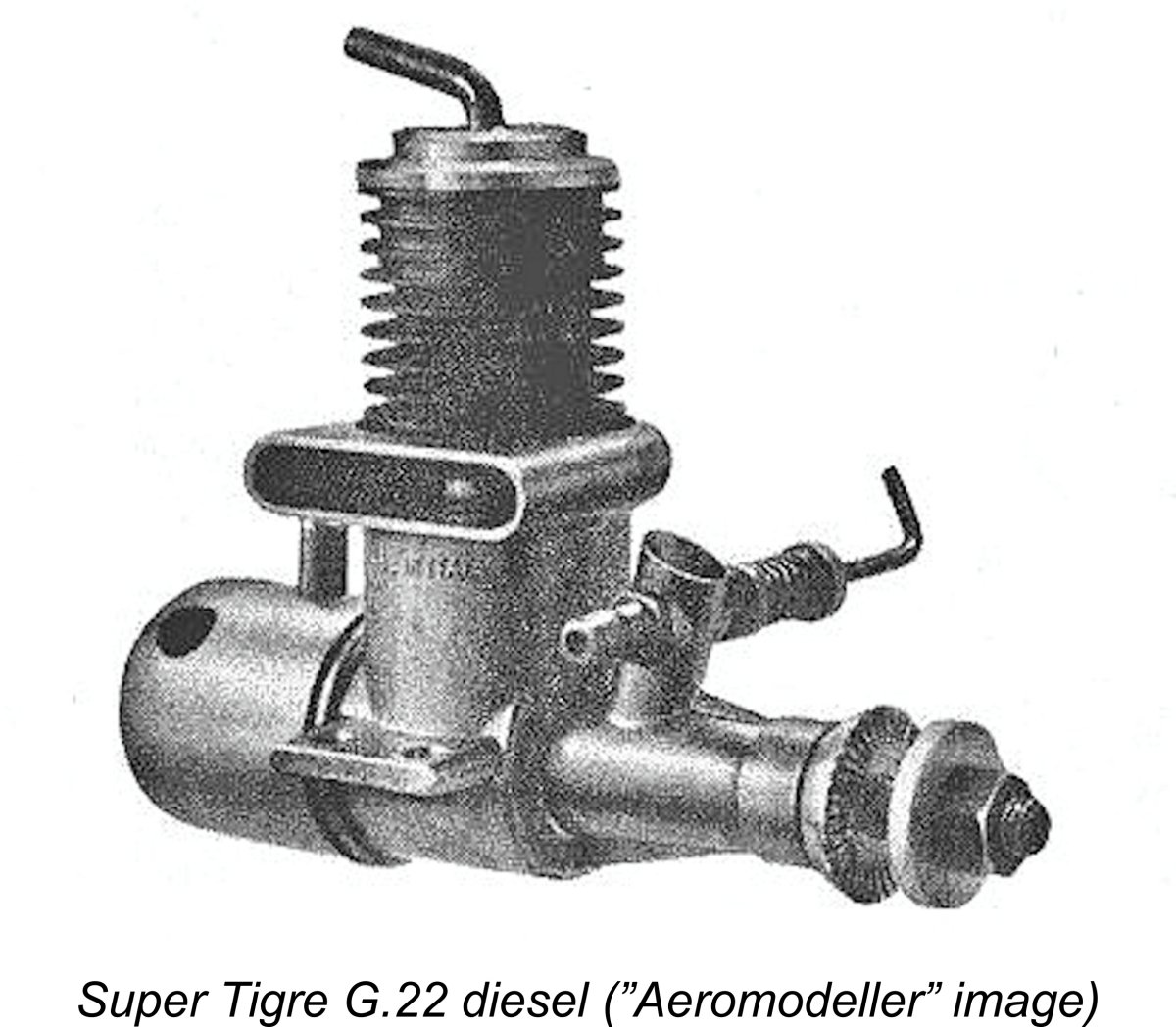

The use of the engine was not confined to stunt competitions - at the 1948 Italian Nationals, the previously-mentioned G. Ridenti, who remained active as one of the father figures of Italian modelling, achieved the then-remarkable speed of 178 km/h (110.6 mph) with his GB.16 powered speed model using 60-foot lines. This constituted a noteworthy accomplishment for the time in question. Sparey’s comment about the worldwide popularity of the GB.16 is interesting insofar as the international model engine market had yet to open up at the time in question. Import and currency restrictions were in place in many countries as various economies struggled to recover from the effects of WW2. Accordingly, buyers outside of Italy must have gone to great lengths to acquire their examples. Sparey actually commented on this point in his published test of the G.19 and G.20 (see below), noting that imports to Britain required one to take out an Import License and pay taxes and duties amounting to as much as 50% Returning to our main thread, early 1948 also saw the appearance of the smaller OSAM GB.18, an RRV diesel of 2.82 cc and Garofali’s smallest design up to that point in time. For some obscure reason, the GB.18 was introduced to the market before the lower-numbered OSAM GB.17, of which the GB.18 was in effect a scaled down version. The GB.17 appeared slightly later in 1948. It was a very powerful 9.8 cc RRV diesel having a twin ball-race crankshaft. Its design layout generally followed that of the third variant of the GB.16 and the GB.18. Bore and stroke were 24 mm and 22 mm respectively. This design was highly unusual by contemporary diesel standards in that it continued to feature a lightweight two-ringed aluminium alloy piston. A peak output of 0.70 BHP @ 12,000 RPM was claimed by the manufacturer. During 1949, Jaures Garofali parted company with Mr. Boreani, who retained the OSAM name while Garofali retained control of the Super Tigre title. The OSAM company had a rather short life thereafter, producing only a few different engines. These were the OSAM 1700 “Lilliput” glow-plug engine of 1.7 cc displacement and a 2.5 cc OSAM 2500 model which appeared in both diesel and glow-plug versions. Jaures Garofali was not involved in the design of these models. Enter Super Tigre Having parted company with Signor Boreani, Garofali quickly established his own manufacturing facilities in Bologna and set about the further development of his model engine range. Since Boreani had retained the OSAM name, Garofali needed a new name for his company. He chose the soon-to-be-famous company title of Micromeccanica Saturno while continuing the use of the Super Tigre brand name to identify the products of his company. Hence "Super Tigre" is a brand name rather than that of the manufacturer. From this point onwards, the engines were marketed as members of the Super Tigre range, although they also bore the Micromeccanica Saturno company name.

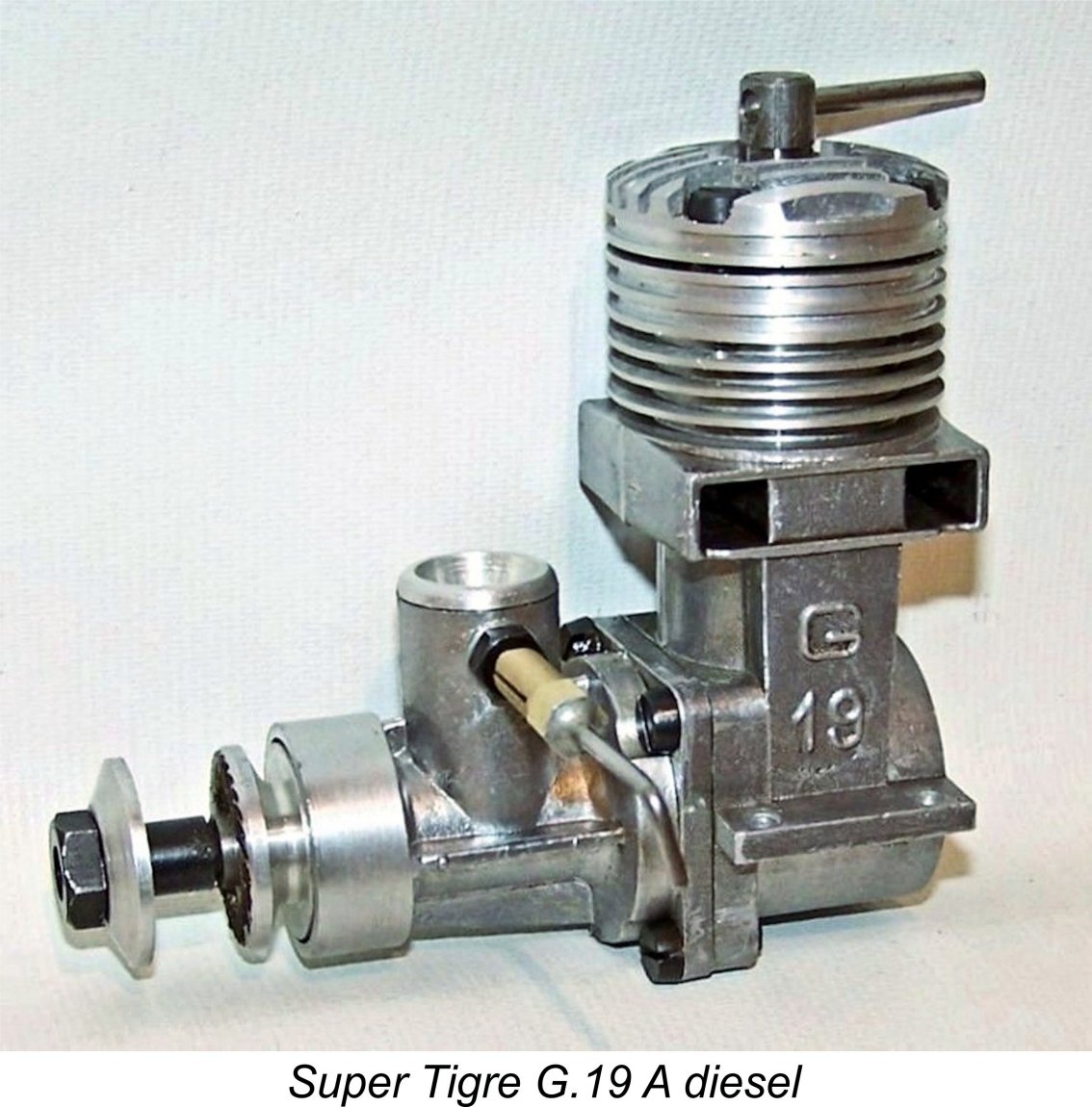

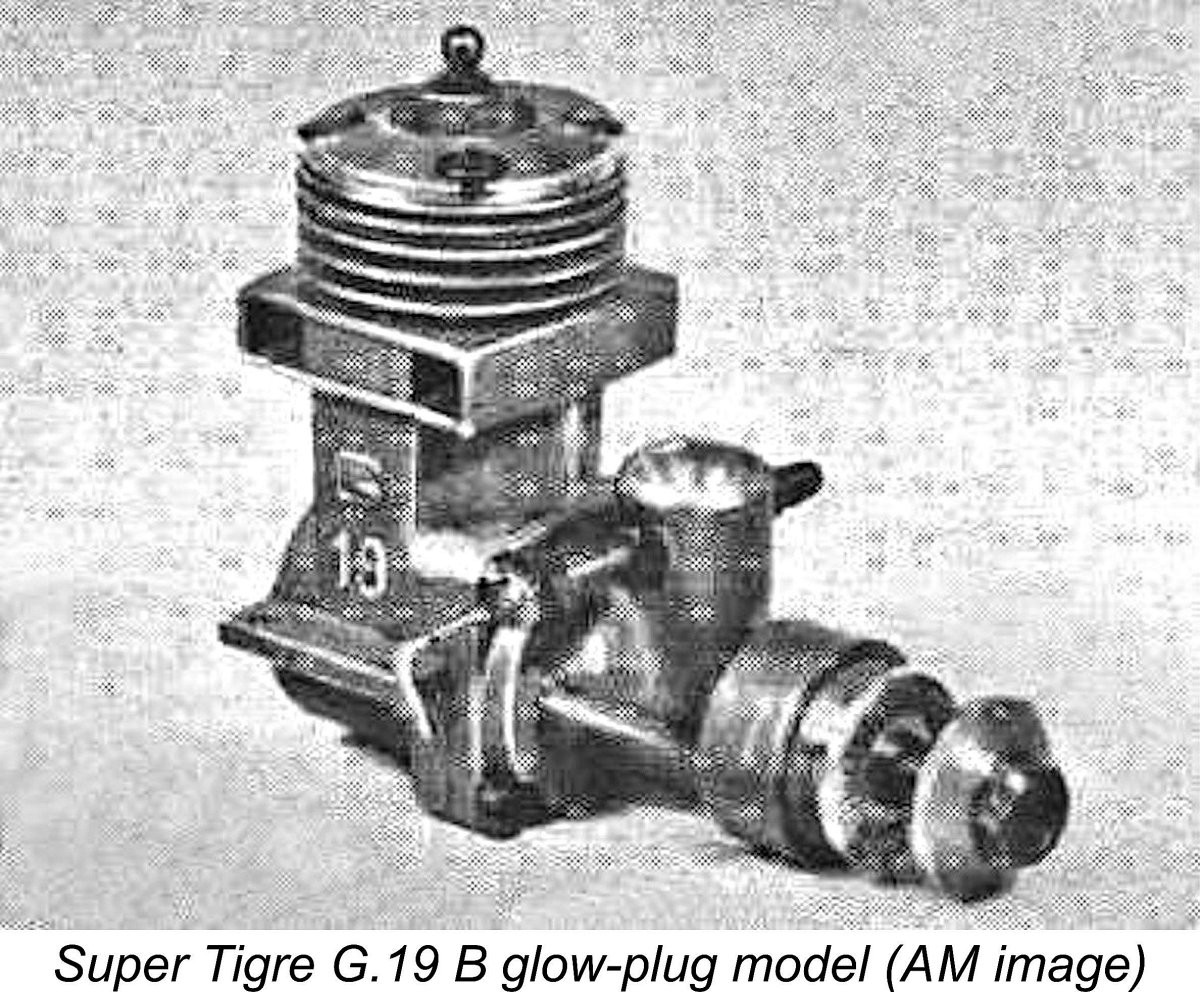

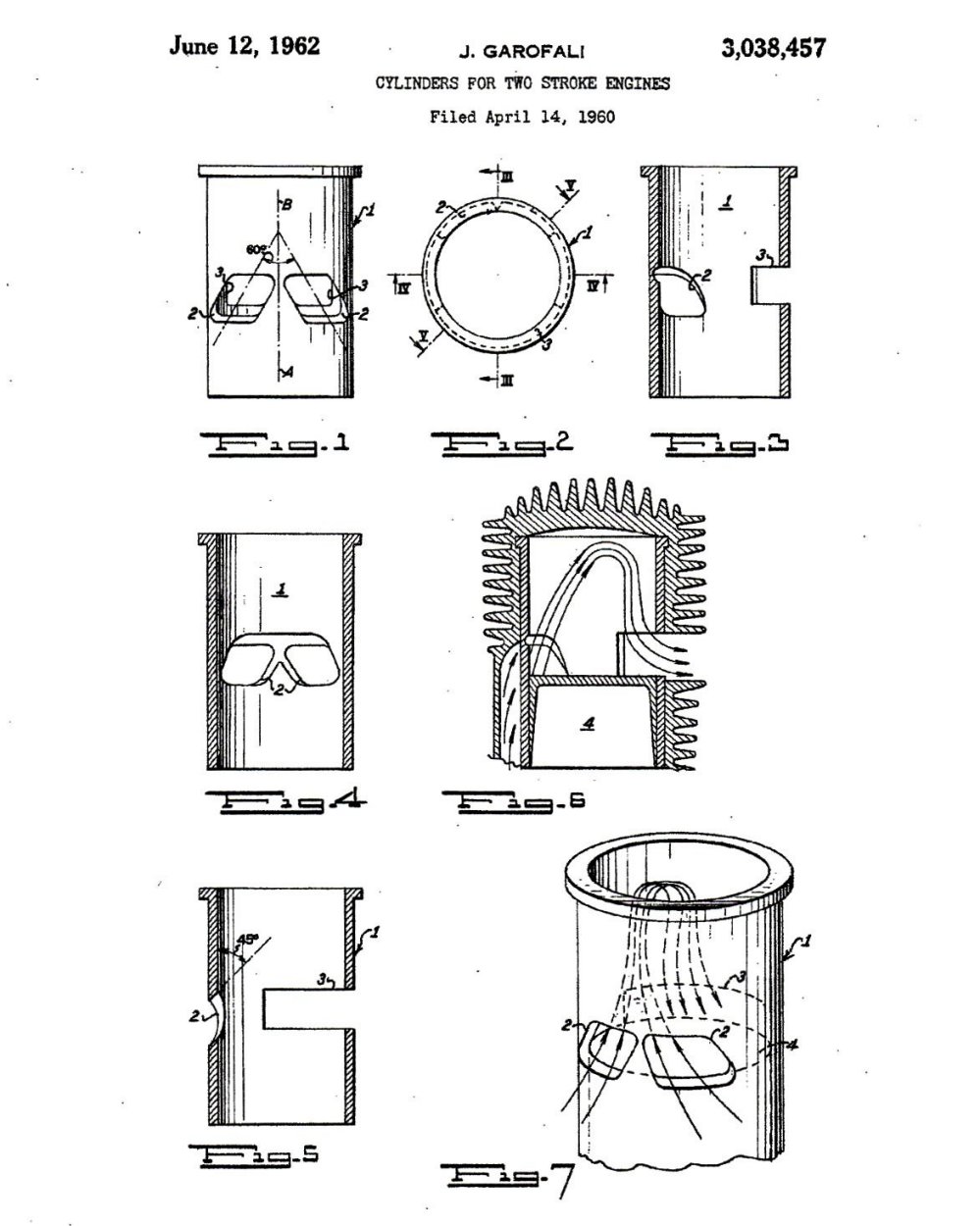

Both variants of the G.19 were twin ball-race FRV designs which were built to the very high standard which Garofali had set himself to maintain. They continued the established Super Tigre design configuration of having twin exhaust stacks, one on each side. However, the two transfer ports were now located at the sides, being supplied through two large bypass passages located beneath the exhaust stacks. The four exhaust openings in the cylinder were arranged with one on each side of both transfer ports. Each of the four exhaust ports discharged through its own aperture in the exhaust stacks. The front end was a separate casting which was attached to the main crankcase by four screws. The backplate was cast integrally with the main crankcase.

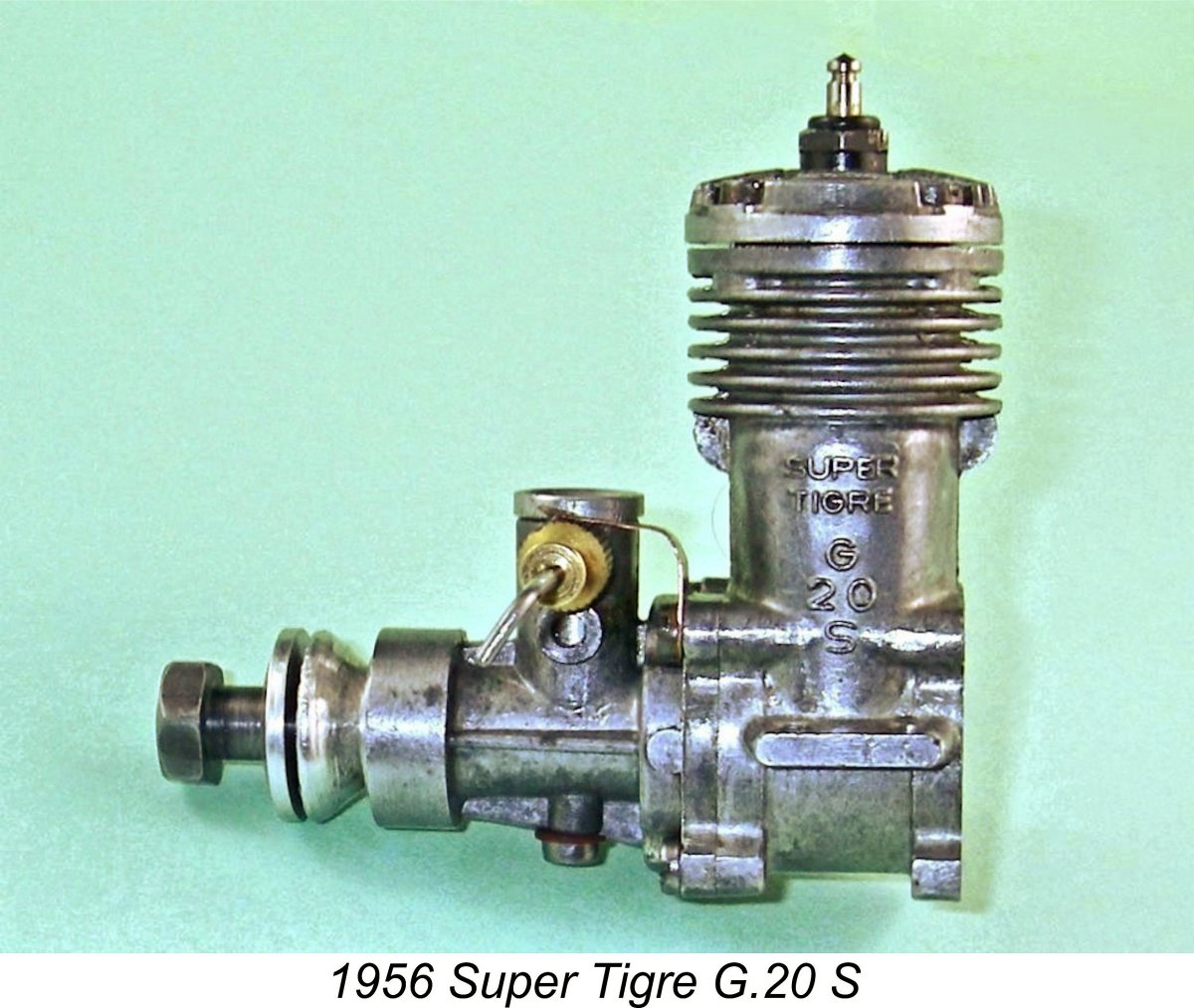

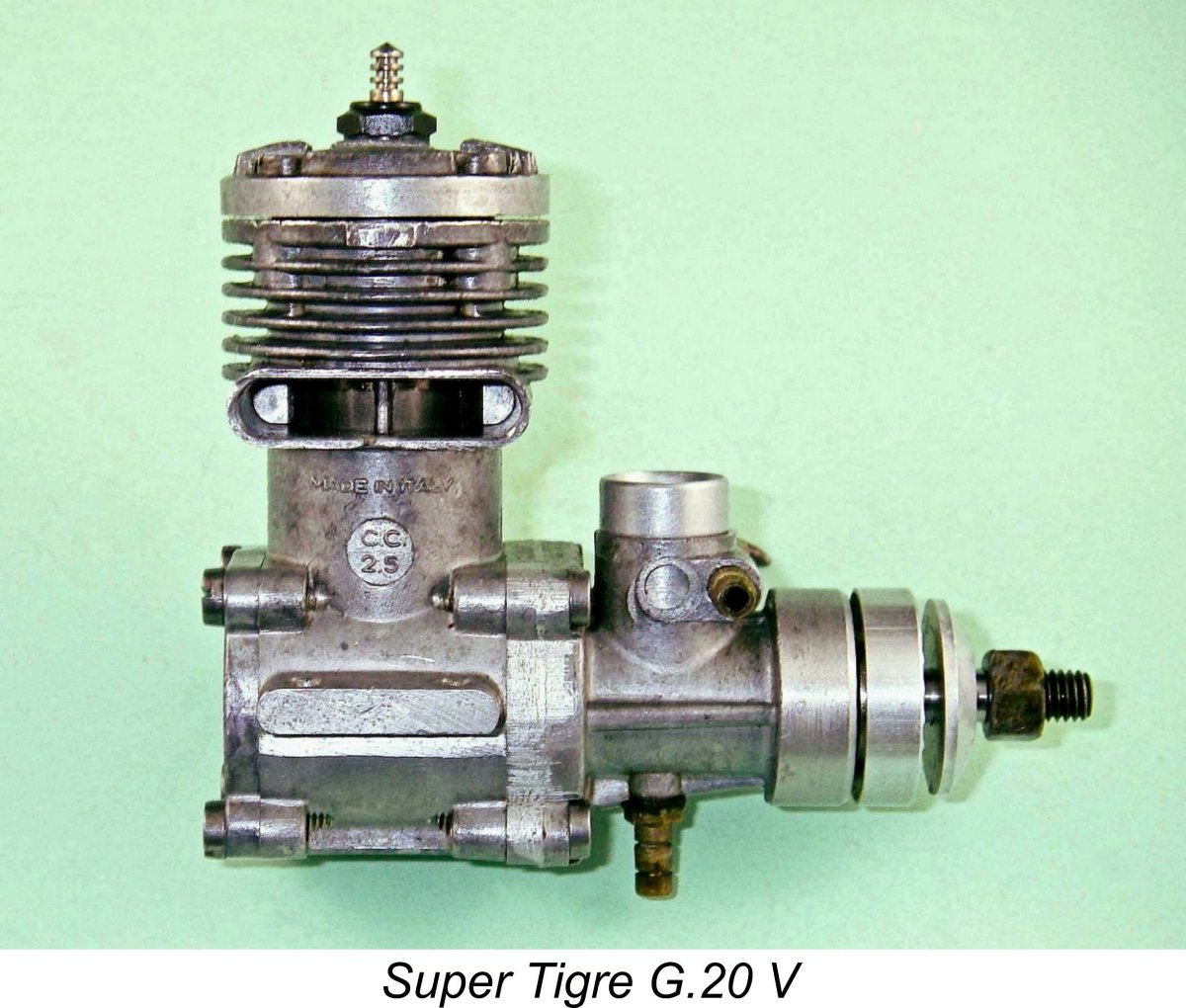

Both variants of the G.19 were excellent engines which got the independent Super Tigre range off to a very good start. However, the next model to appear was the one which really put Super Tigre on the map. This was the G.20 glow-plug motor, which was destined to become one of the most famous and most widely-used Super Tigre engines of them all. In its various forms, the G.20 was flown by contest modellers all over the world for the next fifteen years, producing more than its fair share of contest wins in the process. The original version of the G.20 made its debut in 1950. This model had the distinction of being the first Garofali design to feature cross-flow loop scavenging. It utilized a sandcast crankcase with a square exhaust stack; a bolt-on front housing with provision for FRV induction; a single inboard ball bearing on the shaft; a finless head with the plug offset towards the bypass side; a conventional split thimble needle valve; and a light alloy baffle piston with two rings. Bore and stroke dimensions were 15 mm and 14 mm respectively, a combination of dimensions which was destined to become more or less a standard for Continental 2.5 cc motors. These dimensions yielded a displacement of 2.47 cc (0.151 cuin.). This early variant of the G.20 weighed in at a very modest 120 gm (4.25 ounces).

One weakness of the original G.20 that was never corrected prior to the 1957 introduction of the G.20 V version was its remarkably skimpy mounting lugs. The engine's layout was such that there was a greater than usual overhang between the prop and the lugs, which would give rise to elevated impact loadings during a crash (wot - me crash?!? Never....!!). The lugs did not take advantage of the full available length of the main crankcase casting, also being made relatively thin. These lugs would not do well in a hard crash. All such comments aside, by this time the reputation of the Super Tigre engines had travelled far beyond the borders of Italy. The resident model engine tester for “Aeromodeller” magazine, Lawrence H. Sparey, was sufficiently interested that, although Super Tigre engines were not generally available in Britain until several years later, he managed to gain access to examples of both diesel and glow-plug versions of the G.19 as well as an example of the early G.20 design. His test report on all three models appeared in the April 1951 issue of “Aeromodeller”. Sparey praised the robust construction of all three models (evidently overlooking the weak mounting lugs on the G.20!), also reporting them to be very easy to start. He found a peak output of 0.485 BHP @ 13,300 RPM for the glow-plug G.19 B model. While a little down on the manufacturer’s claimed figure of 0.56 BHP @ 15,500 RPM, this was still a highly respectable figure by 1949 standards. The difference was most likely due to Sparey's use of a low-nitro commercial fuel (Mercury no. 5) for his test - the factory doubtless used a more potent mixture to establish their figure. Sparey did not conduct a full test of the G.19 A diesel version, but voiced the unsubstantiated opinion that it should at least match the output of its glow-plug companion, albeit at a lower peaking speed. Sparey reported a peak output of 0.24 BHP @ 14,000 RPM for the G.20 glow-plug model, figures which closely approached the manufacturer’s claim of 0.25 BHP @ 15,500 RPM. He characterized these figures as “exceptional”, which they undoubtedly were by then-prevailing standards. Again, the difference between Sparey's figures and those of the factory are most likely down to fuel variations. At this juncture, our story arrives at a logical division point. From this time onwards, the design efforts of Jaures Garofali and his colleagues were divided between engines which were intended for all-out competition applications and those which were aimed at the less charismatic but far larger and hence potentially more lucrative “Sunday flier” sport market. It seems logical to embrace this split and to follow these two production sequences individually. I’ll begin with the classic Super Tigre competition models. The Classic Super Tigre Competition Engines We have already seen that Super Tigre’s first outright competition engines were the G.19 B and G.20 glow-plug models which first appeared in 1949 and 1950 respectively. The 5 cc G.19 B was soon replaced, as we shall see, but the 2.5 cc G.20 was subject to the incorporation of a long series of improvements scattered throughout an unusually lengthy production life. In what follows, I’ll attempt to place the design progression of this iconic engine in context. I'll also comment upon the companion 5 cc and 10 cc competition models where appropriate.

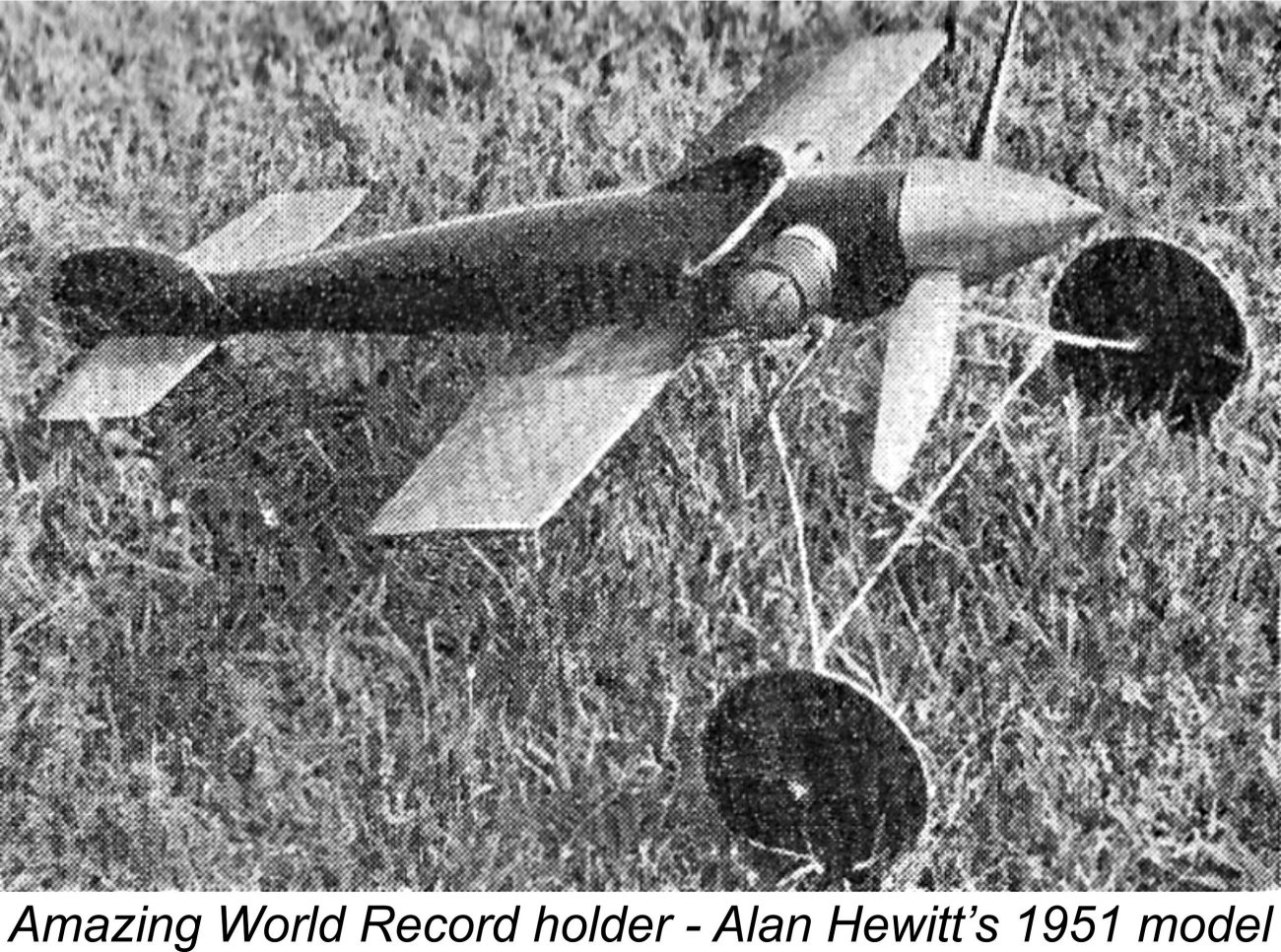

Both versions of the engine now featured pressure die-castings in place of the former sand-castings. Somehow the manufacturer managed to keep the weight of the "Speed" variant unchanged from that of its predecessor at just over 4 ounces. The head used on both models continued to be a plain unfinned component with the plug offset towards the bypass side of the cylinder. The flimsy mounting lugs were also carried over from the original sand-cast version. The 1952 "Speed" variant was tested by Ron Warring, whose report was published in the November 1952 issue of “Aeromodeller”. Despite some difficulties arising from a seemingly poor compression seal provided by the two piston rings (which presumably required some more bedding in), Warring found the engine to be an excellent runner once going. Using Mercury no. 7 fuel, he measured a peak output of 0.26 BHP @ 14,000 RPM, thus slightly exceeding the figure obtained the previous year by his predecessor Lawrence Sparey. It's highly probable that the use of the manufacturer's recommended fuel mixture containing 22% nitromethane would have improved these figures substantially. Althought at the time the 2.5 cc displacement category had yet to achieve World Championship status in the control line speed arena (see below), the engine did see service in international free flight power competition. At the 1952 World Free Flight Power Championships held at Dubendorf Aerodrome in Switzerland, contestants using this engine finished 3rd, 8th and 16th - a very good result.

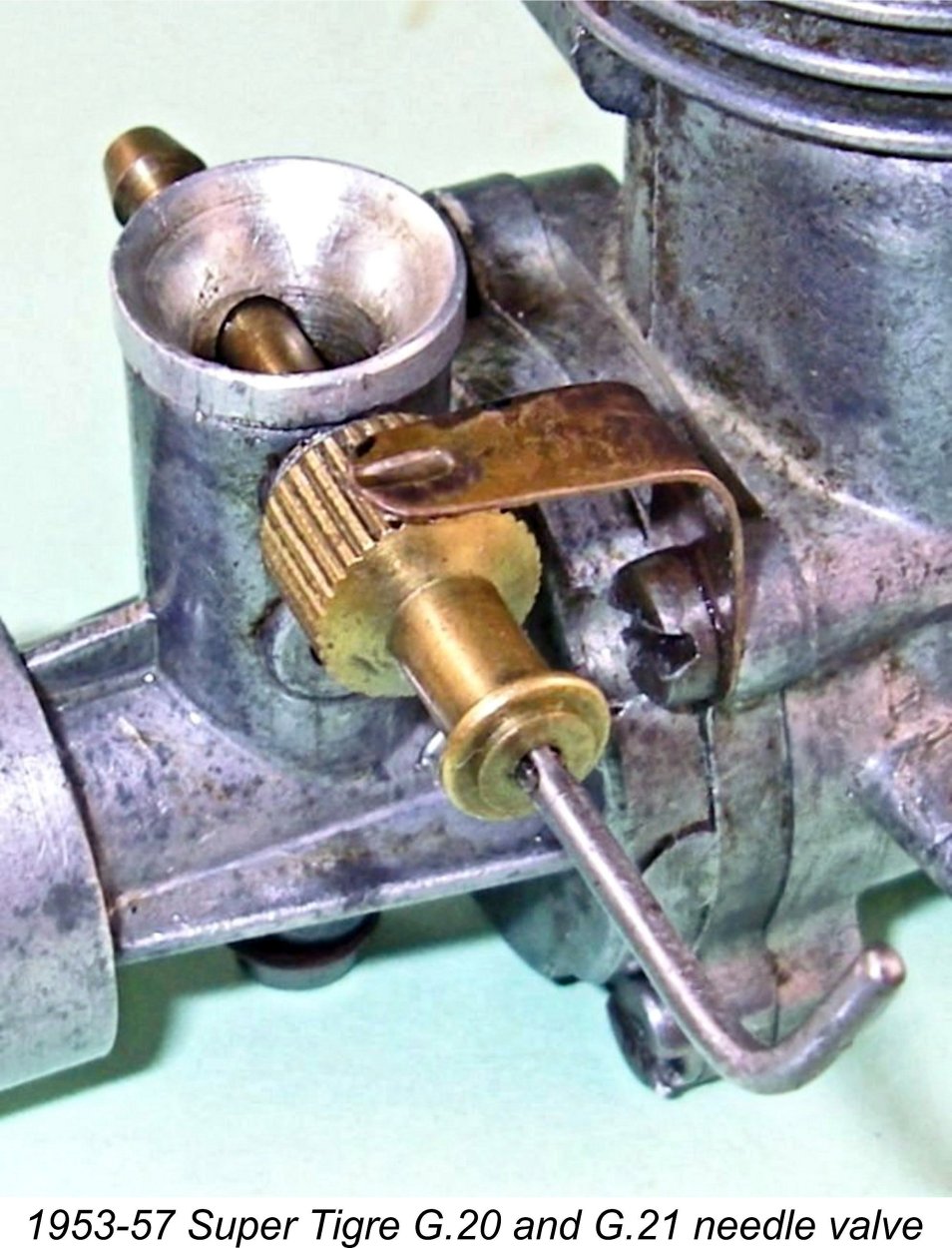

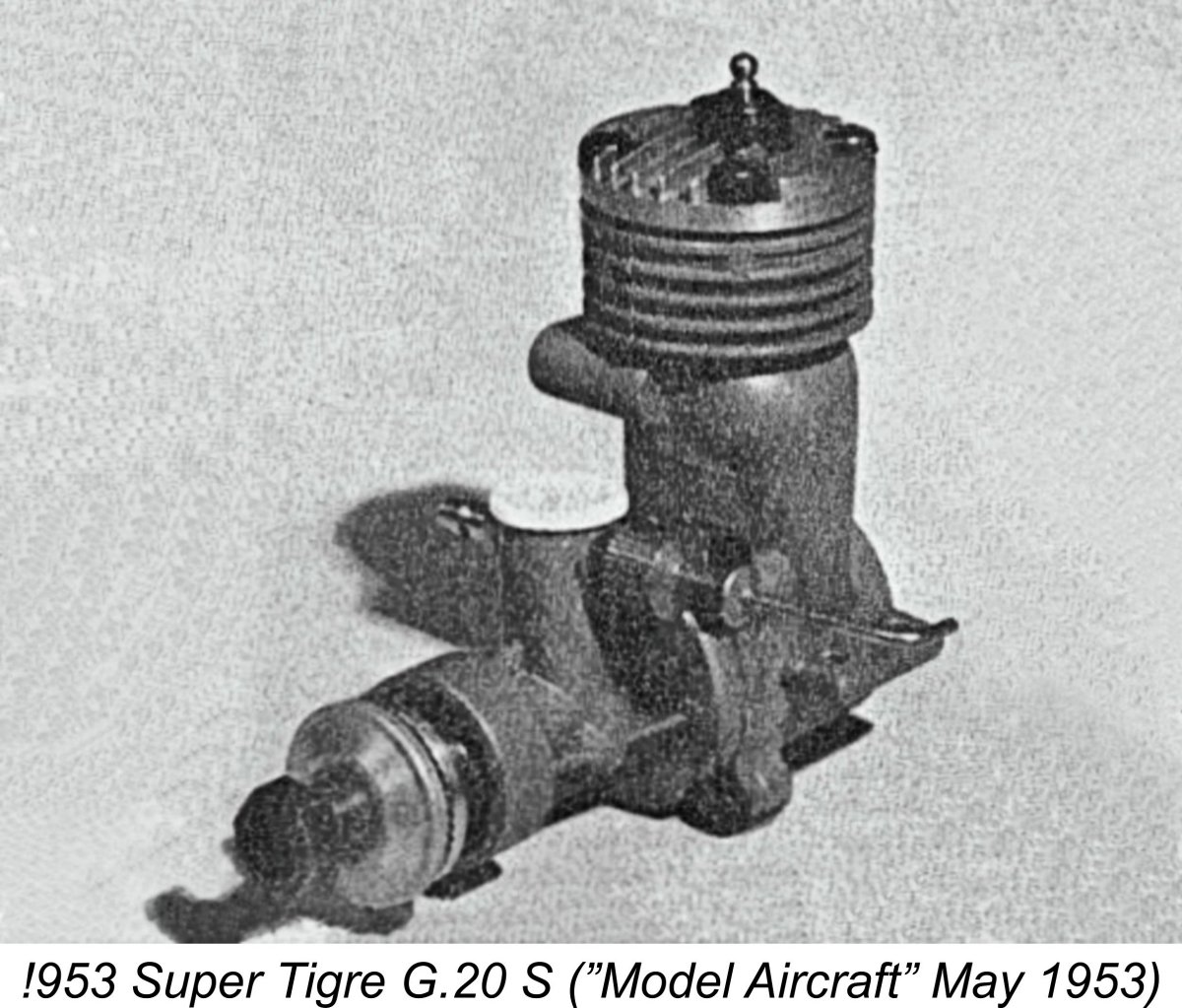

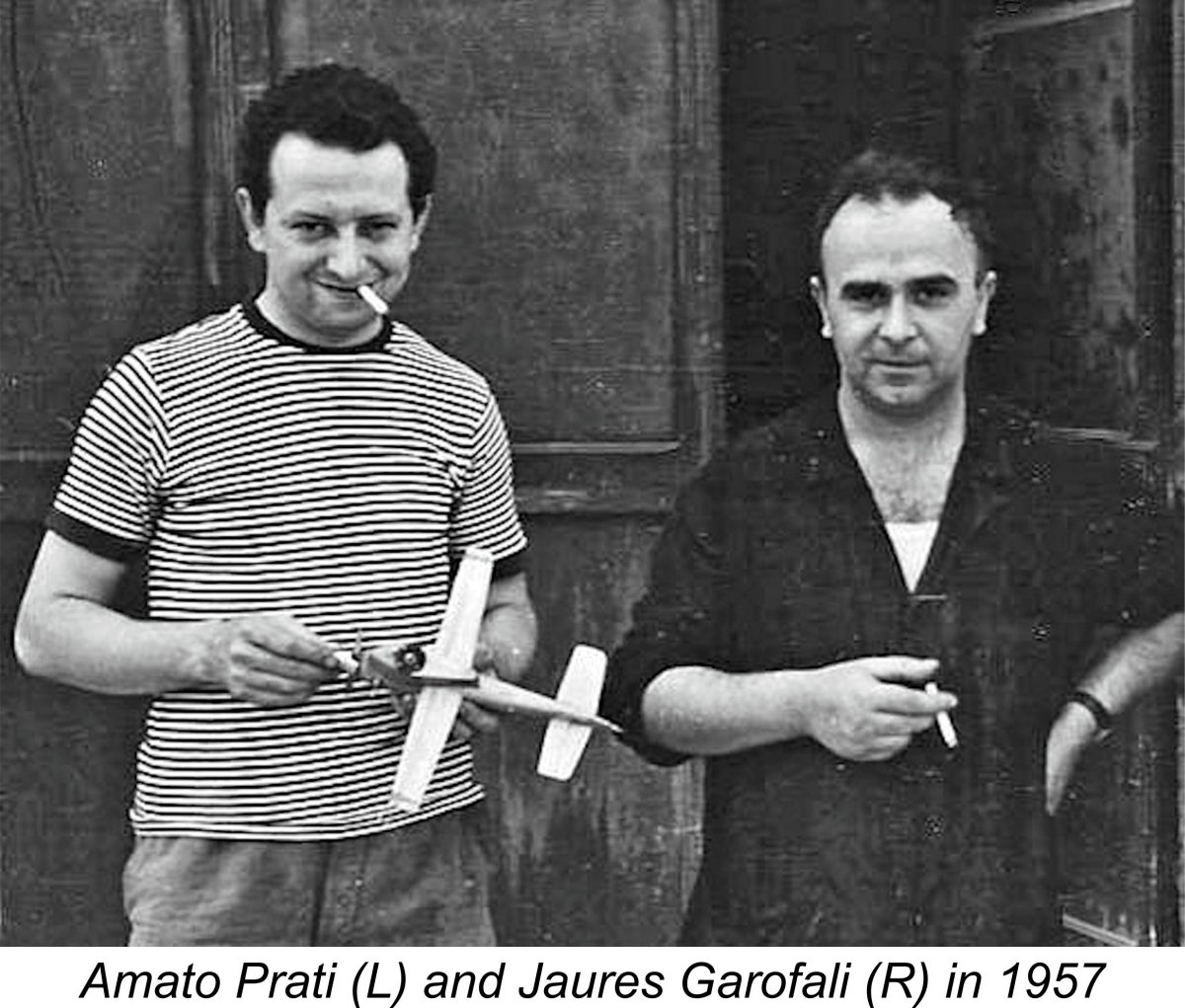

A revised needle valve was also introduced at this time. The component used formerly had featured a conventional split thinble which was machined from hexagonal bar stock. This had evidently been found wanting, leading to the introduction of Garofali's highly individualistic thimble design having a large-diameter serrated barrel which was tensioned by a bronze leaf spring secured using one of the four front housing attachment screws. The thimble was internally threaded to match the spraybar, while the inner end of the barrel was recessed to clear the spraybar installation nut. Extremely neat, and it worked very well indeed. This assembly was used on both the G.20 and the companion G.21 glow-plug models for the next four years. The 1953 “Speed” variant of the G.20 was the subject of a test by Peter Chinn which appeared in the May 1953 issue of “Model Aircraft”. Chinn praised the quality of the engine’s construction very highly, characterizing the Chinn found the engine to be easy to start and adjust, with excellent running qualities. Using a fuel containing 25% nitromethane, he reported a peak output of 0.25 BHP @ 15,200 RPM, somewhat shy of the manufacturer’s claim of 0.29 BHP @ 16,500 RPM but certainly consistent with Ron Warring’s earlier findings. He summarized the engine as being “the fastest 2.5 cc engine yet tested”. To underscore this comment, Amato Prati of Bologna used one of these engines later in 1953 to establish a new Italian national 2.5 cc speed record of 161 km/hr (100.04 mph). In 1954, Jaures Garofali introduced a further modified version of the G.20 S which utilized a lapped cast iron baffle piston in place of the ringed light alloy component used up to that point. This was known as the Super Tigre G.20 S "Lappato". The result was a considerable performance improvement. Amato Prati used a stock example of the new lapped piston variant in his “Speed King” model to record a speed of 190.47 km/h (118.36 mph) at the 1954 Giornate Aeromodellistiche Ambrosiane meeting held in Milan, thus establishing a new FAI World Speed Record for the 2.5 cc class.

Having followed the development of the G.20 up to 1954, it’s now necessary to leave that model for a while and backtrack to 1951. The early success of the G.20 encouraged Garofali to develop what amounted to a 5 cc version of the same engine. This appeared in 1951 in the form of the Super Tigre G.21 glow-plug model, which replaced the old G.19 B design.

Unfortunately for Garofali, there was a significant difference in terms of the respective levels of competition which the G.20 and G.21 faced, at least at the outset. Until the mid 1950’s, the G.20 faced very little serious competition from other commercial producers of 2.5 cc competition engines. By contrast, the G.21 faced very stiff competition from the outset, having to compete with such established powerhouses as the Dooling and McCoy 29’s from America as well as the ever-improving ETA 29 from England. These were joined in 1954 by the excellent Micron 5 cc racing model from France. Despite this, the G.21 was a fine performer which achieved some notable results. In various forms, it was destined to continue in production for many years. The perceived importance of the 5 cc category at this time largely stemmed from the fact that this class was very prominent in the National competitions of many nations, including Italy, both in control-line and Open Power F/F categories. In addition, many International contests were still being run with a strong focus on this displacement class. The FAI had yet to adopt the 2.5 cc category as its standard for International competition. Indeed, the speed events at the prestigious International meeting held in 1950 at Knokke, Belgium had not even included a 2.5 cc category.

The 1952 World Championships were held at Brussels, again in Belgium. The same three classes were again offered, the winners being Britain’s Pete Wright in the 2.5 cc category at a speed of 158.590 km/hr (98.54 mph), using a modified example of the then relatively new E.D. 2.46 Mk. III “Racer” in glow-plug form, and Dr. Millet of France in the 5 cc class at a speed of 198.395 km/hr (123.28 mph), with Pete Wright a close second. Again, the Italians did not send an official team, although they were represented by a couple of individual entries in the 2.5 cc and 10 cc categories. Garlato of Italy finished fifth in the 2.5 cc class using his G.20 S to achieve a speed of 129.963 km/hr (80.76 mph), while Italy’s Guido Battistella of Venice won the 10 cc category outright with a speed of 233.766 km/hr (145.26 mph) using a Dooling 61, thus proving that Italy had some speed fliers of real talent. For 1953, a decision was taken that the control-line speed World Championships would be restricted to a single displacement category. Inexplicably, the 1953 Championship meeting which was held in Milan, Italy over the June 12th – 14th period was restricted to the least well-supported class, the 10 cc category. Consequently, only Britain, France and Sweden sent representatives to compete against the powerful Italian team.

However, the established engines still ruled the roost. Overall winner Battistella once again used his trusty Dooling 6l to achieve a winning speed of 250.000 km/hr (155.35 mph), narrowly beating Britain’s Ray Davenport‘s second-place mark of 244.897 km/hr (152.18 mph) using a Dooling-based Carter Special. Davenport evidently had an “off-day”, since he had previously recorded a speed of 255.412 km/hr (158.71 mph) at the 1953 British Nationals, which would have secured him a comfortable win at Milan. Enrico Fanoli finished third using a McCoy 60 Series 20, while Fiorini came in fourth with his G.24, returning a very creditable speed of 233.766 km/hr (145.26 mph) which equalled the previous year’s winning mark. Fiorini actually tied with third place Fanoli’s best speed but was relegated to fourth courtesy of a lower average for all attempts. Still, a very promising debut for the new model.

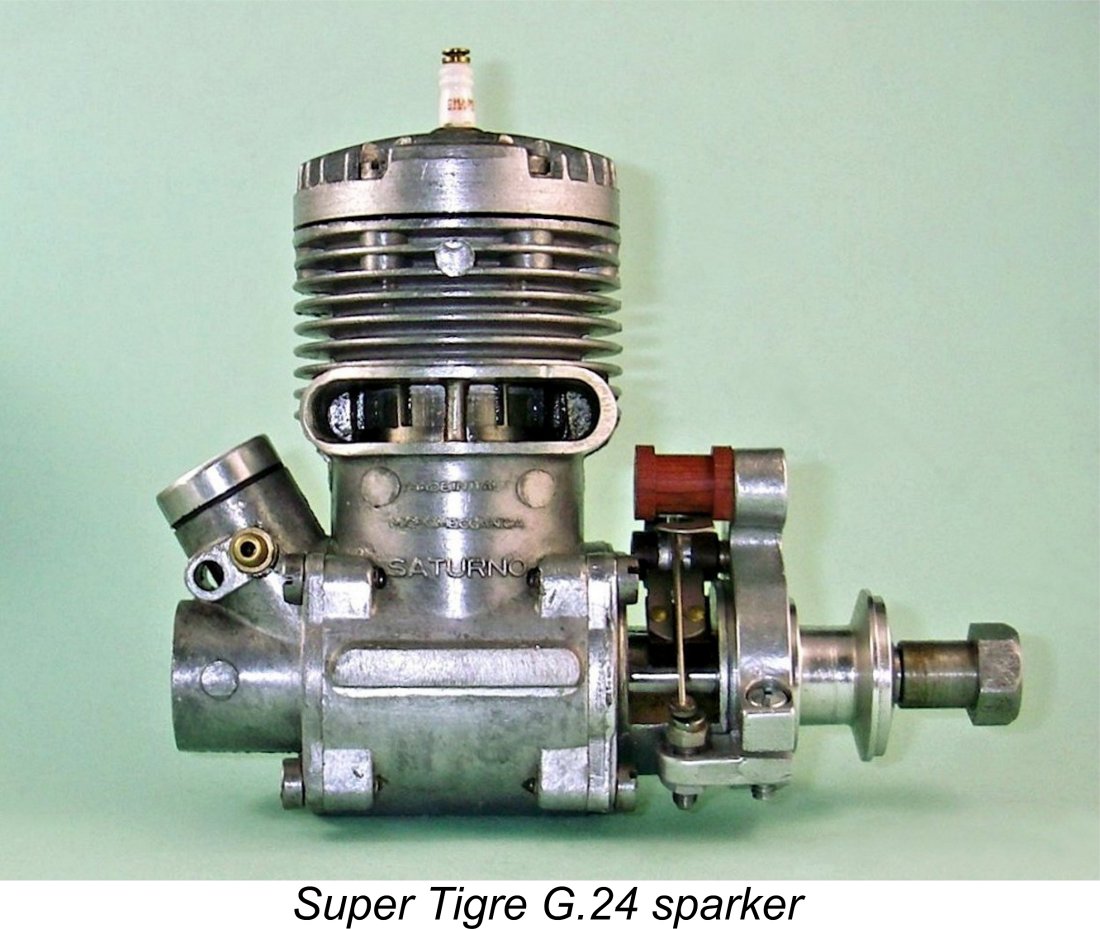

Since there was still some residual debate regarding the relative merits of glow-plug and spark ignition for large racing engines, the G.24 was made available in both forms. The illustration of the spark ignition version seen on page 179 of Mike Clanford’s previously-referenced book is incorrectly dated 1948. This engine was aimed squarely at the tether car, tethered hydroplane and control line speed fields, all of which were specialist markets which did not represent large sales potentials. The engine attracted a group of loyal adherents in Italy, hence remaining in limited production for some years, but it never had the opportunity to duplicate the fame and ongoing success of its smaller brother, the G.20, or even the 5 cc G.21. Consequently, it never achieved much prominence in the international marketplace. It is a very rare engine today.

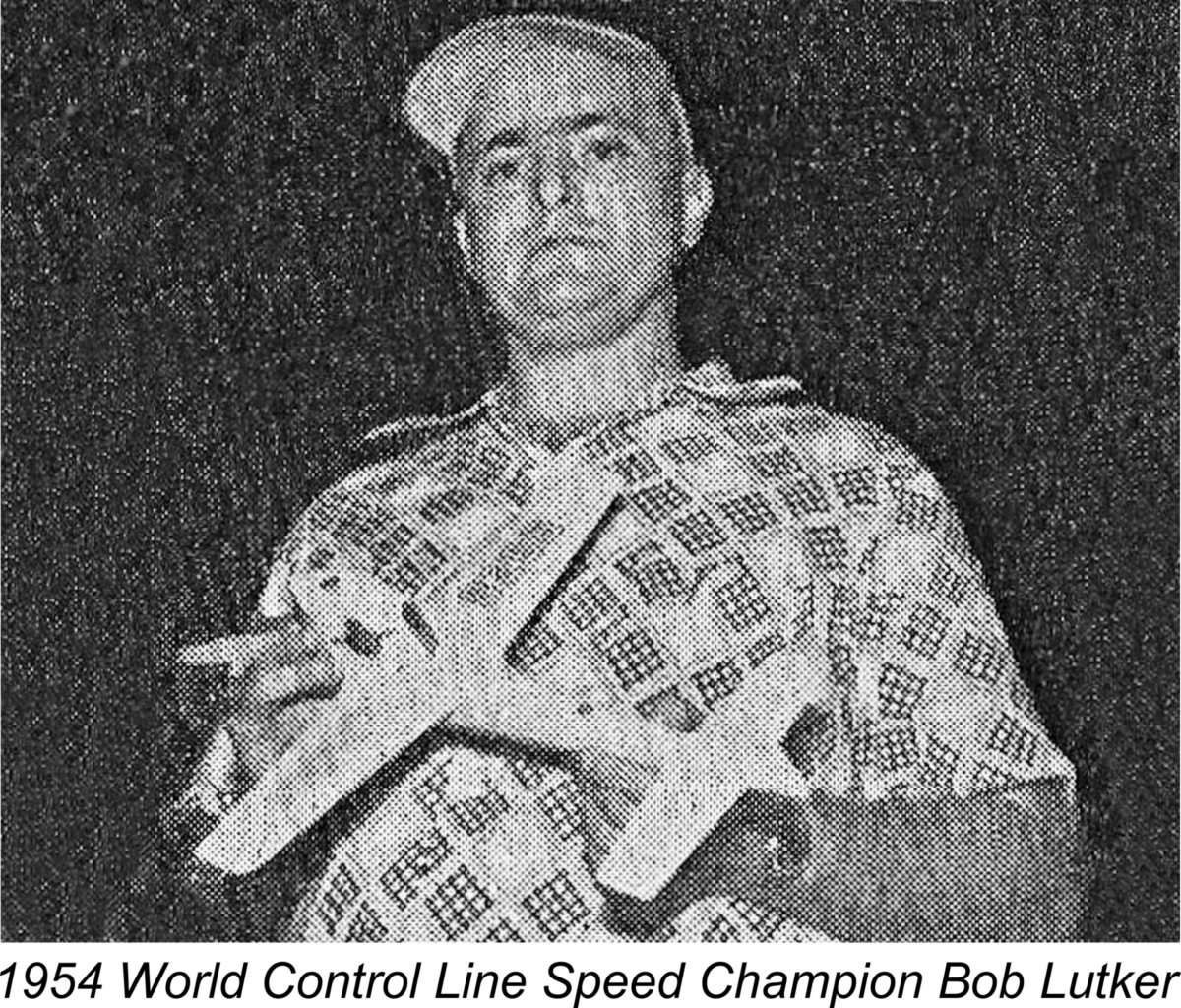

However, an American contestant did show up this time, and to very good effect. The 5 cc World Championship class was won by Bob Lutker of Texas using a Dooling 29 to record a speed of 221.92 km/hr (137.90 mph). Pete Wright had to content himself with sixth place this time out with a speed of 200.03 km/hr (124.30 mph). He did however win the non-championship 2.5 cc class with a remarkable speed of 179.92 km/hr (111.80 mph), amazingly enough still using his well-tried E.D. 2.46 cc Mk. III Racer glow-plug powerplant. For context, this would have been just good enough to win the overall title at the following year's event in Paris (see below). Although not directly related to our main thread, it's worth mentioning that Bob Lutker also competed in the Control Line Stunt World Championship event at the same meeting, finishing second by only three points (1279-1276) behind the winner, Henri Stouffs of Belgium. A remarkable achievement by a great all-rounder! By the time 1955 came around, Signor Garofali had had enough of seeing his engines relegated to the sidelines while other makes dominated the winner's circle - he wanted to see Super Tigre sitting comfortably at the top of the heap! The FAI had finally decided that beginning in 1955 the World Championship for control-line speed would thenceforth be contested in the 2.5 cc displacement category. Here at last was a chance to show the world what the Super-Tigre G.20 S could do! Garofali set to work to improve the G.20 S as much as possible in anticipation of the forthcoming opportunity to display its merits to the modelling world.

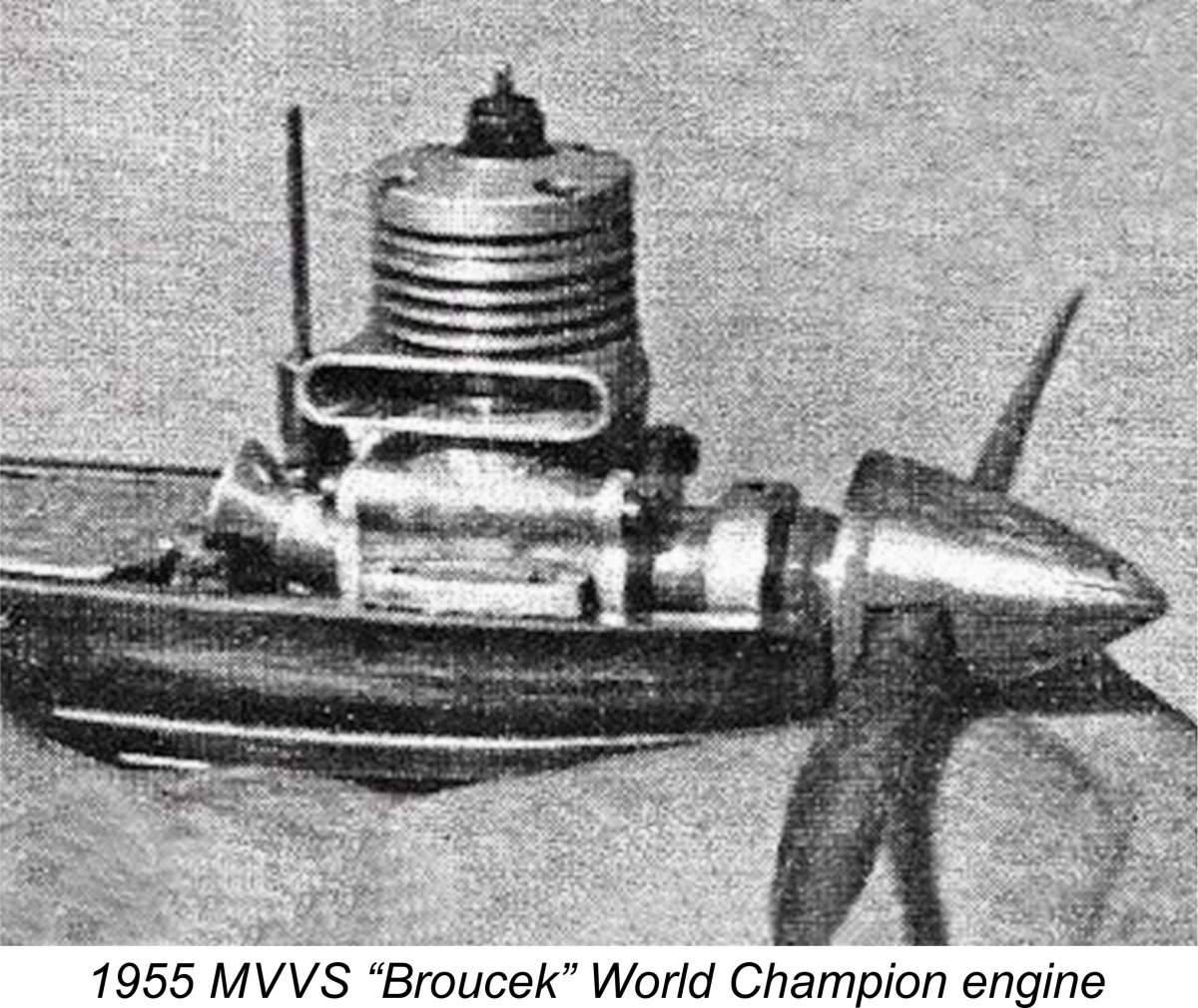

The first World Championship event to be run under the new displacement rule took place on July 2nd - 3rd, 1955, at Croix-de-Berny, a few miles south of Paris, France. Garofali was instrumental in ensuring that a strong Italian team equipped with well-prepared examples of the latest Super Tigre G.20 S lapped-piston powerplants appeared at this meeting. Among other improvements, these 1955 engines featured revised cylinder heads (still retaining the offset plug location), along with a re-designed piston and rod. The new piston featured a large skirt port on the bypass side which registered at bottom dead centre with a matching port cut through the lower cylinder wall. This improved gas access to the bypass while also improving piston cooling and reducing reciprocating weight. The intake stub on the front housing now sported twin sets of transverse holes, one above the other, to allow for the fitting of either a conventional spraybar (as commercially supplied) or a two-piece racing-style setup with a separate surface jet and needle carrier threaded into opposite sides of a matching alloy venturi insert. Alternative venturi inserts were available to suit the two systems. The inserts were now made from aluminium alloy - the former plastic items were no longer used. This 1955 variant was later the subject of yet another published test, this time by Peter Chinn, whose report appeared rather belatedly in the March 1956 issue of "Model Aircraft" after this version had already been supplanted by the following design variant to be described below. Using the spraybar needle valve assembly along with a fuel containing 25% nitromethane, Chinn measured a peak output of 0.28 BHP @ 16,000 RPM - an outstanding performance for a commercial 2.5 cc glow-plug motor by the standards of 1955. The use of the two-piece racing needle valve and intake venturi (as likely employed at the Paris meeting) would doubtless have raised these figures considerably. Chinn also praised the engine's handling as well as its quality of construction. As events transpired, the hopes of the Italians for a clean sweep at the 1955 Paris meeting using this engine were derailed by the fact that this event coincided with the emergence of a new threat from the other side of the Iron Curtain. In October 1953 the Czech authorities had established an organization called the Modelářského Výzkumného a Vývojového Střediska (Modelling Research & Development Centre), better known by its initials of MVVS. The early history of the MVVS organization has been recounted in detail elsewhere. This organization was tasked with developing a series of individually-built specials which would power Iron Curtain modellers to International success, thus showcasing the technical capabilities of the Communist regime. The Centre had focused its initial efforts upon the 5 cc class, but the announcement of the switch to the 2.5 cc category for 1955 soon changed that. The Czech team showed up at Paris with a number of individually-constructed 2.5 cc powerplants which had emerged from the MVVS workshops in Brno.

Sladký’s success signalled the beginning of what might be termed the “works team” or “special” era in international control-line speed. Thenceforth there were in effect two distinct tiers of competitors – those using well-prepared examples of commercially-available engines and those using non-commercial individually-made “specials”. Events were to prove that the “specials” generally ruled the roost, with the commercial engines competing in what amounted to a separate category. As a commercial manufacturer having his eye upon the international market, Garofali naturally remained true to the second category, choosing to compete using individually-prepared examples of his own commercial products.

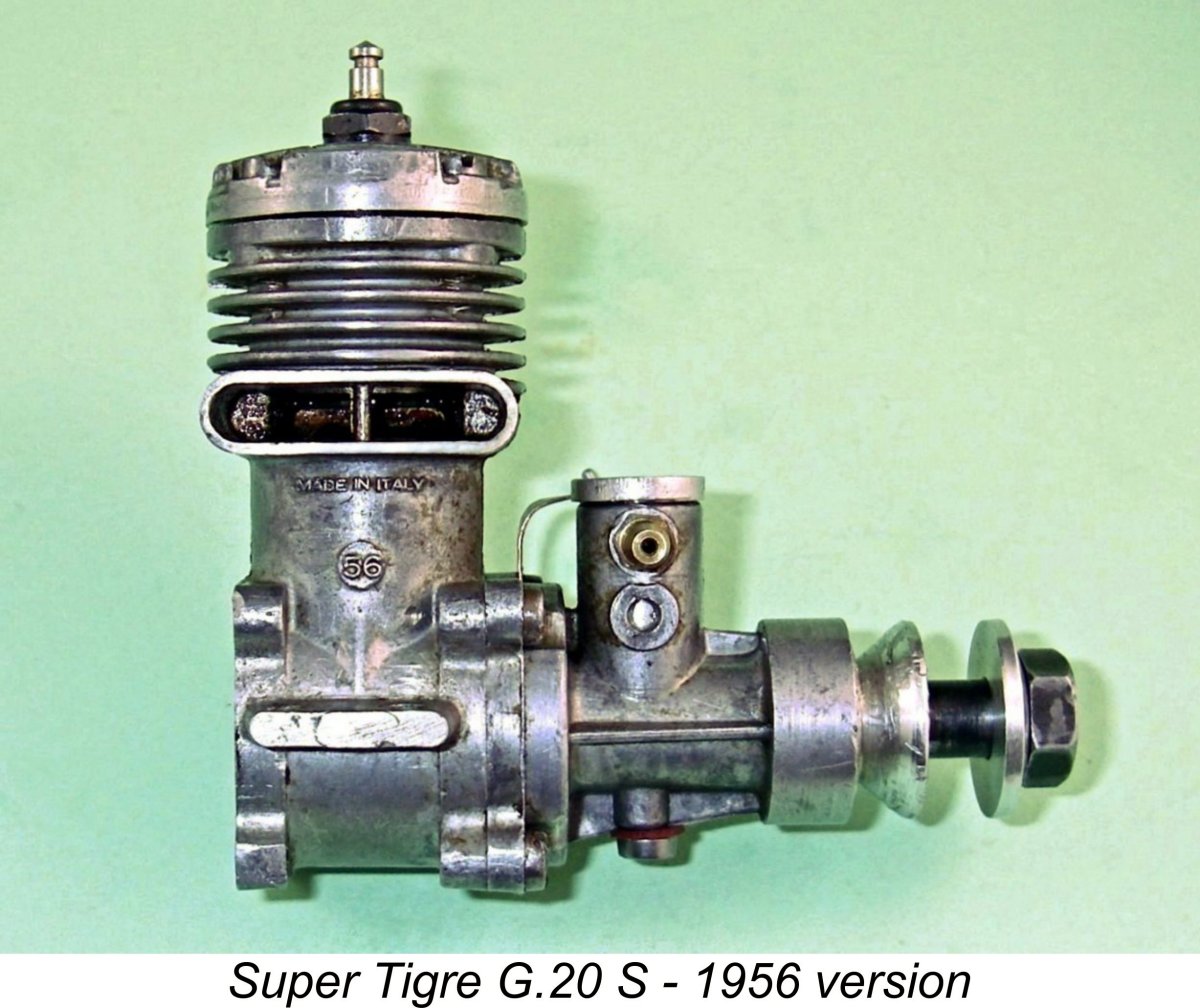

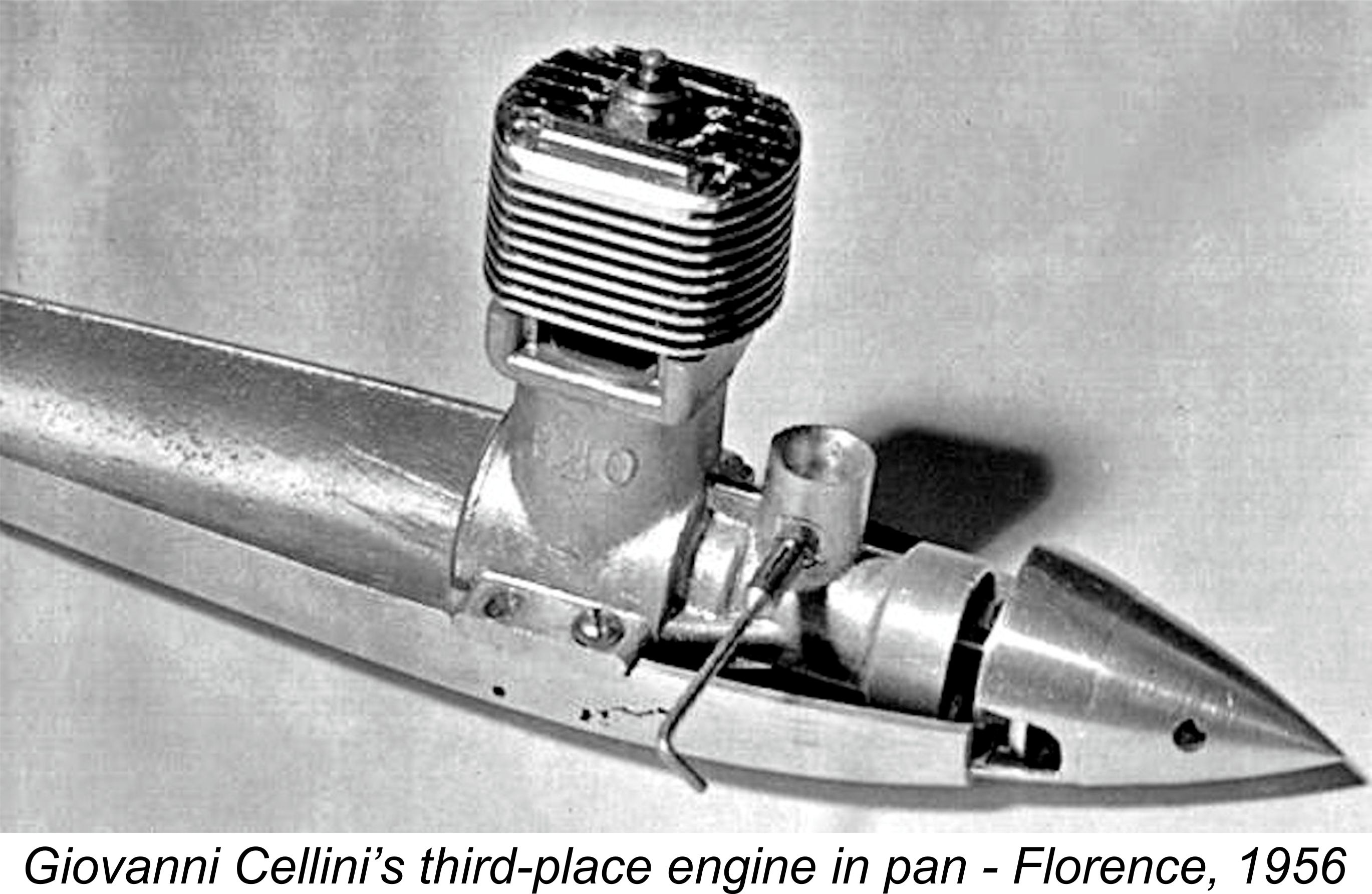

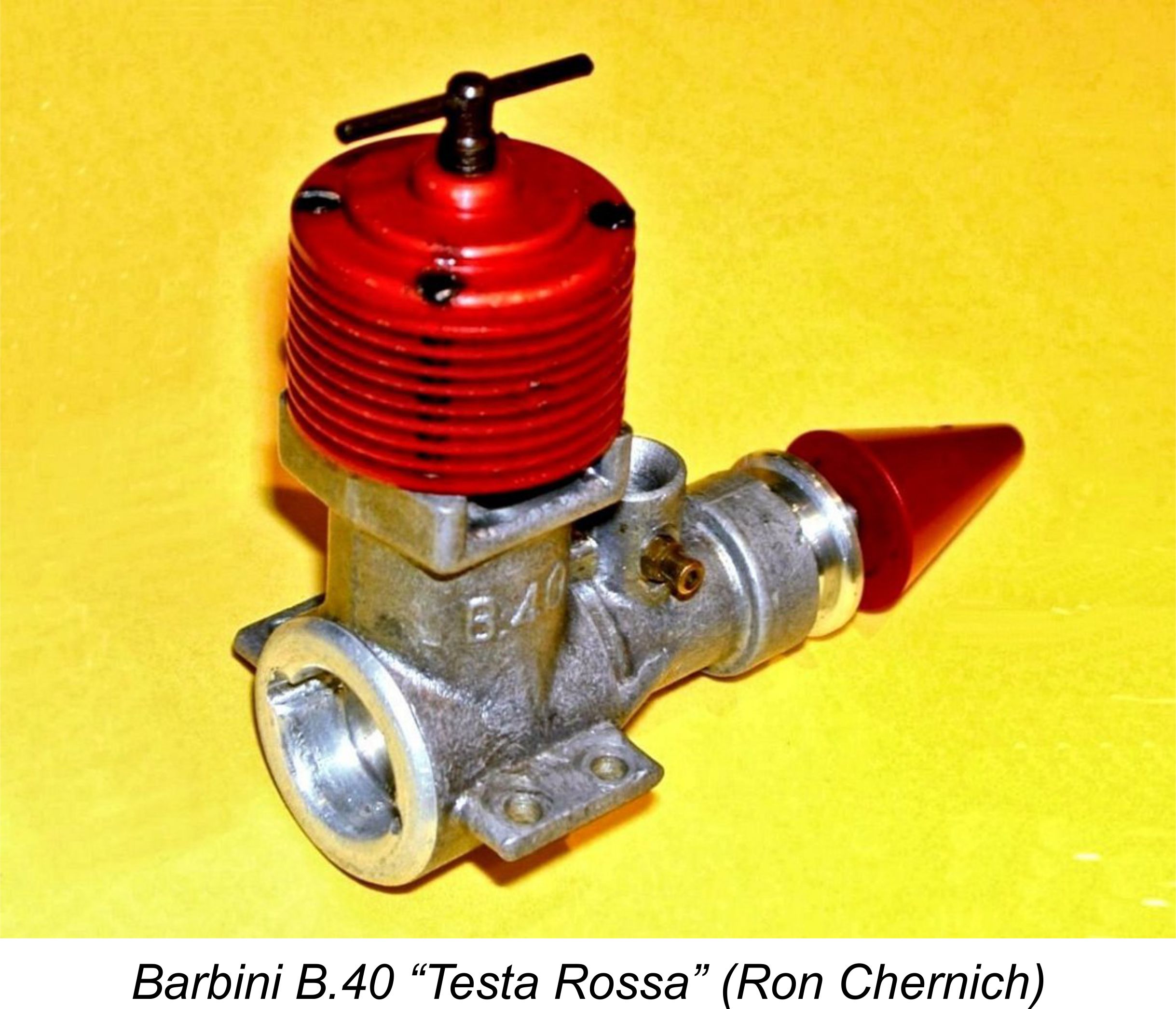

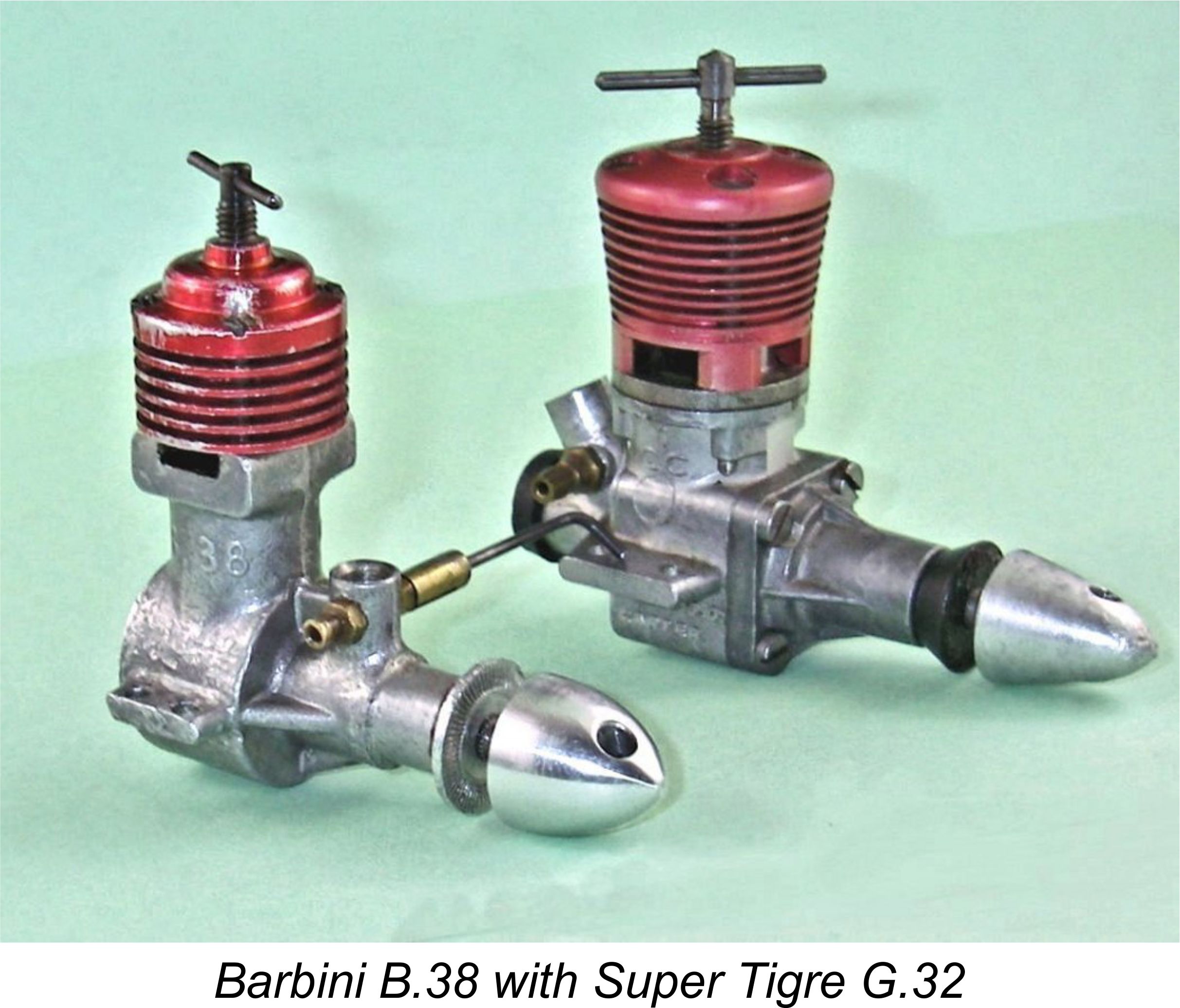

Barbini too saw the upcoming Florence meeting as a perfect opportunity to display the merits of the Barbini engines before both the Italian modelling public and the international audience. Working with an up-and-coming young Italian speed flier name Giovanni Cellini, he immediately began preparing and testing engines to be used at the contest. It’s worth noting at this point that the Barbini B.40 TN was one of only two then-current competition glow-plug engines (the other being the Webra 2.5R) which retained reverse-flow scavenging. The Barbini compounded this by also featuring long-stroke internal geometry. By this time all of the other front-running high performance glow-plug motors such as the Super Tigre and MVVS models were short-stroke designs which used the cross-flow loop scavenging arrangement pioneered in the USA during the 1940’s. Viewed in this light, Barbini’s competitors such as Jaures Garofali and the MVVS squad must have anticipated little threat from this “old fashioned” design. How wrong they were soon proved to be ……….. Whatever his views of the Barbini "threat", there could have been no doubt in Garofali's mind that he would face stiff opposition from the still-evolving tool-room specials from Czechoslovakia (as it was then) and elsewhere. Accordingly, for 1956 Garofali produced a further-improved version of the G.20 S. This updated model appeared around the same time as Peter Chinn's March 1956 published test of the earlier 1955 model.

The year of introduction of the revised case was clearly indicated by the numbers "56" cast in relief onto the right hand side of the upper crankcase below the exhaust stack, as seen in the accompanying illustration. The revised model retained the unique needle valve assembly which had been introduced in 1953. Tthe offset location of the plug towards the bypass side was maintained, along with the seemingly vulnerable mounting lugs. The new model also retained the lapped skirt-ported piston of its predecessor. However, many internal changes were incorporated. This new model was not long in proving its worth for all to see. At the 1956 Criterium of Europe meeting at Brussels, Belgium, held on April 30th - May 1st, which was in effect a tune-up for the later World Championship meeting, J. Battlo of Spain used his new 1956 G.20 S to achieve a speed of 202.0 km/hr (125.5 mph) to narrowly defeat Britain's future World Champion Ray "Gadget" Gibbs and his Carter-powered Nipper. And there was even more to come - on May 20th, 1956, another well-known Italian speed flier, A. Marconi, used one of these engines in his “Tajavento” (Wind Cutter) model to achieve the then-remarkable speed of 215.56 km/h (133.95 mph), which established yet another 2.5 cc FAI World Speed Record. Things were looking really good for that autumn World Championship meeting in Florence - based on its early competition successes, the revised design evidently represented real progress compared with its 1955 predecessor!

Given the attainment of such levels of performance, hopes must have run high for a good result at Florence. However, things did not go Garofali’s way at all at the meeting. Using a well-prepared but surprisingly close-to-stock Barbini B.40 TN, Giovanni Barbini’s colleague Giovanni Cellini finished in third place with a speed of exactly 200 km/hr (124.28 mph), beating all of the fancied Super Tigre and MVVS entries. Only the two one-off toolroom “specials” of Miclos Vitkovics of Hungary (BRMV Special) and Ray “Gadget” Gibbs of England (Carter Special) achieved higher speeds, with Gibbs winning at a speed of 211 km/hr (131.11 mph). At the same meeting, Gibbs subsequently established a new 2.5 cc World Record at a speed of 225 km/hr (139.81 mph) using thinner lines than those permitted in FAI competition, thus rubbing salt in the wound by eclipsing Marconi's previously-noted Super Tigre mark from earlier in the year.

The best Super Tigre-powered Italian team speed was Amato Prati’s sixth place mark of 194 km/hr (120.55 mph) using a well tweaked 1956 Super Tigre G.20 S. It is to be doubted that Jaures Garofali viewed this result in a positive light! However, Garofali could take some comfort from the fact that no fewer than 12 entrants out of a total of 28 were using Super Tigre G.20 powerplants at this meeting. This certainly underscored the international reputation and consequent popularity which the engine had attained. It was undoubtedly the most powerful 2.5 cc racing glow-plug unit then available to the general public. While all of this development of the G.20 had been taking place in the context of what was now the World Championship 2.5 cc class, its larger 5 cc G.21 companion had been quietly soldiering on. Although now out of the World Championship limelight, the G.21 had continued to enjoy considerable success in Area and National speed and open F/F power competitions, hence acquiring a high degree of popularity in its own right.

This variant utilized the same crankcase as the contemporary 1956 version of the 4.82 cc G.21, having an integrally-cast backplate with four "eyes" at the corners. However, it featured a new bolt-on front end with a bronze bushing taking the place of the former twin ball-races. In addition, the intake was now angled forward instead of being dead vertical. The lapped piston was retained in this variant. This model represented the first “crack in the wall” with respect to the Super Tigre model identification system. The ongoing use of the G.21 crankcase casting with its cast-on identification ensured that the G.21 name would continue. However, this model was aimed squarely at the emerging international market for control-line stunt engines in the .35 cuin. category, hence having the 35 suffix attached to its name. As time passed, this was to become an increasingly common form of Super Tigre identification, doubtless in large part to deal with the confusion which the former system had created in market areas such as America whose participants were accustomed to engines being identified by their displacements in cubic inches. To them, a G.21 was a 3.45 cc engine! The G.21/35 enjoyed the distinction of being the first stunt glow-plug model of its displacement to be marketed by a European manufacturer. Although according to Peter Chinn it was a somewhat less than stellar performer, it proved to be quite popular, being revised in 1957 by increasing its bore to 20.0 mm for a slightly increased displacement of 5.65 cc (0.345 cuin.), thus approaching its designated displacement. The 5 cc G.21 racing model continued unaltered at this point in time.

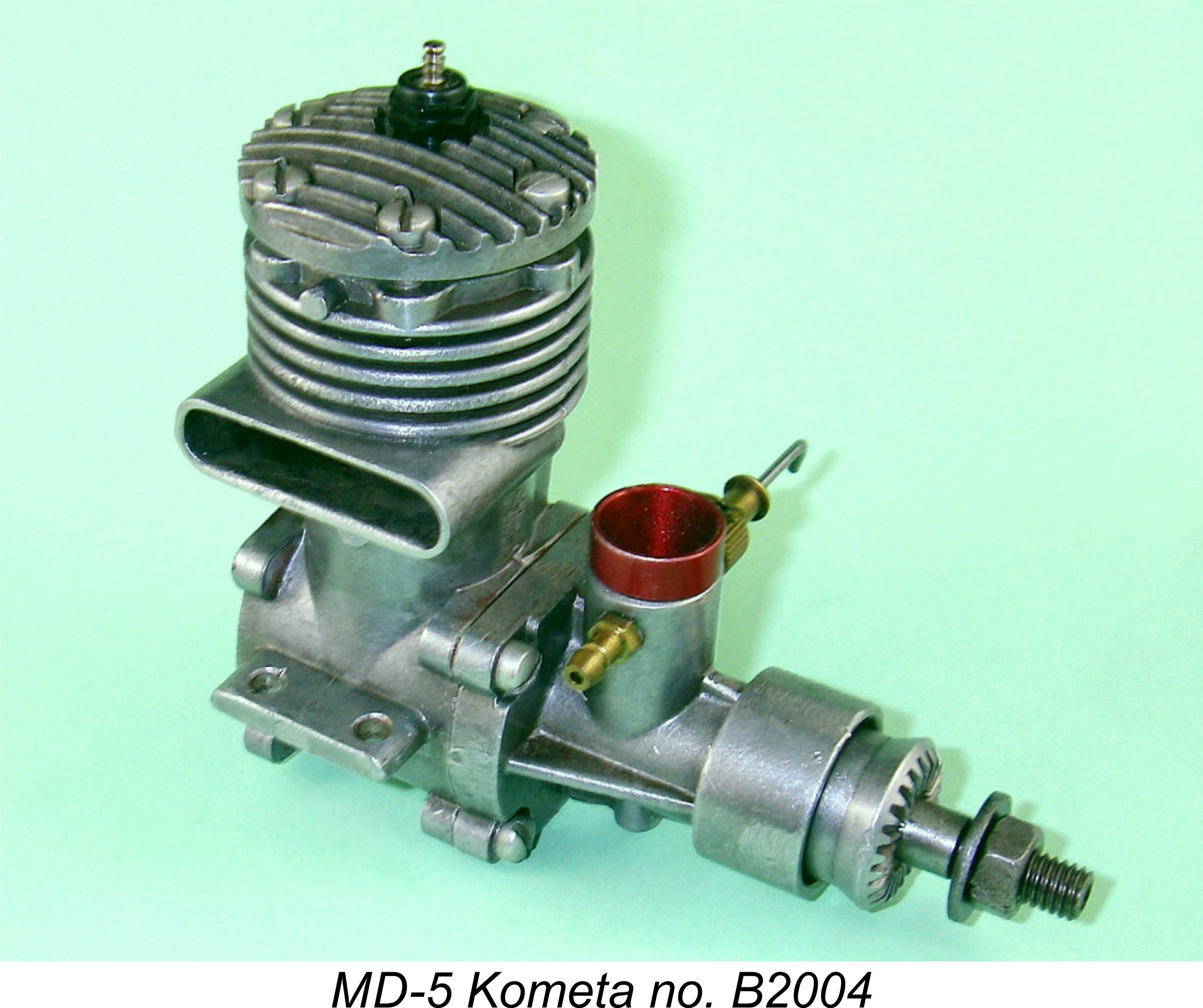

Interestingly enough, the Kometa was a copy of the original G.21 with integral backplate and ringed light alloy piston, although it did feature the "eyes" at the corners of the backplate which had been introduced by Super Tigre in 1956. As we saw earlier, Super Tigre had gone to a lapped piston for this model as early as 1954. Presumably the Russians had only an example of the earlier model to guide them, so that was what they copied. A lapped piston version of the Kometa was produced much later along with a diesel version. However, the engine never lost its integrally-cast backplate. In various forms, it remained in production up to the early 1990's, thus enjoying a 35 year production run. Meanwhile back in Italy, Jaures Garofali had by no means forgotten his drubbing in the 1956 World Speed Championships! He clearly possessed more than his share of Italian technical competitiveness, hence being unwilling to take this lying down. Work was immediately put in hand to develop a significantly further improved version of the G.20, which appeared in 1957 as the Super Tigre G.20 V in time to compete at the 1957 World Championship meeting held in August at Mlada Boleslav, a small town in Czechoslovakia (now the Czech Republic) located some 57 kilometres from Prague in MVVS’s back yard.

For the first time since the G.20 series had been introduced, the plug was centrally located instead of being displaced to the bypass side as in all former models. Compression ratio was unchanged at 8:1. A revised needle valve giving more precise mixture control was incorporated as well, using an externally threaded needle with a split internally-threaded spraybar and gland nut for tension. In addition, a number of internal improvements were also featured. My own test of an example of this model showed a peak output of 0.415 BHP @ 17,000 RPM using a fuel containing 30% nitromethane. This was more or less identical to the performance which I measured for the earlier G.20 S model of 1956, although my example of that model was undoubtedly better freed-up and may have been internally tweaked in addition. Still, the G.20 V was clearly a very sturdy performer. One structural feature to note if you ever have to dismantle the carburettor assembly on one of these engines is the fact that the spraybar is threaded into the venturi insert body on the needle side. People have been fooled by this into thinking that the spraybar was merely stuck in there by congealed castor oil residues. Not so - it has to be unscrewed from the fuel supply side. Attempts to push it out can potentially lead to damage being done. A set of parallel changes were also made to the companion 5 cc G.21 model at the same time to produce the G.21 V. The "V" in the designations of these engines reportedly stood for Super Tigre's "Victory Series" - a clear indication of expectations! Garofali showed up at the 1957 meeting along with the ever-faithful Amato Prati, who had both his own G.20 V powered model and a similarly-powered model which he flew proxy for Paolo Berselli. Giovanni Barbini was unable to attend personally, but once again sent Giovanni Cellini to uphold the honour of the B.40 TN, also supplying engines to both Renzo Grandesso of the official Italian team and England’s Pete Wright. Once again, things did not go as well as hoped for the Super Tigre squad. The Czechs and Hungarians filled the first five places with their MVVS and Alag tool-room specials, while the top “commercial” engine was once again the pesky Barbini B.40 TN, this time in the hands of Renzo Grandesso, who finished sixth as the highest-placed Italian team member with a very creditable speed of 206 km/hr (128 mph). However, using a prototype of the MVVS 2.5R-58, Josef Sladký achieved a winning speed of 216 km/hr (134.2 mph). This not only beat out Grandesso's Barbini but also totally eclipsed the best Super Tigre G.20 V speed of 198 km/hr (123 mph) which gave eighth place to the ever-persistent but doubtless frustrated Amato Prati. Paolo Berselli’s proxy-flown model came in just behind Prati with an almost identical speed. The feelings of Jaures Garofali at this point can best be imagined …………… it appeared that the new Super Tigre model had not advanced the cause at all.

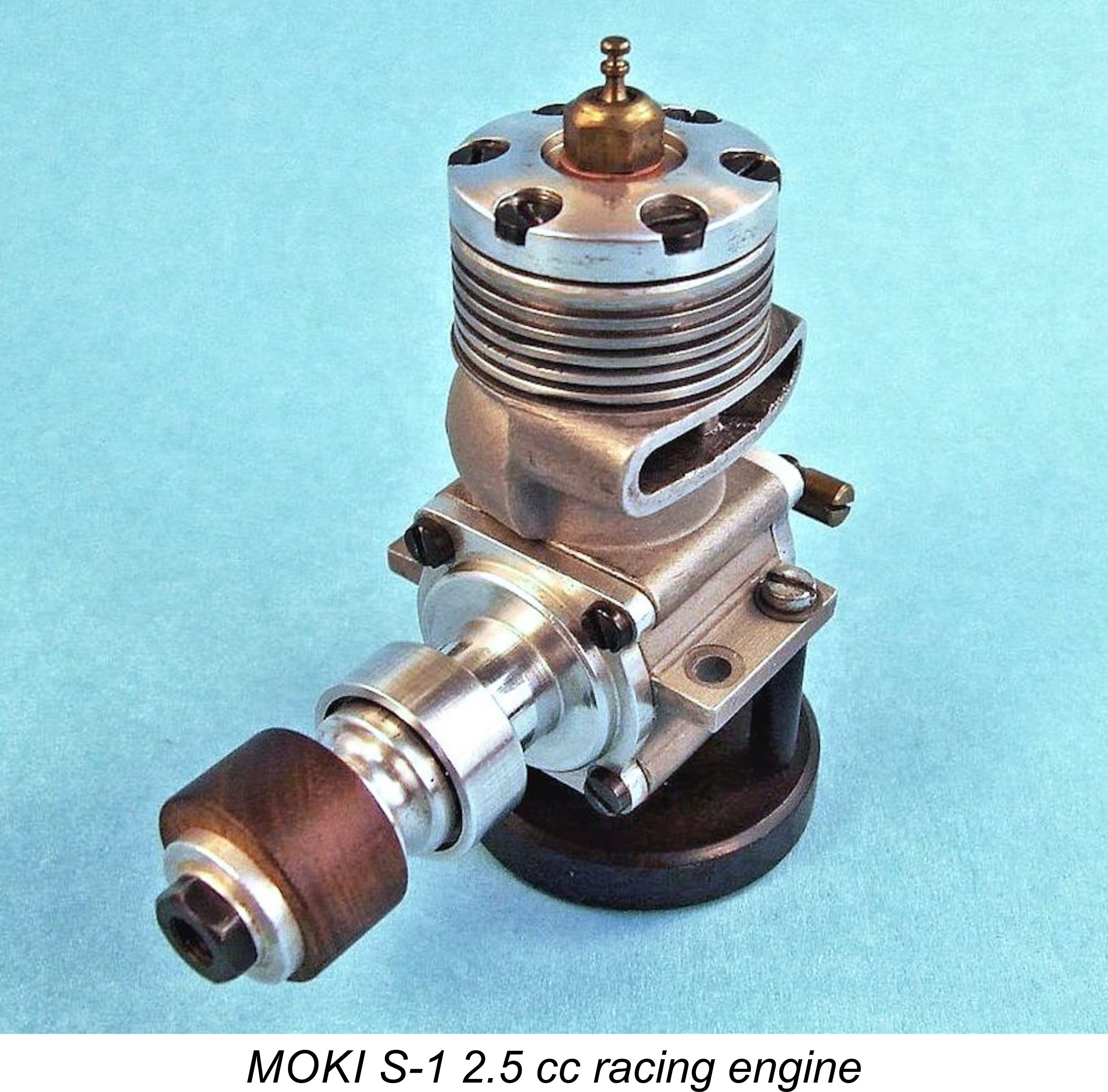

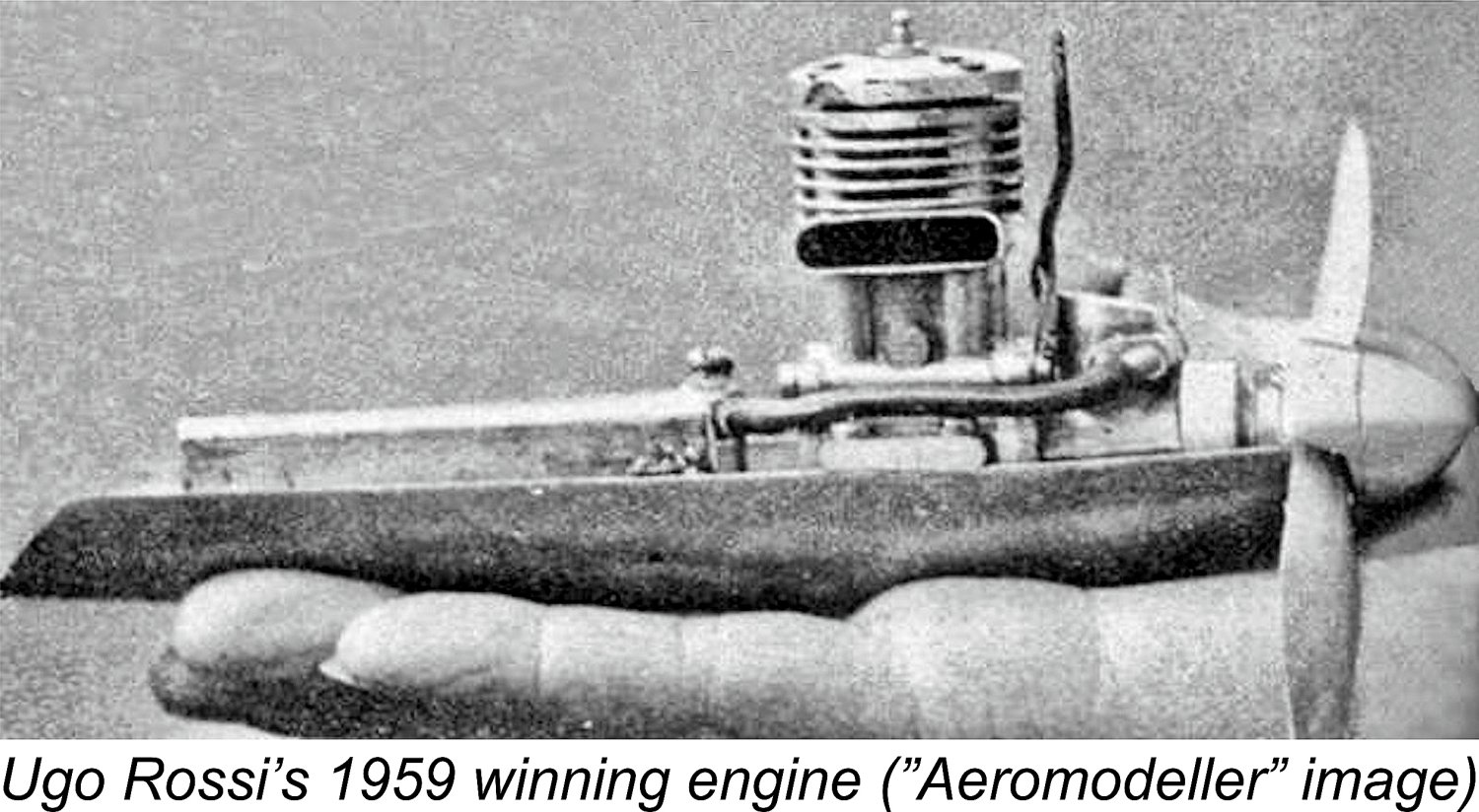

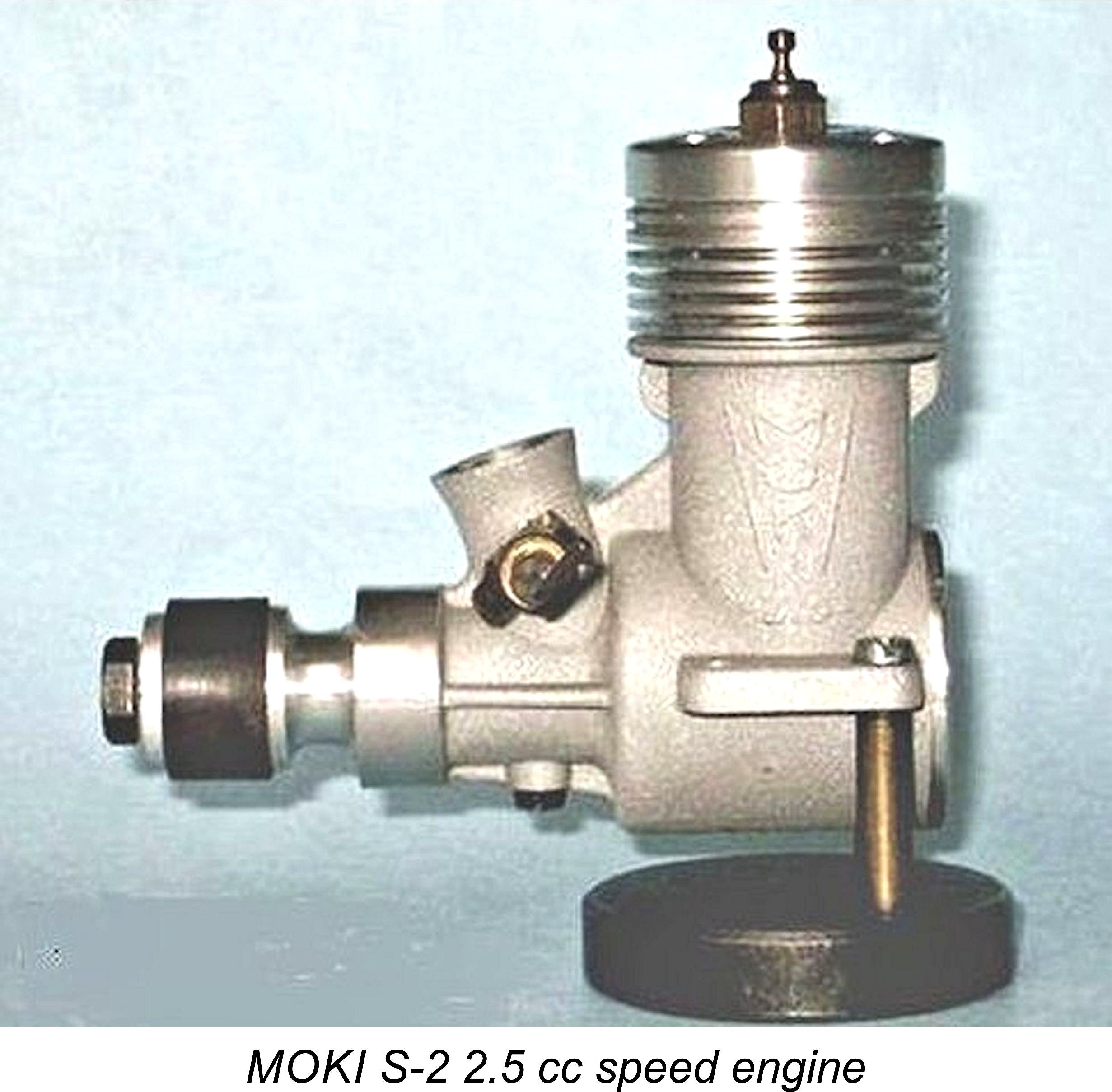

This establishment was generally known by its initials MOKI, the full story of which has been recorded in a separate article on this website. Its first product was the Dooling-influenced 2.5 cc MOKI S-1 glow-plug model which was ready in time to compete in the 1958 World Control Line Speed Championships to be held once again in Brussels, Belgium. The 1958 Championship meeting at Brussels turned out to be a straight dog-fight between the MVVS and MOKI works specials from Czechoslovakia and Hungary respectively. The MOKI squad came out on top, taking the first two places, followed by three MVVS entries. This was a remarkable achievement considering that this was the MOKI S-1’s first-ever major contest. Top Italian was the sixth-placed Cesare Rossi (later of Novarossi fame), whose best Super Tigre G.20 V powered speed of 204 km/hr (126.76 mph) was no threat to Imre Toth’s winning mark of 216 km/hr (134.22 mph). Indeed, it represented only a very small advance over the best speed achieved by the G.20 V at the 1957 meeting. In their desperate efforts to surpass Toth's lead, several of the Italian and Czech team members resorted to highly questionable pylon tactics, going well beyond the "standard" continental technique of having the handle held in the pylon at a 40 degree angle to the lines. The extent to which they did so went beyond the patience of the event officials, resulting in the second-round disqualifications of one member each of the Czech and Italian teams. Not only was Kočí's handle held at such an acute angle to the lines that they were actually brought across his right shoulder, but Cesare Rossi actually used an outrigger attached to his handle! In both cases, the result was the shortening of the effective line length, thus reducing the distance covered during the timed laps. The need for an indicator projecting from the handle to visibly line-up the flier and his model was never more obvious. This episode was to be recalled at the 1960 event which will be discussed in detail below. Redemption finally came in 1959 at the tenth Criterium of Aces meeting held once again at Brussels, Belgium. Although not officially assigned the title, this meeting in effect constituted the World Championship event for 1959. At this event the further improved Super Tigre G.20 V’s finally broke through, with Ugo Rossi of Brescia winning at a much improved and very creditable speed of 222 km/hr (137.95 mph) and brother Cesare placing third at 210 km/hr (130.49 mph). Observers at the meeting noted with approval that Rossi's winning speed was achieved without a trace of whipping.

It's interesting to note in passing that Rossi would almost certainly not have won this contest had it not been for the misfortune suffered by Jaures Garofali's favorite entrant, his faithful employee Amato Prati. Garofali had carefully checked all of the engines in advance, giving the best of them to Prati. Sadly, Prati suffered a broken lead-out in flight at a very early stage, causing his model to crash. This destroyed both Prati's model and Garofali's best engine, leaving the way clear for Rossi to come through to win. All such misfortunes aside, this was an outstanding result in the face of the ongoing presence of the MOKI specials, which could only manage second and fourth places. The result was somewhat tempered by the fact that the MVVS "works team" did not contest this event, due in large part to the unfortunate circumstance that MVVS team leader Zdenek Husicka was then very ill after suffering a heart attack. This came at a time when the Institute was focusing upon the commencement of limited commercial series production of some of their designs, including the MVVS 2.5R-58. A hint of the effect that the presence of an Institute-backed MVVS team might have had on the results was the 193.9 km/hr (120.5 mph) speed achieved by K. Jaaskelainen of Finland to earn 6th place using one of the early production versions of the 2.5R-58 which he had somehow acquired. A highly creditable performance for a lone individual working without official support!

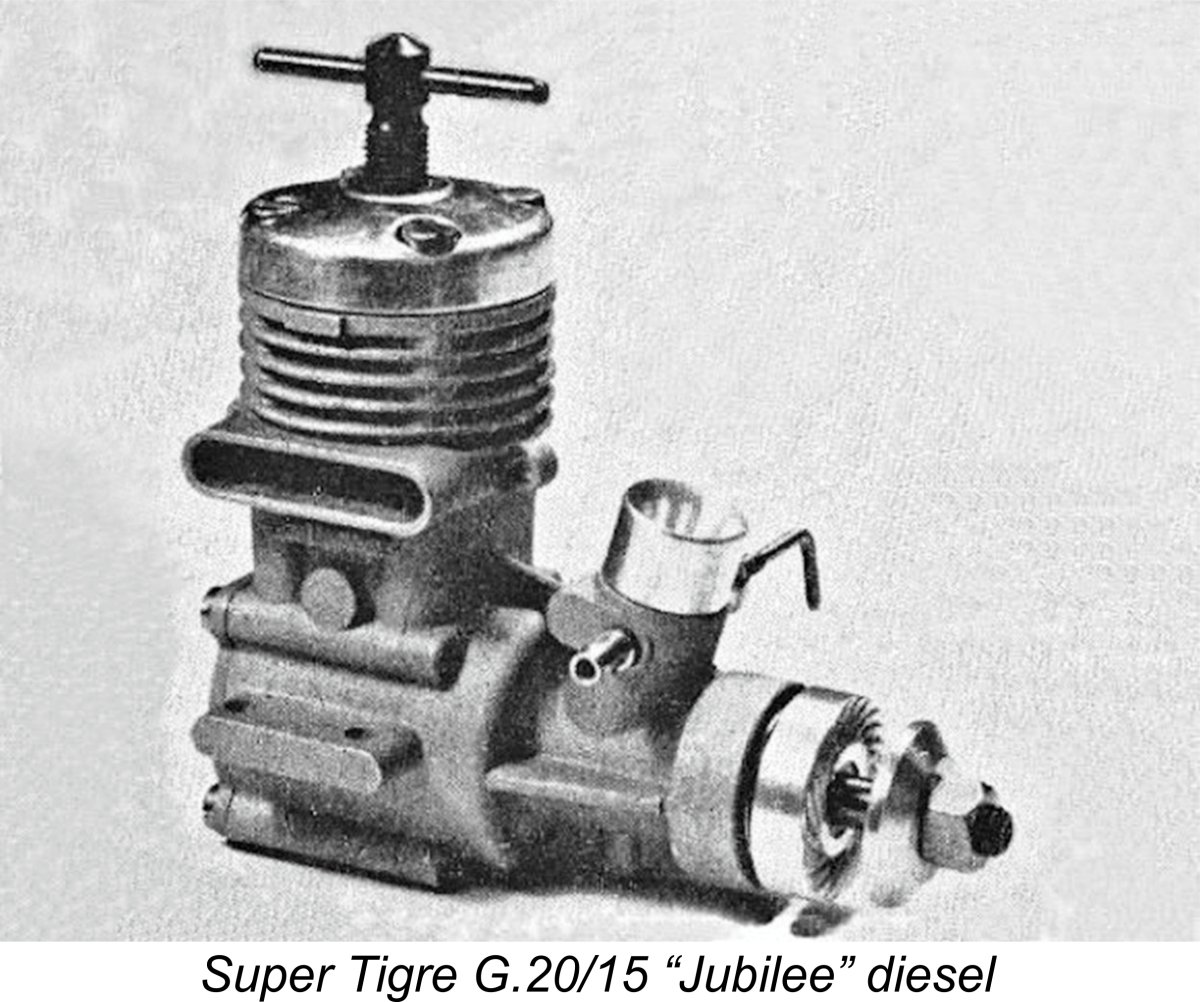

The 1960 World Control Line Speed Championship event was held at MOKI’s home base of Buadörs Airport near Budapest, Hungary. Having finally won the title fair and square in the previous year, as noted earlier, the Italian team was naturally very keen to repeat their success in 1960. They showed up at Buadörs with prototypes of the completely redesigned Super Tigre G.20/15V “Jubilee” engine, now featuring a one-piece crankcase and front end. This engine retained the radically new form of transfer porting which had first appeared at the 1959 event, complete with flat-topped piston lacking a baffle. The Italians arrived at the contest with the clear expectation that this remarkable new design should by rights be their ticket straight to the top of the podium. Unfortunately for the Italians' expectations, this event also saw the arrival on the World Championship scene of America’s Bill Wisniewski (1929-2007) with his remarkable 2.5 cc specials which were actually prototypes of the famous K&B 15R series of 2.5 cc racing engines which were to make their commercial debut in 1961. The Czechs also returned in force with their improved MVVS specials which had been absent the previous year. Now all of the top speeds in previous years had been achieved using two-line models. For 1960, the FAI had inspected and homologated the monoline systems which had been developed by both the Czechs and Americans and approved by FAI officials well in advance of the meeting at Buadörs. Having previously confirmed their legality under the rules, both teams naturally brought their approved monoline models to this meeting. It's important to note that quite apart from their prior approval by the FAI, these models all passed both technical inspection and pull-testing by FAI event officials at Buadörs prior to the commencement of the event itself. If there was a problem with the equipment's adherence to the rules, that was the time for it to be raised. In actual fact, no objections were identified, officially clearing both the Americans and Czechs to use their monoline equipment if they so chose. Despite experiencing some needling difficulties on his first official flight, Wisniewski still managed an average speed of 230 km/hr (142.92 mph) over the timed distance on monoline using a fuel later confirmed to contain the very effective but dangerous (and soon to be rightly banned) tetra-nitromethane. His maximum speed during the first few timed laps before the motor went "off" was estimated by experienced observers to be not far if at all short of 257 km/hr (160 mph)! As an interesting aside, Wisniewski's flight was unofficially timed by a number of attendees at the event. One of these was the late Kevin Lindsey, a future British speed flying great. He told his near neighbour Martin Radcliffe that he had begun timing Bill's flight but stopped the watch when the engine went "off" after a few laps. Up to that point the model had been averaging no less than 262 km/hr (163 mph)!! Jim Nightingale of the USA also experienced needling difficulties, but ended up right behind Wisniewski with an average first-round tetra-fuelled monoline speed of 227 km/hr (141.05 mph). The Czech team elected to fly their two-line models in the first round, with both Zbynek Pech and Jaroslav Kočí returning identical speeds of 213 km/hr (132.35 mph). Sadly, the first-round performances of the two Americans brought out the worst in the Italian team, whose need to win evidently overrode their sense of fair play and sportsmanship. Recognizing immediately that their two-line models powered by prototypes of what would become the Super Tigre G.20/15V "Jubilee" model (see below) could not match those speeds, they immediately protested against the Americans’ use of monoline despite the previously-noted fact that it had been formally homologated by the FAI prior to the meeting and had been inspected and approved by event officials at Buadörs prior to the first round. As stated earlier, if there was a problem under the rules with the American equipment, that was the time for it to be dealt with by the officials. The fact that this protest was only lodged after the officials had cleared the Americans to fly in the first round instead of at the outset revealed its motivation all too clearly. If it becomes clear that you can’t beat a competitor, find some way to get rid of him!! The Italian argument was evidently based on the idea that as sole users of the monoline technology at this event, the Americans were playing on a tilted field. Incredibly, this groundless protest was initially upheld, giving an unsavory appearance of the “fix being in”. A number of teams at the meeting registered strong disagreement with the ruling, to the extent that several threatened to withdraw if the ruling was upheld. However, it was left to the Czech team to directly underscore its unfairness by bringing out their own previously-approved monoline models for the second round, thus making the point that the technology was not only approved but was available to all, including the Italians if they so chose, and that the Americans did not in fact have a monoline monopoly even at this meeting. To further underscore the point, their switch did not improve their second-round speeds sufficiently to threaten either the Americans or the Italians. As a result of this very sporting gesture by the Czechs, the use of monoline at the meeting was reinstated, since the Czech action had demolished the “monopolistic” basis for the Italian protest and the alternative would have been to disqualify both the Americans and the Czechs. The threat of withdrawal by several other teams doubtless played a part in influencing this decision, since if the ruling had been allowed to stand the event would have dissolved into chaos and irrelevance, with the results becoming meaningless. Bill Wisniewski and Jim Nightingale both continued to experience difficulty in getting clean motor runs, although Bill had demonstrated to everyone's satisfaction that with a clean run over the full timed distance his "Pink Lady" was well capable of topping 250 km/hr (155 mph). Even so, his 230 km/hr first-round speed stood through the first two rounds and should have been good enough to win. On his second flight, Ugo Rossi had managed to equal Jim Nightingale's first-round speed of 227 km/hr (141.05 mph), but had to resort to some pretty strenuous whipping to do so. This mention of whipping makes it important to clarify the point that at this stage whipping was not specifically banned under the FAI rules then prevailing. In fact, the majority of contestants whipped their models up to considerably better than their "unassisted" speed before entering the pylon and immediately calling an attempt, continuing to whip as best the pylon would allow throughout their timed flights. Rossi was not alone in this by any means. In support of this impression, following the original appearance of this article in 2017 I was very pleased indeed to hear from Italian reader Gianni Mattea, who was an eyewitness to the event. At the time, young Gianni was in Budapest on holiday with some friends of his parents. As a keen enthusiast, he naturally persuaded his hosts to take him to the contest at Buadörs. He was present for all of the key flights described here. Gianni supported my comment that almost all of the speed competitors whipped to varying degrees. This certainly extended to the Czech team, Zbynek Pech in particular achieving both his third round contest speed and his subsequent World Record through the use of significant whipping of his monoline model. I said "almost all" because there were a few very notable exceptions, namely the American team with their monoline equipment. Gianni recalled that they were alone among the top competitors in not resorting to whipping during their timed runs. Setting aside the means by which it was achieved, Pech used his monoline model very effectively in the third round to match Rossi's whip-assisted second round speed of 227 km/hr (141.05 mph), thus moving past Nightingale, whose engine blew up midway through a partially-timed 240 km/hr (149 mph) third-round flight, giving him a zero score for that round since he didn't complete the 1 km distance. To place Pech's performance in context, it's worth repeating Gianni Mattea's eyewitness recollection that Pech achieved his third round contest speed through the use of significant whipping of his model. Once again, we have to remind ourselves that whipping was inexplicably not banned under the rules then prevailing. Gianni also voiced his own unsubstantiated impression that the Czech team may have somehow got hold of some tetra-nitromethane themselves, either from the Americans (perhaps as pay-back for their sporting gesture relating to the monoline equipment) or from some other source. His basis for raising this possibility (which is all that it is) is the fact that the speeds achieved at this meeting by the Czechs using the MVVS 2.5R/59 were consistently some 15 km/hr faster than those achieved using the same equipment both before and after the 1960 contest. In particular, the jump in Pech's speed from his second round 213 km/hr to his third round 227 km/hr seems to require an explanation. An interesting speculation, but one which will probably have to remain forever unresolved. Even so, the use of tetra-nitro by the Czechs would have been completely legal under the prevailing rules. Regardless, this put Pech into a second place tie with Rossi behind Wisniewski. It’s worth noting in passing that after the conclusion of the championship rounds Pech went on to set a new FAI World Speed Record of 244.6 km/hr (152 mph) using a thinner monoline that that permitted in the actual competition. Once again, Gianni Mattea witnessed this flight, recalling that some pretty strenuous whipping was involved. Pech's third-round achievement naturally acted as a further spur to Rossi's efforts. His exaggerated use of whipping in the second round had naturally been noted by those in attendance, the consequence being that all eyes were on Rossi to see what he'd try next when he came out for his third and final flight. By now the Italian team were clearly prepared to do anything to prevent Wisniewski from winning the individual title and to avoid sharing second place with the Czechs. Having failed to persuade the event officials to disqualify Wisniewski after the first round, and having learned in the second round that even whipping to the max did not result in a winning speed, they now resorted to outright cheating. Ugo Rossi’s third flight was marked by a degree of whipping so extreme that Rossi was actually wrapping his lines around his own right shoulder while supposedly in the pylon! In doing so, he was shortening his flight circle radius, as the attached image from “Model Aircraft” clearly shows. Incredibly, his "speed" of 236 km/hr (146.65 mph) was allowed to stand as the winning mark despite having been produced by flagrant line-shortening in clear contravention of the rules.

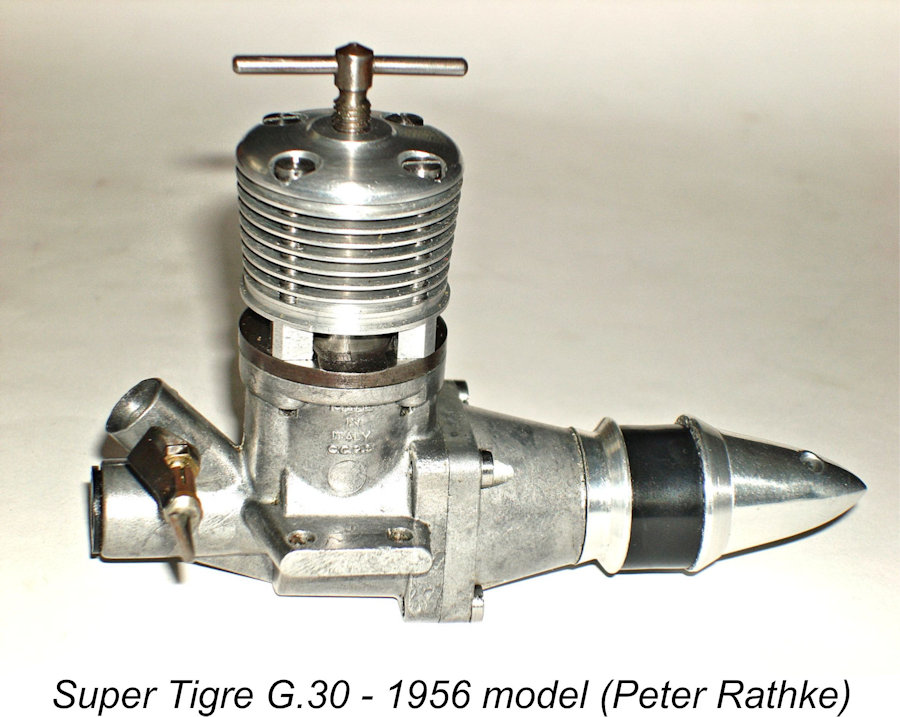

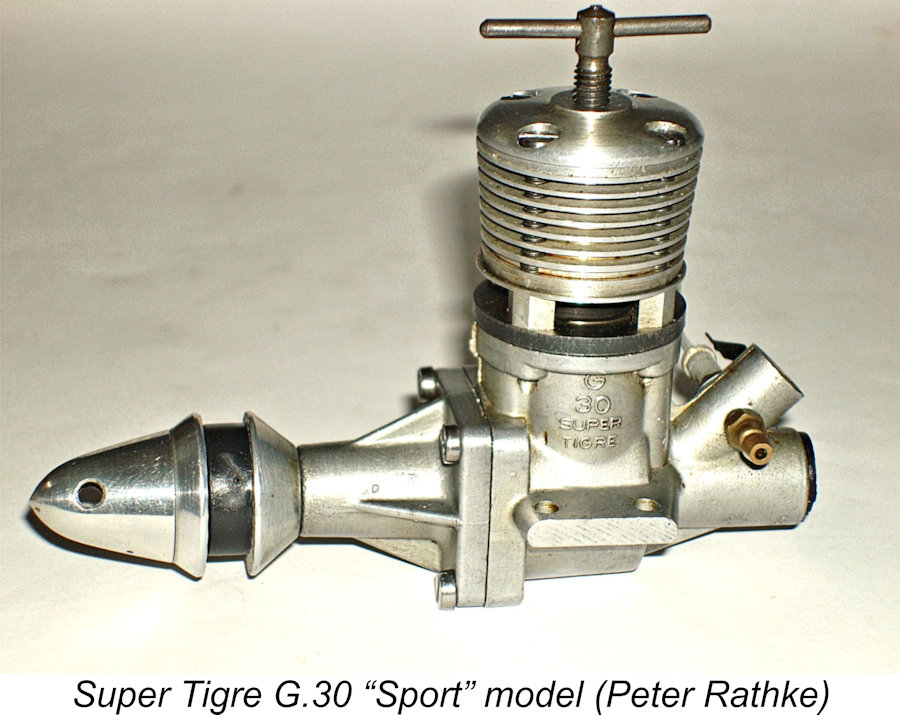

When the dust settled, the upshot was that Rossi had not won the title - it had been awarded to him by the FAI Jury. The impression of the fix being in was now so marked as to taint the entire meeting, with the reputations of both Italy and the FAI in tatters. This view of the matter was heightened by the recollection that Ugo Rossi's brother Cesare had been disqualified from the second round of the 1958 meeting for line-shortening using an outrigger attached to the handle, while Czech team member Kočí had also been disqualified in 1958 for using exactly the same line-shortening technique that Rossi used in 1960! If Kočí's action was illegal in 1958, then why wasn't Rossi's identical action just as illegal in 1960?!? Given the 1958 precedent, the impression of those at the 1960 event was that the Italians must have received assurances from the FAI Jury in advance that Rossi's third-round tactics would not lead to his disqualification despite their clear illegality. Otherwise, it seemed inconceivable that he would risk disqualification by flying in this overtly illegal manner. It's very much to the credit of a truly great champion and sportsman that Bill Wisniewski rose above the resulting morass of ill-feeling, refraining from stepping into the controversy and thus putting his Italian rivals to shame. After all, everyone (including Rossi and Garofali) knew who the champion really was .......and the Americans had taken the team trophy by a convincing margin, with the Czechs in a well-deserved second place ahead of third-place Italy and fourth-place Hungary. Rossi’s best speed without whipping and line-shortening was a still respectable 219 km/hr (136.08 mph). This would have given him seventh place in the final results just behind the officially seventh-place Super Tigre entrant, the clean-flying O. Stefano with a speed of 220 km/hr (136.70 mph), which should have given Stefano a well-earned sixth place but for Rossi's tactics. Stefano’s speed underscored the fact that this was about the best speed (and a very creditable one) that the Super Tigres could produce on two lines under the prevailing conditions without a “helping hand” (or in Rossi’s case a line-shortening shoulder). Consequently, although Super Tigre went into the record books as the winning motor at this event, very few event participants or modelling enthusiasts worldwide recognized this result as legitimate. I was one of them, and I still am even after the passage of 64 years. Rossi slunk away with his stolen trophy and a shredded reputation, while Bill Wisniewski returned to the USA with his sporting reputation enhanced and his head held high as the moral victor. I have personally always considered the great Bill Wisniewski to be the indisputable 1960 World Champion, and I’m very far from being alone. I also never bought a Rossi engine, even when it was the one to own ……… Rossi was never again to appear as a member of any Italian team at future championships. My Italian correspondent Gianni Mattea agreed completely with my assessment of Ugo Rossi's tactics, stating that he was well known in Italy and elsewhere as having "a very strong right arm". In Gianni's eyewitness opinion, Bill Wisniewski was undoubtedly the winner of the contest on the field. Taking the whipping out of it, he considered that a fair result would have been Wisniewski, Nightingale and Rossi in that order, since Rossi had shown in Brussels the previous year that he could potentially reach 225 km/hr without excessive "help" and could amost certainly have done so again in 1960 if he had given it a fair trial. Gianni discounted Pech's best speed because it too was apparently produced by whipping. Another eyewitness to this event was my late and much-missed Hungarian friend and colleague Ferenc "Somi" Somogyi. He was in attendance throughout as part of the organizing committee, which everyone agreed did a really superb job of organizing the event. However, they naturally had no influence over the decision-making by the FAI jury. After reading this article following its initial publication in 2017, Somi contacted me to state for the record that he fully agreed with Gianni Mattea - in his view, Bill Wisniewski was indeed the true 1960 World Champion.