|

|

Made in Moscow - the MARZ 2.5 D

My original article on the MARZ (Russian: МАРЗ) appeared on the late Ron Chernich’s ever-fascinating “Model Engine News” (MEN) website in May 2008 – one of the earliest articles that I wrote for MEN. However, my mate Ron left us in early 2014 without sharing the access codes for his heavily-encrypted site. Consequently, no maintenance has since been possible, resulting in the slow but perceptible deterioration of the MEN site - an inevitable process which can have only one ending in the long run. I was unwilling to risk the loss of the information so painstakingly gathered on the MARZ, hence the article’s re-publication here. I’ve also taken advantage of the opportunity to bring certain aspects of the story up to date. I was greatly assisted in this latter endeavour by my good mate Maris Dislers of Glandore, South Australia, who went to the trouble of conducting both bench and flight tests of his own example and writing up his findings for inclusion in this revised article. Such assistance is greatly appreciated! This is a tale in which an unusually significant element of skullduggery played a major part. We must be extremely grateful to the late Ed Carlson of Carlson Engine Imports in Phoenix, Arizona, for supplying a good deal of the following information regarding the murky details of this engine's defection to the West in substantial numbers during the Iron Curtain era prior to 1990 when The Wall was still in place. I’m also greatly indebted to Ilya Leydman of Australia, who was instrumental in the world-wide marketing of the MARZ and other Russian engines in the early 1990's following the collapse of the Soviet Union and the consequent changes to the business climate in Russia. After reading my original article, Ilya was kind enough to fill in many additional details of this interesting period. Such first-hand information has a very high value in studies of this sort, and Ilya has my sincere thanks for his generous assistance. Background

During the period from the mid 1950's into the early 1960's when they were first beginning to make their presence felt in the international aeromodelling competition arena, the Soviets contented themselves for the most part with supplying would-be contestants with Russian-made copies of successful engine designs from elsewhere, using which they could sharpen their skills. There were a few original designs of considerable merit, such as the excellent 1.5 cc MK-16 diesel of 1954 and the 2.5 cc MK-12S diesel of 1955, but the clones formed the bulk of Russian model engine production from the mid 1950's to the early 1960's. I’ve covered the Russian cloning era in a separate article to be found elsewhere on this website.

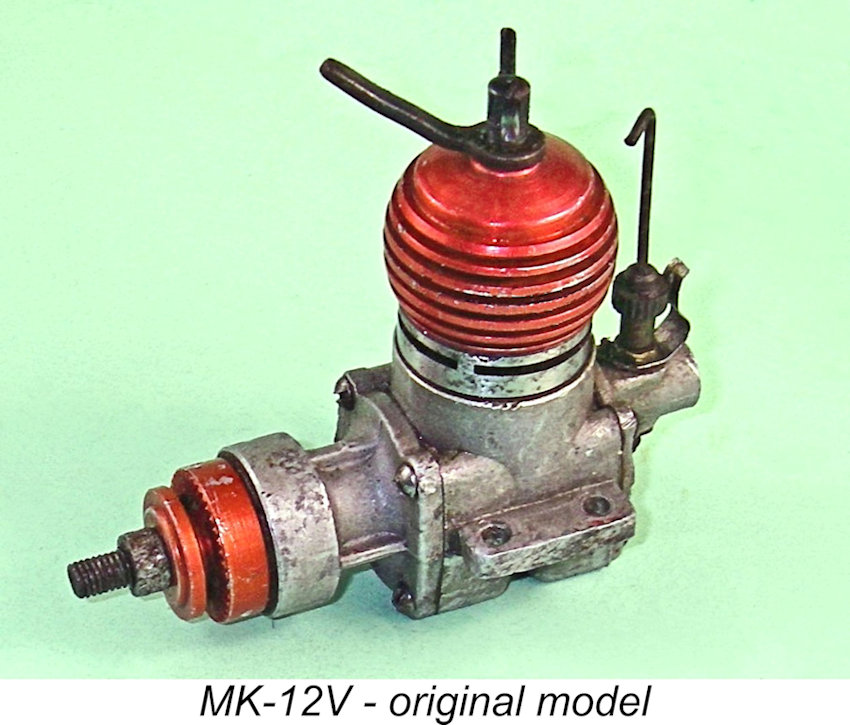

The engines selected by DOSAAF for series production were manufactured in very significant quantities over surprisingly lengthy periods of time at facilities sited in various geographic locations within the Soviet Union. While their quality and performance generally didn’t match those of the originals upon which they were based, these engines sufficed to allow aspiring Soviet competitors to gain the necessary experience to compete for places on national teams representing the USSR at the highest levels. They also served as aids in the technical and aeronautical training of young people in the State-sponsored school and club systems throughout the vast geographic area of the Soviet Union. As time went by, the political capital to be gained through Soviet success at the international contest level became increasingly obvious to State officials. Aeromodelling was a far more widely-practised activity than it is today - back in my own long-ago schooldays, very few of my friends and school-mates were not involved with some aspect of modelling. Indeed, my school maintained a thriving aeromodeller's club which was among the most well-supported after-school activity groups of them all, using the extensive school playing fields as a flying site. How times do change ....... The Russians were well aware that international contest results were reported and analyzed in detail in the widely-read Western modelling media of the day, consequently being discussed at length both at club meetings and on the flying field. As a result, news of Russian contest successes would reach and potentially influence a wide spectrum of Western society, both young and older. The performance of the clones generally fell well short of reaching the standards required to achieve such success. Accordingly, the more prominent Soviet competitors began to FAI team racing was one of the "glamour" classes which became a major preoccupation of Soviet modellers from the late 1950's onwards. This class was dominated by high-performance 2.5 cc diesels, although the odd competitor did try a glow-plug engine from time to time, generally finding the fuel consumption issue to be a major barrier to success. Initially, the majority of aspiring Soviet team racers at the club level had to make do with rather inferior Russian-made copies of successful 2.5 cc team race diesels from elsewhere, including a long-running series of engines based on the Webra Mach 1 which were distributed under the MK-12V designation as well as a later copy of the Super Tigre G20/15 produced The first more-or-less original FAI team race engine design to become generally available to Soviet modellers seems to have been the RITM 2.5 cc diesel designed by the well-known team-race competitor and future mutiple World Champion Boris Krasnoroutski of Kiev in Ukraine (then part of the Soviet Union). The original production version of this engine first appeared in around 1962. The engines were manufactured at DOSAAF’s Kiev plant where Krasnoroutski worked. The RITM was to all intents and purposes a rear drum-valve version of the Oliver Tiger Mk. III, with a bore and stroke combination plus a piston/cylinder set-up that very closely resembled those of the Oliver. However, the performance of the production version did not come up to then-current standards in stock configuration, although the engine could be tuned to yield a greatly improved performance. Generally speaking, these engines were manufactured to quite reasonable standards, although they did have their flaws. As a general rule, the quality of the Iron Curtain-era engines manufactured in Ukraine tended to surpass that of the contemporary designs produced in Russia, at least at this stage.

The makers of the RITM claimed an output of 0.32 BHP at 15,000 rpm for the original version, figures which appear to be quite readily achievable based on my own tests of a properly set-up example. However, a test by Ron Warring of a standard production unit which was published in the July 1963 issue of "Aeromodeller" magazine yielded far more modest figures. Warring conceded that much of the performance claimed by the Russians appeared to be "there" in the design - it was a few identified manufacturing deficiencies exhibited by Warring's test example that let it down.

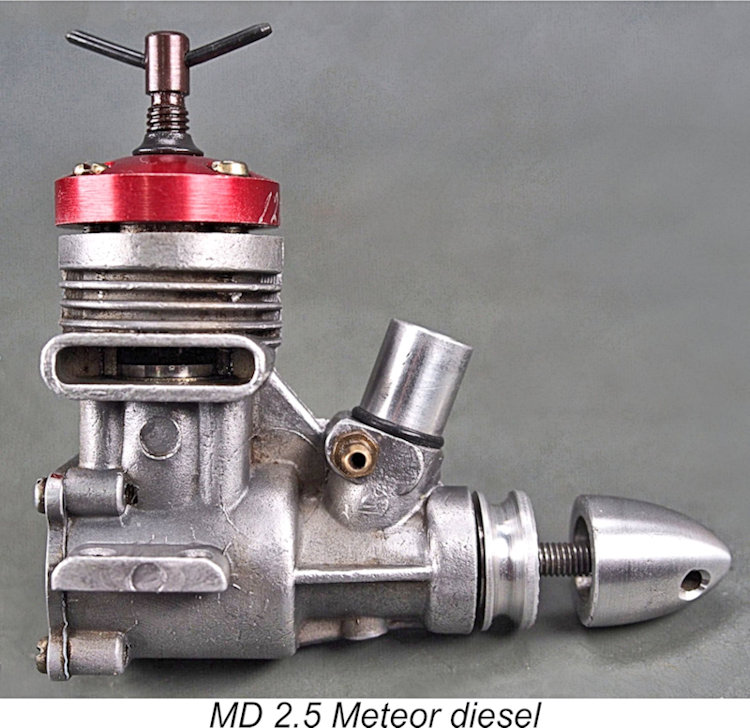

In the late 1960’s, a group of Moscow-based Russian competition experts known collectively as the Central Sports Model Flying Club (ZSKAM - Russian ҴCKAM) was assigned the primary responsibility for the ongoing development of commercial Russian competition engines. In a separate article on this website, I’ve traced the history of the engines which were designed by this group and distributed under the ZSTKAM name. The advent of ZSKAM (later ZSTKAM) signaled a noticeable improvement in the quality of many new series-produced Russian designs, particularly since the manufacture of the more promising models developed by the group was assigned by DOSAAF to a number of military production facilities to which DOSAAF had some level of access. These facilities generally worked to significantly higher manufacturing standards. Although its design pre-dated the central involvement of ZSKAM, the RITM remained in production in its later versions until at least 1975 - I have a New-in-Box example factory-dated from that year. It was seemingly in the late 1970's or soon thereafter, according to some rather sketchy information gleaned by the late US model engine importer Ed Carlson from business contacts behind the Iron Curtain, that the engineering department of the University of Moscow took a hand. The unsubstantiated story runs that they were asked by DOSAAF to investigate the problem of coming up with an improved design for a 2.5 cc competition training diesel suitable for mass production at reasonable cost and that the MARZ 2.5 D was the result. The primary objective was seemingly to develop an updated replacement for the MK-12V model which could be produced by the same Moscow facility. It's unreasonable to expect that we'll ever be able to prove or disprove this story, but it does make a great deal of sense. Although the influence of a number of previous Russian engines and others from elsewhere is quite clear in its design, the MARZ displays a refreshingly original combination of features which reflect a considerable amount of practical thinking in engineering terms. It would have made an excellent design assignment for a group of mechanical engineering students working under expert supervision in accordance with clear terms of reference. Based on first-hand information supplied by Ilya Leydman, it appears that an increasing proportion of Russian model engines during this period were manufactured by arrangement with DOSAAF in normally-restricted military production facilities as an off-peak activity to promote full utilization of equipment and staff. The MARZ 2.5 D was produced in a Moscow plant which was dedicated primarily to the servicing of military helicopters. Indeed, the name "MARZ" was derived from the Russian-language initials of the facility which made the engines - in English, the "Moscow Aero Service Factory". This facility had previously undertaken the manufacture of the MK-12V diesels and the Moscow and Meteor diesel and glow-plug models which preceded the MARZ. Description

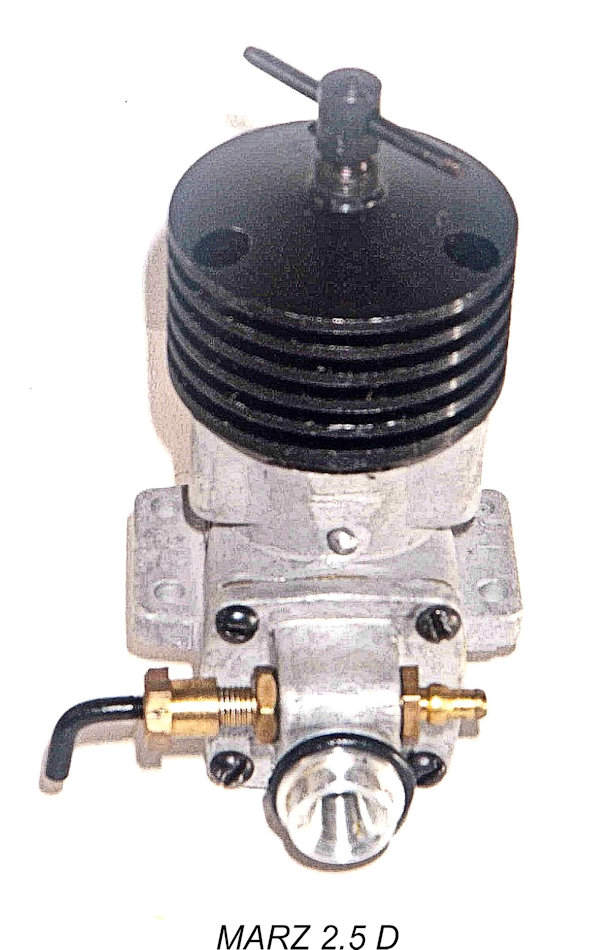

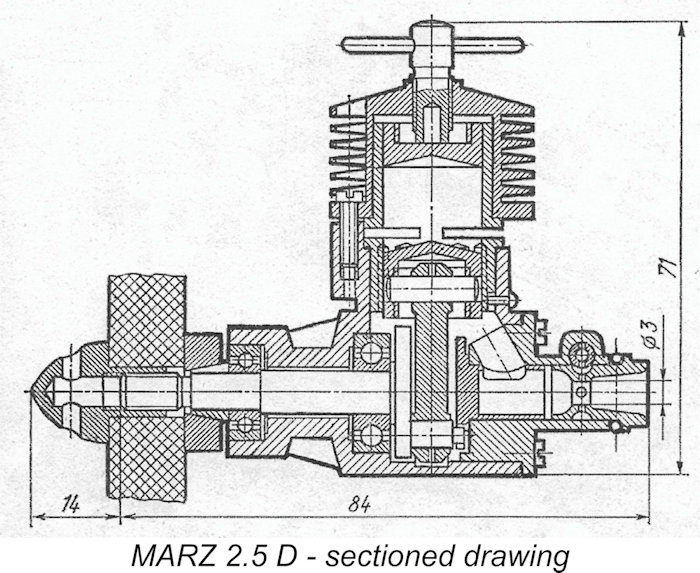

The MARZ was tested by Richard Herbert for "Aeromodeller" magazine, the test report being published in the July 1994 issue. This report includes a full description of the engine, making it unnecessary to repeat it in detail here. The most noteworthy design features of the MARZ are:

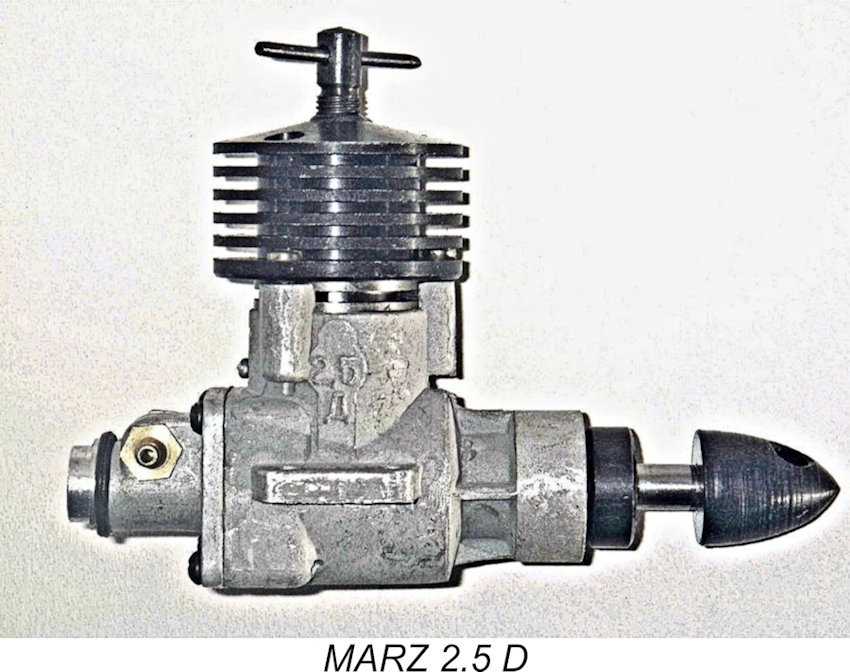

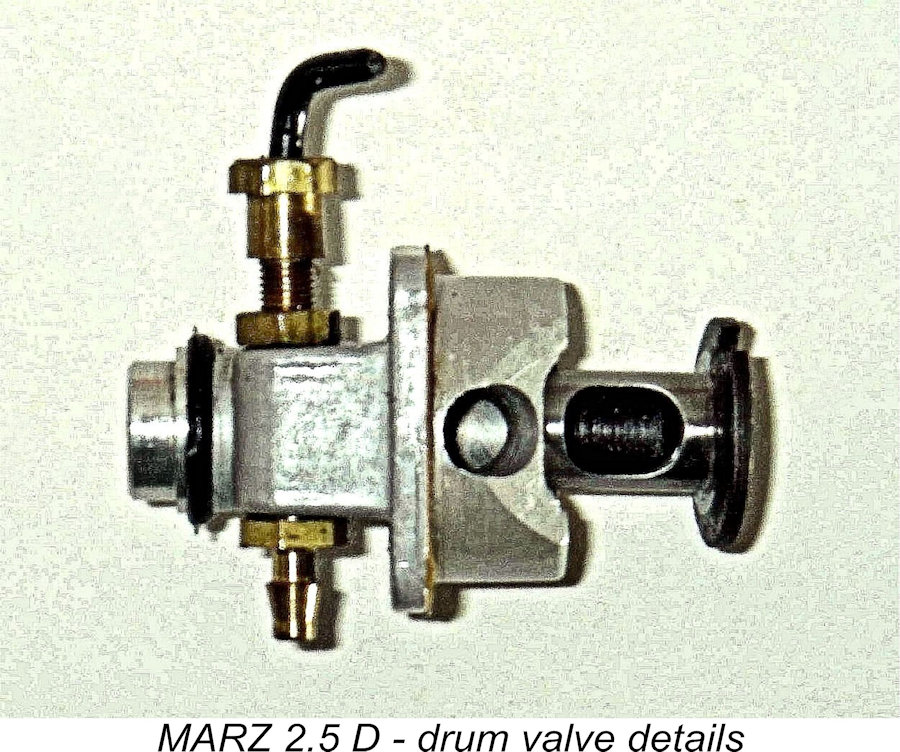

Otherwise, the MARZ is a more-or-less conventional twin ball-race diesel of classic "racing" pattern, with three conventional radially-disposed sawn exhaust ports completing the gas flow arrangements. Fits and finishes are generally good, although there are a few potential flaws (to be discussed below) arising from the fact that the engines were very much "mass-production" items dating from a time and place during which production quantity was far more highly valued than quality. The bare weight of 5.5 ounces (156 gm) is by no means excessive for an engine of this specification and performance, while the unit has a nicely compact appearance with a very low frontal area. Production and Distribution

Despite these design similarities, Ilya Leydman confirmed that the manufacturers of the MARZ had no connection with the makers of the MK-17. The latter engine, like the later KMD 2.5 cc team race diesel of 1975, was aimed specifically at the export market, hence being built to a higher standard of quality than other Soviet engines like the MARZ which were intended more or less exclusively for domestic distribution at the club level.

The MARZ was launched upon the Soviet modelling world at some point in the early 1980's and remained in production at some level for 10 years or so. Evidently the intent was that it would replace the long-established MK-12V as the standard "consumer-grade" competition diesel using which aspiring competitors could gain experience and with which Soviet youth could receive technical and aeronautical training. Like a good few other Russian engines, it appears to have been produced (or perhaps more accurately, over-produced) in very large quantities for distribution throughout the Soviet school and model club systems as well as being made available through official channels to aspiring competitors for use in learning the basics of their sport. It was evidently designed specifically for use as a training powerplant.

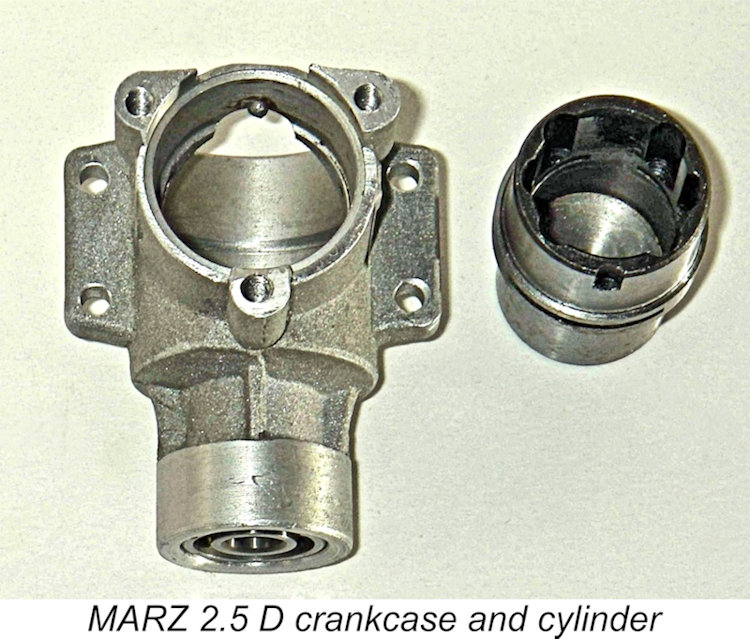

One of the underlying weaknesses afflicting the Communist regime in the Soviet Union was the fact that rational economic principles were often set aside when the interests of the State were concerned. It was considered desirable to make State-sponsored products such as the MARZ readily and affordably available to the USSR school and model club systems as well as the "official" Soviet aeromodelling organizations for which they were intended. Consequently, the "book" value of such products was often set at a figure which in many cases bore no relation whatsoever to the actual production cost. The State sponsorship under which the products were made presumably picked up the slack. Ilya Leydman pointed out that there was a dark side to this state sponsorship, which might otherwise be taken to indicate a genuine interest in expanding the recreational and educational opportunities for Soviet youth. In fact, a political agenda was very much at work - the school and club activities were closely monitored on behalf of the State by DOSAAF, who picked out the most promising participants from the school and club modelling programs and diverted them into training for military purposes. The stated value of the MARZ in the USSR throughout its production history was 11.50 Rubles. This was at a time when a senior Russian engineer might be paid 150 Rubles monthly. Hence, the direct purchase of a MARZ engine represented a substantial investment for a Russian citizen. Despite the close State control which evidently existed, it appears that a number of individuals in various Iron Curtain States managed by one means or another to find a way to "divert" significant numbers of these engines (and presumably other products) into their own hands at a cost (to them) which was well below the actual cost of production and far short of the engines' intrinsic value. This in turn led such individuals to consider ways and means of turning the engines obtained cheaply in this way into cold hard cash, a scarce commodity in the Communist bloc during the Iron Curtain era. Foreign currency was particularly desirable, leading to thoughts of exploring the possibility of somehow selling at least some of these engines on the Western market. It was through this initiative on the part of a few of the aforementioned underground Iron Curtain entrepreneurs that the late Ed Carlson, former owner of Carlson Engine Imports of Phoenix, Arizona, first became involved (along with others) in selling the MARZ engines in North America and elsewhere beginning in the mid 1980’s. Even as late as 2008, Ed was understandably reluctant to go into great detail, never providing me with the full details of how this under-the-table trade in model engines was initiated. Presumably he didn't want to get anyone into trouble! Suffice it to say that lines of communication were somehow established with certain individuals in the Communist bloc who had access to examples of the MARZ and other Russian engines which they were able to offer at prices which were far below their intrinsic worth. As a businessman eager to build up his then-new model engine import business, Ed was only too happy to oblige. Now, it must be clearly understood that there was no legal impediment in their own countries to Ed and others purchasing these engines through appropriate channels from suppliers in the Soviet sphere of influence. The problem lay at the other end - since the MARZ engines (and other models which were also being offered at this time) were specifically intended for use in the DOSAAF-controlled Soviet school club system and sports programs, their commercial export for personal gain was highly illegal and would have netted the Iron Curtain participants at least 6 months in jail for a first offence if they had been caught! 6 months in a Soviet jail was no joke ............. Accordingly, the engines which were somehow diverted from DOSAAF’s official supply system and sent to Ed and others could not be shipped in bulk as above-board export items. Instead, they were somehow sent out of the Communist bloc in tiny batches of two or three engines at most, minus any papers, boxes or anything else that would give them the appearance of being new products exported for commercial purposes. The papers and the flattened boxes would arrive separately, to be re-united with the matching-numbered engines. This may look at first sight as if it should have been far more hassle than it was worth, but from a Soviet perspective the economics of the operation made a compelling case for participation despite the obvious risks. The suppliers could apparently get “diverted” engines for the equivalent of a few dollars - far below their true cost of manufacture. They were thus able to sell them to Ed and others like him at a typical cost of, say, US$15 each and make an instant 700% profit right off the top! Nice work if you can get it .......... At the time in question, these engines were viewed in the West as rather exotic and hard-to-get units from behind the forbidding and mysterious Iron Curtain. As a result, they attracted high levels of interest from collectors and engine aficionados worldwide. This interest enabled Ed and others to sell examples of the MARZ for prices in the US$90 range at the outset. In other words, everyone made money! Other Russian engines intended strictly for domestic use were made available "under the table" in the same way. Ed recalled sending monthly payments of up to US$500 at a time (by unspecified means) to his Communist bloc suppliers, and this at a time when a typical Soviet State take-home wage was perhaps some $14 monthly, according to Ed's contacts at the time. One can see why the State needed to keep the "book" selling prices of these engines down if they were to be put into wide circulation within the USSR. At my request, Ed consulted his records, which showed that he received his first examples of the MARZ through these means in 1984. The engines continued to arrive in the above clandestine manner for most of the balance of the 1980's. The engines received during this period had their original papers (sent separately). As was usual with Russian By this time, of course, the MARZ had in any case been overshadowed by more sophisticated production designs such as the KMD 2.5, a purpose-built team race diesel which carried over a number of features from the MARZ but adopted the far more efficient Schnuerle porting system. The KMD was of course aimed specifically at the export market, as noted earlier, accordingly being built to quite high standards at the aircraft turbine plant in Leningrad (now St. Petersburg). By series production standards, it was a very good performer. However, this was very far from being the end of the MARZ saga. Being made specifically for use in the school and sporting systems of a geographically huge group of politically-aligned States, the engines were produced quite literally by the warehouse-full, and large numbers of unassigned engines remained in storage in Russia and possibly elsewhere when the old political system finally came to an end in 1990. The next move in the marketing game came from a company called Macheast Trading which was located in Sydney, Australia. This business had been founded in 1988 by Ilya Leydman for the purpose of marketing a range of model engine designs and accessories. In 1991, following the collapse of the Soviet Union and the consequent changes to the prevailing system, Ilya travelled to Russia to assess the possibility of adding to Macheast's range of products from Russian sources. Ilya found the country short of almost everything except model engines, which they had stockpiled in extremely large numbers for the reasons stated earlier. It was during this trip that he acquired the first batch of MARZ engines to be marketed in Australia by Macheast. The initial sales response was sufficiently encouraging that Ilya decided to attempt to expand his marketing efforts in connection with Soviet products. In 1992 he returned to Russia and visited a number of production facilities, including the Moscow helicopter servicing facility at which the MARZ engines were made. It was only after the collapse of the Soviet system that foreigners like Ilya were allowed supervised access to these previously-restricted plants. Ilya found that the Moscow factory was well equipped with good quality CNC machinery, using which the majority of the machining required to make the MARZ engine was undertaken. Use was made of materials recovered during helicopter repairs – for instance, the 50 mm steel rods supplied with MARZ engines for tightening the spinner nut were in fact discarded needle bearings from helicopter rotor assemblies! The model engines were produced in a dedicated area consisting of two large rooms in which the special equipment required to make the engines was located. A key piece of equipment was the die-casting machine, which produced two crankcases and two rear drum valve housings from a single die as a single casting which was then parted off to create the four components.

Many of these engines were distributed as intended through the State educational and sports club systems under DOSAAF supervision, although some were sold in Soviet hobby shops and others left the USSR by the clandestine means described earlier. Still others lingered for years in various storage facilities. Perhaps some of them still do ......... Ilya found that the MARZ factory had been making another model - a 2.5 cc ABC glow-plug unit intended for F2D control-line combat called the Taifun 2.5 K (Russian ТАӤΦуН 2.5 K). This had been designed by the ZSTKAM organization. It appeared in three successive variants having different crankcase designs, but only some 20,000 were produced – a paltry figure by Russian standards. Relatively few of these seem to have left Russia, although that has changed somewhat in recent years.

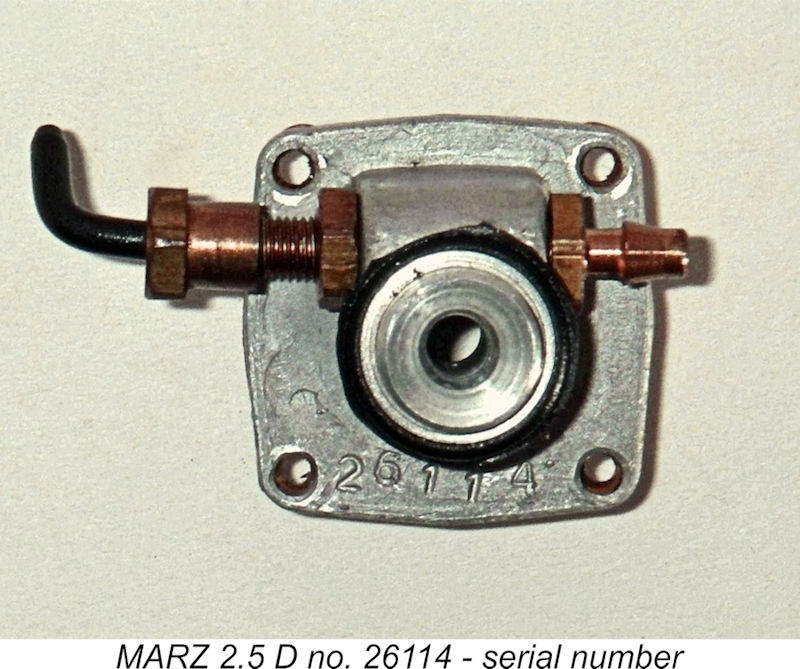

Australian-based clubs and hobby shops quickly bought some 1,000 examples of the MARZ engines, but this didn't go far towards liquidating the 9,000 engines that Macheast still had on hand. Accordingly, the marketing effort soon went worldwide. Ed Carlson and others like him were now able to obtain these engines quite legitimately and straightforwardly from the new Australian source, and the MARZ thus became readily and openly available worldwide, with none of the former cloak-and-dagger arrangements being necessary. Apart from Ed's ongoing imports to the USA, the engines were also imported into America by RJL (MECOA) and Hobby Club, as well as into Britain by Modusa & Co of Kingston-on-Thames in Surrey (Electronic Development's old stomping grounds). Consequently, although actual manufacture had now ceased, the MARZ was in fact just entering its international sales hey-day, with examples finding their way around the world in quite large numbers. They are still frequently encountered today in Australia, Europe, North America and elsewhere, while New-in-Box examples continue to be offered for sale from Russian and Ukrainian souces. The fact that the engines were now readily available on demand naturally brought prices down, and the engines were (and still are) sold for the most part at very reasonable prices. In 1994, Macheast initiated what amounted to a "fire sale" of these and other Russian engines from the Communist era, offering substantial discounts for purchases of ten or more engines. This led to Ed Carlson acquiring substantial stocks of the MARZ engines, among others. In April 2010 Ed informed me that NIB examples of the MARZ remained in good supply from his company (Carlson Engine Imports) and would likely continue to do so for years to come. Ed’s view has been amply confirmed by subsequent events. Following Ed’s passing in 2023, his son Randy took over the business with its remaining inventory. As of 2024 the Carlson Engine Imports website continued to list three of the four versions of the MARZ (see below) as still being available. According to Ilya Leydman, RJL (MECOA) had also acquired a significant inventory of these engines, although these appeared to be gone as of 2024 – certainly, they were not being advertised on the MECOA website. Apart from those available from other sources, new or near-new examples of the MARZ continue to be offered on eBay by sellers located in the former Soviet Union, particularly in Ukraine. It appears that the engine remains in widespread circulation in its homeland. It’s reasonable to suppose that new or as-new examples of the MARZ will remain available at reasonable cost for years to come, along with "bones" examples which can provide spare parts. Serial Numbers I have been unable to discern any readily accessible pattern in the range of serial numbers encountered other than a possible straight sequence. All of the MARZ engines that I've ever see do have such numbers stamped on the rear face of their backplates below the carburettor, but it's difficult to extrapolate any obvious rational basis for them other than a straight sequence.

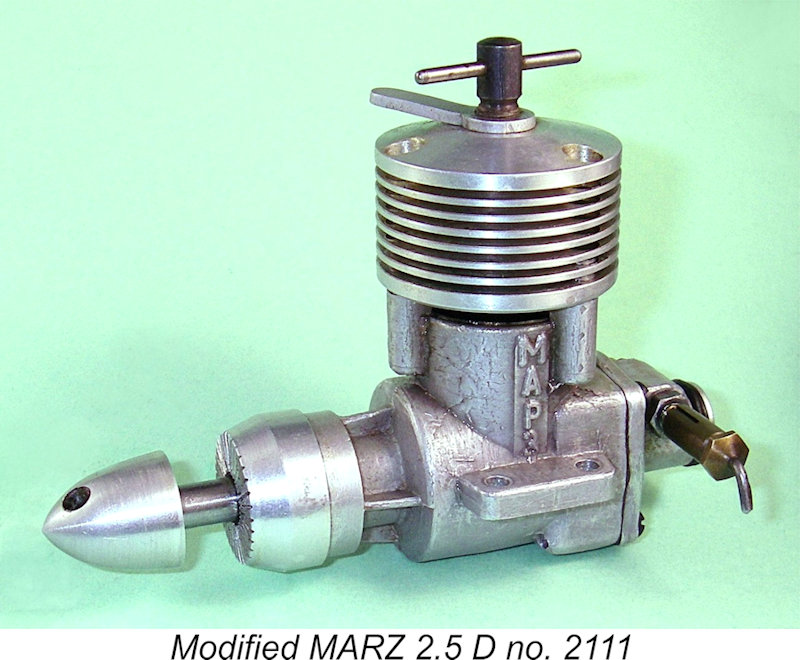

In many years of looking, I've encountered MARZ serial numbers ranging from a low of 2111 (my own "flyer" example) to a current high of 86633. If the numbers form a simple sequence, this appears to confirm the manufacture of at least 87,000 examples, although this figure still falls well short of the numbers shared with Ilya Leydman by the Russian manufacturers. Oddly enough, the majority of MARZ serial numbers with which I'm acquainted (and that's quite a few) have started with the number "2". I'm unable to comment with authority upon this rather odd fact - the only suggestion that I can offer is that the majority of "in circulation" MARZ engines in the West come from the same batch of engines. Possible, I suppose - the fairly large stash which was brought out of the former USSR to create the inventory established by Macheast might all have come from one batch given that they probably all came out of the same factory warehouse. But we'll probably never know………..if anyone out there can straighten this out, please get in touch! Variants

However, the engine is to be encountered in at least four different configurations:

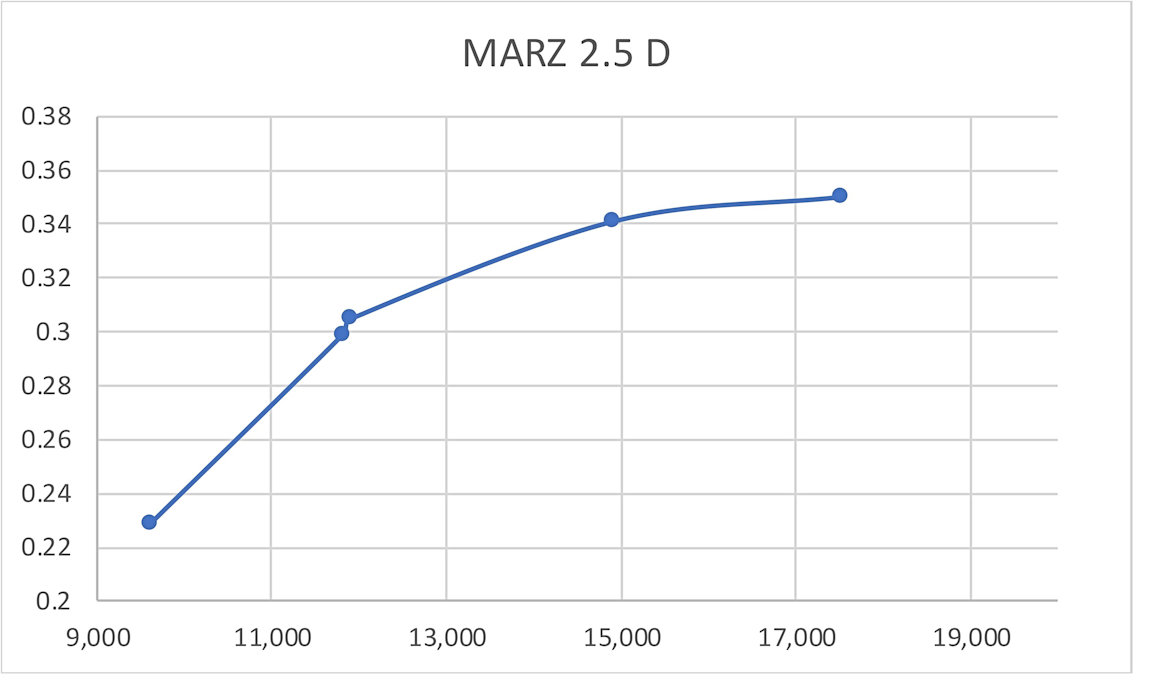

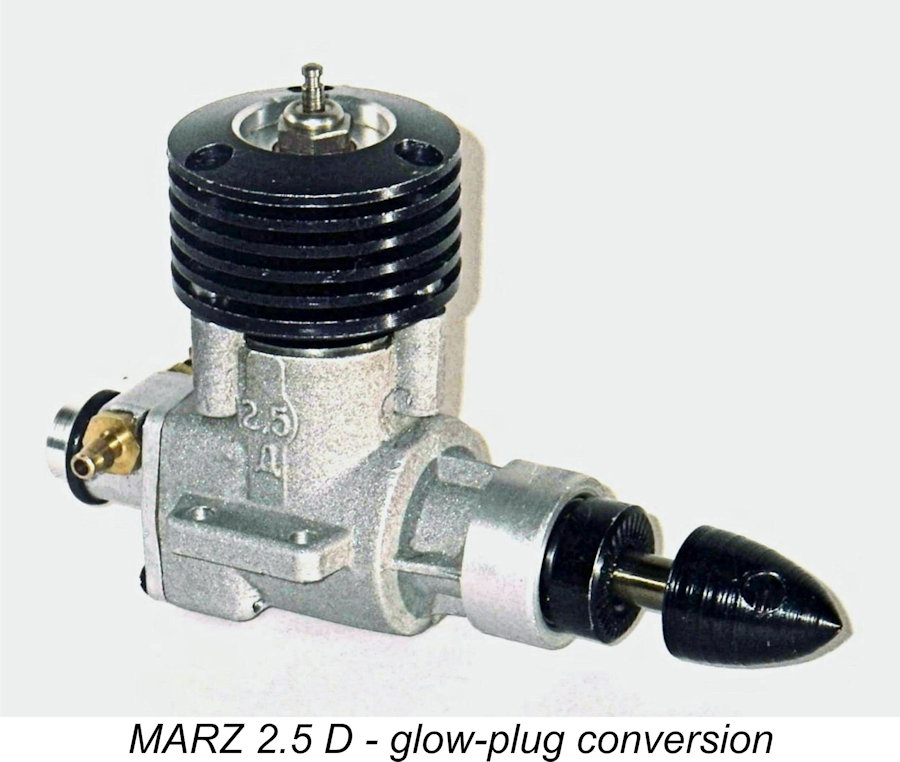

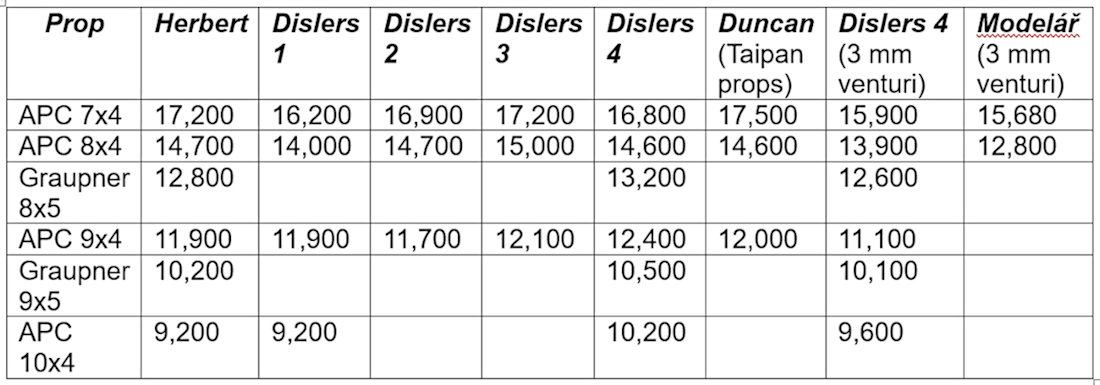

Ilya confirmed that there was only one Soviet-made version of the MARZ – the variant with the black cooling jacket, prop driver and spinner nut designated as variant no. 1 above. These engines were supplied in the previously-illustrated clearly-labelled cardboard box with a matching 8x4 nylon airscrew, an alternative venturi insert, a tommy bar for prop mounting and a Russian-language instruction manual. Recommended fuel was equal parts of ether, kerosene and castor oil for normal use, with an interesting mix of 5 parts ether, 3 parts kerosene and 1 part each of mineral oil and castor oil for competition use. Seemingly, ignition improvers were hard to come by in the Soviet Union! The other three versions were all assembled in Australia by Macheast. The un-anodized cooling jackets were the last MARZ components made at the Moscow factory, but they were assembled into engines in Australia. The glow-plug conversions were also Australian-made. Most MARZ engines sold through Macheast did not have their original packaging and were shipped in simple plastic tubs with a copy of a set of English instructions developed by Macheast. Ed Carlson sold the engines in small cardboard boxes bearing his own Carlson Engine Imports stick-on label. At the time of this update (2024), Ed Carlson’s son Randy still had stocks of three of the above versions - version 2 was sold out by then. The standard diesel model (version 1) and the glow model (version 4) together formed the greater part of the remaining inventory. Performance The instruction leaflet provided with the engines was translated into English by Macheast for distribution with their stock of engines, which were sold for the most part in English-speaking markets. The Russian makers claimed an output of 0.34 BHP at 15,500 RPM for the standard un-silenced diesel engine which was the sole variant that they produced. They also stated that an 8x4 prop allowed the engine to reach its full potential. The instruction leaflet included very specific 12-month warranty information. In his previously-mentioned 1994 test of the MARZ, Richard Herbert reported a level of performance which actually exceeded the Russian claim for the un-silenced engine, achieving a very creditable test performance of 0.362 BHP at 16,000 RPM with an unmodified over-the-counter unit. The addition of the collector ring/silencer supplied by Macheast reduced these figures to 0.26 BHP at 14,500 RPM, still a useful enough performance for sport flying use allied to an acceptably low noise level. Without the collector ring, Richard’s test example turned an APC 8x4 prop at 14,700 RPM, lending credibility to the maker's comment regarding the utility of this size of propeller. Richard also commented that the engine was very easy to start, particularly in its un-silenced form. I can bear out this comment completely from my own extensive experience. The MARZ is in fact one of the least "fussy" diesels of my acquaintance, both to start and to adjust. Running qualities are beyond reproach. An earlier evaluation of the MARZ by the late Brian Winch had appeared in the January/February 1993 edition of the Australian magazine “ Airborne”. This included both the diesel and glow variants of the engine as offered by Macheast. Both engines were tested with the Macheast mufflers fitted. Brian commented on the easy starting characteristics of both versions and was quite complimentary regarding the standard of construction and finish. He did not measure actual power output, but did publish the following prop-rpm figures:

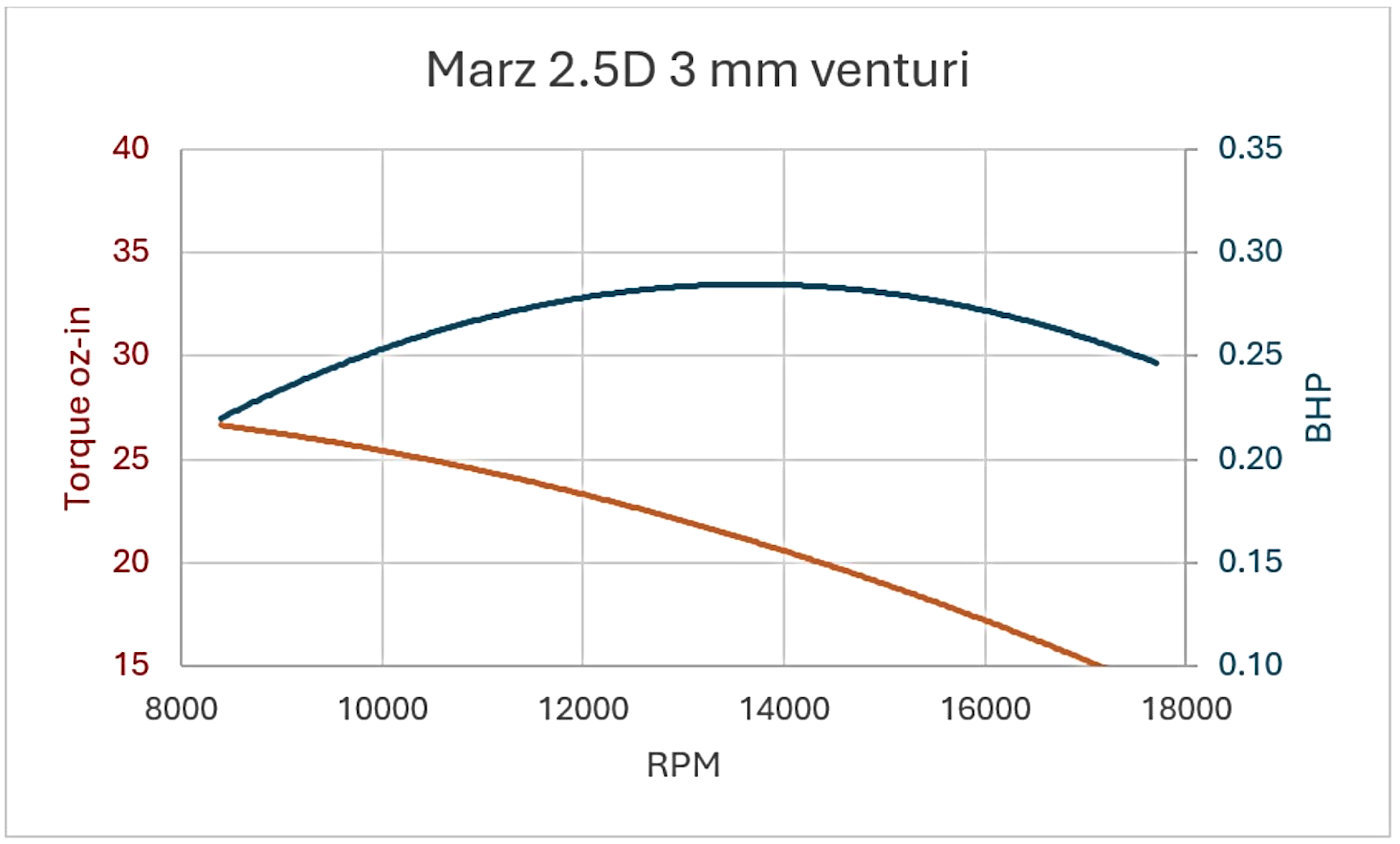

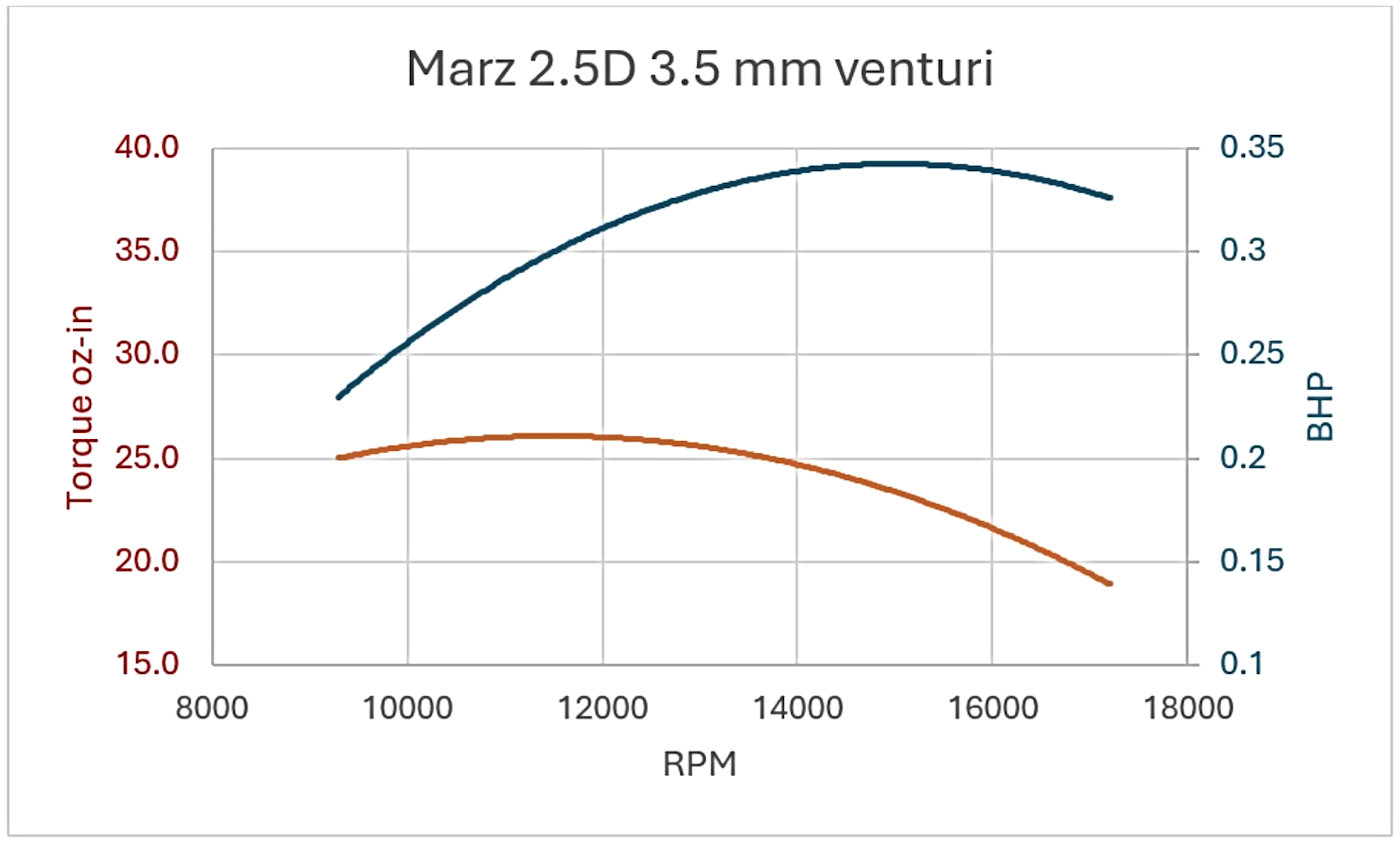

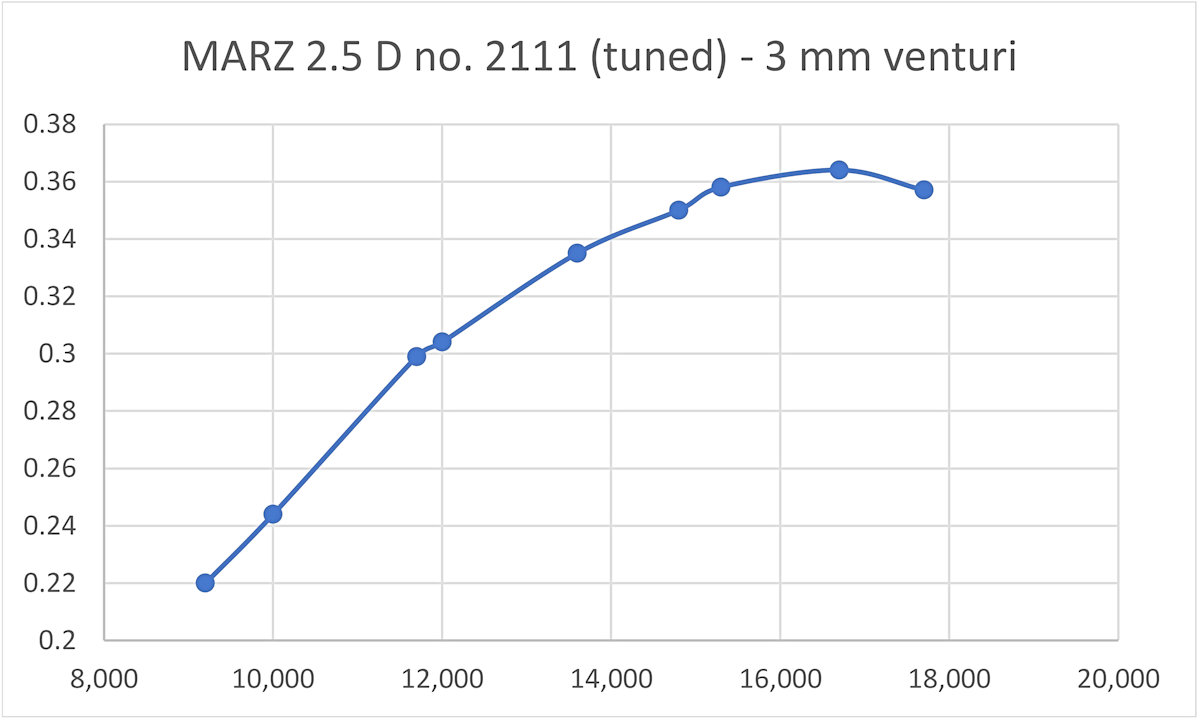

The implied power output from these figures is considerably below that obtained by Richard Herbert. This is doubtless due to the fact that Brian's data were obtained with the Macheast mufflers fitted to both engines. We would expect the use of a muffler to have a more than normal impact upon output due to the sub-piston induction, which will encourage the ingestion of spent exhaust gases instead of air. Before being put into service in 2007, my own unmuffled "flyer" example of the MARZ, engine no. 2111, was subjected to a tune-up and careful rebuild followed by a lengthy break-in. It subsequently accumulated a couple of hours of high-speed running time in the air, after which I put it on the test bench in 2008 to assess its performance. The engine as tested was fitted with a 3 mm dia. venturi, which I had found to be far more consistent in the air than the optional 3.5 mm dia. fitting. The following data were recorded:

Although the power curve derived from this minimal amount of data is tentative at best, the 8x4 figure conforms almost exactly to the manufacturer's claim. Indeed, the above results are very much in line with those achieved by Richard Herbert in his 1994 test and well in excess of those obtained by Brian Winch with the muffler fitted.

It also seems clear that there's no point in under-propping this engine just to make it turn faster in the air. This is one of the most common errors that I’ve seen being made by new diesel users - they mistakenly believe that the route to higher airborne performance lies simply in the achievement of higher airborne rpm. As a result, their models sound really impressive in flight, but go nowhere! In fact, the strong point of a diesel tends to be its ability to produce high torque at moderate speeds. Consequently, there's even less justification for pushing a diesel past its peak than there is with a glow-plug motor – doing so squanders the diesel’s greatest asset.

I suspect that a slightly higher compression ratio would do wonders for the engine running in this form, and a squish band wouldn't have hurt either with a bore of this diameter. Basically, in its glow-plug configuration the MARZ is strictly a high-speed low-torque engine in practical terms. That said, it's a really nice engine to use in this form. User Comments The fact that the MARZ become so widely distributed and looks set even now to remain readily available at reasonable cost for years to come makes it an obvious choice for those wishing to have an economically-priced "classic" 2.5 cc diesel of quite spirited performance to use in non-competition control-line or free flight applications. But there are a few pitfalls................. I used these engines myself for some years in a variety of control line models. My most "experienced" in-service example, engine no. 2111, was last installed in a "Dongus" vintage combat model, which is a very suitable vintage combat design for use with a rear induction powerplant given the upright mounting. It performed very sturdily in the speed-limited 64 MPH .15 cuin. vintage diesel combat class that was run for some years in the Pacific Northwest where I live. I actually had to slow things down by over-propping to make the speed limit – the motor was easily able to pull the Dongus well into the 70 MPH range if propped appropriately. Airborne consistency in this highly aerobatic application was extremely good with the 3 mm intake venturi fitted. If you're planning to use one of these engines for actual in-flight applications, there are a few points to consider. Firstly, like all mass-produced consumer-grade Russian engines, a new and un-run MARZ benefits from being completely dismantled and cleaned out very thoroughly prior to any attempt being made to start it or even to turn it over. The issue of internal cleanliness during assembly is a factor which never seemed to receive sufficient attention from Russian mass producers, and it's totally unsurprising to find that the MARZ was no exception. Ed Carlson was always very open regarding this issue, recommending a thorough cleaning prior to any attempt to start the engine. Another issue that may require some attention while the engine is apart is the fine-tuning of the cylinder alignment. The dowel and small channel mentioned above are sometimes incorrectly placed, the result being that the exhaust ports do not align properly with the spaces provided for them in the crankcase casting. It's a simple matter to use a Dremel Moto-Tool with a suitable small grinding bit to carefully grind one side or the other of the cylinder channel to allow the cylinder to be secured in its correct radial alignment. Do not mess with the dowel, however - you can upset the crankcase seal if you do. While the Dremel grinding tool is in action, it's also worth removing the contra piston and inserting the cylinder sans piston with the backplate installed to check the base of the cylinder at the rear where it meets the updraft induction port in the backplate. In most examples of the MARZ, the exit of this port is partially obscured by the bottom lip of the cylinder liner. This cannot be good for induction efficiency. The fix is very simple - grind a small upwardly-chamfered crescent-shaped cut-out in the base of the cylinder liner at the point where it intersects the alignment of the induction port. This removes the partial obstruction and allows the engine to make best use of what is in fact a very efficient induction system. My good mate Maris Dislers has found by experiment that this modification adds an average of 500 RPM to prop speeds in the useful range. Just one warning - be careful not to make this cut-away so high that the gudgeon pin can potentially foul it at bottom dead centre. Just a little does it nicely; the engines run pretty well even without this tweak, so it's by no means essential. While the contra-piston is out of the cylinder, it's a simple matter to add a squish bowl to its underside and truncate the conical piston crown to the extent allowed by its relatively small thickness. With such a large bore, the resulting combustion improvement could well yield positive results. At least this modification can do no harm provided that the dimensions of the squish bowl are held to appropriate limits. Do not overdo it, otherwise piston to contra-piston contact may result at higher compression settings, with disastrous consequences.

Perhaps a greater benefit would result from some efforts to lighten the relatively heavy big-bore piston. There’s certainly a fair bit of superfluous metal in the interior of that component, the removal of which would reduce reciprocating weight quite substantially. Reduction of reciprocating weight has long been recognized as one of the most effective approaches to performance improvement in high-speed engines. However, be really sure that you know what you’re doing and have the appropriate equipment before tackling such a task. A milling machine is the ideal tool. A final point worth checking is to ensure that there's no air leakage past the ends of the spraybar where it is secured to the carburettor body. Several examples of my acquaintance have exhibited significant leakage at those points, with highly negative effects upon running consistency. Easily fixed with one or two small gaskets. All of the above issues arise simply from the fact that the MARZ was a mass-produced engine that was not manufactured to anything approaching tool-room standards and did not receive a great deal of individual attention at the factory. It's therefore up to the owner to give it that attention. This does not detract in any way from the fact that this is a very well thought-out design which is quite well made where it counts and which performs at what would have been viewed as a quite high level by then-contemporary non-competition standards. Once the engine is properly set up, the two remaining points to consider are intake choke area and fuel. The MARZ was supplied with two alternative intake venturis having throat diameters of 3.0 mm and 3.5 mm respectively. The engine delivers its highest power output with the 3.5 mm intake fitted, but the resulting 9.6 mm2 choke area provides very marginal levels of suction if the engine is used in an aerobatic application. The 3 mm fitting provides a more reasonable choke area of 7.0 mm2, which allows the engine to perform very consistently in such an application. I always used the 3 mm venturi for aerobatic flying - I suspect that it was the preferred standard fitting. Turning now to fuel, the reader may recall that the manufacturers recommended an un-doped fuel containing 33% castor oil for general use. This may seem excessive, but there is actually some sound reasoning behind it. The major down-side of the reverse drum valve induction arrangement is the fact that it has a tendency to starve the conrod big end of both oil and direct incoming cooling mixture flow, causing it to run hot or even fail. It was this issue that led to the progressive abandonment of the reverse drum valve design in leading-edge team race diesels as time went on. I always used at least 25% castor oil in my operational MARZ engines. I also added up to 2% ignition improver, to which the engines responded well.

When I first started using the MARZ engines in June 1997, I noted the above points and accordingly anticipated no problems with the crankshaft. Alas, in service these shafts have unexpectedly proven to be the one potential Achilles' Heel of the MARZ. Since I started using MARZ engines myself, I naturally followed the fortunes of other users of the engine in my area. In the intervening years, I saw no fewer than four MARZ engines break their crankshafts in normal operation (as opposed to crashing or other abuse). Three of these were owned by others, but the fourth was my own favorite MARZ no. 2111, which broke its crank in flight after only 5 hours of running time (I log all my engine runs), admittedly for the most part in flight at or near its peak after break-in. All of the others failed after logging generally similar amounts of running time. It must be stressed that by no means all MARZ engines of my acquaintance have suffered in this way - I know of some which are still hanging together after quite a few hours of hard running. And I have yet to hear of a glow-plug model failing in this manner. But four relatively early shaft failures out of a group of some 12 or so diesels with which I have had direct operational contact does give reasonable grounds for concern, and there has to be a reason for such a relatively high proportion of failures of the same apparently sturdy component. All of these failures were identical in nature - the crankweb sheared off cleanly at the point where the shaft journal joined it. As noted earlier, the unavoidable corner at this point is nicely radiused during the grinding of the journal and the journal diameter itself appears more than adequate for the job - you'd actually expect the far thinner crankpin to go first. Therefore, the problem must surely be either with the steel used or with the heat treatment applied - more likely the latter in my personal view, given the fact that the crankpins don't seem especially vulnerable to failure. The break invariably presents the appearance of a brittle fatigue failure, so perhaps some of the shafts are over-hardened or prone to the development of internal stresses at that particular point during manufacture. Certainly, the very short-stroke design is bound to place higher-than-normal cyclic shear stresses upon this point due to the high combustion loads allied to the pounding action of the big-bore piston transmitted through the conrod – perfect conditions for initiating a fatigue failure.

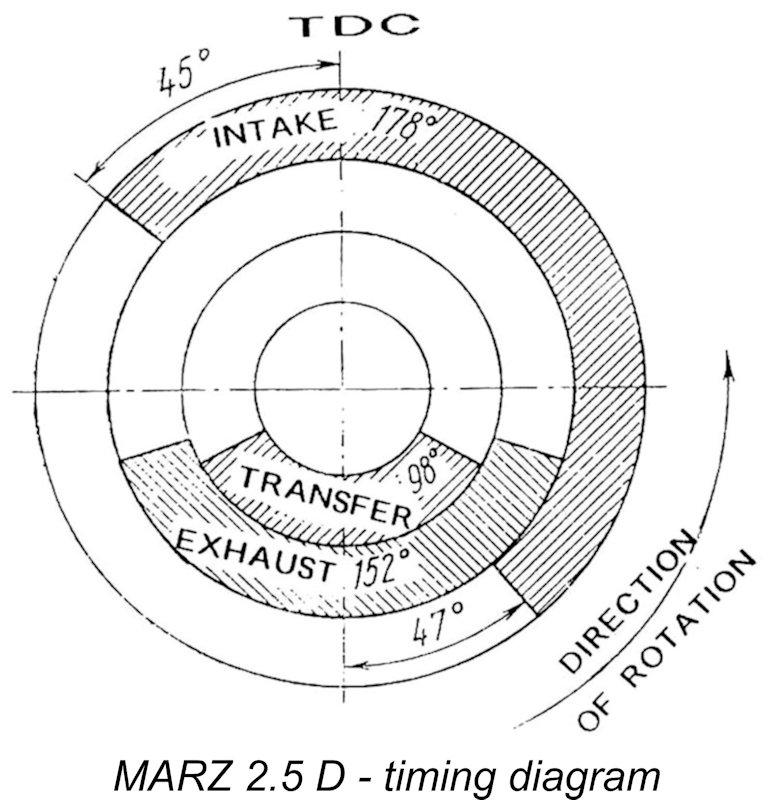

I've found this to be quite effective in other cases where shaft failures have been observed to be a routine occurrence. It certainly does no harm, seeming to produce good results in other breakage-prone designs such as the Chinese-made Silver Swallow 2.47 cc diesel. Others may or may not wish to copy, but I personally recommend that prospective users take this step, just to be that little bit safer. I repeat - by no means all examples of the MARZ have exhibited this behavior, but it's best to take precautions in my view. My repaired MARZ has since done over two more very satisfactory hours at full chat in the air with no problems. All other components remain in great shape with little wear thanks to my use of at least 25% castor oil. So far so good, and I'm happy! If the normalized shaft ever lets go, I'll give up on the Russian steel and make two new shafts of proper material from scratch so that I can repair my trusty flyer yet again and also restore the otherwise pristine example from which I borrowed the present shaft. My rebuilt engine is still running on the original Russian-made ball races. Although those in my unit appear by "feel" to be of quite reasonable quality, I would expect some performance improvement to result from their replacement with higher-quality bearings from elsewhere. If the shaft ever requires replacement again, I'll make such a switch. After learning that I intended to transfer this article over from MEN to my own website, my good mate Maris Dislers was kind enough to share his own insights and experiences with the MARZ. Maris's observations constitute the next section of this article. Thanks, mate!! MARZ and MeBy Maris Dislers Back when Ilya Leydman sold MARZ engines through Macheast in Sydney, he’d give a discount on batches of ten. I’d bite, after which I’d strip, clean and adjust the engines before selling them on, mainly to foster more control line flying activity. Typically, eight in ten were fine, while the other two were “for spares” or needed substantial extra work to make them useable. No different from other “consumer grade” Soviet engines from the Iron Curtain era when production quantity was prioritised over quality, and an acceptable trade-off for the bargain price. Timing figures of these engines were all over the shop - I've measured exhaust timing durations ranging between a high of 160° all the way down to 135°! Transfer periods have ranged from a high of 100° down to only 92°. Piston/cylinder fits too have been found to be highly variable. Reflects a certain lack of precision and consistency in the manufacture of these engines, with considerable variations in performance to be expected.

After a couple of my MARZ engines succumbed in this way, admittedly after a fair bit of use, I decided to investigate the problem. I found that in some cases the crankshaft is not ground parallel all the way to the crankweb shoulder. This is likely due to not dressing the grinding wheel often enough. It results in a substantial increase in diameter just before the crankweb that can prevent the ball-race from seating completely against the crankweb face as designed. The effect is to increase the crankshaft overhang beyond the bearing and hence the bending load exerted by the conrod on the crankshaft during each firing stroke by as much as 17%. Add to this the likelihood that the conrod will ride back on the over-long crankpin till it rubs against the intake rotor, and the extra loading goes up by around 34-40%. This is not good news for the modestly proportioned crankshaft’s life expectancy! If your MARZ is afflicted in this way, a rebuild of the bottom end might be a good idea if you want to increase its chances of long-term survival. You will need a lathe to make some simple spacers to relocate the critical parts. It's a bit of a fiddle, but not really very difficult to do. You will end up with a correctly aligned bottom end that keeps the conrod smack bang in the centre of the cylinder bore where it belongs and significantly reduces the cyclic bending loads experienced by the crankshaft during operation. The rebuild involves dressing the rear of the crankshaft journal with a fine whetstone just sufficiently to allow the rear ball-race to sit all the way back against the crankweb while remaining a light press fit on the shaft. This may position the crankshaft a little forward of its ideal position relative to the bore, so it may be necessary to turn a thin alloy ring spacer to move the rear ball-race towards the rear by an appropriate amount. If this is done, it will probably also be necessary to turn a second spacer to position the front ball-race correctly as well relative to the front shoulder on the crankshaft. If the crankshaft has been moved back appreciably, it may bind against the drum valve driving disc when an attempt is made to tighten down the backplate. Such a problem will require the turning of the front face of the drum valve housing to move the drum itself reawards, re-establishing sufficient clearance between the drum valve and the crankshaft. The one remaining issue is the fact that the crankpin is somewhat longer than it needs to be, allowing the conrod big end to wander rearwards and increase the cyclic bending stresses on the crankpin and crankshaft. It's wise to make a shim to fit onto the crankpin behind the conrod to prevent the rod from moving rearwards to any appreciable extent. I made mine out of brass.

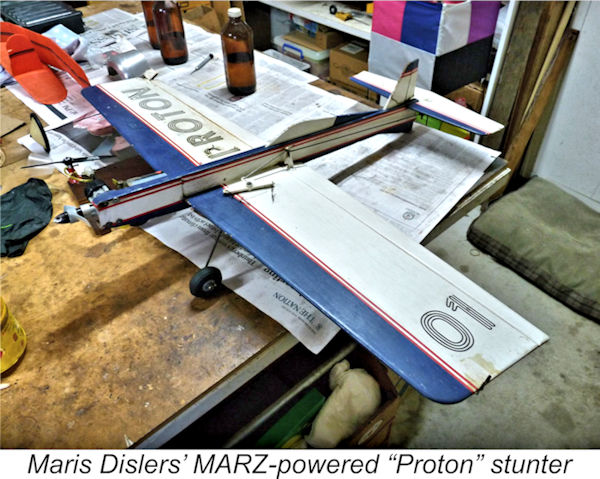

The thick cylinder wall takes some time to reach full operating temperature. Upping compression speeds up the process, but don’t forget to revert to the minimum needed for smooth running once the warm-up is complete. The MARZ tolerates over-compression very well but loads the seemingly-vulnerable crankshaft needlessly in that condition – best to operate at minimum warmed-up compression. I put my modified test MARZ to good use at the 2025 Oily Hand meeting, using it to power my old Proton profile control line stunt model. It performed this assignment with authority and consistency. An 8x6 JXF airscrew works very well with this combination - the modified MARZ turns it at 13,300 RPM on the ground. A few comments on specific points: Diesel vs. Glow - going by Brian Winch’s previously-mentioned tests for “Airborne” magazine, the glow engines created by Macheast gave a little less power with mid-range propellers (both engines fitted with muffler). Results without the muffler could be different (my own results certainly were – A.D.). The glow version was found to be particularly easy to start. Muffler vs. open exhaust – the Macheast muffler robs power quite significantly, particularly at mid-range or higher speeds. This is almost certainly due to the ingestion of exhaust gases via sub-piston induction (SPI). Richard Herbert found 1000 RPM less with larger propellers, maybe 2000 RPM with smaller ones. My results suggested maximum power drop at mid-range speeds. The muffler can be repositioned upside down for open exhaust, but omitting the muffler altogether leaves the cylinder sitting too low on the Macheast-modified crankcase. A spacer ring under the cylinder location flange to eliminate SPI might improve its muffled performance. 3.5 mm vs. 3 mm venturi - the larger choke area adds 500 – 1,000 RPM to the rotational speed of a given prop but results in significantly trickier operation and reduced consistency in an aerobatic application. My experience using the engine in C/L aerobatic and combat models showed that extra care was needed with fuel tank design to make the larger venturi work, whereas the engine with the 3 mm venturi is much nicer to use. As a comparison of effective choke areas;

The original instruction book lists 3 mm as standard and 3.5 mm as an added option. Mine has had the line for the 3.5 mm venturi crossed out before despatch. This suggests that field testing had shown the smaller venturi to be best suited to the majority of users. All Macheast offerings that I’ve seen have had 3.5 mm venturis fitted, partially explaining their reputation for somewhat inconsistent running in the air. Performance Test ResultsThe MARZ was extensively tested/reviewed in the UK, Czechoslovakia, Canada and Australia – diesel, glow, with and without muffler, large and small venturi. I’ve set out the observed effects of these variables in general terms above. Some reviews provided performance curves, others only a table of propellers and associated RPM. How about a summary of “typical” open-exhaust diesel performance? Like the MK 12 series engines that it replaced, the MARZ is essentially analogous to the Webra Mach 1. The use of modified Arden-style cylinder porting means plenty of noise and a notable thirst for fuel, particularly with the 3.5 mm venturi. Despite its short stroke, the engine develops decent low-end torque, but it’s certainly not in the “slogger” category. It develops its maximum power at relatively high speeds for a 1950’s core design. Working fits and finishes will undoubtedly affect individual performance outcomes. For comparison purposes, I’ve tabulated available prop/RPM results using Richard Herbert’s chosen propeller set.

Dislers engine no. 4 ran unevenly at speeds approaching 16,000 RPM and higher. This behaviour could not be cured by adjusting controls and was only slightly improved by increasing the fuel’s ignition improver content from 1.5% to 2.5%. This characteristic was not noted by other testers and is probably unique to that one example.

The above graphs represent typical MARZ engine performance as reflected in the tests summarized above. The effect of increased induction capacity through the larger venturi is evident in the torque trend, which is extended and maintained considerably further along the RPM scale, allowing peak power to increase from 0.28 BHP @ 14,000 RPM to 0.34 BHP @ 15,000 RPM. Particularly well-fitted examples peak at slightly higher speeds. The larger venturi means slightly faster airspeeds in level flight or allows working with a propeller “one size up”, but compromises easy starting and suitability for aerobatic work. Now back to Adrian .............. An Experienced MARZ Re-tested

This well-used example is very far from stock. It has had the piston truncated and internally lightened, with a squish bowl being added to the underside of its contra-piston. In addition, the rear of the liner has been blended into the inlet tract as described earlier. The cylinder alignment has been corrected and the induction porting optimized. The standard cooling jacket has been replaced by one of my own making having more fins for improved cooling. The wrap-around prop driver and compression screw locking lever which I made for this engine reflect its earlier use in vintage combat service - its last model was a Dongus, as mentioned earlier.

As mentioned earlier, the engine has had its shaft replaced once - the original broke after about 5 hours of hard use, and the oven-normalized replacement has done over two more hours at high speed in the air. All fits remain excellent - the engine should logically be in peak operating condition. Its components other than the replacement shaft have done over 5 hours of high-speed airborne running since the engine's original test in 2008. It is still fitted with the original Russian ball-races, which feel very smooth when the engine is turned over.

Once running, response to the controls was both positive and progressive, making the establishment of optimal settings a very simple matter. Both controls held their settings perfectly - the compression screw locking lever seen in the photos was never required. Running was completely smooth and miss-free at all speeds tested. Vibration remained well within acceptable limits throughout - my piston-lightening efforts evidently paid off, also hopefully contributing to reduced cyclic stress reversals in the crankshaft. The following data were recorded on test:

These are very good figures indeed for a MARZ 2.5 D operating with a 3 mm intake venturi. A comparison with the previously-cited figures for Maris's engine no. 4 with a 3 mm venturi fitted shows that my tuned engine had a very clear performance edge over Maris's unit and an even greater advantage over the unit tested by Modelár using the same 3 mm venturi. Evidently my tuning paid off! My tuned engine seems to develop a peak output of around 0.364 BHP @ 16,700 RPM. I imagine that it would do even better with a 3.5 mm venturi fitted, probably getting close to the 0.400 BHP mark at over 17,000 RPM. I was extremely impressed with the handling qualities and performance characteristics displayed by my very "experienced" tuned MARZ during the course of this test. No wonder that I found this engine to be such an effective powerplant in service! Conclusion

But having said this, let's inject a little perspective here! The current cost of a new or as-new example of the MARZ is little more than the cost of a replacement crankshaft in many other latter-day units. Indeed, "bones" examples retaining an unbroken shaft can readily be found at a cost of a few dollars. So what do you have to lose, really? Experience shows that it generally takes a few hours of hard running to break one of these shafts. Even if you end up chucking the engine away after the shaft breaks, you'll almost certainly get your money's worth out of a MARZ given the excellent performance coupled with the low prices for which these engines can still be obtained quite readily. Then just go buy another, and away you go again! Anyway, there it is - the MARZ is a great engine to use and a really good deal in terms of value for money as long as you're aware of the possible pitfalls involved. I'd be interested to hear of the experiences of others with this very interesting and strong-running engine. ___________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published on MEN May 2008 This revised edition published October 2025 |

||

| |

Here's a tale of dark deeds and derring-do from the cloak-and-dagger side of the model engine trade - the fascinating saga of the Russian-made 2.5 cc MARZ 2.5 D diesel. Although long out of production, this interesting engine continues to be readily available worldwide today, partially as a result of a rather "intriguing" (pun intended) past history. Accordingly, it seems well worth recording what is known about its origins, travels and technical attributes while we can still find someone who's both willing and able to talk!

Here's a tale of dark deeds and derring-do from the cloak-and-dagger side of the model engine trade - the fascinating saga of the Russian-made 2.5 cc MARZ 2.5 D diesel. Although long out of production, this interesting engine continues to be readily available worldwide today, partially as a result of a rather "intriguing" (pun intended) past history. Accordingly, it seems well worth recording what is known about its origins, travels and technical attributes while we can still find someone who's both willing and able to talk! The origins of this refreshingly out-of-the-rut engine are somewhat shrouded in mystery, since the MARZ 2.5 D made its initial appearance during the period in which the Russian-based Communist regime was still very much in control of affairs in the Soviet Union. During that period, reliable information regarding such matters as Russian model engine production remained hard to come by, and I'm extremely grateful to my previously-acknowledged informants for doing so much to draw the veil aside for our benefit, Even so, I’m sure that there’s still a lot that I don’t know, so if anyone out there knows more, let's hear from you!

The origins of this refreshingly out-of-the-rut engine are somewhat shrouded in mystery, since the MARZ 2.5 D made its initial appearance during the period in which the Russian-based Communist regime was still very much in control of affairs in the Soviet Union. During that period, reliable information regarding such matters as Russian model engine production remained hard to come by, and I'm extremely grateful to my previously-acknowledged informants for doing so much to draw the veil aside for our benefit, Even so, I’m sure that there’s still a lot that I don’t know, so if anyone out there knows more, let's hear from you! The production and distribution of these engines was overseen by

The production and distribution of these engines was overseen by  use special engines produced in very small numbers to very high standards by a few members of their own elite group. The rest had to make do either with the clones or with competition engines obtained somehow from elsewhere.

use special engines produced in very small numbers to very high standards by a few members of their own elite group. The rest had to make do either with the clones or with competition engines obtained somehow from elsewhere. as the

as the  In a rear drum valve induction system, the drum is unstressed by the conrod and does not have to transmit the engine's torque to the prop. Accordingly, the use of this system allowed the tuner to take whatever liberties he chose with respect to the induction timing and porting without weakening any stressed component. This is in fact the greatest advantage of the drum valve set-up by comparison with the crankshaft rotary valve arrangement. A revised form of it was to be employed on the later MARZ and

In a rear drum valve induction system, the drum is unstressed by the conrod and does not have to transmit the engine's torque to the prop. Accordingly, the use of this system allowed the tuner to take whatever liberties he chose with respect to the induction timing and porting without weakening any stressed component. This is in fact the greatest advantage of the drum valve set-up by comparison with the crankshaft rotary valve arrangement. A revised form of it was to be employed on the later MARZ and  The RITM’s Oliver-based cylinder design was later changed to a configuration based on the Cox opposed twin-port system, but that did not help matters much and quality became increasingly inconsistent over time. Clearly there was an ongoing need for an improved "consumer" general-purpose powerplant using which beginning competitors could gain valuable experience. The long-established Webra-based

The RITM’s Oliver-based cylinder design was later changed to a configuration based on the Cox opposed twin-port system, but that did not help matters much and quality became increasingly inconsistent over time. Clearly there was an ongoing need for an improved "consumer" general-purpose powerplant using which beginning competitors could gain valuable experience. The long-established Webra-based  The MARZ 2.5D is quite an interesting and original design in terms of the particular combination of technical features which it displays. All of these features had been used previously by others, but the MARZ did embody some quite original thinking in terms of the combination of these ideas into an effective package.

The MARZ 2.5D is quite an interesting and original design in terms of the particular combination of technical features which it displays. All of these features had been used previously by others, but the MARZ did embody some quite original thinking in terms of the combination of these ideas into an effective package.

The use of a Cox-influenced remote needle valve, with fuel being fed from an annular chamber around the venturi directly into the 3 mm dia. venturi throat via a ring of very small holes drilled around the circumference of the venturi. This creates an unencumbered venturi section and promotes excellent homogeneity of the incoming mixture, at some cost in terms of suction. Tuning for range and performance (critical for team racing) is a simple matter of changing venturis to a larger or smaller bore. The very efficient induction system which results from all of this is supplemented by a modest degree of sub-piston induction (SPI), which unaccountably is not shown on the accompanying factory timing diagram. That said, I've never seen a MARZ that did not display some degree of SPI.

The use of a Cox-influenced remote needle valve, with fuel being fed from an annular chamber around the venturi directly into the 3 mm dia. venturi throat via a ring of very small holes drilled around the circumference of the venturi. This creates an unencumbered venturi section and promotes excellent homogeneity of the incoming mixture, at some cost in terms of suction. Tuning for range and performance (critical for team racing) is a simple matter of changing venturis to a larger or smaller bore. The very efficient induction system which results from all of this is supplemented by a modest degree of sub-piston induction (SPI), which unaccountably is not shown on the accompanying factory timing diagram. That said, I've never seen a MARZ that did not display some degree of SPI.  flutes, as do the Webra, the Alag, the Silver Swallow and the MK-12, but the flutes in the MARZ are grouped together in two groups of three flutes on each side of the liner rather than being uniformly distributed around the bore as with the others. This eliminates the front and rear transfer flutes, which would be largely encumbered by the crankweb and backplate anyway and could potentially be fouled by the gudgeon pin. It also prevents any interference between the transfer ports and the induction arrangements. The downside of this set-up is the fact that the transfer flutes have to terminate below the exhaust ports, thus restricting the available transfer period, which is only 98° on the MARZ, with a blow-down period of 27°. But the total transfer port area is very large, which doubtless does much to compensate for the short transfer period. Moreover, a fully-floating gudgeon pin can be used, making for greater simplicity of manufacture.

flutes, as do the Webra, the Alag, the Silver Swallow and the MK-12, but the flutes in the MARZ are grouped together in two groups of three flutes on each side of the liner rather than being uniformly distributed around the bore as with the others. This eliminates the front and rear transfer flutes, which would be largely encumbered by the crankweb and backplate anyway and could potentially be fouled by the gudgeon pin. It also prevents any interference between the transfer ports and the induction arrangements. The downside of this set-up is the fact that the transfer flutes have to terminate below the exhaust ports, thus restricting the available transfer period, which is only 98° on the MARZ, with a blow-down period of 27°. But the total transfer port area is very large, which doubtless does much to compensate for the short transfer period. Moreover, a fully-floating gudgeon pin can be used, making for greater simplicity of manufacture.  The retention of the cylinder liner by means of a slip-on light alloy cooling jacket which is secured to the crankcase by three screws at its base rather than in the more conventional manner by screws which pass through the entire length of the jacket. This ensures that the hold-down stresses are transferred to the liner at the exhaust port ring and that there are no distortional stresses set up in the jacket which might affect the liner above the port ring. This concept had been seen previously on engines such as the original

The retention of the cylinder liner by means of a slip-on light alloy cooling jacket which is secured to the crankcase by three screws at its base rather than in the more conventional manner by screws which pass through the entire length of the jacket. This ensures that the hold-down stresses are transferred to the liner at the exhaust port ring and that there are no distortional stresses set up in the jacket which might affect the liner above the port ring. This concept had been seen previously on engines such as the original  On the basis of a number of common characteristics, it appears quite probable that the design of the earlier 1.5 cc

On the basis of a number of common characteristics, it appears quite probable that the design of the earlier 1.5 cc  The MK-17 was reportedly produced at the Moscow aircraft fuel systems plant (ZNAR), a facility that was quite distinct from the MARZ aircraft maintenance operation, while the KMD was manufactured at the aircraft turbine plant in Leningrad (now St. Petersburg). Both of these facilities were accustomed to working to extremely high standards, a capability which was amply reflected in the superior quality of the engines that they manufactured for DOSAAF.

The MK-17 was reportedly produced at the Moscow aircraft fuel systems plant (ZNAR), a facility that was quite distinct from the MARZ aircraft maintenance operation, while the KMD was manufactured at the aircraft turbine plant in Leningrad (now St. Petersburg). Both of these facilities were accustomed to working to extremely high standards, a capability which was amply reflected in the superior quality of the engines that they manufactured for DOSAAF.  The engines were supplied in somewhat flimsy cardboard boxes complete with a supposedly matching but very poorly-balanced 8x4 nylon airscrew, a detailed set of Russian-language instructions, an alternative venturi insert for tuning purposes and a steel tommy bar for tightening the prop.

The engines were supplied in somewhat flimsy cardboard boxes complete with a supposedly matching but very poorly-balanced 8x4 nylon airscrew, a detailed set of Russian-language instructions, an alternative venturi insert for tuning purposes and a steel tommy bar for tightening the prop.  products at the time, these papers were dated, and the latest date that Ed recalled seeing was some time in 1987. Ed considered it likely that manufacture continued up to the final days of the Communist regime in the USSR in 1990 and ceased shortly thereafter.

products at the time, these papers were dated, and the latest date that Ed recalled seeing was some time in 1987. Ed considered it likely that manufacture continued up to the final days of the Communist regime in the USSR in 1990 and ceased shortly thereafter. Ilya was provided with production figures for the MARZ which indicated that some 500,000 examples of the engine were made during the 10 years or so that it was in production. No wonder there are still so many new or as-new examples available today! For a time during its heyday, the MARZ apparently became one of the most widely-used engines in the USSR.

Ilya was provided with production figures for the MARZ which indicated that some 500,000 examples of the engine were made during the 10 years or so that it was in production. No wonder there are still so many new or as-new examples available today! For a time during its heyday, the MARZ apparently became one of the most widely-used engines in the USSR.  At the time of Ilya's second visit in 1992, production of the MARZ had ceased. Ilya and his Russian partner acquired the remaining stocks as well as the die-casting machine and some of the CNC lathes. They established their own manufacturing facility in Moscow making Zeus engines, but made no more MARZ engines given the substantial number of completed engines that already existed. They shipped some 10,000 MARZ engines to Australia, both complete and as parts. It's a sobering reflection that these engines represented only some 2% of the total number of engines produced! The incomplete engines were assembled in Australia and the world-wide marketing effort was run from there.

At the time of Ilya's second visit in 1992, production of the MARZ had ceased. Ilya and his Russian partner acquired the remaining stocks as well as the die-casting machine and some of the CNC lathes. They established their own manufacturing facility in Moscow making Zeus engines, but made no more MARZ engines given the substantial number of completed engines that already existed. They shipped some 10,000 MARZ engines to Australia, both complete and as parts. It's a sobering reflection that these engines represented only some 2% of the total number of engines produced! The incomplete engines were assembled in Australia and the world-wide marketing effort was run from there. The engines are stamped with a simple four, five or six-digit number with no intervening breaks or other symbols. Ilya Leydman advised that both the engines and components received from the MARZ factory in 1992 were already stamped with their serial numbers, so this must have been done prior to the final assembly stage.

The engines are stamped with a simple four, five or six-digit number with no intervening breaks or other symbols. Ilya Leydman advised that both the engines and components received from the MARZ factory in 1992 were already stamped with their serial numbers, so this must have been done prior to the final assembly stage. In design terms, the MARZ does not appear to have evolved at all following its introduction. Presumably it was found to be quite satisfactory for the educational and training roles to which it was assigned, and that was the end of it - changes were not considered to be warranted.

In design terms, the MARZ does not appear to have evolved at all following its introduction. Presumably it was found to be quite satisfactory for the educational and training roles to which it was assigned, and that was the end of it - changes were not considered to be warranted.

Ilya Leydman pointed out that MARZ engines will be encountered with both plain as-cast crankcases and sandblasted components. It seems that the single die which was used to produce the castings (as noted earlier) sustained some damage, resulting in flaws to the castings. Repairs were made and the subsequent castings were sandblasted to minimize the evidence of the problem. A fascinating insight indeed!

Ilya Leydman pointed out that MARZ engines will be encountered with both plain as-cast crankcases and sandblasted components. It seems that the single die which was used to produce the castings (as noted earlier) sustained some damage, resulting in flaws to the castings. Repairs were made and the subsequent castings were sandblasted to minimize the evidence of the problem. A fascinating insight indeed!

The indication that a fast 8x6 prop should make a good control line airscrew is amply borne out by actual experience. If the engine is propped to run at around 12,000 RPM on the ground when used in control-line service, it will operate in the air quite close to its peak - somewhere in the region of 15,000 - 16,000 RPM or so. And when it does so, the results are more than satisfactory - an efficient 8x6 prop turning at that speed moves plenty of air!

The indication that a fast 8x6 prop should make a good control line airscrew is amply borne out by actual experience. If the engine is propped to run at around 12,000 RPM on the ground when used in control-line service, it will operate in the air quite close to its peak - somewhere in the region of 15,000 - 16,000 RPM or so. And when it does so, the results are more than satisfactory - an efficient 8x6 prop turning at that speed moves plenty of air!

The more ambitious would-be tuners can also use the Dremel to match the induction port in the drum valve more closely to the induction port in the backplate. The axial alignment of these two ports is not always perfect, and there may be some benefit in matching them up in this way. But once again the improvement is probably not all that significant.

The more ambitious would-be tuners can also use the Dremel to match the induction port in the drum valve more closely to the induction port in the backplate. The axial alignment of these two ports is not always perfect, and there may be some benefit in matching them up in this way. But once again the improvement is probably not all that significant. All of this having been said, there is one more factor lurking in the weeds which cannot be passed over so readily. This is the somewhat problematic MARZ crankshaft. At first sight, this appears to be a well-made and extremely sturdy item which should be well up to its task. After all, it is not weakened in any way by the presence of an induction passage, as would be the case if the engine used crankshaft front rotary valve induction. Moreover, the corners are nicely radiused during grinding to minimize any tendency for stress concentrations to develop.

All of this having been said, there is one more factor lurking in the weeds which cannot be passed over so readily. This is the somewhat problematic MARZ crankshaft. At first sight, this appears to be a well-made and extremely sturdy item which should be well up to its task. After all, it is not weakened in any way by the presence of an induction passage, as would be the case if the engine used crankshaft front rotary valve induction. Moreover, the corners are nicely radiused during grinding to minimize any tendency for stress concentrations to develop. I repaired my own MARZ by "borrowing" a crank from another new and unrun example of the engine that I had lying about. Before fitting the replacement crank (which was un-run), I stress-relieved and normalized it by placing it in a cold oven, heating the oven to 550° Fahrenheit, holding it there for two hours, then switching off and allowing the oven to cool slowly with the shaft still inside.

I repaired my own MARZ by "borrowing" a crank from another new and unrun example of the engine that I had lying about. Before fitting the replacement crank (which was un-run), I stress-relieved and normalized it by placing it in a cold oven, heating the oven to 550° Fahrenheit, holding it there for two hours, then switching off and allowing the oven to cool slowly with the shaft still inside. The Russian "8x4" propellers supplied with the engines were well out of balance, needing up to 10 mm snipped from the heavy blade. They were too low-pitched for control line flying, but OK for running in. In addition, some of the needle valves left much to be desired, sometimes being bent along the threaded length or having gland nuts that wouldn’t clamp the needle no matter how tightly they were set. Despite such issues, the engines generally did a decent job but did not endear themselves, especially when a number of them broke their crankshafts. Not all did so, and perhaps only after plenty of use, but the reputation stuck.

The Russian "8x4" propellers supplied with the engines were well out of balance, needing up to 10 mm snipped from the heavy blade. They were too low-pitched for control line flying, but OK for running in. In addition, some of the needle valves left much to be desired, sometimes being bent along the threaded length or having gland nuts that wouldn’t clamp the needle no matter how tightly they were set. Despite such issues, the engines generally did a decent job but did not endear themselves, especially when a number of them broke their crankshafts. Not all did so, and perhaps only after plenty of use, but the reputation stuck.

Dislers engine no. 1 might have had a tighter than usual piston fit. The MARZ gives its best performance when piston fit is more like that of a typical glow engine - somewhat looser than the typical diesel.

Dislers engine no. 1 might have had a tighter than usual piston fit. The MARZ gives its best performance when piston fit is more like that of a typical glow engine - somewhat looser than the typical diesel.

Inspired by Maris's example, and noting that my own contribution to his table was based on the use of Taipan props, I decided to re-test my previously-mentioned "flyer", engine number 2111. I therefore removed it from the "Dongus" combat model in which it had been resting unused for a few years. It seemed that I had done a good job of cleaning it after its last flying session, since it still turned over freely, with minimal external residue.

Inspired by Maris's example, and noting that my own contribution to his table was based on the use of Taipan props, I decided to re-test my previously-mentioned "flyer", engine number 2111. I therefore removed it from the "Dongus" combat model in which it had been resting unused for a few years. It seemed that I had done a good job of cleaning it after its last flying session, since it still turned over freely, with minimal external residue.  I also replaced the standard needle valve components with a P.A.W. assembly, which gave much improved consistency in operation as well as increasing the standardization of the spares in my field tool kit. The venturi is a standard MARZ 3.0 mm unit - the replacement needle valve will have no effect upon performance apart from possibly enhancing the precision and consistency of settings. It has certainly worked well for me in service!

I also replaced the standard needle valve components with a P.A.W. assembly, which gave much improved consistency in operation as well as increasing the standardization of the spares in my field tool kit. The venturi is a standard MARZ 3.0 mm unit - the replacement needle valve will have no effect upon performance apart from possibly enhancing the precision and consistency of settings. It has certainly worked well for me in service!

The above analysis should have confirmed that the MARZ is an interesting design which handles extremely well and runs very strongly if set up and used appropriately. The engine is well suited to a variety of sport-flying applications. Over 30 years after production ceased, new or as-new examples remain readily available at reasonable cost from a variety of sources. The engine’s main Achilles’ Heel appears to be a certain tendency to break crankshafts after some hours of running.