|

|

The DeLong 29 Diesel

In many ways this must be seen in hindsight as a great pity. American mass production techniques were virtually unsurpassed at that time. Moreover, American model engine designers possessed a great deal of practical know-how gained over a decade or more of design and manufacturing experience. Given these facts, it comes as no surprise to find that many of the American diesels that did make it into production between 1946 and 1948 possessed considerable merit. The Micro, C.I.E., Speed Demon, The outstanding McCoy “9” .099 cuin. diesel of late 1954 provided a hint of the kind of quality and performance that we might have seen from American manufacturers if the arrival of the glow-plug had not derailed their diesel development programs so comprehensively in late 1947 just as they were getting into their stride. I sometimes find myself wishing that Ray Arden had been a year or two later in marketing the glow-plug – given a few more years to take root, diesels might have gained as much acceptance in America as they did in the rest of the world, and American manufacturers might well have continued to carry the diesel torch for quite a while with very positive results. Of course, America must also shoulder responsibility for producing arguably the world’s worst-ever diesel There were other North American designs which reached the prototype stage but never made it into series production. These included the Thermite, AHC, Ken, EDCO, Queen Bee and Strato diesel prototypes (the latter two in Canada) which undoubtedly reached the testing stage. During this period the number of North American firms actively engaged in model diesel development and manufacture at least equalled the number of their counterparts in Britain. In this article we’ll focus on another American “diesel that never was” – the legendary DeLong 29 diesel from The present article is based upon my own direct examination of one of only three presently-known surviving original prototypes. However, I’d like to preface the main text by acknowledging the immense amount of assistance and encouragement provided by my good friend and valued colleague Tim Dannels, publisher of both the ever-informative but now sadly discontinued “Engine Collector’s Journal” (ECJ) and the equally invaluable “American Model Engine Encyclopedia” (AMEE). I wouldn’t even consider writing about any American model engine without consulting Tim, who is undoubtedly the most broadly knowledgeable individual around today when it comes to the history of the American model engine manufacturing industry. Now, before I get into my review of the Delong 29 diesel, I’ll spend a little time looking at the engine’s antecedents. What’s in a Name?!? The DeLong series of engines were made by Super Motors Inc. of Cleveland, Ohio. This company was founded by one Everett M. DeLong. Making that statement requires me to deal with another of the “legends” surrounding the DeLong enterprise. The name of the individual responsible for the DeLong engines has long been generally accepted as “Joe DeLong” – this is the name by which he is called in Tim Dannels’ generally authoritative and highly recommended AMEE.

All such possibilities aside, my first thought was that there was more than one DeLong, one called Joe and another having the initials E.M., perhaps a brother or son. However, a December 1947 article about the DeLong diesel (see below) specifically states that the engine was designed by “Mr. DeLong of Super Motors, who also developed the DeLong 30 gasoline engine”. There’s a very clear implication here that there was only one Mr. DeLong, otherwise his given name would surely have been mentioned to distinguish him from any other DeLongs who may have been involved. Does anyone ever call Tom Dooling “Mr. Dooling”, thus inviting the question “which one …..”?!? Seeking clarification, I approached AMEE author Tim Dannels, a valued friend and trusted colleague, to ask what evidence lay behind his use of the name Joe. Tim was refreshingly and characteristically candid on this point. Apparently he was participating in a bull session many years ago during which someone whose identity he can no longer recall happened to mention the name Joe DeLong during some discussion of the DeLong engine range. Tim admitted that no context for the use of that name was included in the conversation – it just slipped out at one point, and Tim simply assumed that this was the name of the gentleman in question.

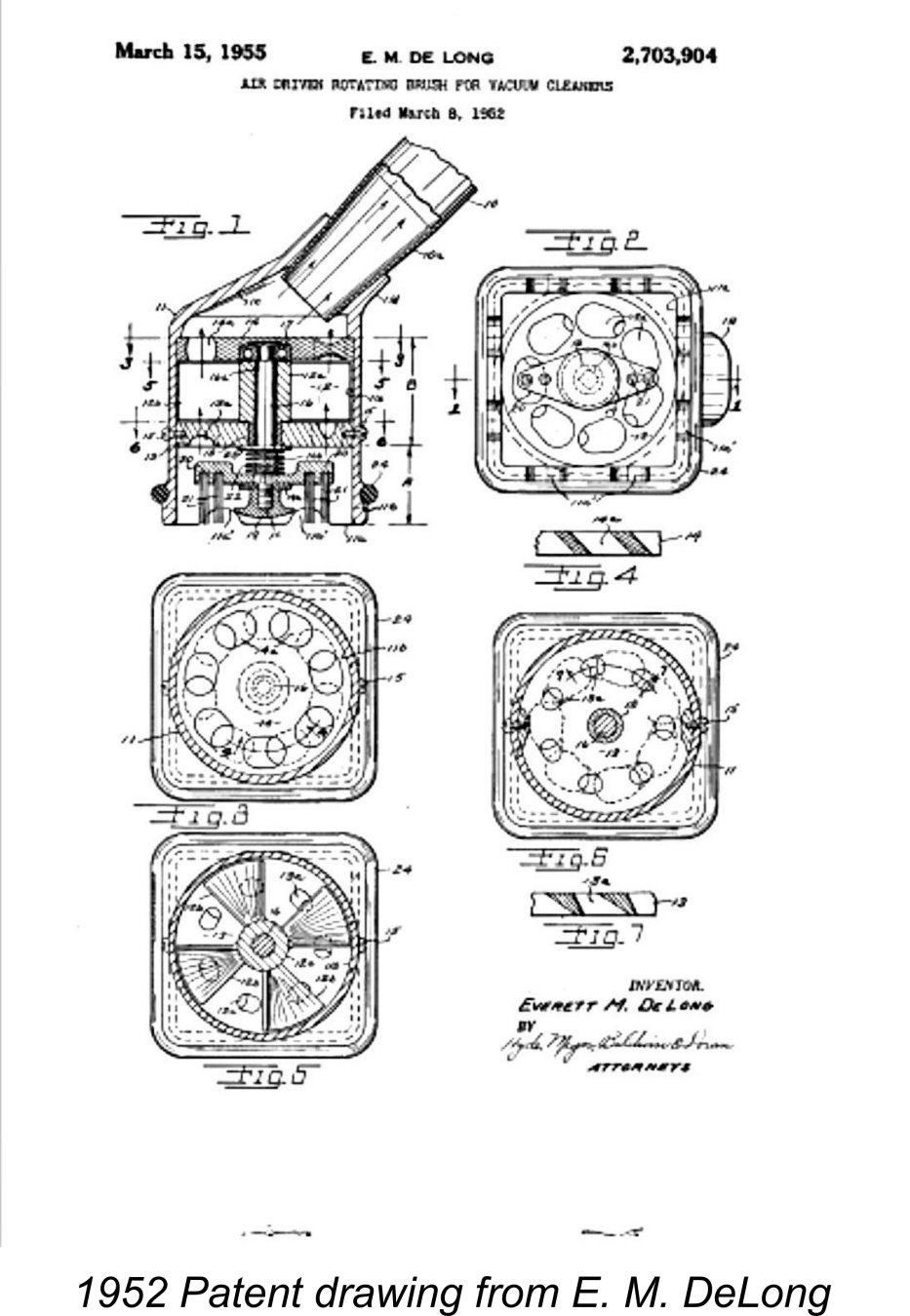

However, being the incurable detail-hound that I am (as my critics frequently remind me!), I wasn’t content to leave it there! I started searching for references to an E. M. DeLong in the context of Cleveland, Ohio. Lo and behold, what should I come up with but a pdf copy of US Patent no. 2,703,904 with respect to an air-driven rotating brush for vacuum cleaners! The patent application was filed on March 8th, 1952 by one Everett M. DeLong of Cleveland, Ohio!! This can surely be none other than the originator of the DeLong model engine range, who had evidently moved on into other fields of invention and manufacture after abandoning the DeLong model engine line in the early 1950’s. Seeking confirmation, I undertook further investigations which revealed that Everett M. DeLong was born in 1900 in Pennsylvania but had moved to Akron, Ohio by 1920. In 1935, while residing in Cleveland, Ohio, he had applied for a US Patent with respect to a new design of motorcycle frame (US D95948 S, applied for on April 15th, 1935, when he was 35 years old). Shortly thereafter, he moved to Lima, Ohio, where the 1935 US census listed him as a resident. The right name, the appropriate age, the right line of work and living in the right locations at the right times – this simply has to be “our” Mr. DeLong!! If anyone can present persuasive evidence to the contrary, please speak up! Having sorted out the matter of the identity of the designer to my own satisfaction at least, we’ll now take a look at the antecedents of our subject engine – the DeLong 29 diesel model. The Delong 29 Diesel in Context

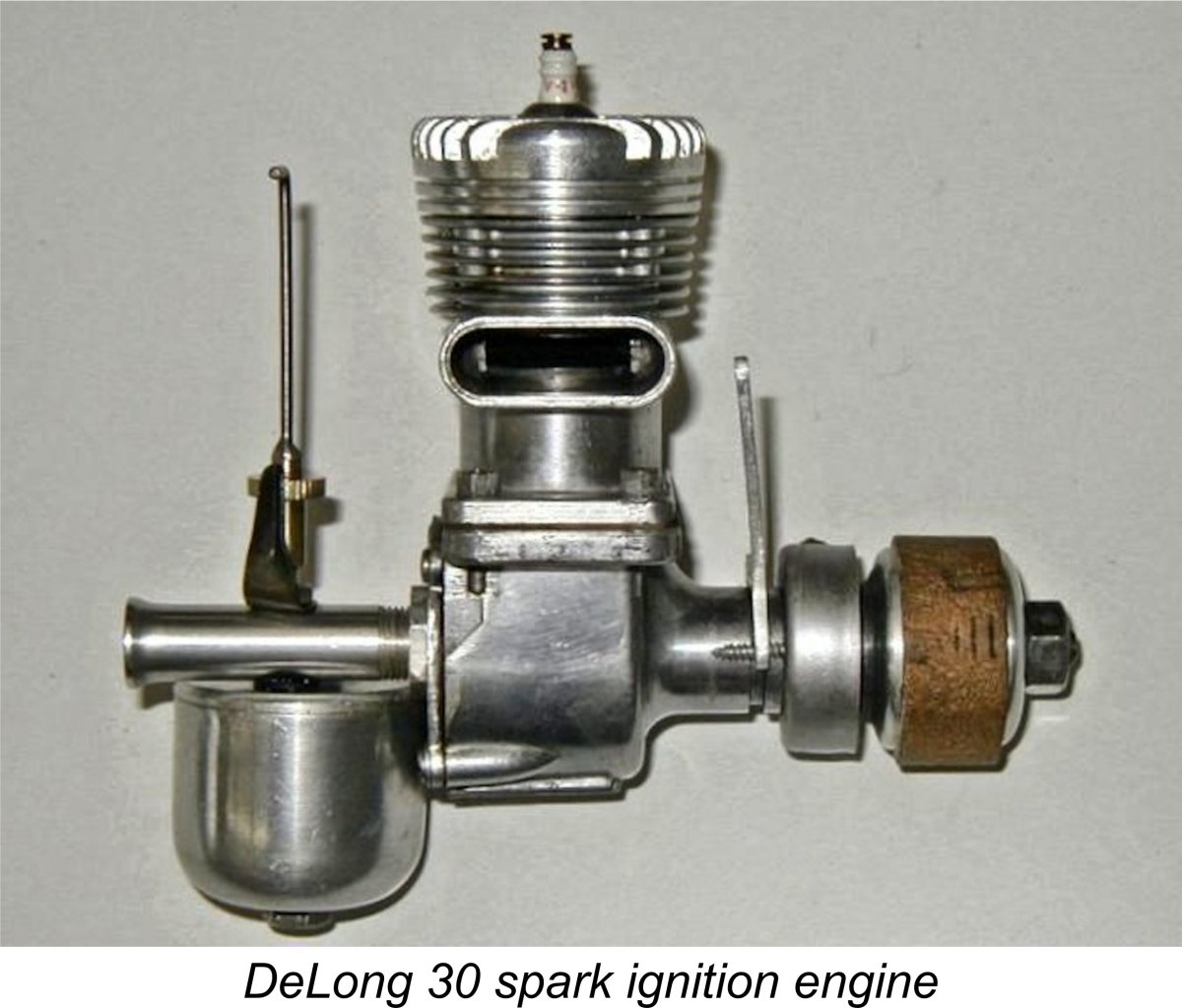

In 1941 Everett DeLong relocated back to Cleveland, Ohio. There the earlier D&S .29 cuin. models were developed into the Cannon range, which first appeared on the market in 1941 and continued for some time after the conclusion of WW2, being produced by the Cannon Manufacturing Co. at 1878 East 18th Street, Cleveland. An in-depth article about the Cannon range appears elsewhere on this website. Following the cessation of hostilities, Everett DeLong went out on his own with his Super Motors Inc. company which was located in Cleveland at 2093 East 19th Street, very close to the Cannon factory. A series of .30 cuin. DeLong models was produced beginning in 1945 and continuing through two subsequent variants, the last of which appeared in 1949. In 1946 a pair of additional models having displacements of .45 cuin. and .60 cuin. made a brief appearance, although these seem to have barely made it past the prototype stage. If any were produced in series, their numbers were extremely small.

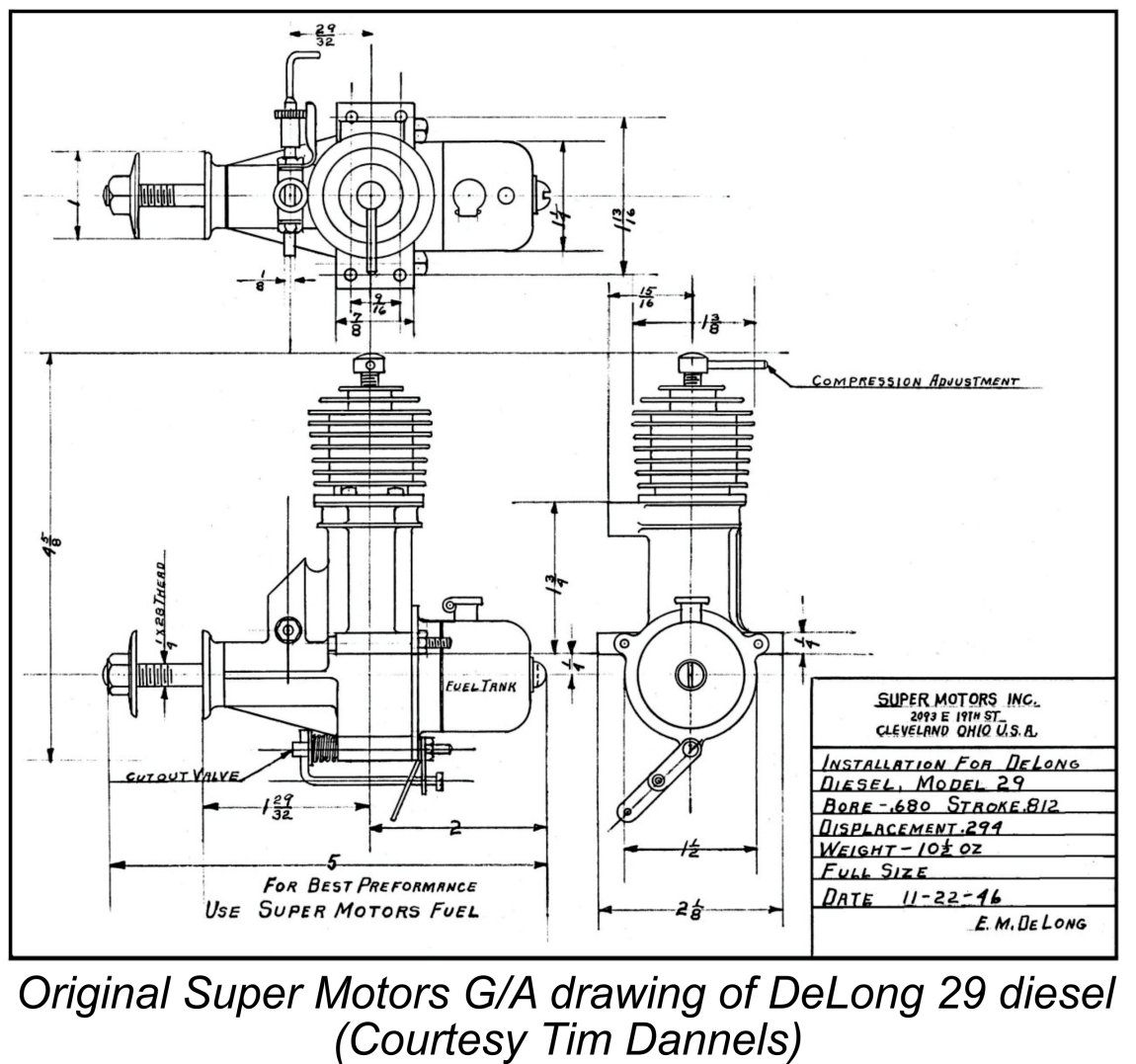

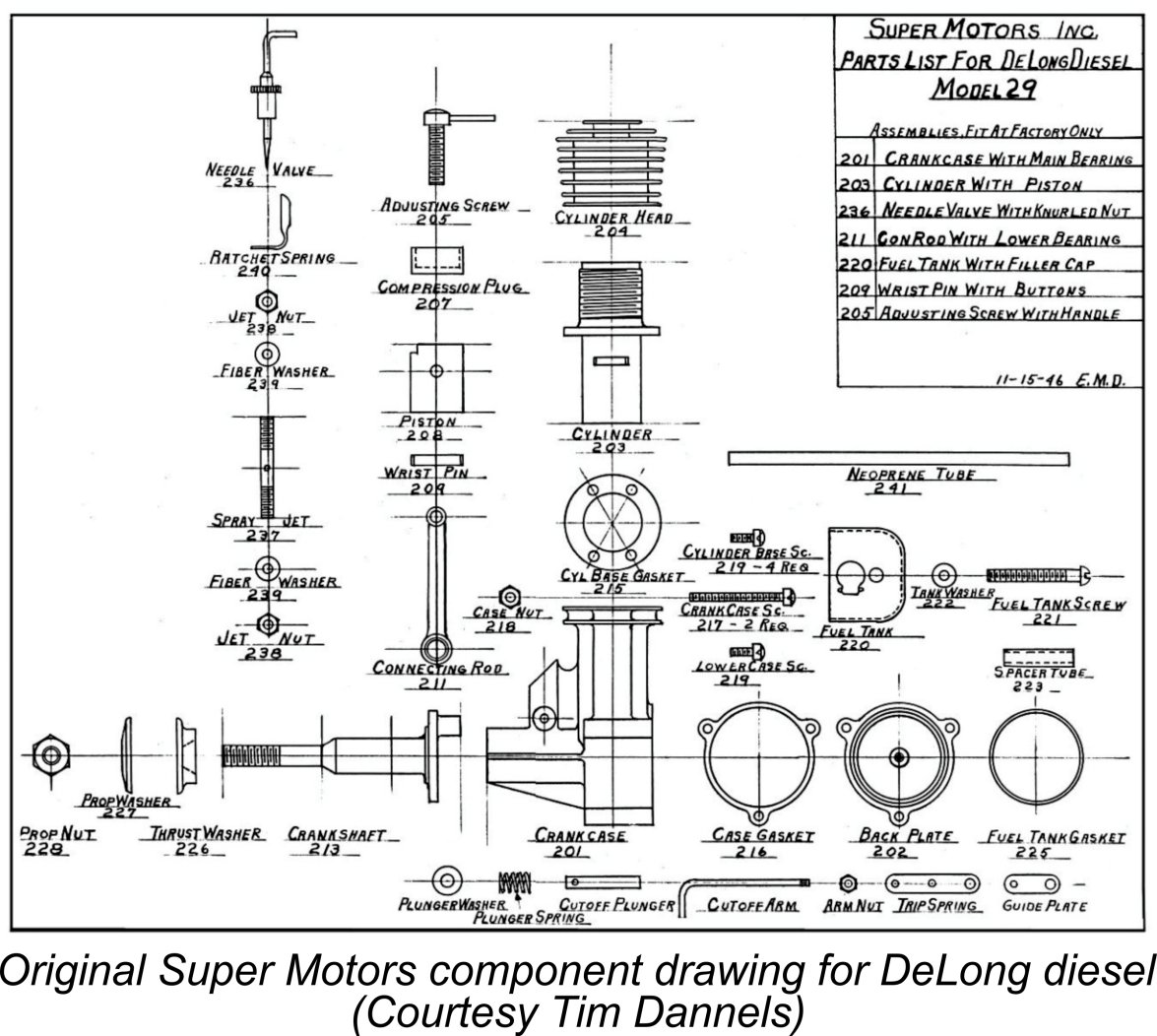

Now all of these models were spark ignition units apart from the final 1949 .30 cuin. model, which featured glow-plug ignition. However, Everett DeLong was clearly an inventive individual who was attracted towards experimentation, as witness his previously-mentioned .45 cuin. and .60 cuin. models as well as a four-stroke design of which he made a prototype at some undetermined point in time. That engine was featured on the cover of ECJ no. 158. A different concept that came to Everett’s attention at some point in 1946 was the application of compression ignition to model engine operation. Since the commercial miniature glow-plug had yet to appear on the market at this time, the development of diesels was still being energetically pursued in America as a viable commercial proposition. Like many other American modellers and manufacturers of the day, Everett DeLong clearly appreciated the diesel’s potential for eliminating the heavy and potentially undependable ignition support system required by the spark ignition engine. Once having grasped the essentials of this rather different technology, DeLong wasted little time in drawing up a design. Several of the resulting plans survive today and are reproduced here courtesy of Tim Dannels. They are dated November 15th and 22nd, 1946 respectively. They are both credited to E. M. DeLong as their creator.

However it came about, an examination of the three generally-accepted original Super Motors prototypes of which we presently have knowledge (see below) reveals a number of departures from the design shown on the plans. One of these modifications was the lengthening of the crankshaft journal and its main bearing by some 3/16 in. – not all that surprising given that this is a relatively large diesel which would impose considerable loadings on its main bearing. A longer main bearing would doubtless wear far better in such an application. Another feature shown on the plan which did not appear in any of the presently-known original prototypes was the cut-out. The parts of this device are included on the component drawing reproduced above at the left. After a bit of puzzling, I finally figured out how this device was supposed to work. Note that the lower backplate screw is shown as a shortened item – only the rear end of the matching crankcase hole was evidently tapped. There was clearly a hole (not shown on the drawing) drilled vertically through both the case and the fore-and-aft extrusion at the bottom of the case. This hole intersected the axial hole running fore and aft through that extrusion. How the thing worked was as follows. A spring-loaded cut-off plunger was inserted into the front end of the axial lower case hole. If unrestrained, the spring would move it forward to the point where it didn't obstruct the vertical hole connecting the crankcase with the outside world. Ergo, no crankcase compression (or not as much, anyway!). The length of wire with the bent end (called the cut-off arm on the drawing) was the key to the activation of the system. The bent end passed laterally through the transverse hole in the cut-off plunger, thus retaining the coil spring in conjunction with a washer. The rear end passed through holes in the trip spring and guide plate (in that order), both of which were attached to the engine by the short lower machine screw. The cut-off arm and attached plunger were secured in their "open" (forward) location by a nut at the rear of the cut-out arm which limited the available forward movement. To set the cut-out in the "run" position, the cut-off arm was slid rearwards by gripping and pulling on the cut-off arm nut. This in turn forced the plunger to move rearwards against the coil spring pressure. In its rearmost location, the plunger closed the crankcase compression release hole, thus restoring base compression so the engine would run. To lock the system in this position, one simply pulled the outer end of the trip spring forward to lock the trip spring onto the cut-off arm by wedging – just like the lock on a screen door closure arm. To activate the cut-out, all that was required was to pull the outer end of the trip spring rearwards so that it lost its grip on the cut-off arm. The spring-loaded plunger would then snap forward under coil spring pressure, taking the cut-off arm with it and opening the crankcase compression bleed aperture. Since none of the three known original engines has any provision for such a system, we can only assume that it was tried and found not to work too well. Hardly surprising – crankcase bleed is a notoriously chancy method of stopping an engine. It takes one hell of a leak to dependably stop an engine that’s running at full chat, as I know from seeing diesels continue to run quite well while their backplates are unscrewing right before my eyes! Really not worth the cost and complexity. Whatever the reason, there's no doubt at all that this device was omitted from the later prototypes, nor did it appear in the late 1947 promotional images of the engine. By the time that the revised prototypes were completed and put through their own initial testing program, it must have been mid 1947. It seems clear that at this point in time Everett DeLong still had every intention of releasing this model into the marketplace, since he had gone so far as to create dies for the crankcase, backplate and prop driver castings. American manufacturers typically only went to this trouble for engines which were intended for series production in quantity (unlike some of their Japanese counterparts at this time, who made dies for everything!).

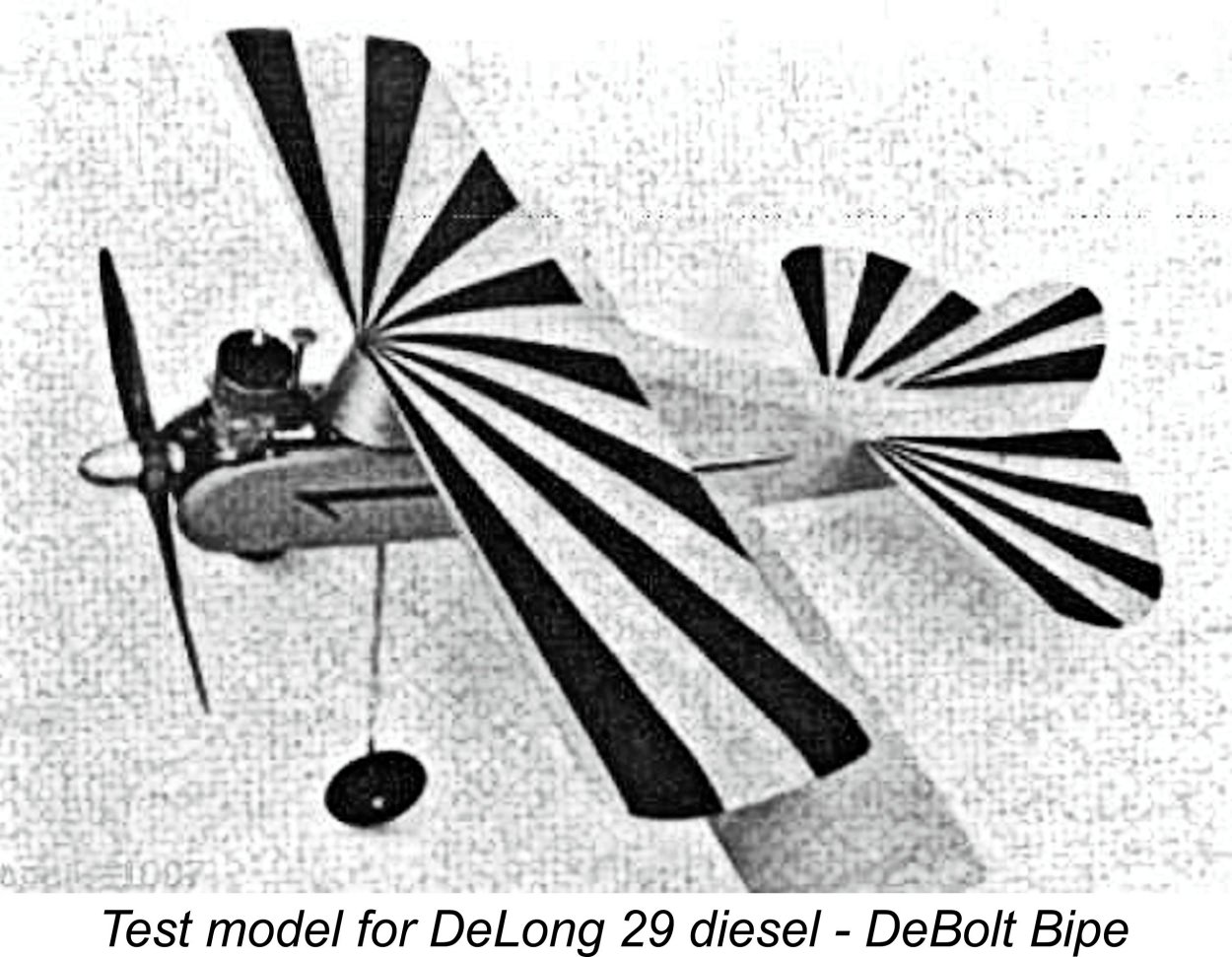

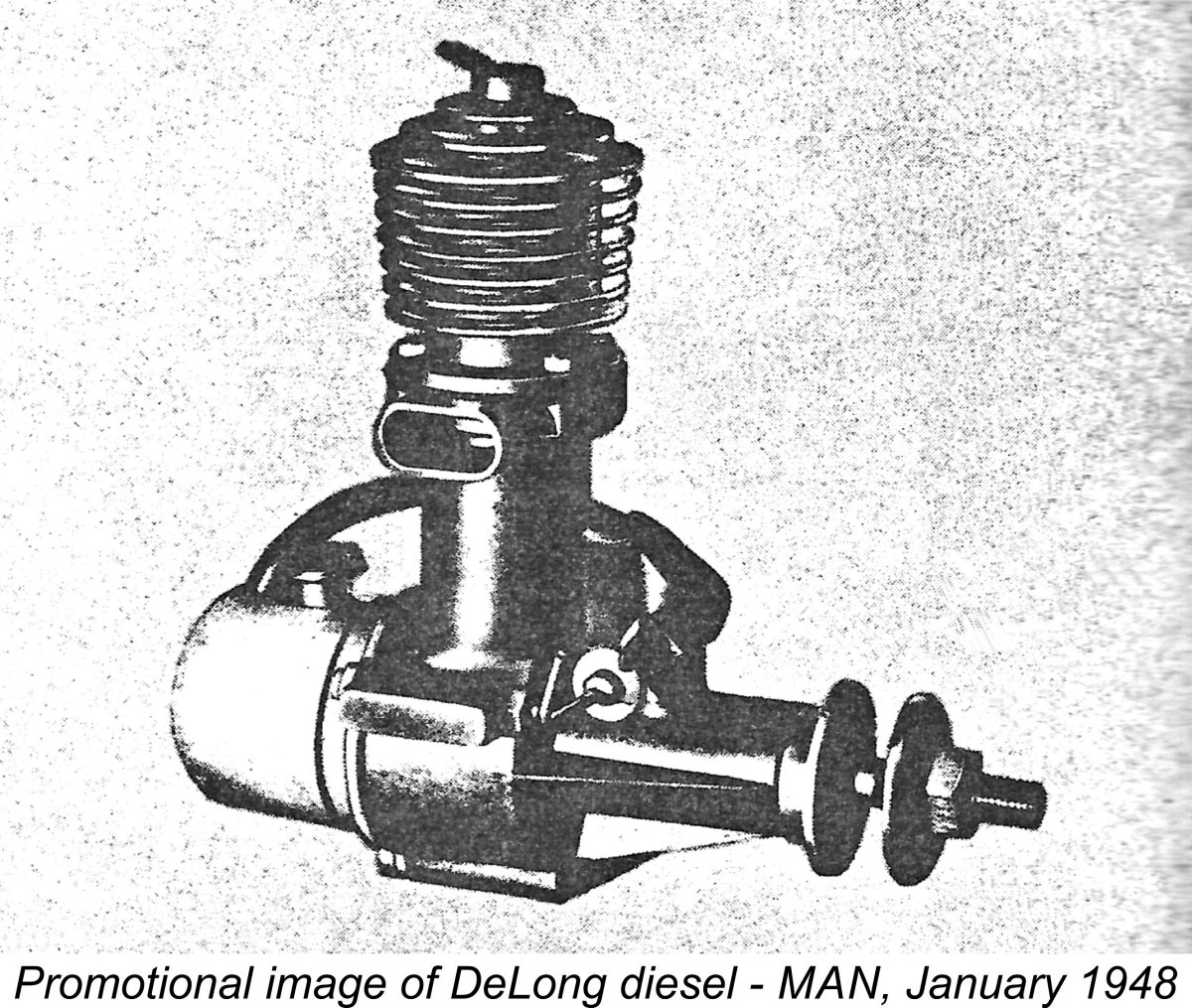

“We tried (the DeLong diesel) out at the DeLong factory in Cleveland, before it had reached the market. It’s a variable compression ratio engine, with a .299 displacement. We found it easy starting, and it seemed to put out considerable power. We saw it test flown in a Bipe stunt ship, and the results were very satisfactory. It’s designed by Mr. DeLong of Super Motors, who also developed the DeLong 30 gasoline engine”. It’s apparent that at the time of Bayha’s late 1947 visit to the factory the DeLong 29 diesel was certainly viewed by all concerned as a planned production item. This impression was heightened by the engine’s inclusion in an article by Edward G. Ingram entitled “Model Motors for 1948” which appeared in the January 1948 issue of MAN. Presumably written in late 1947, this article dealt exclusively with American model engines for which production was planned in 1948. Ingram provided a quite informative description of the DeLong diesel which seems worth quoting in full. The text read as follows:

Ingram also quoted the engine’s bore and stroke as 0.680 in. (17.27 mm) and 0.812 in. (20.63 mm) respectively for a displacement of 295 cuin. (4.83 cc). The illustrated example of the engine checks out at almost exactly those figures. It’s interesting that the weight given by Ingram was 11 ounces, while the original drawings cited a weight of 10½ ounces, presumably complete with cut-out. Perhaps the difference was down to the extra material required to make up the longer crankshaft and main bearing on the late 1947 versions. That said, the featured example weighs in at 298 gm (10.51 ounces) with tank but without the cut-out.

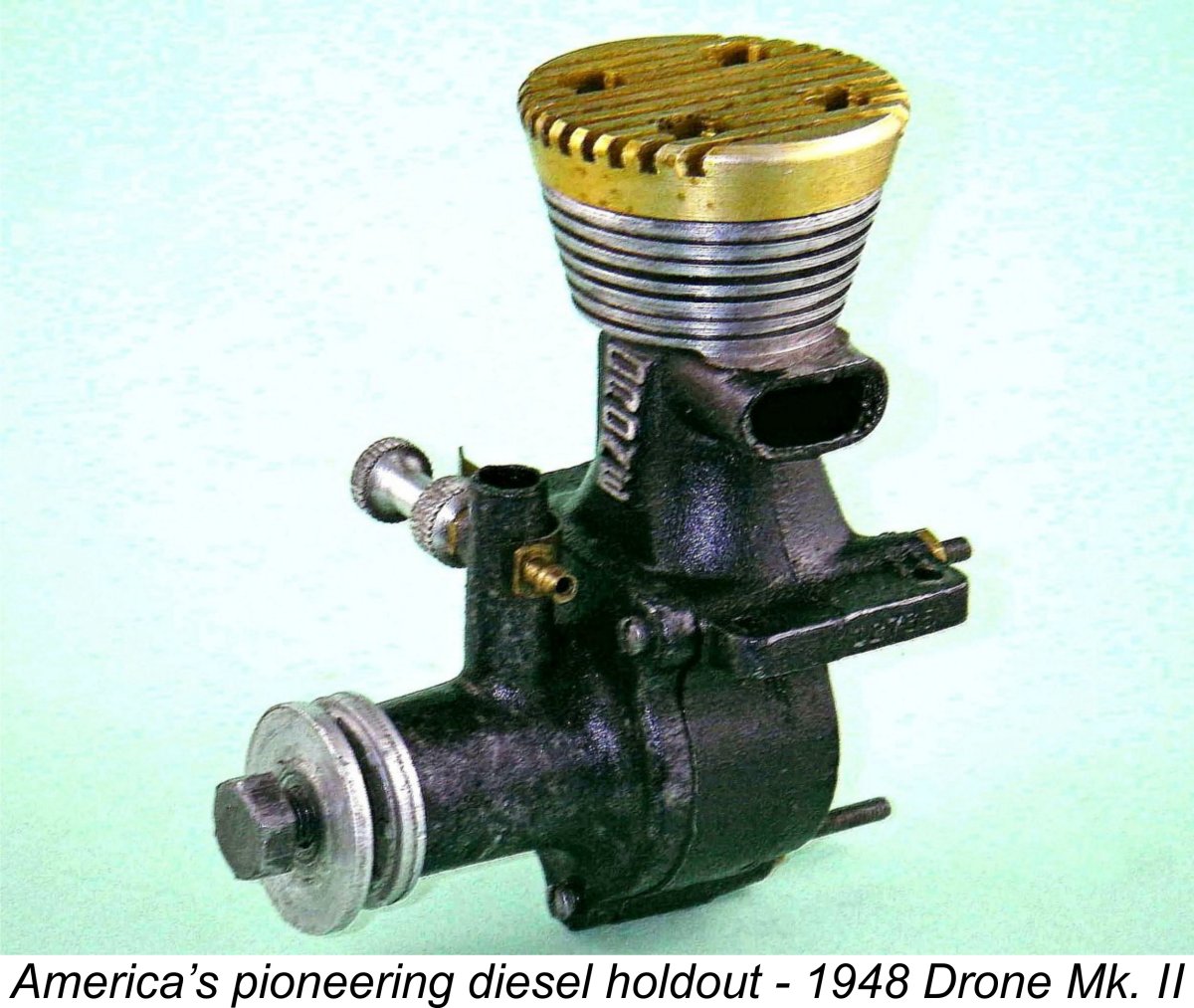

I suspect that Ingram was basically regurgitating information supplied by the manufacturers (or perhaps by his MAN colleague Jack Bayha) and that they had correctly referred to the cylinder jacket as being a screw-on item for which the upper cylinder was threaded. This evidently became misinterpreted, something which could not have occurred if Ingram had actually handled an example of the engine. Indeed, the promotional image which was supplied for inclusion with the article should have clarified this point, since it clearly showed the cylinder hold-down screws. The manufacturers did not provide Ingram with any quantitative performance data. However, they did provide fuel recommendations as well as a specified prop size. This clearly implies that they had themselves tested the engine sufficiently to form definite recommendations regarding both fuel formulation and prop size. Bayha’s evidence certainly support this view. However, as events transpired, the DeLong diesel never actually appeared on the American market – that small handful of prototypes were all that would ever leave the factory, all latter-day legends to the contrary. So what happened?!? Well, in a nutshell, the Arden glow-plug happened! In November 1947 Ray Arden released the first commercial examples of his miniature glow-plugs for model engines, setting the entire American modelling scene on its ear. People using spark ignition engines could now throw away the heavy and undependable The American model engine manufacturing industry immediately dropped any further consideration of diesels (apart from Leon Shulman with his excellent 1948 Drone 5 cc ball-bearing model) and rushed instead to get new models out onto the market which were specifically designed to operate on glow-plug ignition. Even Leon Shulman finally had to throw in the towel after unsuccessfully trying to promote both variable compression and glow-plug conversions of the Drone design. Super Motors Inc. was one of those firms which dropped its diesel program like a hot potato immediately following the appearance of the commercial glow-plug. Correctly reading the writing on the wall, Everett DeLong concentrated instead upon developing a glow-plug version of his company’s well-established and deservedly highly regarded DeLong .30 cuin. model, releasing this variant in 1949. It was a fine engine, having a sand-cast crankcase, a ball bearing shaft and a needle roller big end bearing on the con-rod. However, it was destined to be the final DeLong model engine of them all. After Everett DeLong moved on to other ventures, the DeLong diesel project was relegated to the shelf and allowed to rest there quietly in retirement. However, the project materials survived down through the years, residing today in a private collection. There the matter would likely have remained had it not been for an initiative put forward by a group of talented model engine construction enthusiasts called Motor Boys International. Thanks to their efforts, the DeLong diesel was rescued from the obscurity into which it had sunk and was brought back to life. Let’s look now at that story as told by my late and greatly missed mate Ron Chernich, one of the founders of Motor Boys International. The Saviours – Motor Boys International

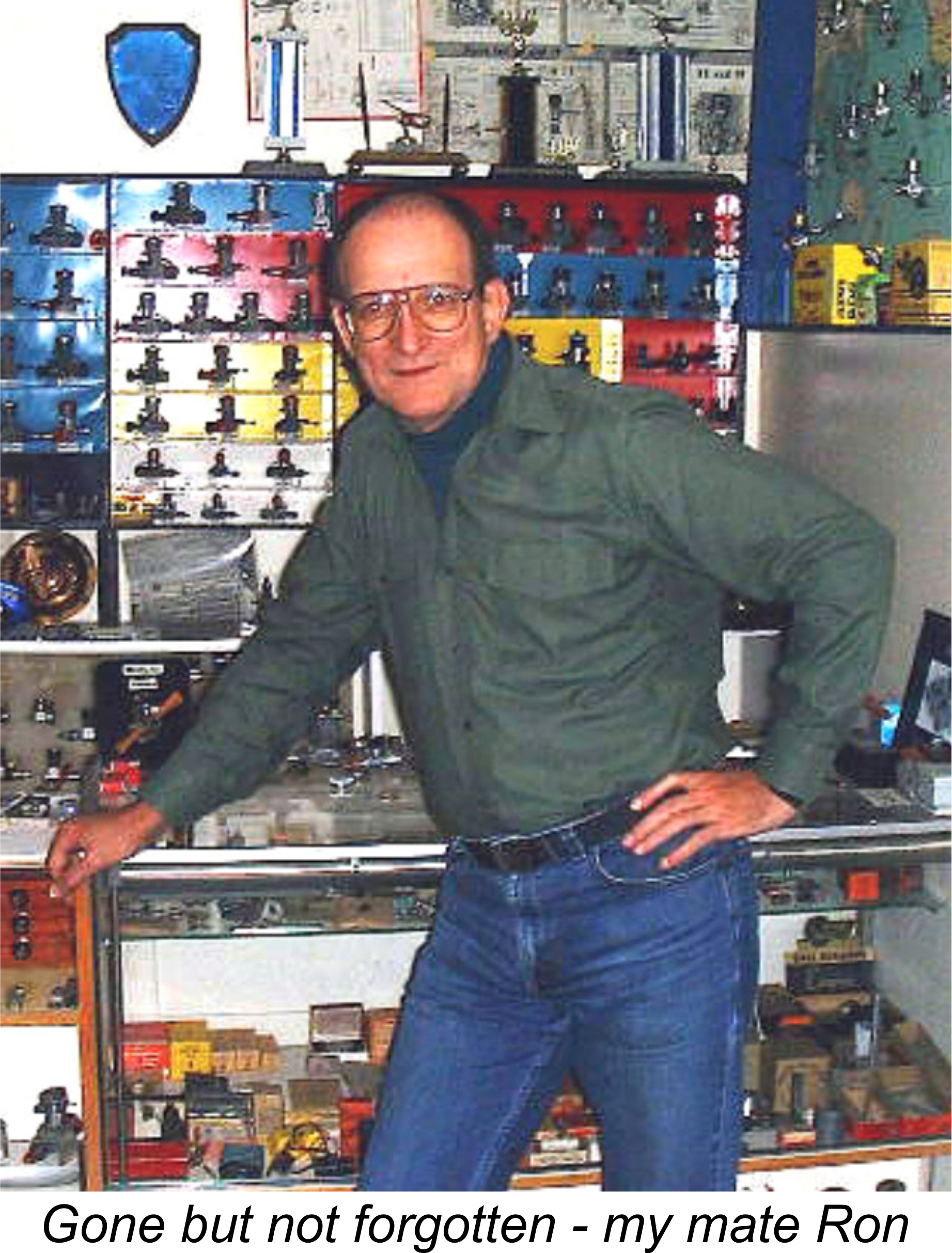

The name "Motor Boys" originated from a series of books written by Clarence Young in the early part of the twentieth century at a time when the technologies of I/C engines, automobiles and aircraft were all new and exciting. It was the late Roger Schroeder who proposed the name. Roger was a very well-known engine builder and restorer who contributed columns and articles to such publications as ECJ and “Strictly I/C” magazine. The added “International” qualification reflected the widespread geographic locations of the various Motor Boys, who resided in such widely-spaced locations as Australia, England, the USA, the south of France and Canada. I myself was greatly honoured to be added to the membership by unsolicited invitation not long before Ron’s unhappy demise, mainly on account of my historical research and engine restoration activities, I suppose – I certainly didn’t qualify as an engine builder! As a group of like-minded guys, the Boys spent much of the time simply entertaining and amusing each other from the comfort of their computer terminals with information, advice, gossip and pictures. However, on occasion they undertook group projects to make reproductions of engines that took their collective fancy for whatever reason. In such cases, each member undertook to build some part(s) both for himself and for all the others. When complete, the parts were snail-mailed out to the membership. Not all parts were made this way - components requiring individual fitting were necessarily machined individually. This way, no-one had to tool up to make the entire engine, and each member eventually ended up with a complete set of parts from which he could assemble his own complete replica of a rare or unusual engine to run and display. The group placed no time pressures on their work because their prime directive was just to have fun!! For this reason, they jointly made a conscious decision early on that they would not enter into any commercial activity relating to the engines that they produced. They did not make spare parts for sale and they didn’t sell castings or plans as a group. That having been said, Motor Boy Ken Croft reminds us that the late Roger Schroeder did sell his castings commercially. Some of those castings originated from Motor Boys projects. Moreover, drawings were included with Roger's casting sets. The one such venture which the Motor Boys did pursue as a group was the production of a book of plans which was made available to the AMA in America for sale to the public. The only stipulation was that all proceeds were to go to aid the AMA’s junior encouragement programs. This arrangement ended in 2008. Thanks to the initiative of Ken Croft, both the Motor Boys Plan Book and the Members Only Plan Collection (which was provided free to financial supporters of MEN) are now freely available online through this website. Sadly, all too many of the Motor Boys group have now left us. George Aldrich, David Owen, Roger Schroeder, Gordon Burford, Don McClusky and Ron Chernich have all departed on the next stage of the journey. The final straw that broke the camel’s back (although not the final departure) was the untimely death of Ron Chernich in early 2014. Ron’s MEN website had become the main vehicle for reporting on the work of the group, and that asset was now lost along with a growing shortfall in the critical mass of the surviving membership. Consequently, the group disbanded at that point. But long before that time, they had completed another of their collaborative replication efforts in the form of the DeLong diesel! I must hasten to add that I myself was not involved in any way in its construction, which took place long before my addition to the group. Since it’s highly relevant to the topic on hand, let’s briefly review the story of the Motor Boys replicas of this interesting “diesel that never was”…….. The Motor Boys DeLong Diesel Replicas Well over a decade prior to his passing, Ron Chernich commenced the writing of a report on the DeLong Diesel project undertaken by the Motor Boys. The project was still ongoing at the time when he began the article, which accordingly carried the designation “This page under construction” when it appeared on MEN as an interim report. Unfortunately, Ron never got around to finishing the article, which accordingly retains that “under construction” designation on Ron's now-frozen website to this day. Still, it remains well worth a read. The main story runs something like the following. In the year 2000, the Motor Boys were granted the privilege of being loaned the “remains” of the aborted DeLong diesel project. There were a few conditions attached to this loan. Firstly, castings and drawings were not to be made generally available. Secondly, the then-current owner of the material was to be given one or two examples of any casting(s) which were produced. Since these terms seemed reasonable, the project entered the planning stage. Ken Croft bravely accepted the challenges of producing the initial CAD drawings for the use of the group and (gulp!) making the die-cast crankcases. He was also appointed Project Manager for his sins! The various other tasks were soon appropriately allocated, and the project got underway.

At the time when Ron wrote his interim report, the sole example of the replica engine which had been completed was Ken Croft’s prototype, which was running before the end of the year 2000. Ron stated that it would likely be some time before the rest of the engines were completed. Unfortunately, he never got back to the article to add any information about other completed engines. Hence we don’t know for sure how many examples were in fact finished, and by whom. Ken later recalled having produced 20 fully machined cases, even though there were only about 12 Motor Boys involved with the project at that time. Some of the others went to individuals who had assisted with the project research. There’s no way of knowing if any of them completed their own examples of the engine. Ken has advised that the die which he so painstakingly produced is still in existence, albeit no longer in his keeping. Hence there is always the possibility that more replicas may appear some day. That said, it does appear certain that at least a few more examples of the Motor Boys replicas did reach completion. Tim Dannels (himself a Motor Boy) advised that he had the late Roger Schroeder’s completed example through his hands at one point. Bert Streigler’s example is illustrated in Volume 2 of Tim’s outstanding “American Model Engine Encyclopedia” (AMEE), and I would guess that a number of other examples reached completion. Tim estimates that between 6 and 8 examples may have ended up being completed by the Motor Boys. In 2022, folloing the original publication of this article, I herd from the very talented home constructor Olli-Matti Karhunen of Espoo, Finland. Having obtained one of the few remaining Motor Boys crankcase castings for the DeLong 29 diesel from Ken Croft, Olli-Matti was inspired to complete his own superb replica of this design. He has carried this project through to the very highest standards - I was thoroughly impressed! Video records of his efforts may be accessed here and here. Very well worth a look!! Now, here’s the key point. As far as Tim is presently aware, no other replicas of this engine were ever completed by others. If this is the case, then any example encountered today must be either a Motor Boys replica or one of the very few original prototypes. The issues become – are there any surviving originals; and if so, how can one distinguish between the two? An Original Prototype Example

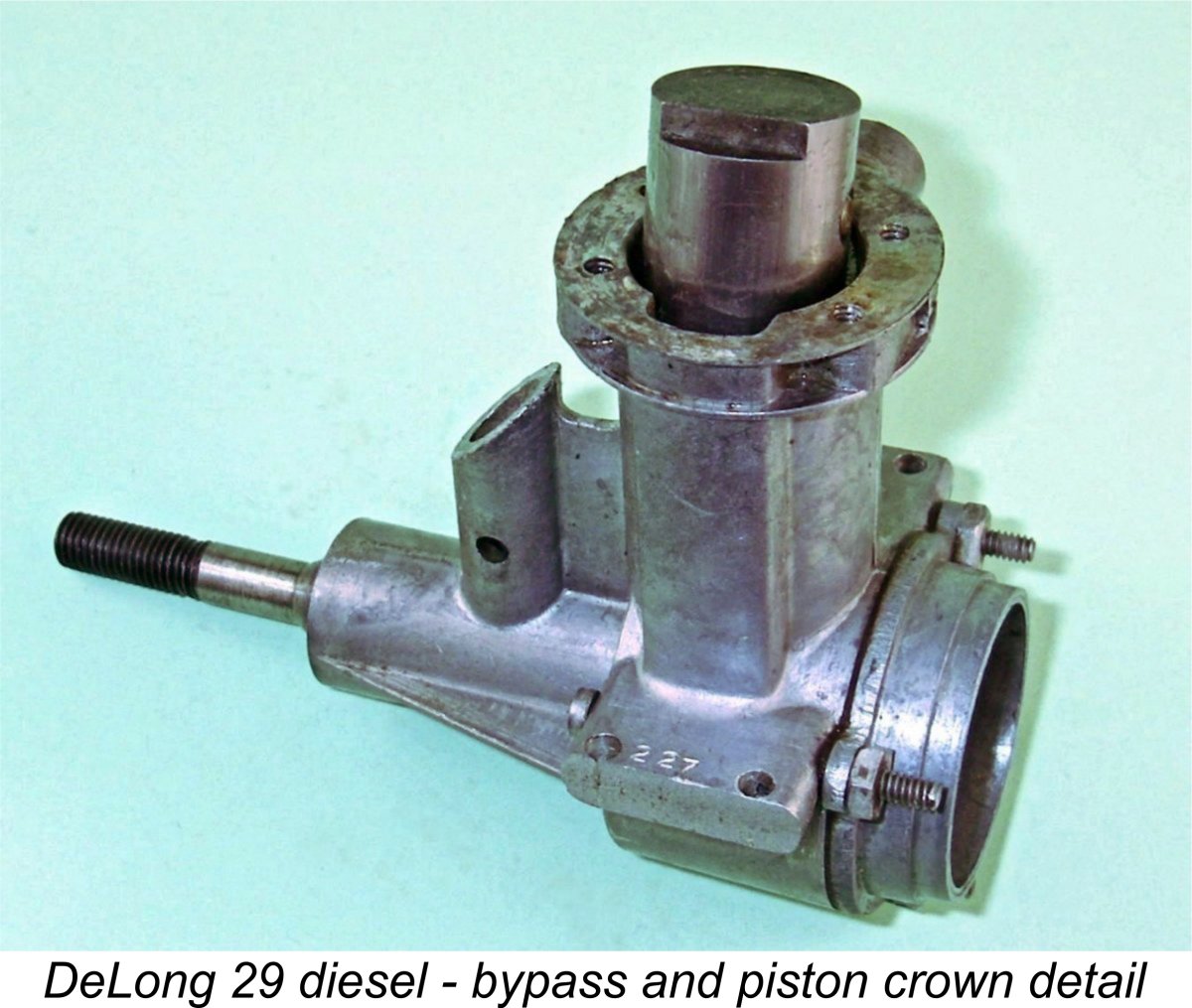

However, when the engine arrived it became immediately apparent that whatever it was, it was definitely not a Motor Boys replica! How can I make this statement with such certainly? Very simple – the only casting used in the Motor Boys replicas was the die-cast crankcase produced by Ken Croft. All of the other components, including the backplate (with its three “ears” for the installation bolts) as well as the prop driver, were machined from the solid. Tim Dannels has confirmed this beyond doubt, as do the various available images of the Motor Boys replicas. The example with which we are concerned here has both a die-cast backplate and a dimpled die-cast prop driver to go with its die-cast crankcase. These features alone preclude any possibility of its being a Motor Boys replica. It also bears a serial number – 227 – stamped on the top of the left-hand mounting lug (looking forward in the direction of flight). This number was presumably placed there simply to distinguish this example from the other test prototypes. Its numerical significance cannot now be determined.

Tim advised that to his knowledge, the Motor Boys project was the sole initiative ever carried out with respect to the replication of the DeLong 29 diesel. If anyone else had undertaken such a project, Tim would undoubtedly have known about it. He pointed out the differences between the Motor Boys engines and the originals, specifically drawing attention to the respective degrees to which castings were used as opposed to parts machined from solid barstock. His view was that the presence of a die-cast backplate on this example almost certainly made it one of the very few original examples. He also drew attention to the “antique” character of the die-castings by contrast with the very smooth and homogeneous castings produced by Ken Croft.

Armed with this information, I went back to the seller of the engine. He was able to confirm that the engine that he had just sold me was in fact the example to which Tim had referred which was formerly owned by Jim Schiller, now deceased. Upon Jim’s death, the engine passed to his son Larry, who in turn sold it to the gentleman from whom I eventually obtained it. Contact was made with Larry Schiller, but it turned out that he had no knowledge of how and when his Dad acquired the engine. So the provenance trail went cold at that point. However, as far as I’m concerned the weight of the above evidence pretty much confirms that this is one of only three presently-known original examples of the prototype DeLong 29 diesel! A second attested original example formerly owned by Ted Enticknap (illustrated above) found another home during the disposition of Ted’s huge collection a few years ago and was lost to view for many years. Amazingly enough, it re-surfaced in 2022 and ended up joining its counterpart in my collection! It's essentially identical to its counterpart apart from not displaying a serial number. Amazingly enough, a third original example of the Delong diesel showed up in 2023. This one bore the serial number 235. It was missing its tank and prop washer, but otherwise appeared to be in excellent little-used condition. The fact that this number is 8 greater than my engine no. 227 surely implies that there should be at least 7 numbered engines in between? And where did the sequence start? Surely not at 227! It appears almost certain that there are a few more of these engines hiding out there.............the trick is to find them! Regardless, let’s have a look at this interesting engine. The Delong 29 Diesel Described I won’t spend too much time on this section of the article, since the attached photos and drawings should have made the engine’s construction quite sufficiently clear. I’ll just mention a few of the highlights.

As mentioned by Edward Ingram in his previously-referenced January 1948 MAN article and confirmed in the factory drawings, the Delong had bore and stroke measurements of 0.680 in. (17.27 mm) and 0.812 in. (20.63 mm) respectively for a displacement of .295 cuin. (4.83 cc). The illustrated example checks out at almost exactly those figures.

Despite its shorter stroke, the DeLong diesel is considerably taller than either the Micron or Drone. This is partially due to the extra cylinder length needed to accommodate the contra-piston which is absent in the two fixed compression models, but it also results at least to some extent from the use of an unusually long con-rod. The idea there was presumably to cut down on side-thrust friction by reducing the rod’s swing angle. Not wishing to disturb this near-mint example more In any case, Ingram had already provided much of the information that would have become apparent during a tear-down. The con-rod was made of aluminium alloy. The big end rod bearing was bronze-bushed, as was the generously-proportioned main bearing. The steel crankshaft was made in a single piece. The die-cast prop driver was located on the shaft using a self-releasing taper forward of the 0.450 in. (11.43 cm.) diameter main journal.

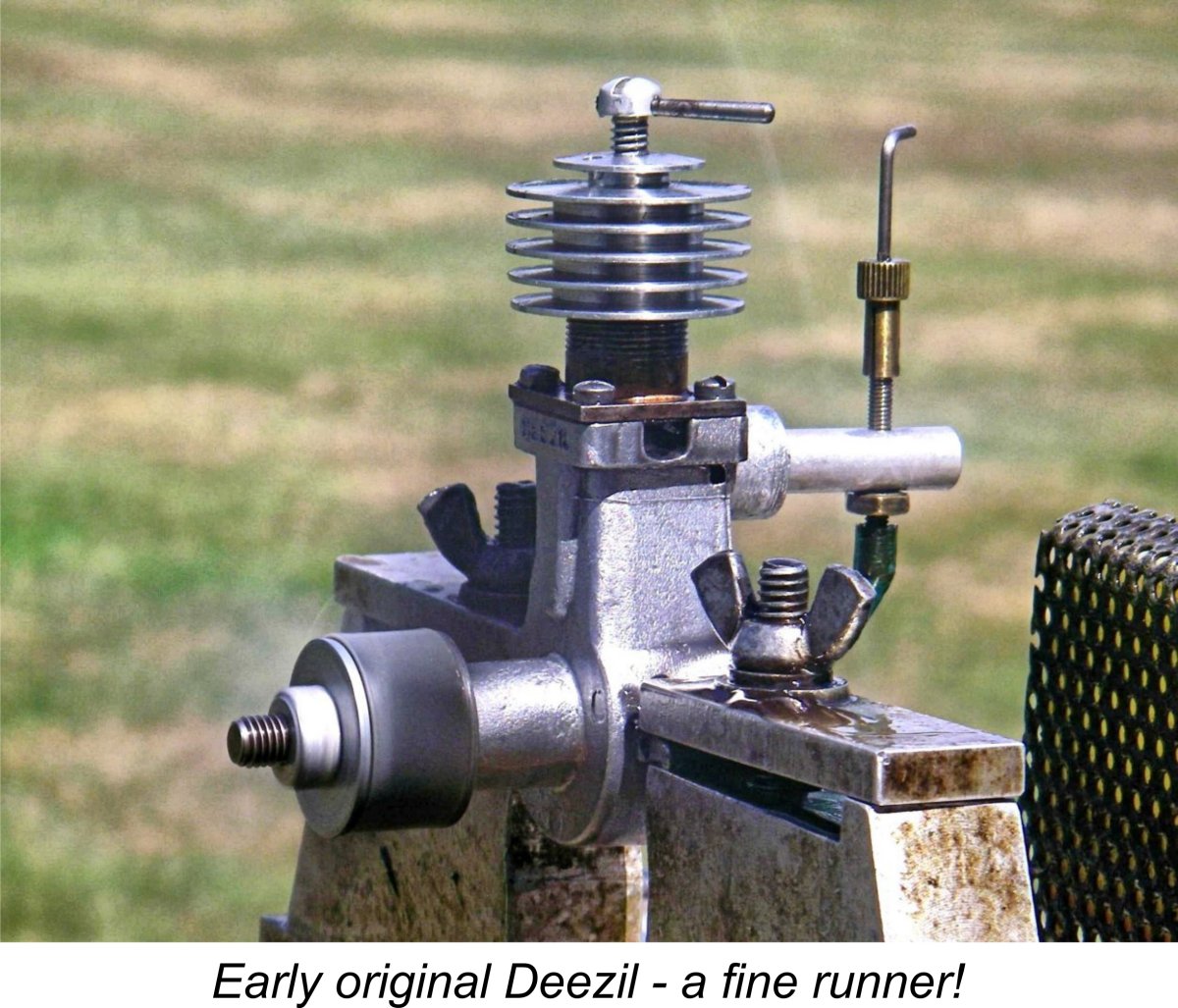

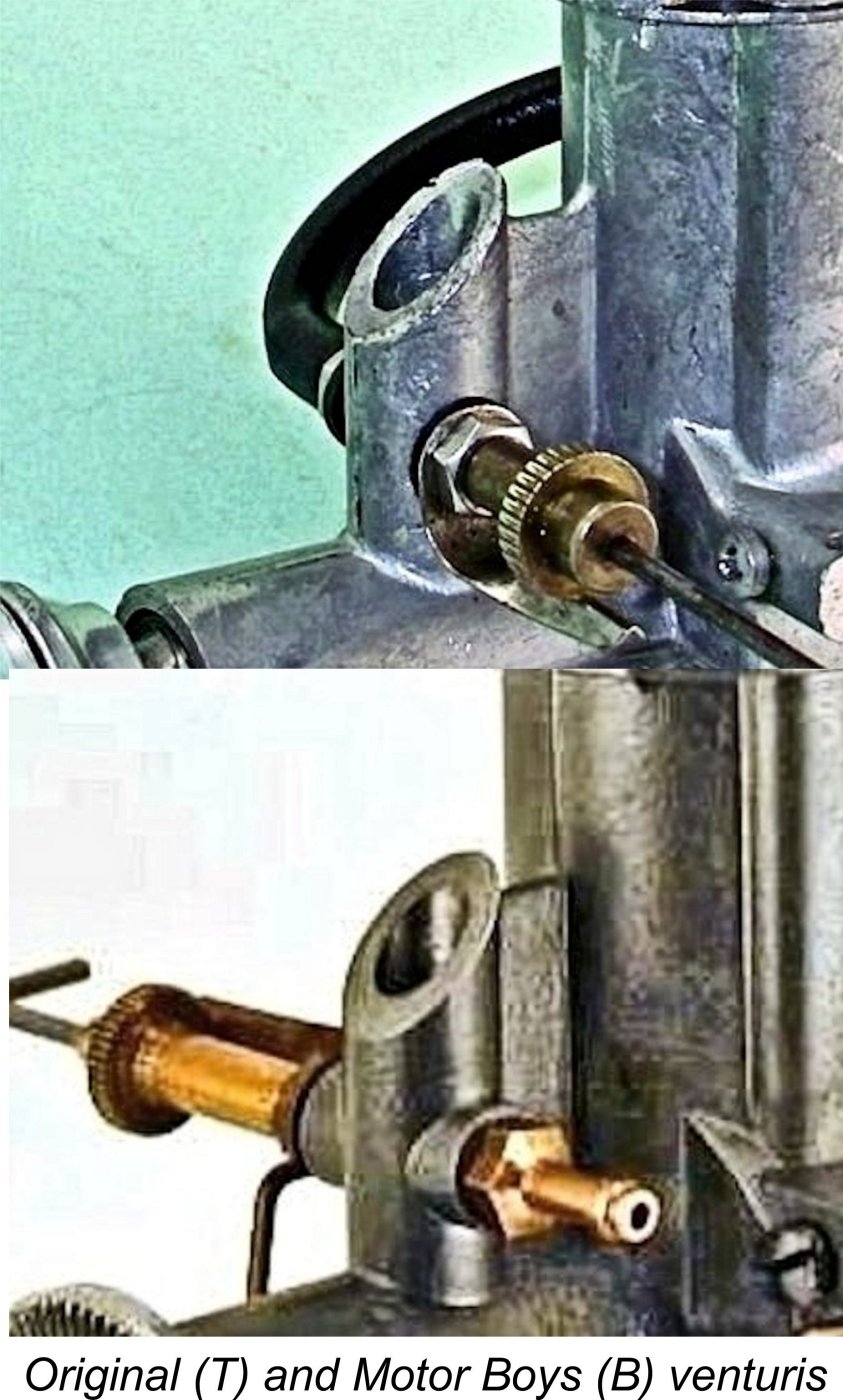

At the rear, the crankcase was sealed by a die-cast backplate which was secured to the crankcase using three long bolts which passed through holes formed axially in the case and thence through three “ears” formed integrally with the backplate. These bolts were retained by standard nuts. A fibre gasket was included to ensure a good seal. The back tank was mounted on a shoulder formed on the backplate perimeter. The illustrated example was missing its tank as received, and the component seen in the images is a replica of my own making. I omitted a Gits fuel filler cap because Ted Enticknap’s original example did not have a cap on its original tank (I could always add one later). Perhaps the Gits cap would have been a feature of the production model if the project had got that far …….. The standard of workmanship displayed in this engine is of the very highest order. All fits and finishes are superb. The engine has clearly done a fair bit of bench running, but there are no witness marks on the mounting lugs to indicate its ever having been mounted in a model. It certainly isn't the example that Jack Bayha saw test-flown in that DeBolt Bipe! Motor Boys Replicas versus DeLong Originals As mentioned earlier, there are a few examples of the Delong 29 diesel in circulation today. It appears that we are looking at the present-day existence of some 8-10 Motor Boys replicas and 3 currently-known examples which are accepted as original Super Motors prototypes. There may of course be others, but if so they have yet to be reported. Unfortunately, human nature being what it sadly is in a few cases, there will possibly be those who may try in the future to pass off a Motor Boys replica as an original. I’ve been the target of a few such attempts in relation to other rare engines in the past. Caveat empor – buyer beware!! The originality issue wouldn’t matter as much to me as it might to some others – I’m mainly interested in experiencing these engines by handling them and running them, and a good replica will serve perfectly well for that as long as the price is set accordingly. I would still have been quite happy if my example had turned out to be the Motor Boys replica that I initially assumed it to be. As matters turned out, I sent some extra cash to the seller in recognition of the engine’s true status, thus keeping things square between us. However, if you care about originality, this is not a trivial issue. Fortunately, there are plenty of ways in which one can tell a Motor Boys replica from an original. Let’s list them for convenience: General – the Motor Boys components are generally more highly finished and “newer-looking” than their original equivalents. If it “looks new”, it probably is new (relatively speaking, of course)!! Main casting – the superb Motor Boys crankcase castings made to such a high standard by Ken Croft have a cleaner and more “modern” finish to them than the typical early post-war flat as-cast patina seen on the originals. Furthermore, Ken has pointed out a very simple way to distinguish his replica cases from the originals. The front and rear edges of the mounting lugs are radiused on the originals, but for ease of making the cast iron die Ken's replica cases have square-cornered mounting lugs. You can see this difference in the two comparative images reproduced below. The same would be true for any replicas which might be made in the future using Ken's still-existing die.

Prop driver – the originals have a dimpled die-cast prop driver, while the Motor Boys replicas use a component that is machined from solid bar stock. Intake – the Motor Boys replicas appear to have an internal intake diameter which is slightly smaller than the measured 0.267 in. diameter of the originals. Note the visibly greater thickness of metal around the intake of the replica …………. Spraybar – the original spraybars are threaded and equipped with nuts and fibre washers at both ends, while the Motor Boys replica spraybars are threaded only at the needle carrier end. The originals also have a shorter needle thimble than the Motor Boys replicas. Check out the previously-reproduced original component drawing for details. I’m sure that there must be other indications – that’s all that I can pick up without having a Motor Boys replica on hand to compare. Still, the above points should suffice. The dead giveaway is the backplate - if it ain’t die-cast, it ain’t original! One specific characteristic that does not help to distinguish between the Motor Boys replicas and the originals is the presence or otherwise of the name “Super Motors” engraved or cast onto the crankcase casting. Ron Chernich’s statement suggesting that the originals carried such an identification is incorrect – none of the presently-acknowledged original prototypes displays such an identification. Neither do the Motor Boys replicas ….. so no help there! OK, now we know a little about the engine’s history, provenance, design and construction. Next question – how does it run?!? Let’s suck it and see …………… The DeLong Diesel on Test As a stated earlier, there is no contemporary information regarding the performance of the original Delong 29 diesel prototypes as examined by MAN staff. However, all is not lost - Ken Croft tested his replica example, obtaining the following figures:

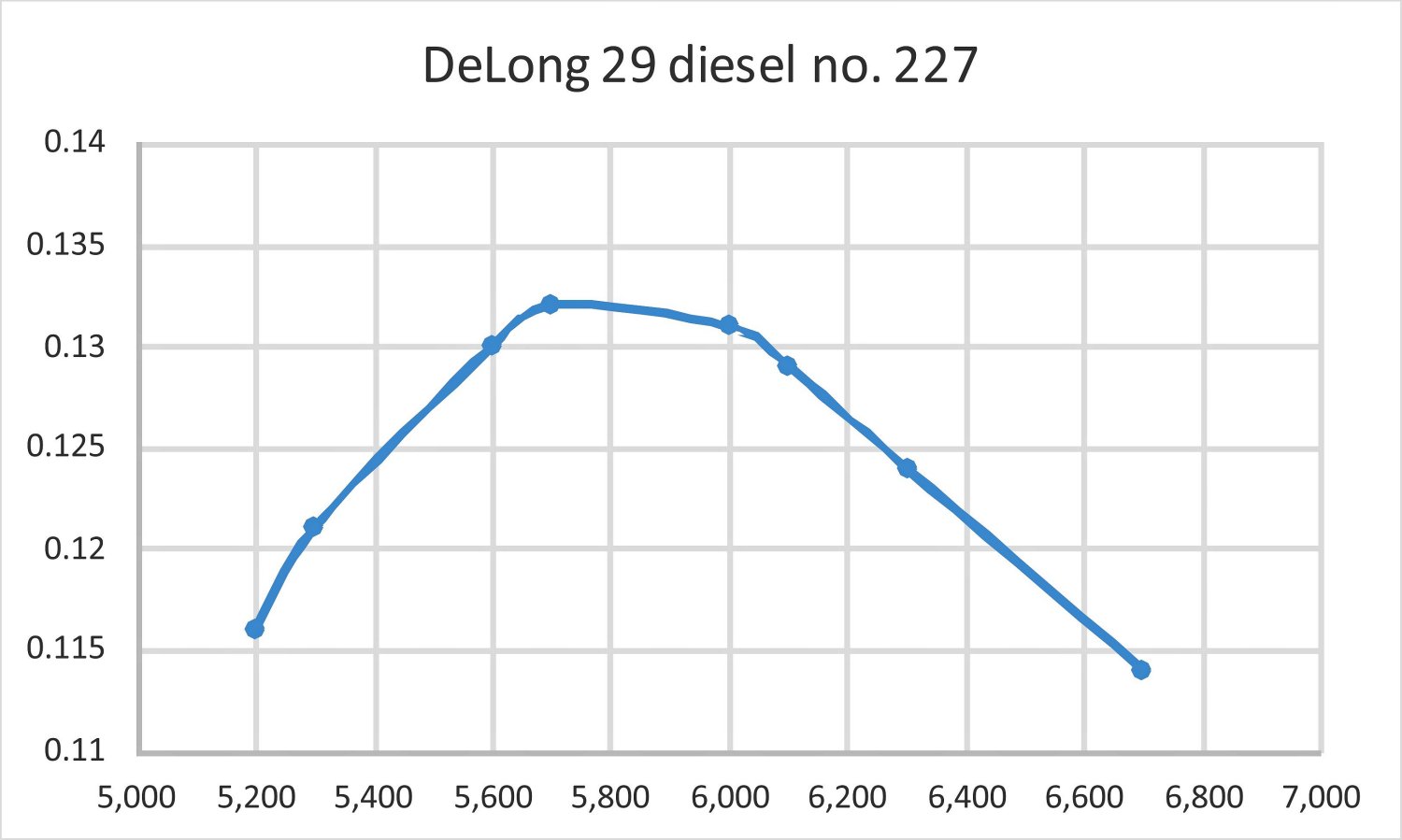

Since I don’t have power absorption coefficients for any of the above props apart from the 12x5 Zinger, I can’t really comment on the output and peaking speed which were indicated by the above results. All I can say is that the figures for the three Zinger props appear to imply that the engine was beginning to run out of breath at around 7,000 rpm and that power output was very much on the modest side if the implied output for the 12x5 Zinger of 0.161 BHP @ 6,400 rpm is anything to go by. It’s also worth recalling that the prop recommended by the manufacturer was an 11x8. Looking at Ken’s figures, I’d hazard a guess that his engine would have turned such a prop at around 6,000 rpm or thereabouts. If this is the case, considerations of airborne speed pickup imply that we’re likely looking at a peaking speed of perhaps 7,000 rpm, with an output of somewhere in the general vicinity of 0.170 BHP. Of course, guesses are worth about as much as the time it takes to make them! All of this speculation left nothing for it but to conduct my own test on the original example now in hand. Naturally, since this is a different example, we can’t necessarily expect a comparable level of performance. However, any data is far better than none at all! So onwards into the breach, dear friends, as Henry V might have said of this test if he or William Shakespeare had been aeromodellers ……..!! As previously stated, this particular example of the DeLong 29 diesel had clearly seen a fair bit of bench running - the castor oil varnish in the exhaust stack and on the piston top confirmed this, as did the superb fits and silky "feel" of the engine. However, there are no traces of the witness marks on the mounting lugs which would be expected if the engine had seen service in a model. Hence I suspect that it was purely a test prototype which was put through its paces on the bench. This being the case, I felt quite comfortable heading straight into the test with no time allocated for break-in. When selecting the props to be used in this test, I naturally stayed with those for which I had well-established power absorption figures. Ken’s test results provided a useful guide, allowing me to come up with a reasonable test suite which I felt would cover the anticipated speed range. The only prop that is common to both tests is the Zinger 12x5 – I don’t have any of the other props tried by Ken.

This being the case, it's always best to give such engines a fair chance by starting out with a really heavy prop. Once the settings are established, the use of smaller props becomes perfectly feasible - I subsequently had no trouble starting the beast on a lightweight 10 inch diameter wood prop. It took a while to establish the starting compression setting, but eventually after some popping and banging along with puffs of smoke I was rewarded with a start. Once running, it was necessary to reduce compression substantially as the engine warmed up. This is a typical characteristic of large low-speed diesels - they often require significantly higher compression for starting than they do for running. The engine proved to be a bit sensitive to the needle setting - the optimum setting was a matter of a couple of clicks either way. However, once the settings were established, the engine ran the tank out smoothly and steadily, never missing a beat. Both controls held their settings perfectly at all times. Subsequent starts were very easy provided a small prime was given - finger choking alone didn't do the trick. When hot, the engine would re-start at its running settings with no difficulty, but cold re-starts required a compression increase plus a slight opening of the needle valve. Even so, the engine may fairly be classifed as an easy starter, especially for a large diesel. The figures obtained for the various test props were as follows:

Although I seem to have missed the actual peak, the above figures reflect a rather modest peak output of perhaps 0.134 BHP @ 5,900 rpm. These are well down on figures which I myself have measured for the competing Mk. I Drone diesel. We may be seeing another reason why this engine never made it into series production - as originally designed, it lacked the levels of performance which were expected of a 0.29 cuin. diesel by late 1947. However, the above figures do support the manufacturer's recommendation of an 11x8 prop for normal use. The engine would turn such a prop at around 5,200 rpm on the ground, allowing it to pick up to somewhere very near its peak in the air. Finally, it seems worth noting that Ken Croft's replica example is clearly a significantly more powerful engine than the Super Motors original prototype tested here. The one prop that was featured in both tests was the Zinger 12x5. The original prototype turned this at 5,700 rpm, while the replica managed 6,400 rpm. In the absence of an opportunity for direct comparison, I have no explanation for this discrepancy. All that I can say is that the difference is not down to any shorcomings in the construction of the prototype - all working fits and finishes are superb, and there is no trace of a base compression leak. Conclusion

However, the meteoric appearance and immediate dominance of Ray Arden's miniature commercial glow-plugs in late 1947 spelled the end of any further serious consideration of diesels on the part of North American manufacturers, at least at that time. If that appearance had been delayed by even six months, we might have seen the DeLong 29 diesel developed into one of the finest model diesels to come out of America. Sadly, it was not to be. Even so, the prototype version of this engine was a really fine unit in its own right, and one which does great credit to its designer Everett M. Delong. I feel extremely privileged to own this fine piece of American model engine history. ________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published August 2016 Updated September 2018 Second update August 2023 (third original example identified) |

||

| |

America is not generally thought of as a major producer of model diesels. Although the country did engage in what proved to be a brief but surprisingly productive flirtation with diesels during the early post-WW2 era,

America is not generally thought of as a major producer of model diesels. Although the country did engage in what proved to be a brief but surprisingly productive flirtation with diesels during the early post-WW2 era,  Air-O

Air-O in the form of the infamous

in the form of the infamous  Cleveland Ohio. I say “legendary” because there remains a widespread belief that this engine did in fact reach series production. The reality however appears to be that while a small handful of prototypes were undoubtedly made, the design was never offered to the public in quantity on a commercial basis. Consequently, the majority of examples which may very occasionally be encountered today on eBay and elsewhere will be latter-day replicas, of which a small number are known to exist. More of those in their place ………..

Cleveland Ohio. I say “legendary” because there remains a widespread belief that this engine did in fact reach series production. The reality however appears to be that while a small handful of prototypes were undoubtedly made, the design was never offered to the public in quantity on a commercial basis. Consequently, the majority of examples which may very occasionally be encountered today on eBay and elsewhere will be latter-day replicas, of which a small number are known to exist. More of those in their place ……….. So why do I call the gentleman “Everett M. DeLong” instead of “Joe”??!? Simple – the original factory drawings of the DeLong 29 diesel are still in existence and bear the name of E. M. DeLong as their creator. It’s difficult to see how one gets “Joe” out of the initials E. M., although there is always the possibility that “Joe” was one of those nicknames that one encounters from time to time which bears no discernable relation to the individual’s given names. I know a young lady named Alyssa who goes by the nickname “Ed”, for example (don’t ask me why - there is a reason, but life's far too short!)!

So why do I call the gentleman “Everett M. DeLong” instead of “Joe”??!? Simple – the original factory drawings of the DeLong 29 diesel are still in existence and bear the name of E. M. DeLong as their creator. It’s difficult to see how one gets “Joe” out of the initials E. M., although there is always the possibility that “Joe” was one of those nicknames that one encounters from time to time which bears no discernable relation to the individual’s given names. I know a young lady named Alyssa who goes by the nickname “Ed”, for example (don’t ask me why - there is a reason, but life's far too short!)! It was solely on the basis of that one unsubstantiated bull session recollection that Tim applied the name Joe to the originator of these engines when writing the text of AMEE. No blame attaches to Tim for doing so – he was simply responding to the one piece of evidence that he had at the time. However, he agreed that the initials on the drawings threw considerable doubt upon this identification. This being the case, historical accuracy clearly compelled me to drop the name “Joe” for lack of evidence.

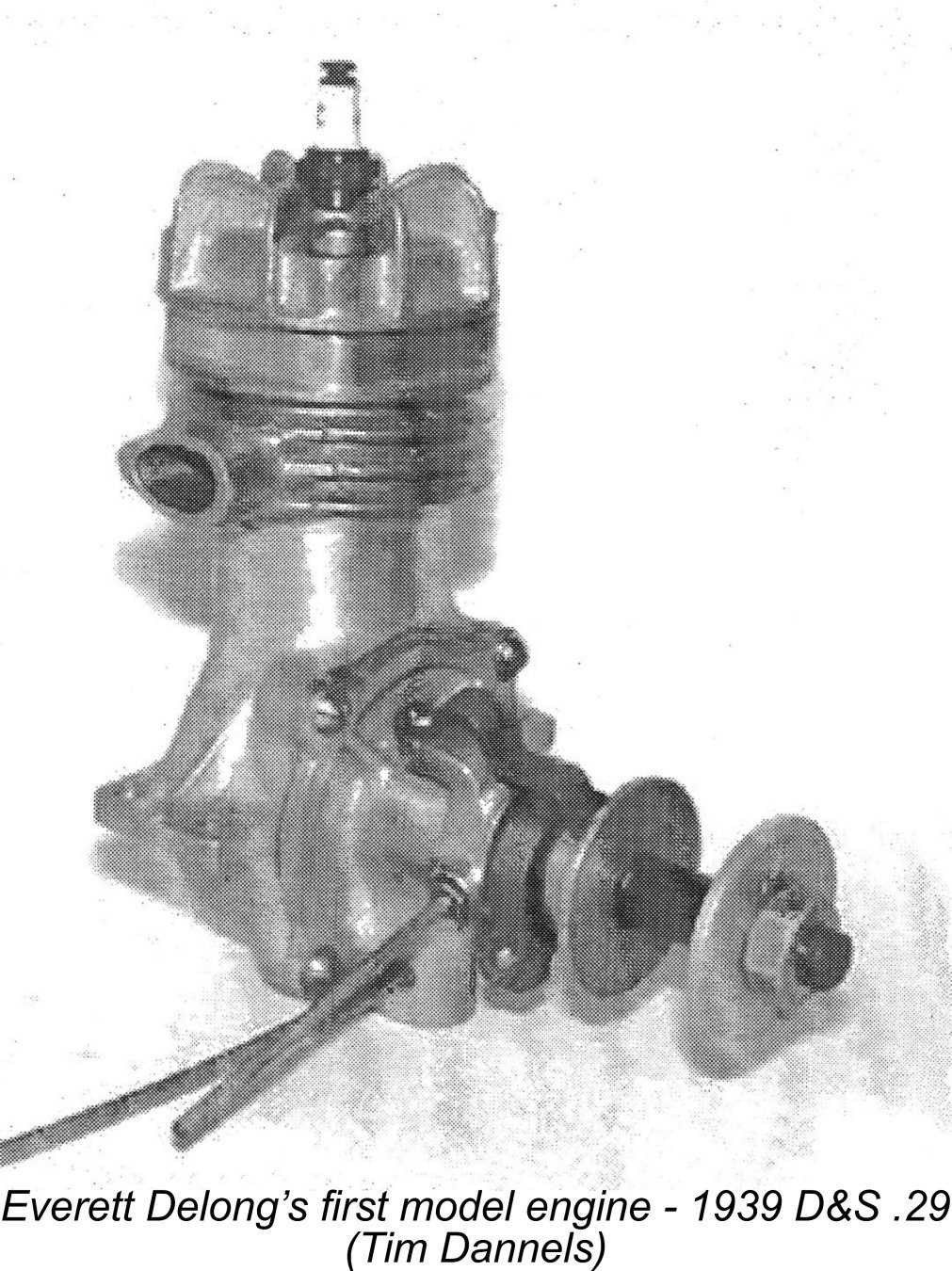

It was solely on the basis of that one unsubstantiated bull session recollection that Tim applied the name Joe to the originator of these engines when writing the text of AMEE. No blame attaches to Tim for doing so – he was simply responding to the one piece of evidence that he had at the time. However, he agreed that the initials on the drawings threw considerable doubt upon this identification. This being the case, historical accuracy clearly compelled me to drop the name “Joe” for lack of evidence. Everett DeLong (as we are now fully justified in calling him) first entered the model engine manufacturing business in 1939 in partnership with Bob Steele while still resident in Lima, Ohio. Their DeLong and Steele (D&S) company of Lima manufactured a pair of .29 cuin. spark ignition models which appeared in 1939 and 1940 respectively. A 0.60 cuin model was also produced by D&S in 1940, although very few of these were manufactured. There have been reports of a .331 cuin. model from the same company, although since there appear to be no surviving examples this cannot be confirmed at the present time.

Everett DeLong (as we are now fully justified in calling him) first entered the model engine manufacturing business in 1939 in partnership with Bob Steele while still resident in Lima, Ohio. Their DeLong and Steele (D&S) company of Lima manufactured a pair of .29 cuin. spark ignition models which appeared in 1939 and 1940 respectively. A 0.60 cuin model was also produced by D&S in 1940, although very few of these were manufactured. There have been reports of a .331 cuin. model from the same company, although since there appear to be no surviving examples this cannot be confirmed at the present time. The DeLong 30 models remained the “bread and butter” offerings throughout. They were very highly regarded, winning many contests. The examples that I have personally handled have all been very well made indeed, fully justifying the engine's high reputation. They're also great runners.

The DeLong 30 models remained the “bread and butter” offerings throughout. They were very highly regarded, winning many contests. The examples that I have personally handled have all been very well made indeed, fully justifying the engine's high reputation. They're also great runners. It would seem logical to assume that at least one prototype was constructed based on these plans, although this is by no means certain. In the event that a prototype was constructed, a testing program would then have been undertaken to identify any residual design shortcomings.

It would seem logical to assume that at least one prototype was constructed based on these plans, although this is by no means certain. In the event that a prototype was constructed, a testing program would then have been undertaken to identify any residual design shortcomings. Moreover, in the latter part of 1947 Super Motors began to promote the engine as if it was going to appear on the market in time for the winter 1947/48 building season. Everett DeLong invited “Model Airplane News” (MAN) contributor Jack Bayha along to test an example of the engine at the Cleveland factory. Bayha included a brief account of his experiences in an article entitled “Diesels Grow Up” which appeared in the December 1947 issue of MAN. Bayha’s account read as follows:

Moreover, in the latter part of 1947 Super Motors began to promote the engine as if it was going to appear on the market in time for the winter 1947/48 building season. Everett DeLong invited “Model Airplane News” (MAN) contributor Jack Bayha along to test an example of the engine at the Cleveland factory. Bayha included a brief account of his experiences in an article entitled “Diesels Grow Up” which appeared in the December 1947 issue of MAN. Bayha’s account read as follows: “Super Motors Inc., manufacturers of the well-known DeLong gasoline engine which has won many contests, has entered the diesel field with a .29 cuin. variable compression engine having a shaft-type rotary valve. It is operated on a fuel mixture of 5 parts ether, 4 parts mineral oil and 1 part naptha. An 11” diameter 8” pitch propeller is recommended. The steel cylinder is threaded at the lower end and screwed into the die-cast crankcase. The steel piston is lap-fitted to the cylinder. Other features of the engine are an aluminium alloy connecting rod with bronze bushing at the lower end, and a bronze-bushed crankshaft bearing. The engine has a stroke-bore ratio of .90 to 1 and is designed for beam mounting. It weighs 11 ounces.”

“Super Motors Inc., manufacturers of the well-known DeLong gasoline engine which has won many contests, has entered the diesel field with a .29 cuin. variable compression engine having a shaft-type rotary valve. It is operated on a fuel mixture of 5 parts ether, 4 parts mineral oil and 1 part naptha. An 11” diameter 8” pitch propeller is recommended. The steel cylinder is threaded at the lower end and screwed into the die-cast crankcase. The steel piston is lap-fitted to the cylinder. Other features of the engine are an aluminium alloy connecting rod with bronze bushing at the lower end, and a bronze-bushed crankshaft bearing. The engine has a stroke-bore ratio of .90 to 1 and is designed for beam mounting. It weighs 11 ounces.” No performance indications were given by Ingram beyond that one prop recommendation - it appears that Ingram never tested the engine himself. Indeed, there is considerable doubt that he ever actually handled an example in the metal, since his statement that the cylinder was a screw-in item was clearly erroneous – it’s actually secured in place by four machine screws.

No performance indications were given by Ingram beyond that one prop recommendation - it appears that Ingram never tested the engine himself. Indeed, there is considerable doubt that he ever actually handled an example in the metal, since his statement that the cylinder was a screw-in item was clearly erroneous – it’s actually secured in place by four machine screws.  ignition support equipment (provided their engines had a sufficient compression ratio, which some sparkers didn’t) and fly with all-weather dependability and relative freedom from “tinkering”. The major advantage over the spark ignition motor which the diesel had formerly enjoyed exclusively had vanished overnight.

ignition support equipment (provided their engines had a sufficient compression ratio, which some sparkers didn’t) and fly with all-weather dependability and relative freedom from “tinkering”. The major advantage over the spark ignition motor which the diesel had formerly enjoyed exclusively had vanished overnight. Motor Boys International were (and happily in some cases still are as of 2023!) a group of multi-talented model makers who came together in the 1990's on the basis of a shared love of model internal combustion engines in all their various forms. Their main focus was on the home construction and restoration of model engines, although all of the members of the group were also active aeromodellers in one form or another. The group kept in touch and exchanged ideas via the Internet. From June 2002 onwards the results of their joint efforts were regularly reported on Ron Chernich’s wonderful “

Motor Boys International were (and happily in some cases still are as of 2023!) a group of multi-talented model makers who came together in the 1990's on the basis of a shared love of model internal combustion engines in all their various forms. Their main focus was on the home construction and restoration of model engines, although all of the members of the group were also active aeromodellers in one form or another. The group kept in touch and exchanged ideas via the Internet. From June 2002 onwards the results of their joint efforts were regularly reported on Ron Chernich’s wonderful “ Ken experienced a good bit of difficulty getting the die-cast crankcases just right, but eventually he succeeded in producing and machining the required number of cases to his usual extremely high standard. According to Ron’s account, the only ways in which Ken’s cases could be distinguished from the originals were: 1) there was no engraving/embossing of the name Super Motors on the side; and 2) there were no originals! Later research has shown that Ron wasn’t quite accurate on either count, but we’ll let that pass for now ……………

Ken experienced a good bit of difficulty getting the die-cast crankcases just right, but eventually he succeeded in producing and machining the required number of cases to his usual extremely high standard. According to Ron’s account, the only ways in which Ken’s cases could be distinguished from the originals were: 1) there was no engraving/embossing of the name Super Motors on the side; and 2) there were no originals! Later research has shown that Ron wasn’t quite accurate on either count, but we’ll let that pass for now …………… In 2016 I was fortunate enough to acquire a very fine example of the DeLong 29 diesel. I’m greatly indebted to my good friend Mike Conner for brokering this opportunity. When I entered into direct negotiations with the owner (off eBay), I assumed that it must surely be one of those constructed by the Motor Boys team – perhaps the product of one of the now-deceased members.

In 2016 I was fortunate enough to acquire a very fine example of the DeLong 29 diesel. I’m greatly indebted to my good friend Mike Conner for brokering this opportunity. When I entered into direct negotiations with the owner (off eBay), I assumed that it must surely be one of those constructed by the Motor Boys team – perhaps the product of one of the now-deceased members. My next step was to make yet another approach to the individual who probably knows more about American model engines than any other – my valued mate Tim Dannels. Over the years, no-one has done more than Tim to preserve America’s model engine heritage. There could be no better potential source of information on this engine.

My next step was to make yet another approach to the individual who probably knows more about American model engines than any other – my valued mate Tim Dannels. Over the years, no-one has done more than Tim to preserve America’s model engine heritage. There could be no better potential source of information on this engine. But Tim went even further than this! He drew attention to the fact that both the first and second editions of AMEE included images of an original prototype example formerly owned by Ted Enticknap. Ron Chernich’s previously-mentioned unfinished article also featured a few images of that example. As far as Tim was aware, the only other surviving example which was generally accepted as a genuine Super Motors original prototype was owned by a gentleman named Jim Schiller of Kirkland, Washington.

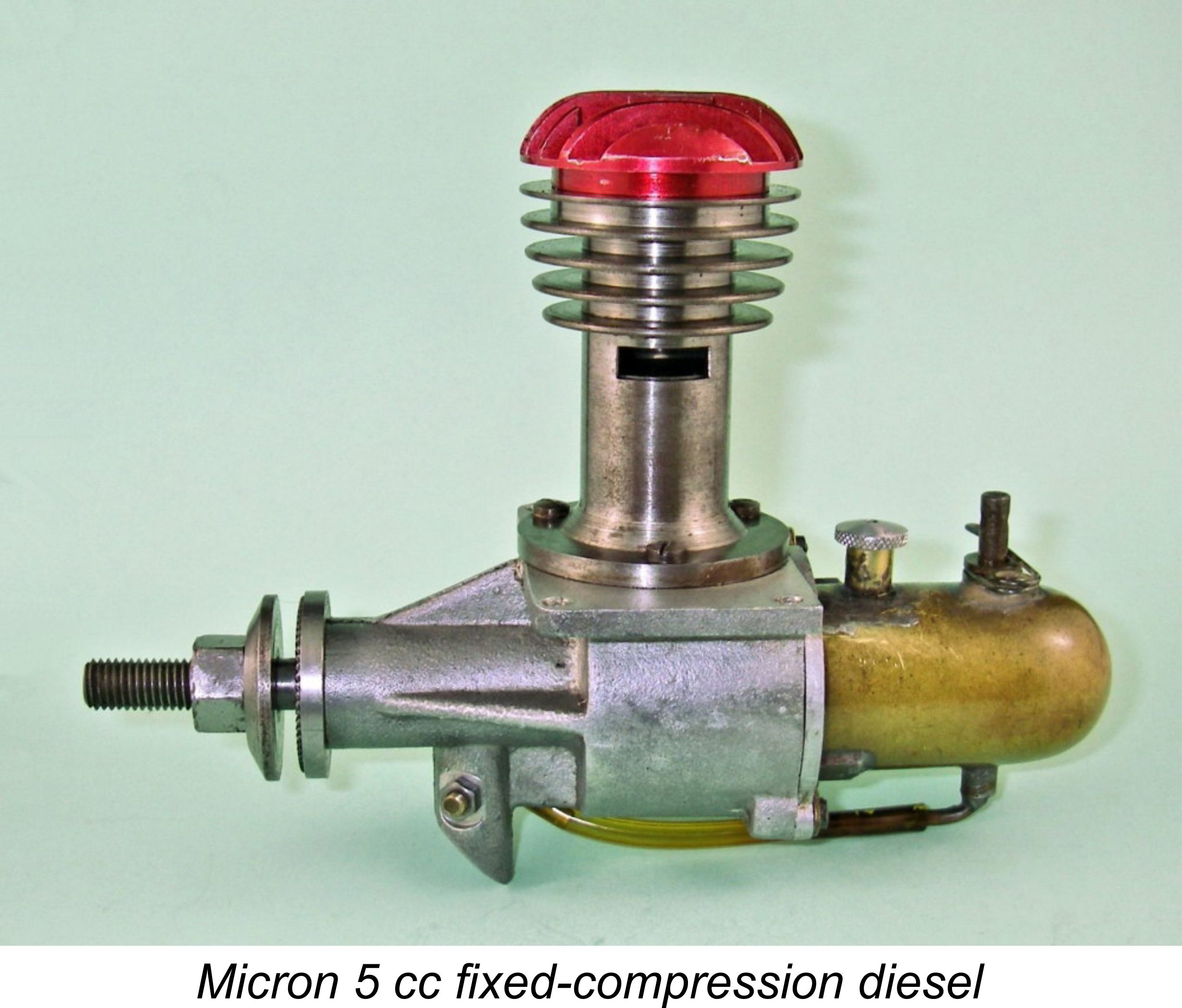

But Tim went even further than this! He drew attention to the fact that both the first and second editions of AMEE included images of an original prototype example formerly owned by Ted Enticknap. Ron Chernich’s previously-mentioned unfinished article also featured a few images of that example. As far as Tim was aware, the only other surviving example which was generally accepted as a genuine Super Motors original prototype was owned by a gentleman named Jim Schiller of Kirkland, Washington. The Delong 29 diesel is basically a typical long-stroke crankshaft front rotary valve (FRV) model diesel of its early post-war era. Like the contemporary Drone diesel which had its origins in coffee-shop discussions at the 1946 US National Championship meet, the design of the DeLong diesel seems to have been heavily influenced by that of the then immensely successful Micron 5 cc fixed compression model from France. It shared the common features of FRV induction, a single vertical bypass passage opposite the exhaust, a flat-topped piston with a deflector step on the transfer side and rectangular transfer and exhaust ports placed on opposite sides of the cylinder. Its main departure from both the Micron and Drone was its use of variable compression.

The Delong 29 diesel is basically a typical long-stroke crankshaft front rotary valve (FRV) model diesel of its early post-war era. Like the contemporary Drone diesel which had its origins in coffee-shop discussions at the 1946 US National Championship meet, the design of the DeLong diesel seems to have been heavily influenced by that of the then immensely successful Micron 5 cc fixed compression model from France. It shared the common features of FRV induction, a single vertical bypass passage opposite the exhaust, a flat-topped piston with a deflector step on the transfer side and rectangular transfer and exhaust ports placed on opposite sides of the cylinder. Its main departure from both the Micron and Drone was its use of variable compression. The resulting internal geometry is somewhat less drastically long-stroke than encountered in the Micron (17.00 mm, 22.0 mm, 4.99 cc / .304 cuin.) and the Drone (16.67 mm, 22.22 mm, 4.85 cc / 0.297 cuin.) respectively. This may reflect Everett DeLong’s spark ignition design heritage. The illustrated example of the DeLong diesel weighs 298 gm (10.51 ounces) as illustrated with tank.

The resulting internal geometry is somewhat less drastically long-stroke than encountered in the Micron (17.00 mm, 22.0 mm, 4.99 cc / .304 cuin.) and the Drone (16.67 mm, 22.22 mm, 4.85 cc / 0.297 cuin.) respectively. This may reflect Everett DeLong’s spark ignition design heritage. The illustrated example of the DeLong diesel weighs 298 gm (10.51 ounces) as illustrated with tank. than necessary, I didn’t carry out a full tear-down, which would have required me to break what appeared to be a gas-tight backplate seal. I did however have to remove the cylinder to free what appeared to be an immovably-stuck contra piston which might have created starting difficulties. Hence I’m able to include the attached image showing both the piston crown with its transfer step and the bypass passage which feeds it. The serial number can also be seen in this view.

than necessary, I didn’t carry out a full tear-down, which would have required me to break what appeared to be a gas-tight backplate seal. I did however have to remove the cylinder to free what appeared to be an immovably-stuck contra piston which might have created starting difficulties. Hence I’m able to include the attached image showing both the piston crown with its transfer step and the bypass passage which feeds it. The serial number can also be seen in this view.  The needle valve assembly was basically of the American standard “universal” style, with a spraybar that was threaded at both ends with a plain length where it intersected the intake venturi throat. Nuts and fibre sealing washers were used at both ends to allow for the precise placement of the single jet hole in the centre of the intake venturi where it would be subject to the maximum gas velocities and hence maximum suction. Needle tension was provided by a sturdy single-blade spring clip acting upon a large-diameter serrated disc formed integrally with the needle thimble. The needle is mechanically very smooth and positive in action.

The needle valve assembly was basically of the American standard “universal” style, with a spraybar that was threaded at both ends with a plain length where it intersected the intake venturi throat. Nuts and fibre sealing washers were used at both ends to allow for the precise placement of the single jet hole in the centre of the intake venturi where it would be subject to the maximum gas velocities and hence maximum suction. Needle tension was provided by a sturdy single-blade spring clip acting upon a large-diameter serrated disc formed integrally with the needle thimble. The needle is mechanically very smooth and positive in action. Backplate – the originals have a die-cast backplate, while the Motor Boys replicas have a component that is machined from bar stock.

Backplate – the originals have a die-cast backplate, while the Motor Boys replicas have a component that is machined from bar stock.

I began with an APC 12x7 - a real club of a prop with a lot of flywheel effect. This is an important factor when attempting to run large-displacement diesels for the first time - it takes a fair bit of flywheel momentum to overcome the inherent self-braking effect of the large-diameter bearings and considerable compression-stroke resistance. This tendency towards self-braking among large diesels was well recognized during the "classic" era - it was a major reason why Leon Shulman incorporated a ball race in the second model of the Drone diesel.

I began with an APC 12x7 - a real club of a prop with a lot of flywheel effect. This is an important factor when attempting to run large-displacement diesels for the first time - it takes a fair bit of flywheel momentum to overcome the inherent self-braking effect of the large-diameter bearings and considerable compression-stroke resistance. This tendency towards self-braking among large diesels was well recognized during the "classic" era - it was a major reason why Leon Shulman incorporated a ball race in the second model of the Drone diesel.

The DeLong 29 diesel represented a serious attempt by a competent designer/manufacturer to jump on board what must have appeared as a potential "wave of the future" in a mid 1947 context. The prototype engine was a very well-made and user-friendly unit whch would undoubtedly have done a creditable job of flying a model. No doubt further development would have resulted in a significantly improved performance - the potential was clearly there in the basic design.

The DeLong 29 diesel represented a serious attempt by a competent designer/manufacturer to jump on board what must have appeared as a potential "wave of the future" in a mid 1947 context. The prototype engine was a very well-made and user-friendly unit whch would undoubtedly have done a creditable job of flying a model. No doubt further development would have resulted in a significantly improved performance - the potential was clearly there in the basic design.