|

|

Barcelona Beauties - the Byra Engines

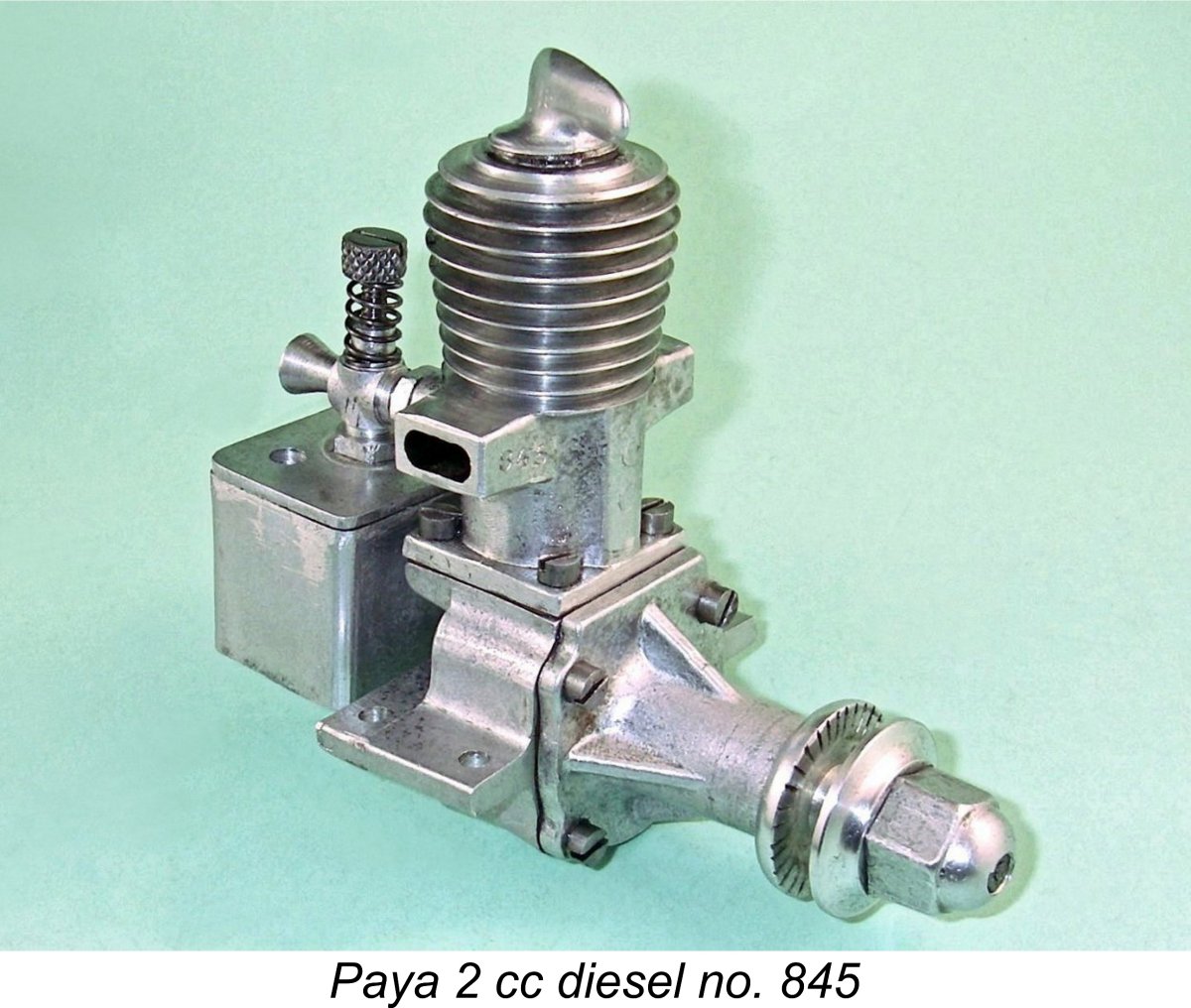

Our last visit to Spain took us up to Pontevedra in the autonomous community of Galicia on Spain’s north-west Atlantic coastline, where we encountered the Payá 2 cc model diesel engine. This elegantly-styled but rather anaemic sideport unit first appeared under a different name in the early part of 1948 as a product of a well-known company whose main business was the manufacture of compact "true" diesel engines for full-sized boats. It was a direct derivative of the E.D. Mk. II diesel from England which had appeared in early 1947. Although a highly derivative design in functional terms, the Payá nonetheless bears the distinction of having been the first model engine to enter series production in Spain. I’ve covered the full Payá story in a separate article. It's now time to review the next commercial Spanish model engine series to appear - the somewhat better-known Byra range.

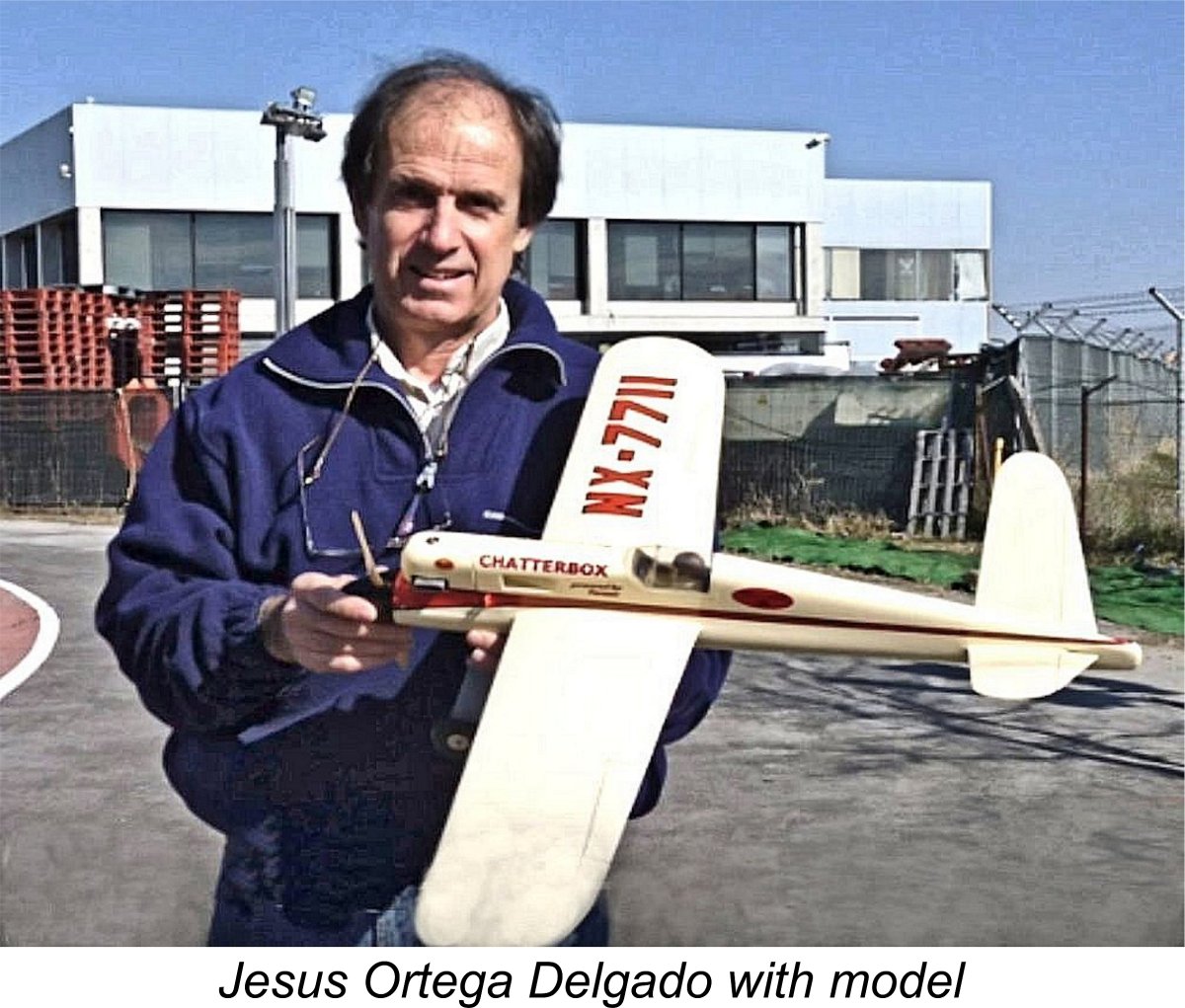

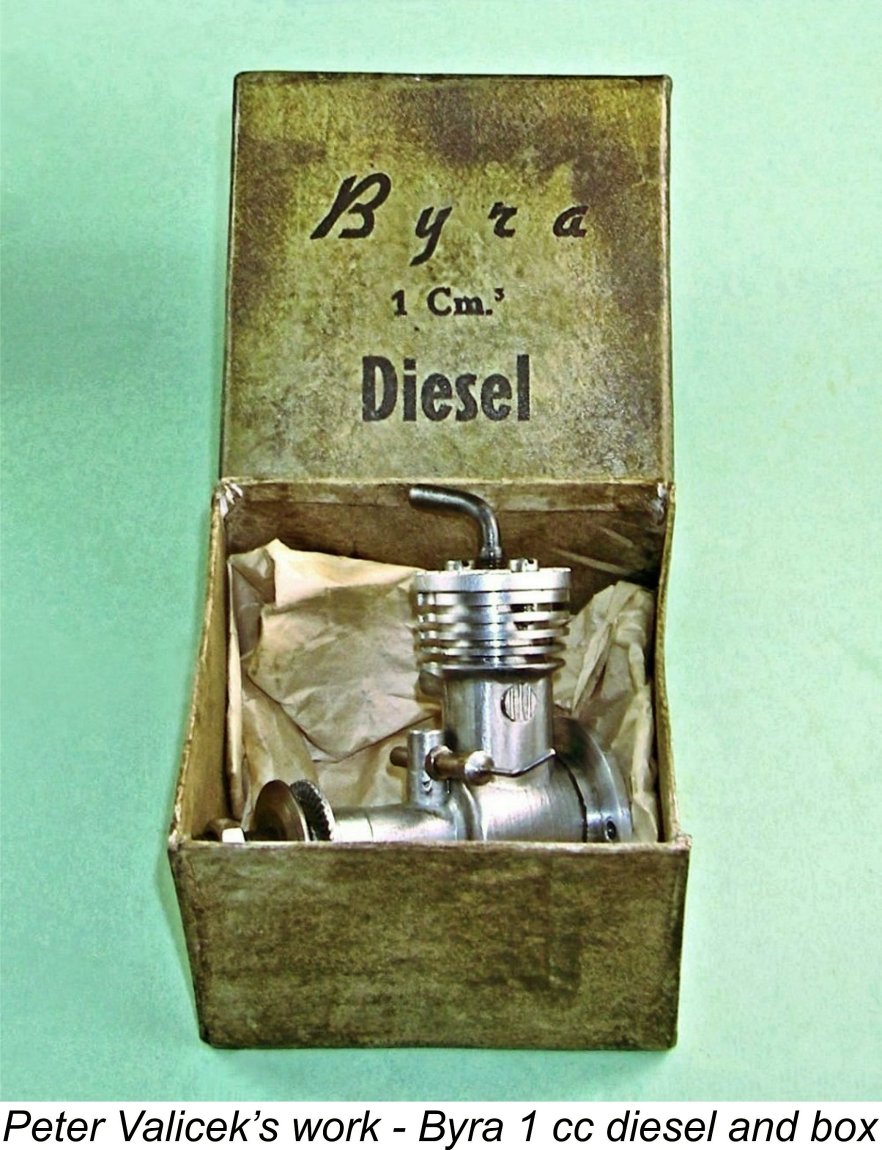

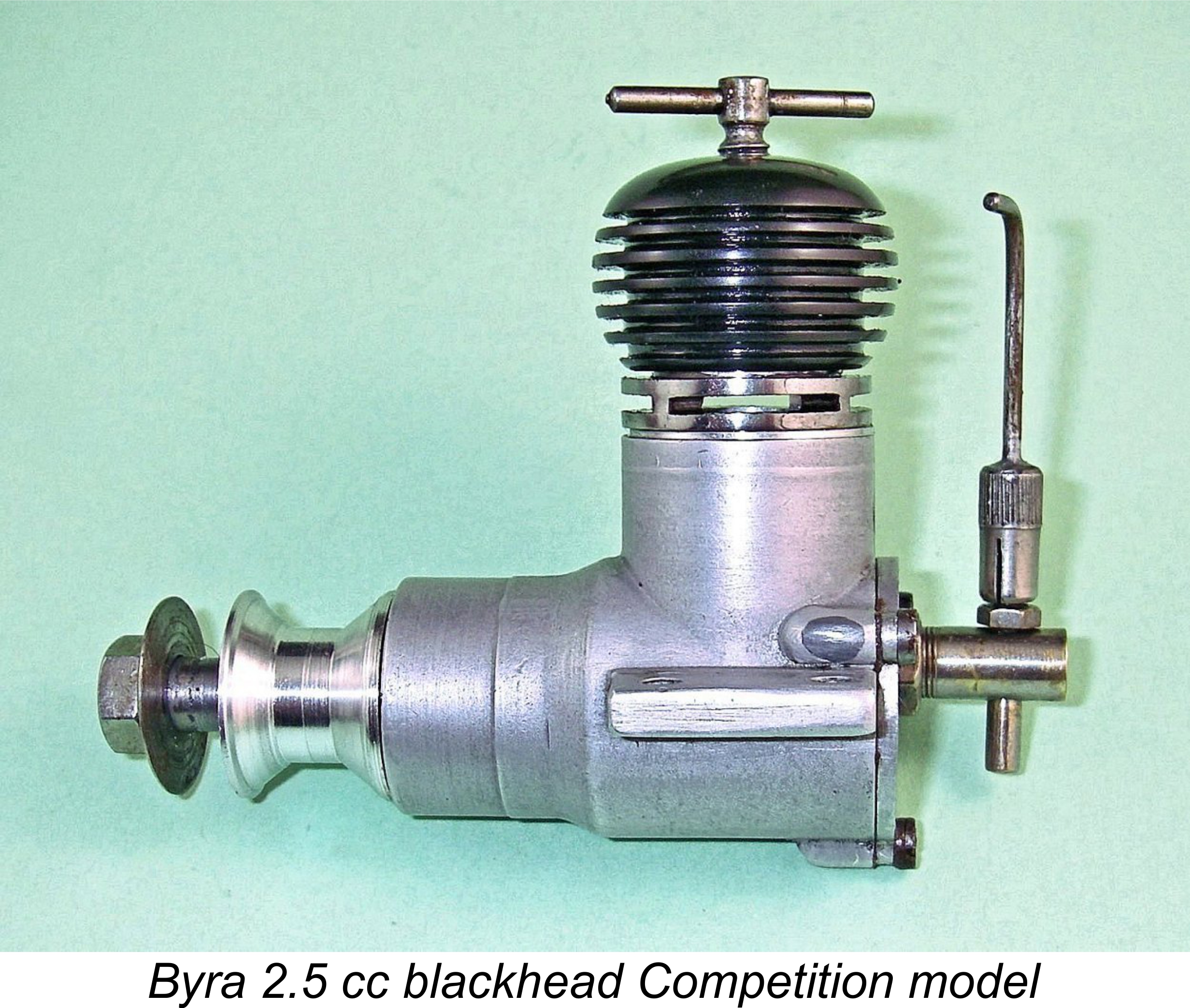

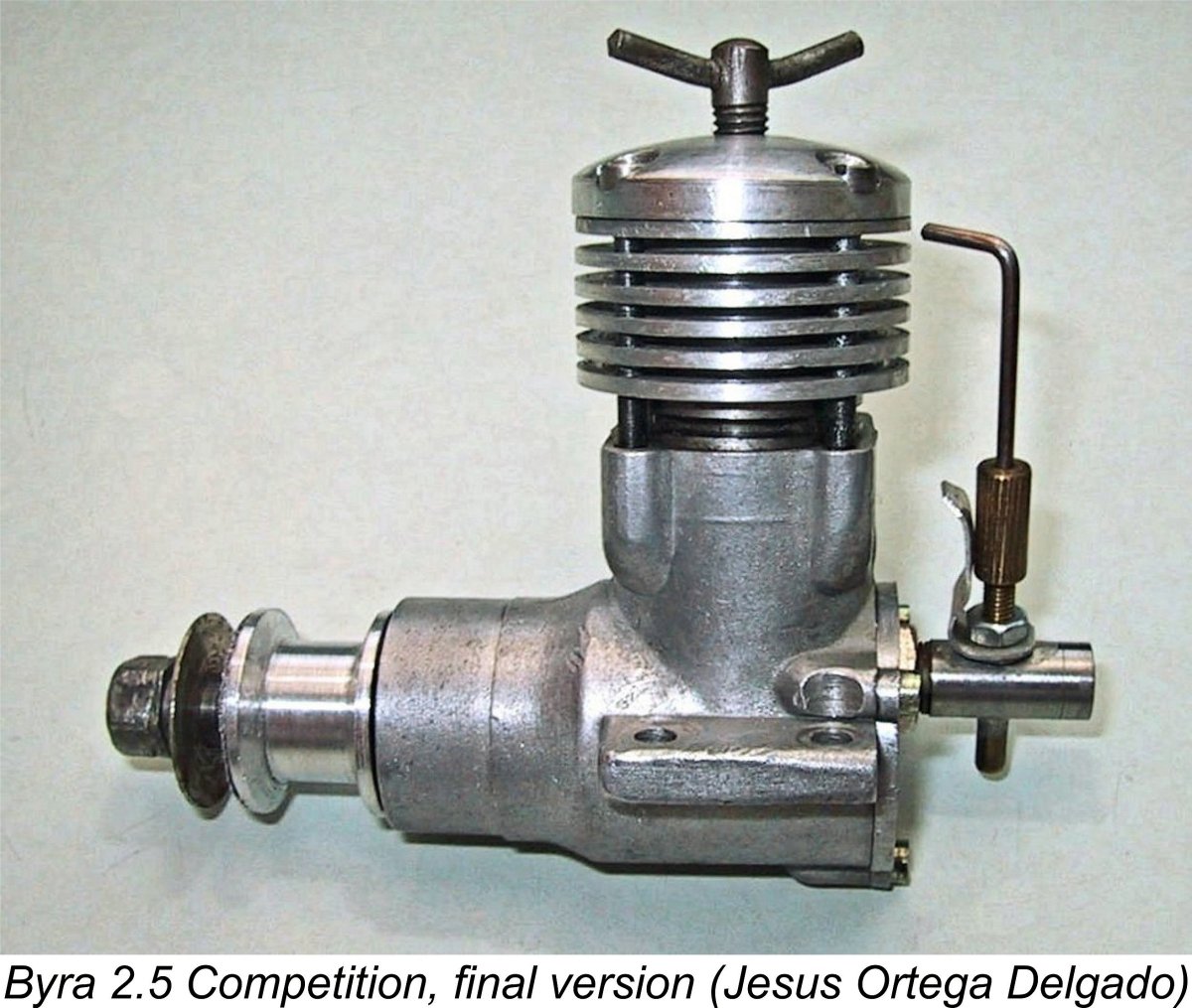

Before proceeding further with the Byra story, it's both a duty and a pleasure to acknowledge the very material assistance provided by a number of individuals, without whose help I'd have got nowhere. One source of information on the Byra engines that many readers have probably already come across is José Manuel Rojo's fascinating and very useful website which presents the world-class JM Rojo model engine collection for interested readers. Although presented in Spanish, it’s easily translated into any language using Google Translate or some similar program. The site includes a number of excellent images of certain Byra models (among many others) along with some very useful descriptive material. Reference to contemporary magazine articles proves beyond question that several of José Manuel's cited dates as well as a few details of the engines themselves are in error, but this in no way detracts from the interest and value of the site. I’ll do my best to correct any such issues as I proceed. That said, with José Manuel's kind permission I’ve used a number of his website images here, with my open and grateful acknowledgement. José Manuel has also spent a considerable amount of time tracking down such personal information about Don Fernando Batlló as remains available at this late date. I'd like to record It's always a genuine pleasure to acknowledge the supportive efforts of my valued mate Peter Valicek of the Netherlands. Peter undertook the very exacting technical work required to restore my test examples of the Byra 1 cc diesel and 2.5 cc Blackhead Competition diesel to near-new and fully serviceable condition for evaluation. Without his help, I couldn’t have even set out upon this journey. A friend indeed ............. I’d also like to thank my buen amigo español Jesus Ortega Delgado, who provided scans of a number of very informative Spanish-language articles along with a hi-res scan of the original design drawing of the test 2.5 cc Byra Competition model. Not only that, but Jesus also supplied images of a number of the rarest Byra models Without his assistance, the present article would be seriously deficient both in scope and authority. Thanks, mate!! With those acknowledgements having been gratefully recorded, it's time to get on with our story. As always, some background is required to set the stage. Background

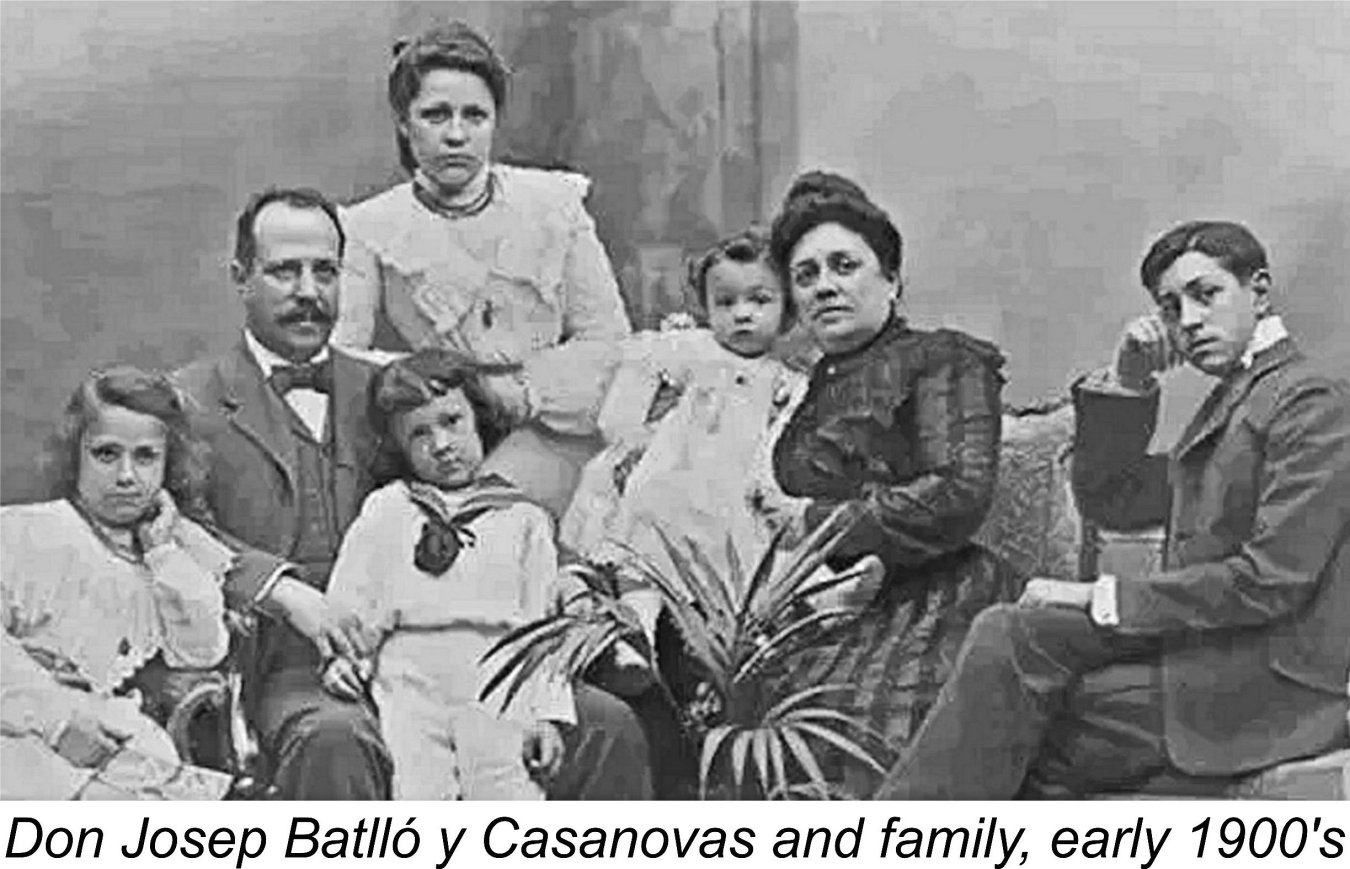

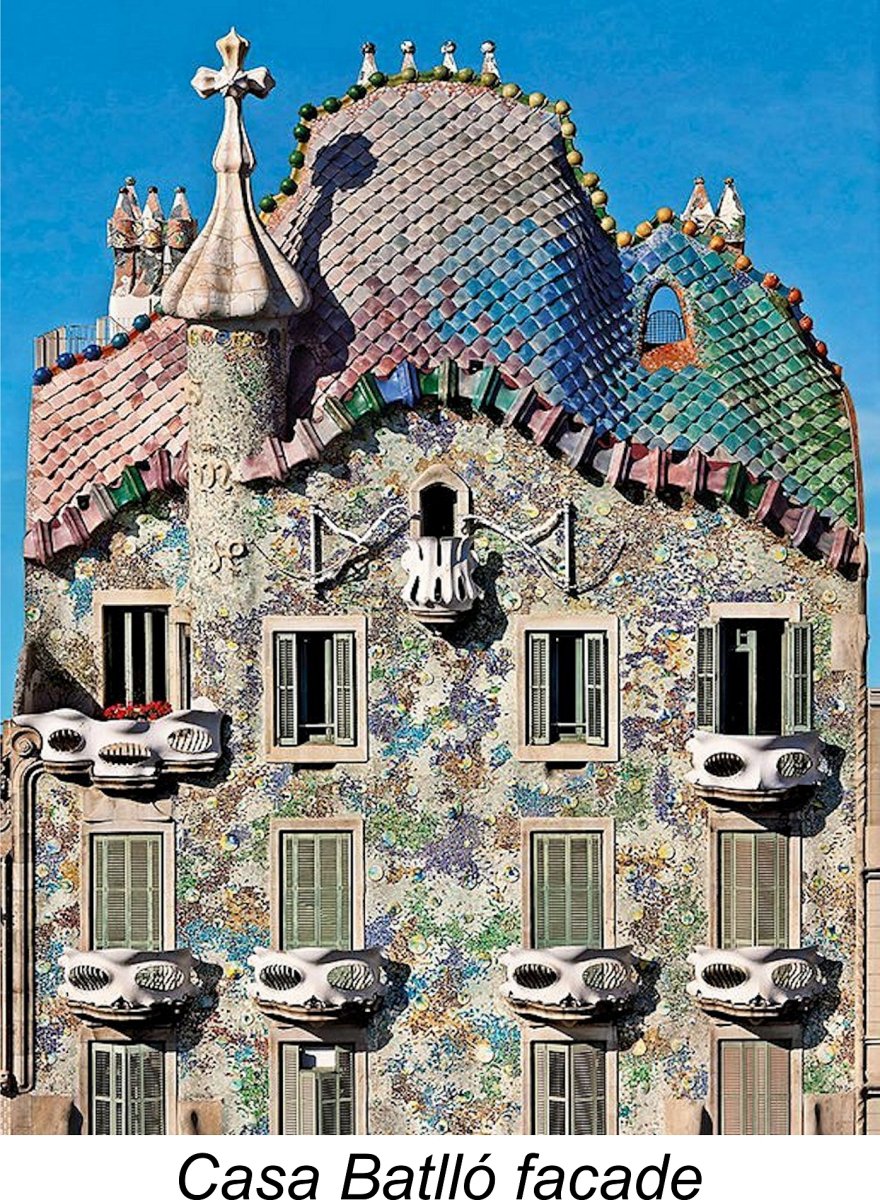

Among those who took the latter route was Don Fernando Batlló, a wealthy resident of the city of Barcelona which forms part of the autonomous community of Catalonia (aka Catalunya) located on Spain’s north-east coast fronting the Mediterranean Sea. Batlló was a leading member of one of Barcelona’s most wealthy and influential high society families. The former residence of the Batlló family, Casa Batlló, is today one of the tourist highlights of a visit to Barcelona. The house was originally built in 1877 by Emilio Sala Cortés, but was purchased in 1903 by Don Josep Batlló y Casanovas, who owned several textile factories in Barcelona at the time. Don Josep granted full creative freedom to the celebrated architect Antoni Gaudi, putting him in charge of a reconstruction project that initially entailed demolishing the original building.

Don Fernando Batlló grew up in this house. However, in 1954 Casa Batlló passed out of the ownership of the Batlló family. After being taken over by a succession of different individuals and companies, the building has been in the hands of its current owners, the Bernat family, since the 1990’s. They have fully restored the building.

The above account should suffice to confirm that Don Fernando Batlló was a member of an extremely wealthy and influential family. As such, he was quite atypical of model engine designers and manufacturers in general, having no economic incentive whatsoever to become involved in that field. It’s clear that his involvement in such a venture was motivated solely by a genuine love of aeromodelling and the engines which powered his models. A true enthusiast! One matter that should be clarified before we go any further is the spelling of Don Fernando's family name. A number of articles in the English-language modelling media have rendered the name as "Battló", with two t's and only one l. Even the published plan of Batlló's "Picador" stunt model (of which more below) perpetuates this error. The correct spelling is undoubtedly "Batlló" (one t and two l's, pronounced more or less as "Bat - lee - yo"), as witness numerous Spanish references. Inquiries made on my behalf by my previously-acknowledged friend and colleague José Manuel Rojo have confirmed that Batlló was trained as an industrial engineer. However, he apparently never practised that profession, serving instead as the manager of the Batlló family’s textile venture which had been established in the 19th century as Sederías Batlló (Batlló Silk Industries). He represented the fourth generation of his family to serve in that capacity.

In this, he was assisted by a machinist friend named Ramirez (first name not recorded), who apparently carried out much of the machining and assembly of the engines. It was this association which led to the adoption of the name Byra for the engines - Batlló y Ramirez. It appears that Batlló used the name Byra on the engines even at this early pre-commercial stage. Batlló soon became quite well-known among Spanish aeromodellers for the excellent engines which he and Señor Ramirez constructed in very limited numbers during the late 1940’s for their own use and that of their friends. Of course, model engine manufacture was by no means Batlló’s primary means of making a living. On the contrary, he approached this activity purely as a hobby while continuing to manage the family textile business as his main preoccupation. Señor Ramirez evidently carried out the actual construction of the engines for the most part. However, this low-key situation was soon to change ............. The Beginning – the 4.5 cc Model

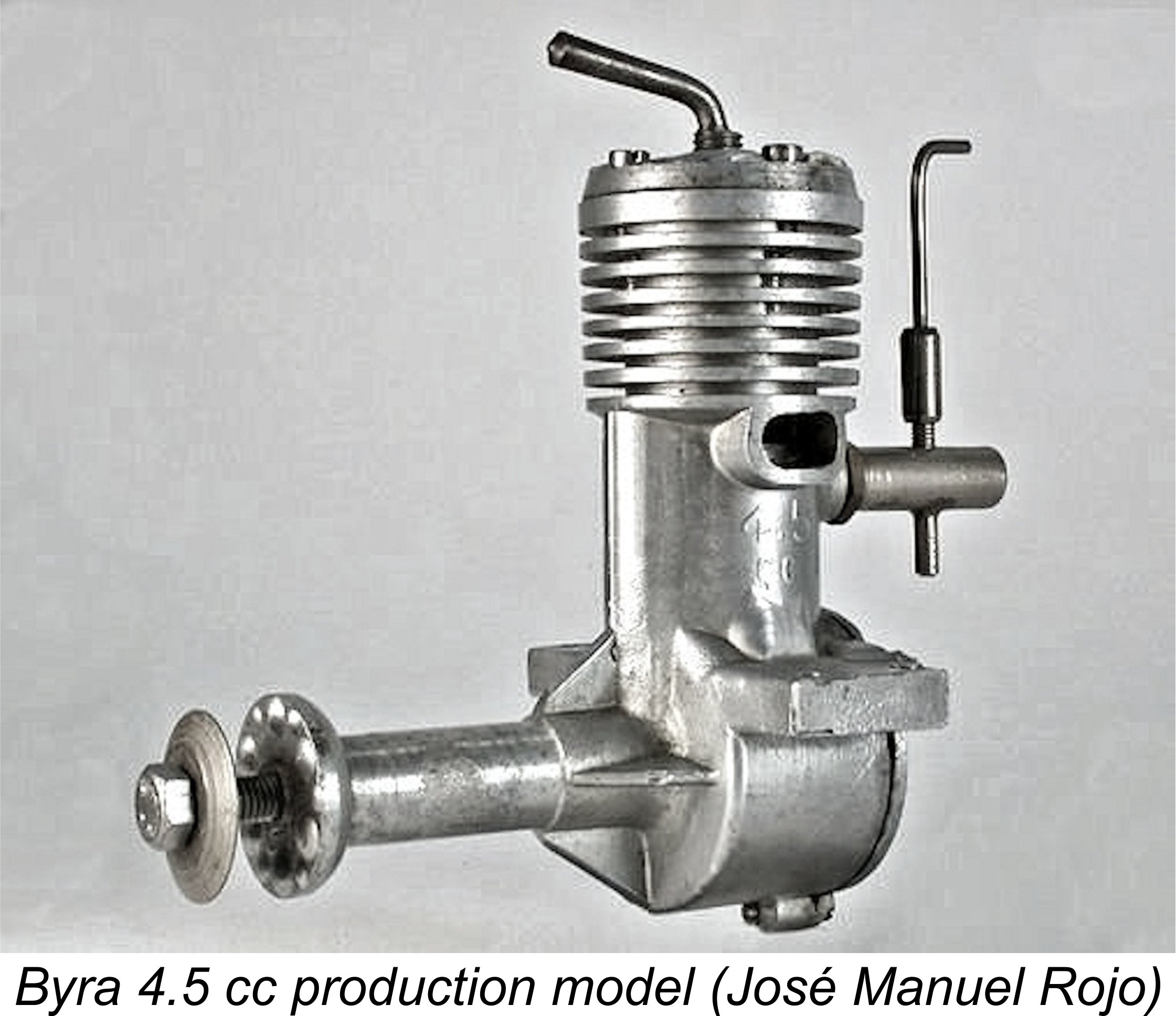

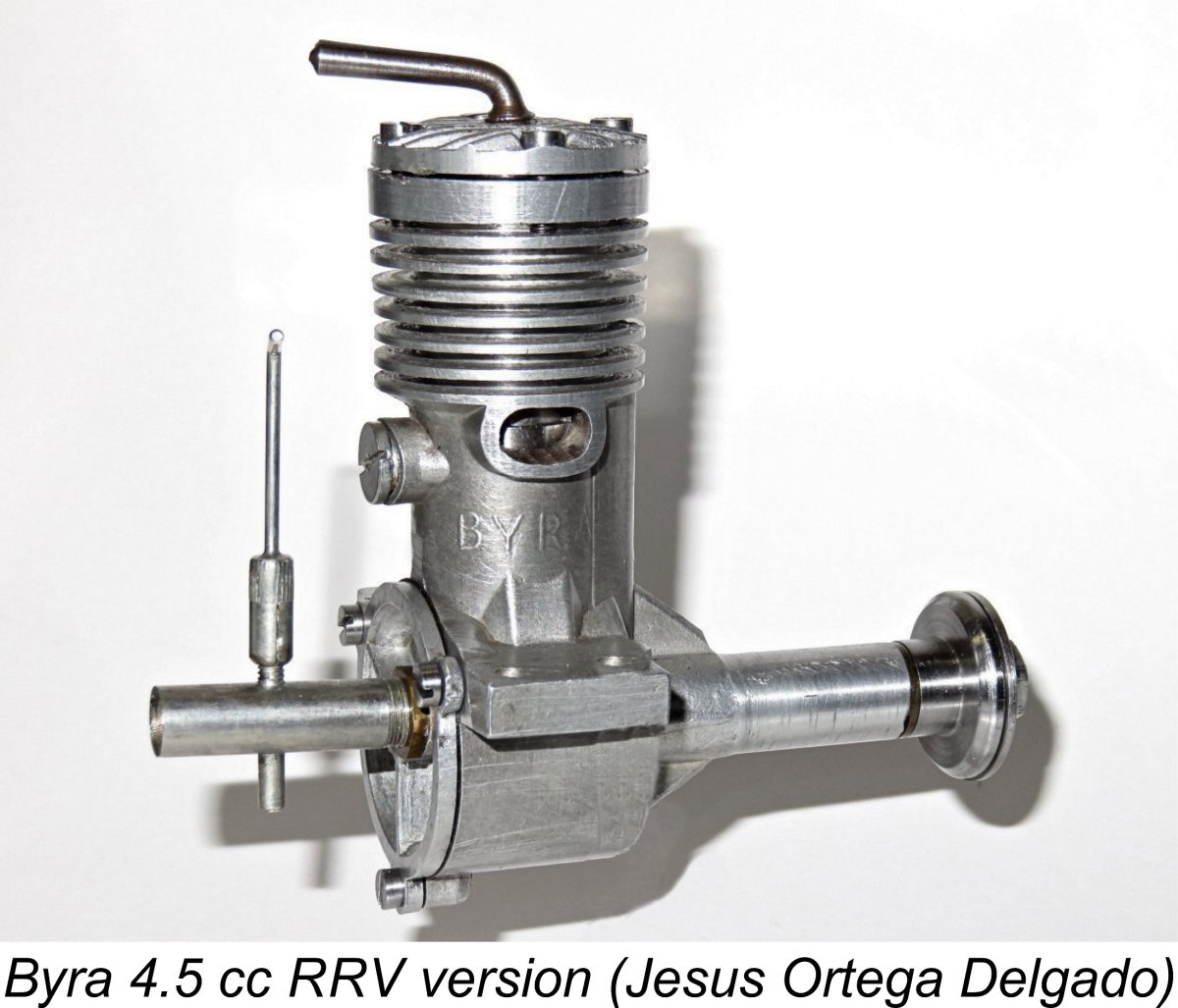

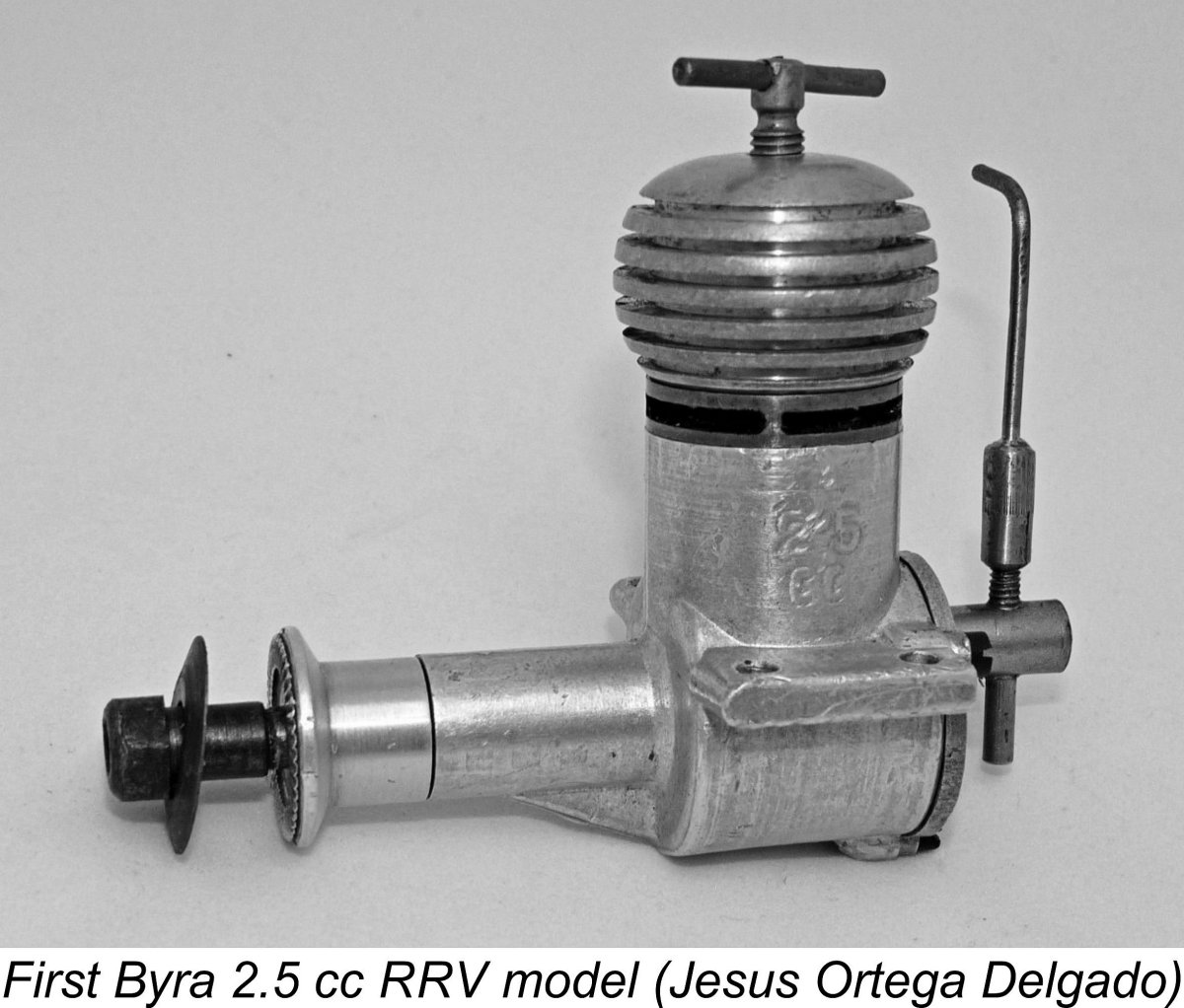

At this stage, Batlló was focusing upon a 4.5 cc sideport diesel model. This long-stroke unit had bore and stroke dimensions of 17.0 mm (0.669 in.) and 20.0 mm (0.787 in.) respectively for an actual displacement of 4.54 cc (.277 cuin.). The un-counterbalanced crankshaft ran directly in the material of the front housing, no bushing being fitted. The attached image at the right provided by Jesus Ortega Delgado shows this engine in its original form before it entered series production.

The first Byra design to be offered commercially was a considerably revised version of the previously-discussed 4.5 cc plain bearing sideport diesel. A comparison between the image at the left and the previous photo will clarify a number of the differences between the pre-production and commercially-manufactured variants of this engine.

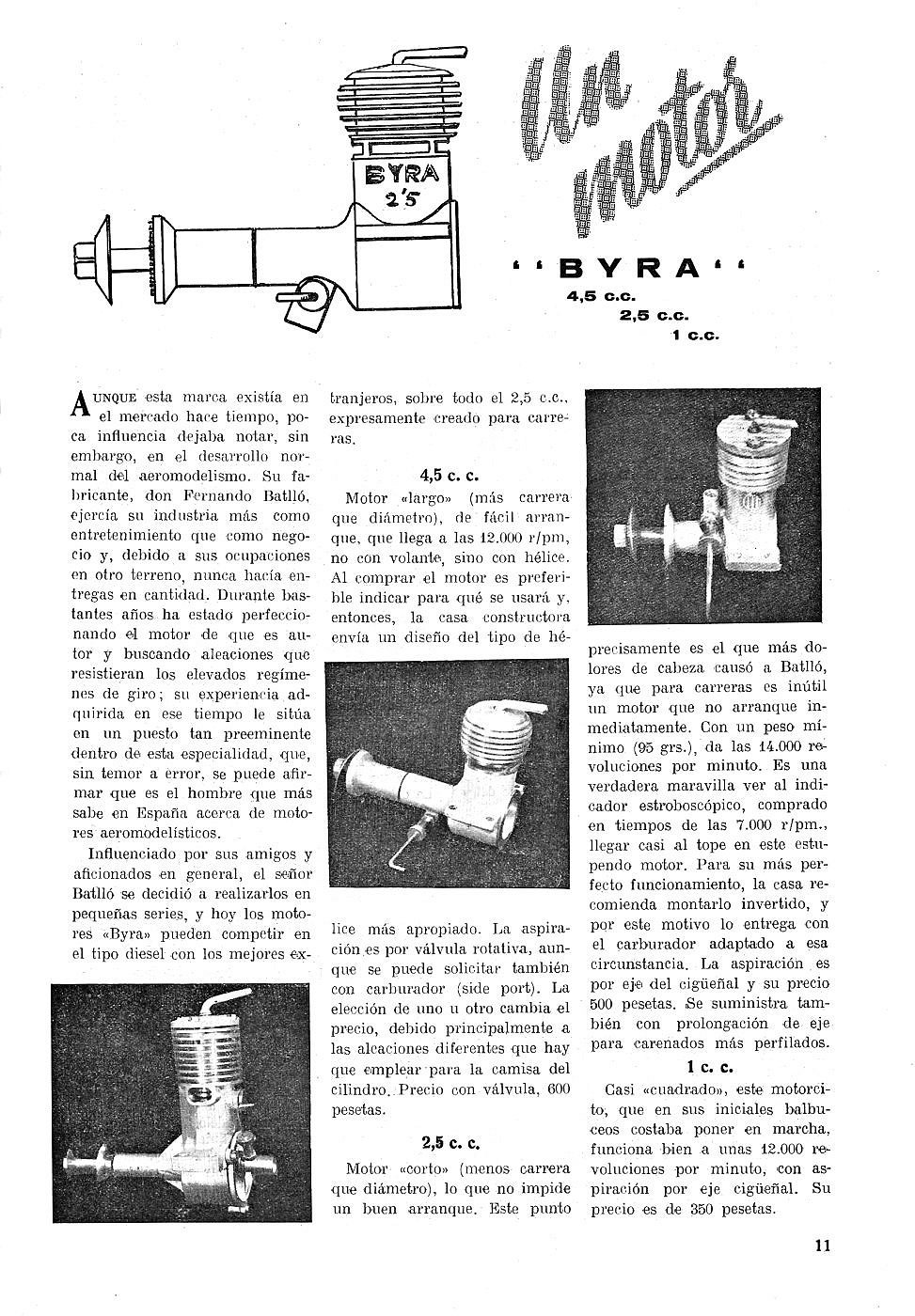

A few comments on this engine were published in the March 1952 issue of the short-lived Spanish modelling magazine “El Aeromodelista”, which was only published for about a year beginning in 1951. This article is reproduced here below at the left for those interested - my sincere thanks to Jesus Ortega Delgado for providing this scan.

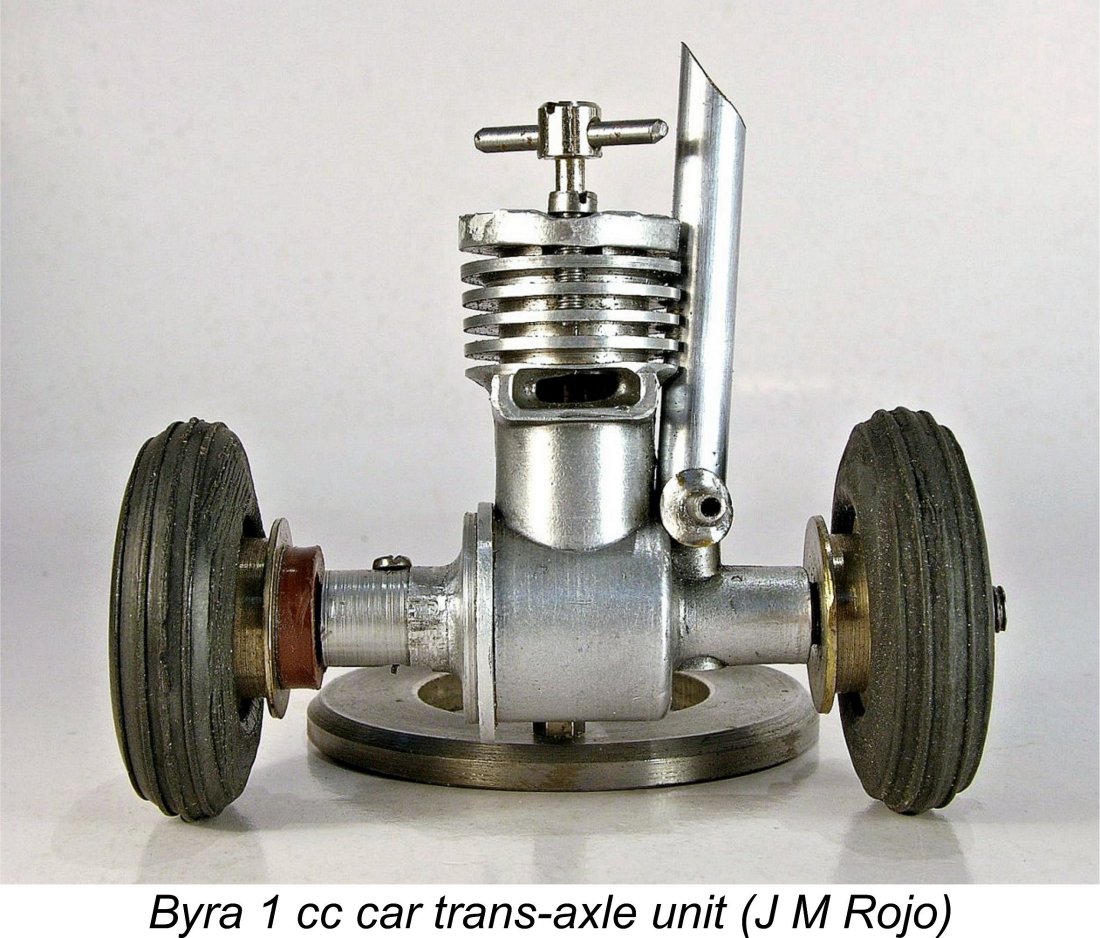

Interestingly, the 4.5 cc model continued to be offered as a sideport unit alongside the flagship RRV model. The sideport version was presumably considered to be better suited to certain applications than its rotary valve companion. The writer of the article commented that when ordering from the manufacturer, a purchaser should specify the use to which the engine would be put, as he would then be supplied with the most appropriate version together with a suitable propeller. The writer also noted that the RRV version could operate at speeds of up to 12,000 rpm when fitted with a suitable airscrew. The price of the RRV version was given as 600 pesetas - a relatively high price by early 1950's standards in Spain. Information posted on the J. M. Rojo website indicates that a car version of this engine was also offered - presumably the sideport version. This was designed for direct drive, with the wheels rotating at crankshaft speed, thus also acting as flywheels. One wheel was mounted on the end of the main crankshaft in the prop location, while the other was mounted on an extended shaft which was supported in what amounted to a duplicate main bearing housing which replaced the backplate of the aero version to complete the "trans-axle". This second wheel was driven by the crankpin, making this a true live axle. Reader Steve Betney wrote in to inform me that in around 1948 Batlló actually imported a number of Cox Champion car components to be used on an OEM basis in the creation of a Byra car using the 4.5 cc engine. It's not known how many such cars were completed, but some definitely were - Steve has an example which he was in the process of restoring as of late 2022. The Range Expands – the First 2.5 cc Model

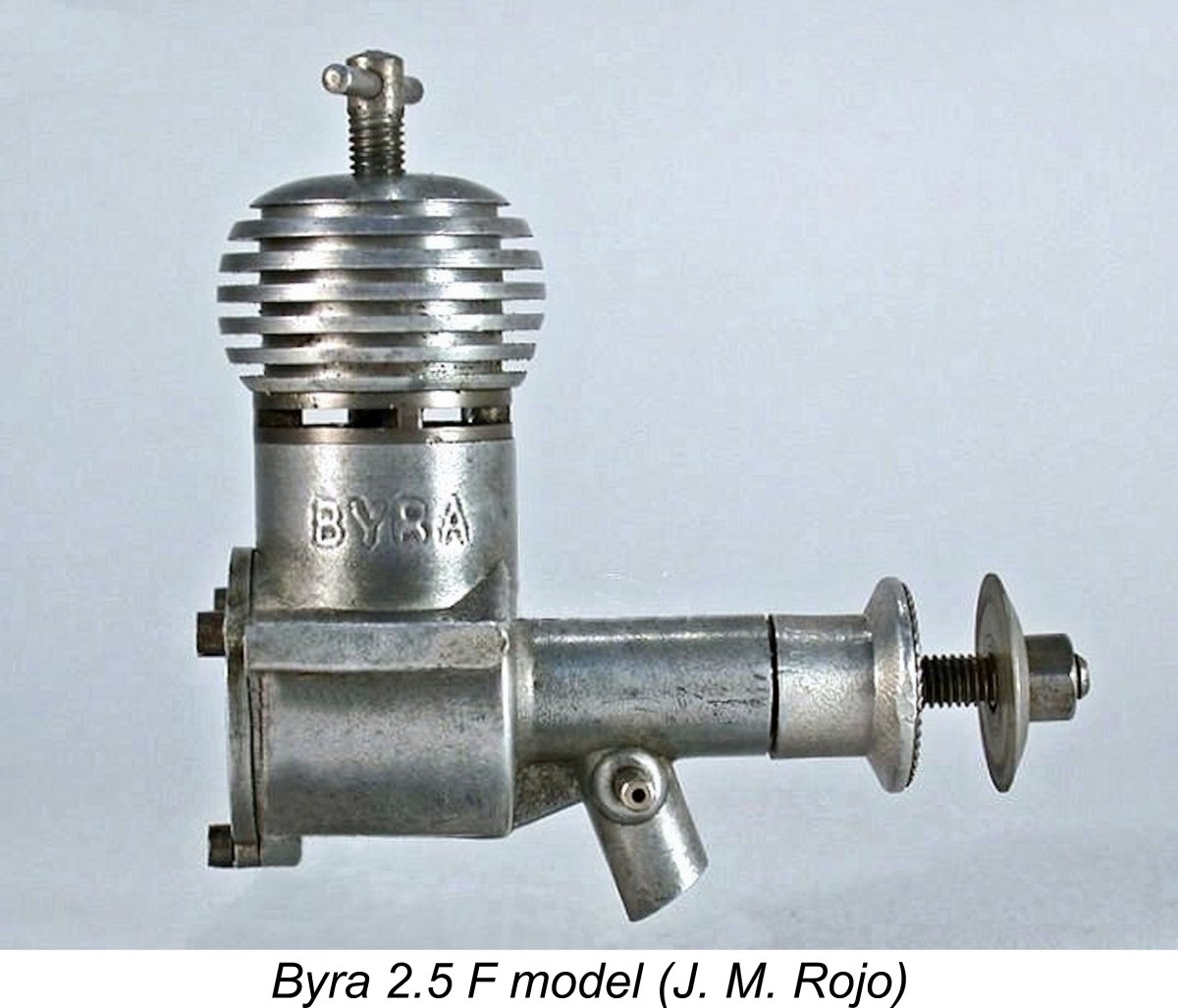

The latter designation reflects the fact that the engine was originally produced in quantity at the behest of the Frente de Juventudes (Youth Front), an organization which had been established in 1940 to oversee the training and political indoctrination of Spanish youth. The organization evidently required a supply of engines to meet the needs of their aeromodelling wing, from which it was hoped that military fliers and aircraft designers might emerge. They turned to Don Fernando Batlló to meet this need. By late 1951 Batlló’s first 2.5 cc design had achieved production status. It was a very simple plain bearing 2.5 cc diesel engine featuring crankshaft front rotary valve (FRV) induction allied to an updraft intake and radial cylinder porting. The transfer ports were formed as substatial channels cut into the interior of the lower cylinder wall. Bore and stroke were 15 mm and 14 mm respectively for a displacement of 2.47 cc (0.151 cuin.). The main bearing was un-bushed.

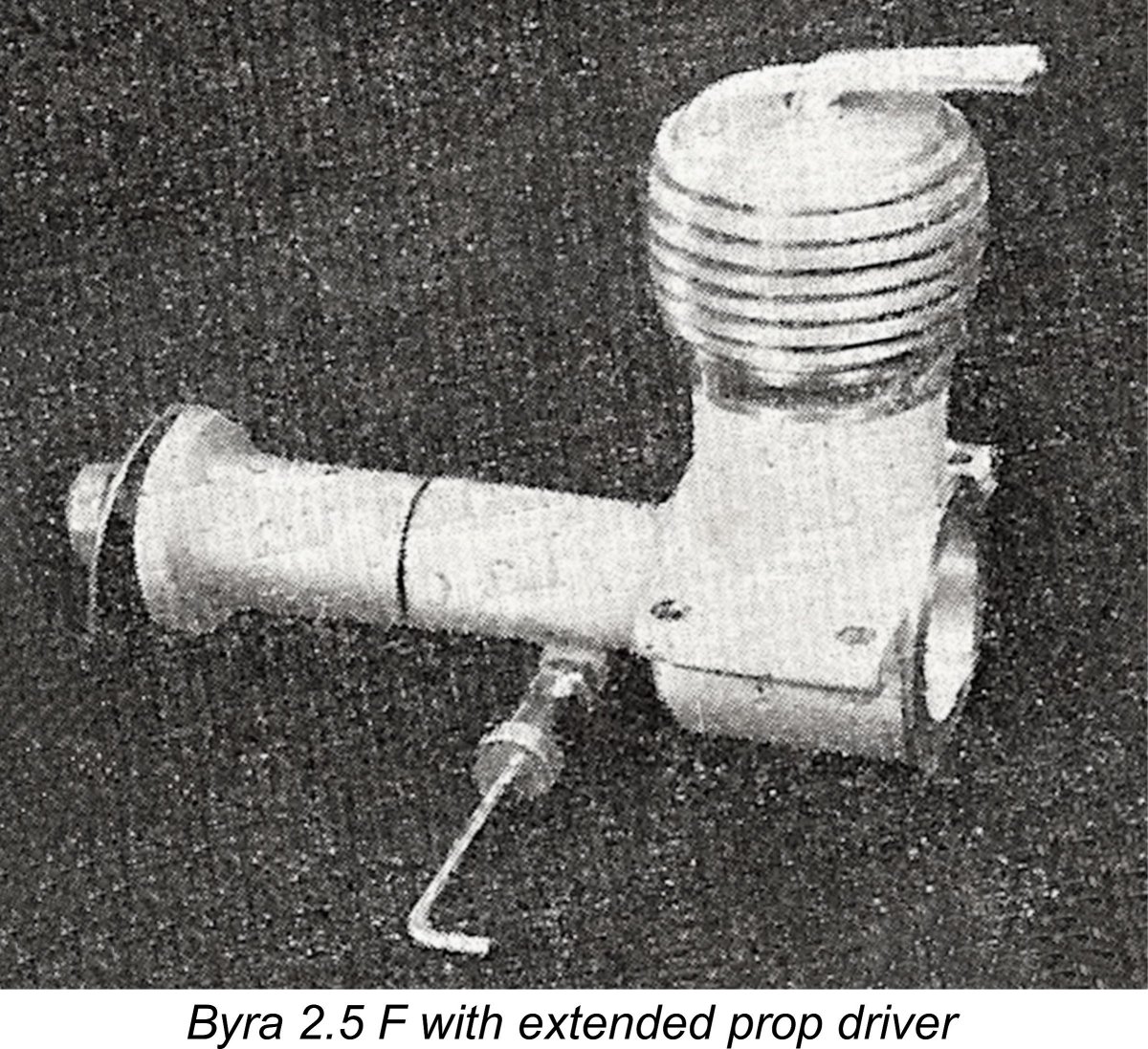

The designer clearly envisioned the motor being mounted in an inverted configuration for the most part, as it would be in a typical team racer or scale model. Probably for this reason, the intake was positioned beneath the main bearing housing, conveniently locating it on top when the engine was inverted. An optional extended prop driver was available, representing another concession to convenient cowling of the motor, again as in a typical team racer or scale model. The attached image at the left extracted from the March 1952 “El Aeromodelista” article shows this accessory clearly.

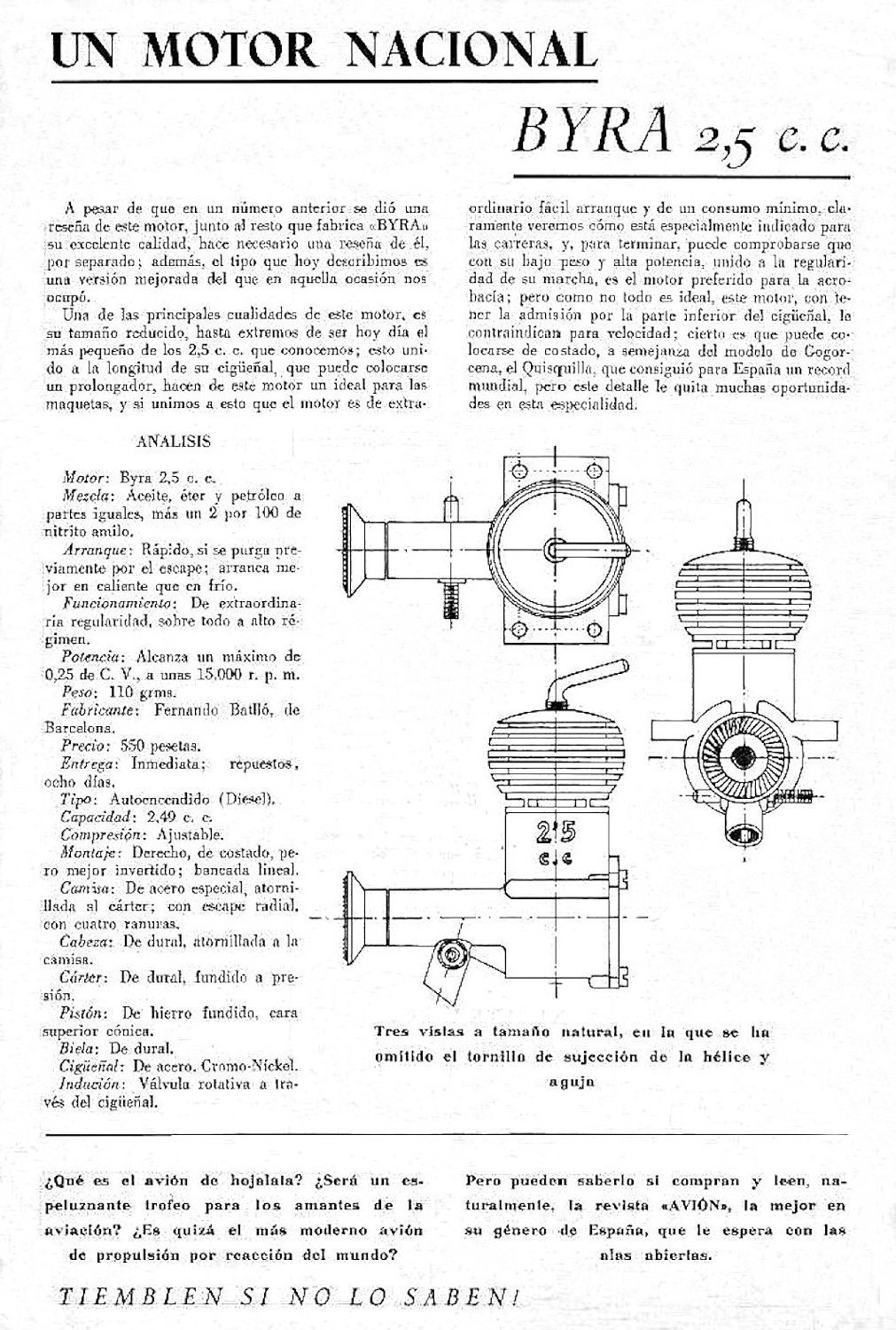

A further article on this model appeared later in the October 1952 issue of the same publication. The writer stated that the general excellence of the engine warranted a separate stand-alone review, besides which a number of improvements had reportedly been incorporated since the publication of the original article.

Some more technical details were included with this article. Recommended fuel was apparently a blend of equal parts of kerosene, ether and castor oil, plus an additional 2% amyl nitrite. Using this brew, the engine was said to develop around 0.25 BHP @ 15,000 rpm. Speaking personally, this claim appears to me to be a bit on the optimistic side, but I could be wrong ………... It appears that Batlló himself may have put the engine to good use in both stunt and team race contexts, since it is in 1952 that we find the first mention of his name in the results of an International competition. He was an entrant at the 1952 European Control Line Championships held at Brussels, Belgium, finishing 10th in the stunt competition and a very creditable 2nd in team racing. Although there is no record of the powerplants used, I would be truly astonished if I were to learn that he used anything other than his own engines at this competition! Further Expansion – the 1 cc Diesel

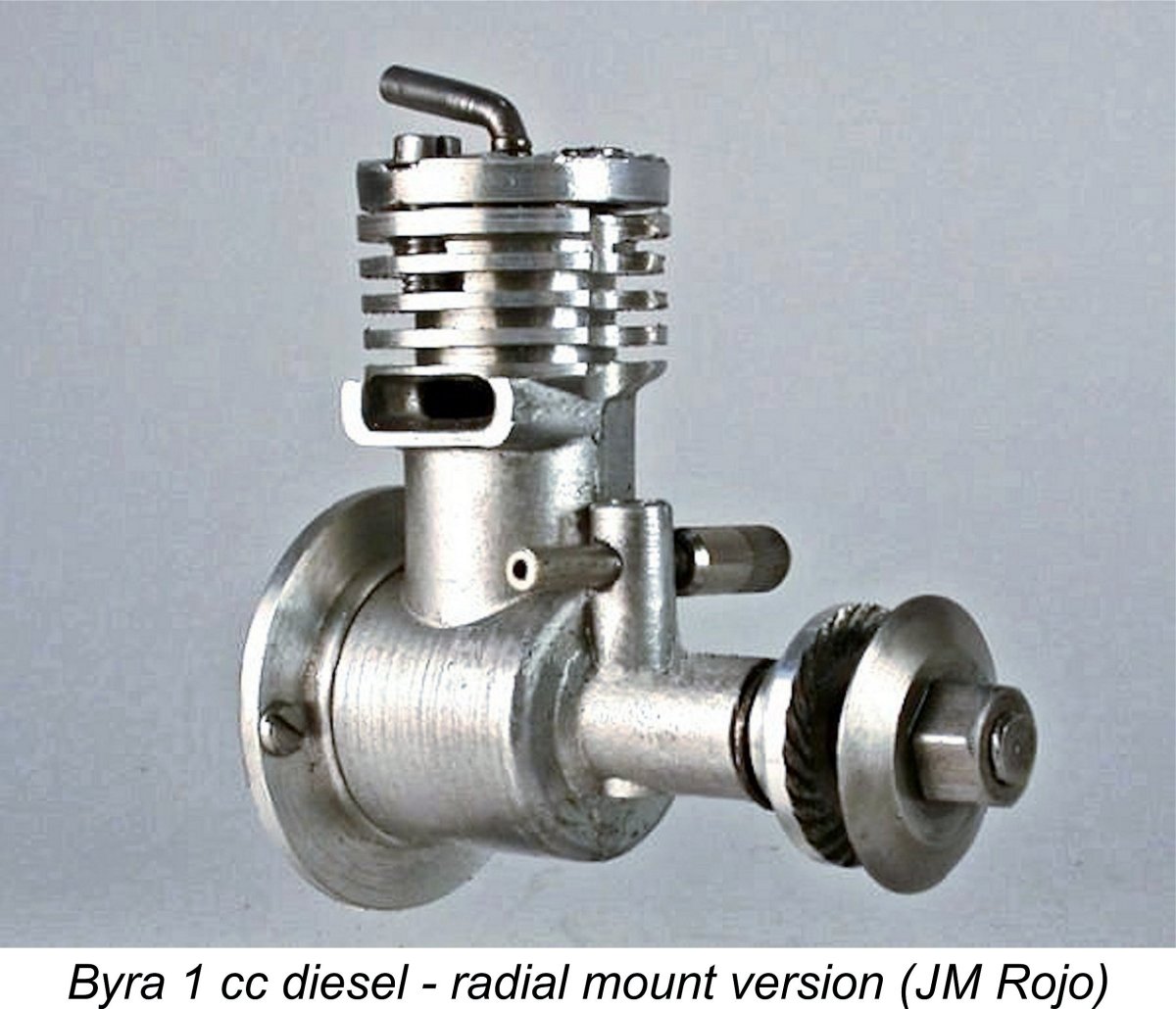

This characteristically compact little motor was introduced in beam mount form, as shown in the attached rather fuzzy image extracted from the March 1952 article. However, a number of radial mount prototypes were also produced, although these apparently never achieved full series production before the 1 cc model was unaccountably dropped quite early on. The engine differed from the larger 2.5 cc model in using cross-flow loop scavenging as opposed to radial cylinder porting. According to the writer of the “El Aeromodelista” article, this engine was initially found to be rather difficult to start, necessitating some further development work on Batlló’s part. This seems to have delayed its market appearance until early 1952, when it became available in rather limited quantities at a price of 350 pesetas.

Both versions featured cross-flow loop scavenging, albeit without a piston baffle. The cylinder porting was actually rather like that of the original Mk. I Series 1 E.D. Bee turned through 90 degrees. The two upwardly-angled transfer ports were fed by modestly-dimensioned bypass passages formed in the crankcase interior wall on the transfer side. The main departures from the E.D. arrangement were the use of a single exhaust port in place of the E.D.’s two apertures and the Byra’s use of crankshaft front rotary valve (FRV) induction through an intake venturi of very modest size.

For reasons which remain unclear, the 1 cc Byra diesel was evidently only offered for a relatively short time. This is more than a little odd, because as far as I can tell there were no other competing domestically-produced 1 cc diesels in Spain at the time. Moreover, the 1 cc displacement category was extremely popular among beginners and sport-fliers elsewhere, so why not in Spain?!? I hoped that a full test might reveal the answer ............. read on!! Regardless of the reason, the very short production life of this engine has had the result of making it almost certainly the rarest Byra model apart perhaps from the original "hobby production" 4.5 cc model. Good examples are very seldom encountered today. A Rare Treat - the Byra 1 cc Diesel on Test

The example of the Byra 1 cc radial-mount model that was available for testing had been fully restored to Peter's usual impeccable standard. Honestly, if no-one told you, you'd swear that it was a LN example! The one thing that Peter did change (with my complete approval) was the operating direction. The engine needed a new crankshaft, but the original was timed for "reverse" operation - possibly a reflection of this variant's intended car application mentioned earlier. The new shaft was timed for operation in the "normal" direction using an airscrew - far more convenient for testing. The port timing was unaltered, however. Peter went even further, displaying yet another facet of his amazing talent by producing an exact replica of an original box, including appropriate aging. Again, if you weren't told, you'd undoubtedly take this for an original 65-year old box! What a craftsman!! Since the restored engine had done very little running since its assembly by Peter, I reckoned that a bit of a break-in was required just to ensure that Peter's fine work wasn't compromised. So I set the engine up in the test stand with an 8x4 APC prop fitted and got stuck in.

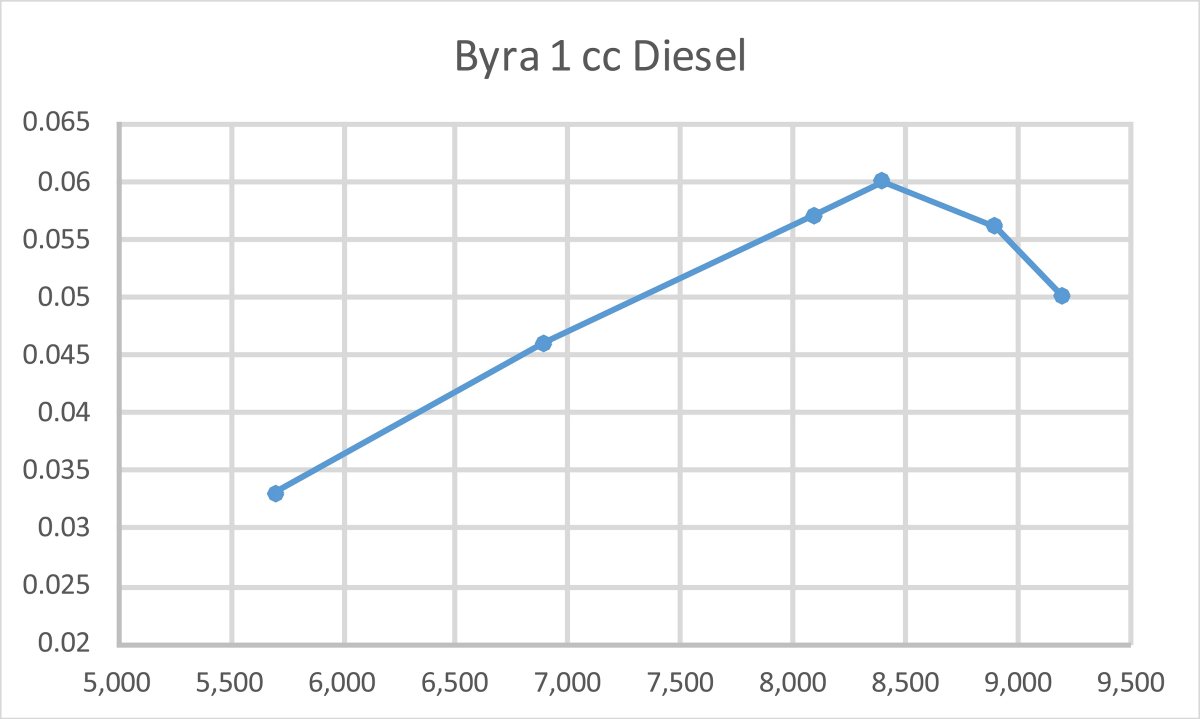

I gave the engine a series of 5-minute slightly rich runs with compression reduced a little. As usual, I leaned out to maximum speeed for the final 30 seconds of each run and then allowed the engine to cool completely prior to a restart. This put the piston through the series of full-range heat cycles which are an essential feature of the break-in process for a lapped iron-and-steel model engine. At the end of this period, the engine felt superb, clearly all ready for testing. I then tried a series of calibrated test props, going for maximum speed on each prop and continuing to allow complete cooling between runs to increase the number of heat cycles. The engine delivered a very solid performance - although by no means remarkable for output, it performed at a very acceptable "sports" standard for its 1952 date of introduction. The following data were obtained.

The above figures suggest a peak output of around 0.061 BHP @ 8,500 rpm - figures very comparable with those reported for the contemporary (and very popular) 1 cc E.D. Bee Mk. I Series 1. Viewed in this light, the little Byra seems to have been a completely acceptable sports performer by the standards of its day. This increases one's puzzlement at its failure to remain in production for any length of time - Spanish modellers certainly had no superior home-grown engine of this displacement at their disposal. The little Byra came though its fairly lengthy running sesion with flying colours. No mechanical difficulties were experienced at any time. I thoroughly enjoyed conducting this test of one of the rarest model diesels that it has yet been my pleasure and privilege to experience! Having enjoyed sampling the very rare Byra 1 cc offering, it's time now to return to the more commonly-encountered members of the range. We'll continue our look at the 2.5 cc models offered by the company. Going for Improved Performance – the First Byra 2.5 cc Competition Models

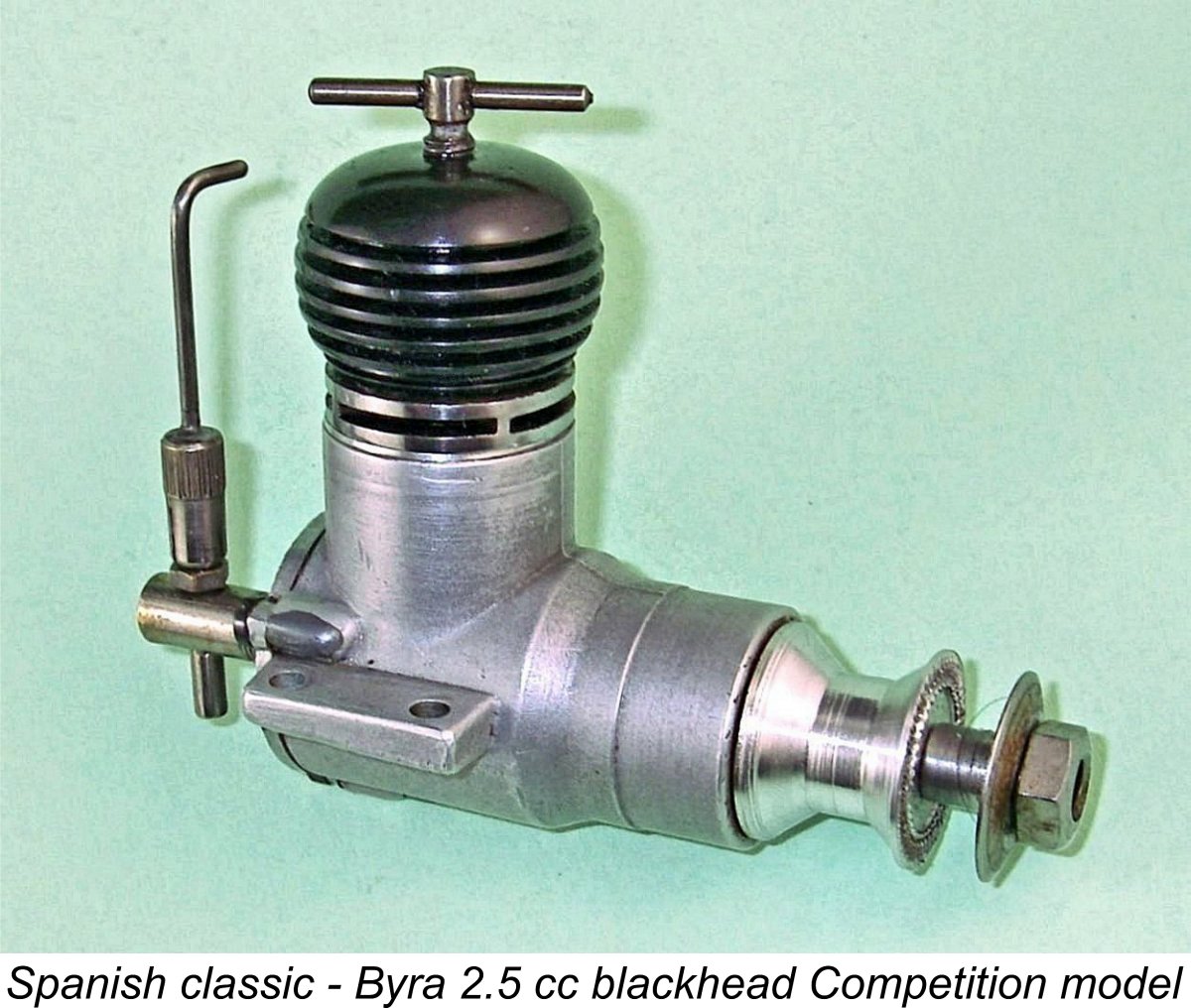

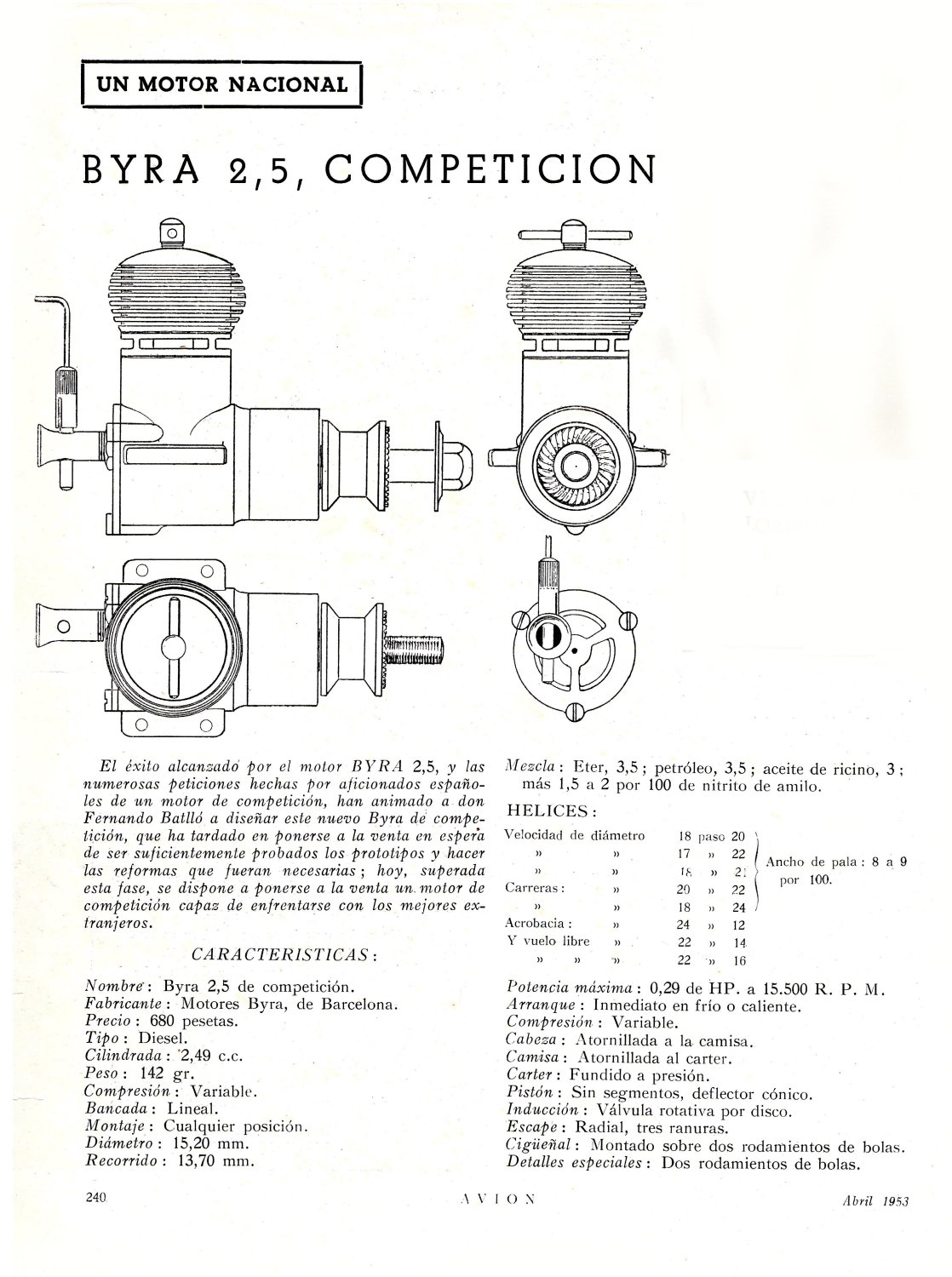

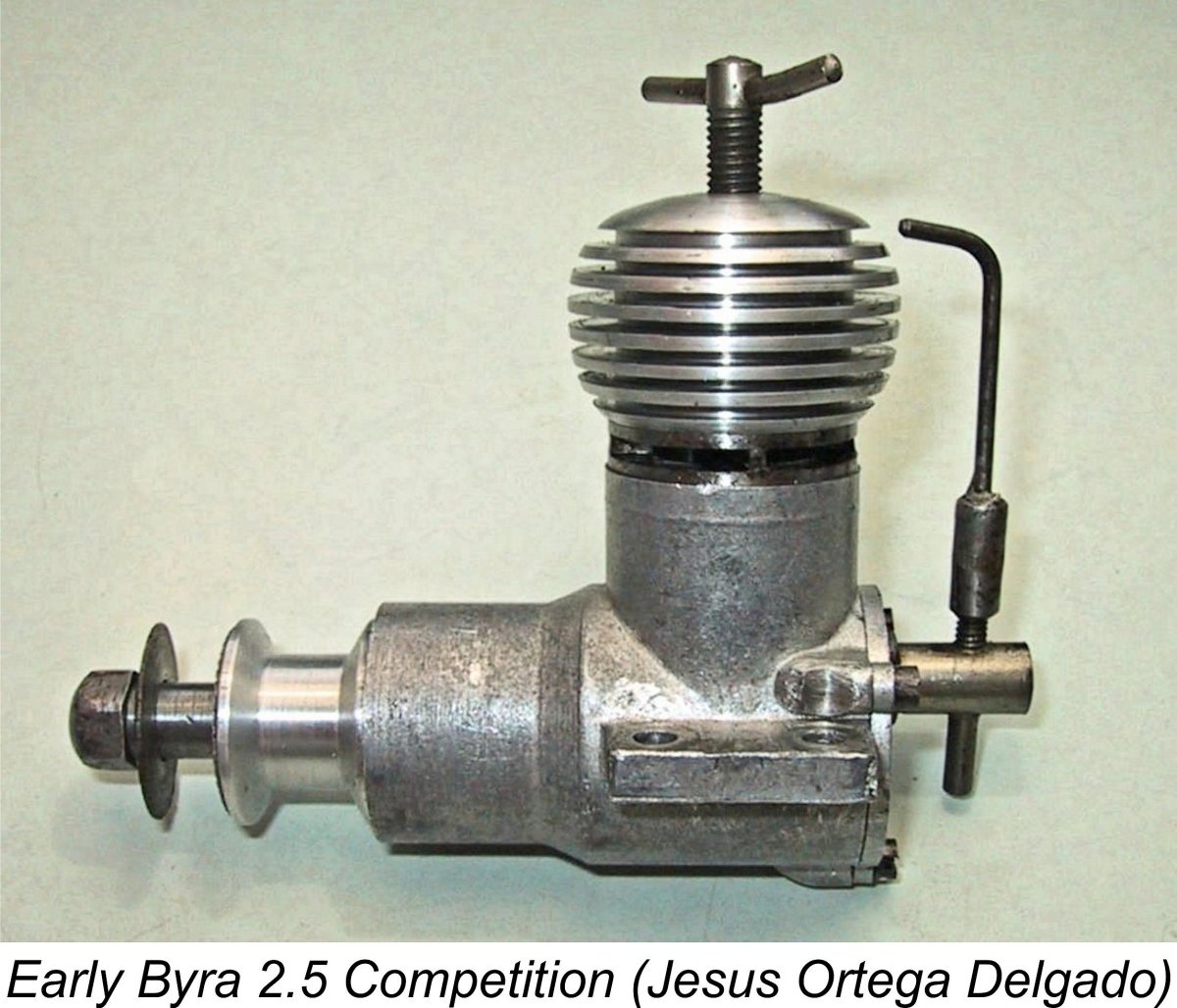

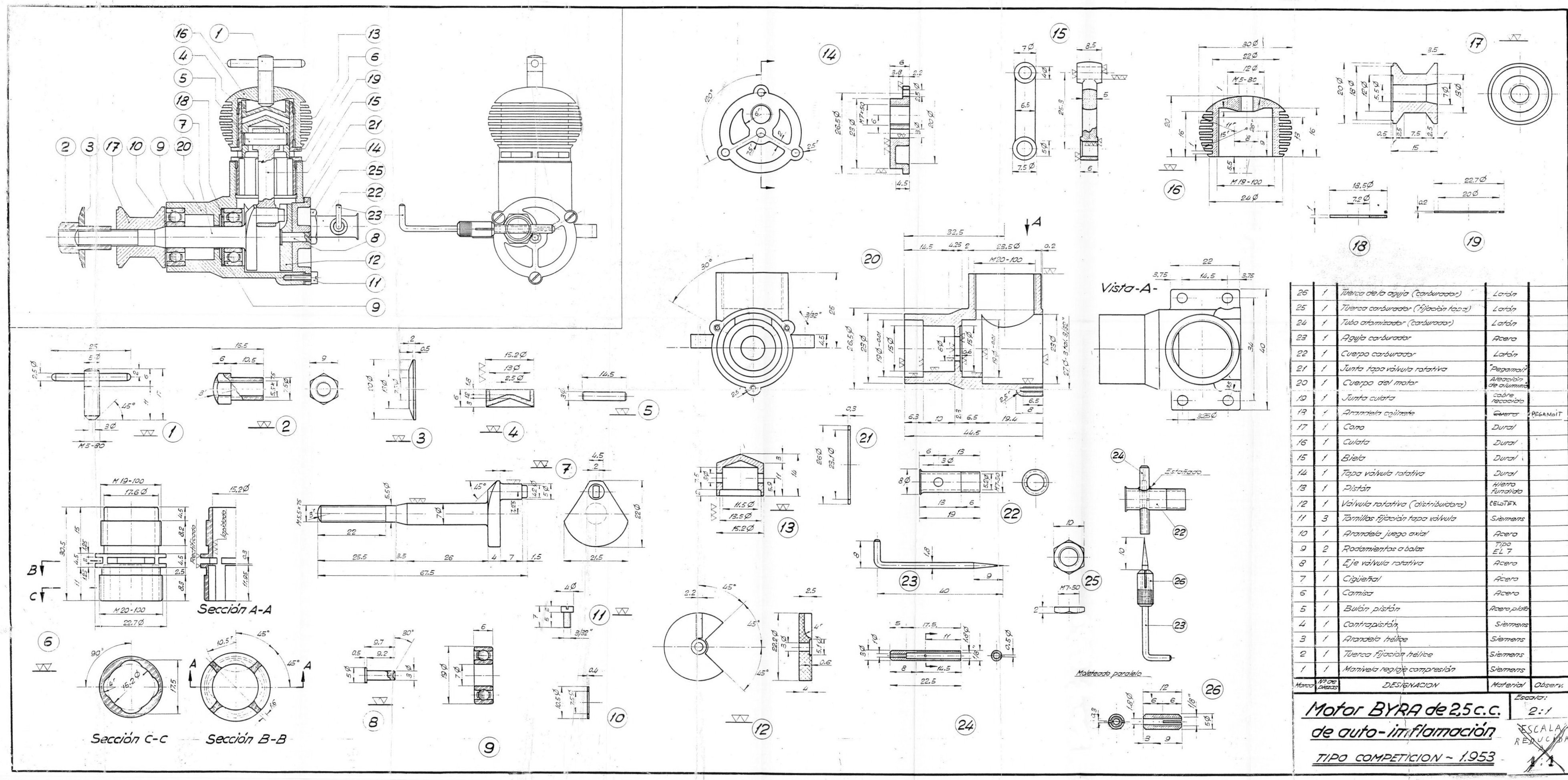

Batlló accepted this challenge with characteristic energy, getting to work immediately on the development of an improved version of his very well-received 2.5 cc model. By some point in the latter half of 1952, Batlló had developed a disc rear rotary valve (RRV) version of this engine, as illustrated at the right. This very rare model retained the plain bearing of the original 2.5 F design but dispensed with the updraft FRV induction system in favour of a revised backplate having provision for disc valve induction. This variant was most likely a very limited-production model which represented no more than an intermediate step in the development of the 2.5 cc Competition design to be discussed next. It may actually have been one of these engines which was By February 1953 the fully developed design was complete and entering production, being termed the Byra 2.5 Competition model. It was essentially a twin ball-race version of the previously-discussed RRV plain-bearing model. The release of this model prompted yet another article in the Spanish modelling media. The short-lived “El Aeromodelista” magazine had folded by this time and had been replaced by a new magazine, “AVION”. It was the latter magazine which published the new article in its April 1953 issue. The article is reproduced here at the left thanks once more to the kind cooperation of Jesus Ortega Delgado. The earliest examples of the new model were released with plain un-anodized cooling jackets, as depicted in the illustration below at the right. The engine’s published bore and stroke figures were revised to 15.20 mm (0.598 in.) and 13.70 mm (0.539 in.) respectively for a displacement of 2.49 cc (0.152 cuin.). This brings up one of the most puzzling anomalies surrounding the construction of this engine. These published bore and stroke figures differ from those which appear on the surviving official 1953 factory drawing which is reproduced here below at the left courtesy of Jesus Ortega Delgado. That drawing cited the bore and stroke figures as 15.20 mm (0.598 in.) and 14.25 mm (0.561 in.) for an actual displacement of 2.59 cc (0.158 cuin.)! These figures are confirmed by measurements recorded independently by Ron Warring during the course of his December 1955 “Aeromodeller” test of the engine (see below).

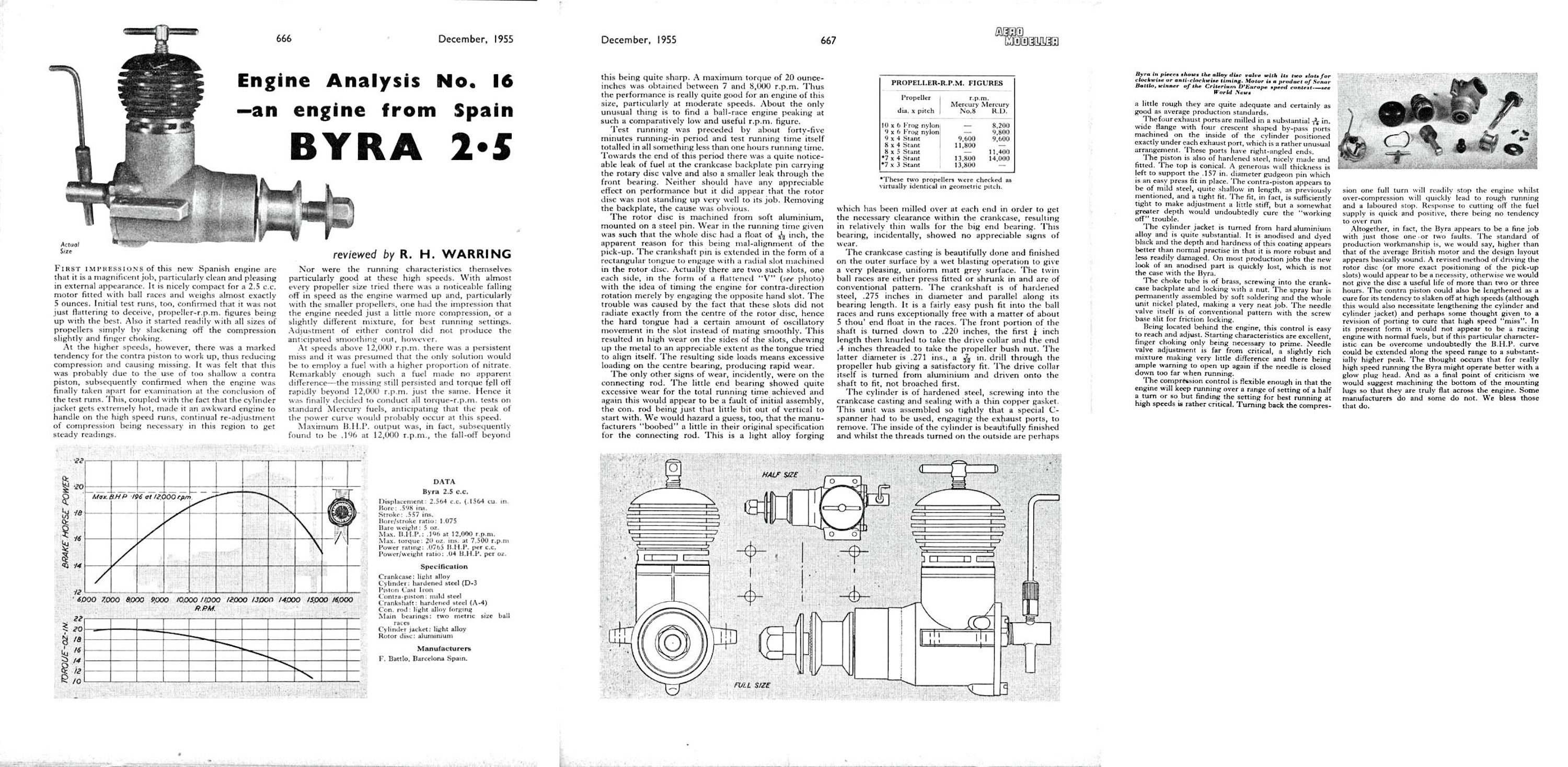

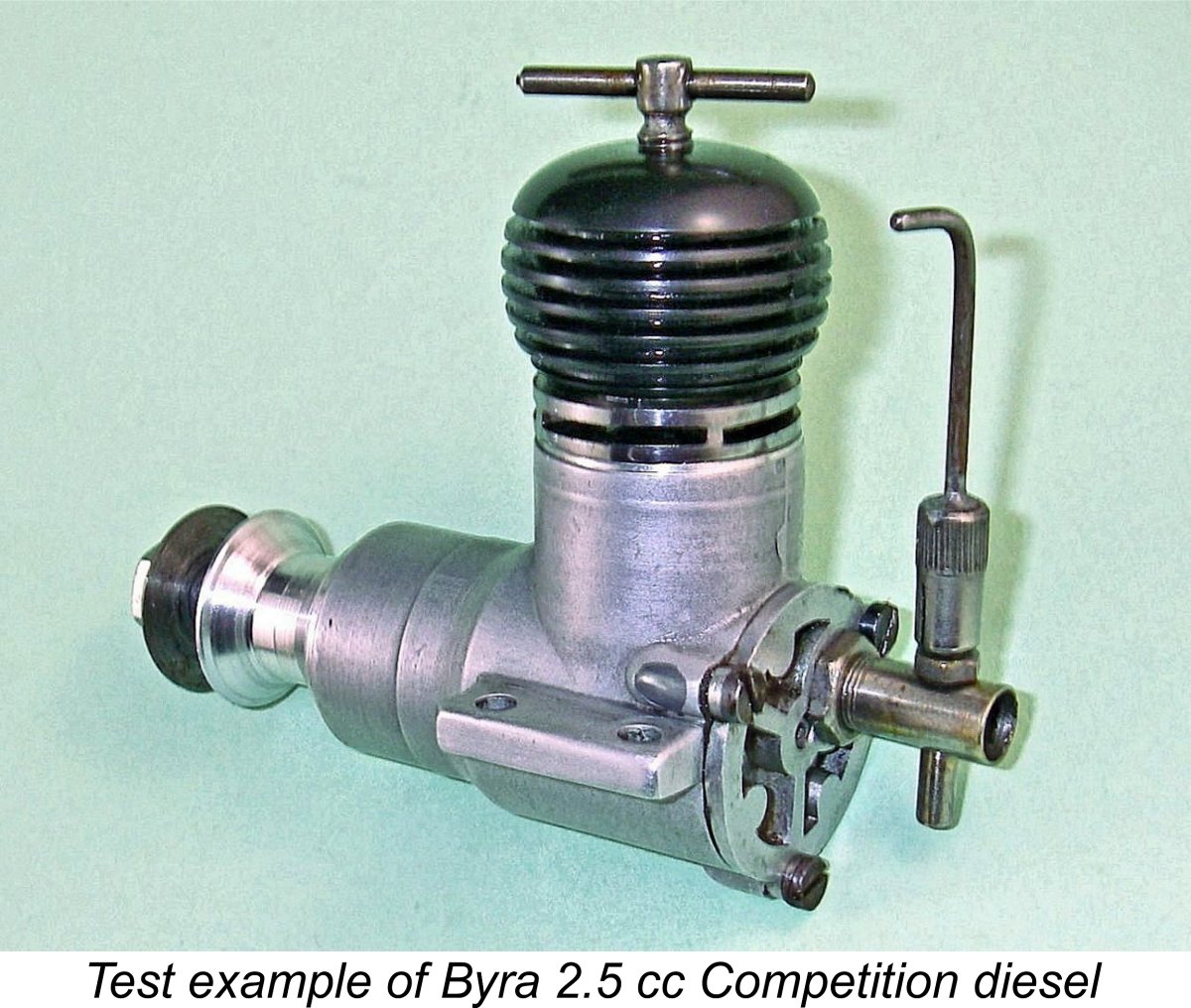

The effect of these dimensions was that the Byra 2.5 cc “Competition” model was actually over the 2.5 cc displacement limit for FAI competition. It’s really difficult to rationalize this aspect of the design, especially given the engine’s intended use in the highly Internationalized field of team racing where a protest might readily be anticipated regarding the engine's displacement once the word got out. Cylinder porting was essentially unchanged from that of the earlier model. The same screw-on cylinder head was An interesting feature of the disc valve design was the fact that it could be assembled to time the induction for running in either direction. Evidently some Spanish modellers continued to favour reverse rotation. The backplate could be assembled in any one of three orientations spaced 120 degrees apart. The disc valve was provided with two different points of engagement with the crankpin, and all that one had to do was engage the disc appropriately and rotate the backplate to provide the correct timing before tightening it down. Shades of the earlier Atsuta 19 design from Japan, although I’m sure that this was a case of independent parallel development. On a less positive note, the disc itself was made of aluminium alloy. By the early 1950’s it had already become readily apparent that this was a quite unsuitable material for this hard-worked component – a steel or non-metallic disc had been found to be far more durable in service. It’s more than a little surprising that a designer of Fernando Batlló’s undoubted calibre would have failed to address this issue. The fuel recommendation had changed slightly, now consisting of a blend of 3.5 parts of ether, 3.5 parts of kerosene, 3 parts of castor oil and 1½ to 2 percent amyl nitrite. In other words, the recommended oil content had been reduced a little. Using this blend, the engine was claimed to develop 0.29 BHP @ 15,500 rpm – a considerable increase over the claim made earlier for the original plain bearing version. The writer of the “AVION” article commented on the thoroughness of the testing program which the engine had undergone, stating that it was now developed to the point at which it could compete with the best of the foreign powerplants. Starting was said to be immediate, hot or cold. But just how legitimate were these claims?!? Let's find out!! The Byra 2.5 cc Blackhead Competition Model on Test With the arrival of the model just described, we’ve finally come to the point at which commentators outside Spain had begun to take notice of the Byra range. This interest prompted the appearance of the previously-mentioned test of the Byra 2.5 cc ball-race "Blackhead" model in the December 1955 issue of the English “Aeromodeller” magazine. The tester was Ron Warring.

Warring’s test report was a rather strange mixture of positive and negative comments. He began his report by categorizing the Byra as “a magnificent job, particularly clean and pleasing in external appearance”. He went on to praise the engine’s compact size, modest weight (for a twin ball-race unit), ease of starting and general performance. So far, so good! However, Warring then turned to a few features which he found less than praiseworthy. Chief among these was the aluminium alloy disc valve, which was found to have become significantly worn during the test. As of 1953 the inadequacy of aluminium alloy for this component had long been well established, leading one to wonder why Batlló didn’t select a more durable material. When my good mate Peter Valicek was restoring my own test example of this model, I had him install an identically-timed disc made of Tufnol, which is a far superior material for this service. Warring also noted that the conrod small end had developed a significant amount of wear during the course of the test, although he put this down to a slight misalignment of the rod. The final point of criticism was the fact that the compression setting tended to run back at higher speeds, evidently due to the use of an unusually short contra-piston to keep the engine's height down. The use of a locking lever would of course cure this issue. Otherwise, Warring commented that starting was excellent at all times with just finger-choking. The needle valve was relatively non-critical, but the compression setting was rather more sensitive. In that context, Warring noted a tendency towards a misfire at speeds above 12,000 rpm which could not be cured either through careful adjustment of the controls or with an increase in the ignition improver content of the fuel. This actually sounds to me like a symptom of the test engine’s worn and hence leaky disc valve, something which Warring seemingly failed to consider.

Warring ended up summarizing the Byra as “a fine job with just one or two faults”. He actually included the statement that “the standard of production workmanship is, we would say, higher than that of the average British motor”. A high compliment to the efforts of Señor Ramirez! Oddly enough, Warring stopped short of commenting on the not inconsequential fact that the motor's displacement was above the FAI competition limit of 2.50 cc. In his basic data table, he reported taking bore and stroke measurements from his example of 0.598 in. (15.20 mm) and 0.557 in. (14.15 mm) respectively for a correctly-cited displacement of 2.568 cc (0.157 cuin.). While the stroke is fractionally shorter than that specified on the previously-reproduced factory drawing, Warring's figures are a very close reflection of those appearing on the drawing. However, he did not comment on this issue in the text of his report despite its potential significance in competition terms. Having a superbly-restored example of this engine on hand thanks to the sterling efforts of my good mate Peter Valicek, I was in a position to second-guess Warring’s assessment on the basis of my own observations. I was particularly interested in the results of such a test given the fact that the non-metallic disc valve on my example was flawlessly fitted and was not subject to rapid wear or leakage, thus eliminating a likely basis for some of Warring’s operational comments. Well done, Peter!! Among other things, Peter had rebored this example. It thus required a full break-in prior to any meaningful test figures being obtained. Peter had warned me that it was set up quite tight and would take some freeing-up. Indeed, this proved to be the case - the engine exhibited the classic "Continental squeak" in full measure! Anticipating a lengthy break-in, I began with an APC 9x6 prop and a break-in fuel containing 30% castor oil.

Response to both controls was excellent, making the desired settings very easy to establish. Once set, both controls held their settings firmly at all times. Suction fuel draw appeared to be first class. I put 30 minutes on the engine in 5-minute runs using a slightly reduced compression setting and a somewhat rich needle. However, in keeping with the procedures summarized in my article on ferrous piston/cylinder diesel break-in, I leaned the engine out and adjusted the compression for full speed over the final 30 seconds or so before stopping it by pinching off the fuel line. I then allowed complete cooling prior to any attempt to re-start. This approach is essential in order to subject the components to the full-range heat cycles which are required to accomplish an optimal fit and surface finish.

The engine maintained its good behaviour throughout, continuing to start very easily indeed on all props with only a few flicks. Response to the controls also continued to be all that one could ask. The non-critical needle response was particularly gratifying - going slightly rich from the sweet spot merely caused the engine to slow down a little while still running absolutely smoothly. Going a little lean introduced a slight "crackle" to the exhaust note while maintaining the engine's speed. This made the establishment of optimum settings very easy indeed - lean out to the "crackle" and then pull the needle out by a fraction of a turn to establish perfectly smooth running at peak speed. Such a non-critical needle would promote a very steady flight performance. The engine continued to free up during the course of this testing, although there was still some residual tightness at the conclusion of the session. Running remained completely smooth and mis-free at all speeds tested. In particular, there was no trace of the misfire above 12,000 rpm which was reported by Ron Warring - my test engine ran absolutely flawlessly all the way up to 15,000 rpm with a notably clean exhaust residue when leaned out. This supports my previously-voiced theory that Warring's troubles were most likely down to disc valve leakage, a fault from which my test engine remained completely free thanks to Peter Valicek's efforts. The following data were recorded during the test. The two WB props are calibrated wide-blade units created by cutting down larger props to fill torque absorption gaps in my calibrated test series.

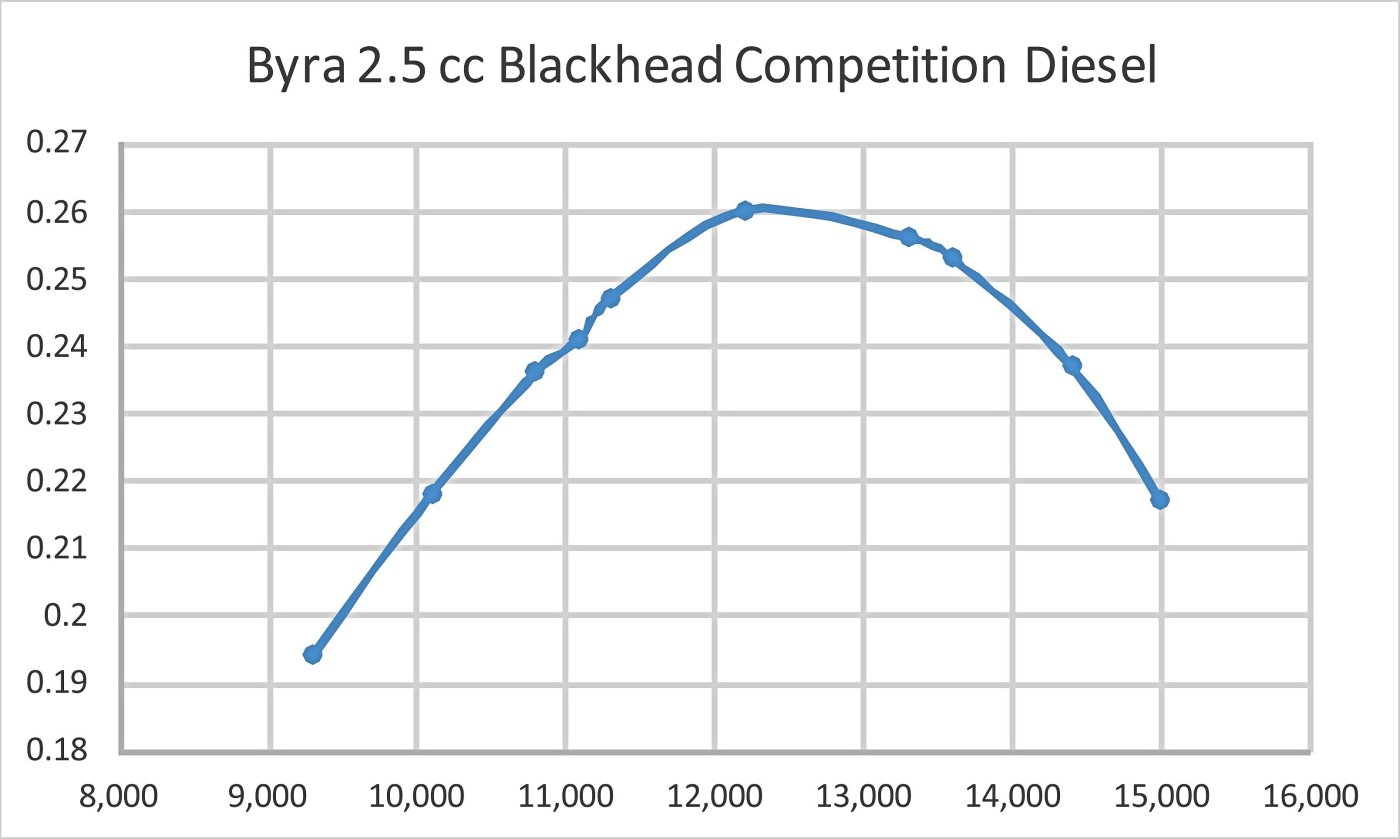

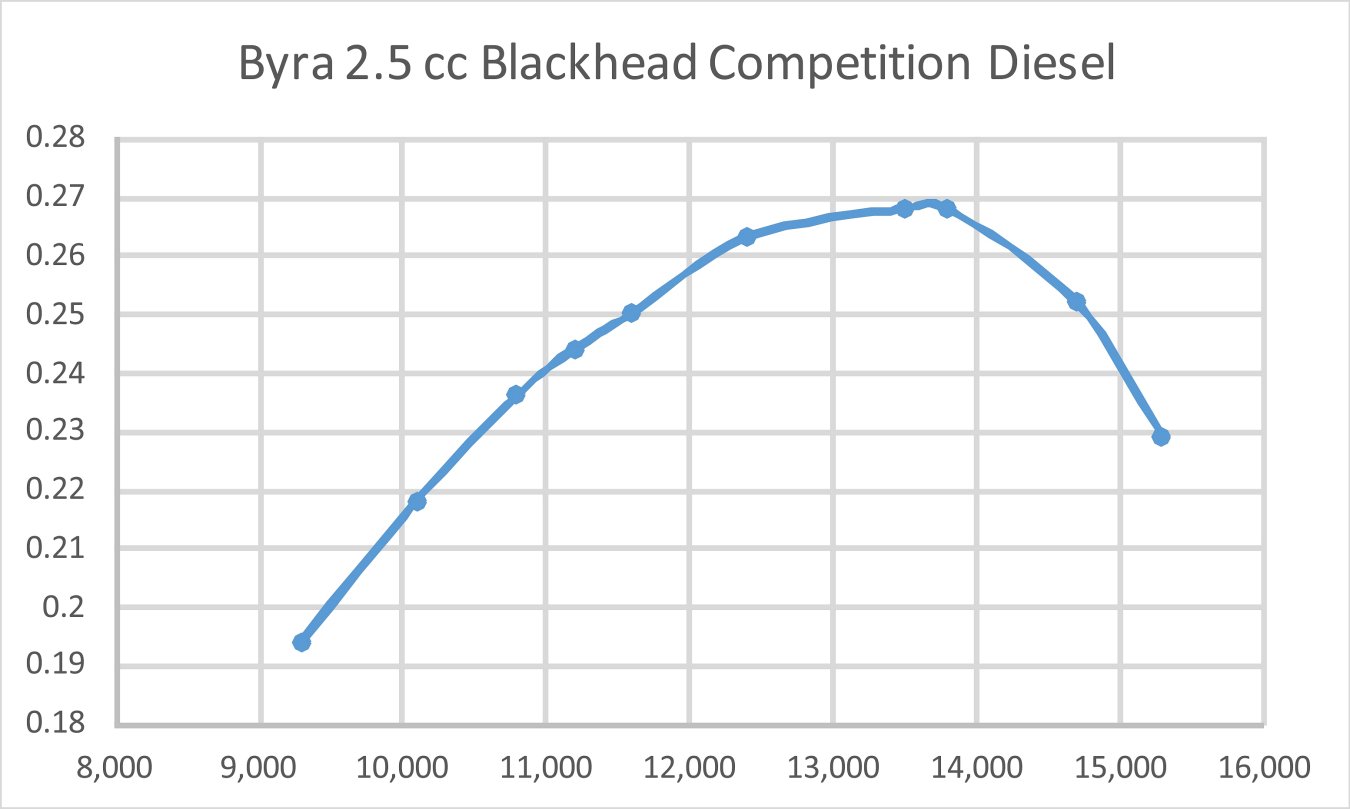

As can be seen from the above data, my test example of the Byra 2.5 cc Competition diesel outperformed Warring's test unit by a considerable margin. In particular, it developed considerably greater torque throughout the speed range, consequently achieving a peak output of around 0.262 BHP @ 12,600 rpm. Once again, I strongly suspect that Warring's leaky disc valve was the primary reason for the difference - such leakage would inevitably have a very adverse effect upon torque development. As stated earlier, my test engine remained a little on the tight side even after all its break-in and test runs. Based upon my long experience, I was pretty certain that once it was properly freed up it would easily develop around 0.270 BHP @ 13,000 rpm or perhaps even more. To test this theory, I bit the bullet and put on a further 40 minutes of fairly hard running in 5 minute runs using an 8x6 prop. By the end of this period, the engine was starting to feel really good, with little residual tightness. It was now turning the APC 8x6 prop at 11,200 rpm, thus showing a slight improvement over its previous performance. Encouraged by this, I repeated the complete test using the same set of calibrated airscrews. I was initially disappointed to find that speeds on the slower props were pretty much unchanged, but things improved considerably as speeds climbed. We'd actually expect this with a reduction in internal friction, which is bound to have a greater effect at the higher speeds. I also noticed that the engine now ran noticeably cooler than it had before - less friction means less heat generation. The revised performance data were recorded as follows:

As can be seen, the freed-up engine was typically some 200-300 rpm faster than before once speeds climbed above 11,000 rpm or thereabouts. It was now peaking at a figure of around 0.270 BHP @ 13,600 rpm. I thought it worthwhile to publish both sets of figures because they demonstrate very convincingly how much difference an optimized piston/cylinder fit can make. It really is worthwhile breaking-in an engine properly! Although still falling somewhat short of the manufacturer's previously-cited claim, the freed-up engine delivered an excellent performance for an early 1953 design, beating figures published up to 1953 for such iconic twin ball-race models as the E.D. 2.46 cc Mk. III Racer and the Webra Mach I. In fact, it's not all that far short of figures published in late 1952 for the Oliver Tiger Mk. II. By the standards of its release date, it was a very competitive powerplant. Pity about the displacement's incompatibility with FAI rules ....... A noteworthy feature of the power curve reproduced above is its relative flatness around the peak. The completely freed-up engine is developing 0.250 BHP or better at all speeds between 11,500 rpm and 14,800 rpm. The implied flexibility suggests that the motor will work very well in the air using a wider than usual range of prop sizes. An 8x6 would work well for control line, while a "fast" 9x4 would doubtless be a good choice for free flight work. All in all, the Byra 2.5 cc Competition model recommended itself to me as a first-class model powerplant in all respects. It came through its unusually lengthy break-in and testing sessions with absolutely no signs of mechanical distress or premature wear. To go along with its excellent handling and more than acceptable performance, it seems to be very sturdily constructed, the only apparent weakness being that pesky alloy disc valve. With that component replaced by a non-metallic disc, as in my test example, I think that this engine would outlast many of its owners! A Smaller Relative – the Byra 1.5 cc Model

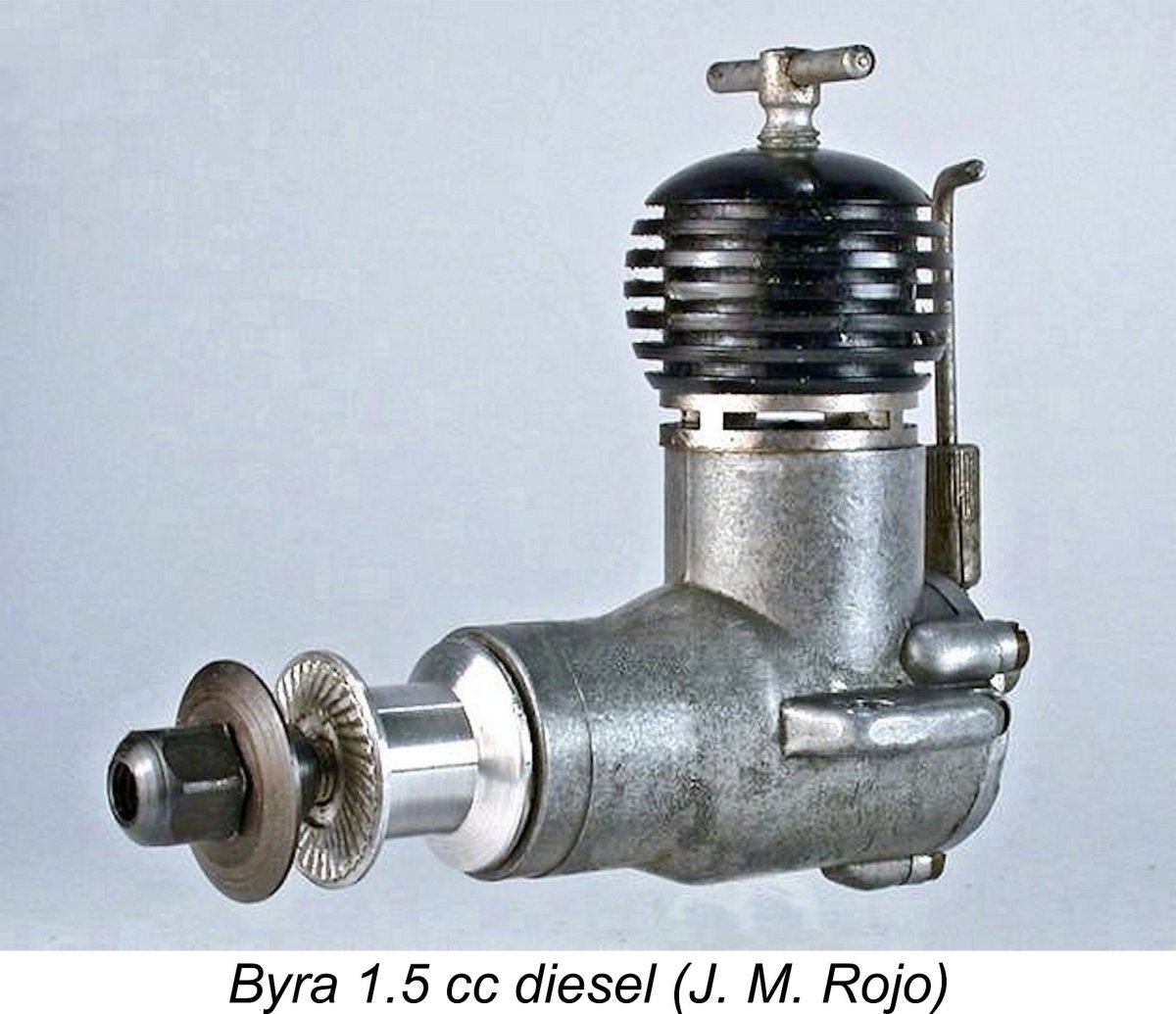

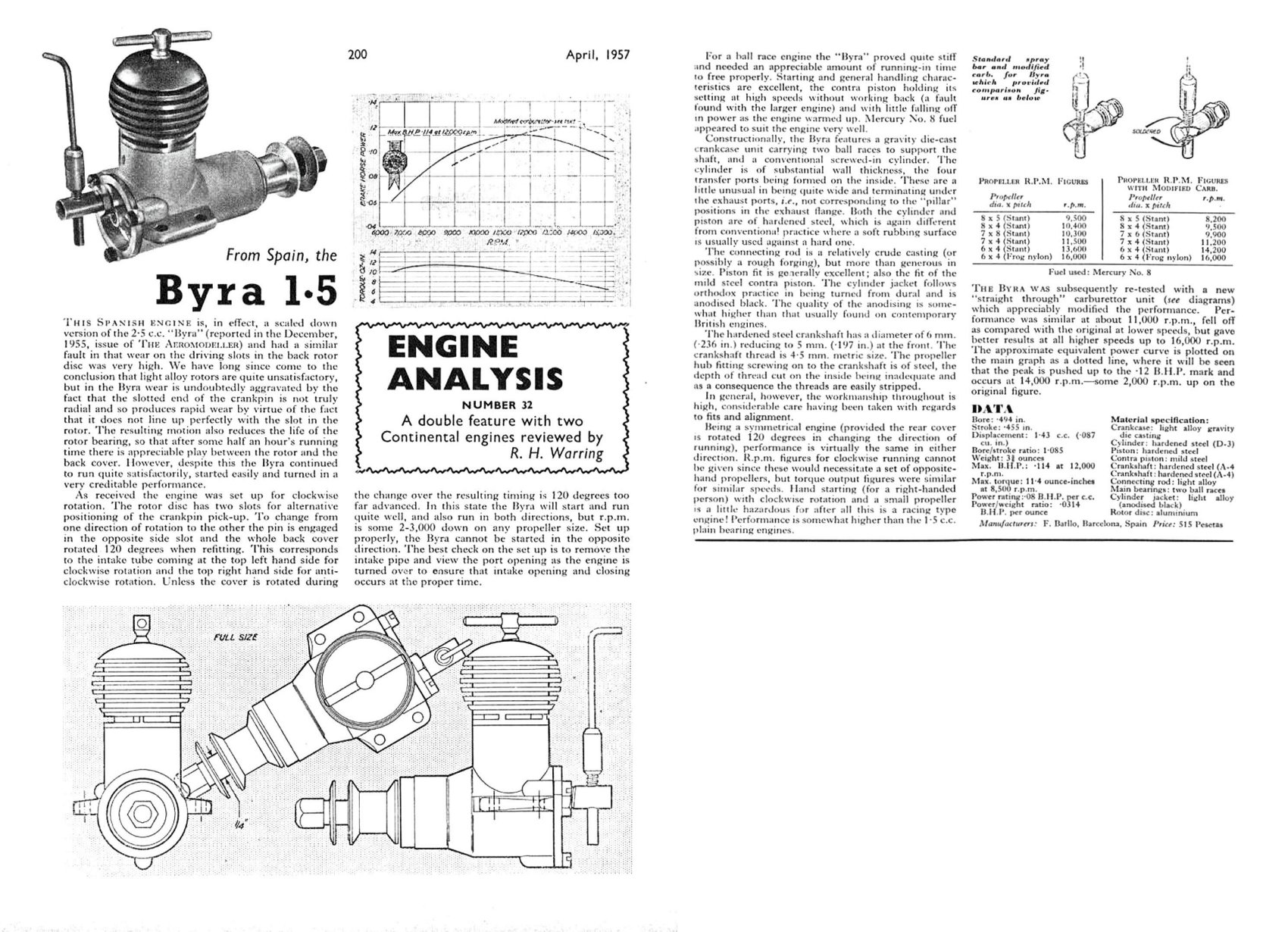

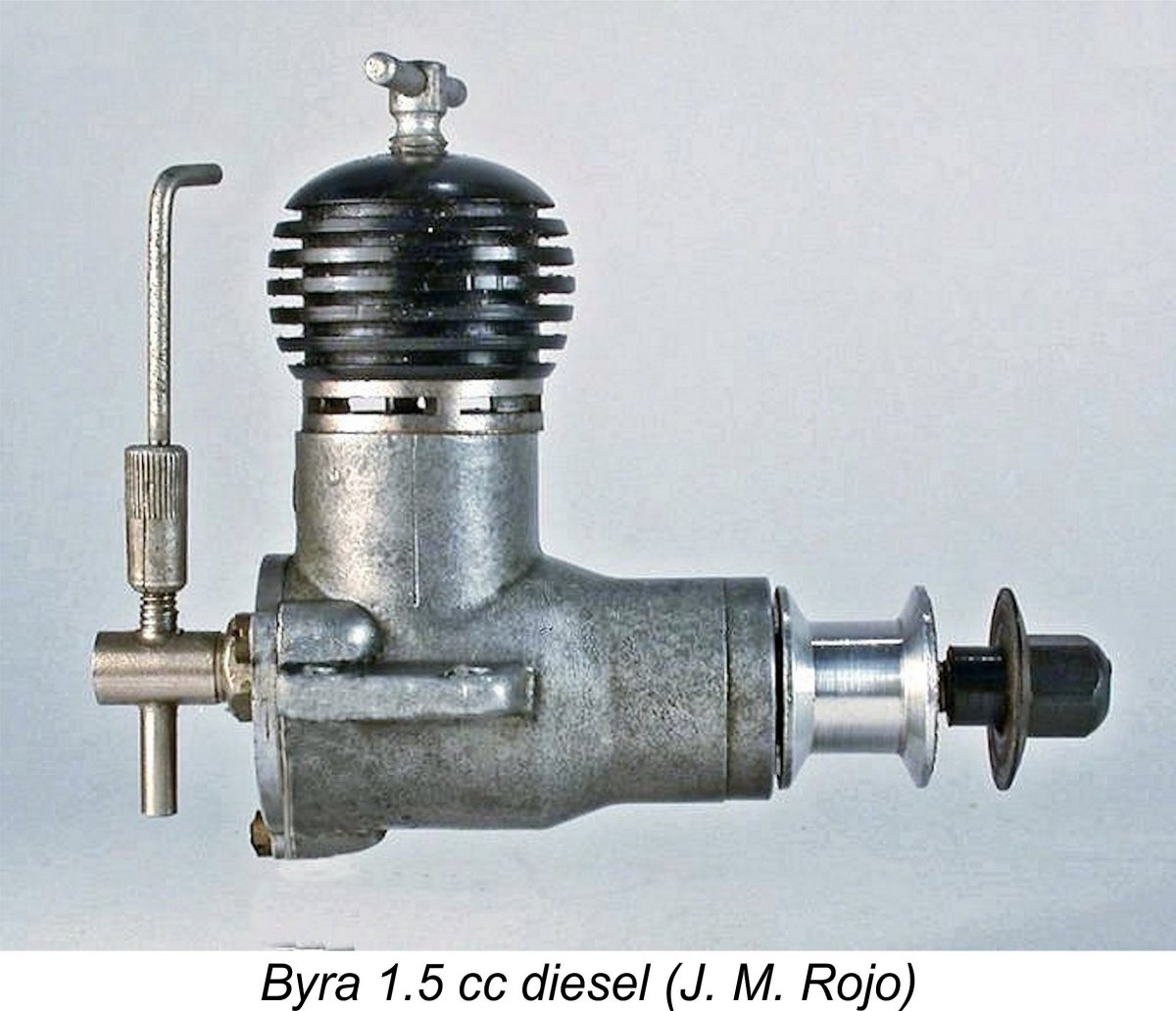

Although the JM Rojo website claims that this model was introduced in 1957, the architectural and structural evidence strongly suggests that the true introductory date was almost certainly 1955. This view is based on the fact that the Byra 1.5 cc model perpetuated a few of the design issues which were highlighted by Ron Warring in his December 1955 test of the 2.5 cc model. A designer of Batlló’s calibre seems highly unlikely to have done this, especially after the very public criticisms which appeared in Warring’s earlier review. In addition, the design of the Byra 1.5 cc model bears no resemblance whatsoever to that of the comprehensively revised version of the Byra 2.5 cc Competition model which appeared in 1956 (see below). Surely if it had actually appeared in 1957, the 1.5 cc model would have been based on the upgraded 2.5 cc design rather than the earlier version of the engine?!? Regardless, the construction of this unit followed that of the previously-described Byra 2.5 cc Competition model in all key respects, even down to the black anodizing of the cooling jacket. Like its big brother, the engine was a twin ball-race radially-ported diesel featuring disc rear rotary valve (RRV) induction. Bore and stroke were reduced to 12.55 mm (0.494 in) and 11.56 mm (0.455 in.) respectively for an actual displacement of 1.43 cc (0.087 cuin.). These figures are those measured by Ron Warring during the course of his April 1957 “Aeromodeller” test, of which more in due course. They are slightly at variance with the numbers cited on the JM Rojo website. Somewhat surprisingly, the engine continued to feature the aluminium alloy disc valve which had proved to be so inadequate for its assigned task in the larger design. The same option for setting the valve up for operation in either direction was also maintained in this unit. It is the retention of this component which strongly suggests that the design preceded the appearance of Ron Warring's rather critical December 1955 report on the 2.5 cc version of the engine. As already mentioned, the Byra 1.5 cc model was the subject of another test by Warring which appeared in the April 1957 issue of “Aeromodeller” magazine.

Starting and general handling characteristics were classified as “excellent”, with no evidence of the compression run-back that had been experienced with the larger model. Warring characterized the standard of workmanship and component alignment as “high”. A far more positive assessment than that accorded to the larger model, the one exception being the retention of the light alloy disc valve. It appears that two different needle valve assemblies could be used with this engine. One was a conventional spraybar, while the other was a racing-style surface jet arrangement. Warring measured peak outputs of 0.112 BHP @ 12,000 rpm and 0.120 BHP @ 14,000 rpm respectively for these two configurations. By 1955 standards, the latter figure represented a quite respectable level of performance for a commercial 1.43 cc diesel. However, the specific output (BHP/cc) of this model fell somewhat short of that recorded above for my test example of the 2.5 cc version. Again, the disc valve seems to be a likely culprit. The Last Hurrah – the Second (and last) Byra 2.5 cc Competition Model It’s abundantly obvious that Fernando Batlló must have taken note of the criticisms levelled very publicly against his original 2.5 cc Competition model in Ron Warring’s December 1955 test report. He evidently initiated immediate steps to address these issues. In consequence, a comprehensively revised version of the Byra 2.5 cc diesel appeared in 1956. This is often referred to as the Byra 2.5 cc Mk. III diesel.

In addition, the means of securing the cylinder and cooling jacket was changed from the former screw-in assembly to a more substantial system employing four long screws which passed through the separate cylinder head and on down through the light alloy cooling jacket to engage with four tapped holes in the upper crankcase. Other significant changes were seen in the induction system. Most significantly, Battló finally abandoned the light alloy disc valve in favour of a non-metallic component which would doubtless prove far more durable in service. The duration of the induction phase of the operating cycle was increased, and a surface jet needle valve assembly was now fitted as standard. The result was an engine having a considerably enhanced performance potential from that of its predecessor. However, it’s clear that by now Batlló was losing interest in continuing his model engine manufacturing activities. As an independently wealthy individual, he was under no financial pressure to continue these activities. In addition, he seems to have had a wide range of other interests. For whatever reason, all Byra model engine production appears to have ceased by the end of 1957, although some engines continued to be available as New Old Stock for some time thereafter. The final version of the 2.5 cc RRV model was accordingly made in relatively small numbers, hence being a somewhat rare unit today. Fernando Batlló’s Competition Record While all of this had been going on, Fernando Batlló had by no means lost interest in participating in competitive aeromodelling. Although there is no English-language record of this, it seems almost certain that he would have participated in Spanish national contests, to showcase the merits of his Byra engines if nothing else.

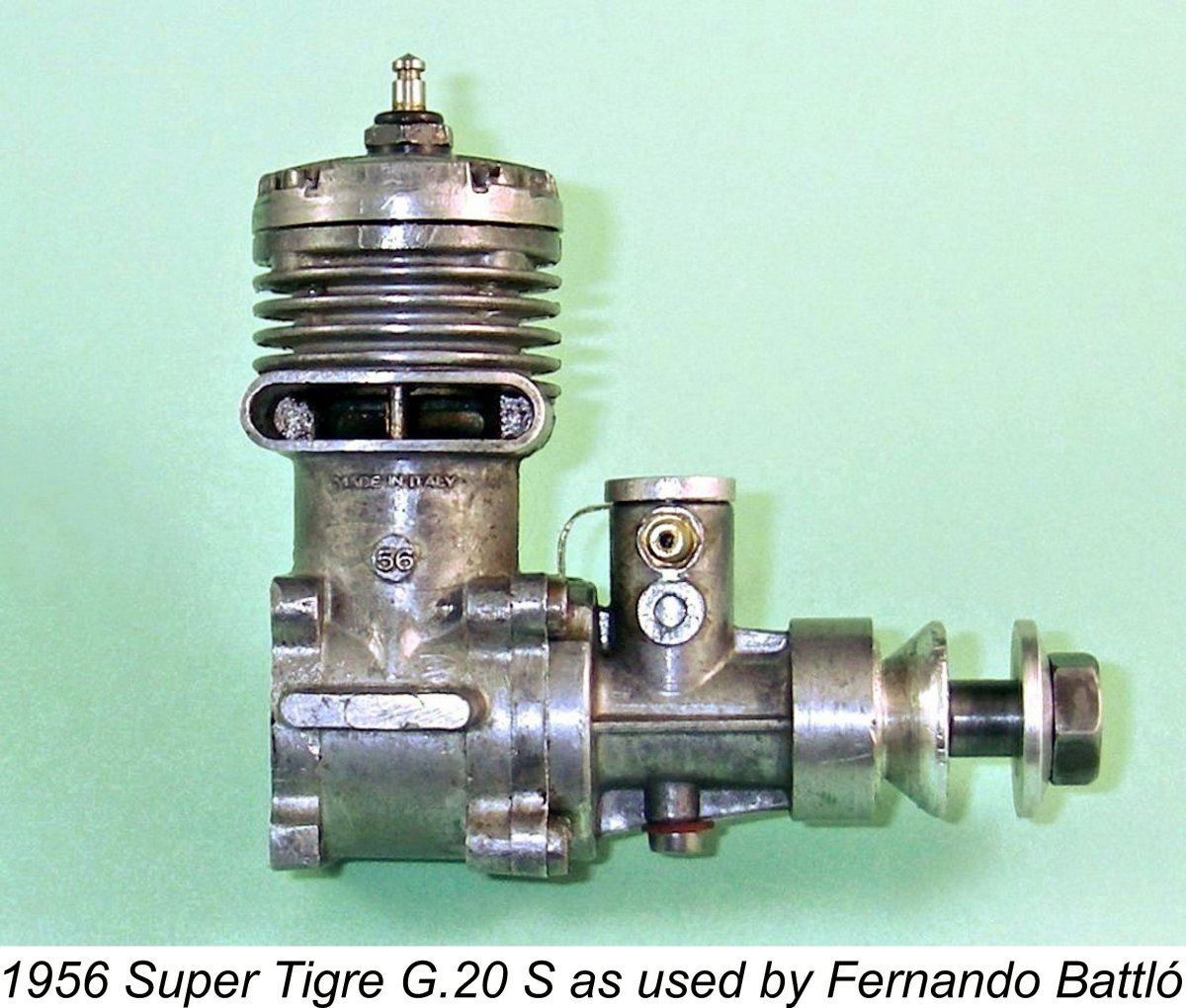

By that time his chief interest had clearly become the 2.5 cc control line speed category, leading him to become an expert engine tuner. However, he continued to compete in the stunt event in addition. Given his increasing focus on the speed category as well as his undoubted talents in the model engine construction arena, it’s a bit odd that Batlló didn’t join the likes of England's Fred Carter by developing his own Byra racing glow-plug engine. Instead, he opted to use over-the-counter Super Tigre powerplants which he tuned himself. His abilities in the latter respect were definitively underscored when he returned to the International contest scene in 1956.

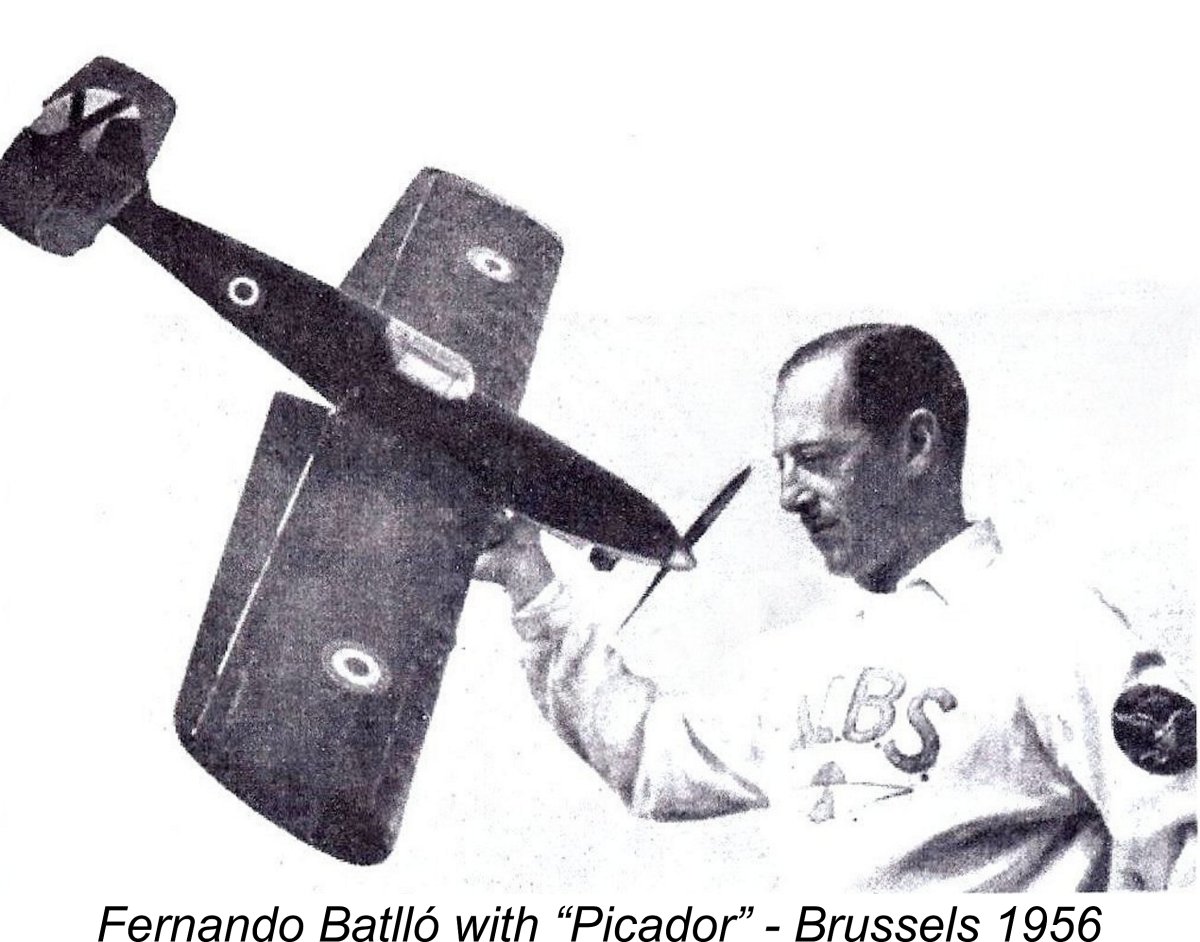

At the Brussels meeting, Batlló used his self-tuned Super Tigre G.20 S to finish in first place, narrowly beating Britain’s future World Champion Ray “Gadget” Gibbs and his McCoy 19 based 2.5 cc Carter Special. Batlló’s speed was a very creditable 125.5 mph, considerably faster than the winning speed of 111.3 mph at the previous year’s World Championship meeting in Paris, in which Batlló had not competed. Standards had clearly improved considerably since that meeting. Batlló also competed in the control line stunt category at this event. Once again, he elected to use a commercially-produced engine from another manufacturer as opposed to developing a stunt engine of his own. He flew his own model called the "Picador", powered by what had by then become the "standard" Fox 35.

The speed result in particular was sufficiently encouraging that Batlló elected to make the trip to Florence, Italy for the 1956 Control Line Speed World Championship meeting held in October 1956. The results were yet another triumph for Batlló, albeit of a somewhat different kind. He didn’t win, but he did finish as the top Super Tigre contestant, beating all of the official Italian factory-prepared entries. Despite suffering from a cracked crankcase in the first round, his second-round mark of 121.2 mph was good enough for fifth place.

There were no Spanish entrants at the 1957 World Championship meeting held at Mlada Boleslav near Prague, Czechoslovakia (as the Czech Republic was then). This was during the time when Batlló was doubtless preoccupied with winding down his Byra model engine manufacturing activities, as recorded earlier. However, Batlló and his fellow Spaniards did appear at the 1958 Brussels Expo International meeting. This meeting was in effect that year's World Championship event. Although none of the Spaniards managed to crack the leaderboard, their combined efforts were good enough to give Spain a very creditable 4th place team finish in the speed event, ahead of Great Britain and the USSR among others. Batlló entered the stunt event as well, now using O.S Max 35 power. He finished 12th on this occasion. Batlló returned to the International contest stage in 1959, competing in the tenth Criterium of Europe (in effect, that year’s World Championship) held once again at Brussels. On this occasion, both the Italian “works” Super Tigres and the MOKI specials from Hungary proved to be too much to overcome in the speed event, but Batlló still managed to finish in 5th place once more as the top “private entrant” with a very creditable speed of 200.0 km/hr (124.3 mph). He also entered the stunt event once again, but his dedication to that category appeared to be waning - he finished in a rather lowly 17th place. The Spaniards gave the 1960 event a miss – indeed, Batlló's commitment to the International competition arena was evidently losing steam as time went by. He did make one more appearance, returning in 1961 to compete in the 11th Criterium of Europe. On this occasion, he competed in both the speed and team race categories, partnering with a fellow Spaniard named Fernandez in the latter event. The results achieved were not spectacular – Batlló finished 17th in both categories. As far as I can discover, this was his final appearance at an International competition. Still, Fernando Batlló had compiled a very respectable contest record over the ten-year period during which he had participated. This is a man who is well worthy of our highest respect! Fernando Batlló’s Involvement with Motorcycles

Fernando Batlló had two sons named Jesus and Javier who both developed a strong interest in motorcycles, competing in hill climbs and road races in their native Spain. They too were friends of Eduard Giró. In 1968, Giró developed a 500 cc twin-cylinder engine created by twinning OSSA’s established 250 cc single-cylinder two-stroke motor. This was intended for the US market. It was fitted into a frame made in the USA by the Yankee Motor Company of Schenectady, New York. A considerable number of these machines were made during the late 1960’s and early 1970’s. The Batlló brothers created their own home-grown version of this model for their own use. In support of his sons' interests, Fernando Batlló was taking a considerable interest in motorcycle engineering at this time. He never worked for OSSA, but as a personal friend of the Giró family the facilities of the OSSA factory were available to him to support his self-funded experimental efforts. One of his early efforts along these lines was the addition of a rotary valve to a 75 cc Derbi engine, using which his two sons won many competitions. By 1970 he had constructed several additional one-off “specials”, the most notable of which featured a 525 cc three-cylinder engine constructed around three 175 cc OSSA cylinders. In the early 1970’s the Batlló brothers persuaded their father to develop a design for a 1000 cc two-stroke motorcycle based upon the use of four 250 cc OSSA cylinders. Fernando Batlló achieved this by simply adding an extra 250 cc cylinder to each side of an OSSA/Yankee 500 cc twin cylinder engine. The engine was mounted in a beefed-up double-cradle frame based upon the Yankee design. It was designated the BYRA 1000, although it was very much a joint venture with OSSA.

Only two examples of this design were ever completed. One was set up for road racing and the other was configured for street use. Jesus and Javier Batlló tested these machines, finding them to have considerable potential. There were some teething troubles with the electrical system (that's a lot of sparks!), while the challenge of getting the engine’s rather fiercely-delivered 100 - 115 BHP to the ground proved somewhat problematic at first. However, these difficulties had been largely overcome by 1972. The Batlló brothers used the street bike for some years, while the road racer competed in both the 1972 and 1973 Montjuich 24 hour race in Barcelona. Sadly, this aspect of the venture did not have a happy ending – the bike crashed heavily at speed in the 1974 race, killing its rider Cufi. It was never rebuilt. However, the street model has survived and may still be seen in the motorcycle museum at Bassella, Spain. It is a lasting testament to the remarkable scope of the engineering talents of Fernando Batlló. Conclusion The Byra engines were very capably designed and manufactured by a talented and versatile hands-on modeller who possessed considerable precision engineering skill combined with a high level of dedication to the modelling hobby. The surviving examples of Fernando Batlló's work and that of his colleague Señor Ramirez stand as a testament to the abilities of both individuals. Anyone lucky enough to acquire one of these fine motors, as I have been, will find themselves owning a significant and impressive piece of Spanish modelling history! ______________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published November 2019 Revised September 2021 - Test of Byra 1 cc diesel added |

||

| |

In this article we’ll be paying our second visit to sunny Spain to review a high-quality model engine range originating in that country during the classic era of the 1950’s. We’ll be sharing an in-depth look at the series of model diesels manufactured in Barcelona by Don Fernando Batlló under the Byra brand-name.

In this article we’ll be paying our second visit to sunny Spain to review a high-quality model engine range originating in that country during the classic era of the 1950’s. We’ll be sharing an in-depth look at the series of model diesels manufactured in Barcelona by Don Fernando Batlló under the Byra brand-name.

Although not made in commercial quantities at this stage, those engines that Batlló did produce as a hobby during the latter half of the 1940’s with the assistance of Señor Ramirez quickly established a high reputation. The engines were locally distributed in very small numbers among Batlló's fellow Catalunyan modellers, becoming very highly regarded for their happy combination of quality, durability and performance. The word spread rapidly, with the result that Batlló soon became widely recognized as Spain’s leading authority on model engine design.

Although not made in commercial quantities at this stage, those engines that Batlló did produce as a hobby during the latter half of the 1940’s with the assistance of Señor Ramirez quickly established a high reputation. The engines were locally distributed in very small numbers among Batlló's fellow Catalunyan modellers, becoming very highly regarded for their happy combination of quality, durability and performance. The word spread rapidly, with the result that Batlló soon became widely recognized as Spain’s leading authority on model engine design.

1950 or early 1951 he succumbed to this pressure, establishing an expanded workshop in Barcelona to undertake the commercial production of model engines, still in partnership with Ramirez. The venture traded under the marque-name Byra.

1950 or early 1951 he succumbed to this pressure, establishing an expanded workshop in Barcelona to undertake the commercial production of model engines, still in partnership with Ramirez. The venture traded under the marque-name Byra.  However, Batlló rightly recognized the fact that model engine design was then moving forward from the sideport era, with rotary valve induction taking centre stage. Accordingly, it didn’t take him long to develop a disc rear rotary valve (RRV) version of the engine. The conversion was accomplished through the blanking-off of the sideport induction aperture and the replacement of the backplate with a revised component having provision for RRV induction. This was the first rotary valve model engine to be manufactured in Spain.

However, Batlló rightly recognized the fact that model engine design was then moving forward from the sideport era, with rotary valve induction taking centre stage. Accordingly, it didn’t take him long to develop a disc rear rotary valve (RRV) version of the engine. The conversion was accomplished through the blanking-off of the sideport induction aperture and the replacement of the backplate with a revised component having provision for RRV induction. This was the first rotary valve model engine to be manufactured in Spain.

The previously-cited article in the March 1952 issue of “El Aeromodelista” was evidently prompted in large part by the fact that in late 1951 Fernando Batlló had moved energetically to expand the Byra range. Perhaps the most important addition to the line-up was the initial variant of the Byra 2.5 cc diesel, sometimes referred to as the 2.5 Mk. I or the 2.5 F model.

The previously-cited article in the March 1952 issue of “El Aeromodelista” was evidently prompted in large part by the fact that in late 1951 Fernando Batlló had moved energetically to expand the Byra range. Perhaps the most important addition to the line-up was the initial variant of the Byra 2.5 cc diesel, sometimes referred to as the 2.5 Mk. I or the 2.5 F model.  The writer of the article commented that the engine was extremely easy to start. He also praised its running characteristics over its full speed range, which extended up to 14,000 rpm. The engine weighed a commendably light 110 gm (3.88 ounces). Although much of the initial production went to meet the immediate needs of the Frente de Juventudes, by early 1952 the engine had become available to the Spanish modelling public at large. It was priced at 500 pesetas.

The writer of the article commented that the engine was extremely easy to start. He also praised its running characteristics over its full speed range, which extended up to 14,000 rpm. The engine weighed a commendably light 110 gm (3.88 ounces). Although much of the initial production went to meet the immediate needs of the Frente de Juventudes, by early 1952 the engine had become available to the Spanish modelling public at large. It was priced at 500 pesetas.  At least some of these engines (and possibly all) were timed for reverse rotation (clockwise viewed from the front). This may seem a little odd to many readers, but in fact reverse rotation was quite widely favoured on the Continent at the time – a number of

At least some of these engines (and possibly all) were timed for reverse rotation (clockwise viewed from the front). This may seem a little odd to many readers, but in fact reverse rotation was quite widely favoured on the Continent at the time – a number of

As of early 1952, when the first “El Aeromodelista” article was published, the 4.5 cc diesel evidently remained in production. In addition to the newly-introduced 2.5 cc design, it was also accompanied in the range by a 1 cc diesel which had apparently then just appeared following a few teething troubles.

As of early 1952, when the first “El Aeromodelista” article was published, the 4.5 cc diesel evidently remained in production. In addition to the newly-introduced 2.5 cc design, it was also accompanied in the range by a 1 cc diesel which had apparently then just appeared following a few teething troubles.

I'm blessed with a number of good friends who share my passion for model engines and are both willing and able to contribute very materially to my knowledge. Standing high among them is my valued mate Peter Valicek of the Netherlands. Peter was kind enough to direct his awesome model engineering talents towards the complete restoration of an example of the mega-rare radial-mount Byra 1 cc prototype model, thus placing me in a position to conduct a hands-on bench test. What an opportunity!

I'm blessed with a number of good friends who share my passion for model engines and are both willing and able to contribute very materially to my knowledge. Standing high among them is my valued mate Peter Valicek of the Netherlands. Peter was kind enough to direct his awesome model engineering talents towards the complete restoration of an example of the mega-rare radial-mount Byra 1 cc prototype model, thus placing me in a position to conduct a hands-on bench test. What an opportunity!

Although it was a very worthy product which did much to confirm Don Fernando Batlló’s pre-eminence as a model engine designer and manufacturer in Spain, the performance of the original plain-bearing Byra 2.5 cc FRV model described earlier fell somewhat short of matching that of the best products from elsewhere. This soon led to the Spanish modelling community placing Batlló under considerable pressure to create a higher-performance version of the engine.

Although it was a very worthy product which did much to confirm Don Fernando Batlló’s pre-eminence as a model engine designer and manufacturer in Spain, the performance of the original plain-bearing Byra 2.5 cc FRV model described earlier fell somewhat short of matching that of the best products from elsewhere. This soon led to the Spanish modelling community placing Batlló under considerable pressure to create a higher-performance version of the engine.

This tendency definitely seems to have affected the engine's performance. The Byra was found to peak at only 12,000 rpm (about the speed at which the chronic misfire started), where it developed some 0.196 BHP, with torque and power falling off rapidly above this speed. As Warring noted, this was scarcely a true “racing” performance. In particular, it fell well short of the manufacturer’s performance claim recorded earlier. It also failed to reflect the design's apparent performance potential. Again, the worn and hence leaky disc valve seems to me to be a likely culprit.

This tendency definitely seems to have affected the engine's performance. The Byra was found to peak at only 12,000 rpm (about the speed at which the chronic misfire started), where it developed some 0.196 BHP, with torque and power falling off rapidly above this speed. As Warring noted, this was scarcely a true “racing” performance. In particular, it fell well short of the manufacturer’s performance claim recorded earlier. It also failed to reflect the design's apparent performance potential. Again, the worn and hence leaky disc valve seems to me to be a likely culprit. Once the settings had been established, the Byra proved to be an almost instant starter. Cold starts were facilitated by a small exhaust prime, but hot restarts required only a finger choke or two. Despite its very tight piston/cylinder fit, the engine started and ran perfectly from the outset. The main evidence of this tightness was the fact that the cylinder became extremely hot, doubtless in part due to friction.

Once the settings had been established, the Byra proved to be an almost instant starter. Cold starts were facilitated by a small exhaust prime, but hot restarts required only a finger choke or two. Despite its very tight piston/cylinder fit, the engine started and ran perfectly from the outset. The main evidence of this tightness was the fact that the cylinder became extremely hot, doubtless in part due to friction.  At the end of this period, the engine was certainly showing signs of freeing up a little, but the piston/cylinder fit was still considerably tighter than I judged to be ideal for best performance. I therefore continued the process outlined above for a further 40 minutes. At the end of this session, things had improved still further to the point where I felt comfortable in switching to a "hotter" fuel and commencing the actual test despite a certain amount of residual tightness. I continued to allow complete cooling between test runs in order to expose the components to further complete heat cycles.

At the end of this period, the engine was certainly showing signs of freeing up a little, but the piston/cylinder fit was still considerably tighter than I judged to be ideal for best performance. I therefore continued the process outlined above for a further 40 minutes. At the end of this session, things had improved still further to the point where I felt comfortable in switching to a "hotter" fuel and commencing the actual test despite a certain amount of residual tightness. I continued to allow complete cooling between test runs in order to expose the components to further complete heat cycles.

Despite the issues identified by Ron Warring, the Byra 2.5 cc RRV model was clearly a success. This encouraged Don Fernando Batlló to develop what amounted to a 1.5 cc version of the same engine.

Despite the issues identified by Ron Warring, the Byra 2.5 cc RRV model was clearly a success. This encouraged Don Fernando Batlló to develop what amounted to a 1.5 cc version of the same engine.

Understandably enough, Warring began by expressing some surprise that the aluminium alloy disc valve had been retained, stating that “we have long since come to the conclusion that light alloy rotors are quite unsatisfactory”. He evidently experienced the same problem of rapid wear which had been encountered with the larger engine.

Understandably enough, Warring began by expressing some surprise that the aluminium alloy disc valve had been retained, stating that “we have long since come to the conclusion that light alloy rotors are quite unsatisfactory”. He evidently experienced the same problem of rapid wear which had been encountered with the larger engine. The revised model retained the same working components, twin ball-races and RRV induction that had been used in its predecessor. Bore and stroke were apparently returned to their original 15 mm and 14 mm dimensions respectively for a displacement of 2.47 cc (0.151 cuin.). The engine was thus brought back into line with prevailing FAI rules for International competition.

The revised model retained the same working components, twin ball-races and RRV induction that had been used in its predecessor. Bore and stroke were apparently returned to their original 15 mm and 14 mm dimensions respectively for a displacement of 2.47 cc (0.151 cuin.). The engine was thus brought back into line with prevailing FAI rules for International competition.

Batlló’s return was nothing short of triumphant! He showed up at the seventh Criterium of Europe (as the European Control Line Championship meet was now called) held at Brussels on April 30

Batlló’s return was nothing short of triumphant! He showed up at the seventh Criterium of Europe (as the European Control Line Championship meet was now called) held at Brussels on April 30 The Picador was a semi-scale model based on the WW2-era

The Picador was a semi-scale model based on the WW2-era  It's perhaps indicative of Batlló's standing as the ranking engine expert among the Spanish modelling fraternity that he seems to have been entrusted with the starting and ground-tuning of all of the Spanish entries in the competition. He is shown in the attached "Aeromodeller" image at the right starting the G.20 S powerplant in the model flown by his team-mate Gogorcena, who finished in tenth place with a very creditable speed of 119.9 mph. This was in flagrant violation of the prevailing rules, which required an entrant to start his own model! However, the "Aeromodeller" report stated that many entrants were doing it, with no action being taken by the officials.

It's perhaps indicative of Batlló's standing as the ranking engine expert among the Spanish modelling fraternity that he seems to have been entrusted with the starting and ground-tuning of all of the Spanish entries in the competition. He is shown in the attached "Aeromodeller" image at the right starting the G.20 S powerplant in the model flown by his team-mate Gogorcena, who finished in tenth place with a very creditable speed of 119.9 mph. This was in flagrant violation of the prevailing rules, which required an entrant to start his own model! However, the "Aeromodeller" report stated that many entrants were doing it, with no action being taken by the officials.  I mentioned at the outset that Fernando Batlló was a member of one of Barcelona's leading industrial families. Also included in that elite group was the Giró family, owners of the Barcelona-based

I mentioned at the outset that Fernando Batlló was a member of one of Barcelona's leading industrial families. Also included in that elite group was the Giró family, owners of the Barcelona-based