|

|

The Ball 60 Racing Engine

The Ball 60 has considerable significance from a historical standpoint in that it was one of a series of pioneering crankshaft front rotary valve (FRV) racing engines which challenged the rise to prominence of the “classic” big-bore model racing engine with its disc rear rotary valve (RRV) induction. The telling of the Ball story thus affords an ideal opportunity to summarize a very interesting technical debate which took place in the context of the early development of model racing engines.

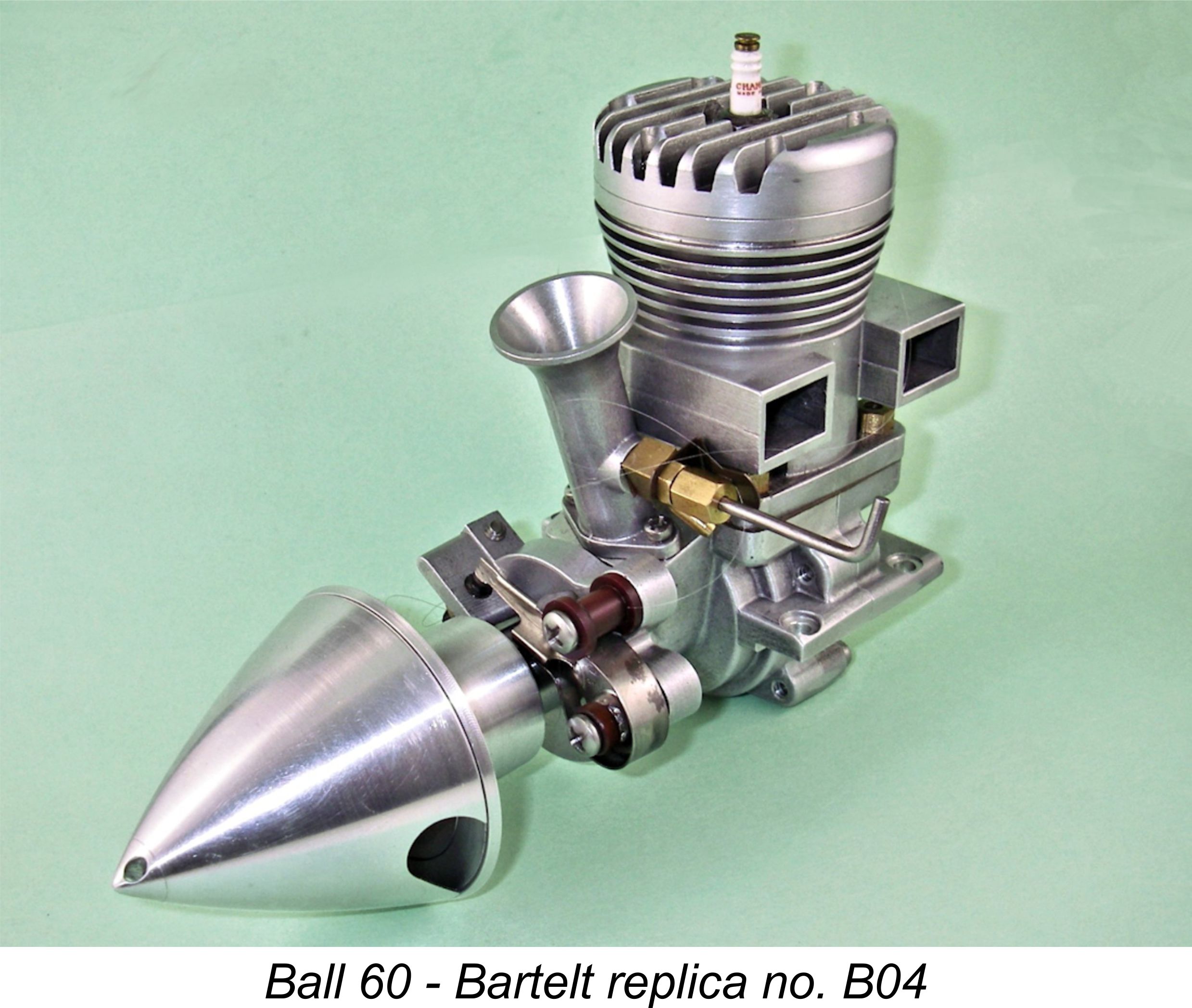

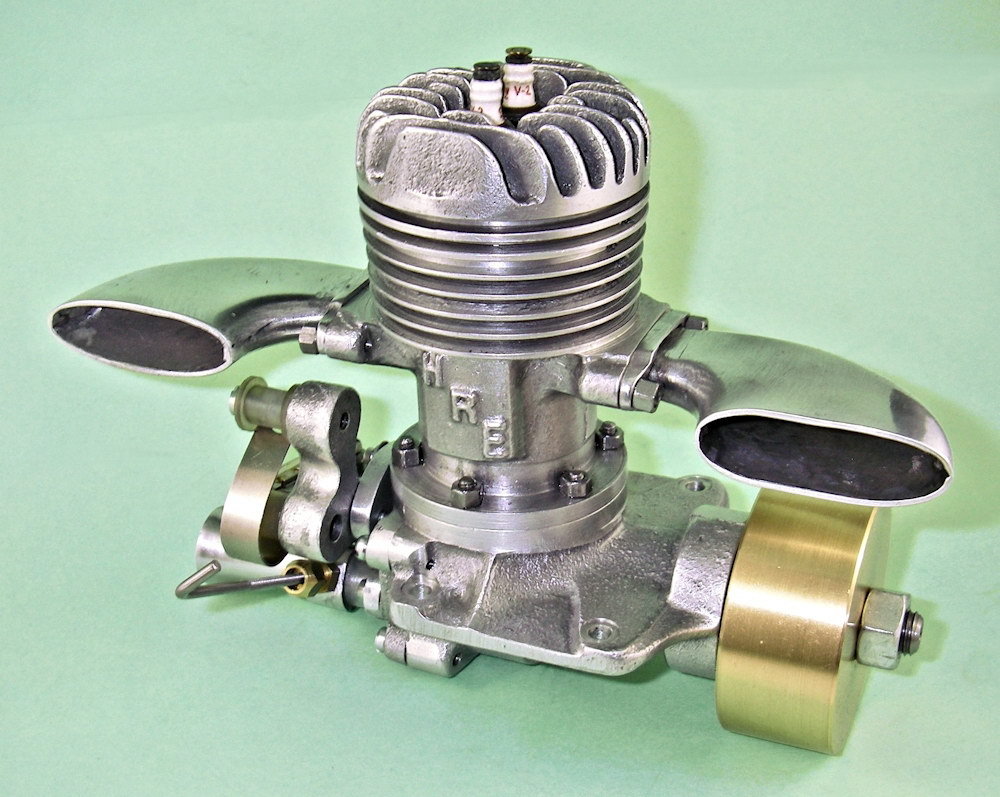

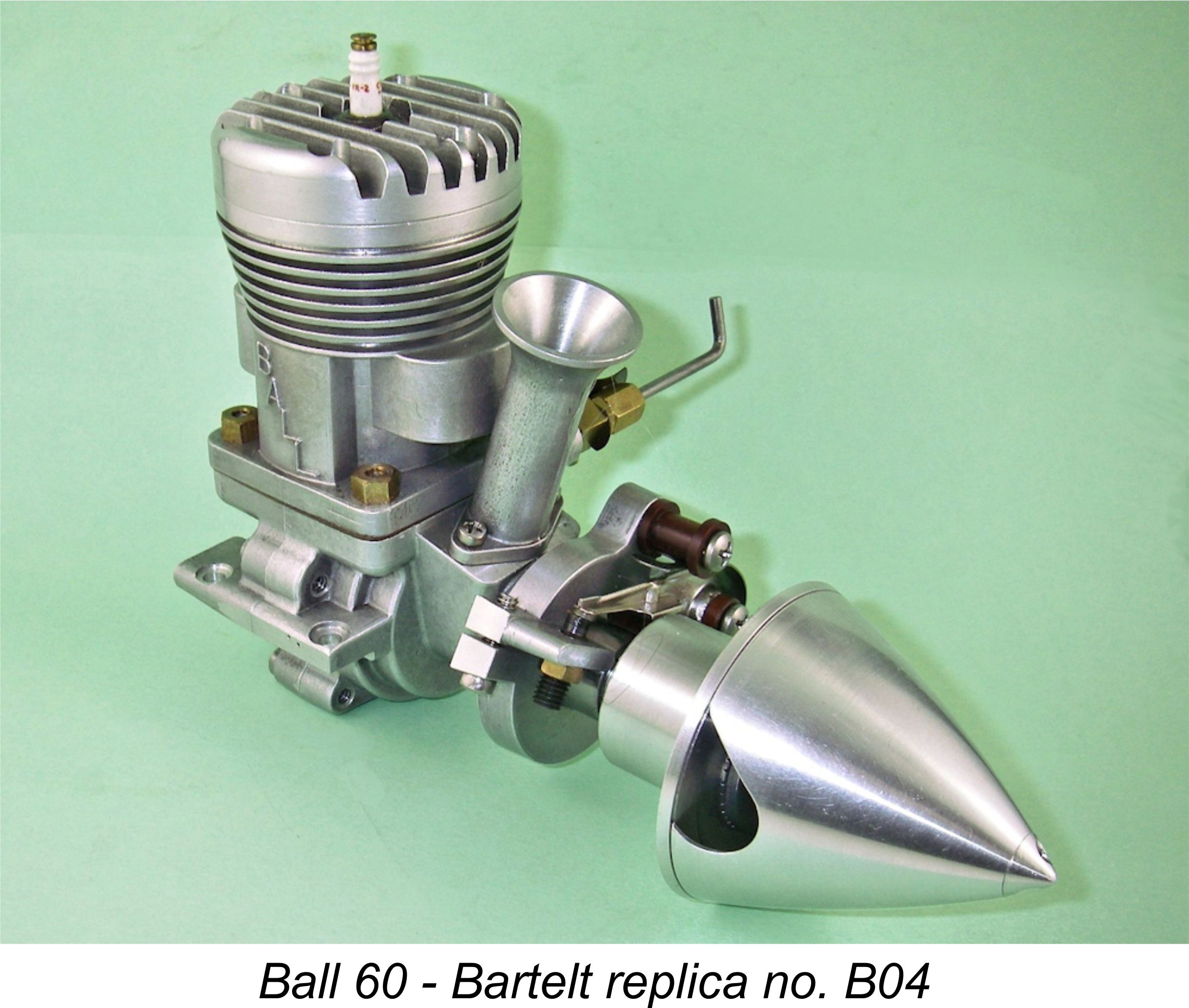

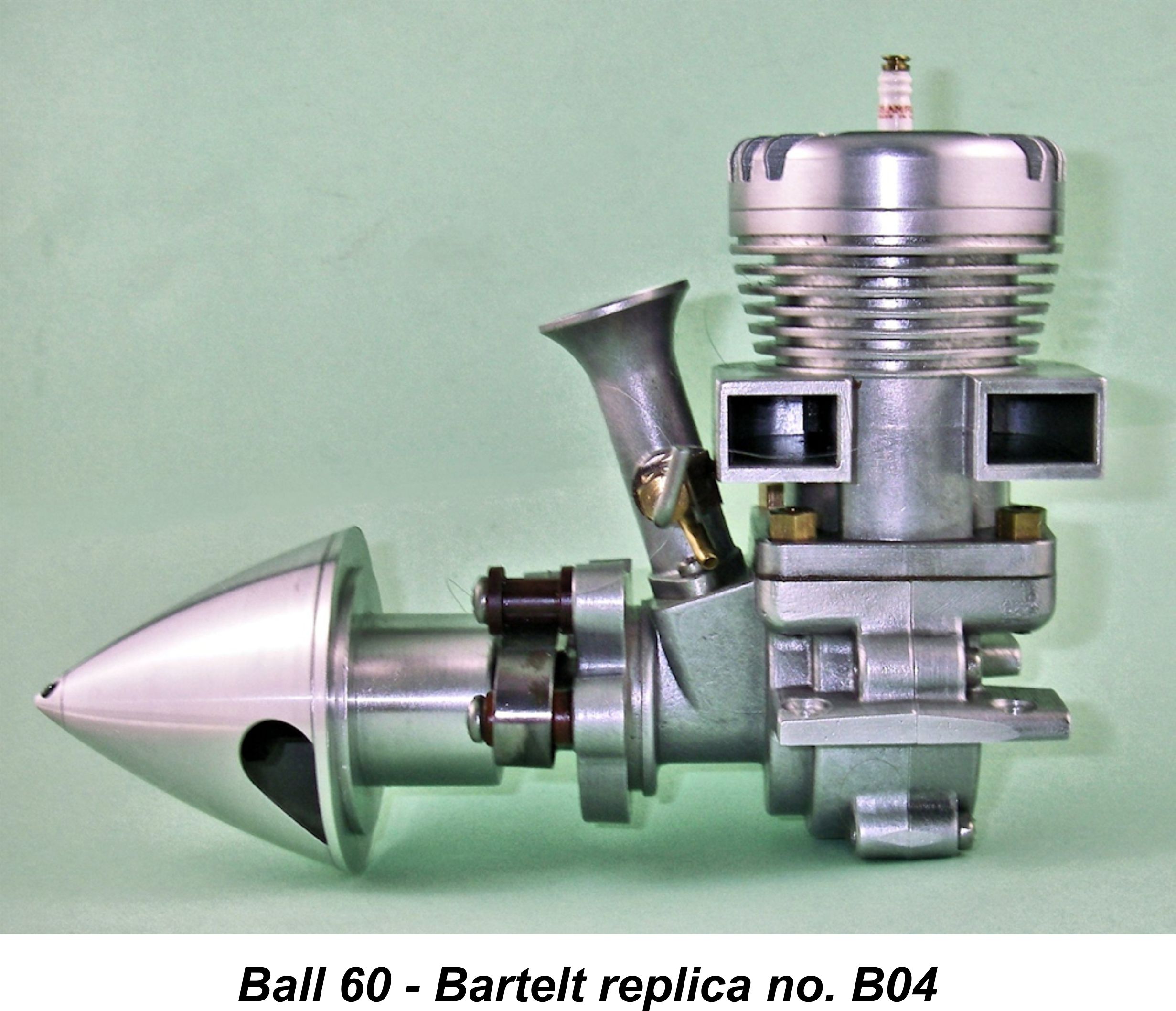

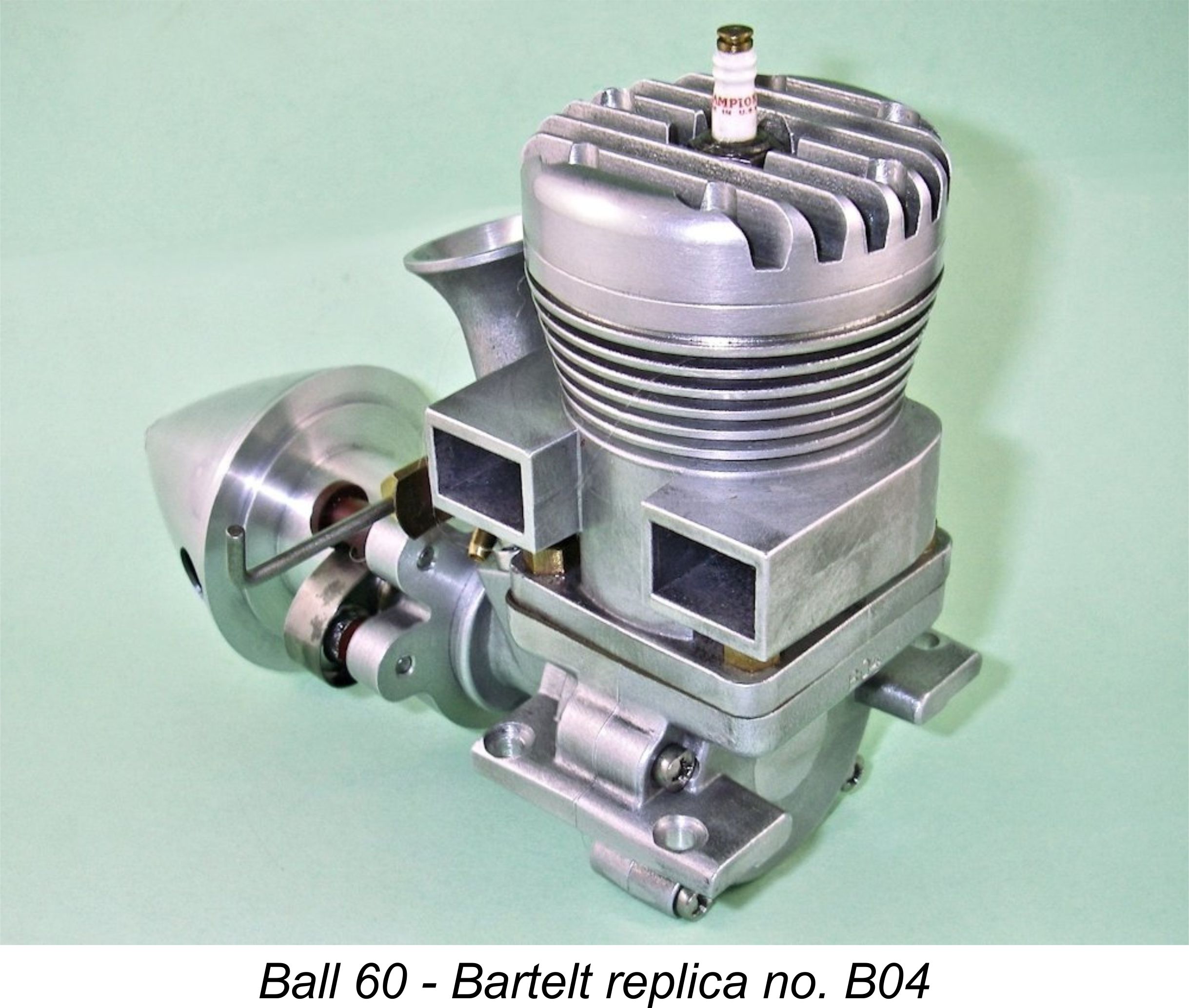

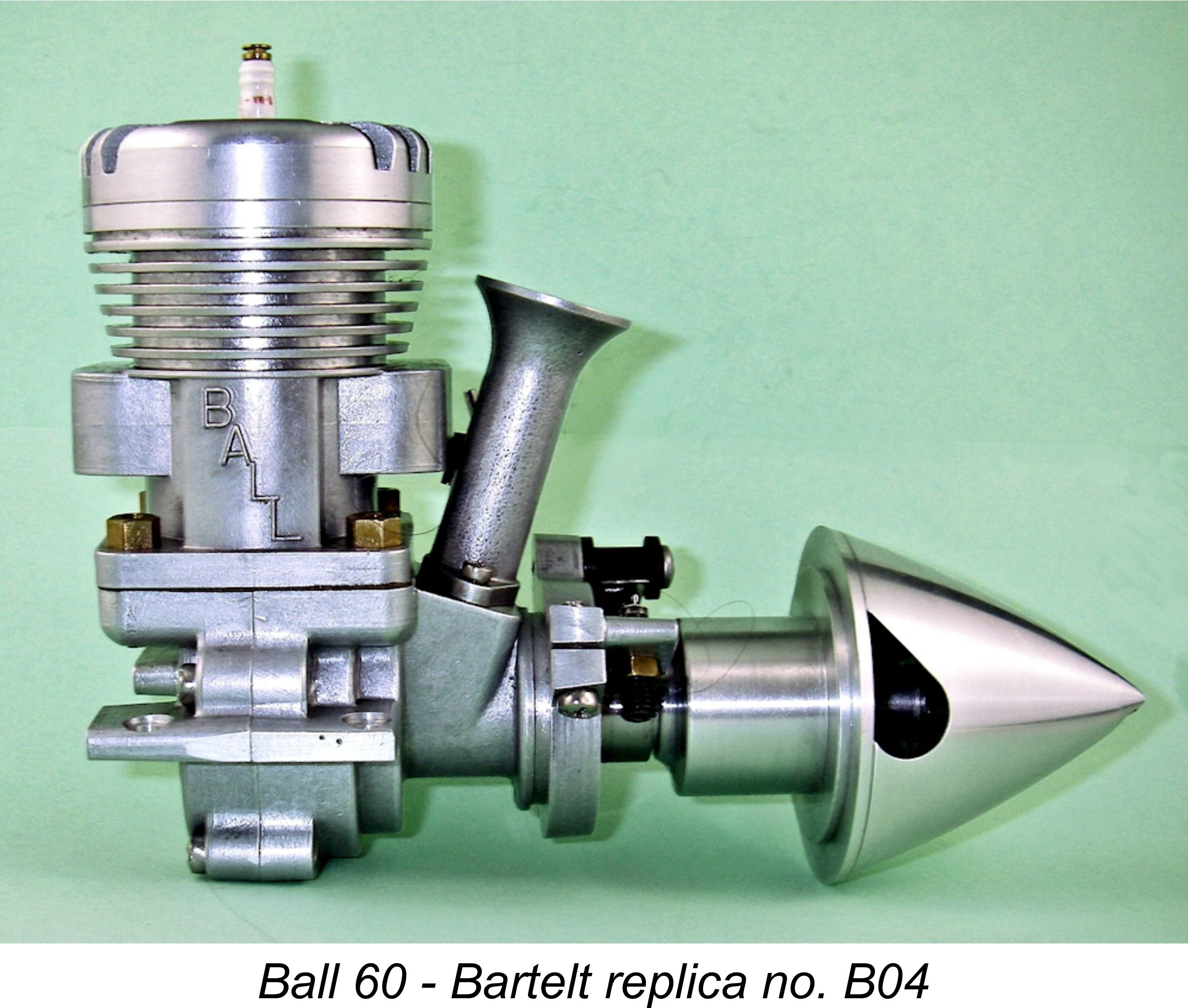

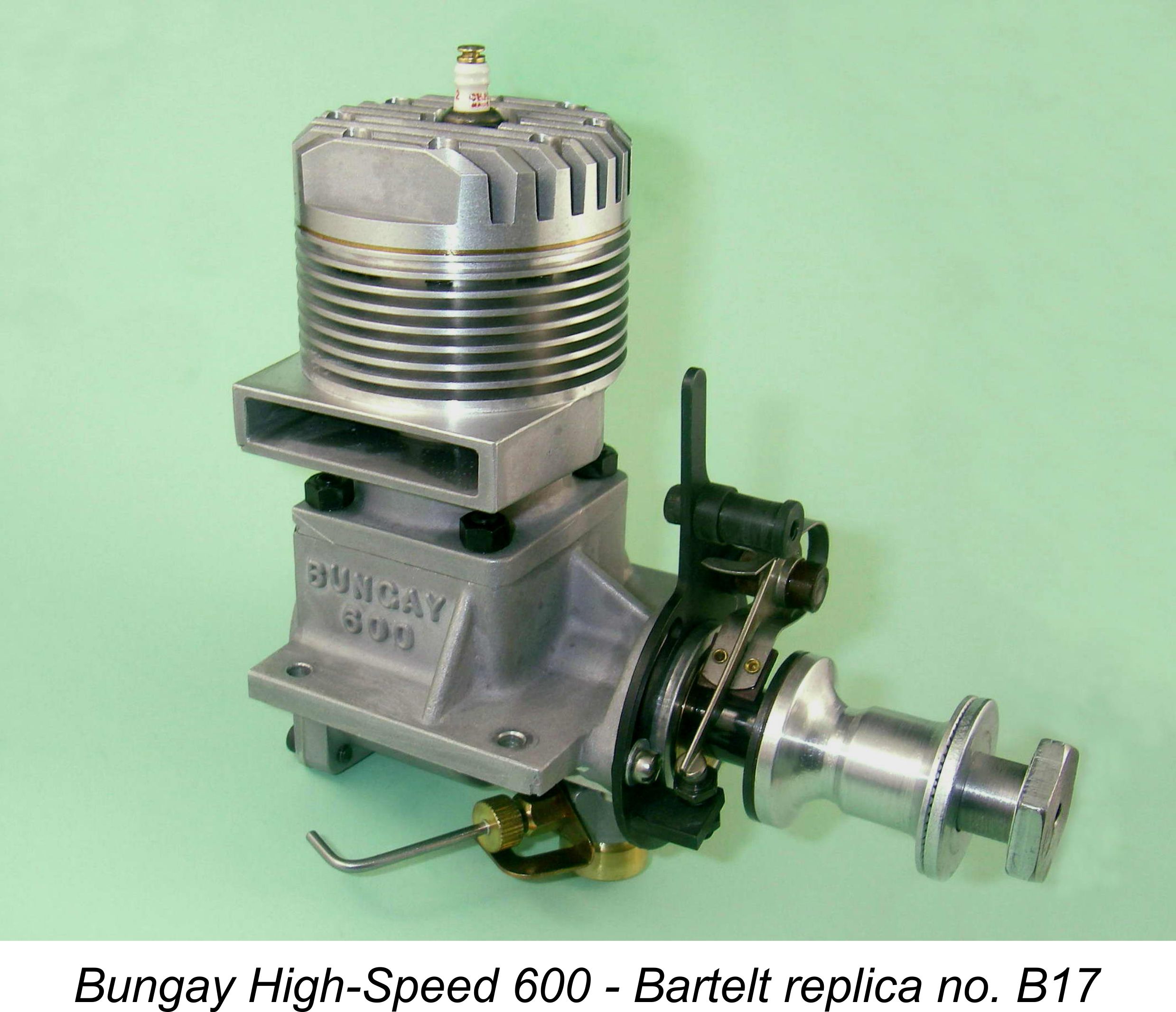

I’m also immensely grateful to Tom Pearson, a past President of the American Miniature Racing Car Association (AMRCA), fo Finally, given the fact that original examples of the Ball 60 are extremely elusive, it’s necessary to confirm that the writing of this article was initially made possible solely as a result of my possession of one of a series of fifty fine replicas of the engine which were made some years ago in Ukraine by the well-known Profi company for the late and much missed Woody Bartelt of Aero Electric fame. The illustrated example is number B04 - an early example. Although all of Woody's replicas were sold out years ago, they will doubtless continue to resurface on eBay and at collectos from time to time. That having been said, two very fine original examples of the engine appeared almost simultaneously on eBay in the latter part of 2018. I was fortunate enough to acquire one of these units, of which more below in its place. It's also worth mentioning that the very talented model engine constructor Don Sohn made a few replicas of the Ball 60 in the latter part of the 1990's. These engines featured the earier-style cylinder head with radial fins (see below). They are apparently very close copies of the originals, but as far as Don can now recall were un-numbered. Let’s begin now by looking at the background to the development of this very original model engine design. Background Prior to 1937, the majority of model engines were used to power large free flight model aircraft. Since these models were uncontrolled following launch, attempts to achieve high speeds would have been potentially hazardous, to say nothing of the difficulty of obtaining accurate speed measurements. Contests were therefore based upon flight duration for a given motor run, thus making light weight and operational consistency the primary goals of engine designers.

There was thus little stimulation for the commercial development of all-out model racing engines during the early to mid 1930’s. However, this all changed in early 1937, when a group of Los Angeles model fliers who were looking for new adventures decided to try using their model aero engines to power model race cars which could be run at high speeds on a tether or rail track, thus keeping them under restraint at all times. The leading lights in this movement were the three Dooling brothers, who were to go on to develop some of the most famous model racing cars and engines of them all. They were soon joined by others, including the legendary Dick McCoy, Ray Snow of Hornet fame, Ira Hassad, Bill Batzloff and Walt Cave. The rapid nationwide increase in the popularity of this new branch of the hobby soon created market conditions in which the commercial development of suitable racing engines became a viable proposition.

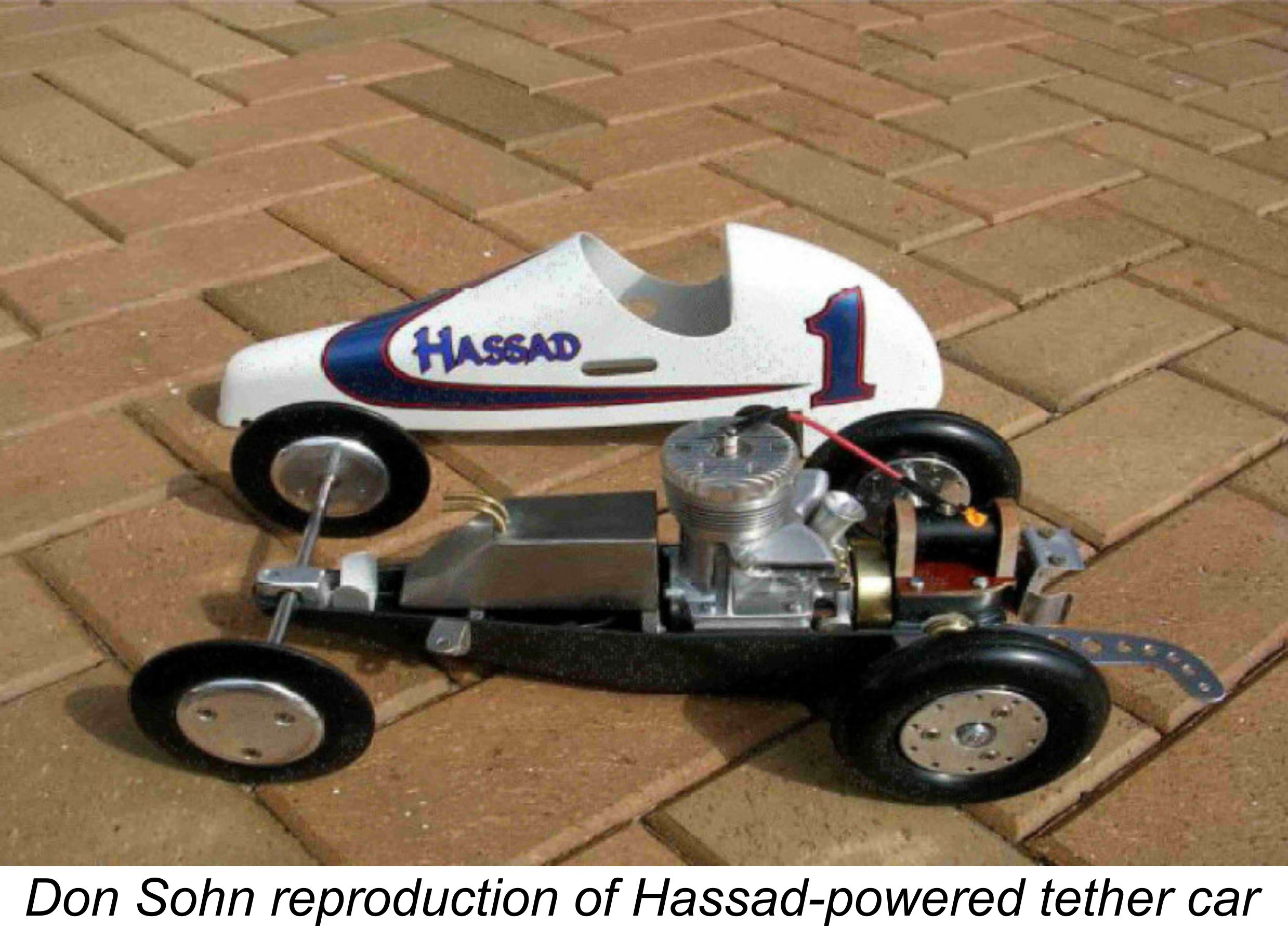

The “formula” established by these front-running early American racing engines was soon to become familiar to performance-oriented modellers worldwide, being widely emulated in many countries outside the USA. When we reflect upon the classic early post-WW2 10 cc (.61 cubic inch) racing engine, we tend to think of a design featuring spark ignition (the only practical option prior to 1948); an automotive-style timer; RRV induction; cross-flow loop scavenging; a ringed aluminium piston having a high-domed baffle crown; and a twin ball-race crankshaft. Apart from the general switch to glowplug ignition in the late 1940’s, this basic design package was to remain the standard for large racing engines well into the 1960’s. However, even at the outset there were those who felt that the above layout could be improved upon. One notable and very influential designer who sincerely believed that FRV induction offered greater potential than the RRV system for racing engines was California resident Ira J. Hassad (1915 - 1981). Hassad’s conviction that FRV induction offered a viable alternative to the RRV system for racing engines was to sustain a 10-year struggle for supremacy between the two systems. The Ball 60 was among the early post-war entries into this particular contest on the FRV side. This being the case, the need to place our main subject in context requires that we spend some time reviewing the development of this very interesting technical debate of over 80 years ago. Ira Hassad and the FRV Racing Engine Movement in the 1940’s Ira James Hassad was one of the true pioneers of model engine development, with a decided preference for ploughing his own furrow in design terms. I've covered his story in detail in a separate article to be found elsewhere on this web-site. However, for convenience I'll summarize the main points here. Those who are already familiar with this subject are invited to move directly to the following section of this article. Otherwise, read on ………….

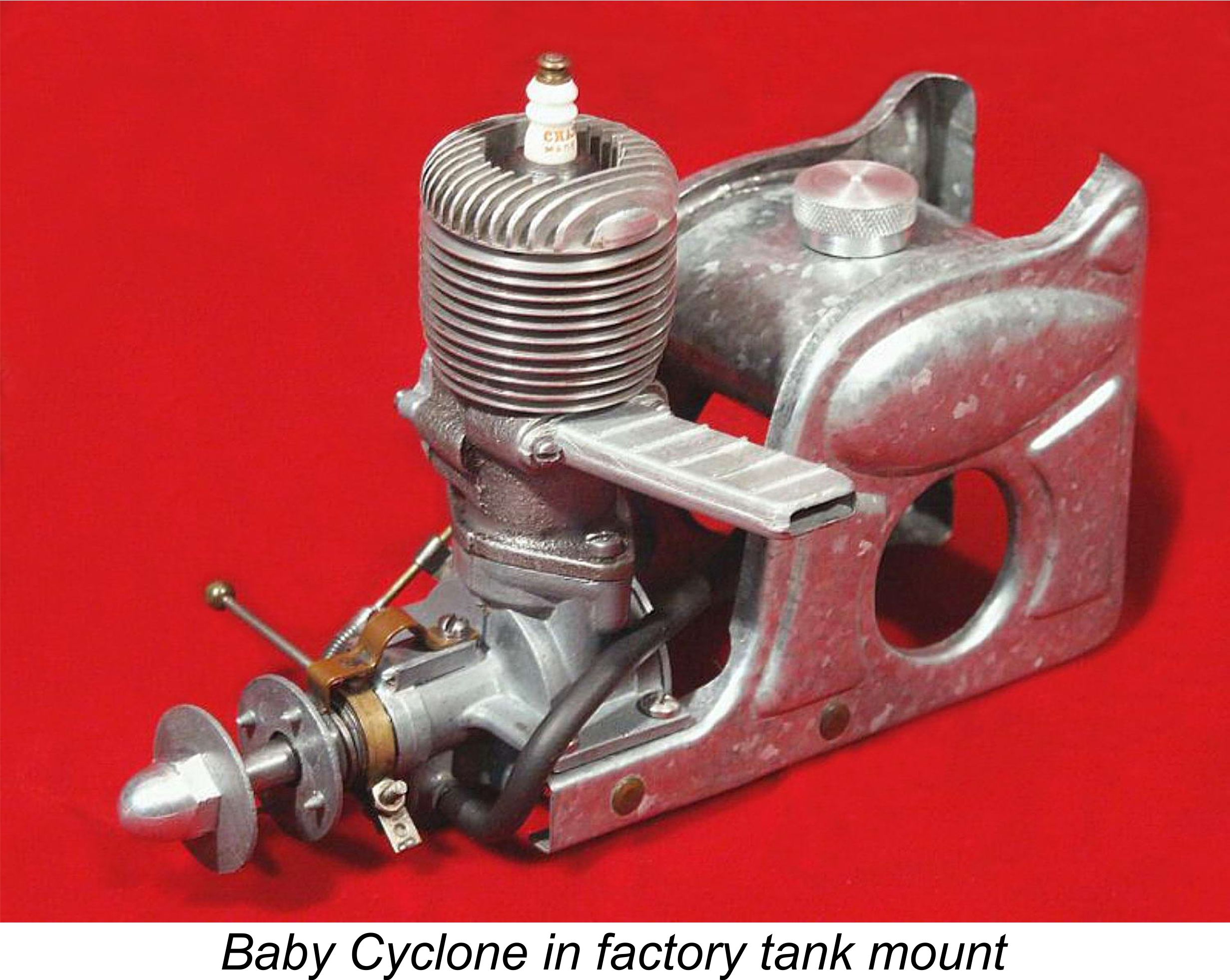

The Baby Cyclone engines were manufactured at a facility owned by Moseley which was primarily dedicated to full-scale aircraft maintenance. This facility was located at Grand Central Terminal in Glendale, California, some 12 miles to the north of downtown Los Angeles. Ira was later to recall that his main task was the lapping of the pistons and cylinders to the required fit. Surviving examples of the Baby Cyclone are a testament to his expertise in this area. Some 20,000 of these engines were reportedly manufactured in total. Hassad remained with Moseley until 1939, when he left to join former colleague Bill Atwood at the Automatic Screw Machine Company in Los Angeles. Atwood had also left Moseley and was getting production going on the Phantom series at this time. However, Ira had now become interested in model car racing and was tempted by the challenge of developing his own all-conquering race car engine. In September 1939, using a $300 loan from close friend and Lockheed employee Louis Schock, Ira bought a lathe which he set up in the garage of his home in Maywood, California, a little to the south-east of Los Angeles. Here he commenced the manufacture of the H/S (Hassad/Schock) .604 race car engine on his own account, with part-time assistance from Schock.

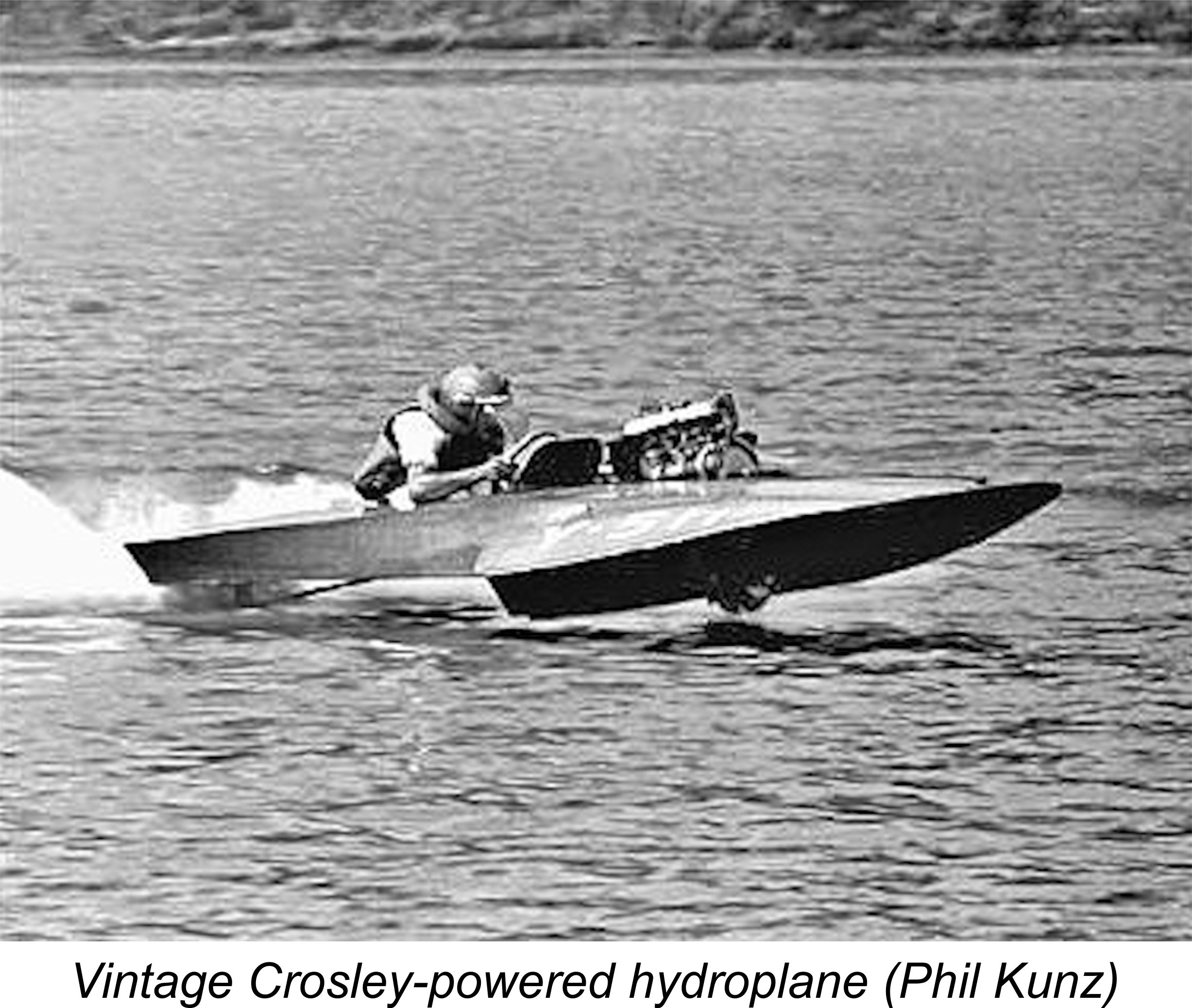

The twin-stack front exhaust was to remain a Hassad trade-mark for most of the following decade. There is much to commend the layout when the engine is used in aircraft service, since it places the hottest side of the cylinder at the front where it receives maximum cooling airflow, thus contributing to more uniform cylinder temperatures. However, any advantage which this layout may possess in terms of operating temperatures is often negated when the engine is used in car service, since in a typical bevel-geared car featuring rear wheel drive (like that illustrated here) the exhaust would then face the rear of the vehicle. The same would apply to the engine’s use in hydroplane service.

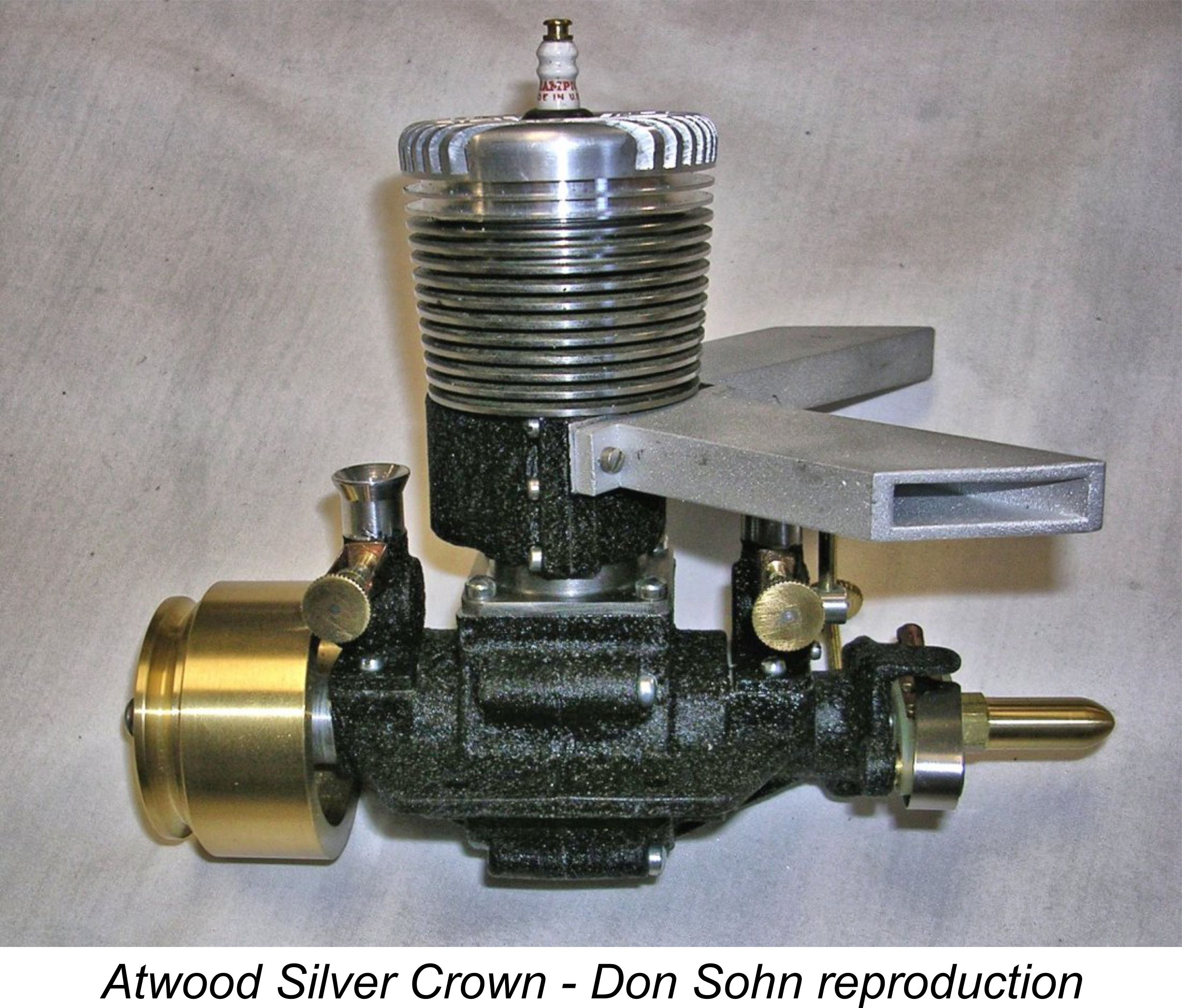

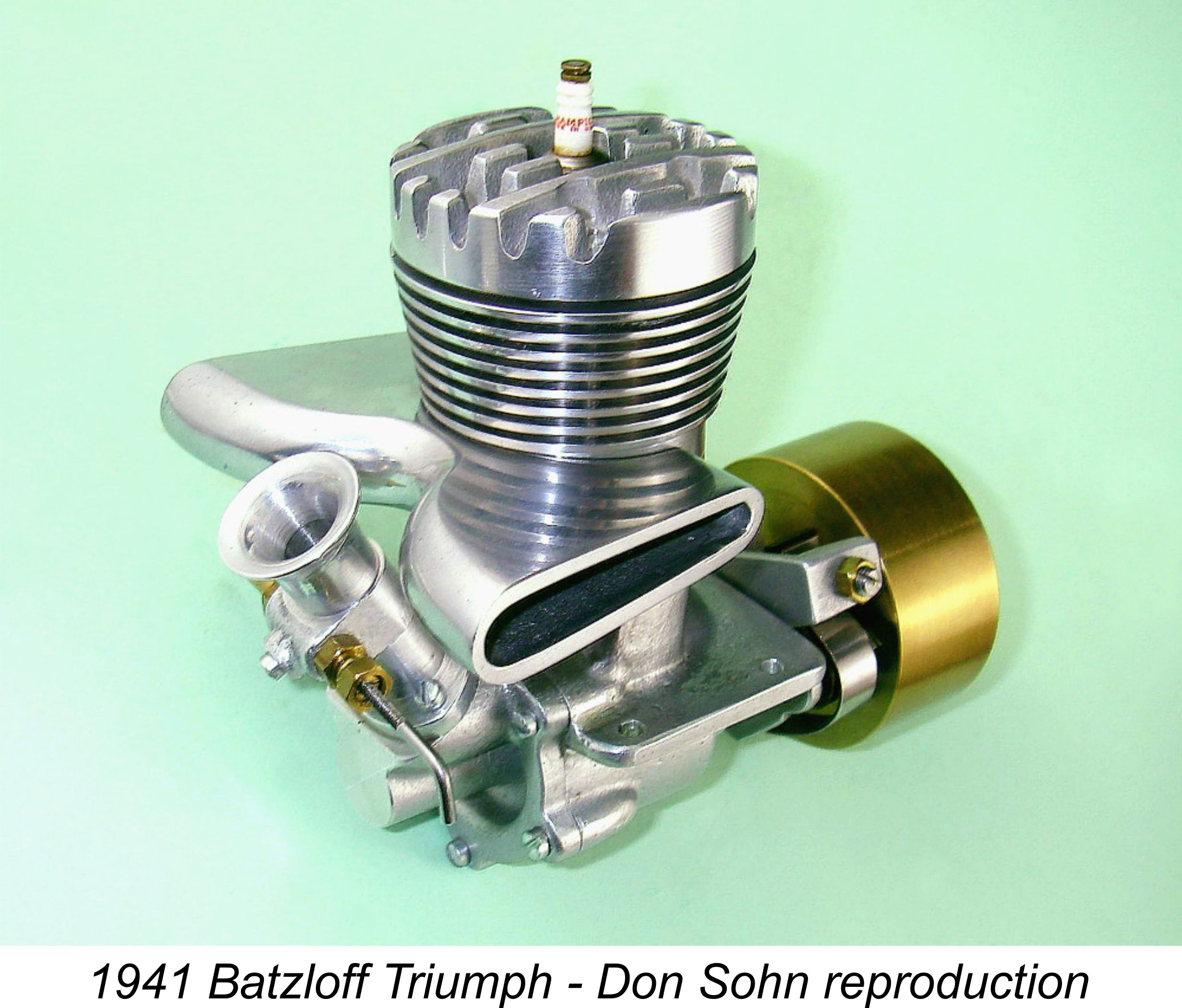

Another small-scale effort which applied a bit of a twist to the basic Hassad formula was the .604 cuin. Batzloff Triumph The Triumph was made by Batzloff in very small numbers, production being quickly curtailed by the onset of WW2 (as far as the USA was concerned) in December 1941. Seemingly no more than a dozen complete engines were supplied to custom order, although others were reportedly sold to fellow enthusiasts as casting kits for home construction. The illustrated example was constructed from castings by the noted model engine and car reproducer Don Sohn. The pre-war Triumph clearly embodied Batzloff’s views regarding how the basic Hassad design could be improved upon. The engine reversed the usual Hassad arrangement by using a rear drum valve instead of FRV induction. The operating principle was of course identical, the difference being that the drum valve did not have to do double duty by transmitting the engine’s torque in addition to controlling the induction cycle. This arrangement allowed the designer to take far greater liberties in terms of induction port size and associated timing without introducing any undue structural weakness. It was presumably this advantage which led Batzloff to adopt the design approach that he did. The engine retained the twin exhaust stacks of the contemporary Hassad models, but these were placed at the rear of the cylinder instead of at the front, thus keeping them in the same orientation relative to the induction system as in the Hassad designs. In effect, the Batzloff Triumph was a “back-to-front” Hassad model - a twin-stack FRV Hassad design with the power take-off at the rear!

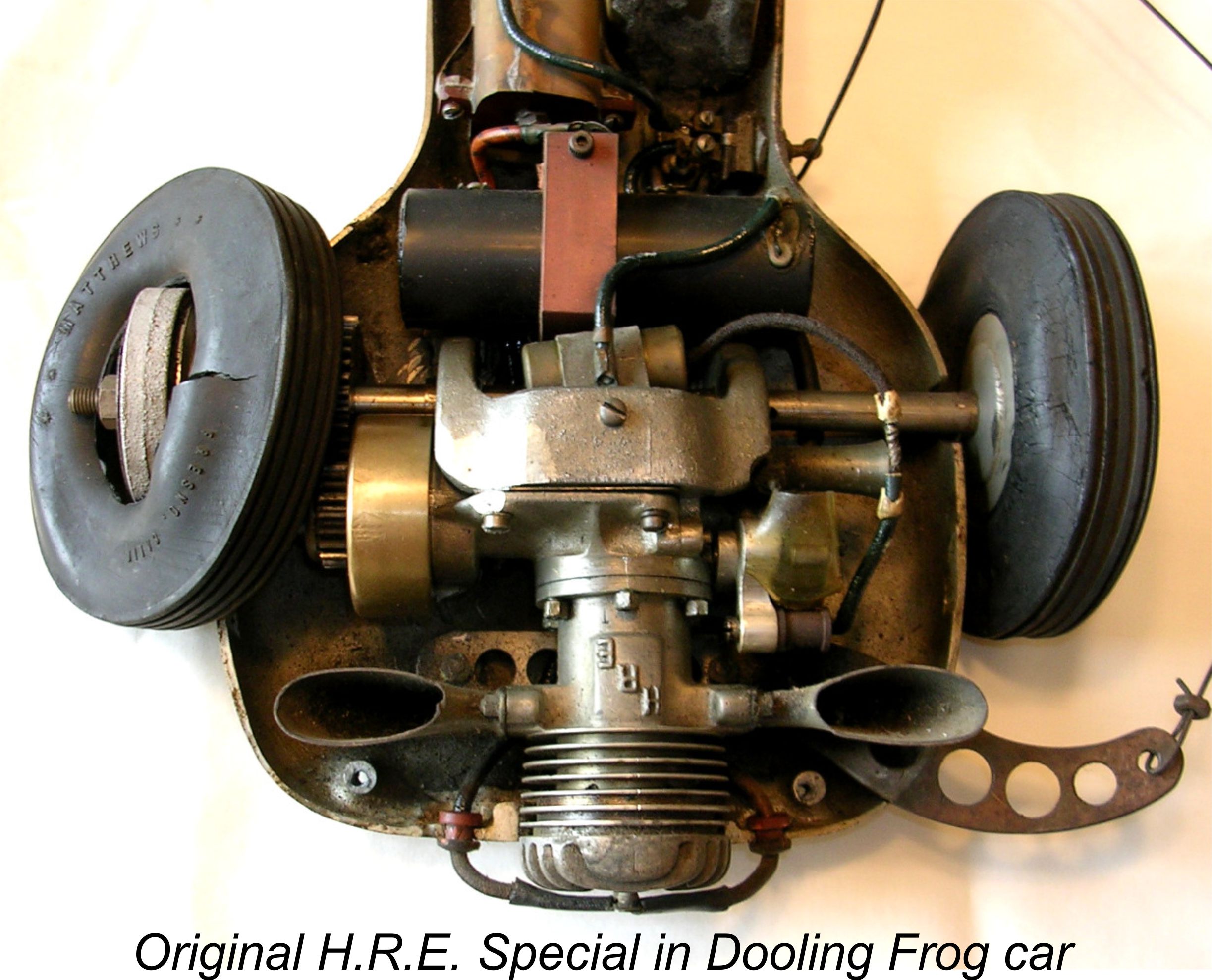

However, in tethered cable car racing where the runs were not interrupted by changes in track radius, the higher peak horsepower of the RRV Hornet 60 gave it a commanding edge. In performance terms, it remained something of a standoff between the FRV and RRV designs – it all depended upon the application. The high standard of workmanship and design expertise which the Hassad engines exemplified inevitably led to Ira’s being consulted by others with respect to their ideas for improved racing engine designs. One such individual who approached Ira during the years immediately prior to America’s entry into WW2 was a gentleman named Adam Cappell, a resident of far-off Dayton, Ohio. Ira was later to recall that Mr. Cappell used to call him at least once a week and talk his ear off for an hour or more about his ideas for an improved racing engine layout! Eventually all of this talk led Ira (perhaps in self-defence!) to design and construct an actual prototype along the lines suggested by Cappell. This more or less unique .61 cuin. design was designated the H.R.E. Quite apart from its then-unique cylinder porting arrangements, the H.R.E. Special also embodied a major departure from Ira Hassad’s previous thinking in that it used disc rear rotary valve (RRV) induction. Equally unusually, the timer was driven by the disc valve spindle rather than operating off the crankshaft. The crankshaft was carried in two ball races – also an evolution in Ira’s design thinking. The engine’s highly individualistic appearance stemmed in large part from the pair of spectacular megaphone exhausts which directed the exhaust gasses from each exhaust port to the right-hand side of the engine (viewed from the disc valve end). These exhausts displayed a total mastery of the metal fabrication art. This engine would have been LOUD!! Gotta run my example sometime to see ........ Ira later recalled that Cappell paid him $200 for the prototype of this model - a lot of money in those far-off days when you could buy a house for $1,000! Ira subsequently made a second example for himself, which he kept until his death in 1981. These were the only two examples made by Ira, although a few replicas have been made since.

The onset of WW2 put an end to Ira Hassad’s experiments with model racing engines, since his engineering talents were required for the war effort. He spent the war years working in the technical field at the University of California in San Diego. However, once the conflict was over he was quick to resume his model engine development activities, continuing to pursue the concept of FRV induction applied to model racing engines.

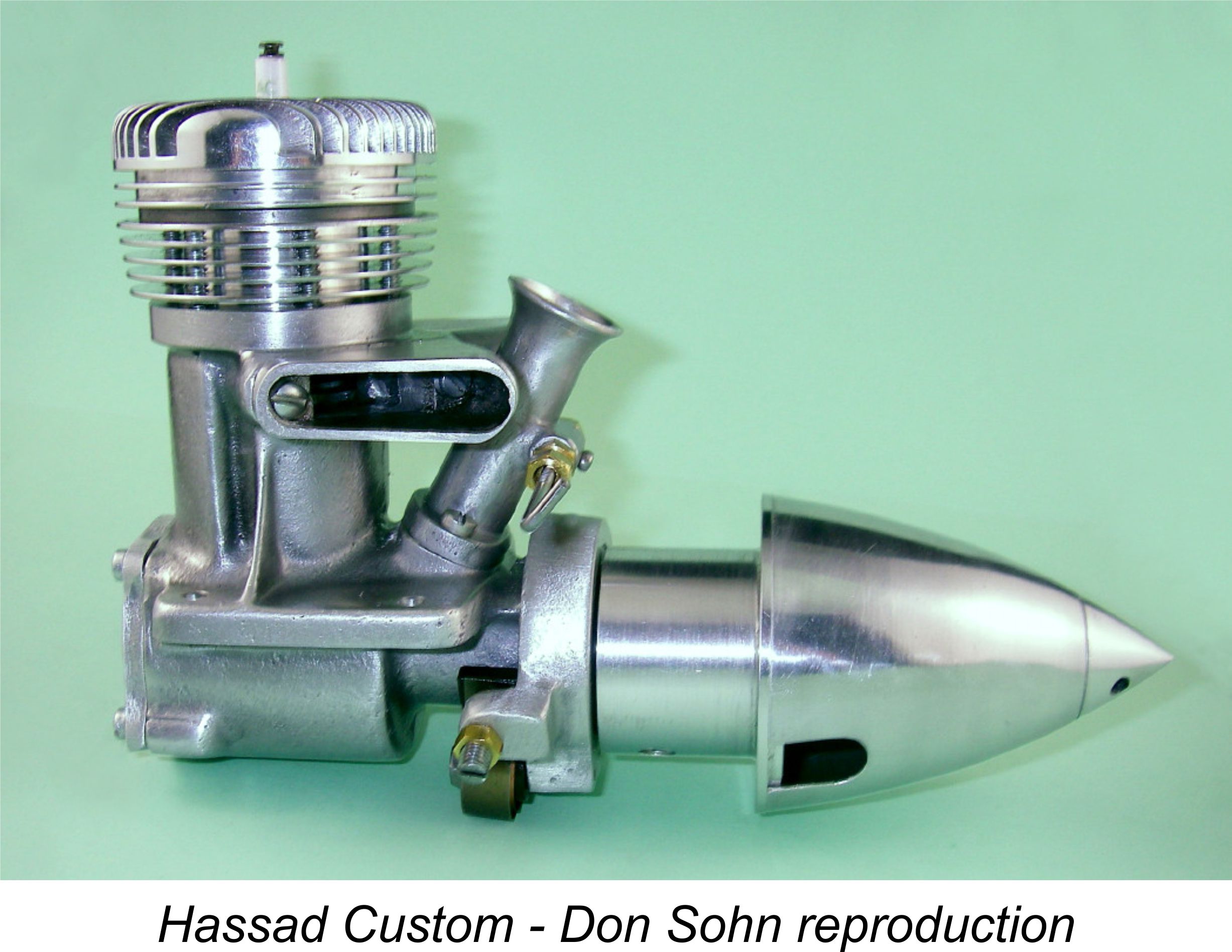

Jim Walker’s wartime development of the control line system for model aircraft had now made all-out speed contests for model aircraft a practical proposition, since high-speed models could be flown safely under complete restraint and control at all times. Accordingly, Ira’s engines were now appearing in aircraft service in addition to the car and hydroplane racing applications in which they had hitherto been employed. The illustrated example of the Hassad Custom .61 is set up for aircraft use, as were many others. From this point onward, the model aircraft market became increasingly important to the designers and manufacturers of model racing engines, to the point where it eventually became dominant. Although he was the most prominent and persistent advocate of FRV racing engines during the pre-WW2 and early post-war periods, Ira Hassad was not the only such individual. This brings us back to our main subject – the Ball 60 (remember that?!?). Over in the small community of Drayton Plains, Michigan, a fellow named Henry “Hank” Ball had established a facility known as the B&D Racing Engine Laboratory. Here he developed and manufactured another FRV racing engine - the Ball 60 which forms the main subject of this article. From this point onwards, we will focus our attention on that model. The Ball 60 Racing Engine Described

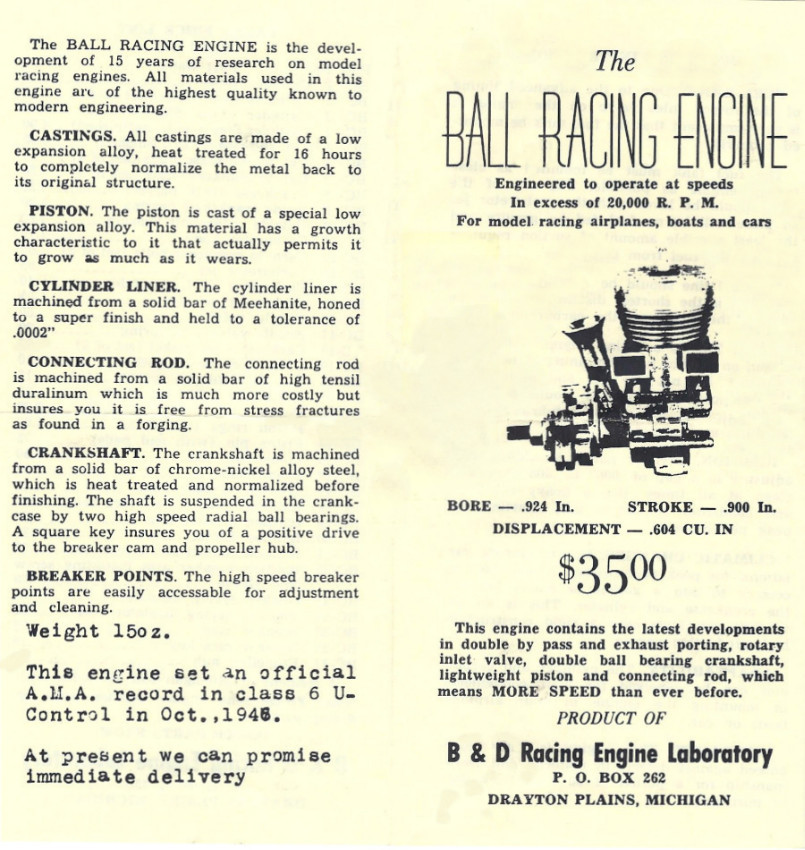

However, Hank Ball clearly had an interest in models, to the extent that he was eventually motivated to enter the model racing engine field himself. The initial model of the Ball 60 appeared in 1946, with limited production continuing into 1948. The instruction sheet claimed that this engine was the result of “15 years of research on model racing engines”. If this claim was There is one straw in the wind in this regard. The only practicable application for model racing engines in the early 1930’s would have been tethered hydroplanes. This branch of the modelling hobby was then well established, with most successful practitioners building their own engines out of necessity given the absence of any commercial racing engines at the time. Hank Ball’s later demonstrated interest in full-sized hydroplanes raises the distinct possibility that this stemmed from an earlier interest in models. If Ball was in fact a model hydroplane racer in earlier years, he may very well have begun his model engine development career when he claimed to have done so.

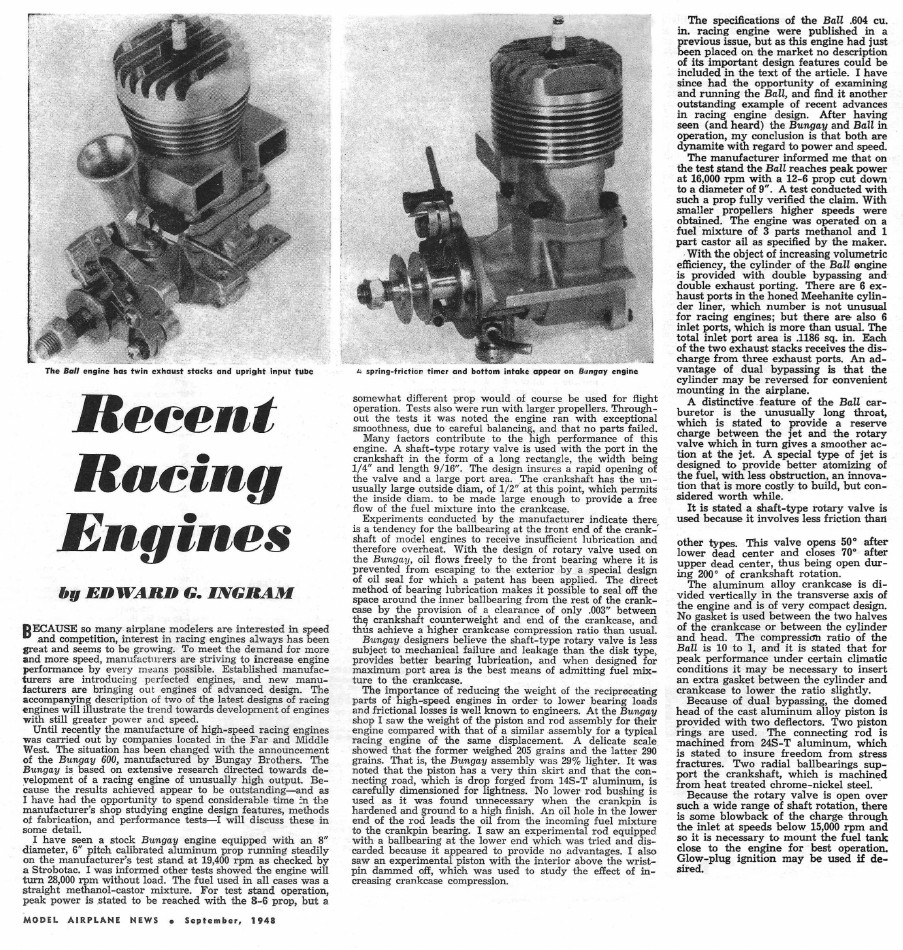

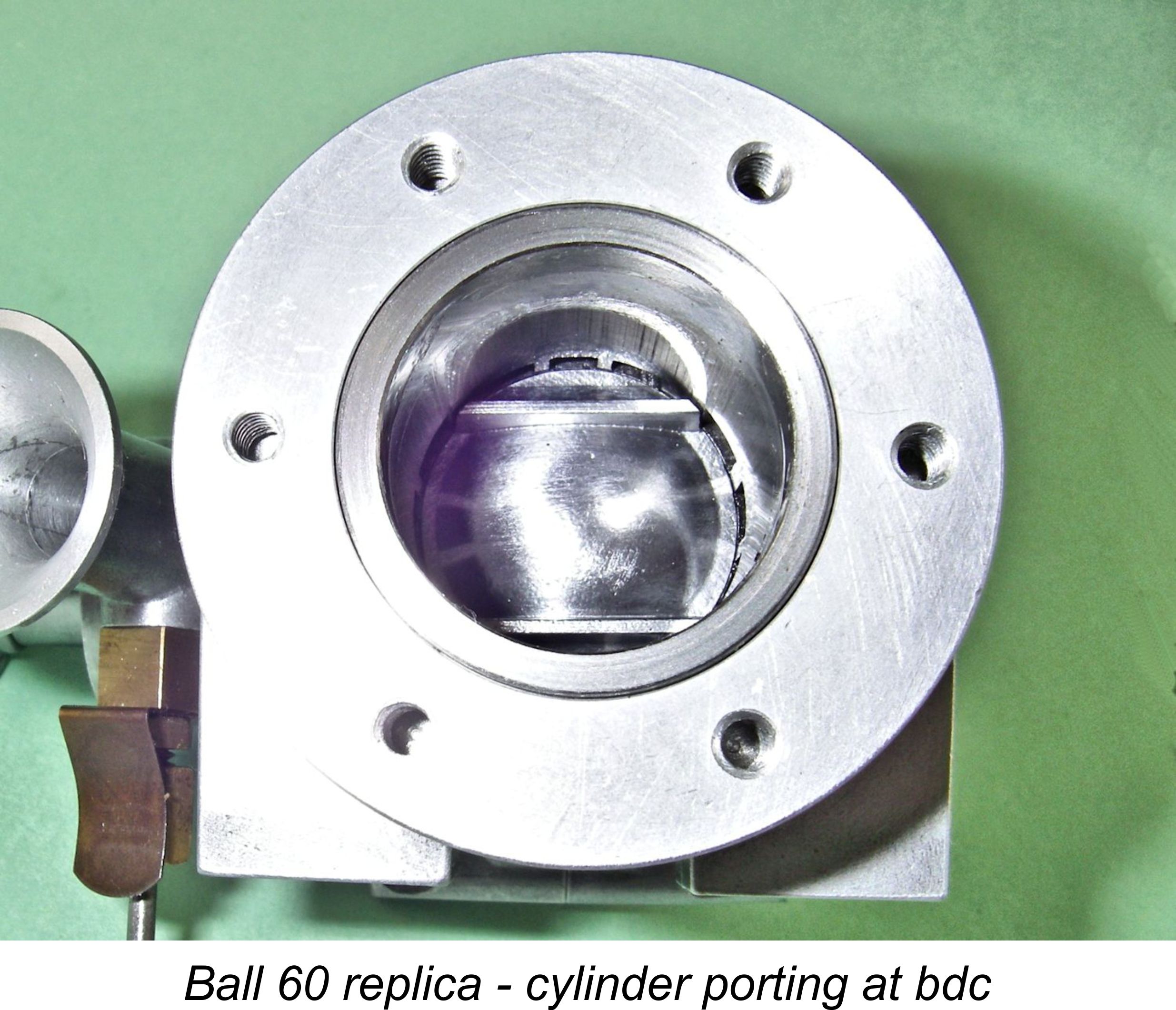

Against that, we have the coverage of the engine in the pages of “Model Airplane News” (M.A.N.). Specifications for the Ball 60 were included in Edward G. Ingram’s article in the January 1948 issue of M.A.N. entitled “Model Motors for 1948”. However, no descriptive material appeared in the text. By contrast, a later article by Ingram entitled “Recent Racing Engines” which appeared in the September 1948 issue of M.A.N. included a detailed description of the engine. In this later article, Ingram referred to the fact that the specifications of the Ball had appeared in “a previous issue” (presumably that of January 1948), but the fact Clearly there is some inconsistency here among our various sources. The most likely explanation is that prior to late 1947 the Ball 60 was marketed either locally or through direct contact with the contemporary racing community, either through their newsletters or simply by word of mouth. Only when the demand generated by this “below the radar” marketing approach began to slacken did Ball commence a broader marketing effort, thus bringing the engine to national attention for the first time. In describing the Ball 60, it seems best to start with a few numbers. The Ball featured bore and stroke measurements of 0.924 inches (23.47 mm) and 0.900 inches (22.86 mm) respectively for a displacement of 0.604 cubic inches (9.89 cc). Interestingly enough, this was one of the earliest instances of a manufacturer departing from the “standard” bore and stroke measurements of 0.940 in. and 0.875 in. respectively for a displacement of 0.607 cu. in (9.95 cc) which had been established by the Hornet and carried over to other designs such as the McCoy 60 and Rowell 60. It would appear that Hank Ball wished to improve the engine’s torque development potential by lengthening the stroke somewhat. Claimed weight of the engine was 15 ounces (425 gm) – a relatively low weight for a .60 cubic inch racing engine. For reasons which are unclear, the illustrated Bartelt replica weighs all of 17.10 ounces (485 gm). As we’ve seen when reviewing the work of Ira Hassad, all of the FRV racing engines developed during this period were highly individualistic. However, none were more so than the Ball 60. Like the majority of the post-war Hassad designs, it featured FRV induction, a twin ball-race shaft and a ringed aluminium piston. However, there the similarities ended. The Ball harked back to the earlier H.R.E. Special in featuring dual exhausts with dual bypasses between them, thus constituting an early example of the style of porting to be used so successfully by Cox (among others) and later developed into the Schnüerle porting system. The bypass passages were sized very generously indeed – I’m not aware of a contemporary design which featured a larger total bypass area.

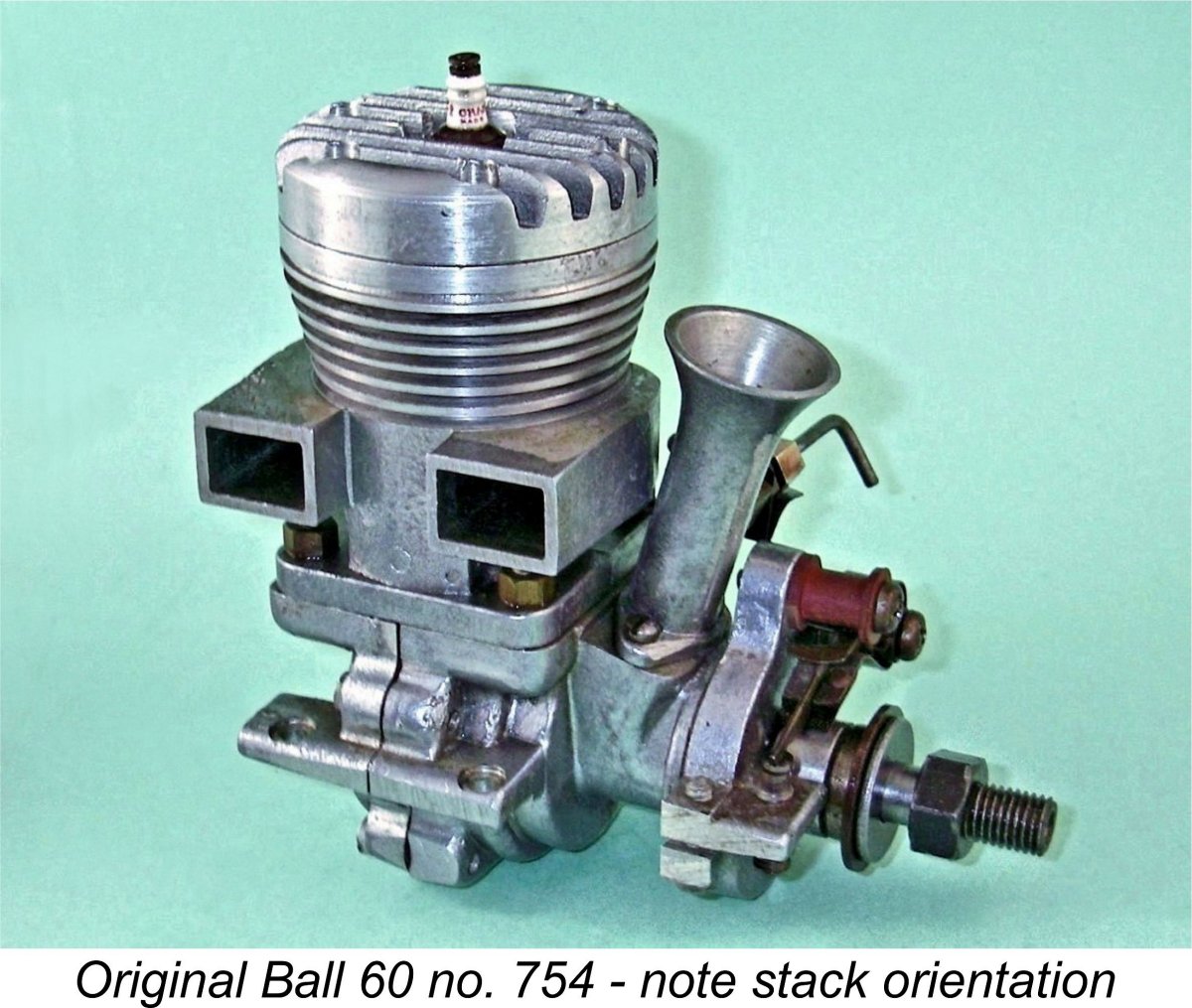

The cylinder featured the usual six exhaust openings which were arranged in two groups of three fore and aft between the transfers. These fed the two exhaust stacks which exited at front and rear. Both exhaust stacks discharged to the same side of the engine, usually to the left rather than the right as supplied. Naturally, this feature imparted a highly unusual appearance to the unit.

Two distinct styles of cylinder head were used. The earlier examples of the Ball 60 featured a cylinder head having radial “bicycle spoke” style head fins, rather like those used on the contemporary G.H.Q. engines. Later models switched to a conventional-looking head having fins which were aligned along the engine’s fore-and-aft axis. In both cases, the fins were cast onto the heads rather than being machined.

The upper cylinder unit complete with exhaust stacks was attached to the lower crankcase using four studs with nuts. This feature harked back to the design of the trend-setting Hornet 60. The use of studs and nuts rather than bolts was forced on the designer by the presence of the exhaust stacks, which precluded the insertion of bolts through the installation holes on the exhaust stack side.

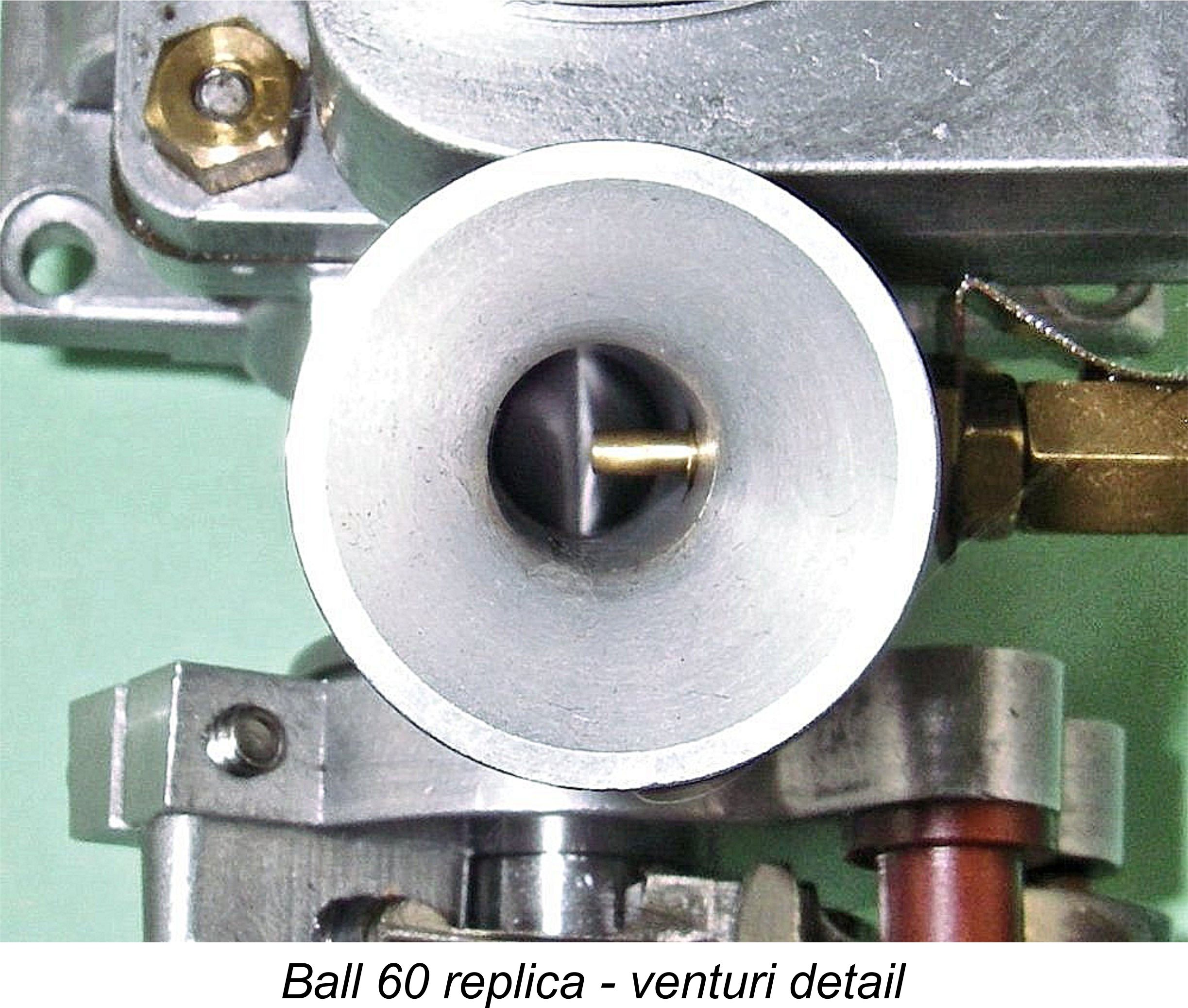

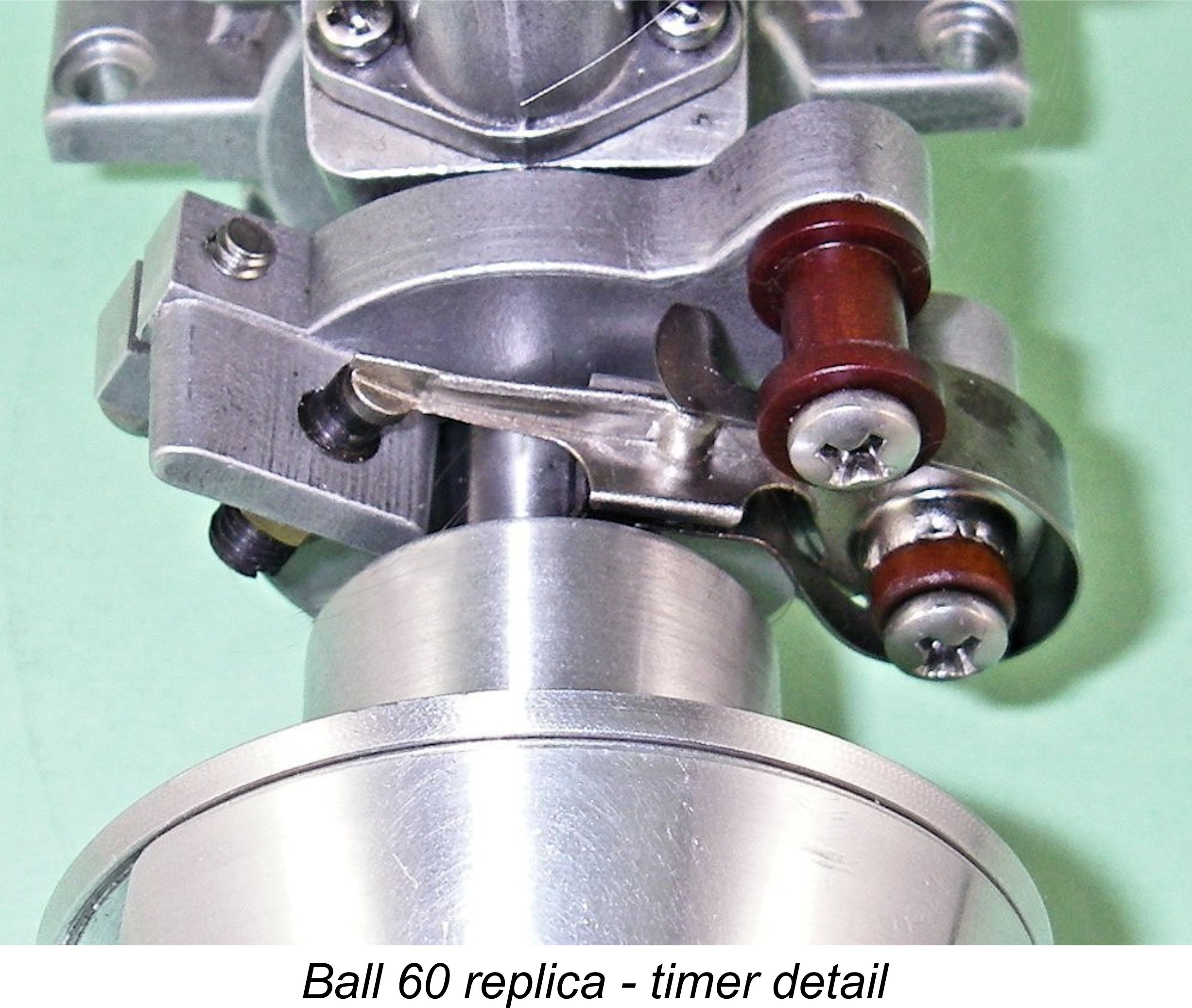

The engine seems to have been generally supplied with the stacks discharging to the left. It appears in that form in all of the contemporary illustrations that I have been able to find, including that which was included in the instruction leaflet as well as the photograph with Ingram's previously-cited article. The Bartelt replicas were configured accordingly. Having said this, it must be noted that original examples are encountered with their stacks assembled in both orientations. The two previously-mentioned original examples which appeared on eBay in September 2018 both had their stacks oriented to the right. I managed to acquire one of those engines, which appears to be new and unrun, making it seem likely that it was supplied in this orientation. The same is evidently The engine featured an unusually long cast intake venturi which was attached to the main bearing housing with two screws, exactly as on the Hassad Custom design. In fact, the entire front end displayed a distinctly Hassad style. The venturi bore was a relatively skinny 0.341 inches (11/32 inch nominal) – rather on the small side for a high speed .60 cubic inch racing engine. A further similarity to the Hassad design was the use of a fuel jet which took the form of a small-diameter nozzle protruding into the centre of The timer was of the usual automotive type, albeit with the moving points positioned forward of the main timer casting rather than in the more usual rearward location. This was of course forced on the designer by the presence of the intake venturi immediately behind the timer body. The cam was unusual in that it was not machined into the shaft itself but was a separate Overall, we’re looking here at a clever and in some ways innovative model racing engine design, albeit one which clearly drew inspiration from a number of earlier designs by others. Let’s look into that matter next. Design Influences In reviewing the above description, it’s actually extremely interesting to note the design similarities between the Ball 60 and Ira Hassad’s pre-war H.R.E. Special described earlier. Setting aside the fact that it departed from the FRV induction arrangements seen on both the Ball and the mainstream Hassad designs by employing RRV induction, the pre-war H.R.E Special featured exactly the same highly unusual cylinder porting arrangements as seen in the design of the later Ball 60, albeit in a less highly-developed form. Both the Ball and the H.R.E. also employed two exhaust stacks discharging to the same side of the engine. The unique exhaust stack layout in particular draws one’s attention to the possibility that the H.R.E. may have influenced the Ball’s design..…..after all, Drayton Plain, Michigan is not actually all that geographically distant from Dayton, Ohio, home of the H.R.E.s previously-mentioned instigator Adam Cappell. It seems entirely possible that Henry Ball was acquainted with Adam Cappell or at least had an opportunity to examine Cappell’s H.R.E., although we’ll probably never know for certain. Either way, the exhaust stack arrangement on the Ball implies pretty clearly that it too was specifically designed for use in a spur-geared streamliner such as the Dooling Frog design. However, the manufacturer clearly envisioned its use in fields other than car racing. The instruction sheet specifically referred to the engine’s applicability to “model racing airplanes, boats and cars” in that order. Some of the later instruction sheets also included a reference to an official AMA speed record for Class 6 control-line model aircraft reportedly set in October 1946. The engine certainly takes on a handsome appearance when fitted out with the necessary prop mounting hardware for speed flying – it actually “looks right” in that configuration.

It seems more likely than not that the design of the Cave Cobra was influenced by that of the H.R.E. Special, since Walt Cave must surely have been acquainted with his fellow California enthusiast Ira Hassad. The Cobra’s needle valve arrangement is a dead give-away for a start - it is precisely modelled upon the Hassad design. However, it must be said that the Cave Cobra embodies a good deal of original thinking, of which more elsewhere in a separate article. Quite apart from the cylinder design, Hassad influence was also to be seen at the front end of the Ball 60, where the carburetion arrangements were essentially identical, notwithstanding the slight differences in the needle valves used on the two models. In terms of its breathing arrangements, the Ball was in effect a combination of two Hassad design influences – the twin ball-race FRV layout featured in the Hassad Custom and the then-unusual style of cylinder porting introduced by Hassad with the H.R.E. Special. The Hornet was not left out of the influence picture either – the Ball drew its bolt-on upper cylinder casting and split crankcase more or less directly from that model. Nonetheless, the Ball melded these design influences into a unique racing engine of considerable potential. Let’s see what one contemporary model engine commentator made of the engine. The Ball 60 in the Modelling Media The previously-noted September 1948 M.A.N. article by Edward Ingram described the Ball 60 in great detail. Ingram began by classifying the engine as “another outstanding example of recent advances in racing engine design”. He noted the manufacturer’s claim that the engine peaked at around 16,000 RPM, a speed which could be achieved on the test bench with a 12x6 airscrew cut down to 9x6. Ingram claimed to have personally witnessed a demonstration of the validity of this claim. Naturally, to take best advantage of the engine’s performance it would have been necessary to load it for a somewhat lower speed on the ground to allow it to pick up to its peak once the model was off and running.

The unusual needle valve design also received favorable comment from Ingram, who felt that it would provide superior atomization of the fuel. Ingram also commented upon the engine’s unusually tall intake venturi, citing the manufacturer’s seemingly somewhat dubious claim that the intake length provided “a reserve charge between the jet and the rotary valve which in turn gives a smoother action at the jet”. How the basis for this claim was substantiated is unclear ………a long intake venturi does generally promote better carburetion, but the “reserve” theory seems a little shaky to me! As in the case of his review of the Bungay High Speed 600 which was also included in this article, Ingram was careful to probe the designer’s reason for the use of FRV induction. In the case of the Ball, the main cited advantage of this system was stated to be the lower friction by comparison with an RRV model. Ingram quoted the engine’s compression ratio as 10 to 1, noting that this could be adjusted in a downwards direction by the use of extra gaskets between the cylinder casting and the lower crankcase. The manufacturer’s instruction leaflet also pointed out this possibility. That said, the standard ratio appears to be quite compatible with the maker’s recommended fuel, which was straight methanol with at least 25% castor oil. Ingram reported that at speeds below 15,000 rpm there appeared to be considerable blow-back from the intake venturi. This doubtless arose from the engine’s relatively aggressive induction timing of 50 degrees ABDC to no less than 70 degrees ATDC. The resulting induction period of 200 degrees was unusually large, especially for an FRV design. It was apparently for this reason that the manufacturers recommended that the fuel tank be mounted as close to the engine as possible. Marketing History and Production Figures We've seen that there's some uncertainty regarding the date of the Ball 60's introduction to the market. It may have appeared (at least on a local distribution basis) as early as 1946, although Edward Ingram seemed to believe that it had actually shown up on the broader market in late 1947. It should be obvious that these two scenarios are by no means mutually exclusive - both interpretations may be true. Be that as it may, the Ball seems to have remained on the market through 1948. However, its disappearance from subsequent model engine listings implies that production did not continue far if at all into 1949. Presumably the fact that even in tuned form the engine could not quite compete on level terms with either the Dooling or McCoy models (see below) spelled the end of the line, as it did for other racing engines such as the Hornet, Orr and Bungay.

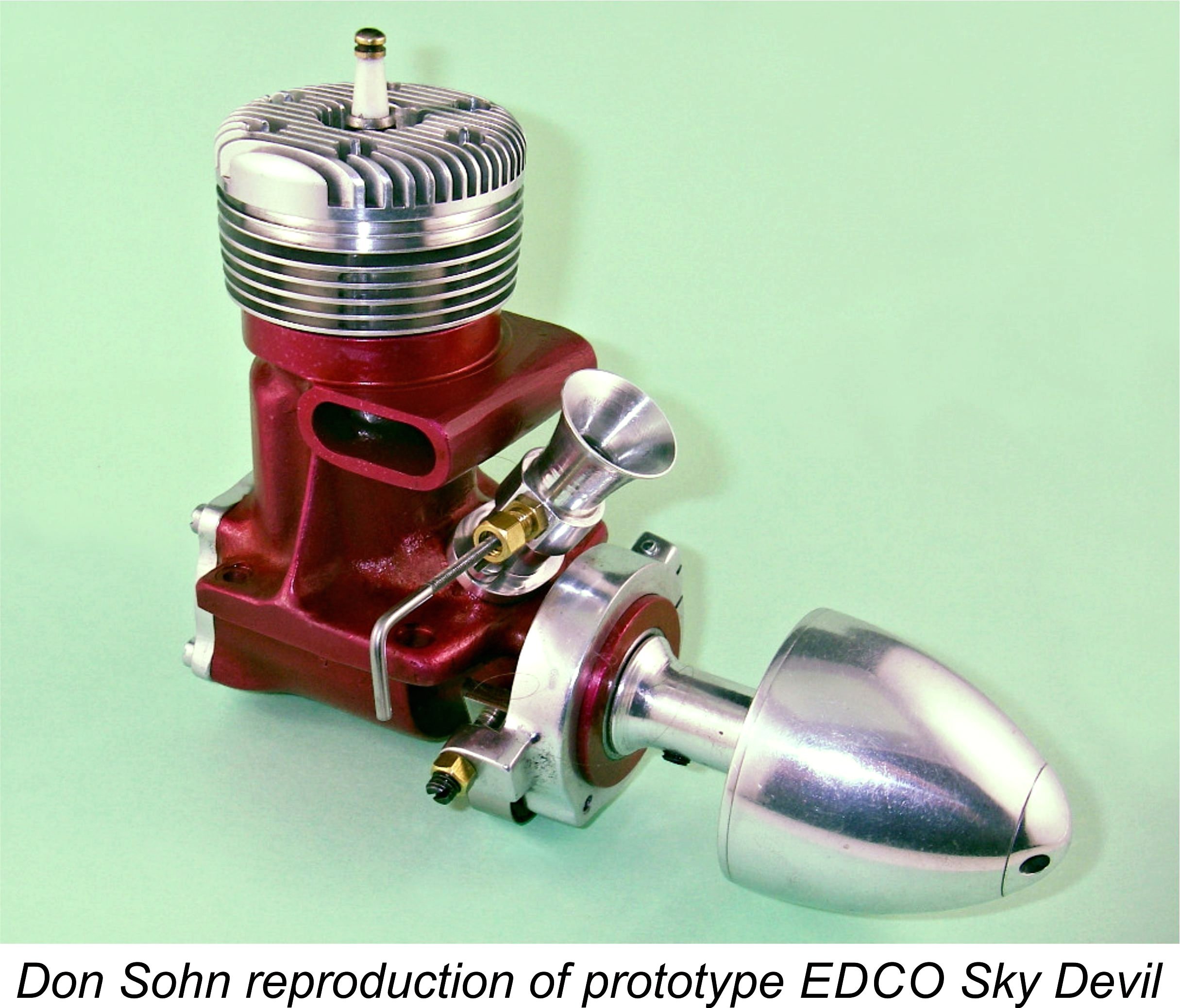

At first sight, the number on my engine seems to imply the production of at least 754 engines, although the relative infrequency with which examples show up on eBay and elsewhere tends to argue against this. Still, it's undeniably possible .......... The significance of the AC and BC letter prefixes to the numbers on the other reported examples is unclear. The A and B letters may well relate to the version involved, since AC 027 is an early example with radial head fins and a left-hand exhaust orientation, while BC 063 is a later model having parallel head fins and a right-hand exhaust orientation. BC 172 and BC 185 both have parallel head fins along with left-hand stack orientations. It would appear that the numbering sequence for the BC engines started at BC 001 and included at least 185 similarly-numbered examples. It also appears that stack orientation was a purchaser's option which didn't affect the serial numbering system. More problematically, where does this leave un-prefixed engine number 754, which also has parallel head fins and a right-hand exhaust?? Only the reporting of additional serial numbers would help us to resolve this conundrum. It should be noted that the Bartelt replicas all have B-prefixed numbers in a Bxx pattern and only go up to engine number B50, making them readily distinguishable from the originals. Any un-numbered engines are likely Don Sohn replicas. Buyer beware!! During the period in which the Ball had been on offer, other designers had maintained an interest in the development of FRV racing engines. Chief among these was our old friend Ira Hassad. Let’s look briefly at the further history of FRV racing engine development during this period. Further FRV Developments We last encountered Ira Hassad manufacturing the Hassad Custom .61, one of his true masterpieces. This engine proved to be a formidable competitor, a fact which did not go un-noticed by others. A certain Mr. Frank Howarth, owner of a company called Engineering Development Co. Inc. (EDCO), decided that a mass-produced version of this engine would enjoy good sales prospects and invited Ira to come to work Hassad’s involvement with this company during 1947 resulted in perhaps his most recognizable design of them all, the EDCO Sky Devil 1500. This was in effect a slightly simplified mass-produced version of the Hassad Custom .61. It was another FRV twin-stack front exhaust unit with a twin ball-race shaft and ringed aluminium alloy piston. The engine was offered in both a .649 cuin. aircraft version (the regulations then in force for model aircraft allowed engines of up to .650 cuin.) and a .607 cuin. race car variant which was used in EDCO’s own race car offerings.

Original unmodified examples of the EDCO engines are pretty rare these days. To meet the demand for operable examples of this engine, some 250 fine .649 cuin. replicas were produced in 1983 by Randy Linsalato of RJL (later combined with MECOA). These were made under contract for the late Terry Toupes. Internally, they are not exact replicas, utilizing some readily-available parts from other engines to keep Randy began work on a second series which was to be closer to the originals, but this project never reached completion due to decreasing demand. My sincere thanks to Randy for personally sharing this information with me. The EDCO Sky Devil never achieved the performance levels of the earlier Hassad Custom model, in large part because it was not individually fitted and assembled as was its progenitor. For an extra charge of $15, Ira Hassad would undertake to personally rework a Sky Devil to realize its full potential, and a number of smart purchasers took advantage of this. However, the big-bore racing engine market was becoming dominated by the McCoy 60, with the Hornet 60 also still very much in evidence. The arrival of the Dooling 61 later in 1947 did nothing to help. Consequently, the Sky Devil did not meet sales expectations, with only some 1000 - 1500 examples being produced in total before financial difficulties forced the EDCO company into liquidation. As a result of the liquidation process, the bulk of the remaining Sky Devil parts and tooling ended up as the property of EDCO’s major creditors, the Tyce brothers, who owned a company called International Tool Corporation of Chula Vista, California, just to the south of San Diego. The established business of this company was the provision of full-sized aircraft engineering services, but they decided to see if anything could be salvaged from the remains of the EDCO venture. To that end, they hired Ira Hassad to come up with a model engine design in which the former EDCO parts and tooling could be used. The design brief this time was specifically for an aero engine for free flight and control-line applications - cars were no longer seen as the major market that they had once been.

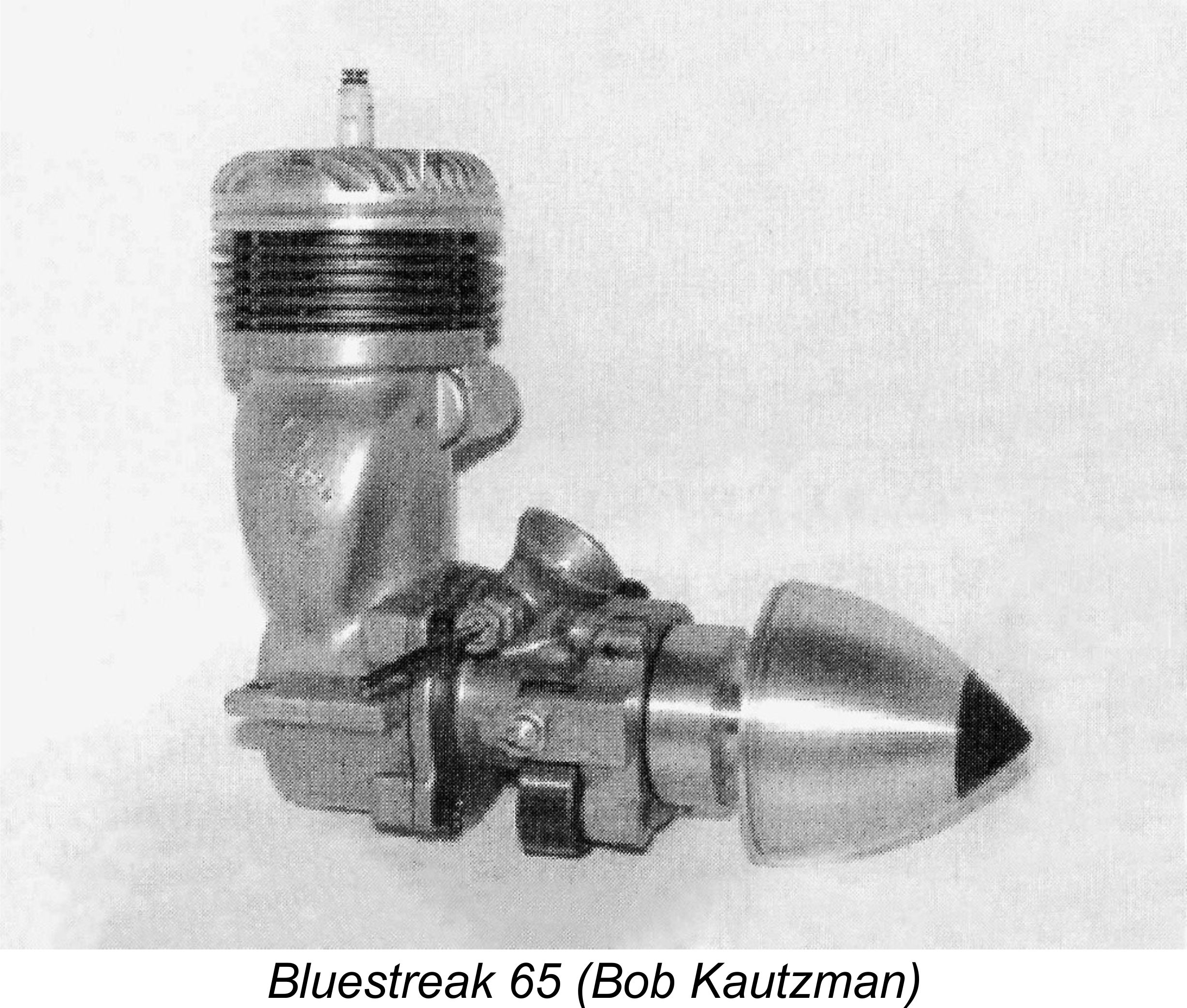

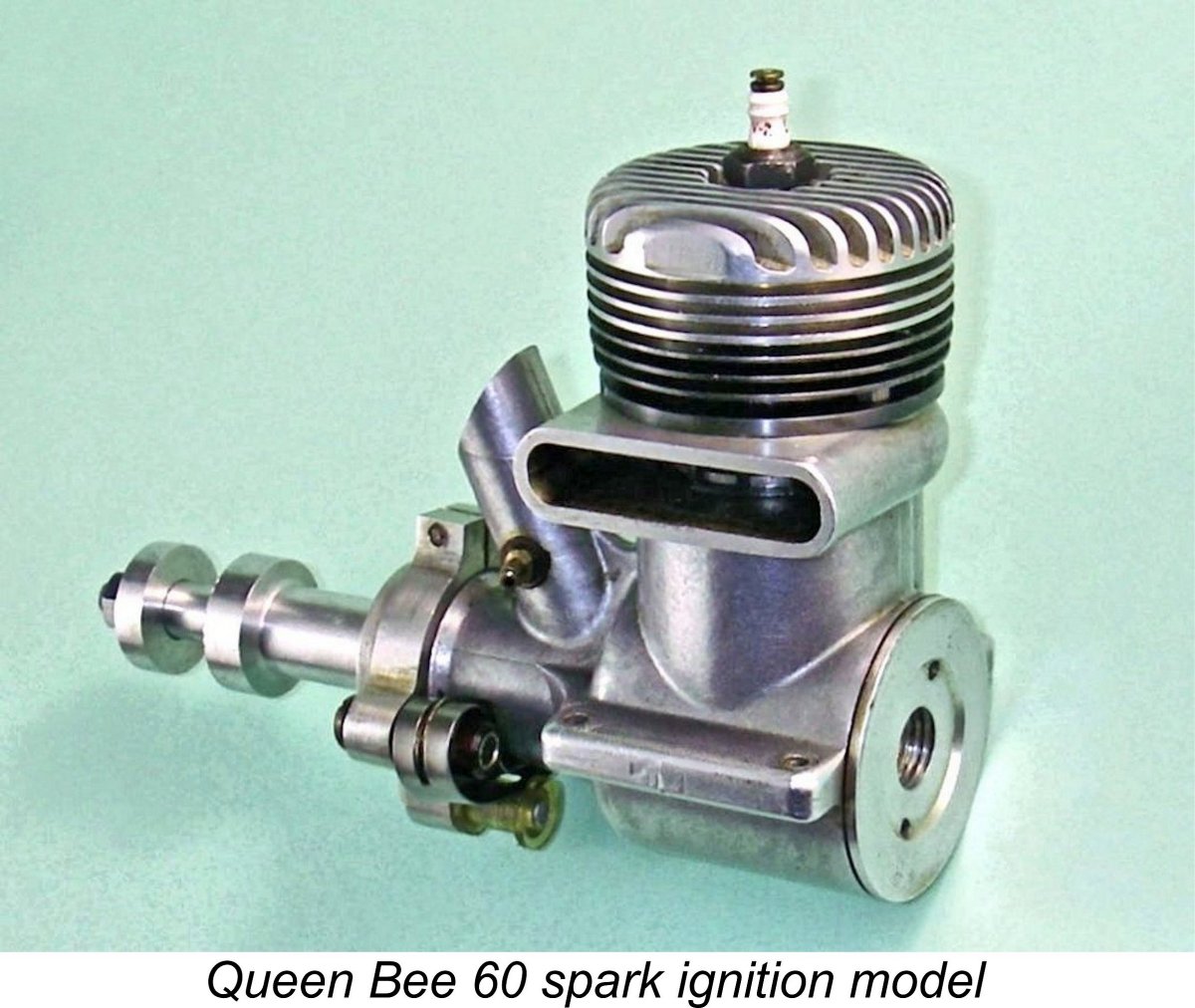

Reflecting its time and place, the Bluestreak was offered in both spark ignition and glow-plug versions. It was reportedly a fine engine for free flight and non-racing control line applications. However, in a racing context it could not hold its own with the then-current crop of big-bore racing engines from other manufacturers. Even so, all 2000 or so examples of this engine which were manufactured did eventually find buyers, although it took a while. Long before that happened, Ira Hassad had moved on into other engineering ventures, leaving model engines behind The final entry in the FRV racing engine sweepstakes originated in 1948 in New York, where the Bungay “High Speed” 600, an almost-forgotten early post-WW2 American model racing engine, was manufactured in very small quantities. This highly individualistic design represented a very sincere and carefully-considered effort by its manufacturers to offer a technological alternative to the leading racing engines of the day. Sadly, it failed to convince the modelling public and did not survive long in production. The Bungay story may still be accessed on MEN. As events were to prove, the Bungay was the last of the commercial big-bore FRV racing engines to appear in the early post-war period. However, another maker who was considering the introduction of an FRV .60 cuin. racing engine at this time was Al Salonen of Vancouver, British Columbia, Canada, who was the artisan manufacturer of the beautifully-made Queen Bee .24 and .29 powerplants There's incontrovertible evidence in the form of two surviving examples that Al Salonen produced at least two prototype examples of a superbly-made twin ball-race ringed-piston FRV racing .60. These were built in both spark ignition and glow-plug forms. Furthermore, the survival of several unfinished additional components confirms that Salonen was in the process of constructing further examples when the whole Queen Bee venture ended at some point in 1950, leaving the .60 models frozen at the prototype stage. This had nothing to do with any shortcomings of the still-born .60 model - rather, it resulted from Salonen recognizing his inability to compete with the mass-produced and hence less expensive offerings from others such as K&B, OK and Ohlsson. The Queen Bee 60 prototypes were almost certainly constructed during 1949. They thus represented the very last attempt by a commercial manufacturer to create a competitive FRV .60 cuin. racing engine. From 1949 onwards the field was completely dominated by RRV models which adhered to the “classic” racing engine formula established by the Hornet and McCoy 60 designs. Personal Recollections of the Ball 60

In this manner, Tom acquired a batch of some 30 cars and even more engines. In his own words, he was “young enough and dumb enough” to think that there might be a gem among those engines that was better than the Series 20 McCoy or Dooling 61 which were the standard speed engines at the time. To evaluate this possibility, Tom proceeded to test all of his new acquisitions on a 9x12 Tornado speed prop, which was pretty much a standard for .60-class control-line speed at The batch of engines that had been given to Tom included such mouth-watering gems as the Ball, Bungay, Cave Cobra, original and bulge-bypass Hornets, Orr, EDCO Sky Devil, Bluestreak, Hassad (prewar), Ancil 60, Atomic, Thunderbird, Baab-Fox, Batzloff, Blakely, Thermite, Talisman and probably some other racing classics which Tom cannot now recall. There were also some older pre-war cars and engines (O&R, Dennymite, etc.) which Tom did not include in his tests since they were clearly obsolete. Other engines such as the Super Cyclone, Atwood Red Crown and OK Tornado were clearly of marginal interest in a 1950’s speed flying context. The results of these tests were most interesting! In Tom’s still-clear recollection, the best engine using the test 9x12 Tornado prop was the McCoy 60 Series 20. The Dooling needed to rev out more to give of its best, hence requiring a smaller prop. The “best of the rest” were the Hornet 60 models, which pushed the McCoy fairly hard. None of the other engines tested could match the original Hornet, which was itself only beaten by a relatively small margin by the later “bulge bypass” Hornet kit conversion. Tom shared the insightful observation that the sustained early success of the original Hornet may actually have had a detrimental effect upon model racing engine development in the USA due to the extent to which its overwhelming dominance led to its being slavishly copied by other makers. Since this influence included the Hornet’s overly-restrictive induction, bypass and transfer arrangements, many of the engines tested by Tom displayed clear symptoms of high-speed asphyxia. It was actually not until 1947 that most designers began to appreciate the need to increase the bypass and transfer capacities of racing engines. The most restrictive bypass set-up of them all was the tiny convoluted arrangement featured in the 1946 Baab-Fox. As a result, that engine was dead at the starting line in competition terms. I've recounted the story of the Baab-Fox in a separate article to be found on this web-site at the above link.

It’s clear from this that the Ball 60 represented a very worthy attempt by Hank Ball to take on the might of Hornet, McCoy and Dooling with an FRV design. In this, he stands revealed as marching shoulder to shoulder with Ira Hassad. The fact that his effort fell just that little bit short reflects no discredit upon his abilities as a model engine designer. Conclusion

Unmodified original examples of this engine are very seldom encountered today. In the past, when they did show up, they commanded some pretty startling prices! This is changing today in the shrinking market for model I/C engines both old and new - the last two examples that appeared on eBay (in 2018) sold for "only" US$450 apiece. Ten years ago you'd have paid at least twice that! However, offerings of original examples are rather rare - there's probably more chance of finding one of the Bartelt replicas like that featured in this article, and they're likely to be more affordable. Anyone acquiring an example of one of Woody's efforts will be getting a very nice replica of an engine that deserves an honored place in the history of big-bore model racing engines! I plan to conduct a test of the replica Ball 60 at some point in the future. When that's done, I will of course update this article with a summary of my findings. _______________________________ Article © Adrian C. Duncan, first published December 2014 Updated February 2019

|

| |

In this article we take a look at the Ball 60, an almost-forgotten early post-WW2 American model racing engine which was among those which unsuccessfully challenged the “classic” racing engine formula established by the

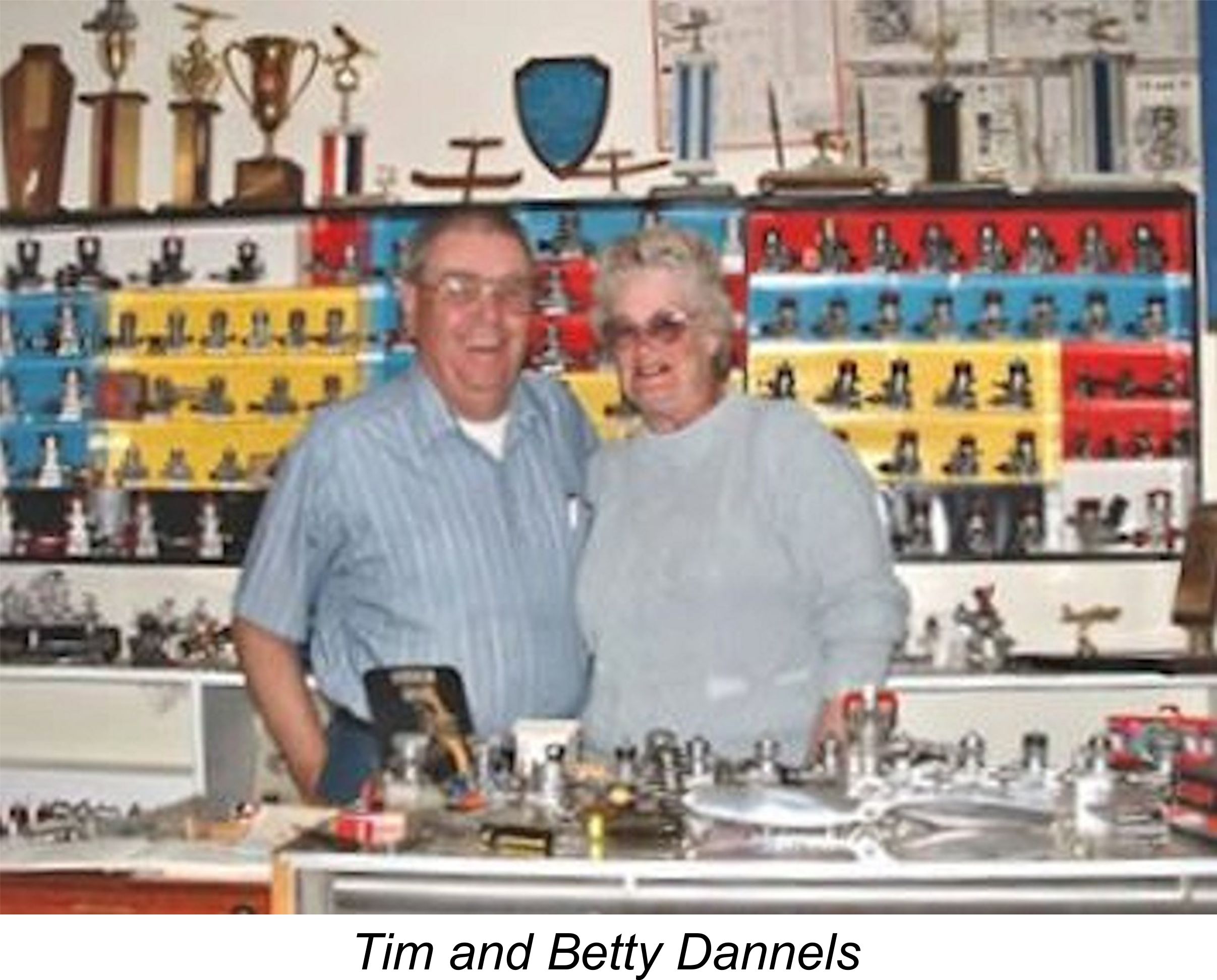

In this article we take a look at the Ball 60, an almost-forgotten early post-WW2 American model racing engine which was among those which unsuccessfully challenged the “classic” racing engine formula established by the  As always when discussing an American model engine from the “classic” era, it’s both a duty and a genuine pleasure to pay tribute right up front to my valued friend and colleague Tim Dannels, Editor of the always-informative but sadly now discontinued periodical “

As always when discussing an American model engine from the “classic” era, it’s both a duty and a genuine pleasure to pay tribute right up front to my valued friend and colleague Tim Dannels, Editor of the always-informative but sadly now discontinued periodical “ r generously sharing his recollections of the Ball and other historic racing engines of the pioneering era. It’s great to see evidence of a sincere interest in classic model engines from outside the mainstream air-head community.

r generously sharing his recollections of the Ball and other historic racing engines of the pioneering era. It’s great to see evidence of a sincere interest in classic model engines from outside the mainstream air-head community. Although tethered hydroplane racing was taking place during this period, the relatively small number of practitioners of this highly specialized branch of the modelling hobby was insufficient to create a viable market for racing engines. The resulting unavailability of any commercially-built racing engines forced the most consistently successful model hydroplane racers to design and construct their own specialized powerplants. A notable example of this was the legendary

Although tethered hydroplane racing was taking place during this period, the relatively small number of practitioners of this highly specialized branch of the modelling hobby was insufficient to create a viable market for racing engines. The resulting unavailability of any commercially-built racing engines forced the most consistently successful model hydroplane racers to design and construct their own specialized powerplants. A notable example of this was the legendary  The resulting powerplants differed quite significantly from their aero predecessors. Weight was far less of an issue - instead, all-out performance and durability were now the primary concerns of the various competing racing engine designers. In a previous article about the

The resulting powerplants differed quite significantly from their aero predecessors. Weight was far less of an issue - instead, all-out performance and durability were now the primary concerns of the various competing racing engine designers. In a previous article about the  An expert machinist and a keen aeromodeller from a young age, Ira Hassad started making model engines for his own use in the early 1930’s while still in his teens. In 1935 the then 20-year old Hassad was hired by former WW1 fighter pilot

An expert machinist and a keen aeromodeller from a young age, Ira Hassad started making model engines for his own use in the early 1930’s while still in his teens. In 1935 the then 20-year old Hassad was hired by former WW1 fighter pilot  This engine featured the unusual combination (for a racing engine) of a front exhaust with twin stacks, a plain bronze-bushed main bearing, a lapped piston, a five-bolt backplate and FRV induction. It also sported an early rendition of the remote needle valve system later to be employed by Cox, among others. Some 200 examples of this model were reportedly made and sold, a figure which encouraged Ira to continue on his own after Louis Schock found it necessary to return full-time to his regular job at Lockheed. A basically identical model was still in production in 1941, albeit by that time under Hassad’s own name.

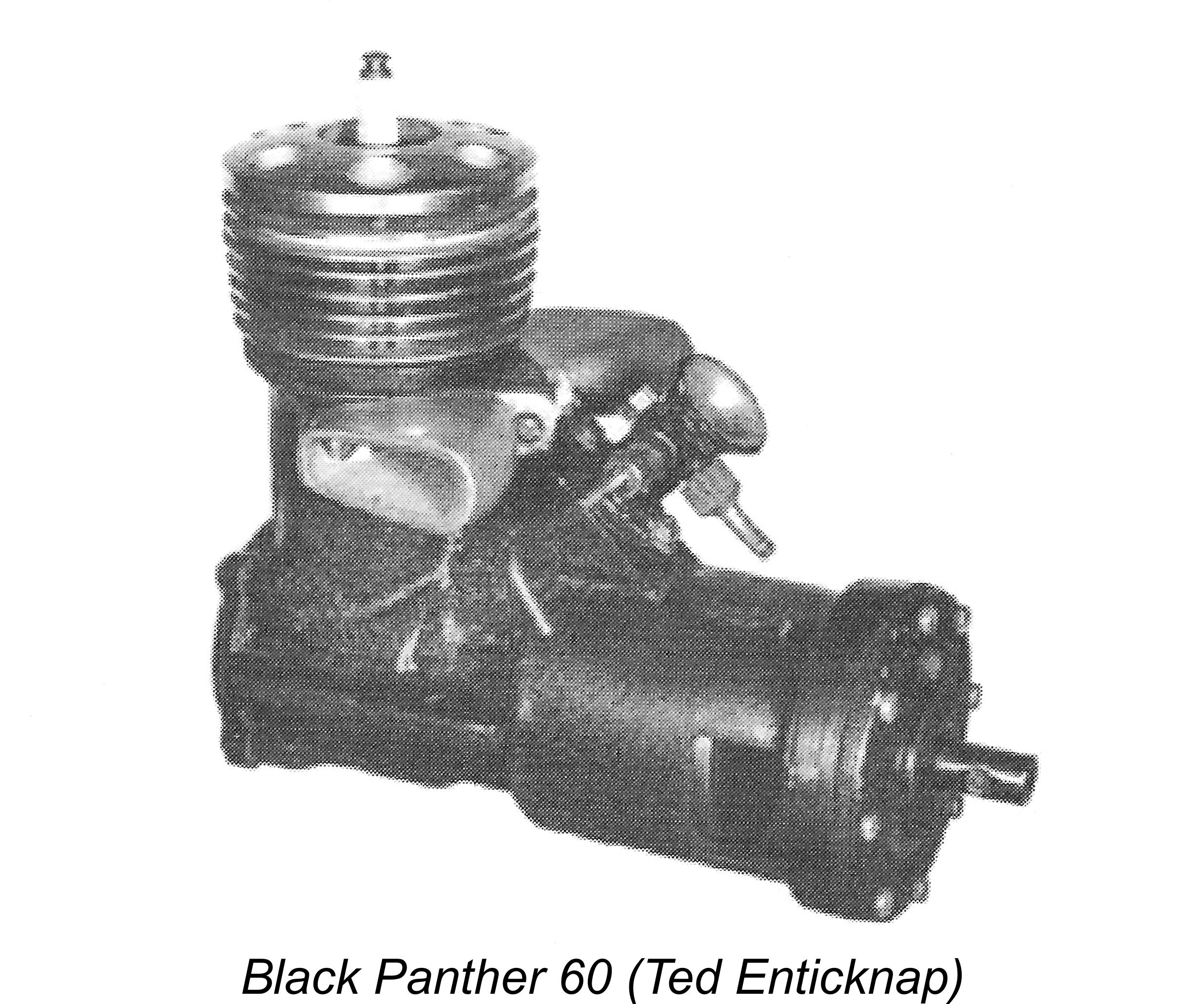

This engine featured the unusual combination (for a racing engine) of a front exhaust with twin stacks, a plain bronze-bushed main bearing, a lapped piston, a five-bolt backplate and FRV induction. It also sported an early rendition of the remote needle valve system later to be employed by Cox, among others. Some 200 examples of this model were reportedly made and sold, a figure which encouraged Ira to continue on his own after Louis Schock found it necessary to return full-time to his regular job at Lockheed. A basically identical model was still in production in 1941, albeit by that time under Hassad’s own name. The Hassad engines were very successful in competition, a fact which did not go unnoticed by other California-based model engine designers. In 1941, Los Angeles resident Johnny Lockridge produced a very few examples of the Black Panther .607 car engine. While the Black Panther certainly incorporated a good deal of Lockridge’s own thinking, it displayed a very definite Hassad influence, featuring FRV induction to go along with a twin-stack front exhaust system. The flywheel and timer of this ultra-rare model were neatly enclosed in a forward extension of the main crankcase. Production of this engine was apparently suspended rather abruptly after a well-heeled friend of Ira Hassad’s called on Lockridge and threatened him with legal action over what he saw as an unauthorized Hassad “rip-off”!!

The Hassad engines were very successful in competition, a fact which did not go unnoticed by other California-based model engine designers. In 1941, Los Angeles resident Johnny Lockridge produced a very few examples of the Black Panther .607 car engine. While the Black Panther certainly incorporated a good deal of Lockridge’s own thinking, it displayed a very definite Hassad influence, featuring FRV induction to go along with a twin-stack front exhaust system. The flywheel and timer of this ultra-rare model were neatly enclosed in a forward extension of the main crankcase. Production of this engine was apparently suspended rather abruptly after a well-heeled friend of Ira Hassad’s called on Lockridge and threatened him with legal action over what he saw as an unauthorized Hassad “rip-off”!! In fairness to Lockridge, the Black Panther displayed sufficient originality in design terms to rob this accusation of much of its credibility. Ray Snow would have had far stronger grounds for suing Dick McCoy for copying the Hornet 60! However, the matter was never put to the test, since Lockridge either lacked the resources to mount a defence or more likely viewed the financial stakes as insufficiently high to make it worthwhile for him to go to the trouble and expense of fighting the matter in court.

In fairness to Lockridge, the Black Panther displayed sufficient originality in design terms to rob this accusation of much of its credibility. Ray Snow would have had far stronger grounds for suing Dick McCoy for copying the Hornet 60! However, the matter was never put to the test, since Lockridge either lacked the resources to mount a defence or more likely viewed the financial stakes as insufficiently high to make it worthwhile for him to go to the trouble and expense of fighting the matter in court. of mid-1941. This very intriguing engine was developed by model car racer (and noted pioneer free-diver) Bill Batzloff (1912-1966) of San Diego, California under the Batzloff Racing Engines label. The very clear Hassad influence arose from the fact that Bill Batzloff and Ira Hassad were close friends and racing buddies who together pioneered the sport of I/C car racing in the San Diego area. Batzloff actually used one of Hassad’s engines at the 1941 US National model car race championships in Chicago, a meeting at which Ira himself finished second, competing against the best in the country using his own engine. In fact, had it not been for igintion problems related to a poor high tension connection to the plug, Ira might well have won that meeting.

of mid-1941. This very intriguing engine was developed by model car racer (and noted pioneer free-diver) Bill Batzloff (1912-1966) of San Diego, California under the Batzloff Racing Engines label. The very clear Hassad influence arose from the fact that Bill Batzloff and Ira Hassad were close friends and racing buddies who together pioneered the sport of I/C car racing in the San Diego area. Batzloff actually used one of Hassad’s engines at the 1941 US National model car race championships in Chicago, a meeting at which Ira himself finished second, competing against the best in the country using his own engine. In fact, had it not been for igintion problems related to a poor high tension connection to the plug, Ira might well have won that meeting.  During the period just described, Hassad engines dominated the rail-guided model car racing category at meets in Southern California. This was evidently due to their superior torque in the 12,000-13,000 rpm range, which helped them to accelerate out of the turns. Notable users of these engines included the prominent rail car competitors Roy Richter and Clarence Felker.

During the period just described, Hassad engines dominated the rail-guided model car racing category at meets in Southern California. This was evidently due to their superior torque in the 12,000-13,000 rpm range, which helped them to accelerate out of the turns. Notable users of these engines included the prominent rail car competitors Roy Richter and Clarence Felker.

The unique exhaust stack arrangement seen on the H.R.E. Special implies pretty conclusively that it was specifically designed to match the revolutionary spur-geared

The unique exhaust stack arrangement seen on the H.R.E. Special implies pretty conclusively that it was specifically designed to match the revolutionary spur-geared  By 1946, Ira had established himself in San Diego, California under the company name of Hassad Experimental Machinists. Here he produced around 125 or so examples of the individually hand-crafted Hassad Custom .61, a true masterpiece once again featuring FRV induction and a twin-stack front exhaust. However, the “standard” formula was beginning to make inroads into Hassad’s thinking – the new model featured a twin ball-race shaft, while some examples also used a ringed aluminium alloy piston as well. Even so, the continued use of FRV induction and the front exhaust set the design well apart from most other leading racing engines of the period.

By 1946, Ira had established himself in San Diego, California under the company name of Hassad Experimental Machinists. Here he produced around 125 or so examples of the individually hand-crafted Hassad Custom .61, a true masterpiece once again featuring FRV induction and a twin-stack front exhaust. However, the “standard” formula was beginning to make inroads into Hassad’s thinking – the new model featured a twin ball-race shaft, while some examples also used a ringed aluminium alloy piston as well. Even so, the continued use of FRV induction and the front exhaust set the design well apart from most other leading racing engines of the period. According to Tom Pearson, the main business of the B&D Racing Engine Laboratory was the development and manufacture of race components for full-sized engines. Their flagship product was a conversion of the 44 cubic inch (721 cc)

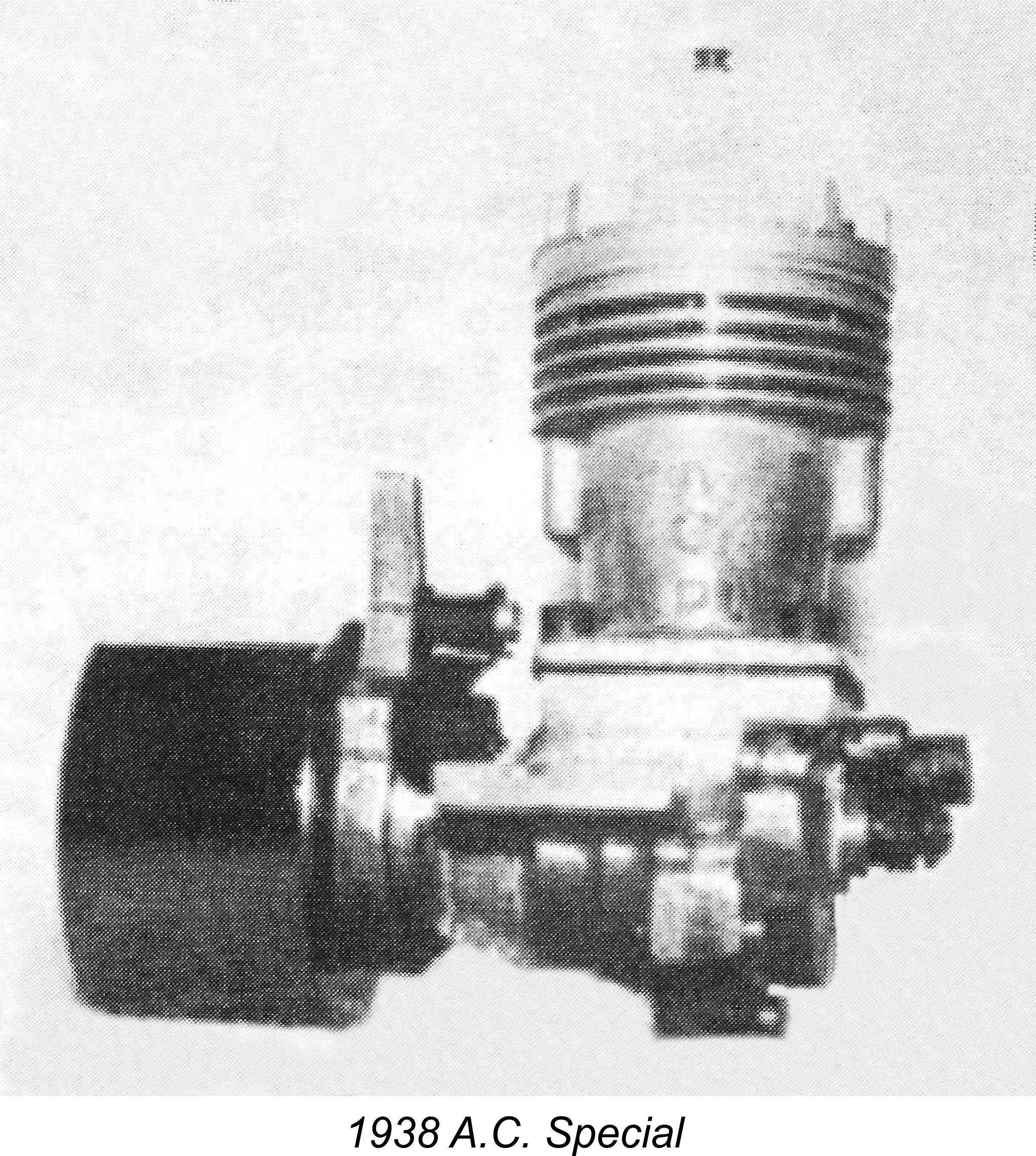

According to Tom Pearson, the main business of the B&D Racing Engine Laboratory was the development and manufacture of race components for full-sized engines. Their flagship product was a conversion of the 44 cubic inch (721 cc)  true, the development of the engine would have started in 1931, some 7 years prior to the appearance of the first recognized purpose-built model racing engine, the 1938 A.C. Special! The claim thus appears to require substantiation, a requirement which is highly unlikely to be met at this late point in time!

true, the development of the engine would have started in 1931, some 7 years prior to the appearance of the first recognized purpose-built model racing engine, the 1938 A.C. Special! The claim thus appears to require substantiation, a requirement which is highly unlikely to be met at this late point in time! There appears to be some confusion regarding the date of the Ball’s introduction. As we saw earlier, the printed instruction sheet for some of the engines included a typewritten notation to the effect that the Ball 60 had established an official AMA speed record for Class 6 control-line model aircraft in October 1946. This unquestionably implies that the engine was available at that time, although the possibility exists that the engine concerned was a pre-production prototype. Regardless, Tim Dannels gives the date of 1946 in his indispensable “American Model Engine Encyclopedia” (AMEE).

There appears to be some confusion regarding the date of the Ball’s introduction. As we saw earlier, the printed instruction sheet for some of the engines included a typewritten notation to the effect that the Ball 60 had established an official AMA speed record for Class 6 control-line model aircraft in October 1946. This unquestionably implies that the engine was available at that time, although the possibility exists that the engine concerned was a pre-production prototype. Regardless, Tim Dannels gives the date of 1946 in his indispensable “American Model Engine Encyclopedia” (AMEE).

The style of porting employed naturally meant that a conventional baffle piston could not be used. The Ball’s twin-ringed alloy piston was unique in my personal experience - it had a domed crown with two baffles, one on each side. These separated the exhaust and transfer areas of the piston. The baffles directed the incoming charge upwards into the cast alloy cylinder head, which had a matching domed shape with two slots milled in to accommodate the baffles at top dead centre.

The style of porting employed naturally meant that a conventional baffle piston could not be used. The Ball’s twin-ringed alloy piston was unique in my personal experience - it had a domed crown with two baffles, one on each side. These separated the exhaust and transfer areas of the piston. The baffles directed the incoming charge upwards into the cast alloy cylinder head, which had a matching domed shape with two slots milled in to accommodate the baffles at top dead centre.  It has to be said that the combustion chamber shape resulting from the above design arrangement was far from ideal. The presence of the two baffles deeply recessed into their clearance slots at top dead centre created two pockets of gas at the sides which were isolated from the main fuel change by the presence of the baffles. Their involvement in the combustion process would unavoidably be delayed as a result. Furthermore, the combination of a domed piston crown (apart from the baffles) with a matching domed cylinder head did nothing to promote swirl and hence rapid flame propagation within the combustion chamber.

It has to be said that the combustion chamber shape resulting from the above design arrangement was far from ideal. The presence of the two baffles deeply recessed into their clearance slots at top dead centre created two pockets of gas at the sides which were isolated from the main fuel change by the presence of the baffles. Their involvement in the combustion process would unavoidably be delayed as a result. Furthermore, the combination of a domed piston crown (apart from the baffles) with a matching domed cylinder head did nothing to promote swirl and hence rapid flame propagation within the combustion chamber. The lower crankcase was itself split vertically across its centre-line, with the two halves being secured with four additional screws. Both the removable upper cylinder unit and the split crankcase were of course borrowed directly from the still-influential design of the Hornet 60. The great advantage of the arrangement was that the engine could be disassembled for servicing without the need to disturb either the head seal or the cylinder liner alignment. In the case of the Ball with its symmetrical porting arrangements, it also allowed the engine to be assembled with the stacks discharging either to the left or right of the engine.

The lower crankcase was itself split vertically across its centre-line, with the two halves being secured with four additional screws. Both the removable upper cylinder unit and the split crankcase were of course borrowed directly from the still-influential design of the Hornet 60. The great advantage of the arrangement was that the engine could be disassembled for servicing without the need to disturb either the head seal or the cylinder liner alignment. In the case of the Ball with its symmetrical porting arrangements, it also allowed the engine to be assembled with the stacks discharging either to the left or right of the engine.

the venturi from one side only. However, this fitting was of somewhat different design to that used by Hassad, with the needle being aligned with the jet rather than being aligned at right angles as on the Hassad. A banjo fitting was used to supply fuel to the assembly. Nonetheless, the principle was identical in functional terms.

the venturi from one side only. However, this fitting was of somewhat different design to that used by Hassad, with the needle being aligned with the jet rather than being aligned at right angles as on the Hassad. A banjo fitting was used to supply fuel to the assembly. Nonetheless, the principle was identical in functional terms. component which was maintained in alignment with the shaft by use of a Woodruff key. The same Woodruff key was used to secure the prop driver or whatever hardware was mounted forward of the cam.

component which was maintained in alignment with the shaft by use of a Woodruff key. The same Woodruff key was used to secure the prop driver or whatever hardware was mounted forward of the cam. The notion that the porting design of the Ball 60 may have owed much to Ira Hassad’s H.R.E Special is not of course an adverse reflection upon Henry Ball’s design capabilities. The same could be said of the fascinating Cave Cobra racing engine manufactured in rather small numbers in California by Walt Cave, co-designer of the pre-war A.C. Special which had started it all in 1938. The Cobra was apparently designed in 1941 before being sidelined by America’s entry into WW2 at the end of the year. It made a belated and all-too brief appearance on the commercial market in 1946, but did not survive for long.

The notion that the porting design of the Ball 60 may have owed much to Ira Hassad’s H.R.E Special is not of course an adverse reflection upon Henry Ball’s design capabilities. The same could be said of the fascinating Cave Cobra racing engine manufactured in rather small numbers in California by Walt Cave, co-designer of the pre-war A.C. Special which had started it all in 1938. The Cobra was apparently designed in 1941 before being sidelined by America’s entry into WW2 at the end of the year. It made a belated and all-too brief appearance on the commercial market in 1946, but did not survive for long. Ingram then described the engine’s main features, offering the manufacturer’s explanations for some of them. He pointed out that the dual bypass system allowed the use of 6 transfer apertures in the cylinder, an unusually large number for racing engines of the era, together with the retention of the standard 6 exhaust apertures divided between the two stacks fore and aft. A further claimed advantage of dual bypassing was the ability to mount the cylinder with the exhaust stacks in either left-hand or right-hand orientations. That said, we noted earlier that the majority of the engines appear to have been supplied with the stacks discharging to the left, as on the illustrated replica example.

Ingram then described the engine’s main features, offering the manufacturer’s explanations for some of them. He pointed out that the dual bypass system allowed the use of 6 transfer apertures in the cylinder, an unusually large number for racing engines of the era, together with the retention of the standard 6 exhaust apertures divided between the two stacks fore and aft. A further claimed advantage of dual bypassing was the ability to mount the cylinder with the exhaust stacks in either left-hand or right-hand orientations. That said, we noted earlier that the majority of the engines appear to have been supplied with the stacks discharging to the left, as on the illustrated replica example. In terms of the number of engines manufactured, we are on somewhat shaky ground. The only serial numbers so far confirmed for unquestionably original examples of the Ball 60 are AC 027 (formerly owned by Clarence Lee), BC 063, BC 172, BC 185 and 754 (no letter prefix). The second and fifth of these examples both appeared almost simultaneously on eBay in late 2018 and sold for over US $450 apiece. I was the lucky winner of the auction for engine number 754, which appears to be new and unrun, while one of my readers acquired the other unit. The other three numbers were reported by Tim Dannels.

In terms of the number of engines manufactured, we are on somewhat shaky ground. The only serial numbers so far confirmed for unquestionably original examples of the Ball 60 are AC 027 (formerly owned by Clarence Lee), BC 063, BC 172, BC 185 and 754 (no letter prefix). The second and fifth of these examples both appeared almost simultaneously on eBay in late 2018 and sold for over US $450 apiece. I was the lucky winner of the auction for engine number 754, which appears to be new and unrun, while one of my readers acquired the other unit. The other three numbers were reported by Tim Dannels.  for him on the engine side. The company was established in premises located at Del Mar Airport in the oceanside community of Del Mar, a little to the north of San Diego, California, where Hassad had been living since the beginning of WW2. Both engines and model race cars were manufactured.

for him on the engine side. The company was established in premises located at Del Mar Airport in the oceanside community of Del Mar, a little to the north of San Diego, California, where Hassad had been living since the beginning of WW2. Both engines and model race cars were manufactured. The version of the Sky Devil which appeared in the advertising for the engine was in fact a mock-up which was created during the engine’s development phase. The engines sold to the public differed in a number of ways from the illustrated version. One buyer’s disappointment at this situation led years later to his commissioning the very talented model engineer Don Sohn to construct a very few examples of the Sky Devil based on the advertising image. One of these fine creations (number 104) is illustrated here.

The version of the Sky Devil which appeared in the advertising for the engine was in fact a mock-up which was created during the engine’s development phase. The engines sold to the public differed in a number of ways from the illustrated version. One buyer’s disappointment at this situation led years later to his commissioning the very talented model engineer Don Sohn to construct a very few examples of the Sky Devil based on the advertising image. One of these fine creations (number 104) is illustrated here. costs under control. However, in many ways their quality equals or even exceeds that of the originals, from which they may be readily distinguished by having the inner surfaces of their exhaust stacks anodized as opposed to the plain milled finish of the originals. They also carry serial numbers having a TDCxxx pattern. These engines run very well indeed and are now fine collectibles in their own right. Engine number TDC059 of this series is illustrated here.

costs under control. However, in many ways their quality equals or even exceeds that of the originals, from which they may be readily distinguished by having the inner surfaces of their exhaust stacks anodized as opposed to the plain milled finish of the originals. They also carry serial numbers having a TDCxxx pattern. These engines run very well indeed and are now fine collectibles in their own right. Engine number TDC059 of this series is illustrated here. The result was Ira Hassad’s last commercial model engine design - the Bluestreak 65, still featuring FRV induction and using many EDCO Sky Devil parts. However, the “classic” formula had made further inroads, since the new design used a revised crankcase casting which featured a conventional side-stack exhaust in place of the twin-stack front exhaust layout used on all previous Hassad designs. Since the engine possessed all of the other classic racing features such as twin ball-race shaft and ringed alloy piston, it followed the now-established racing engine pattern in all respects apart from its continued adherence to FRV induction.

The result was Ira Hassad’s last commercial model engine design - the Bluestreak 65, still featuring FRV induction and using many EDCO Sky Devil parts. However, the “classic” formula had made further inroads, since the new design used a revised crankcase casting which featured a conventional side-stack exhaust in place of the twin-stack front exhaust layout used on all previous Hassad designs. Since the engine possessed all of the other classic racing features such as twin ball-race shaft and ringed alloy piston, it followed the now-established racing engine pattern in all respects apart from its continued adherence to FRV induction. together with his own legend. For a full account of

together with his own legend. For a full account of

Former AMCRA President Tom Pearson was kind enough to share some of his personal recollections of the early big-bore racing engines, including the Ball. As a teenage member of the Chicago U-Liners model flying club in the early 1950’s, Tom was flying control-line speed, which was then the most popular form of power model racing given the plummeting interest in model car racing at the time. It was in fact this very plummeting of interest which led a number of the local car racers from the Harvey, Illinois tether car club who were abandoning the sport to give their now-redundant cars and engines to Tom. Some guys have all the luck ………!

Former AMCRA President Tom Pearson was kind enough to share some of his personal recollections of the early big-bore racing engines, including the Ball. As a teenage member of the Chicago U-Liners model flying club in the early 1950’s, Tom was flying control-line speed, which was then the most popular form of power model racing given the plummeting interest in model car racing at the time. It was in fact this very plummeting of interest which led a number of the local car racers from the Harvey, Illinois tether car club who were abandoning the sport to give their now-redundant cars and engines to Tom. Some guys have all the luck ………!

Apart from the Hornet models, the "best of the rest" was none other than our main subject, the Ball 60! In standard form, the Ball could not compete with either the Hornet or McCoy. Since we have already seen that there was nothing restrictive about the Ball’s bypass and transfer arrangements, this must have been mainly down to the relatively small-bore intake venturi, perhaps exacerbated by the relatively inefficient combustion chamber configuration. Even so, if a larger-bore venturi was fitted together with some opening-out and cleaning-up of the rotary valve, Tom found that a reworked Ball would push the McCoy very hard. In large part this was doubtless due to the Ball’s very free-breathing bypass design. It’s true that the same twin-bypass arrangement had been used on both the Hassad H.R.E. Special and the Cave Cobra, but the design of the Ball carried the development of that layout to its logical extreme.

Apart from the Hornet models, the "best of the rest" was none other than our main subject, the Ball 60! In standard form, the Ball could not compete with either the Hornet or McCoy. Since we have already seen that there was nothing restrictive about the Ball’s bypass and transfer arrangements, this must have been mainly down to the relatively small-bore intake venturi, perhaps exacerbated by the relatively inefficient combustion chamber configuration. Even so, if a larger-bore venturi was fitted together with some opening-out and cleaning-up of the rotary valve, Tom found that a reworked Ball would push the McCoy very hard. In large part this was doubtless due to the Ball’s very free-breathing bypass design. It’s true that the same twin-bypass arrangement had been used on both the Hassad H.R.E. Special and the Cave Cobra, but the design of the Ball carried the development of that layout to its logical extreme. I hope I've made it quite clear that the Ball 60 was very far from being an also-ran in the 1940's racing engine sweepstakes. It actually appears to have been a highly competitive engine when properly set up. The fact that it never achieve a great deal of prominence on the American modelling scene is surely more a reflection of the low profile of its manufacturer in aeromodelling circles coupled with what seems to have been a very limited national marketing effort than it is of any major shortcomings in the engine itself.

I hope I've made it quite clear that the Ball 60 was very far from being an also-ran in the 1940's racing engine sweepstakes. It actually appears to have been a highly competitive engine when properly set up. The fact that it never achieve a great deal of prominence on the American modelling scene is surely more a reflection of the low profile of its manufacturer in aeromodelling circles coupled with what seems to have been a very limited national marketing effort than it is of any major shortcomings in the engine itself.