|

|

The Payá (aka ICA) 2 cc Diesel – the “E.D. Marca Dos”

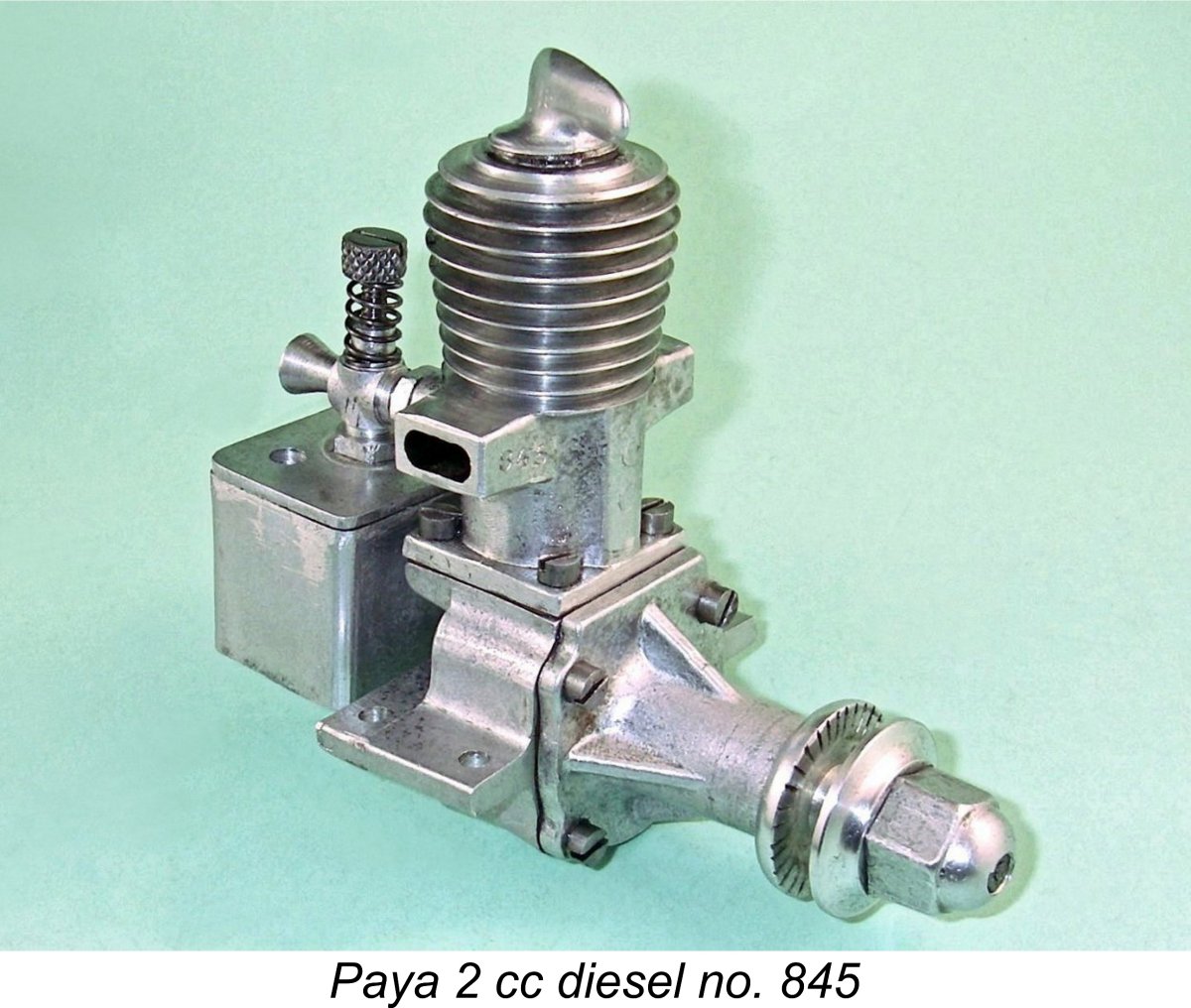

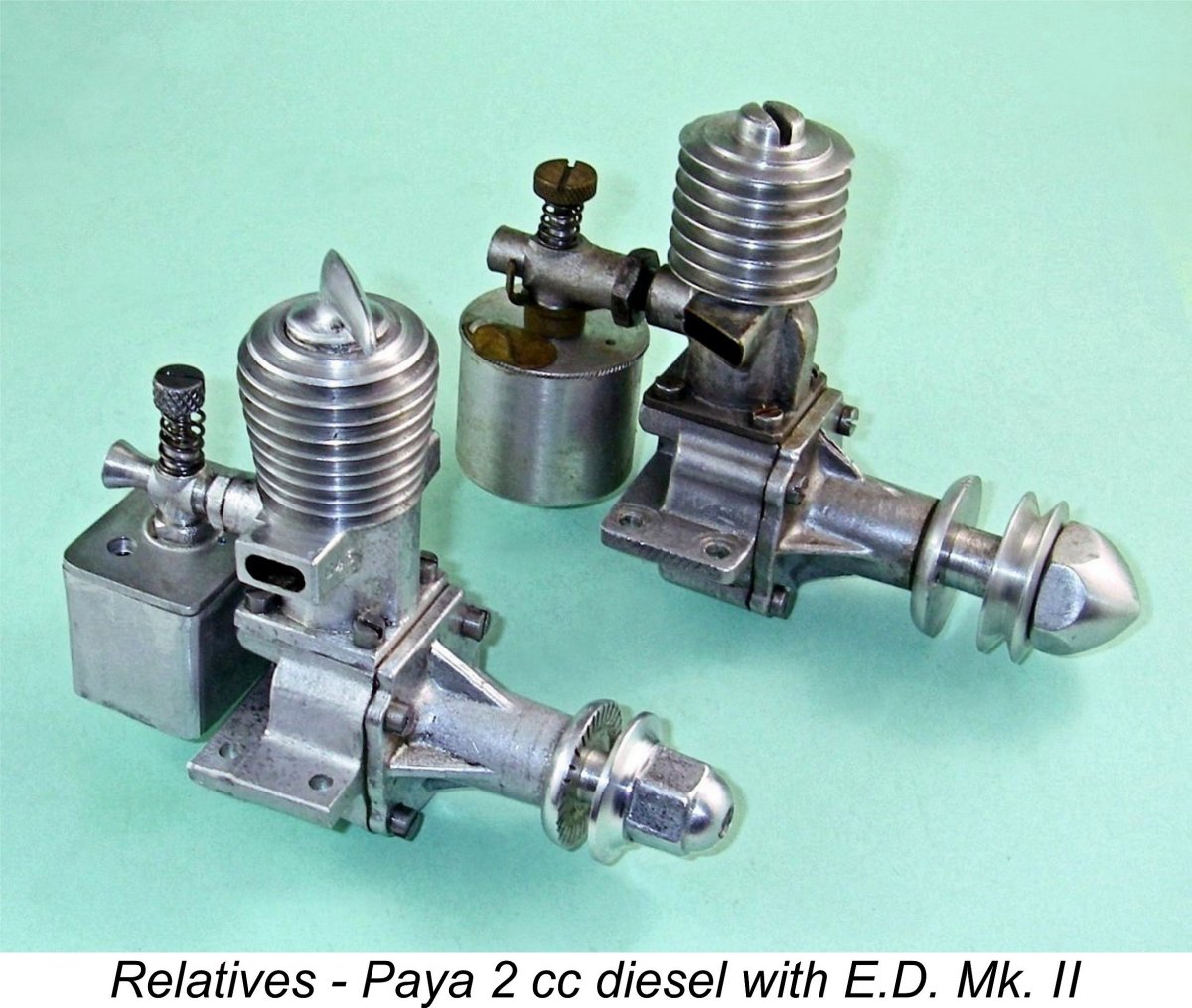

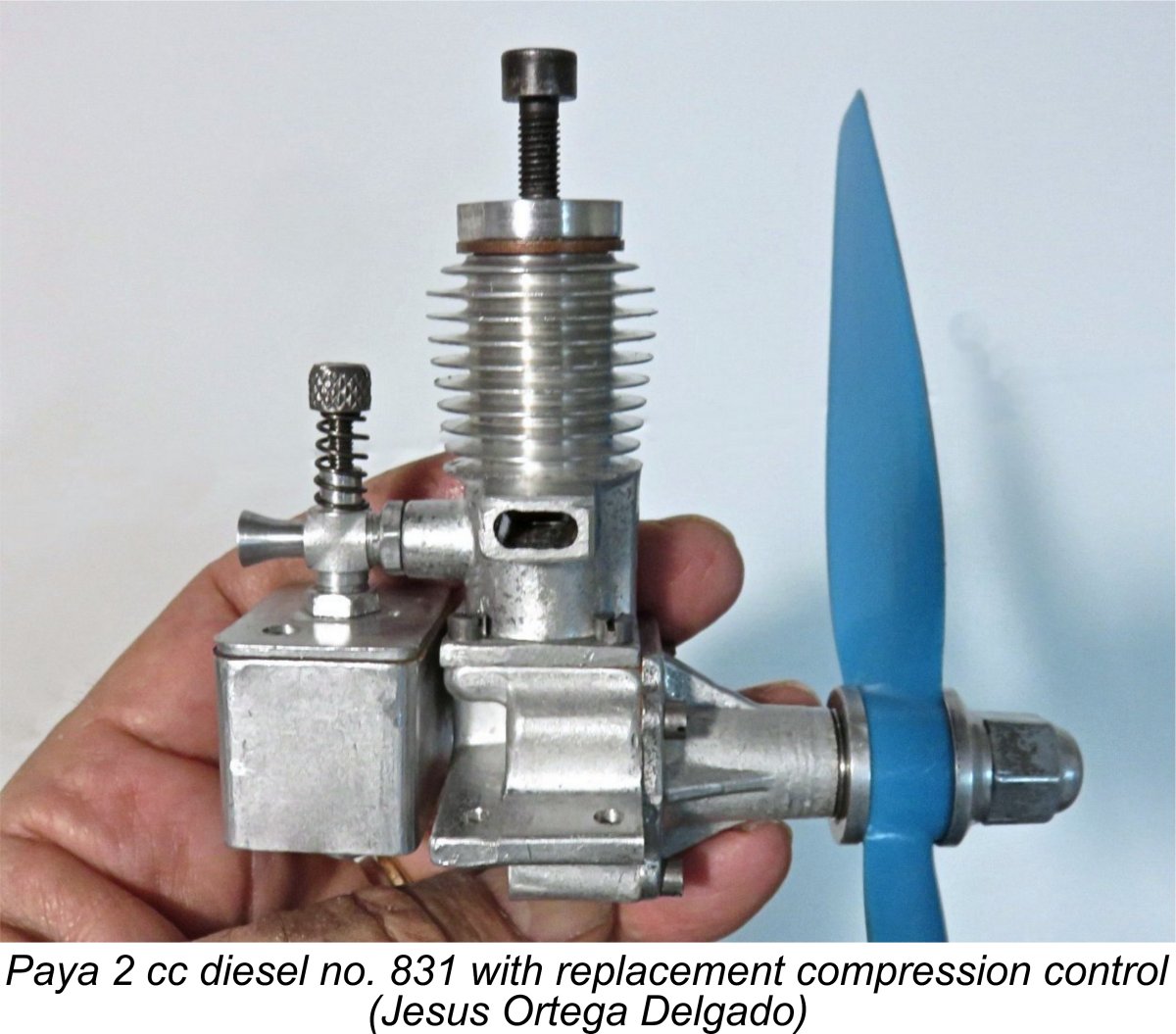

Many aficionados of classic British diesels will be comfortably familiar with this engine, although they don’t yet know it! This is because, as one look should suffice to confirm, the one and only model diesel engine marketed under the Payá name was a direct derivative of the E.D. Mk. II diesel from Britain which had appeared in early 1947. Although very obviously based upon the design of the E.D. Mk. II, the Payá nonetheless displayed a number of design departures which confirm that some original thinking went into its design and construction. However, a certain amount of that thinking resulted in a few design features which were somewhat flawed in their concept and execution. We’ll look at the relevant features in due course, warts and all. Before continuing, I wish to thank my buen amigo and valued colleague Jesus Ortega Delgado for his unstinting help in facilitating the untangling of this interesting and in some ways unique story. Much of the information about the two companies which were involved in the manufacture and marketing of these engines came from Jesus, who also supplied the New-In-Box examples of the Payá 2 cc diesel which enabled me to describe and test the engine. I couldn’t have even contemplated undertaking this project without his help. I’d also like to thank my valued mate Peter Valicek, who kindly supplied replica aero components to allow me to convert the engines from the flywheel-equipped form in which they were generally supplied back into their aero form. Couldn’t do it without you, Peter! Both Jesus and Peter also provided a great deal of invaluable operating advice based upon their own experiences with the engine. I also wish to acknowledge the kind assistance of José Manuel Rojo, whose fascinating and very useful website presents the world-class JM Rojo model engine collection for interested readers. Although presented in Spanish, it’s easily translated into any language using Google Translate or some similar program. José Manuel supported my efforts all along, most notably by tracking down a copy of the original Patent document relating to the engine. More of that in its place below. Finally, I must pay tribute to the various members of the Pazó family with whom I had contact after the initial publication of this article. In particular, Fernando Pazó and his brother Javier were both more than willing to fill in the very wide gaps in my knowledge of the activities of their father Don Diego Pazó Montes, the designer and manufacturer of the Payá engines. Javier went so far as to provide me with a most informative PowerPoint presentation detailing the history of the family business. It's hard for me to adequately express my appreciation. With those pleasant acknowledgements of the assistance provided by good friends taken care of, it’s time to get started. To begin with, it’s necessary to trace the corporate histories of the two companies which were to join forces to put the Payá name on the Spanish modelling map. Corporate Histories

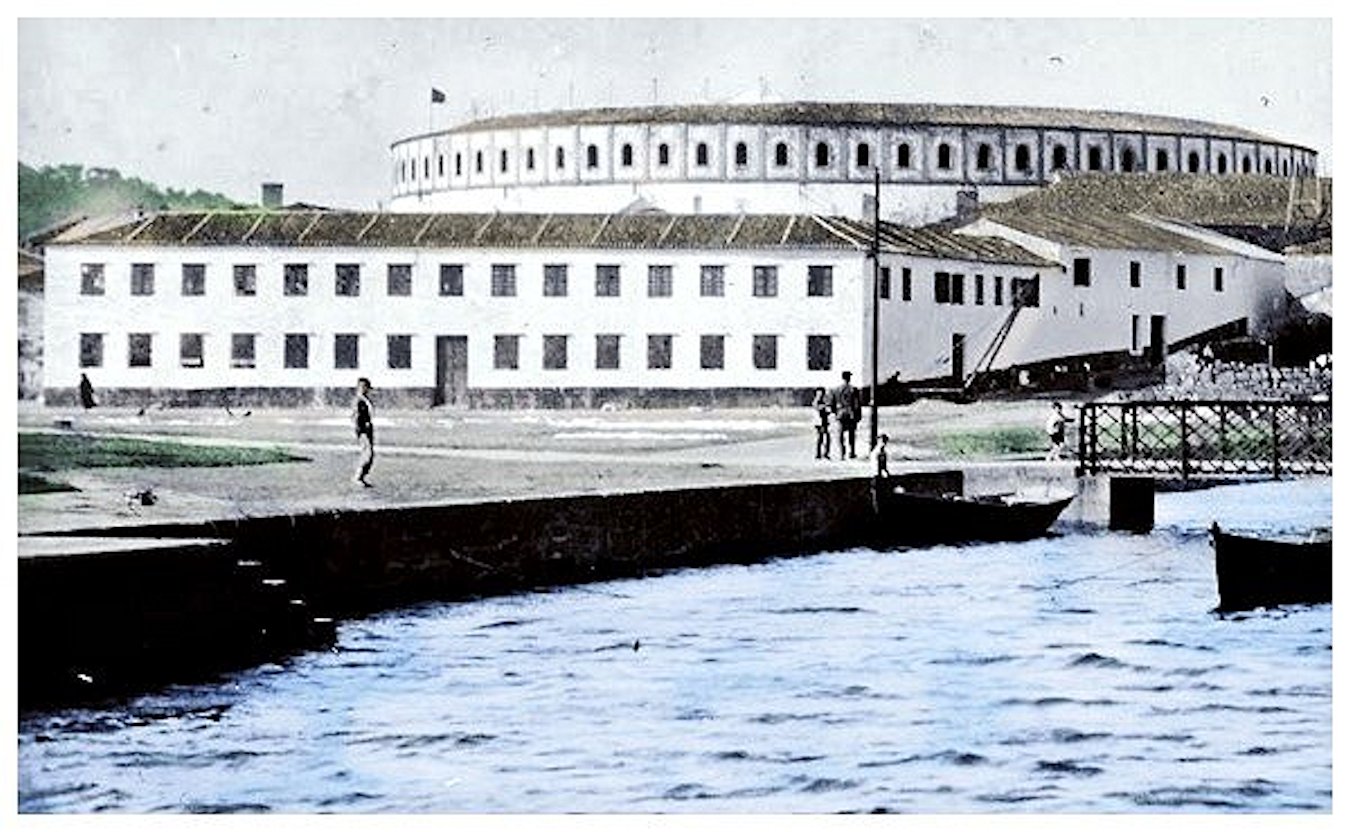

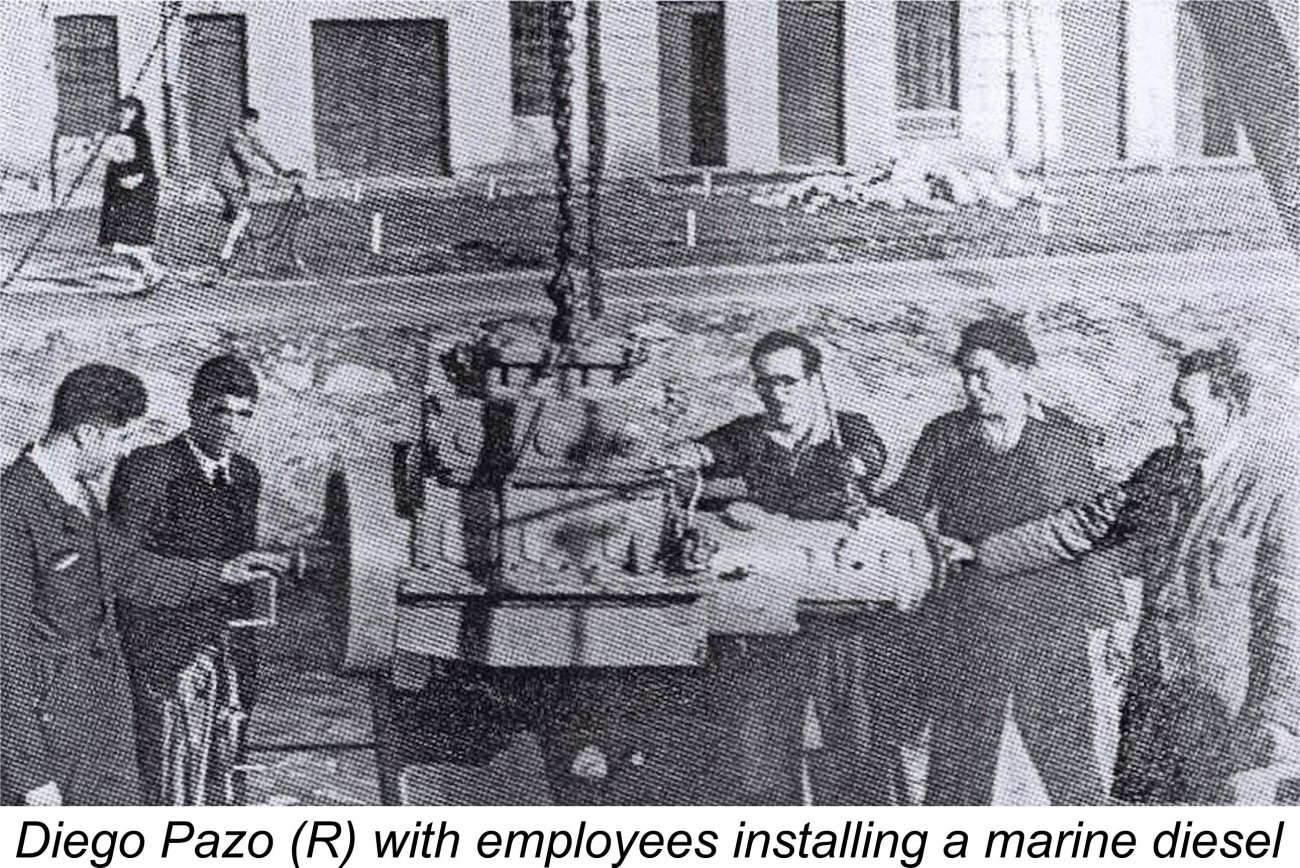

This company was an offshoot from a far older business which had been established as long ago as 1884 by José Pazó Martínez (two surnames are often used in Spain), who is pictured at the right. His Upon the death of José Pazó Martínez in 1925, the operation of the business was taken over by his son Diego Pazó Montes (1903 - 1996), who was a graduate of the School of Industrial Engineering at the University of Vigo, Pontevedra. Don Diego (as I will call him henceforth) soon changed the company name to "Talleres Pazó" (Pazó Workshops) and began to focus on the repair of automobiles as well as the casting and machining of cylinder liners and pistons for a range of commercial applications. Shortly after the 1939 conclusion of the Spanish civil war, Don The city of Pontevedra is situated on the exposed Atlantic coastline immediately adjacent to the estuary of the Lérez river. The fishing industry was a major factor in the local economy. That industry faced a significant problem in terms of the availability of compact marine engines suitable for the type of boats which the fishermen typically used. During the 1940’s (and for some decades thereafter) the importation of marine engines suitable for use in the fishing industry was prohibited by Government regulation. This forced Galician fishermen to rely solely upon sails and/or oars for boat propulsion, making fishing a very hazardous and relatively inefficient occupation on the exposed Galician coast. It was thus logical to assume that a ready local market would exist for the domestically-produced engines manufactured by the Pazó company. Indeed, it was to fill this gap by providing dependable domestic marine diesel engines that Don Diego established his company. He designed the engines himself, and all of the manufacturing processes (including the production of castings) were carried out in-house at the Pontevedra factory. Even the fasteners were manufactured there. However, there was an impediment. In a later interview in 2014 (in Spanish, naturally), Diego Pazó’s son Fernando Pazó Olmedo (today a noted designer of sails for top-level competition sailboats) recalled that at the time in question, the banks would not extend credit to the fishing community. This Don Diego was thus assuming the credit-extending role that the banks were unwilling to fulfil. It appears that his generosity was seldom abused by his grateful customers. The consequent infusion of engines into the community undoubtedly revolutionized the Galician fishing industry, also creating a high level of Pazó brand recognition and loyalty. This subsequently allowed the company’s engines to be sold on a more conventional basis in the rest of Spain as well as in places like Portugal and Morocco. It didn’t hurt the cause that the marine engines produced by the Pazó company were both well-built and very advanced for their time. The range included compact valved 2-stroke units having up to 3 cylinders. Recent communications with members of the Pazó family have done much to clarify the basis upon which the company became involved with model engine manufacture, which they did in late 1947, less than a decade after the establishment of the marine engine venture. One of Don Diego's brothers was José Pazó Montes, who was an aeronautical engineer, pilot and General in the Spanish Air Force. He was to go on to found Aviaco Airlines as well as becoming involved in a number of other successful business ventures, including the SEAT automobile company.

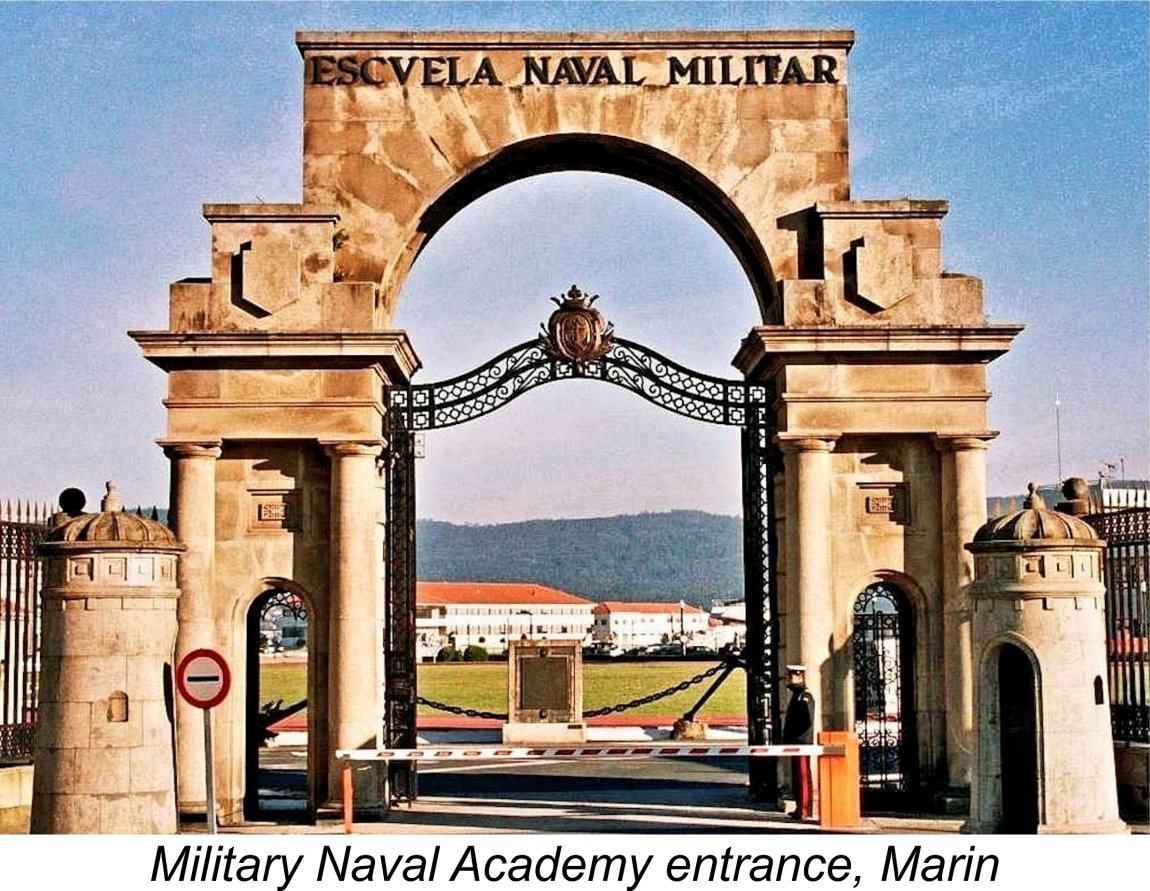

Now it gets complicated! In 1943, the Spanish Navy had established the Escuela Naval Militar de Oficiales (Naval Military Academy for Officers) at Marín, a coastal community located a short distance to the south-west of Pontevedra. As the name suggests, the function of this institution was (and still is) the training of officers for the Spanish Navy. As of 1947, a group of three midshipmen (students) at the Escuela had developed a strong interest in model diesel engines. They appear to have somehow obtained an early example of the 1947 English E.D. Mk. II 2 cc diesel, which they showed to Don Diego along with the suggestion that they collaborate with him in the development of a similar design suitable for commercial manufacture. They appear to have offered him a deal whereby they would assume responsibility for designing and marketing the engines.

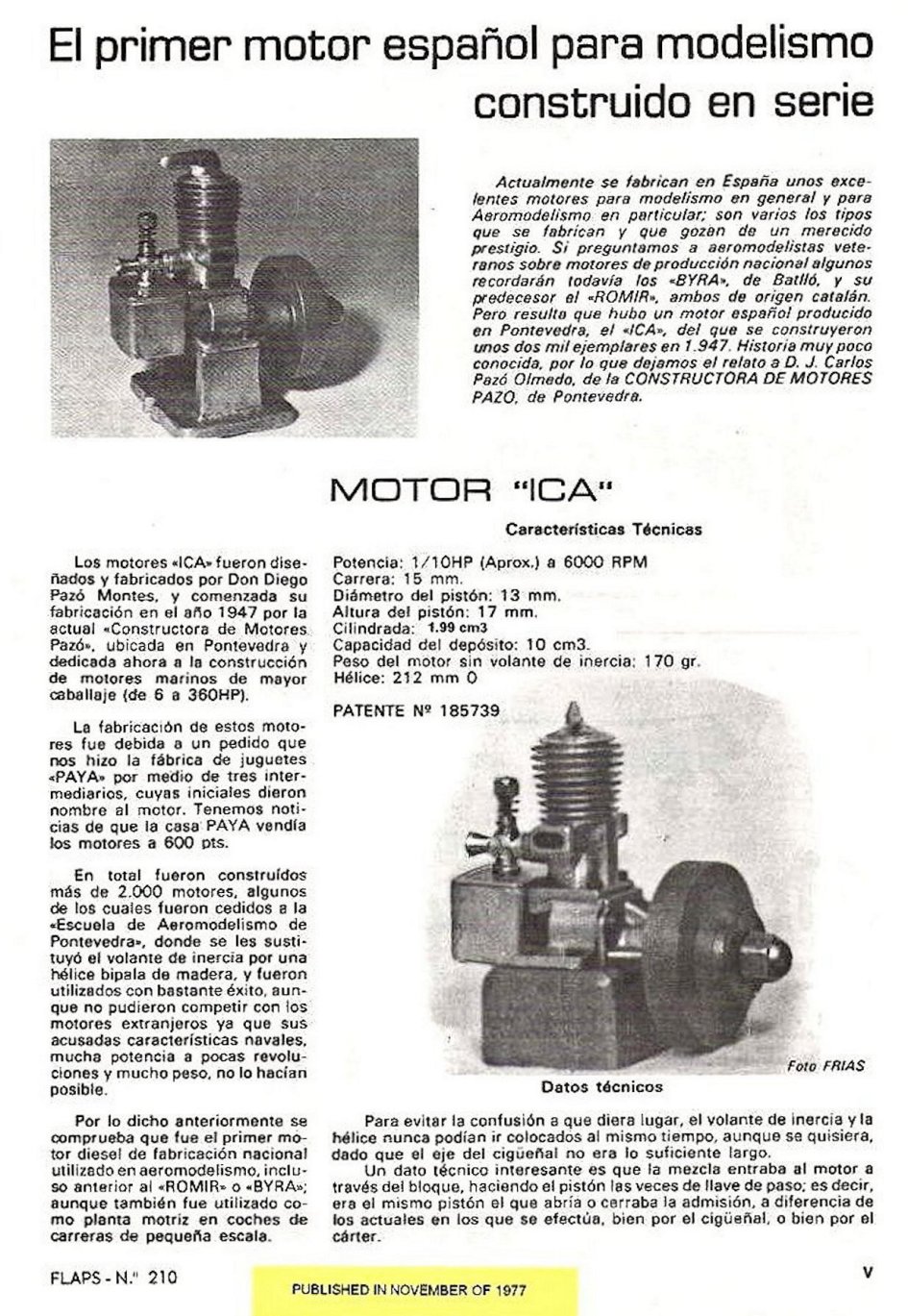

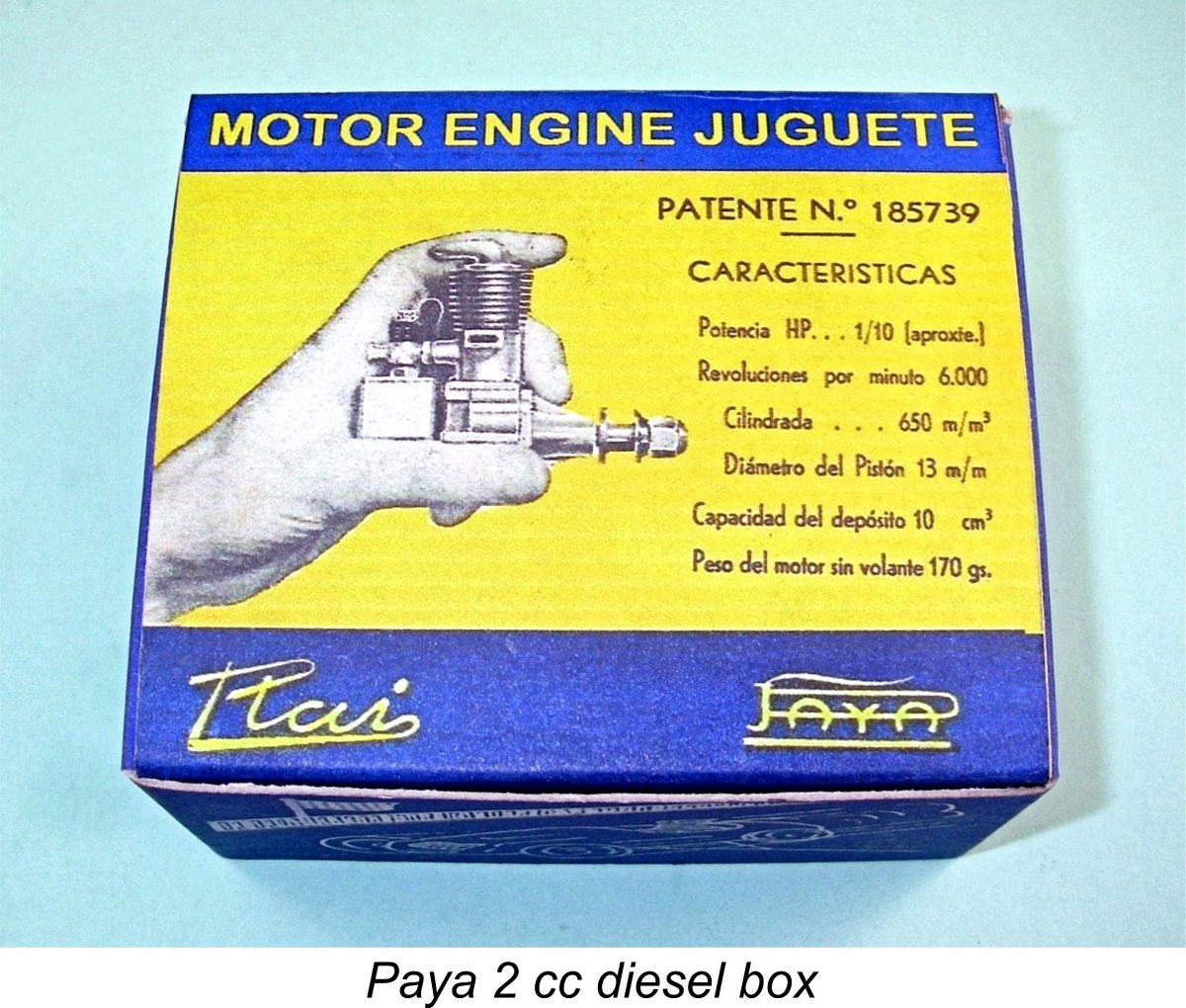

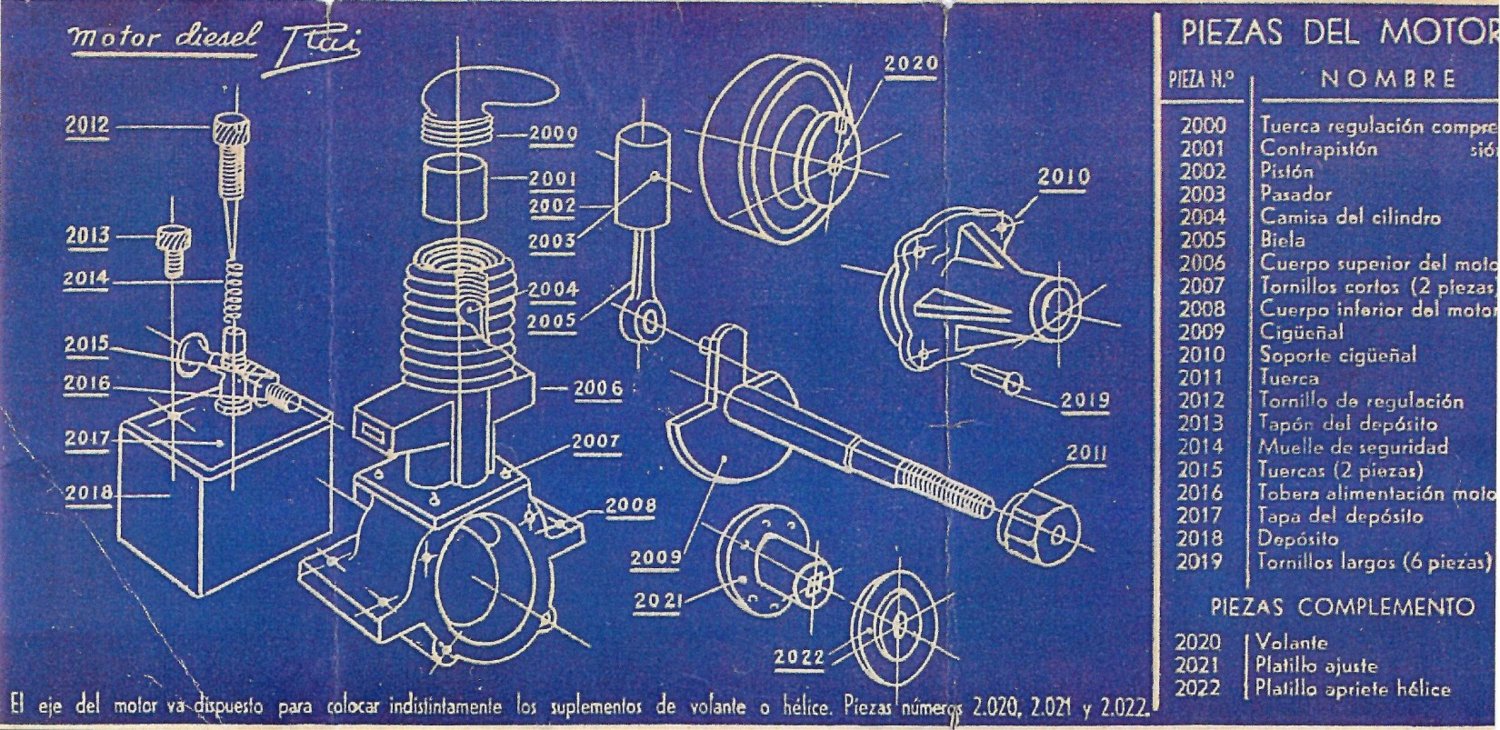

Don Diego was clearly persuaded. Accordingly, the trio of students went ahead and drew up a design which was in effect a slightly re-styled version of the E.D. model. This design effort seems to have been undertaken on the basis that it would count for scholastic credits on the Academy records of the three midshipmen. By late 1947 or possibly early 1948 the design was completed, and a small batch of model diesels built to this design were produced by Don Diego. The resulting 2 cc diesel engine was initially called the ICA 2 cc diesel. It was previously assumed that these must be the initials of the three designers, but this notion has now been conclusively disproved. The design was the subject of a Spanish Patent application in the names of the three designers, Don José María Moreno Aznar, Don Alberto Figaredo Sela and Don Saturnino Suanzes de la Hidalga. Thanks to the efforts of José Manuel Rojo and his father, we now have access to a copy of the Patent in question, which may be viewed here. Interestingly, the three applicants gave their joint address as that of the Marin Naval Academy at which they were enrolled, seemingly confirming the suspicion that the application was submitted in support of the applicants' claims for scholastic credit at the Academy. Regardless, in no way can we get the letters ICA out of those names! The basis for this model identification therefore remains a complete mystery. The Patent was finally issued on October 27th, 1948 in the joint names of the three applicants with the Patent number 185739. Given the significant lead time typically required for the consideration of any Patent application, it's clear that the application itself must have been submitted in early 1948 following the completion of the original ICA design. All examples of the engine produced after October 27th, 1948 carried the relevant Patent number 185739 stamped onto the rear face of the exhaust stacks. It's hard to consider this Patent as anything other than a sham - it contributes absolutely nothing new to the technology of model diesel engine design and construction, being primarity a description of the well-established model diesel design and operating principles which had been under active development since the 1930's and had been very well documented in the International modelling press prior to 1948. It must surely have been taken out purely in support of the applicants' academic credits.

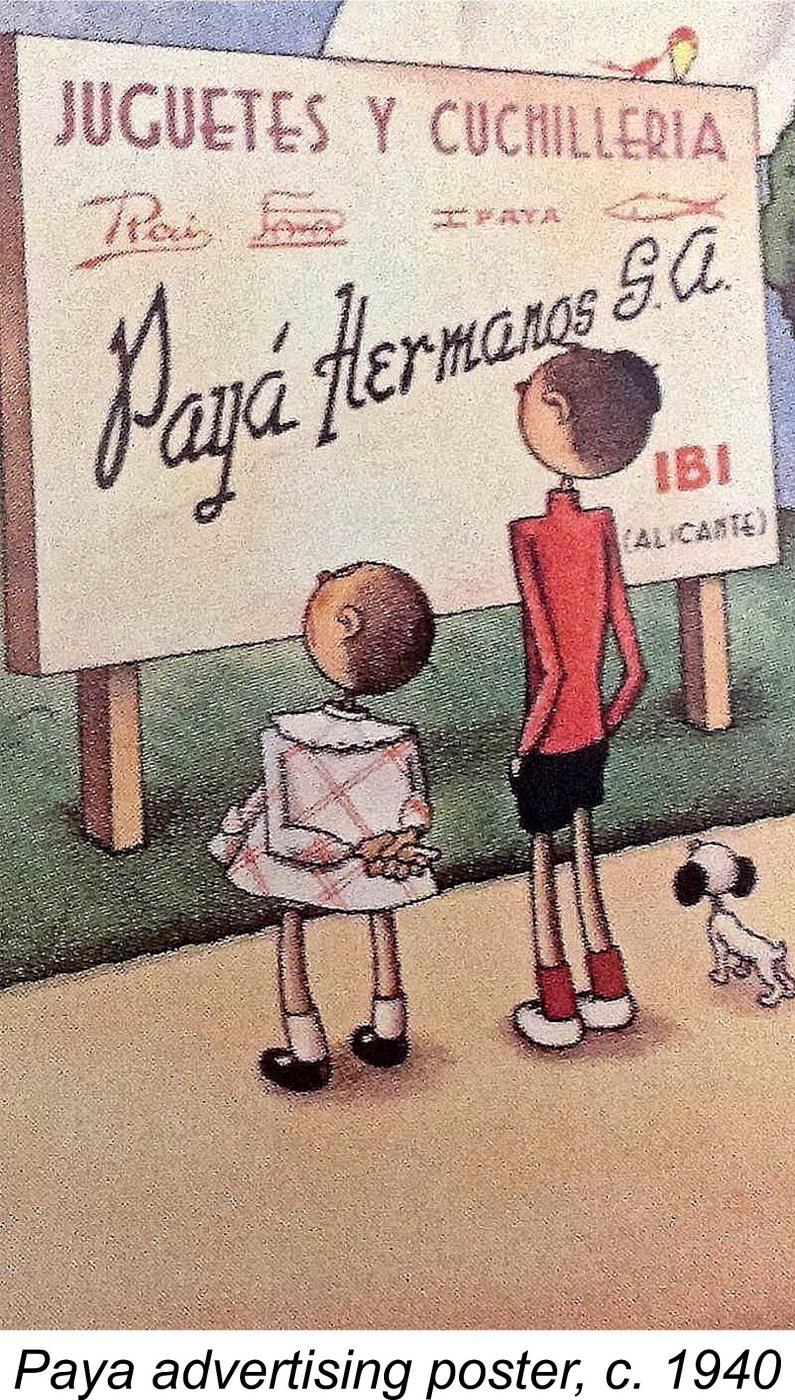

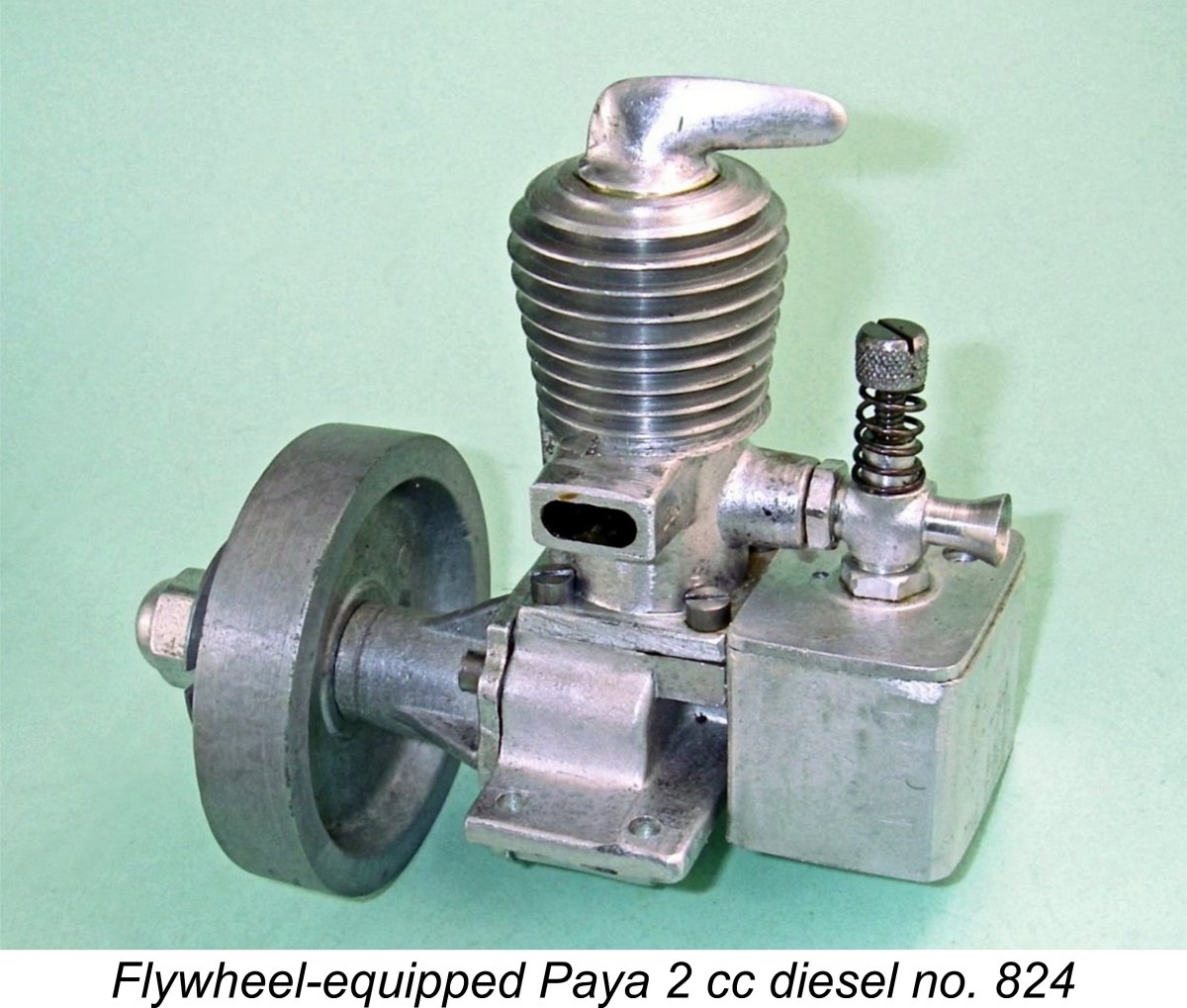

Having been initiated by a group of marine officer candidates at the Naval Academy, and being produced by a manufacturer of full-sized marine diesel engines, the ICA diesel had naturally been designed from the outset as a flywheel-equipped marine powerplant. The drawings which accompanied the Patent application confirmed as much. However, we are told that a number of examples of the completed engine were converted to aero configuration by members of the previously-mentioned Pontevedra Aeromodelling School, where they were used quite successfully. After all, model aero engines were in very short supply in Spain at the time in question - any engine that would start and run reasonably well would be in demand. Carlos Pazó Olmedo notes that although the engines performed well enough in aero service, they could not compete with units from other countries due to their having been designed primarily as boat powerplants, with good torque at low revs accordingly being the priority and the relatively high weight not being seen as a design issue. To modern eyes, a displacement of 2 cc appears to be something of an anomaly. However, engines having displacements of 2 cc or thereabouts were actually quite common at the time in question, although they became relatively less so in later years. Well-known contemporary examples included the Swiss Dyno and its many derivatives; the Italian Delta 2 and MOVO D2; the American Micro Diesel and the British Aerol Gremlin, Majesco "22" and E.D. Mk. II among many others. Electronic Developments (Surrey) Ltd. (E.D.) released the 2 cc E.D. Mk. II in early 1947 as their first commercial model diesel. It’s abundantly clear from the architectural evidence that the design of the ICA 2 cc While all of this was going on in the model engine design and manufacturing field, another Spanish company had been in the process of resuming business as usual following the various conflicts which had swept across Europe and the rest of the world during the previous decade. This was the famous Payá Hermanos (Payá Brothers) toy company which had its beginning as far back as 1902. In that year, a local tinsmith, Rafael Payá Picó, had set up a factory in Ibi, a town in the south-eastern Spanish province of Alicante, to produce sheet metal products as well as to undertake metal foundry work and the repair of metal musical instruments. In the same year, three of his sons, the Payá brothers Pascual, Emilio and Vicente, began to apply the facilities of this factory to the small-scale production of metal toys. The response to this venture was sufficiently encouraging that in 1905 Rafael Payá Picó sold the business to his three sons, who formed a new company called Payá Hermanos S.A. (Payá Brothers plc.) specifically to participate in the toy-making industry.

In 1910 the Payá brothers began to produce high quality painted tinplate sheet metal toys. They focused initially on model cars, which from the outset were of comparable quality to those from well-known international manufacturers. From this point onwards the company and its products made regular appearances at the major national and international toy fairs, often securing awards at such events thanks to the excellent quality of their toys.

During the Spanish Civil War of 1936–1939, the Payá Hermanos company was nationalized and became dedicated to the manufacture of fuses and ammunition. Following the conclusion of that conflict, the business was returned to its previous owners, who resumed toy and model train production since Spain was not involved in WW2 as a combatant. The company was among the first Spanish manufacturers to make extensive used of plastic mouldings and die-casting in the production of toys. At some point in time, one of Pascual Payá’s sons, Raimundo by name, established his own brand called Rai (the first three letters of his given name). However, he appears to have maintained a close relationship with the original Payá Hermanos company all along - his Rai brand-name continued to be directly associated with that of the parent company, as seen in the promotional image reproduced at the left. We shall encounter it again later in this narrative. The Payá Hermanos company was always on the look-out for new product lines. It was this constant search for innovations that was eventually to lead them to become involved with model diesel engines. The Payá 2 cc Diesel Arrives In late 1948, the three individuals who had applied for the previously-discussed Patent relating to the ICA 2 cc diesel decided that the best way to enhance the engine's marketing prospects would be to bring it to the attention of an established company having a well-developed national marketing capacity along with an established connection with model manufacture. The Payá Hermanos company fit the bill perfectly. Accordingly, the ICA marketing trio made contact with Payá Hermanos to bring the ICA diesel to their attention. This contact resulted in a decision by Payá Hermanos to develop a range of ready-to-run model boats which were to be powered by the ICA diesel. The production of the boats themselves was well within the company’s capabilities, but they recognized that the manufacture of model diesel engines was an exercise which lay well beyond the limits of their existing in-house expertise. However, that was already in other better qualified hands.

However, for reasons which remain open to speculation (of which more below), the model boat project was abandoned before any completed boats reached the market. This of course left Payá Hermanos holding 2,000 unused model diesel engines for which they had already paid and which they now wished to sell. To their credit, Payá Hermanos went about this task in a very business-like and above-board fashion – no off-hand disposal of unwanted stock under the table in plain brown bags here! The engines were very enticingly packaged in sturdy and eye-catching multi-coloured printed cardboard boxes. Each engine was accompanied by a very well-presented full-colour However, the company recognized the fact that the engines might well find many buyers in the aeromodelling field. Indeed, the image of the engine on the box lid showed it in its aero form. In anticipation of such a demand, Payá Hermanos quickly developed and offered optional parts (prop driver and prop washer, component numbers 2021 and 2022) to convert the flywheel-equipped engines for model aircraft use, also making available a matching moulded plastic airscrew. They even supplied ready-mixed fuel under the “Carburin” brand name. Two formulas were available - Carburin 1 for break-in and Carburin 2 for normal use. It appears that Raimundo Payá’s Rai brand was very closely associated with the model engine venture. Raimundo's stylized Rai logo appeared prominently both on the box labels and in the instruction sheets along with the Payá logo. In fact, both the instruction leaflet and the parts list that formed part of that leaflet actually identified the engine as These references raise the possibility that the correct name for the engine is the Rai 2 cc diesel. The original ICA name obviously has a strong claim as well, but the engine was never referred to as such by Payá Hermanos. The engine is now so generally referred to in Spain and elsewhere as the Payá 2 cc model that I won't challenge that designation unless someone gives me a very good reason to do so. As a result of the above chain of events, many of the 2,000 flywheel-equipped engines seem to have eventually found owners, some of whom doubtless converted them to aero use. A fair number of them survive today, including a sizeable batch of unused and boxed New Old Stock examples. However, they don’t seem to be all that common outside of Spain. There must surely be a number of the original ICA models out there as well, but I have no information regarding whether or not they are distinguishable from the units marketed by Payá Hermanos. I suspect (but cannot prove) that they would likely be distinguished by the absence of any stamped-on reference to Patent no. 185739. Thanks to the kindness of my friend and colleague Jesus Ortega Delgado, I’m in possession of my own original New-In-Box examples of this engine, which have been fitted with aero prop mounting components so that they can be bench-tested. We’ll get to that, but first it’s time for a description. Description

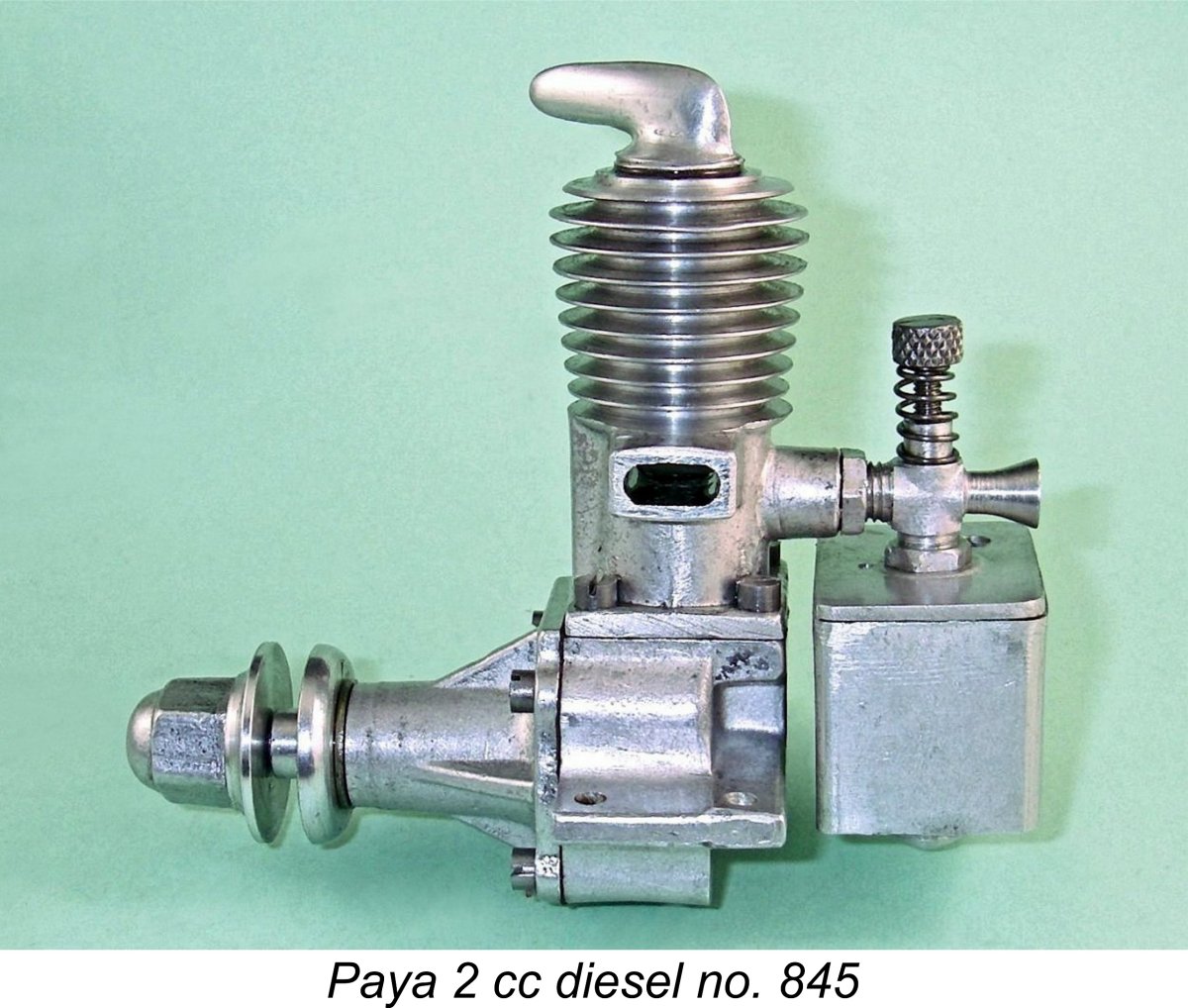

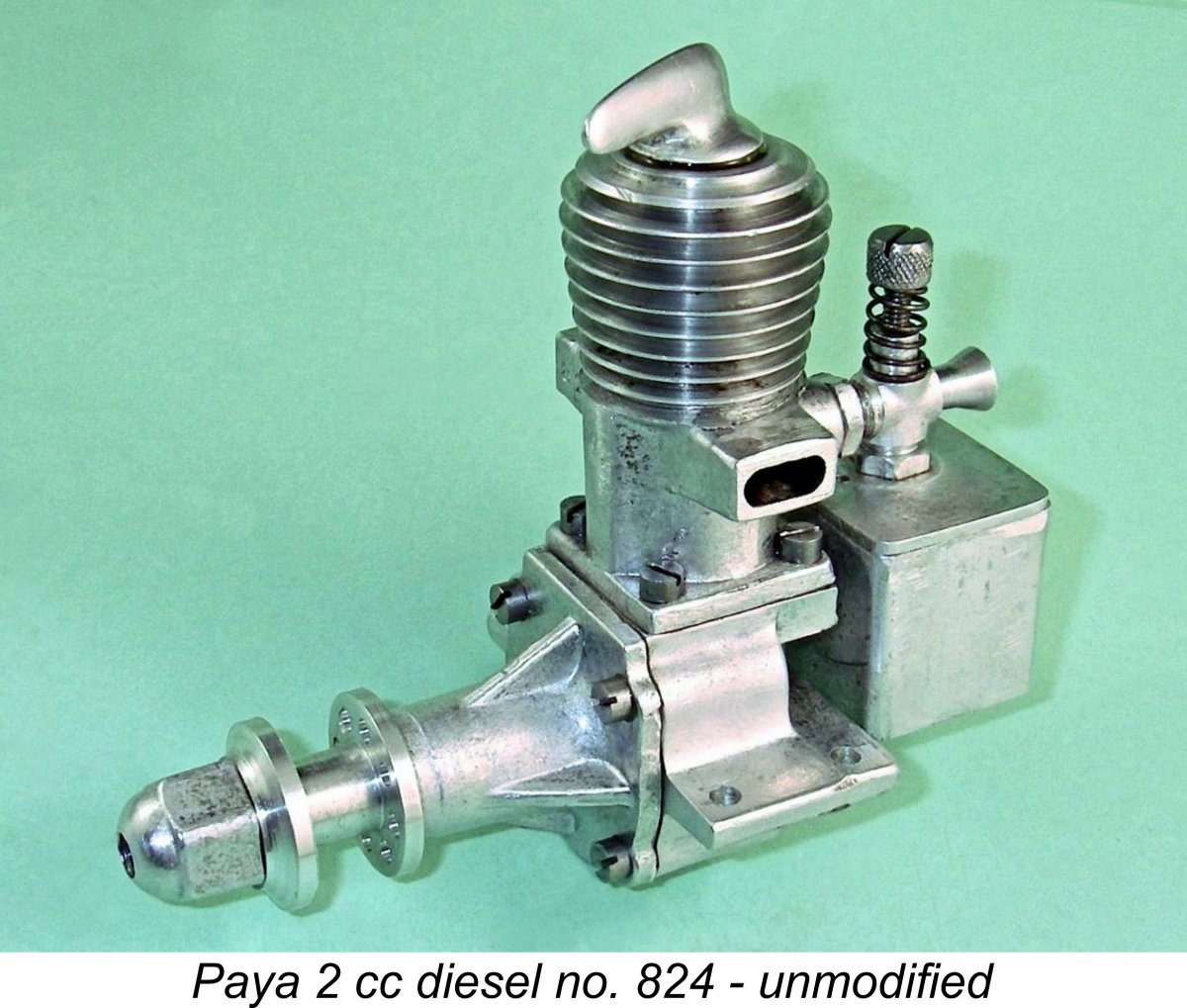

The visible differences between the Payá and the E.D. Mk. II actually create an illusion that the two engines are more different than they are in reality. To take just one example, the fact that the Payá sports integrally-cast exhaust stacks doesn’t alter the fact that the Payá imitates the E.D Mk. II in having two exhaust stacks to begin with – they’re just executed differently. We’ll find many other examples as we continue. We may as well begin with the tale of the tape. The Payá features bore and stroke measurements of 13.0 mm and 15.0 mm respectively for an actual calculated displacement of 1.99 cc (0.1215 cuin.). Both of these dimensions are in essence a metric rounding-off of the corresponding figures of 12.70 mm and 15.87 mm for the 2.00 cc E.D., although the Payá is a slightly less long-stroke engine. The Payá weighs in at 316 gm (11.15 ounces) in its more common marine flywheel-equipped form, while the aero version tips the scales at a still healhy 175 gm (6.17 ounces) with tank, exactly the same as the E.D. Mk. II. The company claimed an approximate output of 0.10 HP, with a maximum operating speed of 6,000 rpm. My own previous tests on an original E.D. Mk. II of somewhat later design configuration implied a rather more modest output of around 0.080 BHP @ 6,700 rpm for that model. I would be extremely surprised if the Payá actually matched the manufacturer's claim, but there's no need to speculate - we'll let the engine speak for itself in a later section of this article.

Both models used a surface jet needle valve with a coil spring to provide tension for the externally-threaded needle. The major departure here was the fact that unlike the E.D., the Payá lacked any kind of fuel cut-out for timing the run. Given its primary intended application for use in model boats, this was an entirely understandable omission. It would be logical to assume that the trainee designers at the Naval Academy would have had boats very much in mind when they developed the engine! Another feature which attracts notice in connection with the induction arrangements is the fact that the venturi (which is machined from a casting) is attached to the crankcase with a male thread on its delivery end which engages with a female thread in the mounting boss at the rear of the cylinder casting. It is held in position with a lock-nut which bears against the end of the mounting boss.

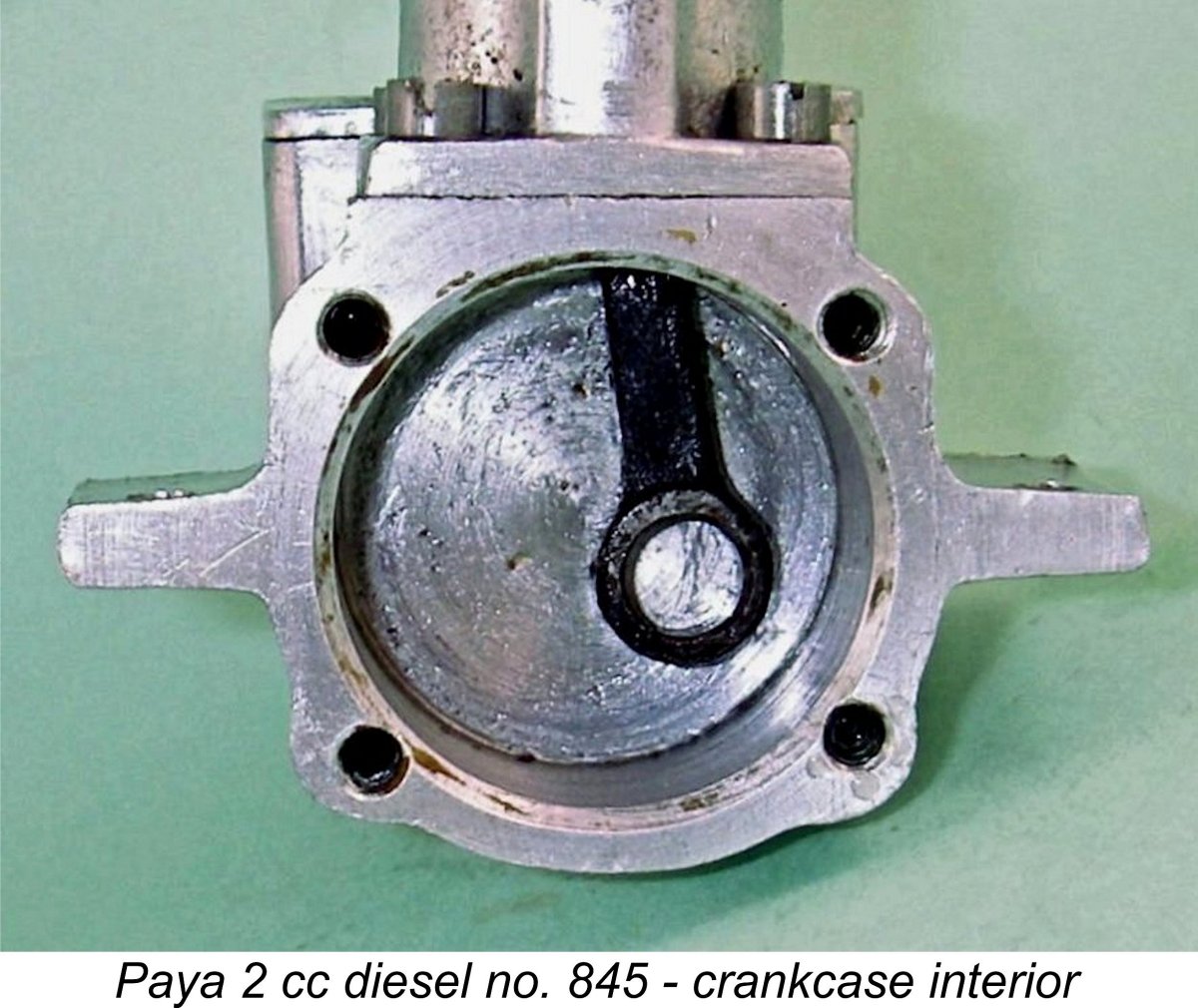

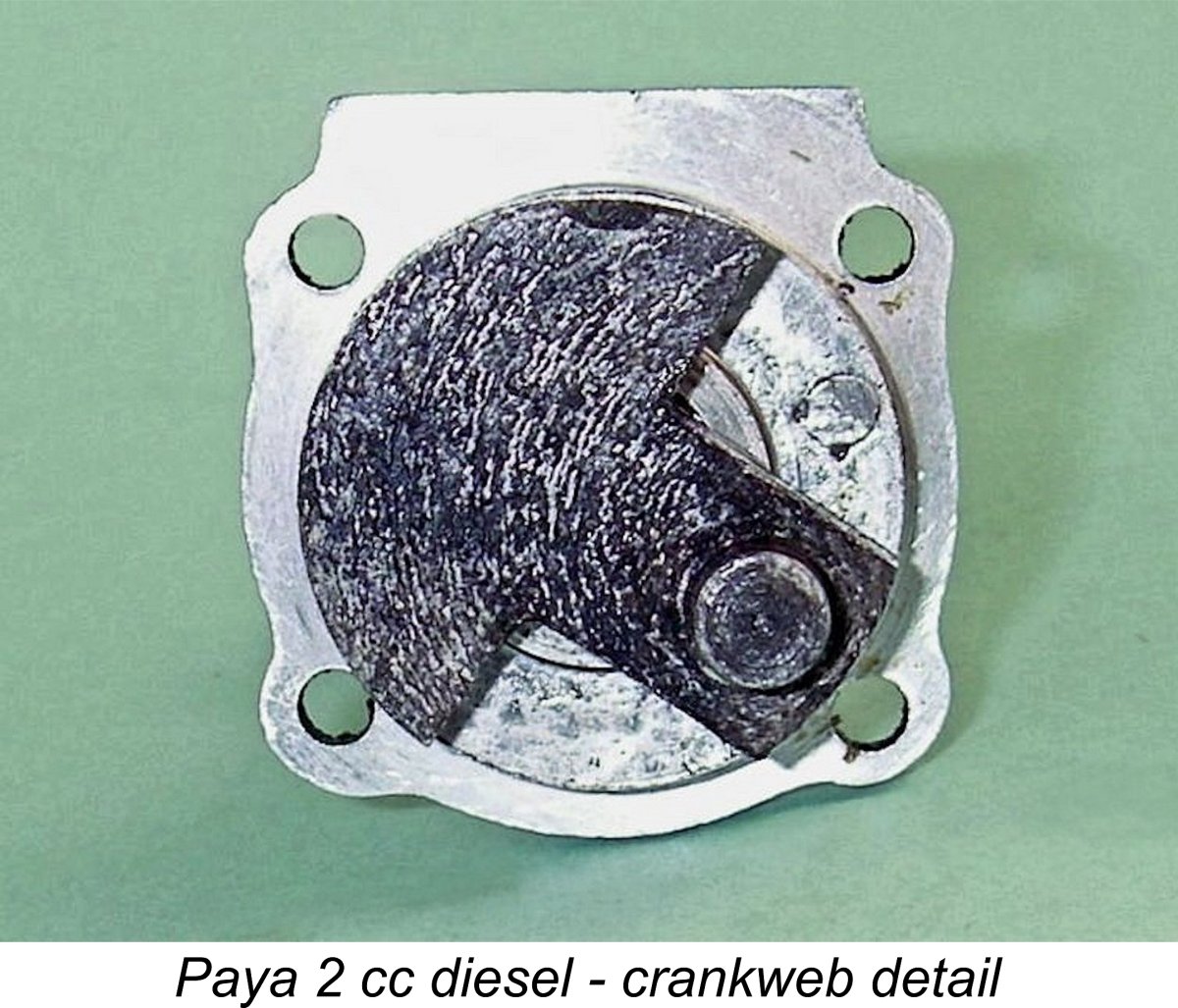

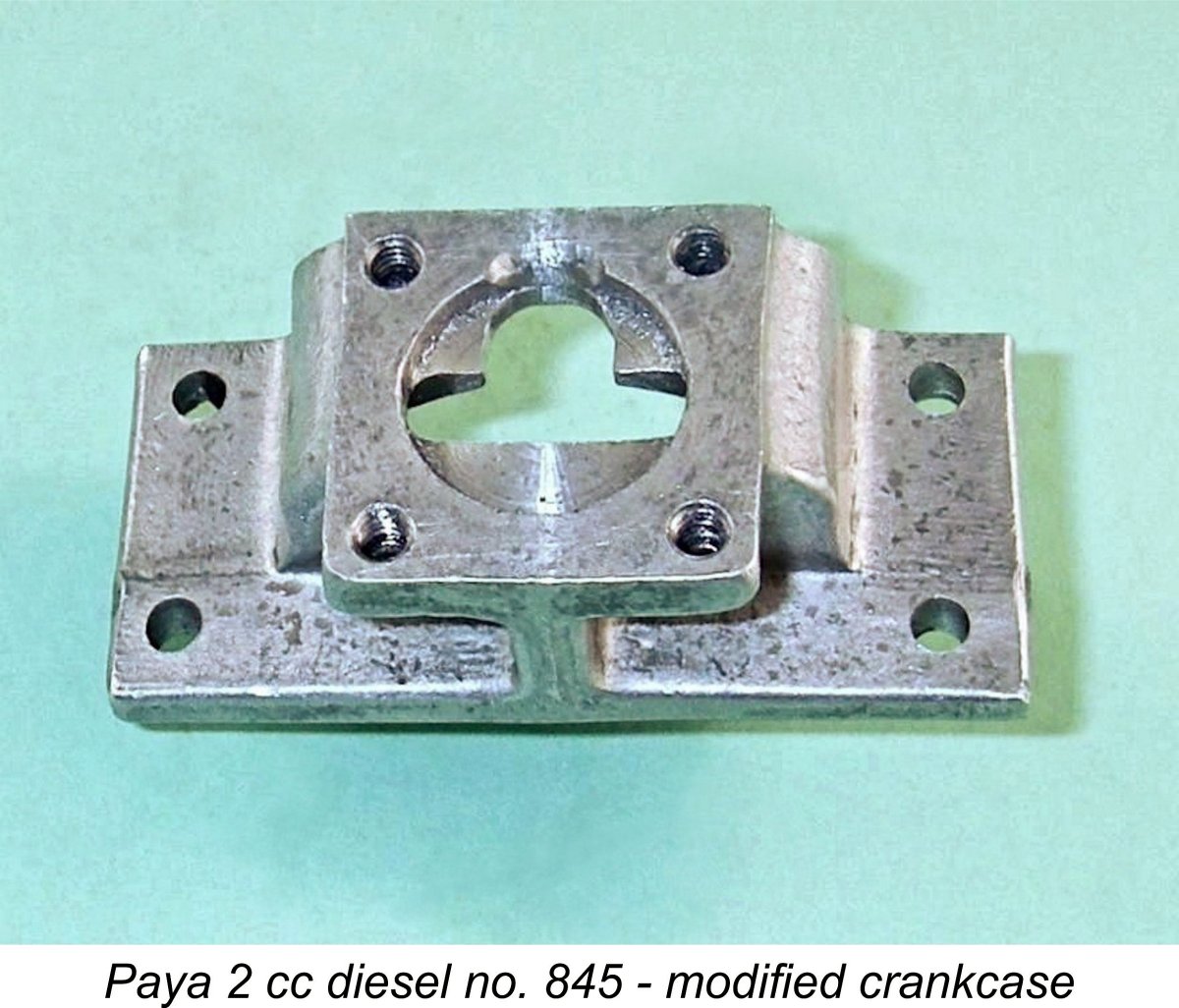

The main crankcase and detatchable main bearing housing of the Payá are virtual clones of the corresponding components used in the E.D Mk. II. Both are gravity die-castings of very good quality. Moreover, the well-finished one-piece hardened steel crankshaft is virtually identical to that of the E.D., having the same kind of heavily counterbalanced crankweb and an identical square section at the front to key the prop driver or flywheel. The main difference here is that the Payá shaft runs in a very well-fitted plain bearing formed directly in the material of the front housing, as opposed to the more durable cast iron bushings used in the E.D.'s main bearing. The Payá conrod is also a little different, being a rectangular-section steel forging as opposed to the turned steel component used in the E.D. However, that is a relatively minor difference – the materials are the same. If anything, the Payá's rod appears to be the more sturdy of the two. Its big and little end bearings are very closely fitted to their respective pins.

A further E.D. related feature is the fact that gas access from the crankcase to the lower bypass is achieved through the use of a port in the front of the lower piston skirt which aligns with a corresponding port in the cylinder wall at bottom dead centre. This port provides gas access to the base of the integrally-cast bypass passage, with a second cylinder port directly above at the top of the bypass serving as the actual transfer port. Again, this precisely mirrors the arrangement used in the early variants of the E.D. Mk. II, although its execution in the case of the Payá leaves something to be desired, as we shall see in due course. It's very important here to note the fact that while all of these features certainly originated with the E.D. Mk. II, the flat topped piston with no deflector step was only used by E.D. until May 1947, while the piston port gas entry into the lower bypass only survived until July of that year. The narrow slot in the upper crankcase through which the original Mk. II’s conrod operated was supplanted in August 1947 by a more open configuration to improve gas access to the bypass from the lower crankcase. We already noted the use of a male thread on the intake venturi, which only survived on the E.D. until June 1947. All of these dates are confirmed through an analysis of E.D. serial numbers, which date a given engine down to the month of production. My good mate Kevin Richards was primarily responsible for undertaking this analysis. Taking all of these observations together, it’s apparent that the designer(s) of the ICA (aka Payá) 2 cc diesel must have used a very early example of the E.D. Mk. II as their design template. Any example of the E.D. product which combines the features of the male venturi installation thread, the narrow conrod slot, the piston port bypass entry and the flat topped deflectorless piston must date from no later than May 1947. It seems that the designers of the original ICA model were quick to get their hands on an E.D. Mk. II following its February 1947 release!

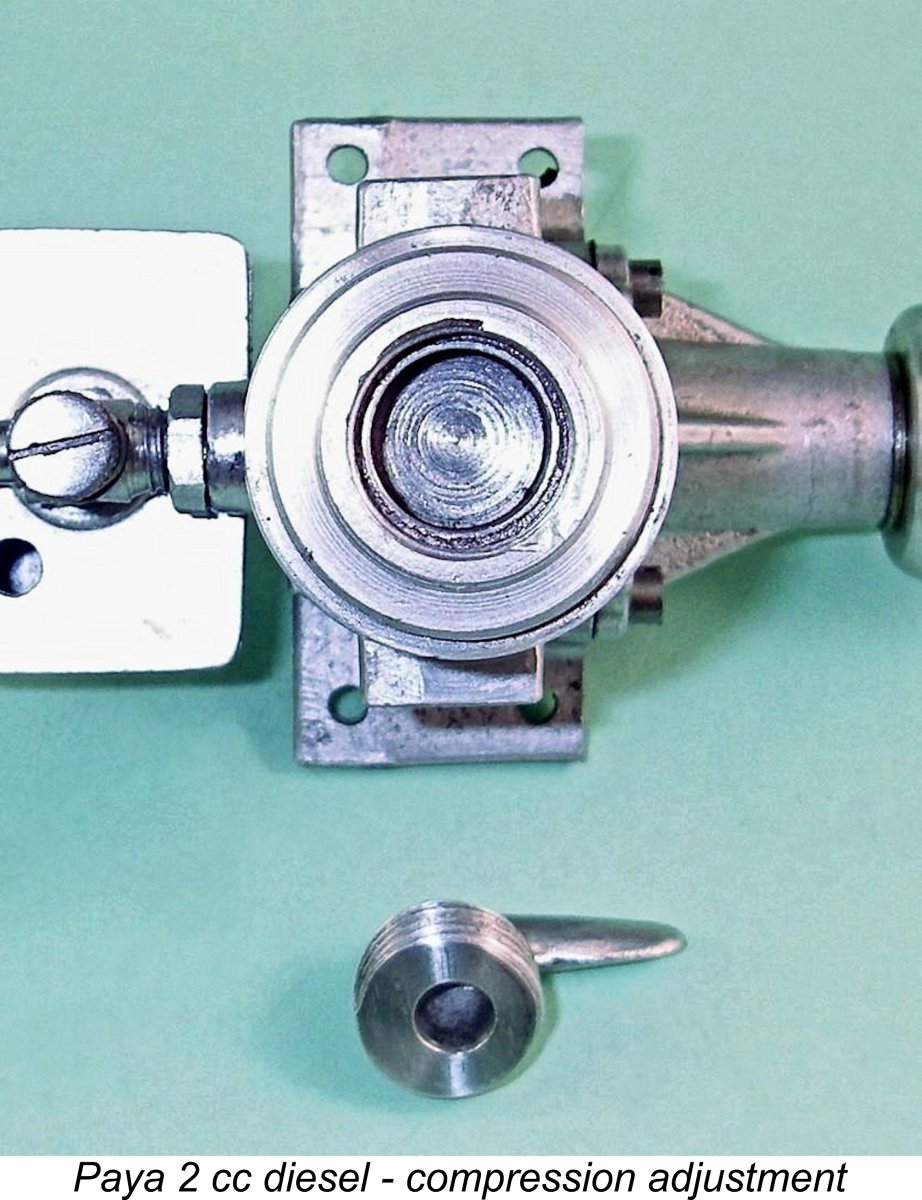

Here once again, the very different structural styling of the Payá obscures the fact that in reality it’s an almost identical design to the E.D. The steel cylinder liner is heat-shrunk into a cast and machined light alloy jacket as opposed to being externally threaded to accommodate a screw-on cooling jacket as in the E.D. However, the cylinder porting design is identical. The two exhaust stacks are formed as part of the upper cylinder casting, but their arrangement precisely imitates that of the Mk. II regardless – they’re just executed differently (and, it must be said, far more securely). Like the E.D., the Payá features a relatively long contra-piston, once again of hardened steel. In both designs, the upper edge of this component protrudes above the top of the steel cylinder liner. In the case of the Mk. II, compression adjustment is achieved through the use of a moveable female-threaded cooling jacket which engages with a fine-pitched male thread on the outside of the In the case of the Payá, this arrangement is effectively turned inside out. Compression adjustment is achieved through the use of a cast alloy compression screw component which is externally threaded to engage with an internal thread in the upper cooling jacket. However, it still bears upon the protruding upper circumference of the contra-piston, thus in effect being an “inside out” rendition of the E.D.’s “moving head” compression adjustment system. Once again, the same basic design, just executed differently. The Payá system is certainly cheaper - no penny required! In practical terms, it has to be admitted that the system used in the Payá is rather poorly thought out. The 18 TPI thread is very coarse and the level of friction arising from the large-diameter thread extremely high. Moreover, the combination of light alloy on light alloy is not a recipe either for smooth operation or long thread life. Unless the contra piston is a relatively easy fit in the bore, operating friction can actually prevent any increase in compression. As we'll see in a later section of this article, I had to relieve the contra piston fit in the illustrated example to gain control over the compression setting – prior to my doing that, it was impossible to increase compression at all, even when the engine was not running. Peter Valicek had to do the same with his example, while even Jesus Ortega Delgado experienced some difficulty. It's quite possible that such problems were far from uncommon with these engines. More of this issue in its place below. Mention of having to relieve the contra piston fit, which necessitated the dismantling of the unit, brings me to a few important points relating to the engine’s assembly. No fibre gaskets are used at any point – instead, the engine is assembled using some kind of silicone-like sealing compound. While very effective in ensuring a good crankcase seal, this material unfortunately sets quite firmly over time, making the dismantling of the 70 year old engines highly problematic. I found it necessary to heat the entire engine in the oven, and even then it took some effort to shift the components. Naturally, I cleaned out all the “glue” and made thin paper gaskets for reassembly, which would alleviate any difficulties should dismantling again become necessary in the future (as it did - read on!!). The components were very well made and fitted - it was just the sealing compound which made them so challenging to remove, on this example at least. Another point worth mentioning is the fact that the steel cylinder liner is heat-shrunk into the upper cylinder casting, along with more of that dratted sealing compound. I suspect that the final finishing of the bore must have been carried out after this was done, otherwise distortion problems would almost certainly have resulted. Do not try to remove the liner from the jacket – it’s in there for keeps, and damage will inevitably result. It’s worth noting that the factory parts list showed the cylinder liner and jacket as a single factory assembly (part no. 2006).

Since all of the engines marketed by Payá were made after October 27th, 1948, they all bore a stamped-on reference to Patent no. 185739. We've previously seen that this Patent represented no previously-unused technology whatsoever, leading us to question its validity. it's possible that Spanish patent law allowed for the granting of a Spanish patent for technology previously developed elsewhere provided that technology was not already covered by a worldwide patent. Other countries such as New Zealand had patent laws of this kind. Such a patent would only be valid in the issuing country, in this case Spain. Anyway, there we have it! The Payá 2 cc diesel (or Rai diesel/ICA diesel, whichever is correct) is functionally a very close copy indeed of the original E.D. Mk. II from May 1947 or earlier. Its styling obscures this fact to a significant degree, but under the skin it‘s virtually the same engine. The general quality of manufacture is also quite comparable with that of the E.D., the too-tight contra piston notwithstanding. This being the case, we would expect the Payá to deliver a steady and dependable if unspectacular performance very similar to that of the early E.D. models. Let's find out to what extent expectations match reality! First Encounters on the Test Bench - Operational Difficulties It must be stated for the record that the testing phase of this review got off to a very poor start! Even before I got as far as mounting the Payá in the test stand, I noted the first of a number of issues which clearly required attention. When the engine was turned over by hand around bottom dead centre there was a certain "scratchy" feel to it, as if the free movement of the components was being temporarily interfered with. In my long experience, this most commonly indicates that the conrod is coming into contact with some other part of the engine and is momentarily “hanging up”.

It turned out that the problem was being caused by the presence of substantial machining burrs protruding from the rear edges of the heavily counterbalanced crankweb. These had been catching the front edges of the conrod in the lower part of the stroke as it swung across the counterbalance, causing it to hang up periodically. I removed the burrs and replaced the housing, using a paper gasket to ensure a seal without compromising any future dismantling of the engine. The Payá now felt really good when turned over. The next problem presented itself after the engine was mounted in the test stand with a 10x4 APC prop fitted. My very experienced starting finger told me that the compression setting was a little higher than required for starting. As usual in such cases, I backed off the comp screw, injected a small amount of fuel and flicked the engine over. It fired immediately, but the contra piston did not shift at all. It was obviously either fitted way too tightly or had somehow acquired its own share of that dratted sealing compound. Either way, the cylinder assembly undoubtedly had to come off. As with the front housing, it took a healthy combination of heat and brute force to shift things, but eventually I was successful. Once the cylinder was off, it was a matter of pressing the extremely tight contra piston out of the top of the bore. Based upon the level of effort required, it was clearly fitted far too tightly - I had to use the lathe tailstock as a screw-press. Once I finally had it out, I lapped some 0.0003 in. off its external diameter and re-fitted it, having considerably less trouble in doing so than I had experienced pressing it out. It was still pretty tight, but at least it moved.

Upon reassembly, I found that the comp screw would now push the contra piston down fairly smoothly, although it still took far more effort than I would normally consider desirable. The one upside that I could see was the extreme improbability of having any difficulties with compression run-back during operation! At this point, my good friend Jesus Ortega Delgado suggested a very practical remedy for this problem, which he also experienced. If you have access to a lathe, it’s quite easy to make a steel insert which fits below the comp screw and re-directs its force from the upper circumference of the contra piston to its centre. This significantly reduces the cumulative level of friction which is inherent in the original system. I took the time to make such an insert, which proved to be quite effective in use. One issue pointed out by Jesus was the fact that the contra piston base is very thin, presumably due to the designer's expectation that compression increases would be achieved through pressure on the top of the contra piston's outer wall rather than by central pressure on the base. Jesus thought it prudent to fit a suitably-sized steel shim inside the contra piston to reinforce it against the central pressure exerted by the steel insert. Sound advice, which I followed.

With its comp screw insert installed, the now supposedly functional engine went back into the test stand for another attempt to run it. To further improve the operation of the comp screw with its steel insert, I shot the entire top end above the contra piston full of molybdenum disulphide anti-seize compound, paying particular attention to the thread, which now generated most of the remaining friction. The control now worked quite smoothly, albeit still far more stiffly than one is accustomed to.

The symptoms were exactly the same as those that you'd encounter if you tried to start a diesel with the backplate removed, thus eliminating crankcase compression and preventing the bypass from functioning. The engine never produced anything approaching the kind of firing burst that would bring the fuel supply system into play, so this was definitely not a fuel system issue. For me, this was a pretty clear indication that the bypass and transfer ports were not doing their job properly. For an engine to pick up to the point at which it will draw fuel from the tank and thus keep running, that first flicked firing stroke has to be quite strong. The engine was behaving as if it wasn't getting enough fuel mixture up into the cylinder after that first flick to allow it to keep going and pick up speed to the point where it could draw mixture in through the induction system. I checked and re-checked the crankcase and intake for leaks, finding none. The head compression seal was more than adequate as well. So how could it be that the engine wouldn't run? To investigate further, I tore the engine down yet again. I first checked that the bypass passage was unobstructed, finding that this was the case. However, I remained convinced that this was a bypass problem. I therefore checked the registry between the piston skirt port and the lower bypass entry port. Aha - it turned out that this might indeed hold the answer! I found that the piston port only began to uncover the lower bypass entry port shortly after the transfer port first opened. This of course is a guaranteed recipe for poor bypass function. Until the lower bypass entry is opened, the bypass passage is isolated from the crankcase and is not becoming pressurized in advance of the transfer port opening. So when the upper transfer port first opened, the Payá's bypass passage was un-pressurized. For proper function, it obviously needs to be fully pressurized prior to the opening of the transfer port to begin driving the transfer process immediately. To make matters worse, the fact that the lower bypass entry port is only partially open for much of the cycle creates a significant impediment to the free low of mixture into the bypass and thence up through the transfer port, particularly at the crtical opening stage.

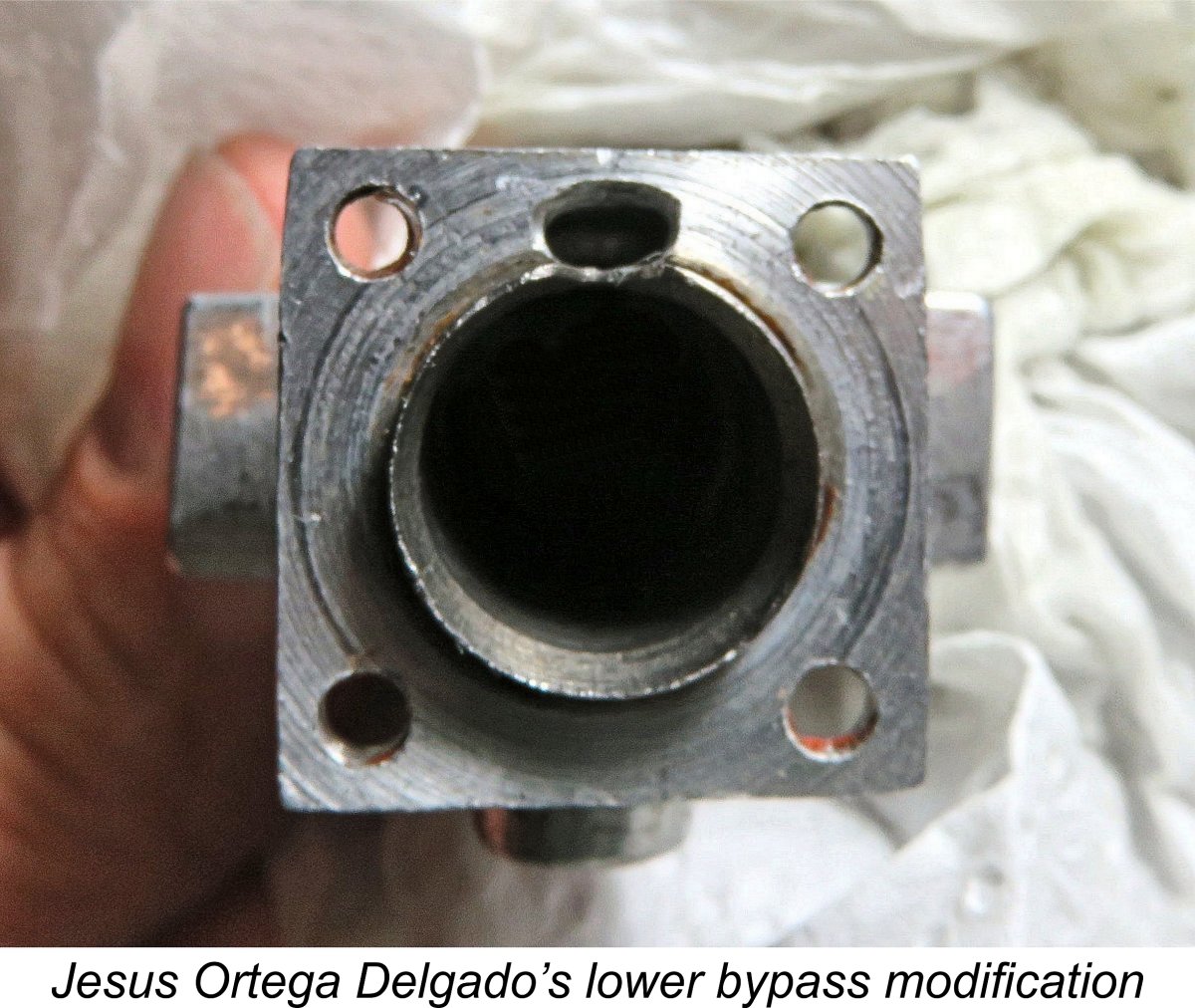

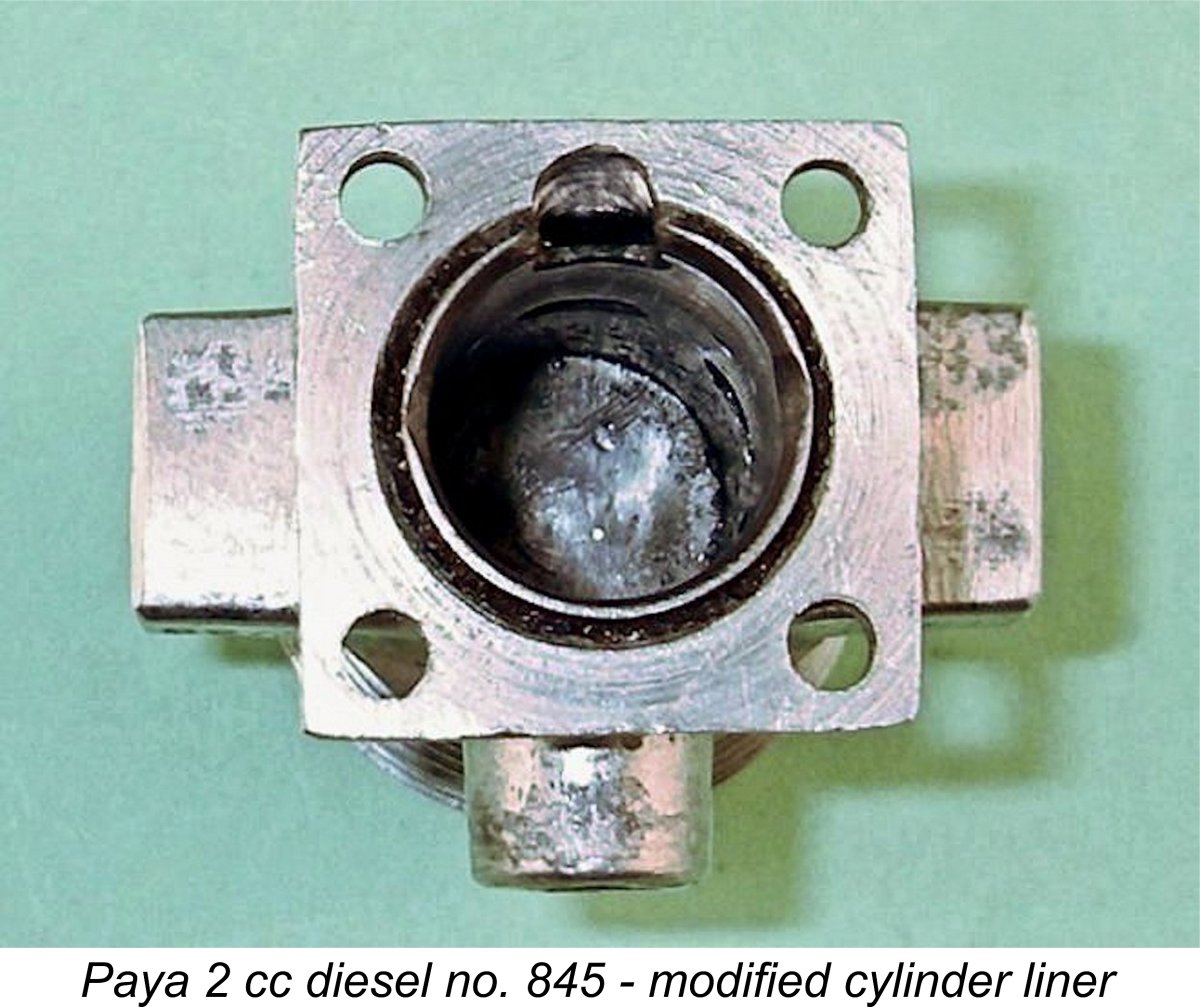

Fortunately, there's a simple fix for this problem, which I immediately applied to my engine. Using a hand-held Dremel Moto-Tool with a suitable small-diameter grinding bit, I extended the piston skirt port downwards to arrange matters so that the lower bypass entry port in the cylinder wall is fully exposed by the time that the upper transfer port just begins to open. What's more, the bypass entry port now renains fully exposed throughout the entire transfer cycle. This simple modification should do much to improve gas flow through the bypass system, something which in my judgment the engine sorely needed. I admit that this issue may have been an incidental problem with my particular engine, perhaps as a result of a machining error. However, there it was, and it definitely required attention. While I was at it, I also added a very small 45 degree chamfer at the front of the piston crown. This is visible in the above image. It had the effect of very slightly advancing the opening of the transfer port, which I figured the design could accommodate. However, the main reason for While I was engaged in making these modifications, my good friend Jesus Ortega Delgado was working independently on a different approach to improving gas access to the lower bypass passage, which he agreed was very necessary. Noting the relatively small thickness of metal between the base of the integrally-cast bypass and the mating surface of the cylinder installation flange, he drilled and then enlarged a vertical passage through the flange, thus in effect extending the bypass downwards all the way through to the mating surface of the flange. He then added a semi-circular opening in the base of the cylinder liner to establish communication between the chamfered annular space surrounding the lower piston skirt at bottom dead centre and the newly-created bypass access port.

Although I had already modified the piston skirt port in my example prior to learning of Jesus's approach to the problem, I reasoned that a further improvement in communication between the crankcase and the bypass couldn't hurt. Accordingly, I went ahead and followed Jesus's example by creating a similar port in the lower cylinder of my own engine. This was easily accomplished using a hand-held Dremel Moto-Tool with appropriate bits. Any competent modeller with a steady hand should be able to accomplish this without difficulty. I actually went further than Jesus - noting that there was almost no cylinder wall left below the standard bypass entry port after I'd made the required semi-circular opening though the lower cylinder wall at its base, I just went ahead and removed the entire cylinder wall below the port, effectively turning it into a bypass flute. The relatively thin cylinder liner is very well supported in the upper cylinder casting, so distortion should not be a problem.

My example (engine no. 845) must surely now have the best-supplied bypass passage of any Payá in existence, having both a fully functional piston port and a direct lower bypass entry. However, I have to say that the upper bypass passage itself is pretty skinny in cross section, to the point that it is almost certainly the critical factor in limiting the engine's performance as matters now stand. Another minor modification which I made arose from a suggestion by Peter Valicek. He pointed out correctly that the top edge of the piston was very sharp, hence possibly scraping the oil film off the cylinder walls. At his suggestion, I used a very fine diamond file to round off the edge a little. Good spot, Peter!

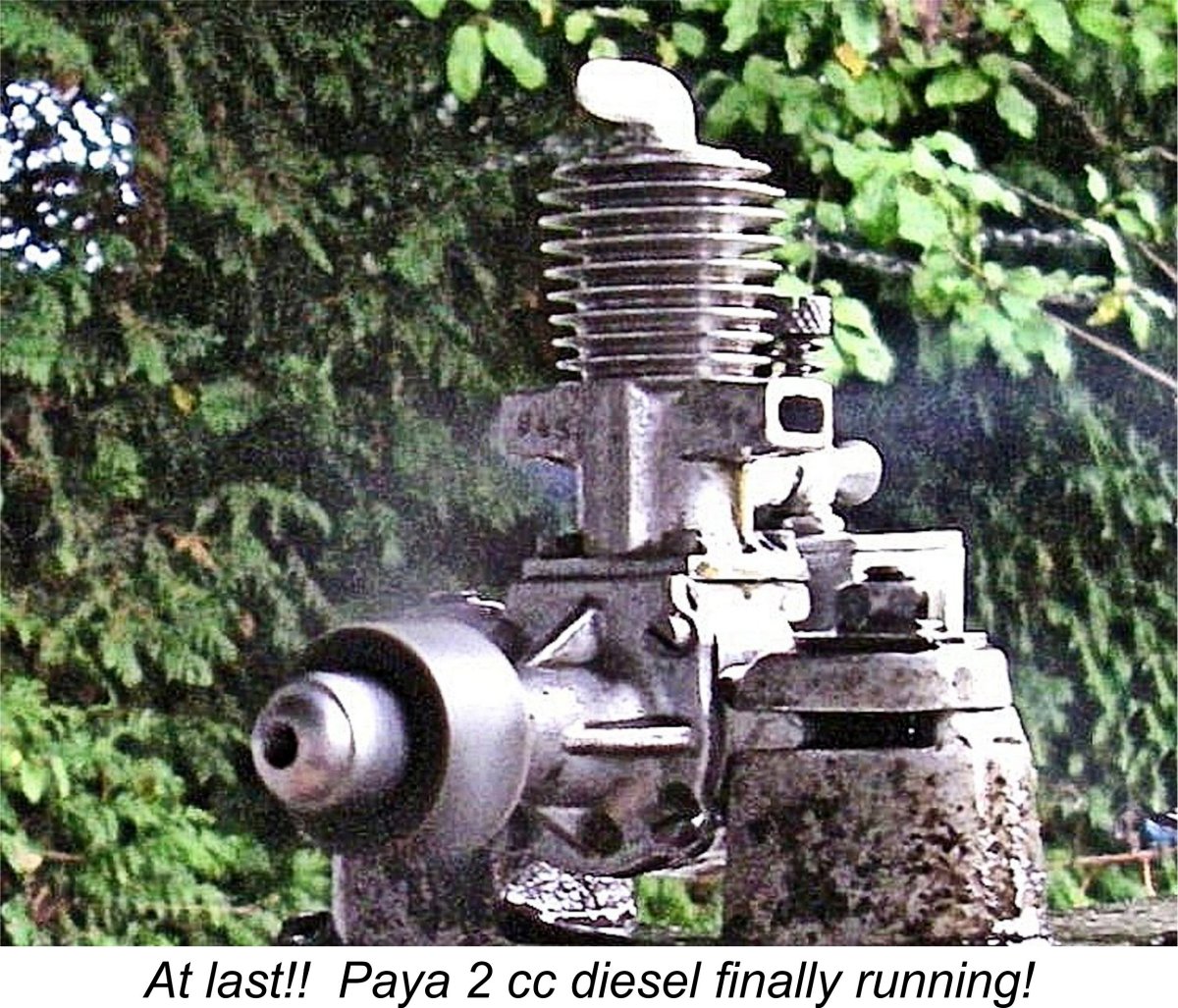

With these modifications having been made, I reassembled the engine once more and put it back into the test stand. This time, things went somewhat better - the engine was now clearly trying to start, which it wasn't doing previously. The problem now was that even with my contra piston insert fitted I had difficulty increasing compression sufficiently to "catch" the initial firing burst and keep the engine running - the system simply locked up due to the additional pressure-related friction resulting from the succession of firing strokes. It felt as if I still needed to relieve the contra piston fit somewhat. So off came the long-suffering cylinder YET AGAIN!! This time I was determined not to re-fit it until I was certain that the compression control was working properly. The threaded holes in the upper crankcase for the cylinder assembly screws can only take so many re-fittings .......... I took a further 0.0002 in. off the contra piston diameter, then re-fitted it and worked it in and out repeatedly for a while. It felt pretty good to me at this point, responding quite well to the comp screw even without the steel insert. I'd classify the fit as a bit looser than normal, but such a fit can be accommodated with a steel contra piston since they tend to stick in a hot steel bore anyway. Feeling that I could do no more, I re-assembled the engine for one final go at running it. Hope springs eternal .........! The Payá 2 cc Diesel on Test (Finally!!) Using a 10x4 APC prop to provide a good flywheel effect, I soon got stuck once more into the hitherto thankless task of starting what I had come to think of as the "pequeño bruto" (little brute). The Payá initially remained as unresponsive as it had been previously, firing somewhat unenthusiastically if at all despite my best efforts with the now-functional comp screw. However, it turned out that I had it too wet. The engine ultimately proved to be unusually sensitive to the amount of fuel in the cylinder – too wet, and it was reluctant to fire with any authority. I eventually found that just a little fuel in the cylinder was all that was required.

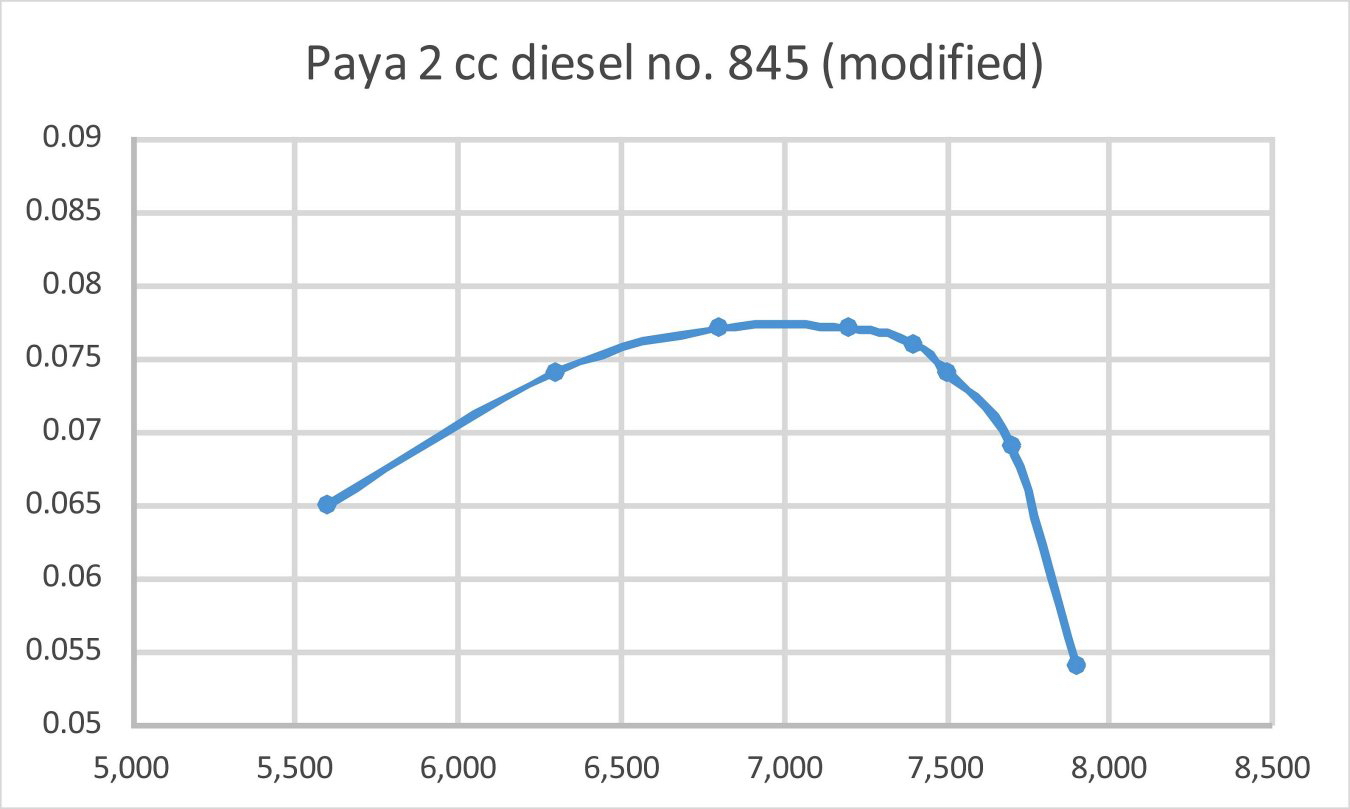

The Payá also appeared to be unduly prone to flooding of the crankcase, a condition which pretty much guarantees that it won't start without a real struggle. For this reason, finger-choking was quickly found to be counter-productive. I think that the problem here is that rather narrow conrod slot which represents the sole communication pathway between the lower crankcase and the upper cylinder. Fuel that collects in the lower crankcase tends to stay there until the engine fires, at which point it all gets thrown up into the bypass and instantly floods the engine to a halt. In addition, the design greatly impedes the clearing of a flooded crankcase. Definitely a condition to avoid! The required technique turned out to be to fill the tank but not choke at all. The engine proved to have excellent suction, so that even a short firing burst immediately drew fuel up from the tank into the venturi, thus allowing the engine to keep running without bogging down or starving. All that was required to produce that firing burst was a "dry prime" - that is, an exhaust prime administered with the exhaust ports closed. Once I figured all of this out, things quickly improved, and soon I was rewarded with a good firing burst which I was able to "catch" with the now-effective compression screw, resulting in an actual start. In fact, once I became familiar with the technique described above and had established a good compression setting, the now fully functional engine turned out to be a relatively prompt starter, usually bursting into life in 2 or 3 flicks. That said, I would not characterize this as an "easy" engine to start - it's straightforward enough once you know how, but it does take some knowing. The main recipie for success - don't flood it!! Once running, the engine performed very well within certain limits. I quickly found that the mixture leaned out quite a bit during the run, as one might expect with the relatively deep fuel tank and surface-jet needle valve assembly. This was of course due to the considerable change in fuel head during the run as the level in the tank went down - I’ve experienced this with other engines having similar deep tanks. For a “hands-off” run (as in a model) you have to set the needle for best running near the end of the run (13/4 turns for this example). When you do this, the engine is too rich immediately after starting but gets progressively better as the fuel level in the tank goes down, running very smoothly for the second half of the run. Once the "smooth" stage was reached, the Payá performed in a perfectly satisfactory manner, running very steadily with no tendency to mis-fire. I took all the prop readings with the engine operating in that mode. It turned the 10x4 APC prop at a steady 6,400 rpm, which is about equivalent to 0.074 BHP. I consider this to be well up to reasonable expectations – about the same on that prop as the early E.D Mk. II from which the Paya design was copied. It's also 400 rpm faster than the maker's cited operating speed! After giving the engine a series of shake-down runs on the 10x4 to get it well settled, I ran a long series of calibrated test props to get some idea of its performance. No further starting difficulties were experienced during this quite extended test. The figures obtained are shown below along with the derived power curve.

The 7x6 WB prop is a cut-down APC 8x6 created and calibrated to fill a gap in my test suite. As can be seen, the modified engine was found to develop around 0.078 BHP @ 7,000 rpm, approaching its peak on the bench using the 9x6 prop. The peak was notably flat - the engine developed in excess of 0.070 BHP at all speeds between 5,900 and 7,400 rpm. However, in typical sideport fashion the power dropped off sharply once the peak was passed. It's a real mistake to under-prop such engines - far better if anything to over-prop them slightly. While the measured output falls well short of the approximately 0.10 BHP claimed by the manufacturers, it is nonetheless quite comparable with the performance of the 1947 E.D. Mk. II from which the design of the Payá was clearly derived. My original unmodified E.D. Mk. II of mid 1947 vintage only managed around 0.080 BHP @ 6,700 rpm on test, so the modified Payá is right in the same ball-park. Also, the tested E.D. was well used, while the Paya is still not fully run in. Even so, this is not a totally dismal performance by 1947 standards. The test Payá's slightly higher than advertised peaking speed (7,000 rpm as opposed to the cited 6,000 rpm) was likely due to my bypass modifications. On this showing, a 10x4 would be a good free flight prop for the modified engine, while a 9x7 or 8x8 would serve well for control line use.

One somewhat less desirable characteristic evidently arose as a result of the previously-noted use of a hardened steel piston in an un-tapered steel bore. Although the piston fit was excellent when the engine was cold, it got noticeably “leakier” when hot. In the case of my engine, this didn’t seem to cause any observable running difficulties, but I heard from Peter Valicek that his example wouldn’t keep going when hot thanks to losing compression almost completely in that state. His engine must have had a somewhat looser piston fit than my tested unit. The use of a well-fitted cast iron piston in a tapered bore would undoubtedly solve this problem, which represents yet another design flaw in my book. Peter planned to lap a taper into the bore and make a cast iron piston for his engine. My tested engine number 845 ran the tank out just fine, but proved to be relatively difficult to re-start when hot thanks to this problem. I found it best to allow almost complete cooling between runs, after which good compression was restored and a re-start was very easily accomplished once I had mastered the required approach through hard experience. Another observed characteristic was more of an annoyance than anything else. Thanks to my lapping of the contra piston to a better fit, the standard comp screw now worked just fine for cold starting and for running adjustments - the steel insert was no longer required. However, I found that after a run was over and the engine had cooled down, the comp screw was well and truly stuck! I actually had to use a crescent wrench with protected jaws to free it, thankfully without breaking it. The way to overcome this during a bench test is to slacken it off while it’s still hot immediately after the run ends, but you generally couldn't get to it in time if the engine was mounted in a model, thus imposing a significant model glide/recovery period following each run. Oddly enough, it doesn't stick while the engine is running - only after it has cooled down a little.

In its present modified state, engine number 845 is a very useable powerplant which runs extremely well and is perfectly straightforward to start once one has learned the correct approach. It also has the potential to deliver a long useful life. That having been said, it’s worth pausing at this point to reflect upon the fact that engine no. 845 was not in running condition as supplied. The burrs on the crankweb would not have prevented it from running, although they might well have had an adverse effect upon its working life. The same can be said of the absence of an oilway to ensure adequate lubrication of the main bearing. Even the issues with the bypass system might not have prevented the engine from running, although they would certainly have constrained its handling and performance. However, the relative significance of the bypass problem in causing my initial starting woes remained unclear, since I had attended to the bypass issue before finally sorting the compression control. It was only after I sorted the latter issue that the engine finally became operable. The compression control was completely inoperable as supplied, thanks in large part to the fact that the contra-piston fit was way too tight (around 0.0007 in. in the case of my example). It took some well focused intervention on my part to make the system fully functional. Relatively few "average" users would have been able to successfully assess and overcome such issues. If a good proportion of the engines were supplied with similar problems, this couldn’t have reflected well upon the engine’s reputation. Perhaps no. 845 was a particularly bad example …… hope so, anyway! It's also worth reminding ourselves that Peter Valicek's example was also in effect inoperable as supplied, albeit for a different reason. Although it would start, his engine evidently suffered from a too-loose piston fit which combined with the use of a steel piston in a parallel steel bore to prevent the engine from keeping going when hot. The only fix for this is the re-lapping of the bore and the making of a new piston, preferably of cast iron. Only a machinist of Peter's very high calibre could contemplate such a fix. A Stock Example on Test The story so far has been one of a series of encounters with design and/or structural issues and the implementation of a range of ultimately successful responses to those issues. It actually seems quite possible that such problems were far from uncommon. If that was the case, these engines might well have developed a rather chequered reputation. Having said this, it must be stressed that almost all of the problems encountered could be easily addressed by anyone having a clear understanding of the issues along with a Dremel Moto-Tool (or equivalent) and a steady hand. The re-lapping of the contra piston is the only operation that might pose problems for the average owner. Once sorted, the engine performs at a fully satisfactory level. Of course, there's a downside from the standpoint of this article. As a consequence of the various activities described above, test engine number 845 ended up being significantly modified from its standard configuration. Accordingly, the test results presented above were obtained with an example of the engine that cannot be taken as in any way representative of the Payá as supplied. What about the engine's performance in "standard" trim? In an attempt to answer this question, I took a second previously-unused example (no. 824) kindly supplied by Jesus Ortega Delgado and tore it down to check the contra piston fit before making any attempt to start it. This one proved even more problematic than the first example to dismantle. The cylinder came off without too much trouble, but I had to work very hard indeed to get the front housing out of the crankcase. It turned out that the housing was a very tight plug fit in the crankcase even without the sealing compound, so I was fighting both an excessively tight fit and that dratted "glue"! It was a struggle, but eventually it came off. I relieved the fit somewhat to facilitate any future dismantling operations.

While I had the engine apart, I added an oil channel to the thrust bearing face on the front housing as described earlier. This would have no influence on performance, but it could do much to extend the life of the main bearing. In addition, I used the diamond file to round off the upper edge of the piston. Again, this should not affect performance but could well benefit the engine's longevity. No other modifications of any sort were made. In functional terms, the engine remained in absolutely stock un-modified condition. With these issues attended to, I reassembled the engine using paper gaskets in place of the highly problematic sealing compound. I then mounted it in the test stand with a 10x4 prop fitted. As recorded earlier, my attempts to start engine no. 845 in stock condition had met with no success whatsoever, but then I hadn't sorted the compression control on that one at the time. This time, I'd made sure that all was well in that department. I also had my earlier experience with engine no. 845 to guide me towards the appropriate starting procedure. Accordingly, I was hoping for better luck on this occasion. The engine felt really good when flicked over, so all seemed to be ready. Flexing my right arm muscles, I filled the tank and got stuck into the necessary flicking ...........

In desperation, I re-installed the previous test example number 845 in the test stand. It started up right away and ran just as well as before, turning the 9x5 prop at the same smooth 7,200 rpm measured earlier. Since I was using the same fuel throughout, this proved that there was nothing wrong with the fuel - one potential source of trouble eliminated. Having confirmed that the fuel was not the problem, I tried engine number 824 again, even going so far as try fitting the unquestionably functional tank and venturi components from just-tested engine number 845 to eliminate that assembly as a possible source of difficulty. Stilll nothing ........... after a further hour of this, both my patience and my flicking finger had reached their limits, and I gave up. Doesn't happen to me very often! It was pretty clear that this example too suffered from a dysfunctional transfer system. I saw nothing for it but to break down and modify this one as well. This time, I went to the trouble of taking some careful measurements of the relative opening points of the upper and lower bypass ports in the cylinder. It turned out that the upper (transfer) port on this example opened about 8 degrees of crankshaft rotation before the lower (bypass entry) port! There's obviously no way that the bypass/transfer system will function properly with this kind of timing. The failure of this example to run was completely explained. You could flick till Doomsday .......! So I went ahead and modified engine number 824 as I had done for the previously-tested unit number 845. The modifications took only an hour to complete, and could easily be carried out by anyone having a Dremel Moto-Tool, a collection of small-diameter bits and a steady hand.

I returned the now-modified engine no. 824 to the test stand, to find that it now started reasonably easily and performed pretty much like number 845 tested earlier. Clearly the dysfunctional bypass was guilty as charged! The compression seal developed a degree of "softness" after some running time, but nothing to prevent the engine from operating OK. I suspect that this issue was caused primarily by the use of an essentially parallel bore with all-steel components. A few checks on several props showed that this one was a hundred rpm or so down on the figures obtained for engine number 845. This may possibly be a symptom of the slightly looser piston fit, although the engine would run the tank out just fine once going. The previously-cited data for engine number 845 will therefore stand as the documented performance figures for the Payá 2 cc diesel as far as this article is concerned. My experience demonstrated conclusively that at least some of these engines, including both of my examples, were supplied in an inoperable condition due to mis-timing of their bypass porting. Moreover, even if this issue was attended to, the over-tight contra piston fit would still prevent the engines from being started. One is forced to wonder how many examples required the level of intervention described above to make them run ........... The Payá in Service One of the most puzzling things about all of this is the obvious fact that not all of the ICA/Payá engines were as problematic as the examples tested by Peter Valicek and myself. They couldn't have been, or Payá Hermanos would never have ordered those 2,000 units. The examples of the original ICA diesel which were reportedly converted to aircraft use by the members of the Pontevedra Aeromodelling School in 1948 seem to have performed at a satisfactory if unspectacular level. Indeed, it may well have been seeing those examples in service that convinced Payá Hermanos to place their large order. It's possible that those original ICA units were constructed to different dimensions as regards their bypass/transfer porting arrangements. A manufacturing error may have crept in at some point. There are precedents for this - the Micro Diesel from America was a case in point, although in that instance it was the conrod length that was incorrectly machined. My Spanish colleague Jesus Ortega Delgado was able to get his own unmodified example of the Payá (no. 831) going without the need for excessive intervention on his part other than some attention to the compression control to make it more useable. To assess the standard engine’s usefulness as an aero powerplant, Jesus built a beautiful Scout biplane from the KeilKraft plans to test his then-unmodified Payá no. 831 in a control-line context. An 8x6 airscrew was used.

In an effort to improve the engine's flight performance, Jesus subsequently added the extra lower bypass entry which was described earlier. However, it's important to note that his engine ran OK even before he applied that modification, albeit with a rather low power output. He did however share my view that the Payá was not the easiest of diesels to start. Jesus subsequently ran a few prop/rpm tests on his modified engine (no. 831), measuring speeds of 7,200 rpm on a Kavan 8x6 and 7,400 rpm on a Kavan 8x4. I don't have power absorption coefficients for Kavan props, but if they were APC equivalents the implied outputs would be in the order of 0.065 BHP and 0.044 BHP respectively. Those figures are reasonably consistent with my findings for engine number 845, which is not really surprising considering the fact that both engines have modified bypass entry ports. The very small difference between the two figures reported by Jesus clearly indicates a very rapid drop-off past the peak, which as stated earlier is completely typical of sideport engines. Even with its modified bypass entry, his engine evidently didn't want to run much past 7,000 rpm, however light the load. To me, this says that Jesus was already well past his engine's peak on the 8x6. This is consistent with the figures obtained with my own reworked example, which peaked at around 7,100 rpm. I'd be surprised if Jesus's engine peaked at a higher speed, even with its modified bypass porting. Indeed, my own engine with its more extensively modified bypass seems to be willing to run somewhat faster than Jesus's less radically modified example, which probably peaks in the upper 6,000 rpm range. Looking at the above performance measurements, I'd say that an 8x8 or 9x7 prop would be a better choice than the 8x6, especially with the modified bypass. The engine is already past its peak on the ground using the 8x6 and will only head deeper into the power drop-off abyss in the air. It should be propped for around 6,300 rpm on the ground for best results in a control line model, which will allow it to speed up to the peak in the air. Hopefully Jesus will try a few different props on his modified engine and report back in due course. A 10x4 still looks like a good match for free flight applications. A fine video Derek Butler's engine no. 583 running may be viewed here. Although it is being run slightly undercompressed in this video, my audio-tach says that it is turning the 10x4 Zingali prop at around 5,400 RPM near the end of the run. Derek's engine has had the compression adjustment system freed up and has been provided with the additional oil channel feeding the main bearing. Otherwise, it is reportedly unmodified. Some of these engines evidently did run with no modifications to the bypass system! Conclusion Being based upon a very early rendition of the E.D. Mk. II, the Payá 2 cc diesel was effectively out of date right out of the starting gate. By December 1947, more or less concurrently with the initial appearance of the ICA diesel which later became the Payá, the E.D. Mk. II had been significantly improved and had been joined by the considerably more powerful E.D. Comp Special. Compared with both of these updated models, the Payá was an also-ran in performance terms, particularly in its standard unmodified form. This was even more the case in late 1948, when the Payá Hermanos company became involved. By that time the world of model engine design was really beginning to move on, leaving the pioneering long-stroke sideport models of the 1940’s on the sidelines for the most part (the E.D. Comp Special, the Allouchéry 0.7 and 1.25 cc models and the Mills engines being notable exceptions). Had the Payá diesels been used to power the model boats for which they were originally intended, this might not have been much of an issue - after all, the E.D. Comp Special deservedly retained its popularity as a model boat engine into the early 1960's. However, in an aeromodelling context the Payá was well behind the times even as of 1948. A good one that was properly set up would have remained a perfectly useable powerplant for low-key sport-flying purposes, but that would have been about it. Reviewing the above article, one gets the impression that the designers of this engine had a relatively limited understanding of the finer points of model diesel design. This doubtless explains the fact that they were content to copy rather than innovate. To make matters worse, it appears that Don Diego had a somewhat loose grasp of the very narrow construction limits within which such engines have to be manufactured. He can be forgiven for this - after all, his well-demonstrated engineering qualifications, experience and abilities lay in other fields.

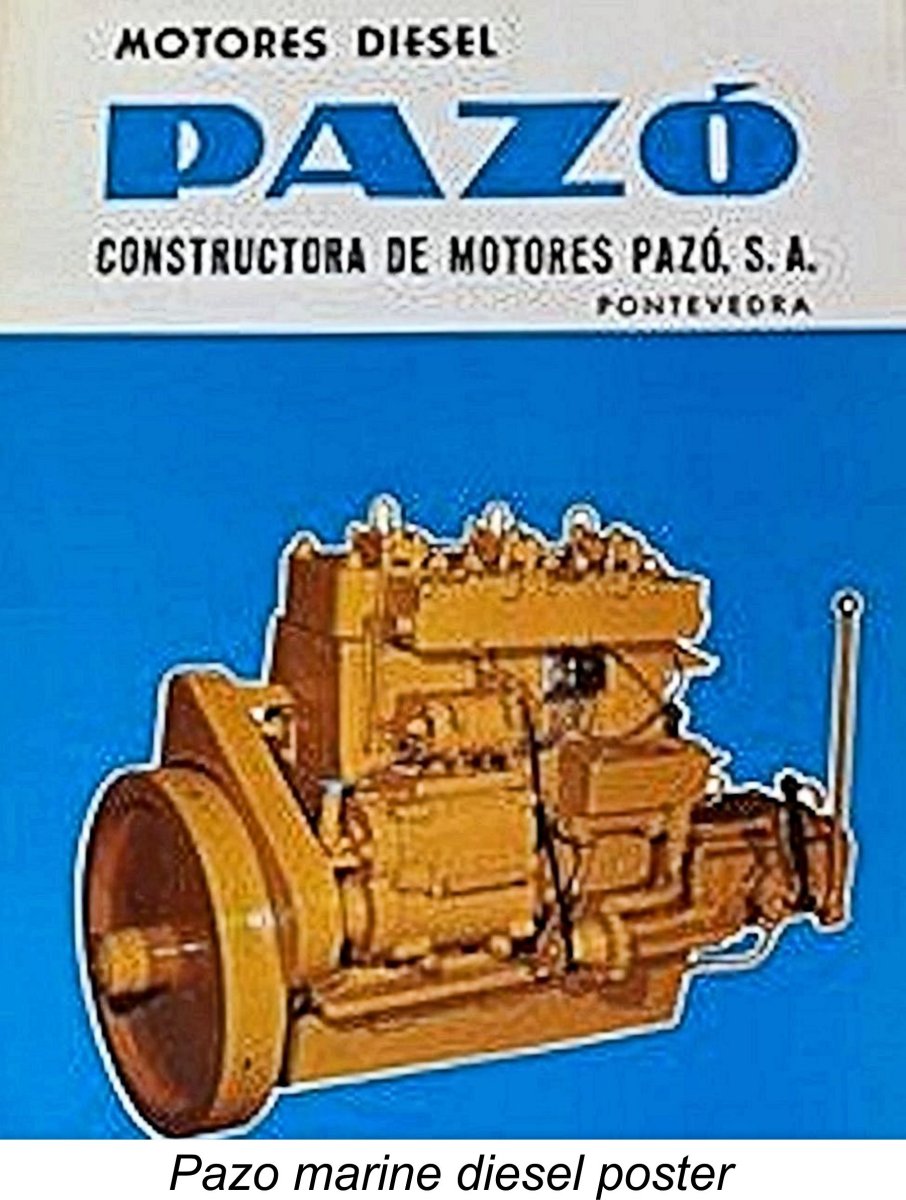

It’s not unlikely that the operational difficulties which Jesus Ortega Delgado, Peter Valicek, Derek Butler and I have all experienced to varying degrees were relatively common. Many others may have encountered the same initial difficulties getting these engines to run. It actually seems possible and perhaps even likely that it was their belated recognition of these difficulties after the motors had been delivered that led directly to the Payá Hermanos company abandoning its plans to use the engines in their proposed ready-to-run model boats. Marketing a range of model boats powered by an engine that no-one could start would not have enhanced the company's reputation! Following its relatively brief flirtation with model I/C engines, the Payá Hermanos company continued its successful involvement with the toy-making industry, surviving in fact until 1984. In that year, a combination of the energy crisis and a number of internal problems forced the company into bankruptcy. A cooperative called Payá S.C.V.L. was formed to pick up the pieces, and this company continued up to 2009, latterly focusing on the manufacture of reproductions of toys from the 1920’s and 1930’s which were produced in limited series of 5,000 units. The Pazó engine-building company never returned to model engine manufacture, continuing to produce its range of compact marine diesel engines for full-sized fishing boats and the like. By the time that it closed down in 1976 due to the relaxation of import restrictions and the consequent flood of lower-priced international competition, the company had produced from 2,500 to 3,000 engines in different outputs from 6 to 375 CV with 1 to 6 cylinders and operating speeds ranging from 550 to 850 rpm. I hope that you’ve enjoyed this introduction to a fascinating Spanish model engine with an unusual history and some challenging characteristics. Examples do turn up from time to time, and the acquisition of one of these engines certainly merits serious consideration by anyone interested in early model diesel engines. Any problems are easily fixed using the approaches described above, while the underlying quality and performance of the engines are more than acceptable once sorted. Plus .........what other engine has such a wonderfully artistic comp screw?!? ____________________________ Article © Adrian C. Duncan, Coquitlam, British Columbia, Canada First published January 2019 Updated October 2019 |

||

| |

In this article, I've joined forces with my friend Jesus Ortega Delgado to describe a little-known Spanish model diesel which bears the distinction of having been the first-ever model engine to enter commercial production in Spain. This is the Payá 2 cc model diesel engine, which first appeared under a different name in late 1947 as a sideline product of a then well-known company whose main business was the manufacture of compact marine diesel engines for full-sized vessels.

In this article, I've joined forces with my friend Jesus Ortega Delgado to describe a little-known Spanish model diesel which bears the distinction of having been the first-ever model engine to enter commercial production in Spain. This is the Payá 2 cc model diesel engine, which first appeared under a different name in late 1947 as a sideline product of a then well-known company whose main business was the manufacture of compact marine diesel engines for full-sized vessels.

prevented its participants from financing the purchase of much-needed engines for their fishing boats. Recognizing this, Don Diego came up with a highly innovative marketing strategy - he would provide the engines to the fishermen without any advance payment or collateral, on the basis that they would subsequently pay him a proportion of their earnings up to the sale price of the engine.

prevented its participants from financing the purchase of much-needed engines for their fishing boats. Recognizing this, Don Diego came up with a highly innovative marketing strategy - he would provide the engines to the fishermen without any advance payment or collateral, on the basis that they would subsequently pay him a proportion of their earnings up to the sale price of the engine.

The new company was immensely successful, achieving a unique and unrivalled position in the Spanish industrial economy while also establishing Ibi as the major toy-making centre which it continues to be today (2018). In effect, the company became the Spanish equivalent of

The new company was immensely successful, achieving a unique and unrivalled position in the Spanish industrial economy while also establishing Ibi as the major toy-making centre which it continues to be today (2018). In effect, the company became the Spanish equivalent of

Having made this decision, Payá Hermanos promptly ordered a production run of no fewer than 2,000 examples of the engine, all of which were to be supplied as originally designed with flywheels. This order was duly filled by Don Diego.

Having made this decision, Payá Hermanos promptly ordered a production run of no fewer than 2,000 examples of the engine, all of which were to be supplied as originally designed with flywheels. This order was duly filled by Don Diego.  instruction sheet (in Spanish, naturally) which included complete technical data along with a parts listing. They were sold primarily in the form in which they had been supplied by Don Diego as flywheel-equipped marine (or car) units. The selling price was reportedly 600 pesetas - roughly equivalent to around US$12.00 at the time.

instruction sheet (in Spanish, naturally) which included complete technical data along with a parts listing. They were sold primarily in the form in which they had been supplied by Don Diego as flywheel-equipped marine (or car) units. The selling price was reportedly 600 pesetas - roughly equivalent to around US$12.00 at the time.

It only takes one look at the Payá in company with an E.D. Mk. II to confirm that the design of the Spanish unit was strongly influenced by that of the E.D. offering. Apart from the tank and cooling jacket, the most immediately obvious departure is the lovely if somewhat impractical cast alloy compression screw, which always attracts the attention of any enthusiast who sees one of these engines for the first time. Otherwise, one engine is pretty much a reflection of the other.

It only takes one look at the Payá in company with an E.D. Mk. II to confirm that the design of the Spanish unit was strongly influenced by that of the E.D. offering. Apart from the tank and cooling jacket, the most immediately obvious departure is the lovely if somewhat impractical cast alloy compression screw, which always attracts the attention of any enthusiast who sees one of these engines for the first time. Otherwise, one engine is pretty much a reflection of the other.  In strictly functional terms, the Payá followed the design of the E.D. Mk. II in all respects. It was a classic variable compression plain bearing long stroke sideport diesel engine having twin exhausts at the sides and one port each fore and aft for the transfer and induction respectively. Like the E.D., it was equipped with a hang tank of more than adequate capacity, although the Payá tank was produced by die-casting rather than being machined like that of the E.D.

In strictly functional terms, the Payá followed the design of the E.D. Mk. II in all respects. It was a classic variable compression plain bearing long stroke sideport diesel engine having twin exhausts at the sides and one port each fore and aft for the transfer and induction respectively. Like the E.D., it was equipped with a hang tank of more than adequate capacity, although the Payá tank was produced by die-casting rather than being machined like that of the E.D.

Moving on upwards, removal of the cylinder assembly reveals the fact that the conrod operates through a narrow slot in the upper surface of the crankcase casting. This is the next indication that the design was copied from a relatively early variant of the E.D. Mk. II. Further indications come from an examination of the piston. The piston crown is flat, with no step to act as a deflector. Somewhat oddly, it is made of hardened steel, which can be a problematic choice of material in a steel cylinder liner. This material choice is somewhat exacerbated by the fact that there is almost no taper in the bore. More of this issue later .......

Moving on upwards, removal of the cylinder assembly reveals the fact that the conrod operates through a narrow slot in the upper surface of the crankcase casting. This is the next indication that the design was copied from a relatively early variant of the E.D. Mk. II. Further indications come from an examination of the piston. The piston crown is flat, with no step to act as a deflector. Somewhat oddly, it is made of hardened steel, which can be a problematic choice of material in a steel cylinder liner. This material choice is somewhat exacerbated by the fact that there is almost no taper in the bore. More of this issue later .......

The evaluation of this issue clearly required the removal of the front main bearing housing. This proved to be rather challenging thanks to the presence of the sealing compound to which reference was made earlier. However, following the application of heat along with a considerable level of physical effort, the housing eventually came off without damage.

The evaluation of this issue clearly required the removal of the front main bearing housing. This proved to be rather challenging thanks to the presence of the sealing compound to which reference was made earlier. However, following the application of heat along with a considerable level of physical effort, the housing eventually came off without damage.

So that problem was apparently solved, but now another reared its ugly head! I found that the engine would fire readily enough when flicked over in the usual way but would not keep running. In fact, it wouldn't even produced a firing burst - it would fire on the starting flick and sometimes carry over to fire on the following stroke, but would then die. It seemed to be burning off the cylinder prime and nothing more.

So that problem was apparently solved, but now another reared its ugly head! I found that the engine would fire readily enough when flicked over in the usual way but would not keep running. In fact, it wouldn't even produced a firing burst - it would fire on the starting flick and sometimes carry over to fire on the following stroke, but would then die. It seemed to be burning off the cylinder prime and nothing more.

adding this feature was to create a tendency for the initial "puff" of high-pressure transfer gas to be directed into the upper cylinder where it's needed. I hoped that this might result in better start-up scavenging and somewhat more powerful initial firing strokes, which were what the engine clearly needed to generate the kind of firing burst required for starting.

adding this feature was to create a tendency for the initial "puff" of high-pressure transfer gas to be directed into the upper cylinder where it's needed. I hoped that this might result in better start-up scavenging and somewhat more powerful initial firing strokes, which were what the engine clearly needed to generate the kind of firing burst required for starting.  This appeared to me to be a very good idea indeed! Although the newly-created bypass entry is largely obscured by the piston skirt at bottom dead centre, that's the very point at which the standard piston port bypass entry is fully open and available to supply the bypass. The new bypass entry will take care of the initial bypass gas requirements at the critical point at which the transfer port opens, and will maintain flow as the piston descends until the piston port opens fully near bottom dead centre and can take over.

This appeared to me to be a very good idea indeed! Although the newly-created bypass entry is largely obscured by the piston skirt at bottom dead centre, that's the very point at which the standard piston port bypass entry is fully open and available to supply the bypass. The new bypass entry will take care of the initial bypass gas requirements at the critical point at which the transfer port opens, and will maintain flow as the piston descends until the piston port opens fully near bottom dead centre and can take over.  Contemplating my work to this point, a little more thought led me to the conclusion that having gone this far I might as well go all the way! So I cut a semi-circular opening in the front of the upper crankcase shelf, creating a direct connection between the lower bypass and the main crankcase. Note that I chamfered the upper front of the aperture to blend smoothly into the bottom of the enlaged bypass passage that I had already created by trimming the lower cylinder liner.

Contemplating my work to this point, a little more thought led me to the conclusion that having gone this far I might as well go all the way! So I cut a semi-circular opening in the front of the upper crankcase shelf, creating a direct connection between the lower bypass and the main crankcase. Note that I chamfered the upper front of the aperture to blend smoothly into the bottom of the enlaged bypass passage that I had already created by trimming the lower cylinder liner.

Honestly, I’m not at all surprised at the measured performance – these figures are about what I would expect from this rather under-developed design, even with my modifications. Remember, I didn’t touch the actual cylinder ports at all, nor did I enlarge the very small intake and bypass passages - I simply improved gas access to the lower bypass, extended the transfer cycle very slightly and made the compression control fully functional.

Honestly, I’m not at all surprised at the measured performance – these figures are about what I would expect from this rather under-developed design, even with my modifications. Remember, I didn’t touch the actual cylinder ports at all, nor did I enlarge the very small intake and bypass passages - I simply improved gas access to the lower bypass, extended the transfer cycle very slightly and made the compression control fully functional.

As with the first example, the contra piston fit was too tight, although not quite as bad as the first one. I relieved the fit by lapping, subsequently re-fitting the lapped component and trying it with the comp screw to ensure that I had a functional compression adjustment system. Apart from that, everything seemed to be fine - the crankweb in this example was completely free from the burrs that had troubled engine no. 845.

As with the first example, the contra piston fit was too tight, although not quite as bad as the first one. I relieved the fit by lapping, subsequently re-fitting the lapped component and trying it with the comp screw to ensure that I had a functional compression adjustment system. Apart from that, everything seemed to be fine - the crankweb in this example was completely free from the burrs that had troubled engine no. 845. ....... and was still flicking 2 hours later! My 60+ years of experience starting recalcitrant model diesels did me no good at all - the engine simply refused to start! The compression control worked OK and I could get the motor firing with no difficulty, but it wouldn't keep going, no matter what I did. Just a few half-hearted firing strokes, and then nothing. The same symptoms as with the other example - the engine behaved as if the transfer system was not working at all. The short firing "bursts" (if you could call them that) were evidently just the cylinder prime burning off. I tried all the tricks - pre-heating the thing with a heat gun, using different props and different fuels, etc. Nothing!