|

|

The Bonnier 5 cc diesel

This is the second of what I hope will eventually be a number of articles about French model engines. The first such article was my examination of the series of engines manufactured by Raymond Edmond Arnoux under the R.E.A. trade-name. That article remains available elsewhere on this web-site. It contains a detailed summary of pre-war model engine manufacturing in France, which will not be repeated here. I've since added additional articles covering the DELMO and Allouchéry engines from Paris. My article about the Airstar 2.15 cc diesel includes some coverage of the Airplan engines from the same French city. For reasons which are unclear, information about engines from the pioneering era in France appears to be in relatively short supply, at least in the English language. This is a great pity, because the history of model engine development in France is every bit as interesting as that of parallel efforts in other countries. In particular, the focused development of the model diesel engine in France preceded British and American efforts along those lines by some four or more years, giving the French a commanding early lead in this field. This of course was a direct result of the focus of Britain and America upon their active involvement in World War 2 prior to mid 1945. By contrast, during much of the wartime period France was either occupied or dominated by Nazi Germany, removing most of the French homeland from the disruption of direct military activity (although certain German-occupied areas became military targets both for Allied forces and the Resistance movement, while Free French forces fought on with courage and distinction elsewhere). This situation left the French homeland population free (if you can call it that) to pursue non-military activities like model engine development within the constraints of the German domination. Other occupied nations such as Norway and Denmark were similarly situated. The result was that at the time when the first British and American commercial model diesels began to appear in mid 1946, no fewer than 11 French commercial manufacturers were already offering model diesels, along with a number of Scandinavian producers! Indeed, some of these firms had been active in the model diesel field for up to five years at that point in time. Another very good reason for any model engine enthusiast to take an interest in French designs is the unquestionable fact that in general their quality was of the very highest order, especially where it counted. The products of pioneering French diesel manufacturers such as Micron, Allouchéry, DELMO, Maraget-Météore, Ouragan, Jide and Bosmorin (to name just a few) were all built to the very highest standards - no early “garden shed” offerings here! It appears that a standard of quality was established early on which any competing manufacturer would have to meet if he was to stay in business. The general excellence of the early French model diesels was such that some of them exerted a strong influence upon British and American designers during the early post-war period. Having made the above statements, honesty compels me to freely acknowledge the fact that I possess very little first-hand knowledge regarding French model engines despite owning a number of examples from different manufacturers. Engines from that country were not imported into Britain to any great extent during the period when I was cutting my modelling teeth there, nor were French engines the subject of much detailed commentary in the contemporary English-language modeling media. Indeed, the various French manufacturers appear to have been less than effective in establishing worldwide export arrangements - most of their products seem to have stayed at home.

Although now out of print, the book remains readily available both through Amazon France and eBay France, the latter being how I obtained my copy. A recent check confirmed that the book remained available as of early 2016 from both sources. However, it is not cheap – typically you’ll pay somewhere around 80 euros (US$90.00) for a clean as-new copy. Well worth it, though – what price knowledge?? Although the book is not free from error, there’s no other equivalent publication. In a very real sense, this is the French equivalent of Tim Dannels’ invaluable “American Model Engine Encyclopedia” (AMEE). I can pay it no higher compliment. I freely acknowledge having drawn extensively upon this outstanding work when carrying out the research for this article. I have also used several illustrations from the book, all of which are acknowledged in the captions. My sincere thanks to Adrien Maeght and his colleagues! That acknowledgement having been made, I must record the fact that, like all model engine historical works of my present acquaintance, Maeght's book is not immune from error. Unfortunately, one very significant error appears in the book's coverage of the Bonnier engines. My valued French colleague Michel Rosanoff has informed me that the book has the Mk. I and Mk. II versions of the Bonnier 5 cc diesel switched - the engine shown as a Mk. I is in fact the Mk. II model, and vice versa. Both the serial number data and the technical evidence support this view. I'm deeply indebted to Michel for setting the record straight on this point. More of the two variants in their place below.

At the time when I first wrote this article I had yet to establish a connection with Michel's forum. As a result, the original version of this text was both incomplete and inaccurate. I finally got around to checking page 61 of the Forum, on which an excellent capsule history of the Bonnier venture is to be found. This passage highlighted such a range of inaccuracies in my original text that I was forced to take it offline and make some major corrections. The present text which you are now reading incorporates all of those changes. My sincere thanks to Michel for setting me straight! As far as I’m aware, the only previously-published English-language online resource relating to the Bonnier diesel is the very brief article on the engine which was posted here some years ago on the late Ron Chernich’s indispensable but now frozen “Model Engine News” (MEN) web-site. Although it contains little in the way of detail, this article nonetheless represented a very good start. My sincere thanks are due to the late David Owen, Bert Streigler and of course my much-missed mate Ron Chernich for their efforts in getting the ball rolling through the preparation of that article. Now, before we dive into the details of the Bonnier engines, it’s well worth spending a little time reviewing the hitherto poorly-documented history of model diesel engine development in France. Accordingly, let’s begin as usual with some background …………… Background

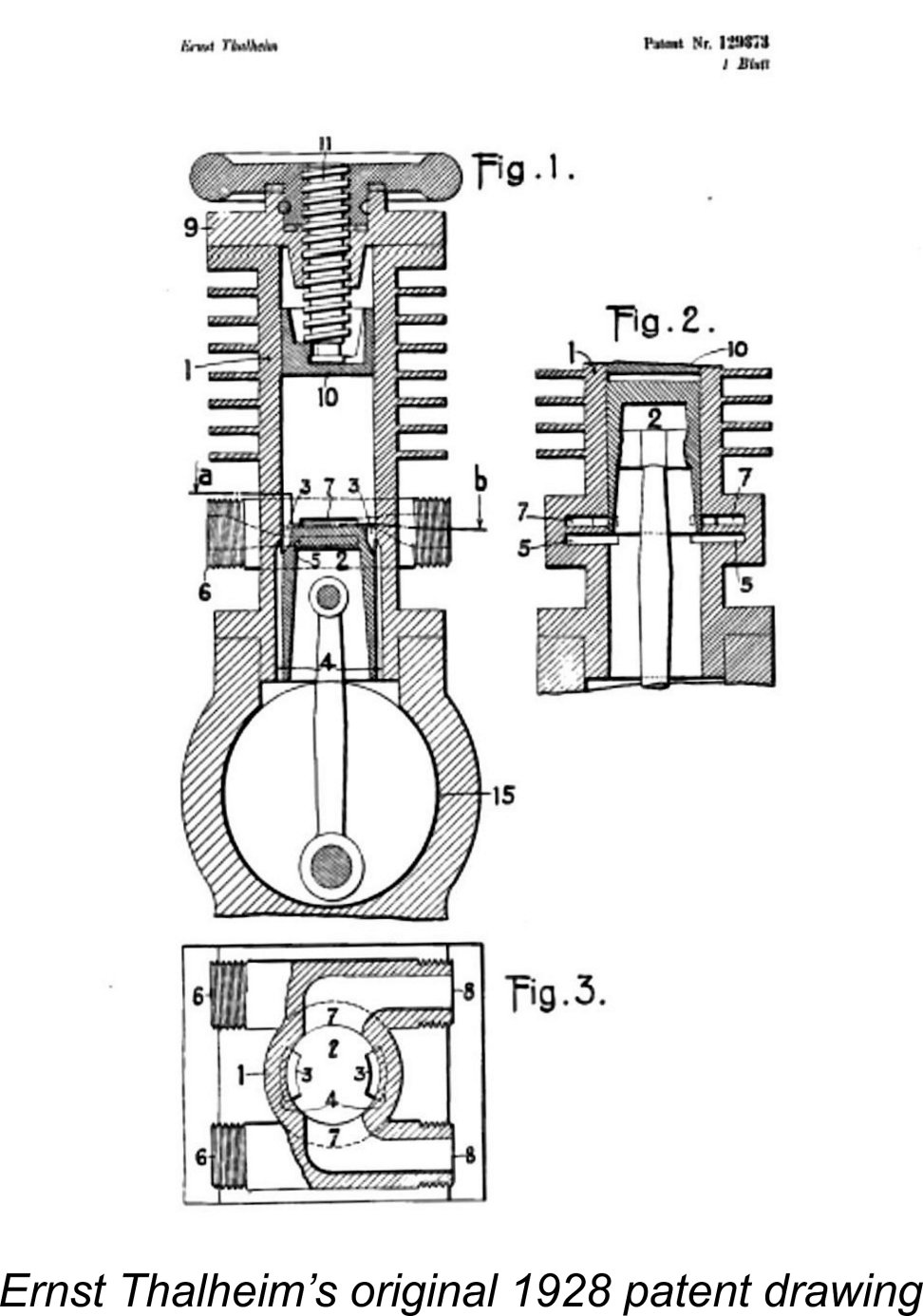

Interestingly enough, the patent specifications did not limit the application of this concept to model engines but were framed so as to encompass the use of the technlogy in engines of any scale. The patent also included the use of variable compression, as the accompanying drawing will confirm. Thalheim demonstrated one of his engines at an inventors’ fair in Basel in 1928. It seems that the demonstration did not elicit offers of instant riches, but Thalheim did produce “full size” ETHA (Ernst Thalheim) two-stroke stationary engines, according to the customer’s particular requirements. These included single cylinder farm engines, an inline 500 cc (30 in3) boat engine rated at 20 HP and a 106 cc (6.5 in3) boxer twin engine reportedly used in a light aircraft (powered glider?).

The next recorded practical experiments with model diesels of which I can find a record took place in Germany, where Gustav Eisfeld embarked upon the development of the concept in 1937. However, Eisfeld chose a far more challenging development path by focusing his attention upon fixed-compression "true" diesels having adjustable high pressure fuel pumps and injectors as opposed to carburettors. This approach may have been motivated by a desire to get around Thalheim's patent, which was not scheduled to expire until December 1942. By late 1937 Eisfeld had produced a successful prototype of a "true" diesel having a displacement of 15 cc (0.915 cuin.). This engine ran on a fixed 22:1 compression ratio and was equipped with an adjustable high-pressure injection pump and needle injector. When properly adjusted, it apparently ran very well on regular full-sized diesel fuel. A promising start, but further development of this remarkable engine was halted in view of the far greater ease of manufacture and superior dependability of the conventional spark ignition engines of that time. Eisfeld's concept would have been prohibitively expensive to produce in series.

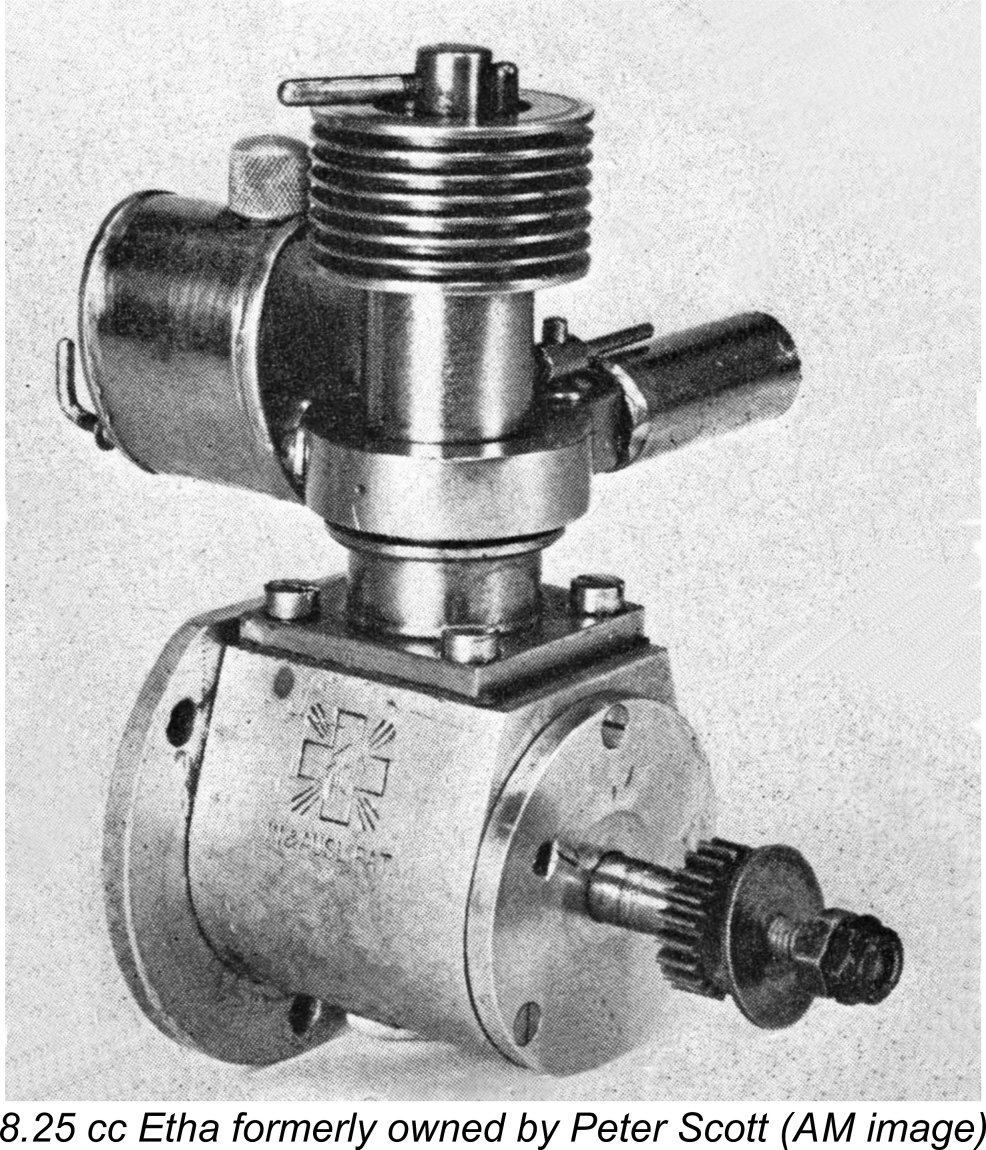

Whatever the precise date of their introduction, Thalheim's engines appear to have been the world's first commercial model "diesels". These units were marketed under the ETHA label, derived of course from Thalheim’s name rather than from a primary ingredient of the engine’s fuel! The ETHA engines were bulky, heavy and cumbersome. However, they were reportedly very competently constructed and ran well, thus proving the concept for all to see. A test by Maris Dislers of a replica ETHA 1 diesel may be found elsewhere on this website. The ETHA range was sold through a shop located at number 48 on the now-exclusive Bahnhoffstrasse in Zurich. This business was then owned by Oskar Hoppler, an optician by profession. As we would expect, this was principally an optical business, but Hoppler also had a keen interest in various forms of modelling which led him to establish a hobby department in part of his store. Here he sold both model railway items and aeromodelling goods as a sideline to the optical services which were his professional concern. We are greatly indebted to prominent English collector and writer Peter Scott, a former resident of Switzerland, for this information.

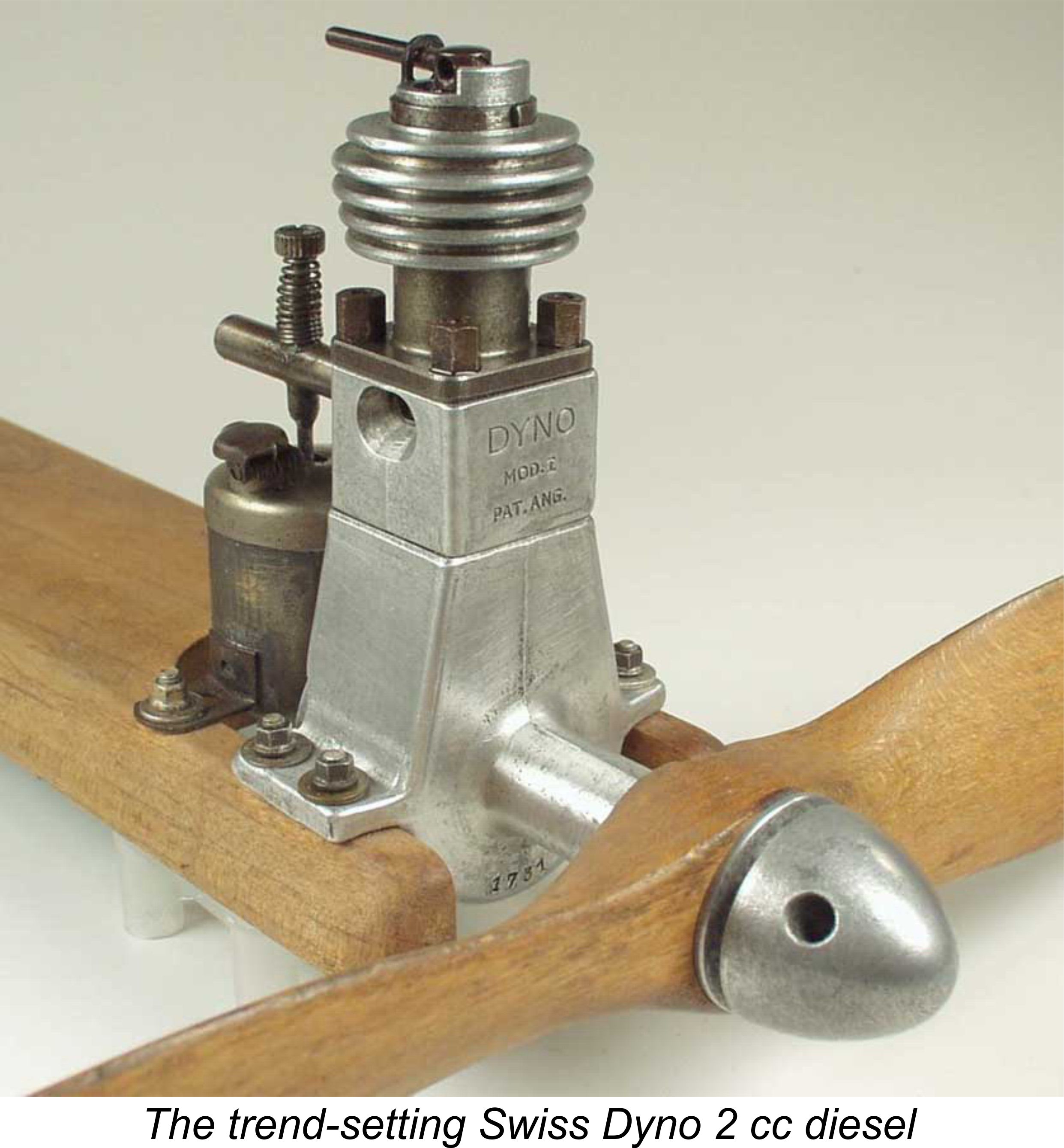

The technological success of the ETHA engines naturally inspired others to have a go for themselves. The previously-mentioned Dyno 2 cc model manufactured in Alfligen, Switzerland by Klemenz-Schenk and distributed once again by Oskar Hoppler (and later Gustav Feucht), was one of the earliest spin-off products, being developed between 1938 and 1940 and making its market debut in 1941. Incidentally, the name of this engine reflected the fact that the main business of Klemenz-Schenk was the manufacture of wheel-driven dynamos for bicycle lighting! The Dyno was a considerable step forward from the ETHA designs, being both smaller and lighter as well as having a higher specific power output. As time went on, the Dyno became one of the most influential and widely-imitated early model diesel designs of them all. It remained in production for some time following the conclusion of WW2, still being distributed from Gustav Feucht’s store on the Bahnhoffstrasse in Zurich. Its influence was such that, as Peter Scott has pointed out, there are probably far more Dyno "copies" around today than there are original examples!

News of the new technology also reached neutral Sweden in 1942, along with an actual example of the Dyno 2 cc engine which somehow crossed war-torn Europe to come into the possession of Gunnar Fahlnäs, then the editor of the popular Swedish technical magazine “Teknik för Alla”. Impressed with the performance of the Dyno, Fahlnäs commissioned the talented Swedish model engineer Ivan Rogstadius to develop a Dyno-based design for home construction, using his original Dyno as the prototype. Plans were drawn up during the winter of 1942/43, after which several engines were constructed. We have documented this story in another article to be found here on MEN.

Naturally, word of the new technology quickly spread from Sweden to German-occupied Norway, where pioneers like Jan David-Andersen and Øivind Andersen (no relation) immediately began their own experiments with model diesels. The David-Andersen story too is covered in a separate article to be found elsewhere on this web-site.

Like Czechoslovakia, Norway and Denmark, much of the French homeland, including the area around Paris, was of course occupied by the Germans during most of the war. Paris itself was occupied on June 14th, 1940, remaining under Nazi control for over 4 years until its final liberation by Allied forces on August 25th, 1944. During most of this unhappy period, the French homeland was largely free from actual on-the-ground armed conflict, allowing residents some opportunity to pursue their former interests. Among these potential interests were of course model engine design, construction and operation. France was another of the occupied countries, like Czechoslovakia, Denmark and Norway, to which information regarding the practical application of the compression ignition principle to model engines had somehow found its way either immediately before or during the early war years. There’s no doubt that word about the new technology reached France quite early on. According to Michel Rosanoff, the model diesel concept was first unveiled in France on July 26, 1942 by two Parisian residents, Pierre Meunier and M. Rietti. They demonstrated an example of the Swiss Dyno in front of an audience of model enthusiasts and journalists from the modelling community and the hobby media.

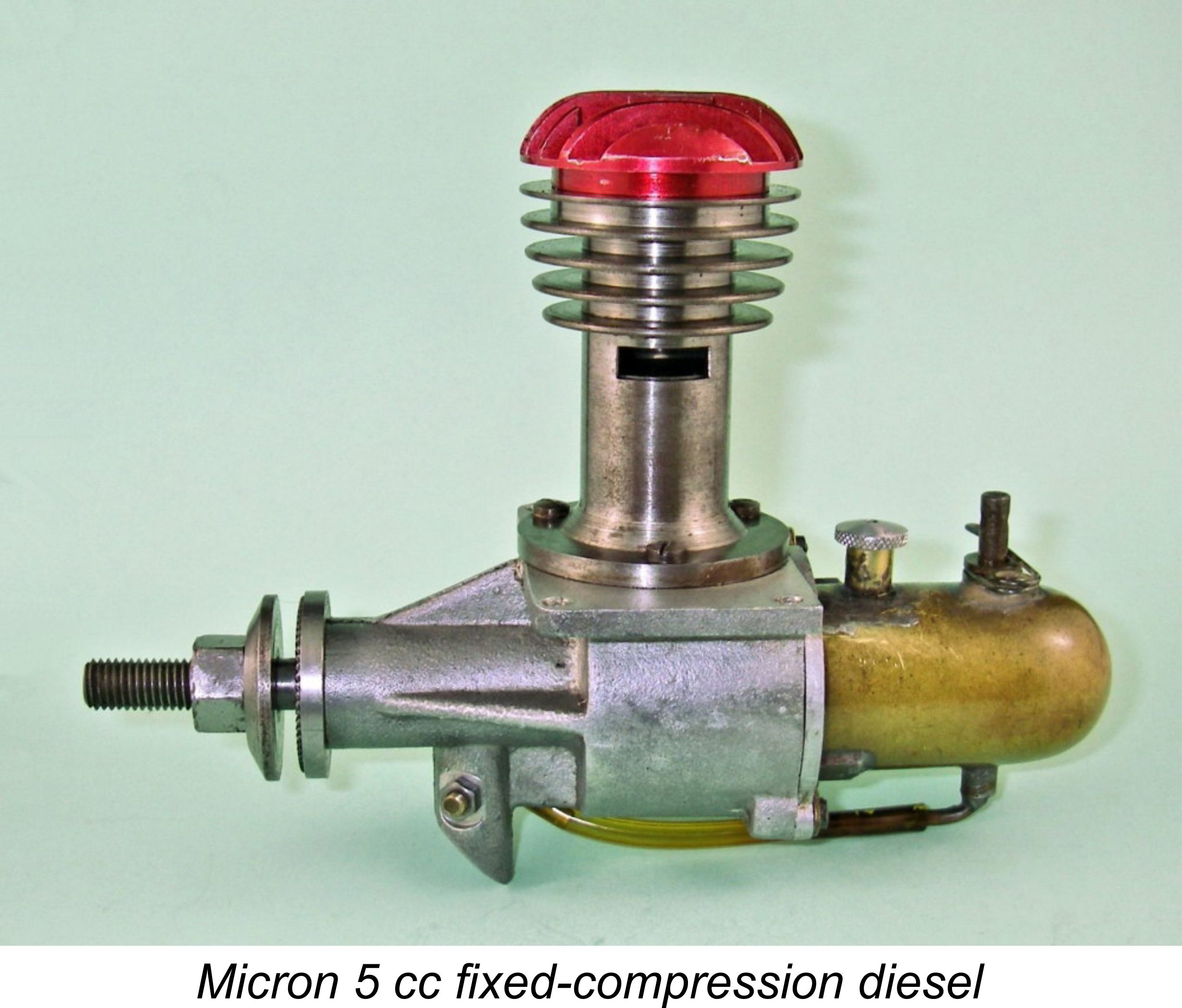

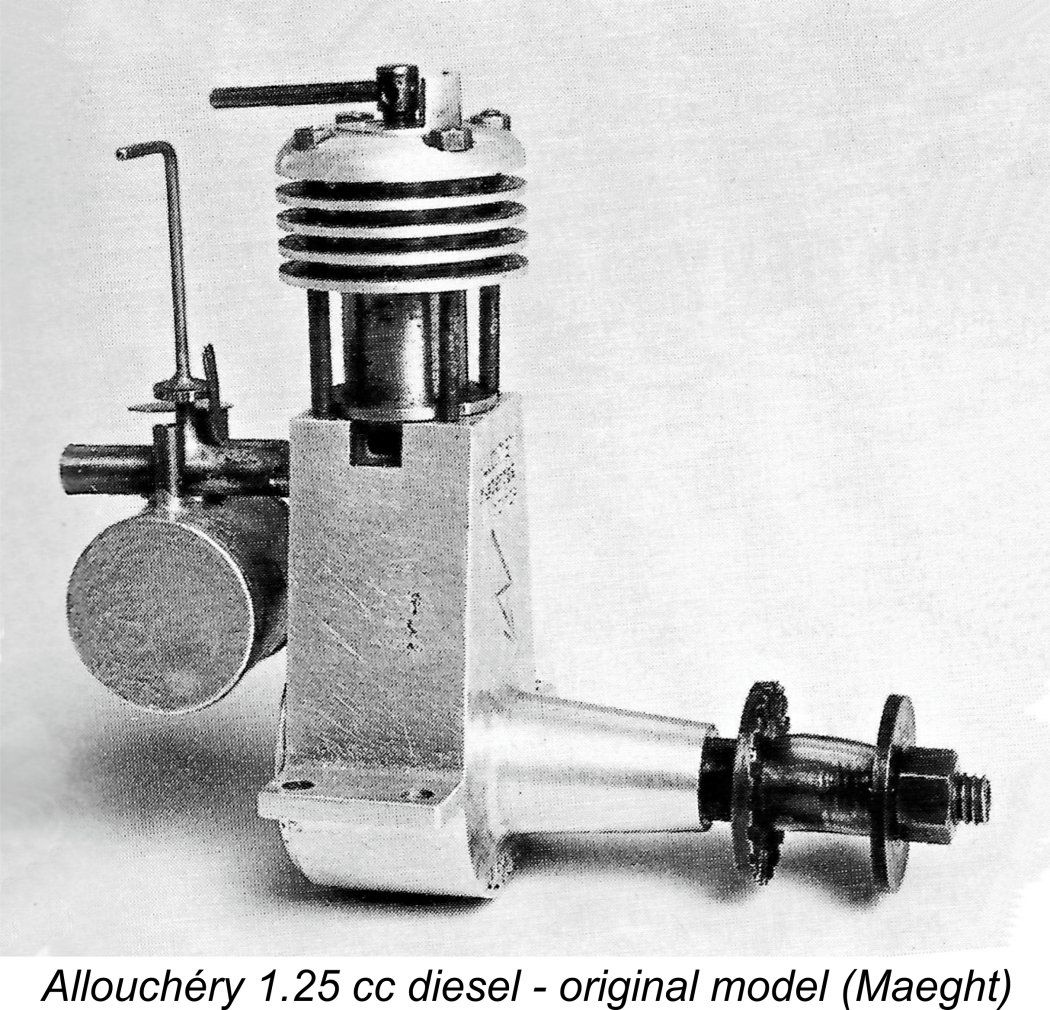

It’s not clear to what extent Thalheim’s patent rights extended beyond Switzerland. Perhaps assuming that they did and that Thalheim would renew his patent beyond its initial expiry date of December 31st, 1942, many of the earliest French diesels had either fixed compression (which worked well enough for larger engines, as the American Drone diesels amply demonstrated) or variable compression via an eccentric crankshaft bush. Either approach would neatly circumvent the Thalheim patent. In the event, Thalheim allowed his patent to lapse. Perhaps he was making his real living from other precision engineering work or was inclined towards a fairly widespread Swiss notion that inventors should not selfishly deny their inventions to others indefinitely. 1943 was the year in which the model diesel really took off in France. Apart from the previously-mentioned Micron 5 cc model, a host of competing French model diesel designs appeared more or less simultaneously from other makers. These included offerings from Allouchéry, Fulgur, Jide, Marquet, Morin and STAB. It’s worth remembering that all of this activity came three years prior to the appearance of the first British production diesels – quite a head start! An interesting observation is the fact that few if any of these early French models displayed much Dyno influence – although the French designers were undoubtedly aware of that engine, they clearly preferred to plough their own design furrow.

The manufacture and marketing of these engines seems to have been carried on quite openly, implying that the German authorities had not placed any specific restrictions upon the flying of model aircraft in occupied or German-dominated France. Presumably they reasoned that allowing people in occupied territories to continue with their hobbies made them less likely to become discontented to the point where they became actively resistant to the occupying power. Even in countries like Norway, where model flying was officially banned by the Germans, they actually appear to have turned a blind eye to the fact that Norwegian modellers continued their activities in defiance of the ban. It's not impossible that some members of the German armed forces may actually have been participants in the hobby and therefore sympathetic to its continuance even in wartime. Another point which merits our notice is the apparent emergence of a French “house style” of model diesel based on the use of fixed compression. There’s little or no doubt that the French designers were first in the field when it came to investigating this approach to the design and operation of model diesels. Adrien Maeght tells us that of the seven diesel models listed above as having been released in 1943, no fewer than four featured fixed compression as a design standard, at least at this early stage. The leading light in the development of the fixed compression model diesel in France was undoubtedly André Gladieux of Paris, who had entered the model engine field in 1941 with a 10 cc spark ignition model. After a small number of these engines had been produced (during the German occupation, remember), Gladieux turned his attention to the compression ignition principle, adopting the trade-name of Micron and introducing the initial variant of his iconic Micron 5 cc fixed-compression model in 1943. A relatively short-lived and now mega-rare 10 cc version of the same engine soon followed. There’s little doubt that although a market for model engines must have existed in occupied France, as noted earlier, any such market must surely have been somewhat constrained during the war years. Moreover, the export market was of course ruled out. However, as the war drew towards its conclusion following the August 1944 liberation of Paris, Gladieux moved quickly to increase production of the Micron 5 cc fixed compression model. That engine was a very dependable and powerful performer by the standards of its day, quickly establishing itself as a top free flight competition engine by winning everything in sight in France and other European countries in 1946 and 1947. Once export avenues opened up again, examples soon found their way to many overseas countries, including Britain and America. The engine’s merits were such that it was to remain in production at some level right up to 1960, with a limited edition “collector’s special” version The success of the Micron naturally encouraged other early post-war manufacturers both in France and elsewhere to follow the lead of M. Gladieux by introducing fixed-compression diesels of their own. Notable overseas examples of such engines which were directly inspired by the Micron design included the Owat 5 cc model from Bradford, England as well as the two successive Drone 5 cc fixed-compression models from America. The excellent Mk. II Drone of 1948 probably represented the high water mark of fixed compression diesel development. Gordon Burford of Australia paid this very successful engine the compliment of more or less duplicating its design in his Gee Bee Stuntmota Mk. III of mid 1949. A major marketing outlet for the various French engines was the famous Paris store “La Source des Inventions”. This was one of Paris’s oldest and most respected scientific supply houses, having opened its doors in 1907. It was located on Strasbourg Boulevard in Paris. Generations of young people with scientific minds dreamed of owning some of the products sold by this company. Model engines were among the early products sold by “La Source”, with steam engines being offered from 1908 onwards. These were joined by compressed air engines in 1920 and finally by petrol engines in 1938. During the early post-WW2 era, the French aeromodelling scene was covered in some detail by "Le Modèle Réduit d'Avion" (M.R.A.) magazine. Many of the major French model engine manufacturers, including Bonnier, advertised in this publication. The magazine's full name translates to "The Model Airplane". It seems to have been in effect the French equivalent of "Aeromodeller". It was still in publication as of the late 1960's.The advertisements placed in this magazine form an enlightening record of the market tenures of a number of French engines, including the Bonnier. From this point forward, we will focus on that model. The Bonnier 5 cc Diesel - Development and Production History

When one Googles the name Claude Bonnier today, no links with model engines emerge (apart, one dares to hope, from the present article!). Instead, one is directed to a number of excellent sources of information about the famed French war hero and Resistance figure Claude Bonnier, who took his own life in Bordeaux on February 9th, 1944 after being betrayed to the Gestapo by an informer. It’s abundantly clear that the Claude Bonnier who manufactured the model engines was a different individual. That said, there was a common interest in aviation, since the war hero Bonnier had worked both before and during the war in the full-sized aeronautical industry as an engine designer. The name association with a deservedly honoured French war hero may well have been an asset for the manufacturers of the Bonnier engines.

Despite the urgent need for major reconstruction as WW2 ended, the resumption of the Bonnier company’s former activity was slow because the businesses which had formerly used their equipment were very much in financial recovery mode as a result of the war. A full recovery was clearly going to take some time. Recognizing that they needed to more fully utilize their machine shop capacity in the interim and also needed to improve their cash flow, the company decided to become involved in the manufacture of model engines. In making this decision, they may well have been influenced by the views of model enthusiasts among their staff. This decision had the advantage of not requiring a large investment in new equipment - the company's existing machine tool inventory was apparently well up to the task, as were its machinist employees. The major hurdle was the fact that the Bonnier company was completely new to model engine manufacture, hence having no in-house design expertise in that field. This being the case, they very sensiby decided to outsource the design of their proposed model diesel engine.

It may seem highly suprising to learn that Gladieux would agree to design an engine for a different manufacturer who would be in direct competition with his own products. The evident reasons for his decision to play along are rather complex. At that time the 5 cc category was the most promising market niche in terms of sales volume, being viewed very positively by the French modelling community. However, French diesel engines of this displacement were thin on the ground at the time - those that were available were produced in very small numbers. In fact, Gladieux was unable to meet market demand for his own 5 cc model due to limitations in his own production capacity, leaving plenty of sales "headroom" for another manufacturer to pick up. But perhaps most compellingly, Gladieux was seeking to earn some extra capital to enable him to eventually expand his own operation, hence evidently being quite amenable to taking on some design work for others on the side. Indeed, the agreement with Bonnier was not Gladieux's first venture into the design consultancy arena - he had previously carried out design work for Airplan promoter J. Durandeaux, possibly including the Airplan "Normandie" fixed-compression diesel. He may even have constructed some of the Airplan engines under contract to Durandeaux.

In the end the Bonnier 5 cc diesel was very far from being a simple copy of the Micron 5 cc model. Except for the displacement, the type of ignition and the tank, everything was different. The blind cylinder jacket cast in unit with the bypass and exhaust stack is immediately noticeable, as are the removable carburettor and very different needle valve design. The testing period undergone by the Bonnier 5 cc diesel was unusually protracted. It was not until the latter part of 1946 that the engine began to reach the market in any quantity. A very positive write-up appeared in issue number 30 of the magazine "Decollage" for October 11, 1946. The manufacturers appear to have started out with high hopes of commercial success, putting a considerable promotional effort behind their entry into the model engine field. The Bonnier advertisements characterized the company’s products as being “designed and constructed by specialists in aero engines”. One aspect of the earlier advertisements is particularly noteworthy, since it implies a level of integrity often absent when it comes to advertising claims. The engines were openly stated to be designed according to the “Gladieux system”. This of course constitutes open recognition of Gladieux's role in the design of the engine, which did undeniably reflect that of the already-famous Micron 5 cc fixed-compression diesel. Perhaps this acknowledgement was a stipulation of Gladieux's agreement to design the Bonnier model. It's actually possible that Bonnier and Gladieux were friends as opposed to being merely business partners. The Claude Bonnier company was listed in Appendix III of the late 1946 first edition of the book “Model Diesels" compiled by D. J. Laidlaw-Dickson as being one of the main distributors of the Micron engines at that time. This arrangement may have been another stipulation attached to the deal. An interesting observation is the fact that although Laidlaw-Dickson appeared to be very well informed regarding then-current French diesels, he did not mention the Bonnier model engine marque. Bonnier's name was mentioned, but only in his capacity as a Micron distributor. This makes it appear certain that the September 1946 introduction of the first variant of the Bonnier 5 cc diesel post-dated the finialization of Laidlaw-Dickson's text. This seems to date the completion of that text to August or September 1946.

Despite the market presence of the Micron 5 cc and increased competition with the arrival of the Comète 5.5 cc and Marquet M5 diesel models, the Bonnier 5 cc diesel experienced some early success following its market launch in the fall of 1946. Both the references cited in the first advertisements and the engine's quality doubtless had a lot to do with this. The engine also attracted some attention at major competitions. In 1946, the Bonnier achieved a 2nd place podium finish at the second International competition held at Eaton Bray in England, thanks to the efforts of M. Deshouillers. This success was achieved against strong opposition. However, in 1947 things began to change - some new competition began to emerge. At the very beginning of the year the 5 cc Ouragan and DELMO Super 5 diesels appeared, both representing formidable competitors to the Bonnier along with the ongoing Micron 5 cc model. The Bonnier now stood out mainly thanks to its slightly lower price. In the advertisements from “La Source des Inventions” in the issues of M.R.A magazine published during 1947, the Bonnier sold for 2,340 francs. The Ouragan 5 cc, Micron 5 cc and DELMO Super 5 cc cost 2385, 2574 and 2700 francs respectively. Despite this slight price edge, the impressive initial sales figures relating to the Bonnier soon tailed off, as did the advertising, which no longer appeared in M.R.A. as of the spring of 1948. It is likely that by this time company management had begun to lose confidence in the long-term viability of this diversification of their production. Perhaps the need for such diversification was now less than it had been. However, a degree of residual optimism evidently remained. Despite the reduction in the effort applied to the Bonnier’s promotion, a decision was nonetheless taken to upgrade the engine. According to a retrospective article by Jacques Morisset which appeared in the late 1954 issue of the magazine "Les Ailes" (Wings), it was in 1949 that a new version of the engine was put on the market. This was most probably developed once again with the help of André Gladieux.

The sole apparent difference between the two variants was the method of sealing the cylinder bore. The previously-illustrated first version from late 1946 featured a blind-bored cylinder. The cylinder barrel casting included the integrally-cast cylinder head in unit. This version of the engine seems to be the more commonly-encountered variant today - all of the examples of my personal acquaintance to date have been of this type. The 1949 version of the engine featured an open-bored cylinder which was sealed and retained in the upper cylinder barrel by a detachable cylinder head. This head was secured by four studs which threaded into tapped holes in the cast alloy cylinder barrel and secured the head through the use of suitable nuts. At this point it's necessary to remind the reader of the previously-mentioned piece of misinformation which appears in Adrien Maeght's generally excellent book to which reference was made earlier. Maeght has the first and second models of the Bonnier switched! There is no doubt whatsoever regarding this point. He also has the assigned dates wrong for both models. Maeght's book is an invaluable source of information on French engines, but it is not free from error. This design change implies that the original blind-bore arrangement had been found wanting in some respects. For one thing, a blind-bored cylinder is notoriously more difficult to finish than a conventional open-ended cylindrical bore. It seems likely that this factor may well have influenced the design change with which we are concerned. Another relevant factor may be the intrinsic unsuitablility of a blind bore when employed in a fixed-compression diesel design. Based upon experience, the manufacturer may well have recognized the desirability of having some easy means of adjusting the "fixed" compression ratio. As the con-rod bearings and main crankshaft bearing wore, the elevation of the piston crown at top dead centre would inevitably become lowered by the amount of that wear. This in turn would reduce the engine's effective operating compression ratio. Likewise, any leakage due to wear of the piston/cylinder fit would also lower the effective operating compression ratio. With the fixed head used in the Mk. I model, no compensatory compression ratio adjustment was possible. The revised design allowed for the adjustment of the compression ratio as necessary by the use of shims or gaskets of varying thicknesses between the head and the cylinder. It's worth noting that every other fixed-compression diesel of my acquaintance (Drone, Vivell, Owat, Micron) utilizes a separate bolt-on head for this purpose.

This improvement in performance was obtained on the one hand by the use of a piston provided with a chamfer on the exhaust side piston crown which increased the opening period of the latter, and on the other hand by a modification of the gas distribution timing figures. But the big news, perhaps a first in France, was the fact that both versions were available in a variable-speed format employing a carburetor fitted with a rotary barrel. This barrel could be rotated either by a cable or by an electronic relay. In both cases a return to the full throttle position was ensured by a return spring.

One positive change in the marketing picture was the fact that by 1954 the only other French 5 cc diesel remaining on the market was the venerable Micron fixed compression model. Moreover, the Bonnier was well positioned in price terms relative to the Micron. In the 1955 catalogue of the "Modelavia" company, the Micron was priced at 6,800 francs, while the Bonnier "A" and "B" models sold for 5,650 and 7,410 francs respectively. The car version was priced at 8,000 francs. These later engines were supplied without tanks. However, the market emphasis was no longer on big diesels - most modellers now viewed glow-plug ignition as being superior in displacements over 3.5 cc. Despite the efforts of the promoters, this revival of activity ended in failure. A final Bonnier advertisement appeared in the July 1956 issue of "Modèle Magazine". The brand was still listed in the 1957 edition of the "Modelavia" catalog, but that year marked the end of the Bonnier model engine range. Having now traced the history of the development and marketing of the Bonnier engines from start to finish. it's now time to look a little more closely at the engines themselves. The Bonnier 5 cc Diesel - Description

Both models featured nominal bore and stroke measurements of 17.0 mm and 22.0 mm respectively for a displacement of 4.99 cc. These figures are identical to the corresponding measurements for the contemporary Micron 5 cc model. Adrien Maeght quoted the weight of both variants as 325 gm (11.46 ounces), a pretty typical weight for a fixed-compression diesel of this vintage and displacement. In the face of this claim, it’s bit puzzling to have to record the manufacturer's own written statement (reproduced below) that the engine weighed 280 gm in running order, a claim which is confirmed by the fact that my own illustrated Mk. I example insists on checking out at 283 gm (10 ounces exactly) all complete and original with spinner and tank as shown. I have no explanation for the discrepancy between Maeght's statement and the actual measured figure. Both models employed the same cross-flow loop Induction in both variants was by a basically conventional crankshaft front rotary valve (FRV) arrangement. However, there were several distinctive points of interest. Firstly, the updraft carburettor was not cast integrally with the main bearing but was a separate casting which was secured with a pair of machine screws to a flat surface formed integrally with the underside of the main bearing housing. A gasket was used to ensure a good seal. There was no spraybar – instead, the externally-threaded needle was carried in an This arrangement would have obvious advantages in the event of the bolt-on carburettor becoming damaged in a crash and requiring replacement. And indeed, the design of the component is such that replacement might have been a fairly regular requirement – the integrally-cast needle carrier looks extremely vulnerable to crash damage. However, perhaps an equally significant advantage was the fact that this arrangement permitted the use of a rotary crankshaft induction valve of unusual efficiency for the period. The bolt-on circular intake venturi fed directly into a large rectangular chamber which served as the actual crankcase induction register. The This system actually belonged on an engine having a far higher operating speed than the Bonnier! The system is in fact identical to that used on the very potent American Bungay Hi-Speed 600 FRV racing engine of 1948. The prop driver was nicely machined from steel. It was very securely located on a squared-off section of the crankshaft just forward of the main journal. A washer and aluminium alloy spinner nut completed the prop mounting assembly. At the rear, the tank was more or less identical to that used on the contemporary Micron fixed-compression diesel. It incorporated a filler spigot with push-on One point mentioned in the previously-noted MEN article on the Bonnier appears to require clarification. This relates to the presence of this tank. Bert Streigler stated on the basis of unspecified evidence that only the first model of the Bonnier had a tank. The truth appears to be that both the first and second models had tanks, but the tank was dispensed with for the final engines sold by the relocated company from 1954 onwards. A final comment on the engine's construction seems worth making for conservation reasons. The big end of the forged light alloy conrod is retained on the crankpin by a screw having a large-diameter head. This screw threads into the centrally-tapped crankpin. The screw has a left-hand thread, as it needs to have in order to guard against any tendency to unscrew when the engine is running. Any If two of the three examples with which I presently have direct contact may be taken as representative, the engines all appear to have carried serial numbers. The number 1053 is stamped onto the top of the left-hand mounting lug of my example, while my late friend and colleague David Owen owned similarly-stamped engine number 1055, only two units later. The third example (which I have since passed on) had had its serial number obliterated by some welding repairs to the mounting lugs. It appears certain that the serial numbering sequence for the Bonnier engines was started at engine number 1 and continued upwards without a break through the transition from the Mk. I to the Mk. II version. The factory test certificate which accompanied my previously-mentioned Mk. I example on which the number has been obliterated by welding bears the number 89. Michel Rosanoff owns Mk. I engine number 421, while Eric Offen has engine number 547. All of these numbers are consistent with the notion of a serial number sequence starting at 1. The number 1055 on David Owen’s Mk. I engine sems to confirm the manufacture of at least that many examples of the Mk. I variant. How many more than this were manufactured is presently unclear. What can be stated with some certainty is that the serial numbering sequence was continued without a break when the switch to the Mk. II variant was made. Michel Rosanoff owns Mk. II engine number 2473, which is consistent with this view. Of course, all that we can say at present about relative numbers of the two models is that the switch occurred somewhere between engine numbers 1055 and 2473. We'd need more serial numbers to narrow that gap. The only other identification which evidently appeared on all of the Mk. I engines was the name “C.BONNIER” cast in relief as written onto the left-hand side of the main bearing housing. I’m unsure at present whether the later Mk. II models were similarly identified, but it seems likely – it would actually appear that both models used the same main crankcase casting. It’s impossible to comment authoritatively on the general standard of construction of these engines on the basis of the three examples for which first-hand data are available. All that can be said is that the standard of workmanship displayed by those three engines bears comparison with that of the better-quality models from other contemporary manufacturers. If they were all this good, we would objectively rate the standard of their construction as high. Although my own more complete engine has clearly been mounted and used, it retains excellent compression with first-class bearing fits throughout, as does its less perfect companion. David’s example was reportedly similarly well-fitted.

This makes it appear likely that the release of the Bonnier 5 cc model marked the end of Bonnier’s role as a Micron distributor. There's no need to postulate a falling-out between Claude Bonnier and André Gladieux to account for such an eventuality – it may simply be that Bonnier fancied his chances as an independent model engine manufacturer. The open acknowledgement of Gladieux’s involvement with the Bonnier design implies the ongoing existence of a friendly rivalry, for which there were many precedents at the time. As far as pricing goes, the illustrated handwritten note which accompanied my second example of the engine (which appears to be the manufacturer's response to a customer inquiry) quoted a price of 2,550 francs for the engine all complete with tank and ready to run. Assuming that this handwritten note dated from early 1947, as seems likely, the prevailing exchange rates at the time were approximately 260 francs to the US dollar and 780 francs to the British pound. The engine's quoted price was thus the equivalent of some US$9.80 or £3.27. It's pretty clear that if International trade restrictions had not been in place, this engine would have been very competitively priced on the export market! A matched 350 mm (roughly 14 inch) diameter "specially painted" airscrew of unspecified pitch was said to be available for an additional 120 francs. The purchaser was also expressly made responsible for additional charges relating to packing and shipping. Finally, the note stated that the engine would be "ready in late January". It was not made clear whether this was the particular engine being offered to the customer or if it referred instead to the date on which the first variant of the Bonnier 5 cc diesel would become generally available. If the note did indeed refer specifically to engine number 89 as cited on the accompanying test slip, then a delivery date of late January 1947 for such a low-numbered engine would imply that the Bonnier had been introduced only a short time previously. Manufacturer's Comments

First, let's look at the instruction manual. This was a nicely-presented and quite informative French-language document which would certainly have helped any new owner. Interestingly enough, the artist's rendition of the engine which appeared on the cover was complete in all respects, as opposed to the advertising images reproduced earlier which were missing the entire induction system! This illustration showed the first variant of the engine. The manual began by stating that all engines were tested and inspected at the factory prior to shipment. The document then proceeded to the all-important issue of fuel. Nothing could better emphasize the extremely fluid state of understanding which existed at the time with respect to the "best" formulation for model diesel fuels than the contents of this section of the manual! At the time when the manual was printed, the recommended fuel mixture was one to stand the hair on end! The printed text recommended a mixture consisting of 80% sulphuric ether, 15% kerosene and only 5% lubricating oil! Such a small proportion of oil in the mix appears to be an open invitation for both starting troubles and wear issues. It would appear that the manufacturers soon came to realize this, probably quite early on because they didn't go to the expense of having a revised version of the manual printed. Presumably they had a sizeable stock of those manuals already printed and naturally did not wish to write off the investment which they represented. Instead, the original printed proportions were crossed out by hand. In place of kerosene, gasoline was now specified as the second ingredient. The proportions were amended by hand to 50% sulphuric ether, 30% gasoline and 20% lubricating oil. Certainly a far more satisfactory oil content.

To add to the confusion, the previously-reproduced handwritten specification and pricing sheet which accompanied my second example of the engine gave yet another fuel mixture! This time the specified formula was 55% ether, 20% gasoline and 25% lubricating oil - the oil content was still climbing! The handwritten note continued to state that one could substitute for the gasoline, but now the range of approved substitutes had been expanded to include kerosene as well as Vaseline (by that name) or lubricating oil. Fascinating - some day I really should mix up a small batch of fuel containing Vaseline to see what happens ............. Having waded through the intricacies of fuel mixtures, the manual then got down to the business of actually operating the engine. Here the manufacturers displayed a good grasp of the basic principles of successful fixed compression diesel operation. Their first recommendation was that the oil content in the fuel be increased to as much as 30% for the initial starting attempts, since this would facilitate starting and would also make the needle setting less sensitive. A very sound recommendation in my book based on my own considerable experience, which is summarized in my separate article on fixed-compression diesel operation. They then laid out the actual starting procedures, beginning with the advice that the neeedle should be fully closed while fuelling the tank for that first start. One was then supposed to open the fuel cut-out and unscrew the needle 3 or 4 turns. Since the tank provided gravity feed to the spraybar, this should cause fuel to drip out of the updraft intake. If it didn't, one was advised to check both the fuel line and the fuel jet to ensure that both were clear. If all was well, the next step was to close the needle once more (thus stopping the drip) and then open it only some 1/4 to 1/2 a turn, i.e., very lean. One was then advised to flick the propeller until firing commenced, keeping the fingers as close to the hub as possible for maximum energy transfer. A really vigorous flick was quite correctly cited as a key to prompt starting. Interestingly, there was no suggestion of priming despite the fact that most of the fuel simply drips out of the intake in a gravity-fed updraft induction system like this one. The manufacturers were evidently relying upon the very wide explosive limits of ether, which allow ignition on a minimal percentage of that fuel component. Once the engine was firing, the manual cited two possibilities - one, the mixture was too rich, in which case the engine might fire once or twice but would not actually start, with fuel dripping out of the intake; and two, the mixture was too lean, in which case the engine would fire and run in short bursts but would not keep running. In the first case, one closed the needle slightly and tried again, while in the second case one opened the needle slightly before renewing the attempt. Once the engine kept running, the operator was then advised to open the needle until best performance was achieved.

In terms of performance, the previously-referenced handwritten information sheet which accompanied the other documents included the clearly-written claim that the engine developed a peak output of 0.18 CV (0.177 BHP) @ 4,200 RPM, with a practical speed range from 2,000 to 11,000 RPM. This is impossible to reconcile with Adrien Maeght's statement that the manufacturer claimed an output of 0.25 CV (0.246 BHP) @ 9,100 RPM. I must say that I have always found that claim difficult to accept. For me at least, the claim cited on the handwritten sheet is far more credible - after all, my own testing of the fundamentally similar Owat 5 cc model which was also based upon the design of the Micron indicated a potential output of 0.18 BHP @ 6,200 RPM or thereabouts. The test certificate reproduced at the right which accompanied engine number 89 confirmed that it had achieved the standard of 4,200 RPM using the recommended fuel mixture and (presumably) matching 350 mm prop. The fact that the 4,200 RPM figure was evidently the test standard lends considerable credibility to the lower figures cited by the manufacturer in the handwritten note. It's amusing to observe that the tester seemed a little unsure of the actual oil content in the test fuel! So now we know how the manufacturer suggested approaching the operation of this engine. How do those recommendations translate into success on the test bench? Let's find out! The Bonnier 5 cc Diesel on Test Credible or otherwise, the performance claim of 0.25 CV (0.25 cheval vapeur, equivalent to 0.247 BHP) at 9,100 RPM cited in Adrien Maeght's book was the same for both models. We might deduce from this that the induction and cylinder porting arrangements were unchanged when the second variant was introduced, supporting our earlier inference that the design change was made for reasons of adjustability as opposed to any significant performance enhancement.

By way of comparison, my own tests of the 1948 second model Drone 5 cc fixed-compression diesel with its ball-race crankshaft yielded a peak output of only 0.240 BHP @ 6,300 rpm. The Drone was almost certainly the finest expression of the fixed-compression diesel to emerge anywhere during the early post-war period. It's really difficult to see the Bonnier outperforming it as claimed by Maeght This being the case, the claim that the earlier plain bearing Bonnier exceeded both of these figures undoubtedly requires confirmation. The alternative claim of 0.177 BHP @ 4,200 rpm cited in the previously-referenced handwritten note seems far more credible. As far as I’m presently aware, the Bonnier 5 cc was never the subject of a published test, even in its native France. This however is a matter that can be remedied! Having on hand a nice example of the first variant in the form of engine number 1053, I was in a good position to test the manufacturer’s claims for myself. I felt comfortable in undertaking a test of this relatively rare engine due to my extensive past experience in running fixed-compression engines such as the Drone, Micron and Owat. The Bonnier had clearly survived a fair bit of previous running, leading me to believe that there was no reason why it should object to doing a little more! I was further encouraged by the knowledge that the late David Owen had tried his example years ago and found it to be a very good runner.

Since the Bonnier was evidently produced as a direct competitor to the contemporary Micron fixed compression model, I decided that the Micron would be the standard against which the Bonnier's performance would be evaluated. I had tested the Micron quite recently in the context of another article, hence having reliable figures for that engine. Anyone interested in learning about the black art of starting and running fixed compression diesels is invited to read my separate in-depth article on that somewhat arcane subject. Suffice it for now to say that the major The imperative of avoiding an overheating situation means that these engines have been found to run best on a fuel containing only ether and mineral oil. Ether has a very high latent heat of vaporization which cools the incoming mixture, thus contributing significantly to internal cooling of the engine. It also burns a great deal cooler than the more potent diesel mixes containing kerosene and ignition improver. Apart from its role as a lubricant, the presence of the mineral oil does much to reduce the tendency of the ether to detonate, which would otherwise impose excessive stresses upon the engine’s working components. In defiance of the manufacturer's fuel recommendations, I elected to conduct this test using a 75-25 mix of ether and SAE 30 mineral oil, a mixture with which I have always had good results. This was the recommended fuel for both the Drone and Micron diesels, and it seems to work well in general for other fixed-compression models, including the Owat. I saw no reason why it should not work just as well in the Bonnier.

To add to my doubts, flipping the Bonnier over with a prop fitted gave the impression that the engine’s compression ratio was in fact very similar to that built into the other models – my experienced and quite sensitive flicking finger was unable to detect any significant difference in compression resistance. In fact, I'd have said that if anything the Bonnier's compression ratio was slightly lower than that of the Micron. On this basis alone, I would not have expected the engine to peak at the kind of speed cited by the manufacturers. Definitely a matter requiring evaluation! I started out with a 14x6 APC prop, which earlier testing had shown to be a very compatible load for a typical 5 cc fixed-compression diesel. This prop has plenty of flywheel effect to help get things off to a good start. I began with my usual 75/25 ether/oil fuel mix. The Bonnier instructions were absolutely correct in noting that when starting a fixed compression diesel, it’s always best to begin at a relatively lean needle setting. Get the engine too rich and it won’t even fire. Moreover, any flooding will be extremely difficult to clear. Having set the needle at a relatively lean setting, a couple of choked flicks should be given in order to fill the fuel line. However, choking alone will not get the required fuel into the cylinder on an upright-mounted engine with an updraft intake like the Bonnier – the excess fuel drawn in by choking simply drips out of the intake under the influence of gravity. It is usually necessary to give such engines a small exhaust port prime to get fuel into the combustion chamber. However, the operative word is small – thanks to the very wide explosive limits of ether, these engines require very little fuel to get them going. Indeed, potential flooding is to be avoided like the plague since you can’t clear a flooded engine by backing off the compression setting and clearing the excess fuel in the usual way. A "dry" prime administered with the exhaust port closed seems to yield the best results.

I soon found that a large part of the problem lay with the needle valve, which was worn to a "wobble" fit and invariably jiggled about on its own after release, changing the setting almost continuously. I actually obtained my speed readings by retaining a hold on the needle and moving it about laterally like a lever until I happened upon the sweet spot! To ease subsequent restarts, I changed props very quickly and restarted the beast while still hot - perfectly straightforward. I got the feeling that 10% extra oil might really help matters, since the addition of oil to a fixed-compression diesel's fuel effectively raises the operating compression ratio. However, the major operating challenge was undoubtedly the very worn needle valve coupled with the low ambient temperature. Of course, none of this is a criticism of the engine's design or construction. It's simply that this example has been well used in the past and really requires a new needle valve set-up. If fitted with such a unit, I got the impression that starting and running would both be significantly improved. However, it won't be getting a new assembly from me since I want to keep the engine completely original! And at least the beast runs well enough as-is - it's just very hard to get at the optimum needle setting. Since I have no intention of flying it, that's not an issue for me.

The almost identical outputs indicated by the two slower props imply that maximum power is developed at some inderterminate speed between 5,200 and 5,700 RPM. I suspect that this example develops around 0.164 BHP @ 5,400 RPM - not all that far out of line with the manufacturer's claim in that hand-written note, albeit at a somewhat higher speed. I certainly found no support whatsoever for the figures quoted by Maeght. This admittedly rather unsatisfactory test was a frustrating experience for me, since I was conscious all the time that the engine was not delivering the best performance of which it was capable. Even so, the figures obtained were well within sight of those previously reported for the very similar Owat and Micron models. The Bonnier was a quality engine which was definitely in the hunt performance-wise! Conclusion I hope that you've enjoyed this look at one of the more elusive model engines from the early post-WW2 era. The Bonnier 5 cc diesel was a well-made engine which paid a very open and sincere tribute to its Micron ancestry. Its relative lack of ongoing market success was doubtless due far more to the speed at which its design became outmoded than to any intrinsic deficiencies in that design. The engine certainly underscored the manufacturing capabilities of the Claude Bonnier company. It's a shame that the company didn't continue in the model engine field with an updated design - they certainly had the manufacturing skills to execute such a design to a very high standard. As it is, we're left with a few examples of their sole product - the Bonnier 5 cc fixed-compression diesel. If you're lucky enough to run across one of these fine engines, I'm sure you'll enjoy the encounter! ___________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First Published June 2017 Comprehensively updated July 2020

|

| |

In other companion articles I've presented information on a few of the pioneering model diesels which incorporated the now-archaic feature of fixed compression. Notable among these were the

In other companion articles I've presented information on a few of the pioneering model diesels which incorporated the now-archaic feature of fixed compression. Notable among these were the  Fortunately, an excellent reference source is readily available to anyone having an interest in this subject. This is the invaluable ”

Fortunately, an excellent reference source is readily available to anyone having an interest in this subject. This is the invaluable ” In fact, I'm indebted to Michel for far more than that! Michel's outstanding

In fact, I'm indebted to Michel for far more than that! Michel's outstanding  The concept of the model compression ignition (aka somewhat incorrectly “diesel”) engine goes back way further than many of today’s model engine enthusiasts may realize. In the past it was frequently claimed that the Swiss Dyno 2 cc model of 1941 was the “first” commercial model diesel. While that may be true in terms of widespread acceptance and design influence, the concept actually dates back to December 17

The concept of the model compression ignition (aka somewhat incorrectly “diesel”) engine goes back way further than many of today’s model engine enthusiasts may realize. In the past it was frequently claimed that the Swiss Dyno 2 cc model of 1941 was the “first” commercial model diesel. While that may be true in terms of widespread acceptance and design influence, the concept actually dates back to December 17 A range of 12 “model” size Ethas ranging from .4 cc to 25 cc were also made to order over the subsequent decade. These were most likely table-top curios for the mechanically minded, much like miniature steam engines. It's doubtful that many of them took to the air.

A range of 12 “model” size Ethas ranging from .4 cc to 25 cc were also made to order over the subsequent decade. These were most likely table-top curios for the mechanically minded, much like miniature steam engines. It's doubtful that many of them took to the air. Meanwhile, the growing availability of proven spark ignition engines from America and the German Kratmo company in the mid to late 1930’s ignited Thalheim's interest in powered models. Perhaps some saw the potential in Thalheim’s unusual little engines, if their power-to-weight ratios could be improved. However it came about, Thalheim’s creativity seems to have been reinvigorated, leading him to further refine his own engine design concept specifically for model aero applications. Assertions by some that his ETHA 1 and 2 engines date as far back as 1938 in commercial form are only tentatively substantiated, but the engines were certainly already there when the far better-known 2 cc Dyno-1 from Klemez-Schenk arrived in 1941.

Meanwhile, the growing availability of proven spark ignition engines from America and the German Kratmo company in the mid to late 1930’s ignited Thalheim's interest in powered models. Perhaps some saw the potential in Thalheim’s unusual little engines, if their power-to-weight ratios could be improved. However it came about, Thalheim’s creativity seems to have been reinvigorated, leading him to further refine his own engine design concept specifically for model aero applications. Assertions by some that his ETHA 1 and 2 engines date as far back as 1938 in commercial form are only tentatively substantiated, but the engines were certainly already there when the far better-known 2 cc Dyno-1 from Klemez-Schenk arrived in 1941.  It’s worth noting in passing that Oskar Hoppler was tragically killed in a ski-ing accident in March 1942, at which point the optical store and the subsidiary hobby supply business were taken over by Gustav Feucht. Herr Feucht continued both aspects of the business.

It’s worth noting in passing that Oskar Hoppler was tragically killed in a ski-ing accident in March 1942, at which point the optical store and the subsidiary hobby supply business were taken over by Gustav Feucht. Herr Feucht continued both aspects of the business. Despite the fact that by the early 1940’s most of Europe was heavily embroiled in WW2, word about this then-innovative type of model engine somehow trickled out of Switzerland to reach a number of other European countries, both neutral and occupied. In an article which may still be found

Despite the fact that by the early 1940’s most of Europe was heavily embroiled in WW2, word about this then-innovative type of model engine somehow trickled out of Switzerland to reach a number of other European countries, both neutral and occupied. In an article which may still be found  An example of this design was successfully

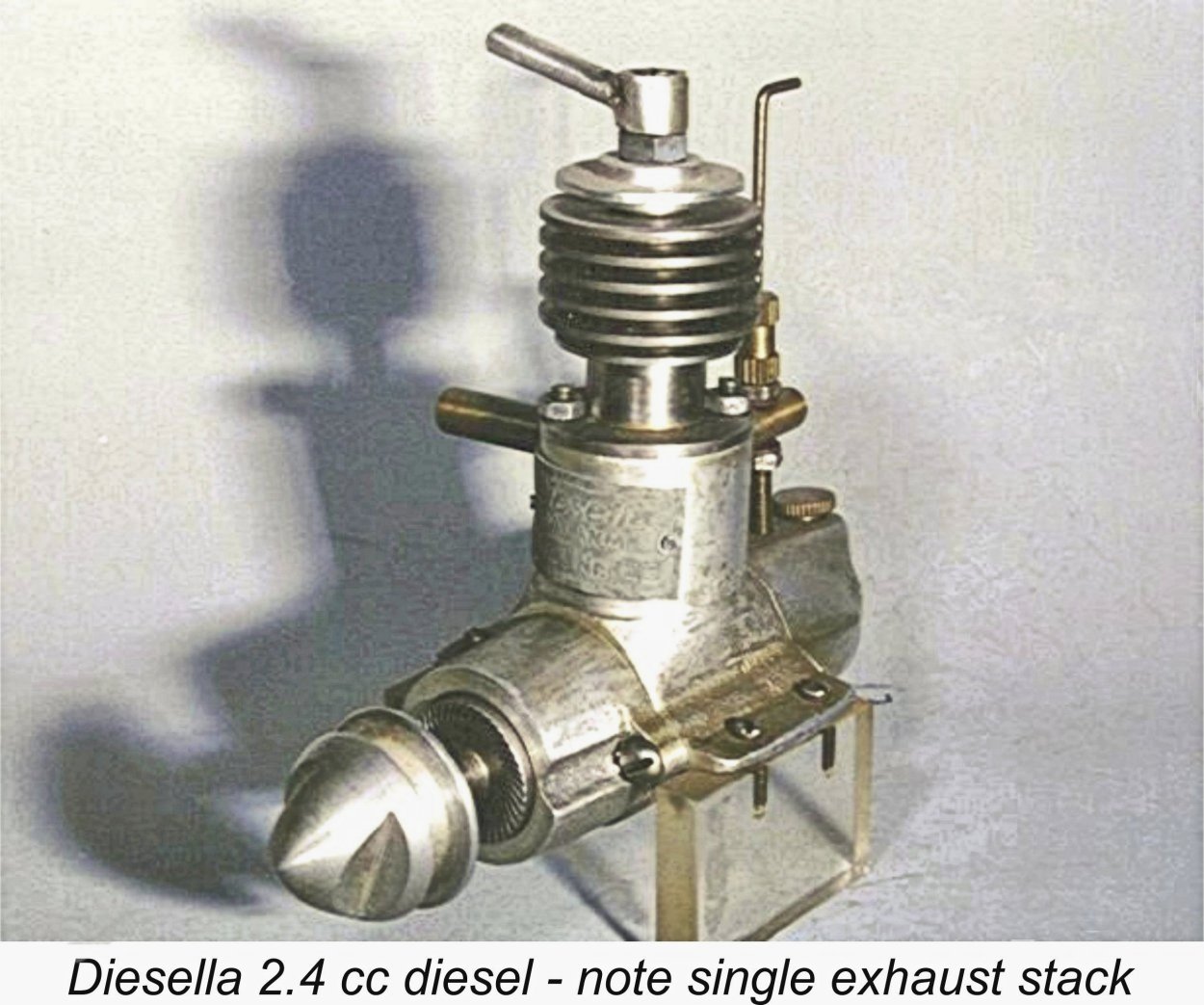

An example of this design was successfully  Another occupied country which was early in the model diesel field was Denmark. The first model diesel to be constructed in that country was reportedly made as early as 1940 by Carl Rose, manufacturer of the CEROS model engine range. However, Rose did not pursue the concept at that time. It was left to Eli Andersen and A. Jeppesen of Kolding to introduce Denmark's first commercial model diesel, the Diesella 2.4 cc model, which they did in November 1943. The full story of the Diesella, CEROS and other pioneering Danish model engine ranges may be found in a

Another occupied country which was early in the model diesel field was Denmark. The first model diesel to be constructed in that country was reportedly made as early as 1940 by Carl Rose, manufacturer of the CEROS model engine range. However, Rose did not pursue the concept at that time. It was left to Eli Andersen and A. Jeppesen of Kolding to introduce Denmark's first commercial model diesel, the Diesella 2.4 cc model, which they did in November 1943. The full story of the Diesella, CEROS and other pioneering Danish model engine ranges may be found in a  Naturally, both French aeromodelling enthusiasts and engine constructors were greatly intrigued by this new technology which allowed modellers to dispense with the heavy and undependable

Naturally, both French aeromodelling enthusiasts and engine constructors were greatly intrigued by this new technology which allowed modellers to dispense with the heavy and undependable  A further very interesting and largely overlooked implication arising from this development is the inescapable recognition that a model engine market of some magnitude must certainly have existed in France during the occupation years. Had this not been the case, it seems inconceivable that so many new French diesel designs would have appeared on the market in 1943.

A further very interesting and largely overlooked implication arising from this development is the inescapable recognition that a model engine market of some magnitude must certainly have existed in France during the occupation years. Had this not been the case, it seems inconceivable that so many new French diesel designs would have appeared on the market in 1943.  being manufactured years later in 1976, just prior to the Micron company ceasing production in 1977.

being manufactured years later in 1976, just prior to the Micron company ceasing production in 1977.

To this end an agreement was concluded with none other than André Gladieux of Micron fame, whose reputation stood high among French model engine designers/manufacturers on the basis of his Micron 2.8 cc and 5 cc diesels. Gladieux was charged with the responsibility for designing a 5 cc fixed-compression diesel very much along the lines of his existing Micron 5 cc model.

To this end an agreement was concluded with none other than André Gladieux of Micron fame, whose reputation stood high among French model engine designers/manufacturers on the basis of his Micron 2.8 cc and 5 cc diesels. Gladieux was charged with the responsibility for designing a 5 cc fixed-compression diesel very much along the lines of his existing Micron 5 cc model.

One rather amusing point arising from a perusal of the Bonnier advertisements is the fact that the illustrated engines lack any form of induction system! The actual engines followed the Micron pattern by using crankshaft front rotary valve (FRV) induction through an updraft intake. However, the advertising images do not include this detail. Odd ……… especially since the artist's rendition of the engine which appeared on the cover of the instruction manual (see below) was complete in all respects!

One rather amusing point arising from a perusal of the Bonnier advertisements is the fact that the illustrated engines lack any form of induction system! The actual engines followed the Micron pattern by using crankshaft front rotary valve (FRV) induction through an updraft intake. However, the advertising images do not include this detail. Odd ……… especially since the artist's rendition of the engine which appeared on the cover of the instruction manual (see below) was complete in all respects!

The introduction of this revised model took place very quietly, in total media silence. In 1950 there was a brief resumption of promotional activity, with advertisements appearing in M.R.A. between the months of May and November 1950, after which the company fell silent once more. it was not until 1954 that the Bonnier engines were advertised again, initially with an insert which appeared in Issue no. 58 of "

The introduction of this revised model took place very quietly, in total media silence. In 1950 there was a brief resumption of promotional activity, with advertisements appearing in M.R.A. between the months of May and November 1950, after which the company fell silent once more. it was not until 1954 that the Bonnier engines were advertised again, initially with an insert which appeared in Issue no. 58 of " The relocated company marketed two 5 cc models. These were said to be assembled, finished and adjusted by M. Bravard. There was the normal Type "A" with a recommended operating speed of 4,250 rpm which corresponded to the revised design first presented in 1949 and the Type "B" higher-speed version. The maximum power of this latter version was enhanced, reaching a claimed 0.25 BHP at 4,800 rpm.

The relocated company marketed two 5 cc models. These were said to be assembled, finished and adjusted by M. Bravard. There was the normal Type "A" with a recommended operating speed of 4,250 rpm which corresponded to the revised design first presented in 1949 and the Type "B" higher-speed version. The maximum power of this latter version was enhanced, reaching a claimed 0.25 BHP at 4,800 rpm.

In undertaking the writing of this next section of the article, I'm working under the handicap of having only an example of the first model on hand for examination and test. Fortunately, the two variants seem to have been virtually identical apart fom the different cylinder head arrangements.

In undertaking the writing of this next section of the article, I'm working under the handicap of having only an example of the first model on hand for examination and test. Fortunately, the two variants seem to have been virtually identical apart fom the different cylinder head arrangements.

integrally-cast extension of the carburettor body, being tensioned by a flat steel spring. The needle engaged with a surface jet which was installed from the opposite side of the carburettor. This jet was fitted with a right-angled fuel spigot for convenient routing of the fuel line.

integrally-cast extension of the carburettor body, being tensioned by a flat steel spring. The needle engaged with a surface jet which was installed from the opposite side of the carburettor. This jet was fitted with a right-angled fuel spigot for convenient routing of the fuel line.

metal cap as well as a spring-loaded cut-out device of identical design to that used on the Micron. A metal fuel line ran forward towards the carburettor, to which it was connected by a length of flexible fuel tubing. This arrangement allowed the engine to be conveniently used with or without the supplied back-tank.

metal cap as well as a spring-loaded cut-out device of identical design to that used on the Micron. A metal fuel line ran forward towards the carburettor, to which it was connected by a length of flexible fuel tubing. This arrangement allowed the engine to be conveniently used with or without the supplied back-tank.

It’s perhaps fair to all concerned to summarize the Bonnier 5 cc diesel as basically a heavily-restyled Micron 5 cc model. The visual differences were certainly sufficient to make the Bonnier a distinct production – you couldn’t mistake one for the other. However, in functional terms the two models were more or less identical apart from the Bonnier's seemingly more efficient induction system.

It’s perhaps fair to all concerned to summarize the Bonnier 5 cc diesel as basically a heavily-restyled Micron 5 cc model. The visual differences were certainly sufficient to make the Bonnier a distinct production – you couldn’t mistake one for the other. However, in functional terms the two models were more or less identical apart from the Bonnier's seemingly more efficient induction system.

As mentioned previously, some time ago I had the opportunity to acquire a second example of the Bonnier 5 cc diesel. This was another first variant example which was in far worse condition than my previous example which appears in the images attached to this article. However, it did possess the immense attraction for a knowledge-seeker like myself that it retained its original factory instruction sheet along with a test certificate and the above-referenced handwritten sheet of notes regarding both specifications and prices. Having translated all three documents, I felt that I should summarize the information which they yielded.

As mentioned previously, some time ago I had the opportunity to acquire a second example of the Bonnier 5 cc diesel. This was another first variant example which was in far worse condition than my previous example which appears in the images attached to this article. However, it did possess the immense attraction for a knowledge-seeker like myself that it retained its original factory instruction sheet along with a test certificate and the above-referenced handwritten sheet of notes regarding both specifications and prices. Having translated all three documents, I felt that I should summarize the information which they yielded.  A most interesting point in the original printed version is the statement that if necessary one could substitute either petroleum jelly (aka Vaseline!) or extra lubricating oil for the kerosene! The use of extra oil sounds like a good idea to me - 20% lubricant inspires a great deal more confidence than 5%! But petroleum jelly?!? Well, the stuff does burn quite well when in liquid or vapor form - a cotton swab well doused in Vaseline makes a superb all-weather fire-starter when out camping, as I know from direct experience. However the high temperature lubricating qualities of petroleum jelly seem rather suspect to me, however effective in other less incendiary applications ..............

A most interesting point in the original printed version is the statement that if necessary one could substitute either petroleum jelly (aka Vaseline!) or extra lubricating oil for the kerosene! The use of extra oil sounds like a good idea to me - 20% lubricant inspires a great deal more confidence than 5%! But petroleum jelly?!? Well, the stuff does burn quite well when in liquid or vapor form - a cotton swab well doused in Vaseline makes a superb all-weather fire-starter when out camping, as I know from direct experience. However the high temperature lubricating qualities of petroleum jelly seem rather suspect to me, however effective in other less incendiary applications ..............

All of that having been said, Maeght's claims cannot be reconciled with the manufacturer's hand-written statement in the previously-reproduced note that the engine developed 0.18 CV (0.177 BHP) @ 4,200 RPM. I have always found the claim reported by Maeght to be extremely difficult to accept. If it was accurate, that claim would represent an outstanding performance for a fixed-compression diesel of this type.

All of that having been said, Maeght's claims cannot be reconciled with the manufacturer's hand-written statement in the previously-reproduced note that the engine developed 0.18 CV (0.177 BHP) @ 4,200 RPM. I have always found the claim reported by Maeght to be extremely difficult to accept. If it was accurate, that claim would represent an outstanding performance for a fixed-compression diesel of this type.  The first issue to be overcome with the Bonnier is that of mounting the thing in a test stand. The problem is that the sharply raked-back needle passes directly beneath the right-hand mounting lug (looking forward in the direction of flight). So you can’t simply mount the beast directly into a conventional test stand. I got around this by machining a pair of extension beams from high-strength aluminium alloy, similar to those that I had previously made for the identically-challenged Micron and Owat fixed compression models. Once bolted on, these effectively extend the engine’s built-on lugs rearward to the point that mounting in the test stand becomes a practicable proposition. Looks like hell, but it works!

The first issue to be overcome with the Bonnier is that of mounting the thing in a test stand. The problem is that the sharply raked-back needle passes directly beneath the right-hand mounting lug (looking forward in the direction of flight). So you can’t simply mount the beast directly into a conventional test stand. I got around this by machining a pair of extension beams from high-strength aluminium alloy, similar to those that I had previously made for the identically-challenged Micron and Owat fixed compression models. Once bolted on, these effectively extend the engine’s built-on lugs rearward to the point that mounting in the test stand becomes a practicable proposition. Looks like hell, but it works!

I have to say that the Bonnier was perhaps the most difficult of the 5 cc fixed-compression diesels that I've tried. I got the impression that the compression ratio had been set very slightly too low for dependable starting. At first I couldn't even get the thing to fire, let alone run! The fact that it was winter and the ambient air temperature was pretty low obviously didn't help. I ended up using the old electric heat gun trick to pre-heat the upper cylinder, followed by an upper cylinder lubricant prime. Under this level of persuasion, the thing finally started up readily enough and kept running.

I have to say that the Bonnier was perhaps the most difficult of the 5 cc fixed-compression diesels that I've tried. I got the impression that the compression ratio had been set very slightly too low for dependable starting. At first I couldn't even get the thing to fire, let alone run! The fact that it was winter and the ambient air temperature was pretty low obviously didn't help. I ended up using the old electric heat gun trick to pre-heat the upper cylinder, followed by an upper cylinder lubricant prime. Under this level of persuasion, the thing finally started up readily enough and kept running.  With its apparently low compression ratio, it came as no surprise to find that the Bonnier was most happy at the lower speeds. It managed a smooth 5,200 RPM on the APC 14x6 (0.163 BHP) - actually a little better than both the Owat and Micron models tested previously. However, it fell behind as speeds climbed towards 6,000 RPM, only managing 5,700 RPM on an APC 12x7 (0.162 BHP) and 5,800 RPM on an APC 12x6 (0.159 BHP). On the latter props, the engine was showing definite signs of being undecompressed. There's no question that the peak had been passed on the 12x6, since both the reduced output and the evidence of under-compression clearly signaled the fact that the engine had no more to give.

With its apparently low compression ratio, it came as no surprise to find that the Bonnier was most happy at the lower speeds. It managed a smooth 5,200 RPM on the APC 14x6 (0.163 BHP) - actually a little better than both the Owat and Micron models tested previously. However, it fell behind as speeds climbed towards 6,000 RPM, only managing 5,700 RPM on an APC 12x7 (0.162 BHP) and 5,800 RPM on an APC 12x6 (0.159 BHP). On the latter props, the engine was showing definite signs of being undecompressed. There's no question that the peak had been passed on the 12x6, since both the reduced output and the evidence of under-compression clearly signaled the fact that the engine had no more to give.